BOPET film high concentration matt masterbatch and preparation method thereof

A high-concentration, masterbatch technology, applied in the field of polymer materials, can solve the problems of not reaching the standard, low transmittance, not providing BOPET film matte masterbatch ratio and preparation, etc., to achieve high effective concentration and compatibility Good performance, good matting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

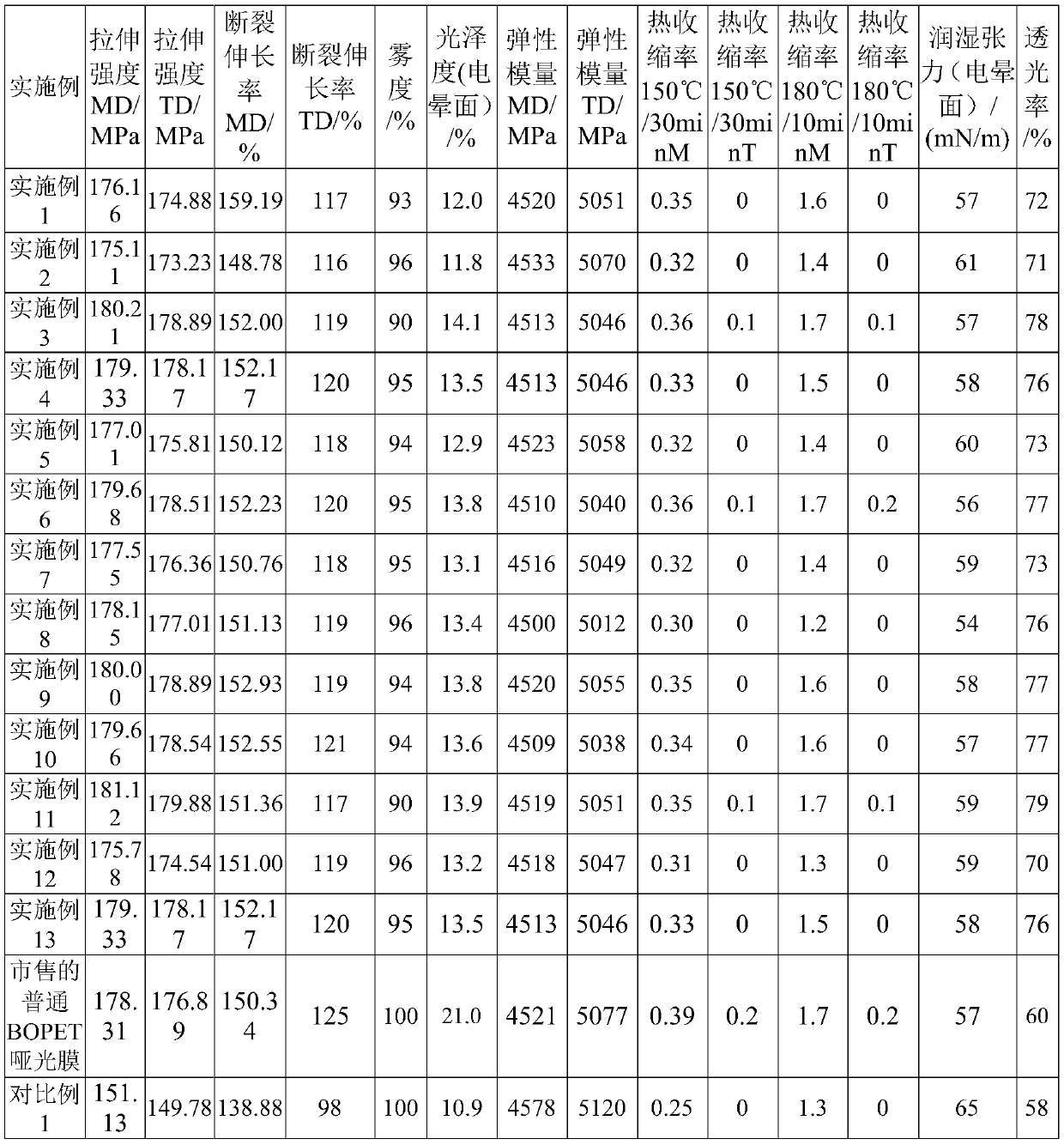

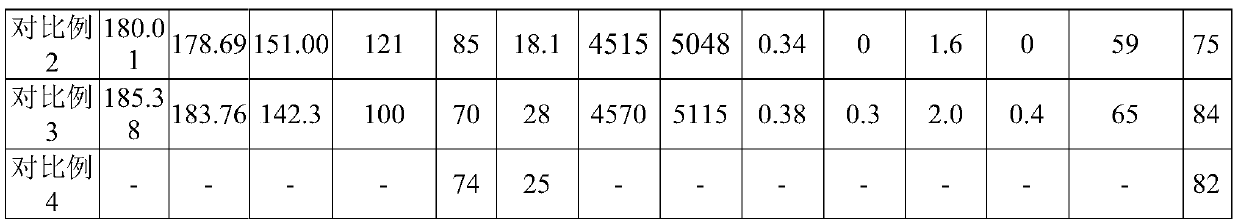

Examples

preparation example Construction

[0052] The preparation method of BOPET film highly concentrated matte masterbatch comprises the following steps:

[0053] S1 First, prepare the raw materials according to the ratio of each component. The PET raw material is ground into powder in advance, and the particle size is 60 mesh to 70 mesh;

[0054] S2 Mix the raw materials evenly for later use. The order of feeding is to add 1 / 2 of the total amount of PET powder in S1 first, then add silicon dioxide, hyperdispersant, silicone microspheres, matting resin, and the remaining PET powder in sequence, and stir. Set the temperature at 90-120°C, preheat to a certain extent, stir at low speed within 5-10 minutes at the beginning, and the rotation speed is 200-240 rpm, then stir at high speed for 8-13 minutes, and the rotation speed is 700-800 rpm / minute;

[0055] S3 Put the raw materials evenly stirred in S2 into the lower hopper of the extruder to be extruded;

[0056] S4 is extruded through an extruder to obtain a high-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com