Patents

Literature

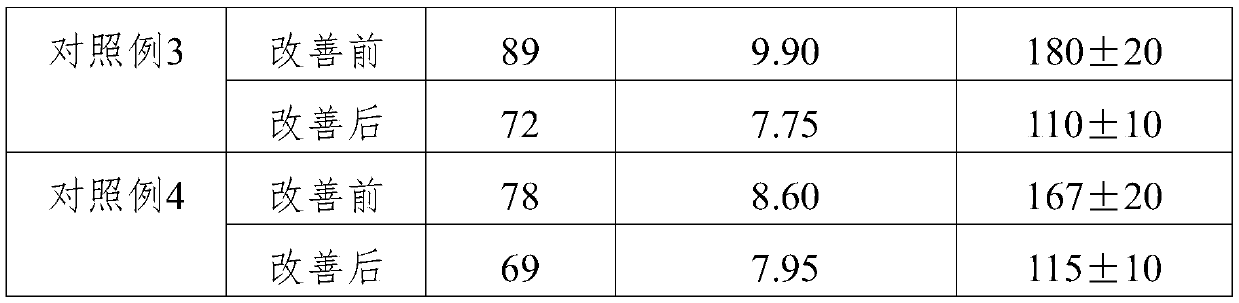

108results about How to "Improve deodorization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiberboard with formaldehyde self-absorbing function and manufacturing method thereof

InactiveCN101585204AAnti-corrosionMoisture-proofWood working apparatusFlat articlesActivated carbonFiber

The present invention provides a fiberboard with formaldehyde self-absorbing function and a manufacturing method thereof. The fiberboard of the invention adopts the wood fiber, aldehyde adhesive and active carbon as main raw materials. The dosage of the adhesive is 9%-12% of that of the wood fiber mass, and the dosage of the active carbon is 2%-30% of that of the wood fiber mass. The invention provides the novel fiberboard which is added with a certain amount of active carbon component with the absorbing function in the manufacturing process of the board so that the fiberboard has the function of free formaldehyde (harmful gas) self-absorbing function in the board for a long time. The releasing of the formaldehyde in the board can be reduced for reducing the formaldehyde pollution to the environment. Simultaneously the fiberboard has the functions of corrosion resistance, moisture resistance, deodorization and fungus resistance. Furthermore the fiberboard has the advantages of high absorbing efficiency, excellent absorbing effect, low cost, no toxicity, no side effect, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY +3

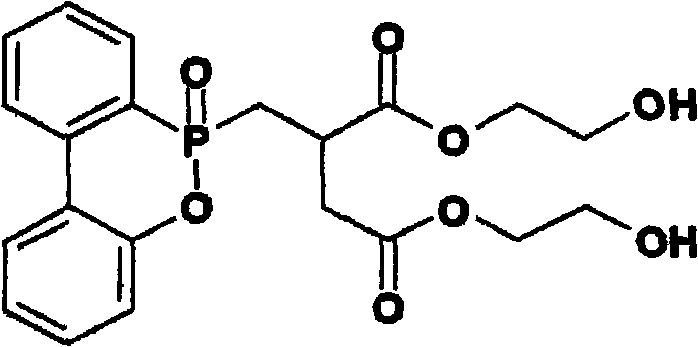

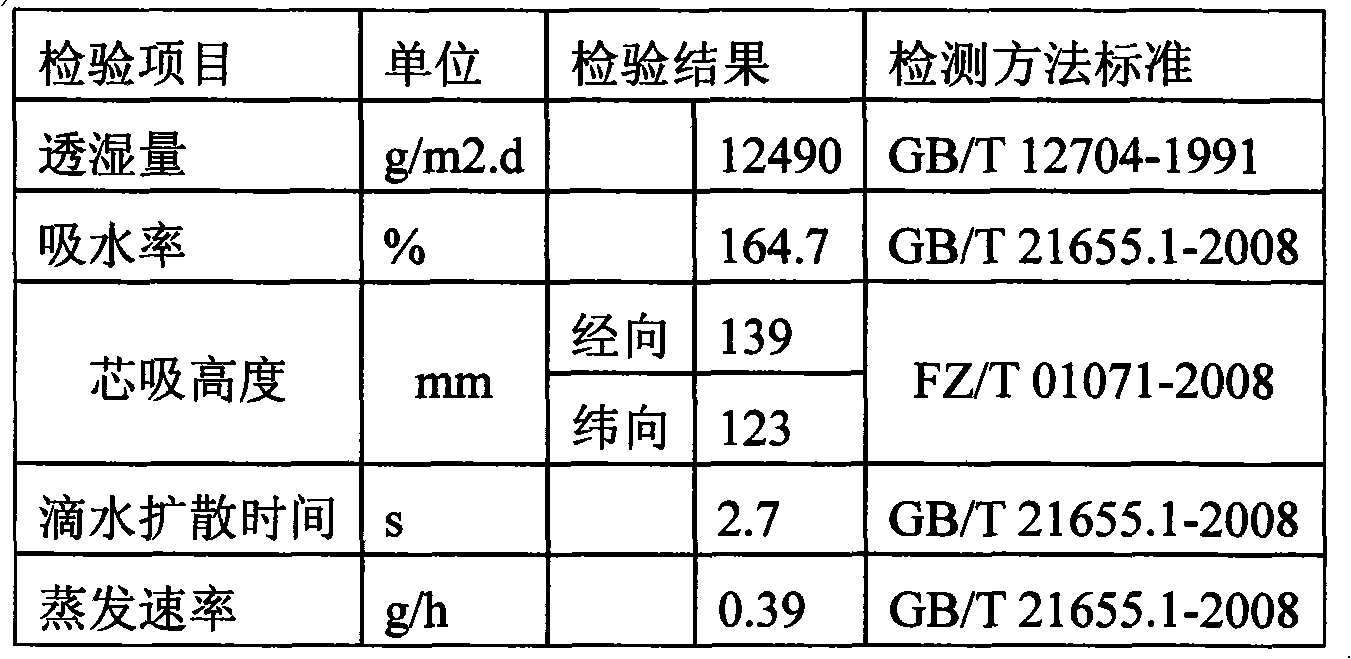

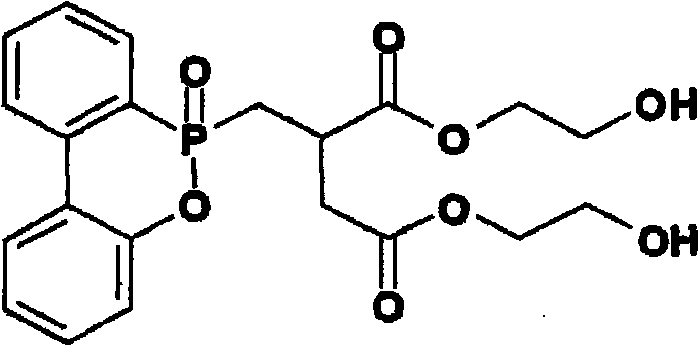

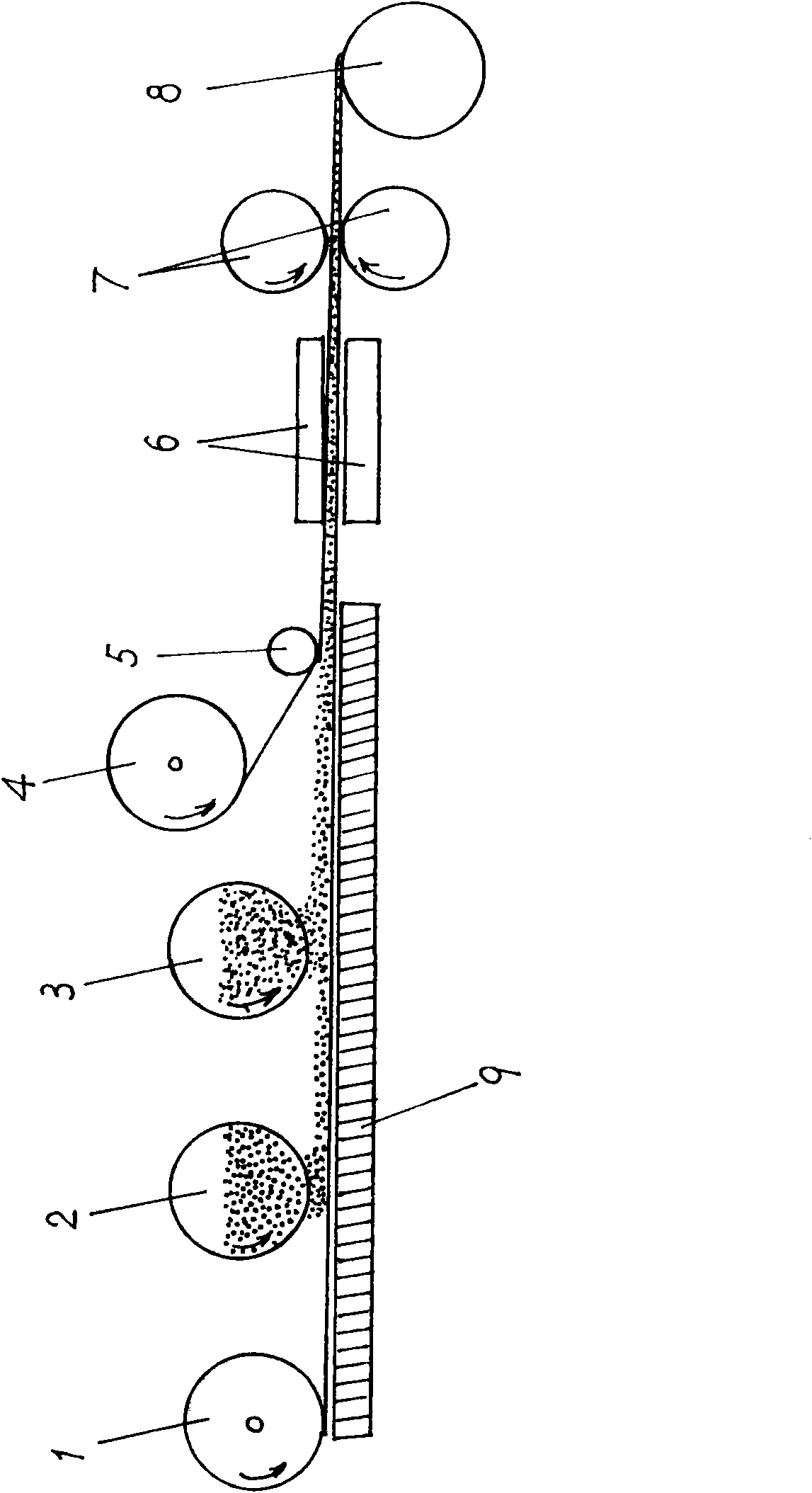

Bamboo charcoal, flame retardant and moisture conductive terylene fiber, preparation method and application thereof

InactiveCN101629333AImprove adsorption capacityImprove deodorizationFilament/thread formingMonocomponent copolyesters artificial filamentFire retardantMoisture

The invention discloses a bamboo charcoal, flame retardant and moisture conductive terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 5-10 percent of active carbon parent granule and 90-95 percent of copolymerized type phosphorus flame retardant terylene fiber forming resin, wherein the cross section of the fiber is a profile cross section. The terylene fiber has good functions of adsorption, deodorization, bactriostasis and rot resistance and flame retardance, and because the cross section of the fiber is the profile cross section, the moisture conductive function of the fiber is also excellent, thus the terylene fiber has wide range of application. The preparation method of the bamboo charcoal, flame retardant and moisture conductive terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:苏州金辉纤维新材料有限公司

Material for multifunctional shoe pad and preparation method thereof

InactiveCN102102299AImprove antibacterialGood moisture absorptionInsolesFibre treatmentMoisture absorptionNonwoven fabric

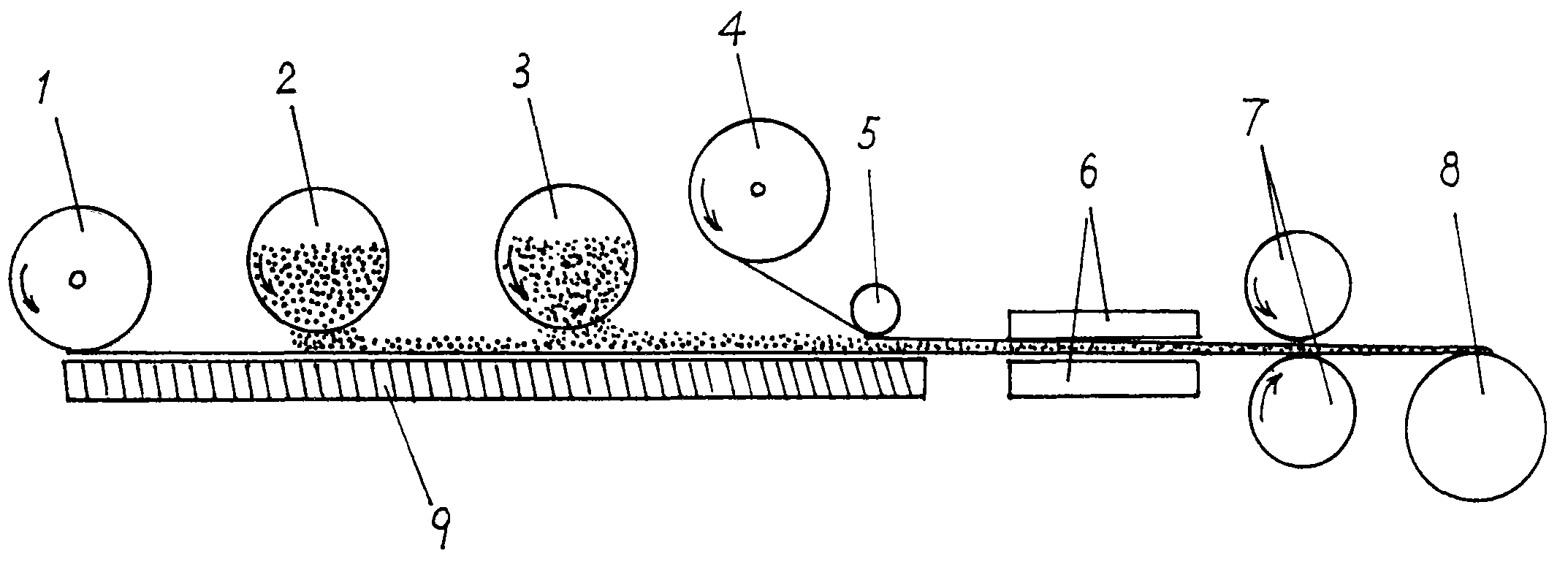

The invention relates to a material for a multifunctional shoe pad, which contains three layers of materials, wherein common fabrics are arranged on the bottom layer; antibiosis non-woven fabrics are arranged on the upper layer; and the middle layer contains high water-absorption resin particles covered by the inorganic nanometer silver antibacterial agent on the surface and hard micro beads covered by the hot melt adhesive on the surface. A preparation method comprises the following steps: (1) coating materials: on a support plate, covering the antibiosis non-woven fabrics, spreading the hard micro beads and high water-absorption resin particles, and covering the common fabrics; (2) heating: heating the compound three-layered materials; (3) hot-pressing: hotly pressing the heated compound three-layered materials so as to form the material for multifunctional shoe; and (4) collecting the finished products. Before the step (1) is performed, the steps of covering the surface of the hard micro bead with hot melt adhesive and covering the surface of the high water-absorption resin with the antibacterial agent are performed. The material for multifunctional shoe has the advantages that the prepared materials have high moisture-absorption property and functions of antibiosis, deodorization and massaging sole of the foot, the functions are lasting, the effects of antibiosis and deodorization are obvious, and the materials are easily produced and have bright application prospect.

Owner:SHANGHAI ANNI CRYSTAL DESIGN

Special care wet wipe for female and preparation method thereof

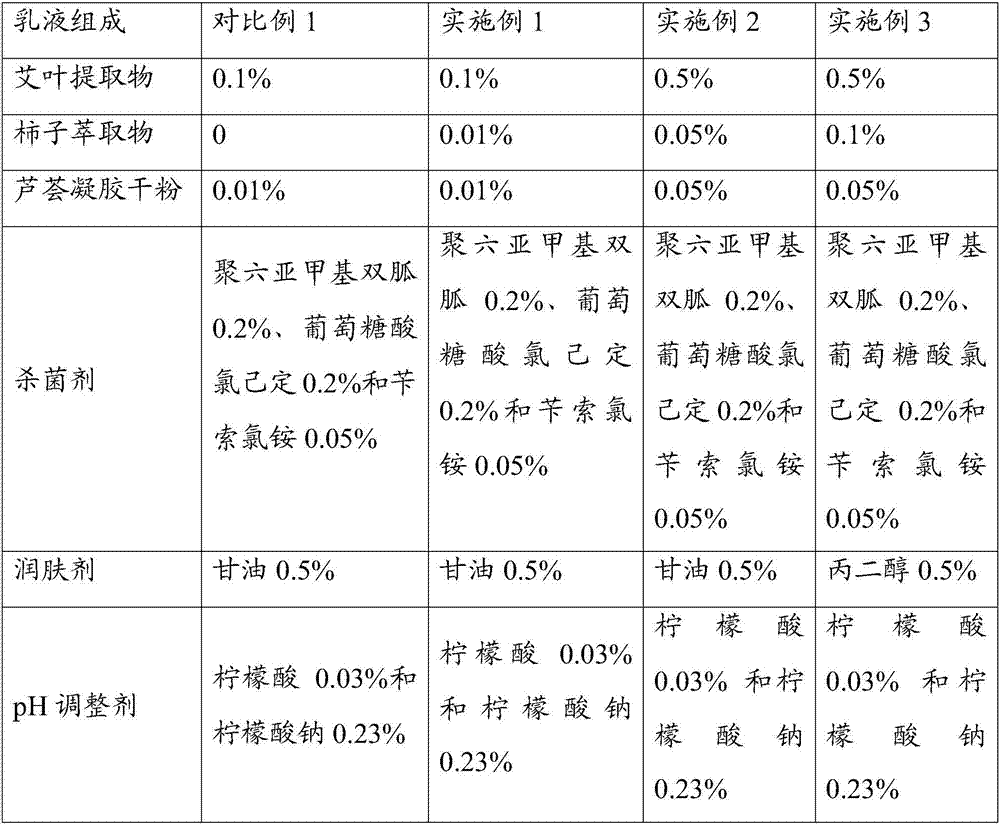

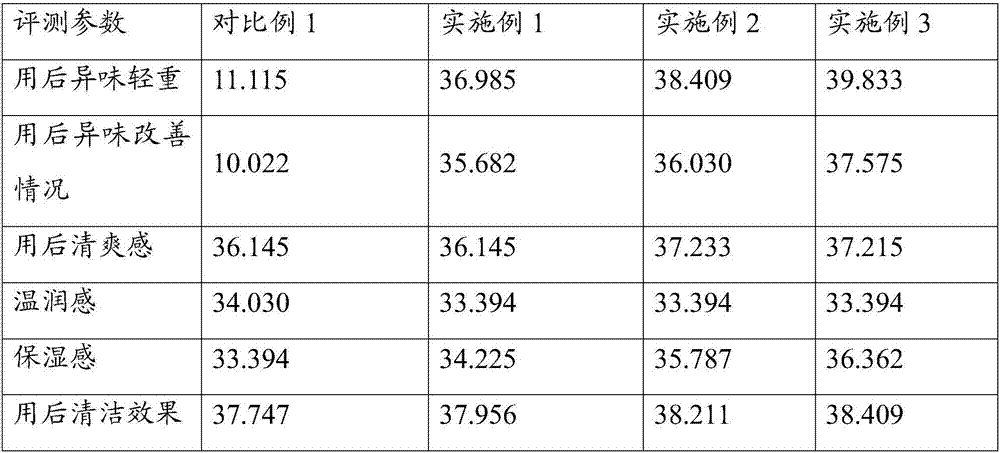

InactiveCN107137299AOdor suppressionTo achieve the effect of deodorizationAntibacterial agentsCosmetic preparationsEmulsionMedicine

The invention discloses a special care wet wipe for the female and a preparation method of the special care wet wipe for the female, belonging to the field of hygienic products. A special care emulsion injected into a non-woven fabric is prepared from the following components: folium artemisiae argyi extract, persimmon extract, aloe gel dry powder, a germicide, a skin moisturizing agent and a pH regulator. The invention further discloses the preparation method of the special care wet wipe for the female. The method comprises the step of preparing the special care emulsion for the female and steeping the non-woven fabric in the emulsion. The special care wet wipe has multiple efficacies including resisting bacteria, inhibiting bacteria, dispelling odor, and caring the health, in addition, a preparation process is simple, convenient and feasible, and the production cost is low.

Owner:SUZHOU BORAGE DAILY CHEM

Multifunctional nanometer polyester fiber

The invention discloses a multifunctional nanometer polyester fiber. The multifunctional nanometer polyester fiber comprises, by mass, 40-80% of a polyester fiber, 20-40% of a nanoparticle, 3-8% of a compatibilizer, 0.1-1% of a surface conditioning agent, 0.1-1% of a nucleating agent, 1-3% of a dispersant and 0.1-1% of an antioxidant. The multifunctional nanometer polyester fiber prepared in the invention has the functions of supplementary lighting enhancement, flame retardation, barrier, bacterium prevention, smell removal, droplet prevention and the like.

Owner:QINGDAO XINZHAN PLASTIC

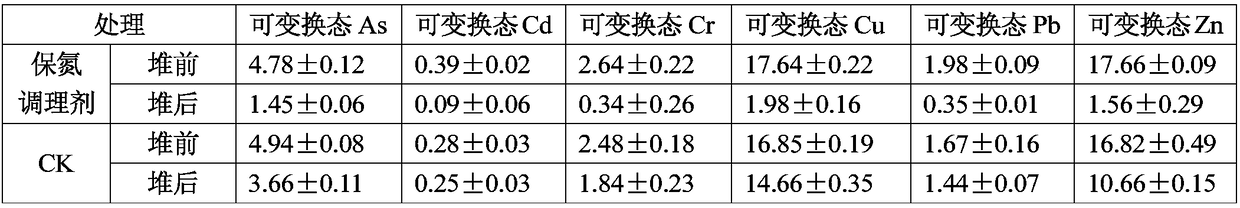

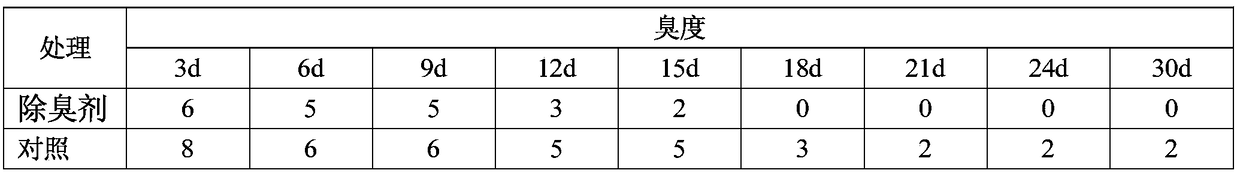

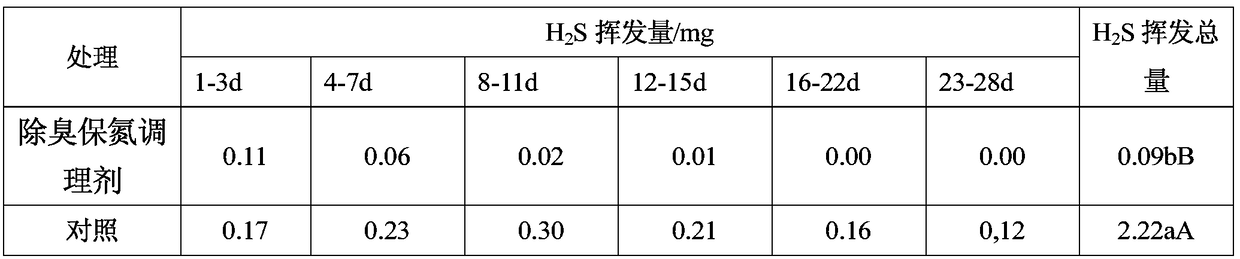

Production method of odorless high-nitrogen livestock and poultry manure fermented organic fertilizer

InactiveCN109279953AInhibition of growth and reproductionImprove the immunityBio-organic fraction processingExcrement fertilisersMicrobial agentAnimal feces

The invention discloses a production method of an odorless high-nitrogen livestock and poultry manure fermented organic fertilizer. The production method comprises the following steps: step 1, uniformly mixing animal manure with crushed straw or stalks of other crops according to a weight ratio of (2-8):1, adding water after uniform mixing, and controlling the water content to be 60-65% to obtaina fermented material; and step 2, adding a prepared microbial agent solution, zeolite powder and calcium chloride respectively according to mass percentages of 2.5%, 3% and 4%.

Owner:内蒙古金地隆农业科技发展有限公司

Modified nanometer bamboo charcoal mask and manufacturing method thereof

InactiveCN104041963ALow costHigh adsorption propertiesFibre typesProtective garmentWoven fabricPolymer chemistry

Provided are a modified nanometer bamboo charcoal mask and a manufacturing method thereof. The modified nanometer bamboo charcoal mask comprises an inner mask and an outer mask, wherein the inner mask is provided with a dismounting opening, and a filer layer is arranged in the dismounting opening. The inner mask and the outer mask of the mask and a filer layer base plate are made of an electrets melt-blowing polypropylene fiber non-woven fabrics, the filer layer uses chitosan as a capsule wall material, microcapsules are made from modified nanometer bamboo charcoal powder, beewax is used as an adhesive for arranging the microcapsules on the non-woven fabrics. The modified nanometer bamboo charcoal powder are modified by adopting nanometer titanium dioxide. The modified nanometer bamboo charcoal mask is green, environment-friendly, safe and efficient, has the broad-spectrum antibacterial effect and has good washability due to the fact that the beewax is used as the adhesive to arrange the microcapsules on the non-woven fabrics.

Owner:广州市威普复合材料有限公司

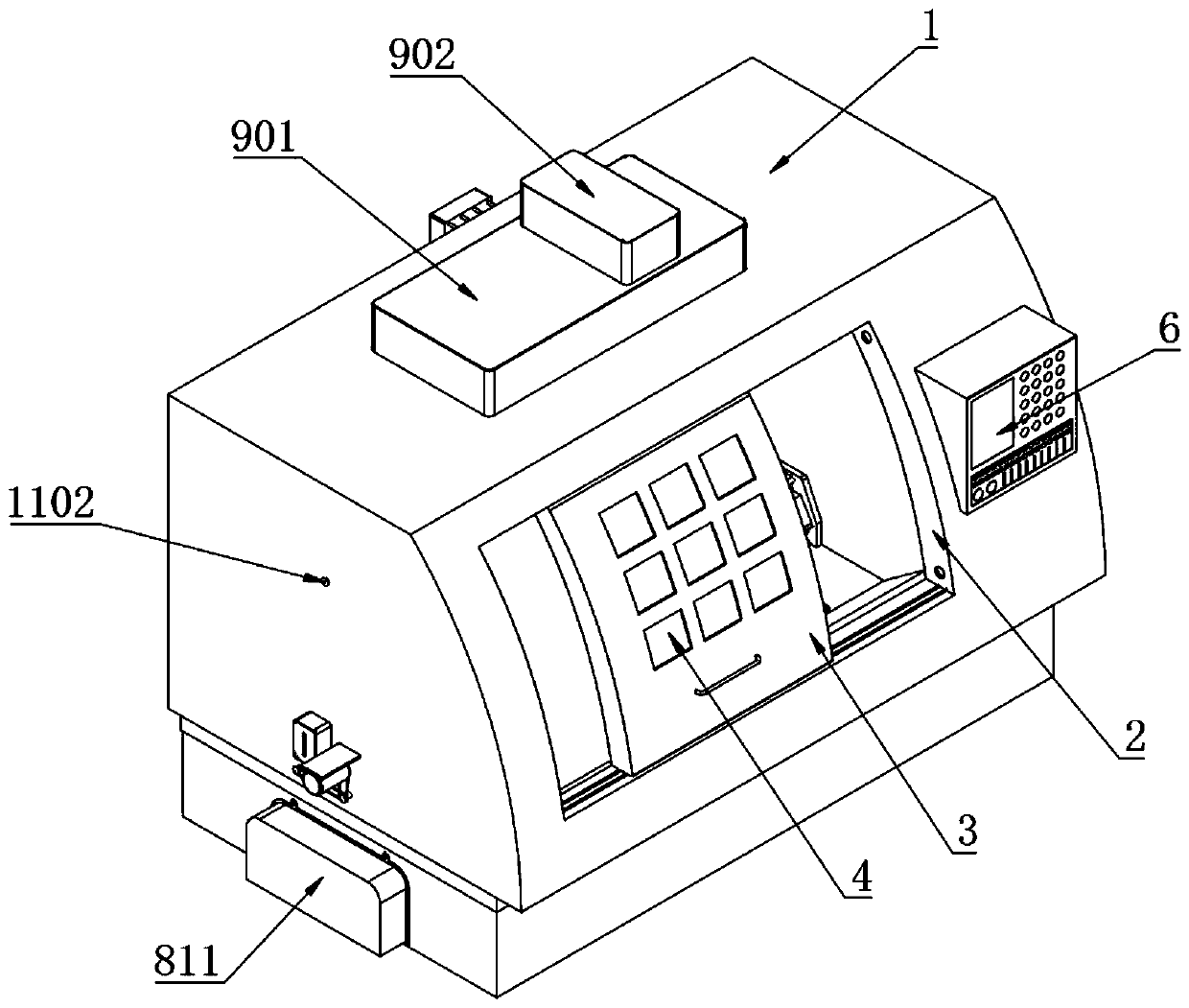

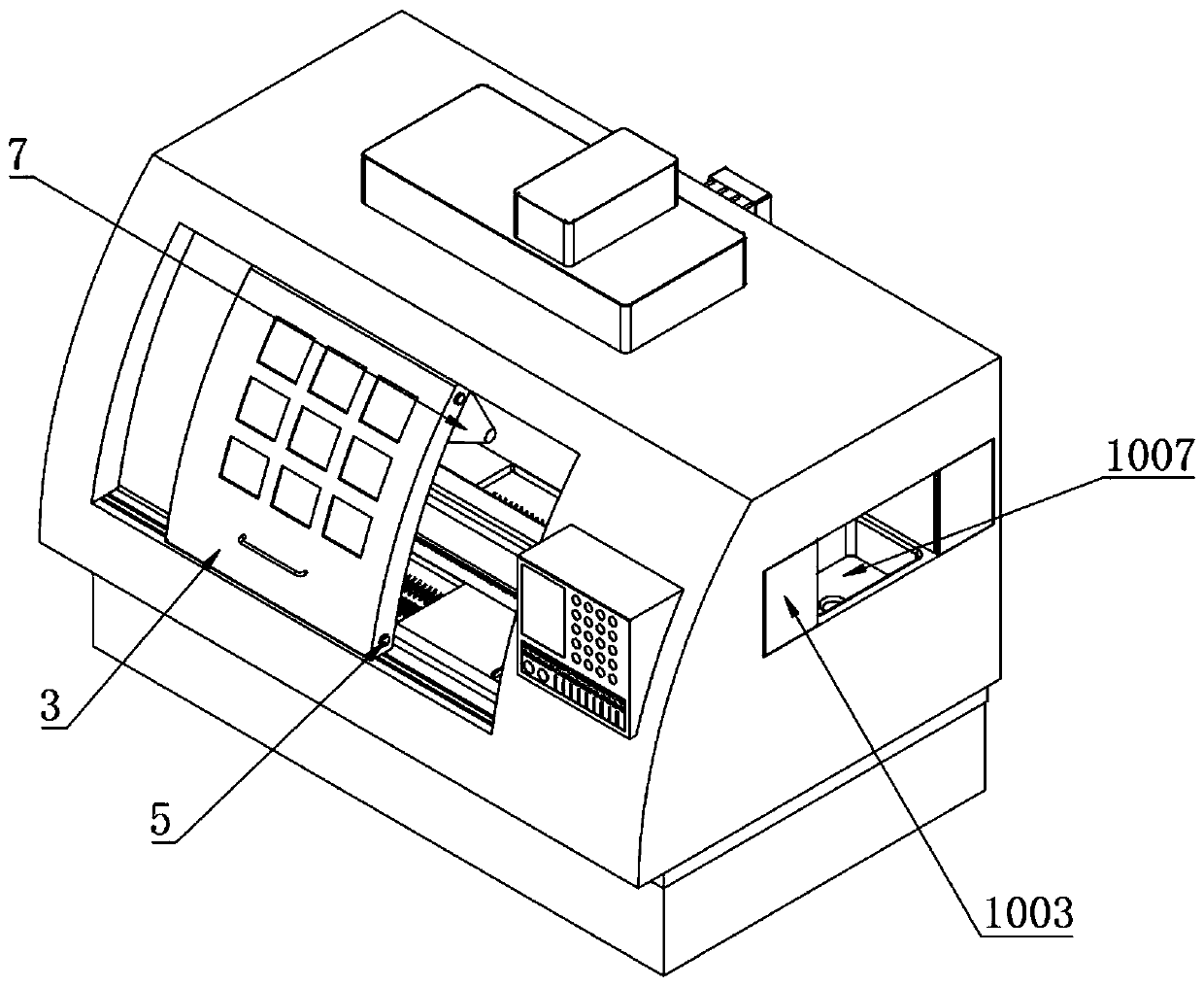

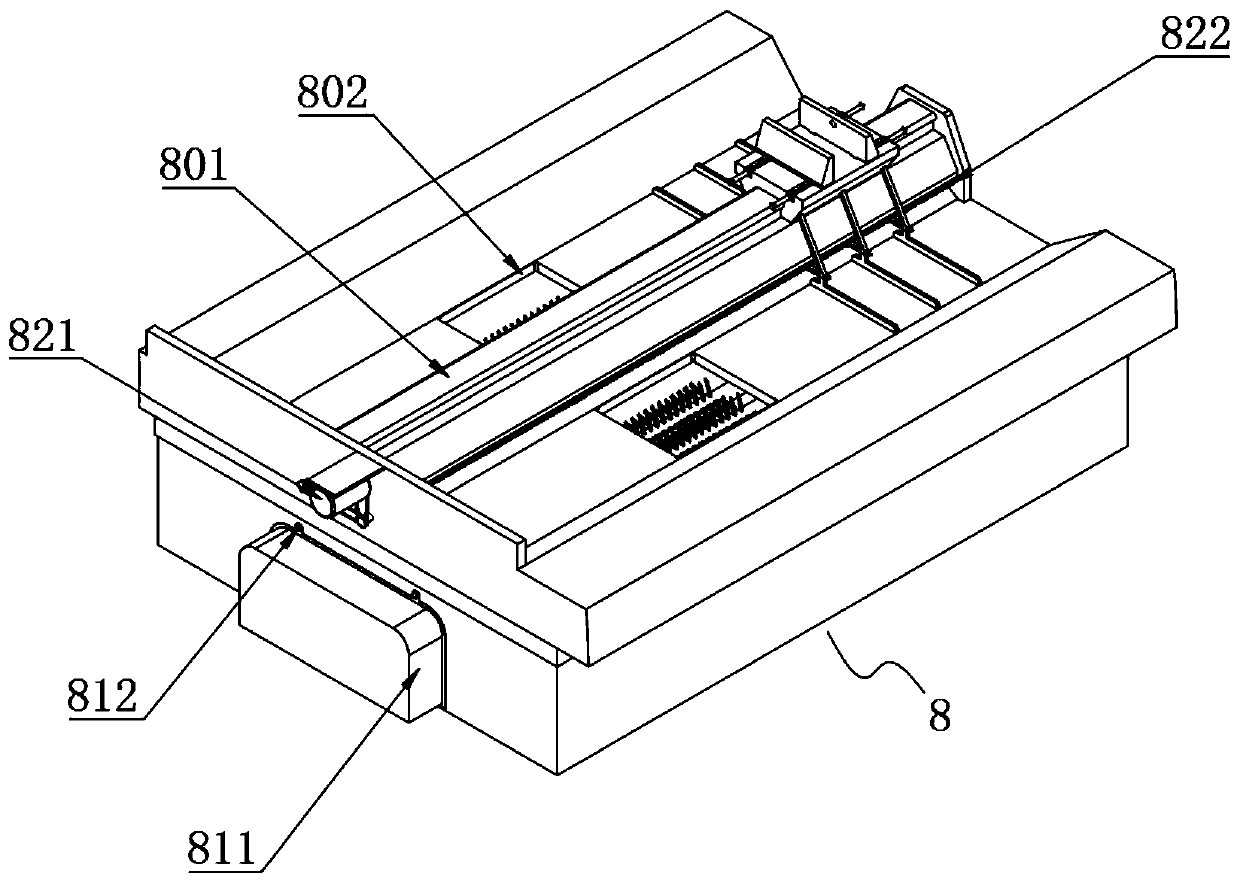

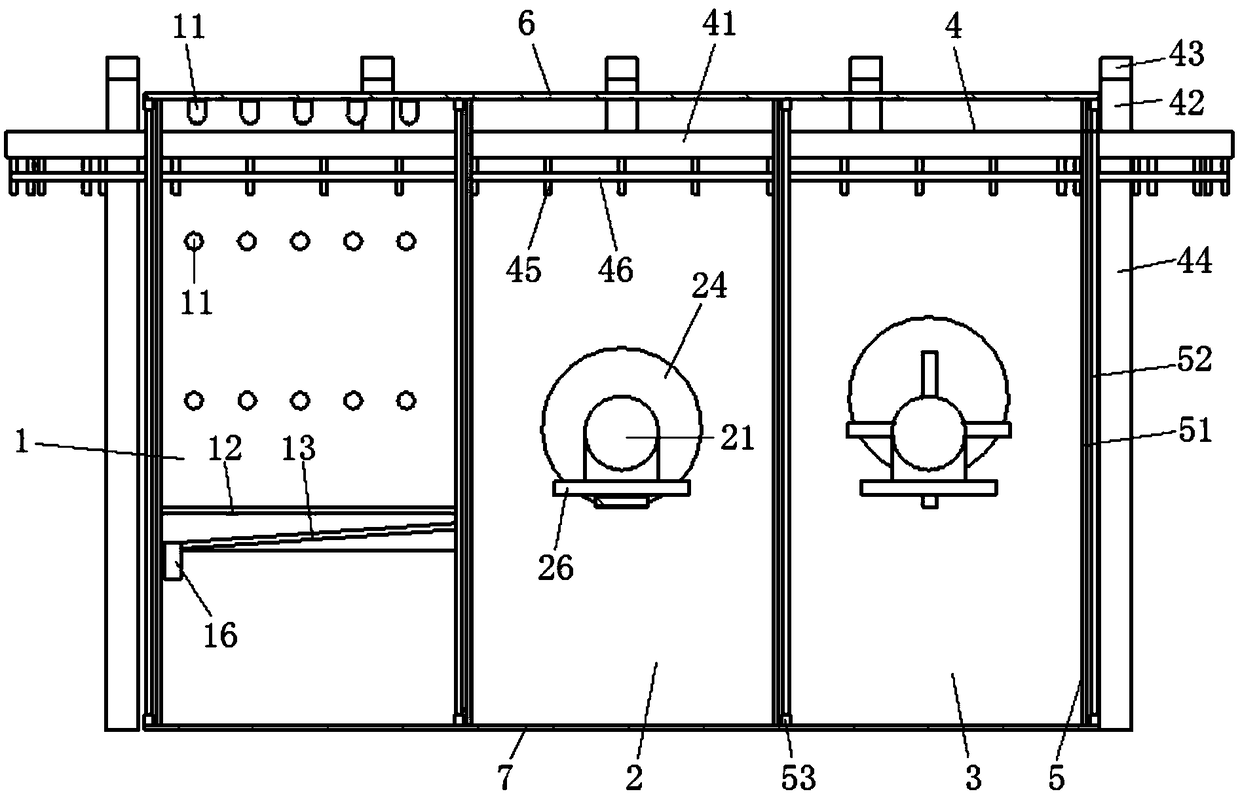

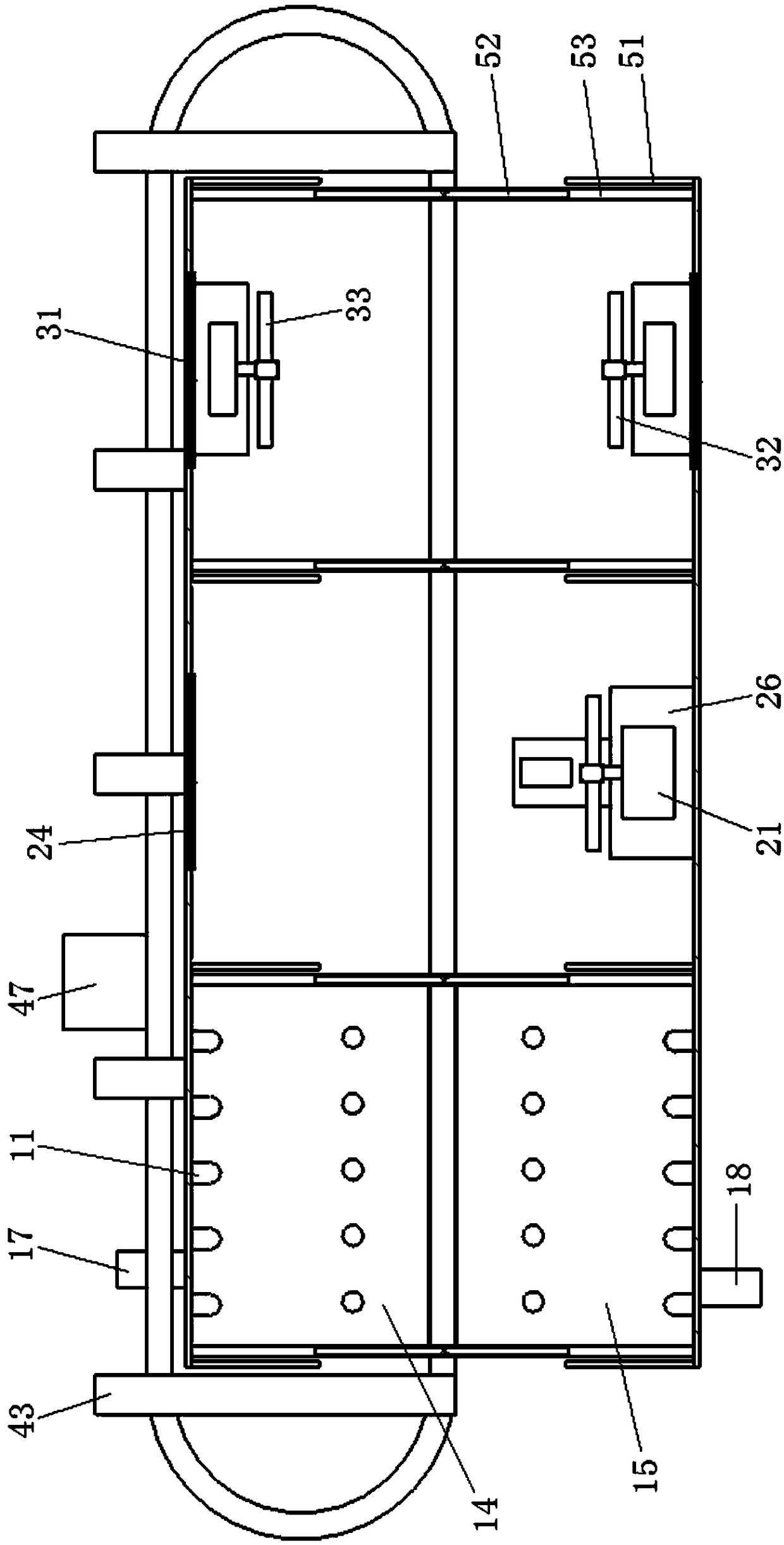

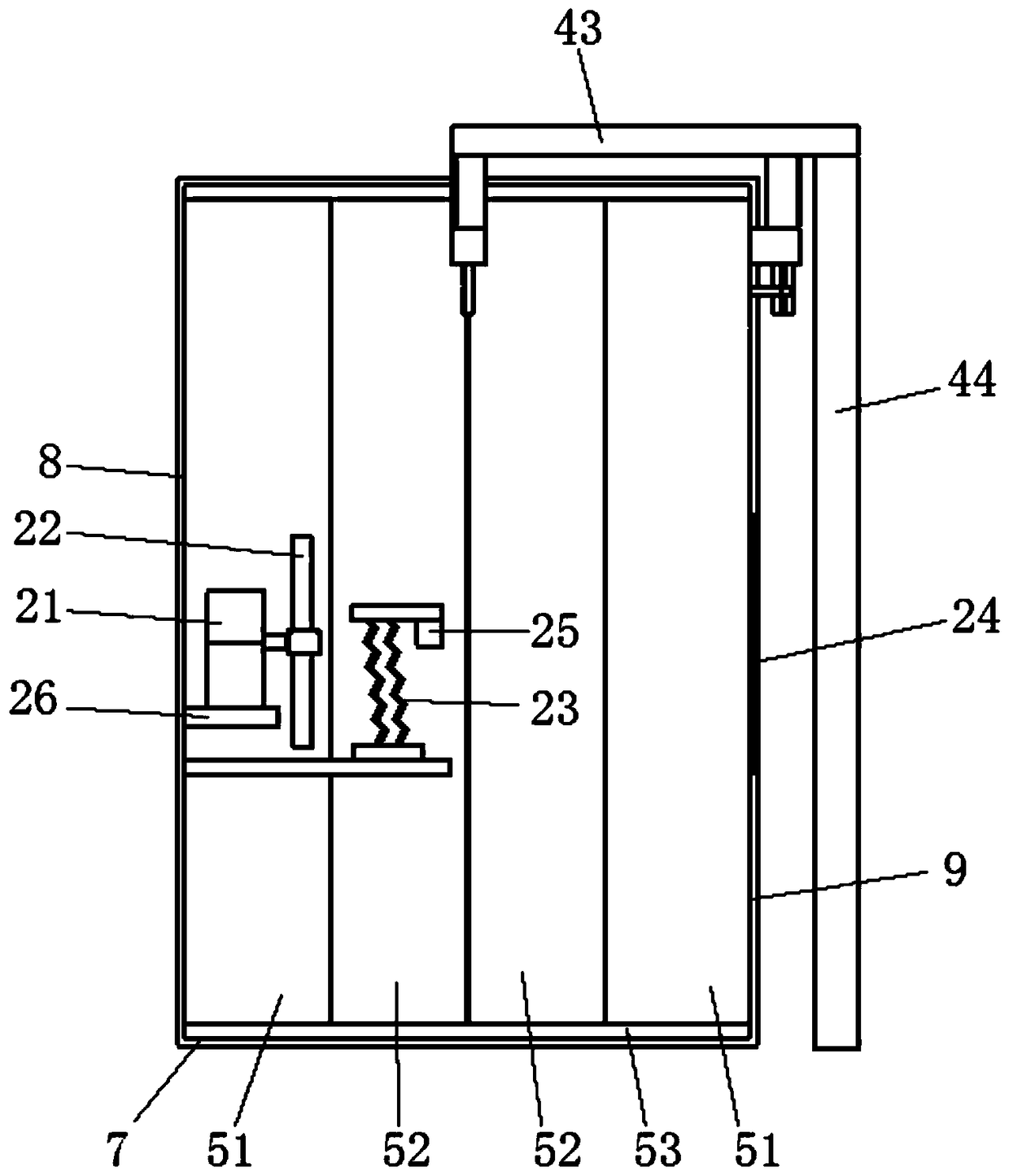

Safety protective production machine tool facilitating waste recovery and achieving environment friendliness

InactiveCN111589543AScientific and reasonable structureEasy to useCleaning using toolsCleaning using gasesElectric machineryEngineering

The invention discloses a safety protective production machine tool facilitating waste recovery and achieving environment friendliness. A placement groove is formed in one end of a machine tool bed, amachine tool cover is installed on the inner wall of the placement groove in a sliding manner, inspection windows are uniformly installed on the outer side of the machine tool cover in an embedded manner, and contact sensors are symmetrically installed at one end of the machine tool cover in an embedded manner. The safety protective production machine tool is scientific and reasonable in structure and safe and convenient to use. By arranging a drive motor, a drive screw, internal thread mounting bases, a sliding mounting plate and cleaning scraping plates, machining scraps can be crushed, collected and stored, the efficiency of scrap collection is improved, and the cleanness of the production machine tool in use is improved. By arranging air cylinders, clamping plates, pressure sensors and the contact sensors, the clamping fastness of workpieces can be monitored and observed, the fastness of workpiece clamping is improved, the safety in the use process of the production machine tool is improved, and the protection performance of staff is improved.

Owner:刘凯

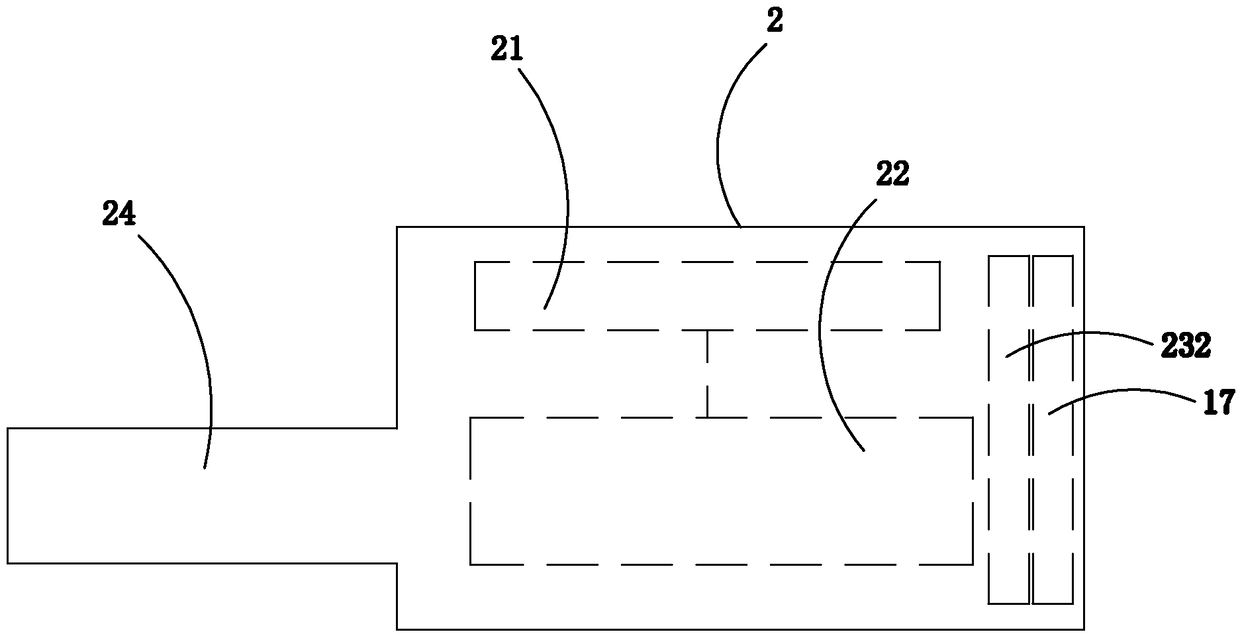

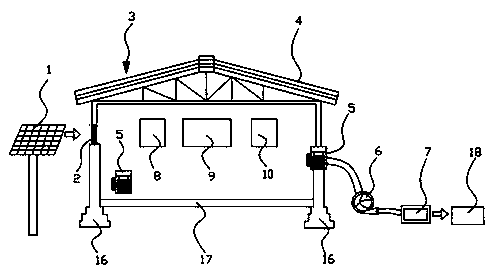

Air purification and deodorization device for kitchens and toilets

InactiveCN108854482AEasy to disinfectEasy to deodorizeGas treatmentDispersed particle filtrationDecompositionAir purification

The invention discloses an air purification and deodorization device for kitchens and toilets. The air purification and deodorization device comprises a negative-pressure deodorization host and an airdraft pipe, wherein the negative-pressure deodorization host is arranged outdoors, one end of the air draft pipe is connected with the negative-pressure deodorization host, the other end of the air draft pipe extends indoors, and the negative-pressure deodorization host comprises a control cabinet, a drug box, a drug pump, a water tank, an atomizing device, a suction eddy blower, an adsorption and decomposition module, a biological module and a moisture treatment module. Compared with related technologies, the air purification and deodorization device for the kitchens and toilets, disclosed by the invention, is better in deodorization, disinfection and air purification effects.

Owner:HUNAN KEMEIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Mixture for manufacturing latex mattress body, manufacturing method and latex mattress body

The invention discloses a mixture obtained by mixing natural latex, artificial latex, nano-silver, nano-zinc oxide and active carbon according to a specific ratio to manufacture a latex mattress body and a latex mattress body which contains the above components and is prepared by the use of the mixture through a given method. The mixture comprises, by weight, 20% of natural latex containing 50% moisture, 80% of artificial latex containing 40% moisture, 3% of nano-silver weighed relative to the total weight of natural latex and artificial latex, 5% of nano-zinc oxide weighed relative to the total weight of natural latex, artificial latex and nano-silver, and 5% of active carbon weighed relative to the total weight of natural latex, artificial latex, nano-silver and nano-zinc oxide.

Owner:DER YOU ENTERPRISE

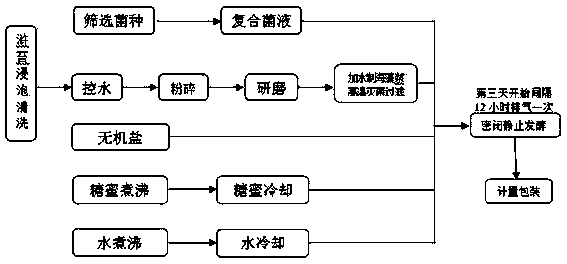

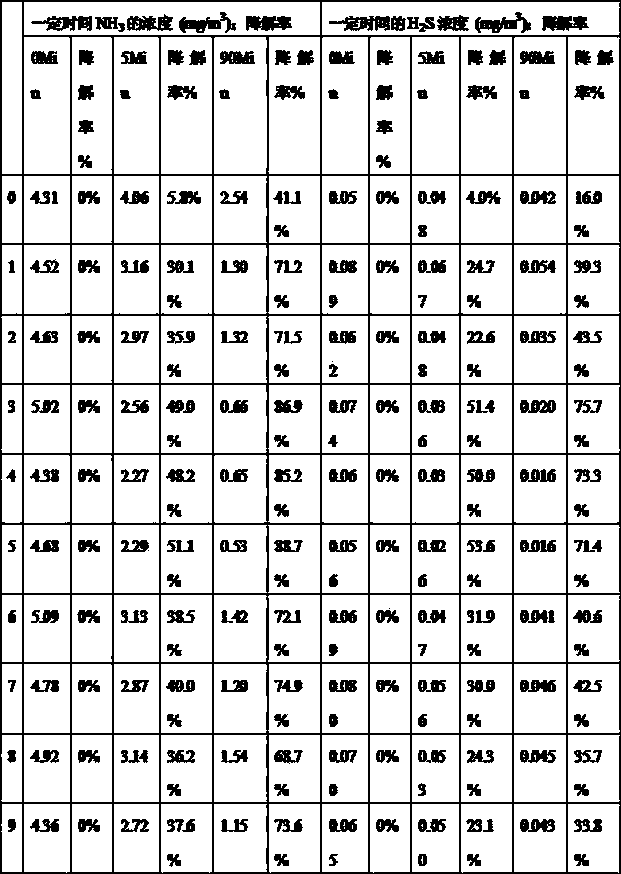

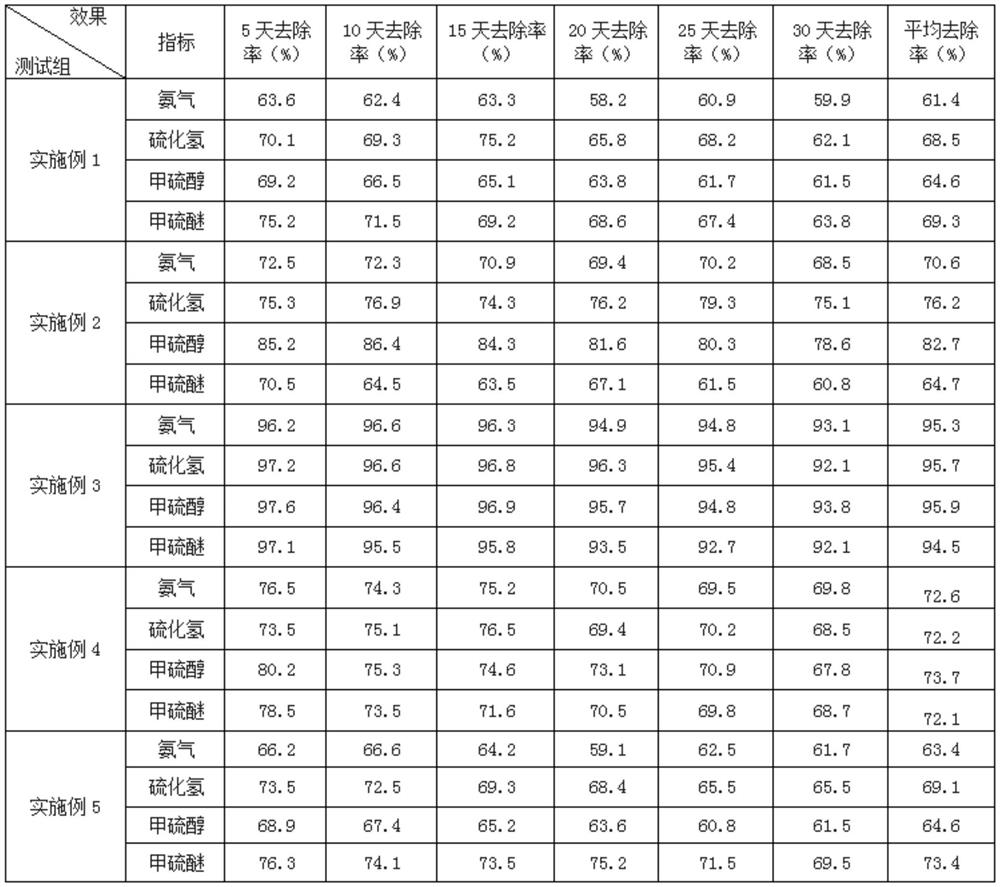

Seaweed biological deodorant and preparation method thereof

ActiveCN103656712APromote proliferationStrong bactericidal abilityDeodrantsBacterial agentProteolysis

The invention discloses a seaweed biological deodorant and a preparation method thereof. The seaweed biological deodorant comprises the following components in parts by weight: 10-20 parts of a composite bacterial agent, 20-40 parts of seaweed pulp, 3-8 parts of inorganic salt, 5-15 parts of molasses, and 40-60 parts of water. The seaweed biological deodorant, provided by the invention, is prepared through the steps of screening and culturing a group of multi-functional microbial flora and fermenting for two times through different fermentation bases, and is the fermented microorganism and metabolite thereof as well as fermentation base material, and can deodorize for purifying air, and can kill pathogenic microorganisms, so that the amount of ammonia gas generated through proteolysis is reduced, and further, environment pollution is reduced.

Owner:日照贝斯特环保生物科技有限公司

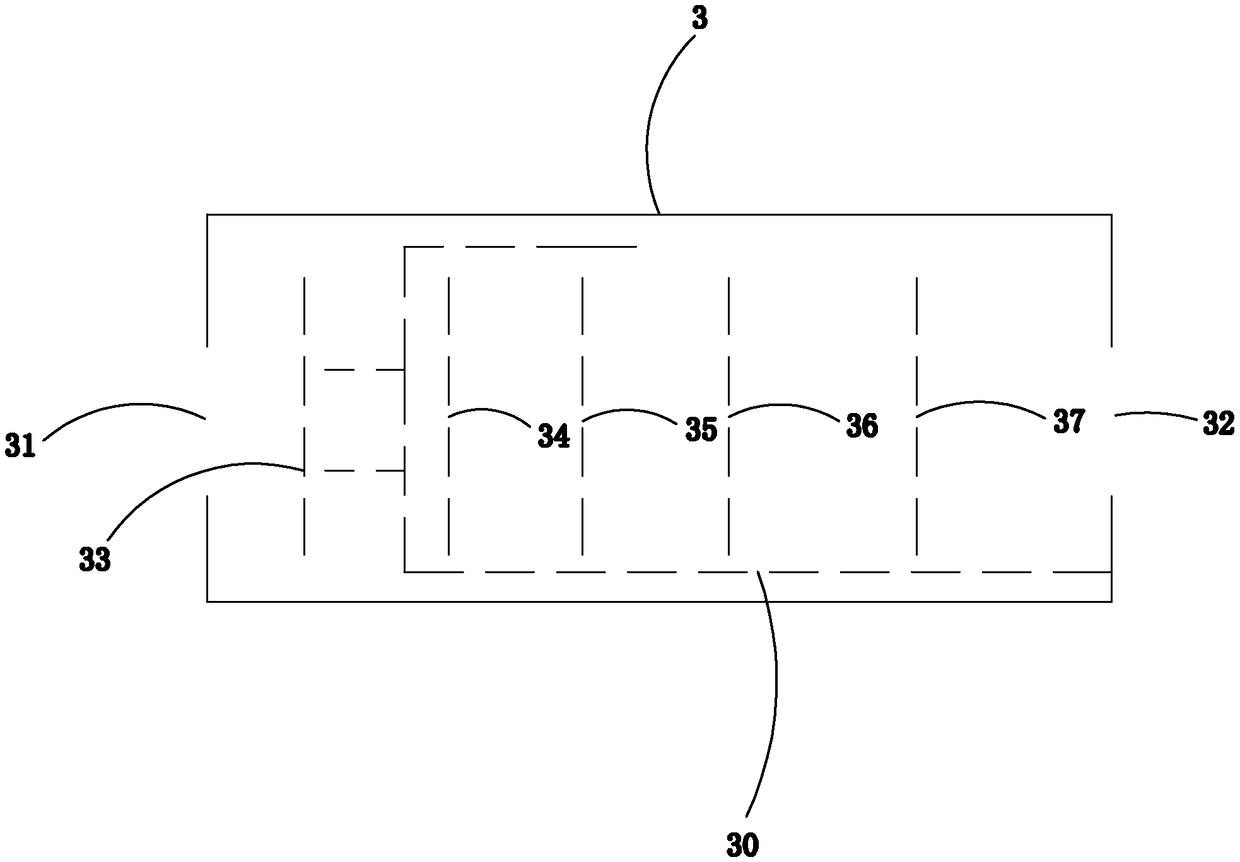

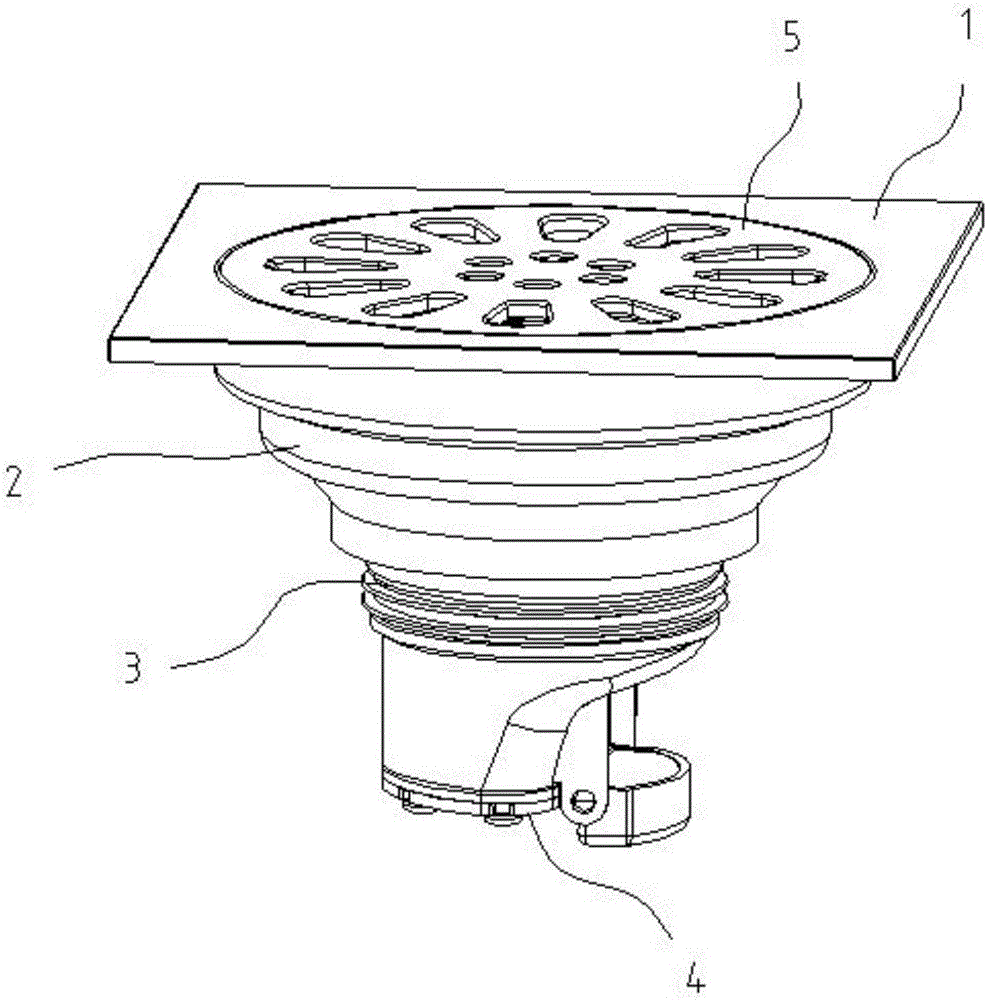

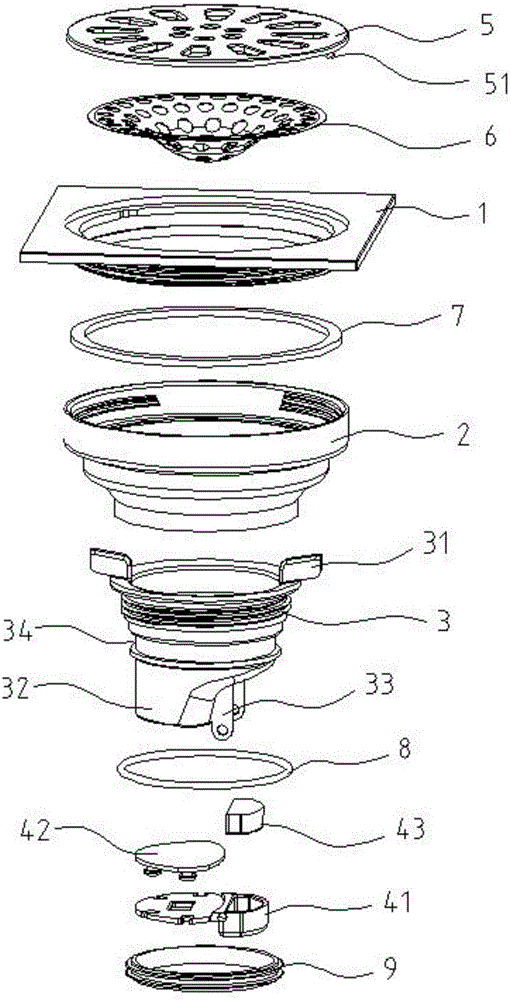

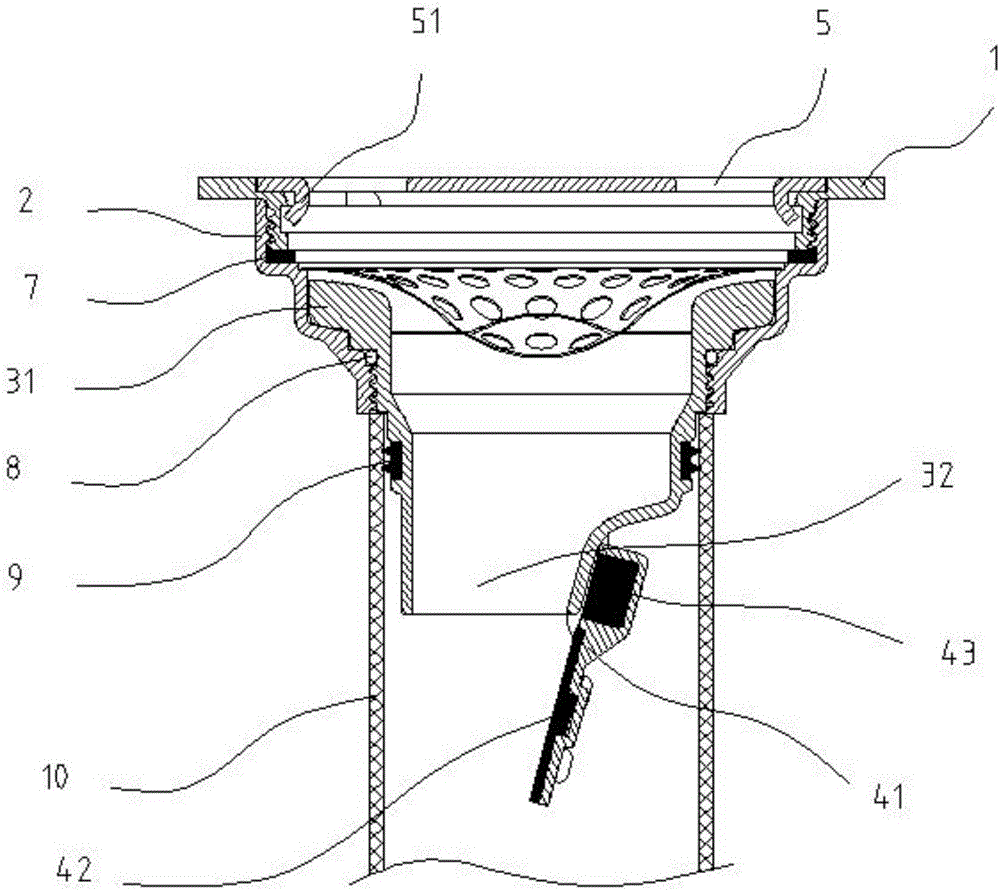

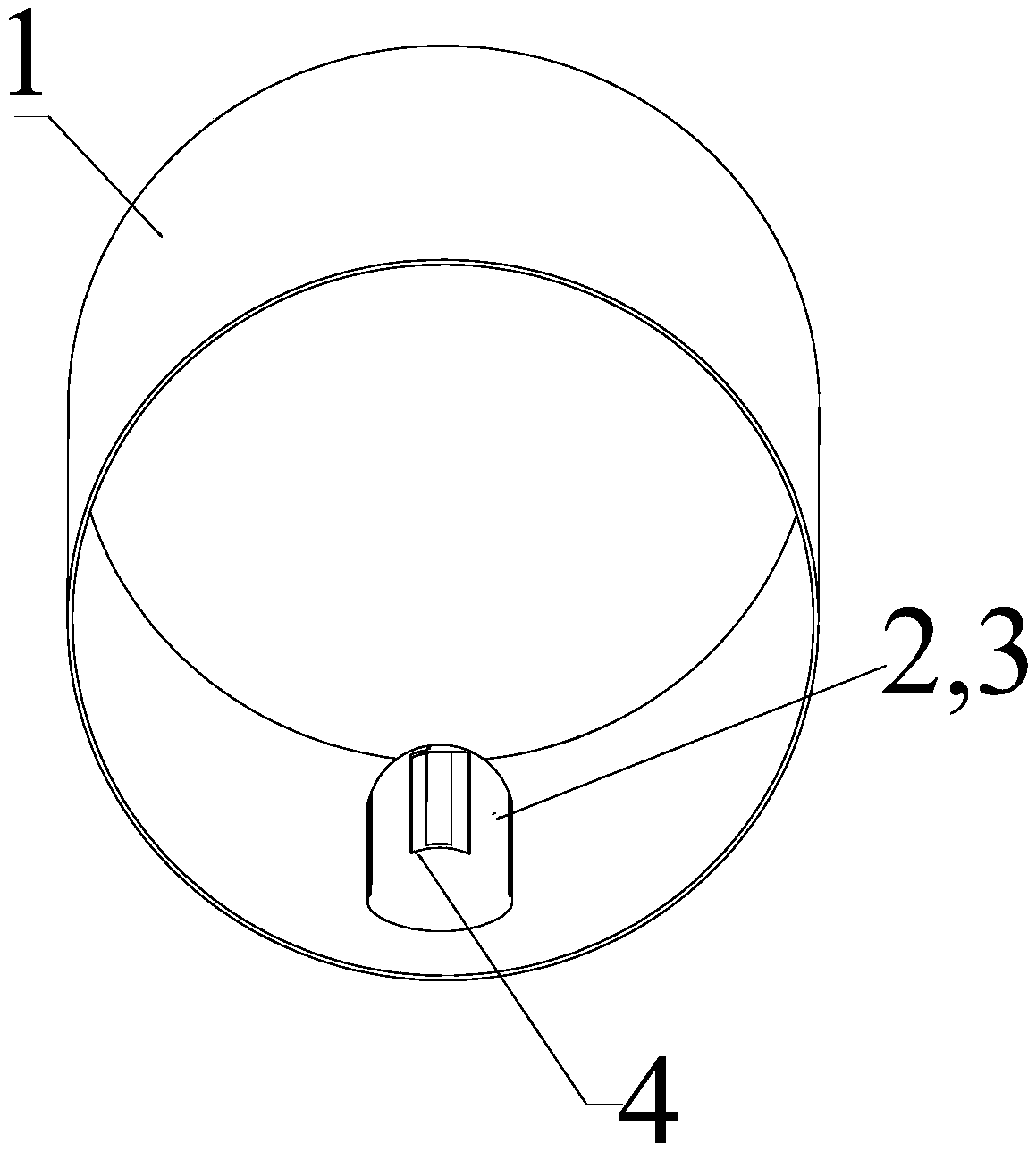

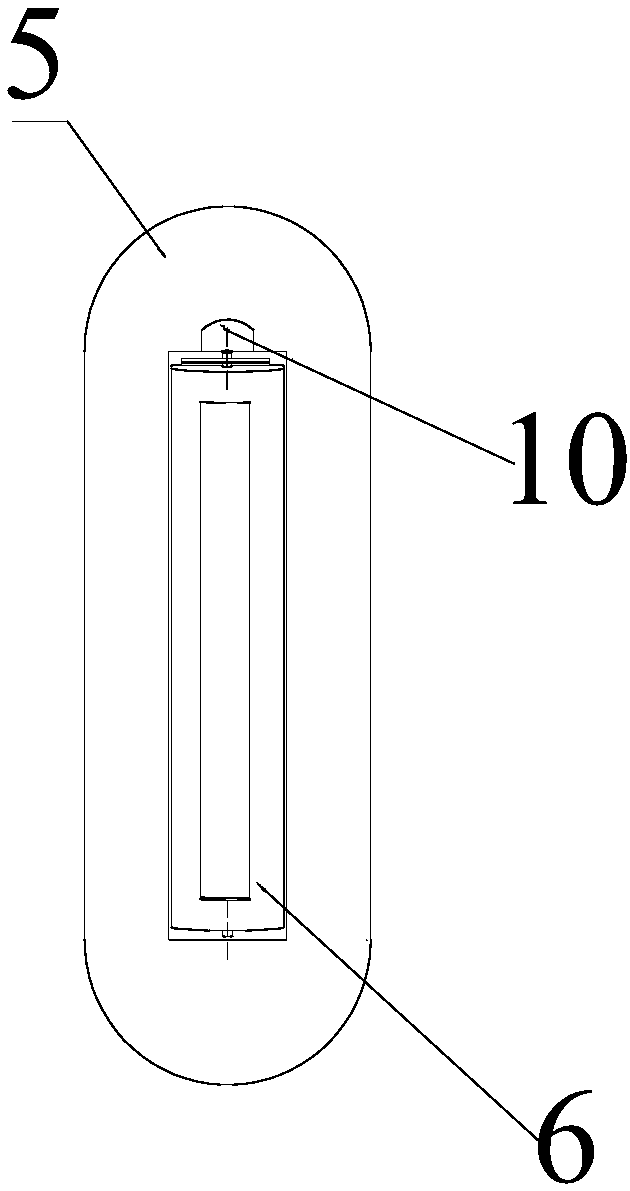

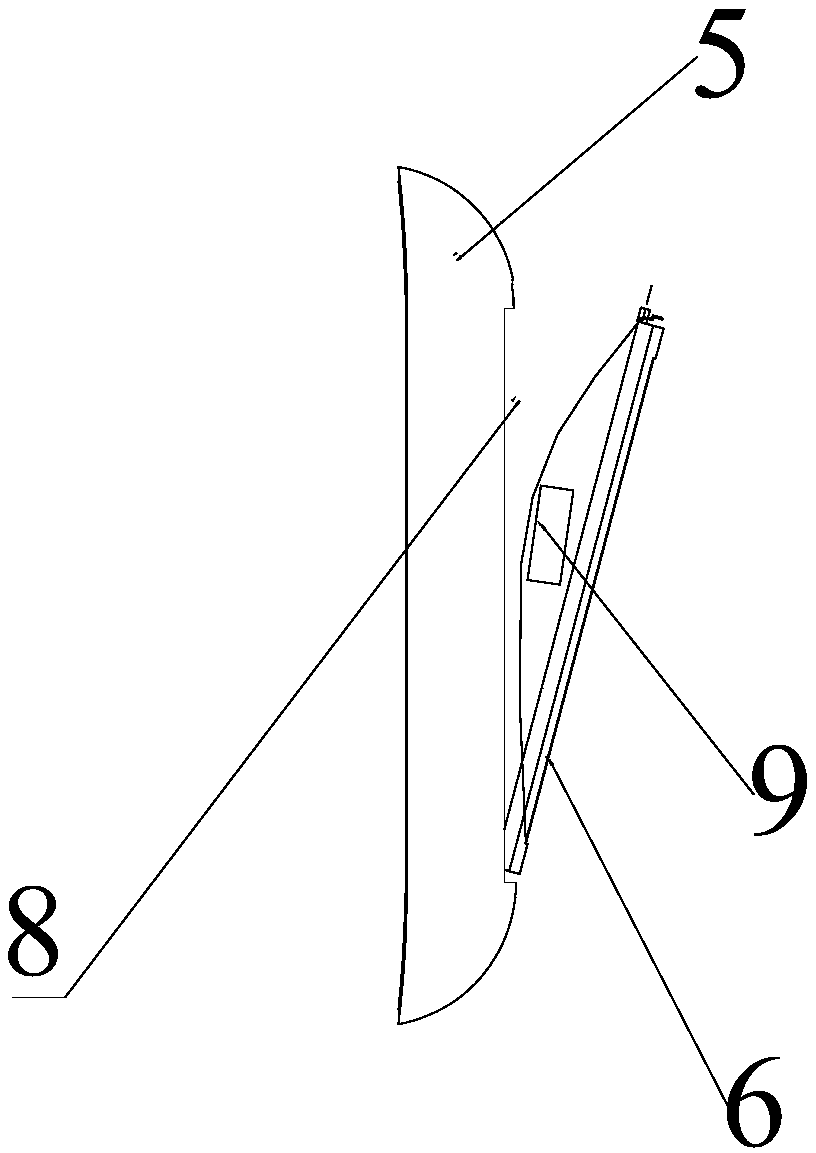

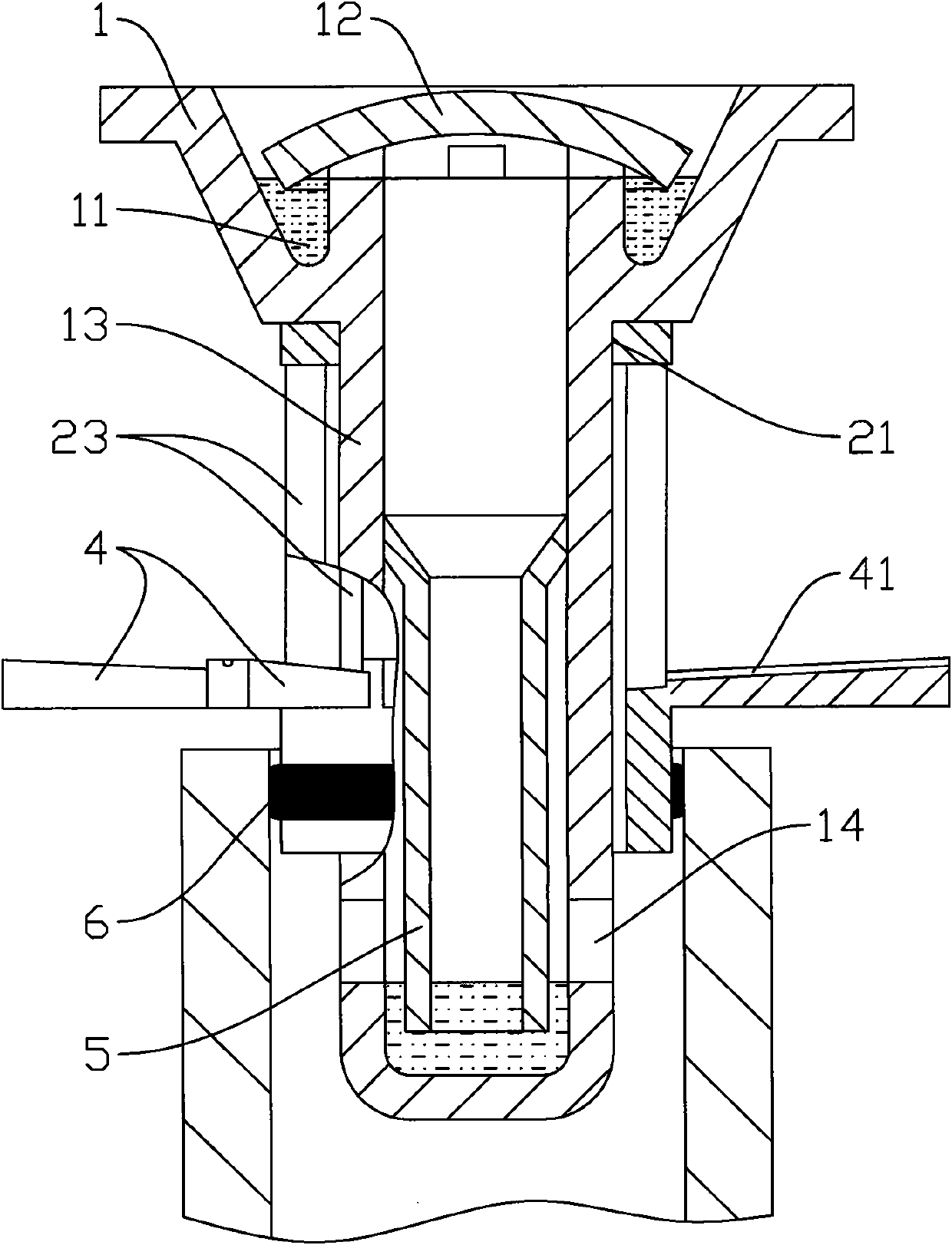

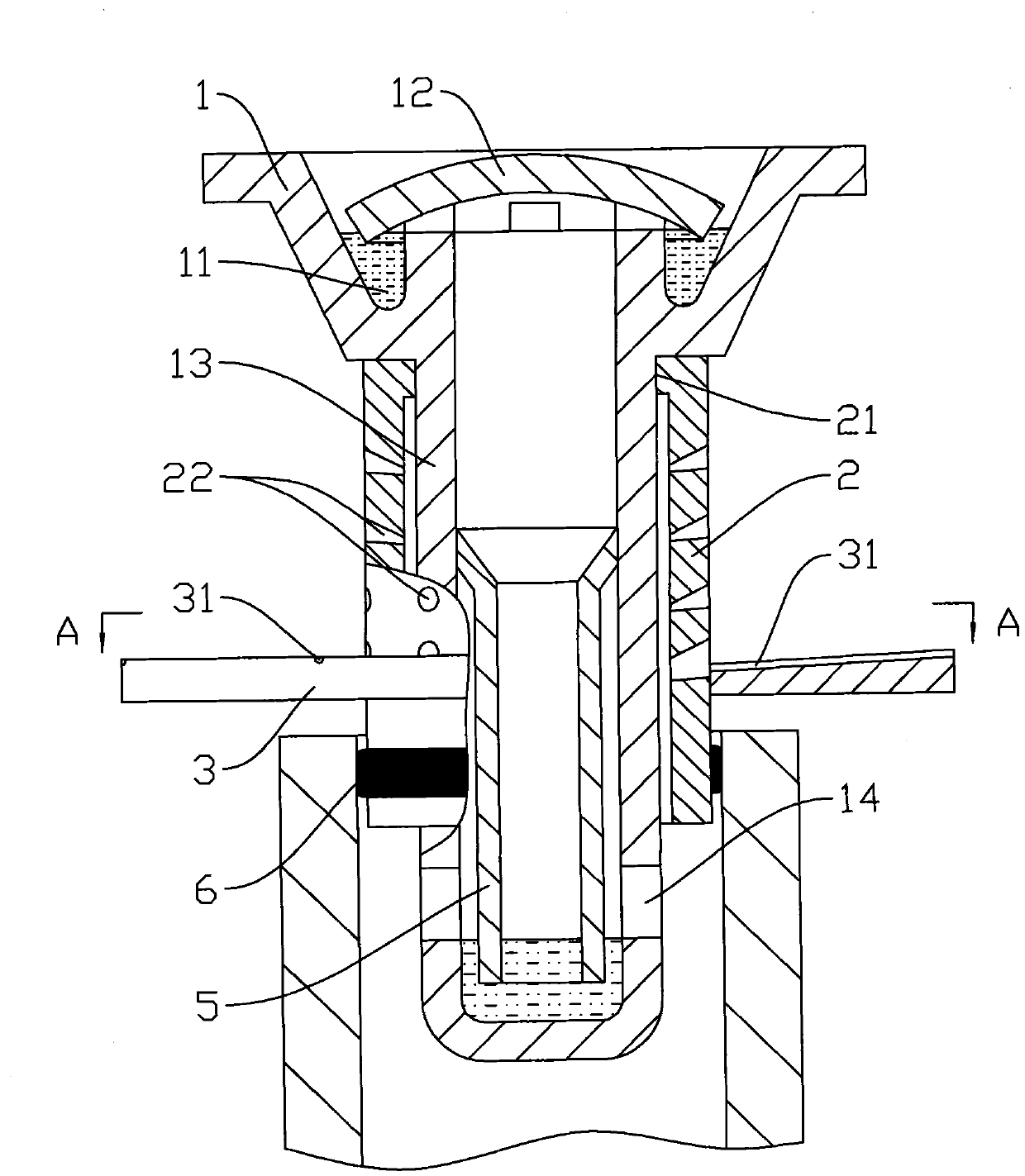

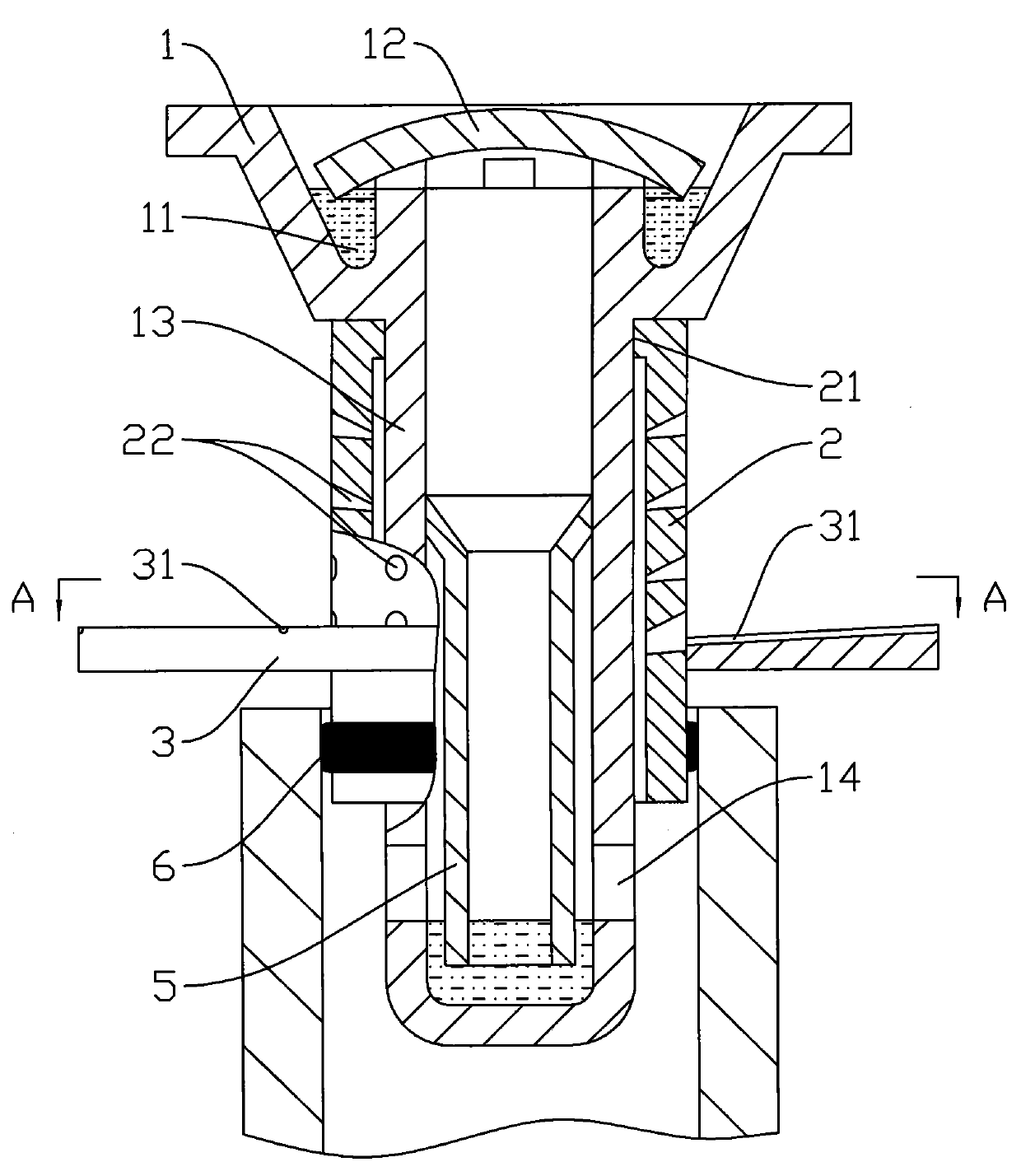

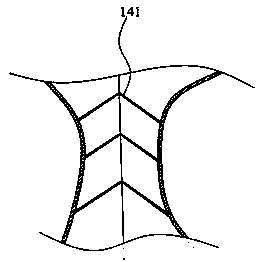

Deodorizing floor drain with dismountable inner core

InactiveCN106759812AEasy to assemble and disassembleGuaranteed tightnessSewerage structuresEngineeringSewage

The invention provides a deodorizing floor drain with a dismountable inner core, and belongs to the technical field of a floor drain. The deodorizing floor drain with the dismountable inner core comprises a floor drain body leveled to the ground, a deodorizing body connected to the lower part of the floor drain body, and a deodorizing inner core placed in the deodorizing body; a deodorizing module is hinged on a lower outlet of the deodorizing inner core. Through the split setting of the floor drain, the splits are in threaded connection, thereby facilitating disassembly and assembly, the component manufacturing is simpler; the repair, replacement and clean in post period are more convenient; a drain outlet is in the shape of approximate cylinder, thereby effectively preventing the sundries residue for being hung, preventing the blockage and insufficient discharge and further preventing health influence for sewage residue; through arranging a cushion ring between the floor drain body and the deodorizing body, an 'O' type ring is arranged between the deodorizing body and the deodorizing inner core, and a sealing ring is arranged between the deodorizing inner core and the sewer pipe; thus the deodorizing floor drain guarantees the inside and outside tightness of the floor drain and prevents the floor drain sealing from failure.

Owner:NINGBO RUNNER INDAL CORP

Splash-proof preparation

ActiveCN105885785AAvoid chokingAvoid stickingOther chemical processesTransportation and packagingSolid acidCarbonate

The invention discloses a splash-proof preparation which comprises solid acid, carbonate and / or bicarbonate, and a thickening agent and / or a foam stabilizer, and particularly comprises the following components in parts by weight: 5-65 parts of solid acid, 15-50 parts of carbonate, 15-50 parts of bicarbonate, 2-70 parts of a thickening agent and 2-60 parts of a foam stabilizer. The splash-proof preparation is a formed body of any shape. The formed body of any shape is an expanded body, or the formed body of any shape is a granular body and / or a blocky body and / or a flaky body and / or a shell body and / or a cartoon body. The splash-proof preparation can be completely dissolved into water seal, the situation that people are choked by a part of powder flying in air can be avoided, the situation that a part of powder is adhered to a closestool wall above the water seal can be also prevented, and great convenience can be brought to closestool cleaning. A foam layer thicker than 2cm can be generated, and a great splash-proof effect can be achieved. Formed products of multiple splash-proof preparations can be produced according to different demands of customers.

Owner:盛毅

Clothing treatment barrel and clothing treatment device

InactiveCN110499623ASimple structureImprove washing effectOther washing machinesTextiles and paperTherapeutic effectEngineering

The invention discloses a clothing treatment barrel and a clothing treatment device. A containing cavity for containing a clothing treatment agent is formed in the wall of the clothing treatment barrel, and the clothing treatment agent is released outwards into the clothing treatment barrel, or air and / or liquid in the clothing treatment barrel enters the containing cavity. The containing cavity for containing the clothing treatment agent is formed in the wall of the clothing treatment barrel and can be formed separately or formed in existing lifting structures, and therefore improvement is realized on the basis of the existing structures; the structures are simple, the cost is not increased, and not only can the clothing treatment effect be improved, but also the economic burden of consumers can be reduced.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Environment-friendly bamboo charcoal mask and manufacturing method thereof

ActiveCN104055246AStrong adsorption propertiesHigh adsorption propertiesProtective garmentPolymer scienceEngineering

The invention provides an environment-friendly bamboo charcoal mask and a manufacturing method thereof. The mask comprises an inner mask body and an outer mask body, the inner mask body is provided with a detachment opening, a filtering layer is arranged in the detachment opening, the inner mask body, the outer mask body and the filtering layer are all made of electret melt-blown polypropylene fiber non-woven fabrics, chitosan serves as a capsule wall material of the filtering layer, nanometer bamboo charcoal powder serves as a core material to be made into micro capsules, and the microcapsules are arranged on the non-woven fabrics through beewax serving as adhesive agents. The chitosan, the bamboo charcoal powder and the beewax are all natural materials, the obtained product is environmentally friendly, safe and efficient and has a broad-spectrum antibacterial function, the microcapsules are arranged on the non-woven fabrics through the beewax serving as the adhesive agents, and good washability is achieved.

Owner:维尼健康(深圳)股份有限公司

Preparation method of chicken farm deodorant

InactiveCN112755231AFast particle surface reactivityHigh activityBiocideSludge treatmentBiotechnologyAnimal science

The invention discloses a preparation method of a chicken farm deodorant. Zinc hyaluronate in the chicken farm deodorant is prepared by performing ion exchange on sodium ions on sodium hyaluronate carboxyl and zinc ions in zinc proteinate. The preparation method comprises the following steps: adding zinc hyaluronate powder into water, performing heating to 50 DEG C in a constant-temperature water bath, continuing performing heating for 6-8 hours, and performing uniform stirring and dispersing until the zinc hyaluronate powder dissolves, so as to prepare a zinc-containing emulsion A; and adding ethanol into the prepared zinc-containing emulsion A, performing stirring and dispersing to obtain a zinc-containing emulsion B, adding citric acid into the zinc-containing emulsion B, performing dissolving to obtain a zinc-containing emulsion C, adding an essence solution into the zinc-containing emulsion C to obtain a zinc-containing emulsion D, adding a dispersing agent into the zinc-containing emulsion D, and performing shearing and dispersing to obtain the chicken farm deodorant. The chicken farm deodorant disclosed by the invention can inhibit breeding of bacteria in a chicken farm, has obvious effects of deodorizing chicken manure and removing flies and mosquitoes, and is free from toxic and side effects.

Owner:南京凯创微锌环境技术有限公司

Durable antibacterial composite fabric based on graphene and preparation method thereof

ActiveCN113442523AWide variety of sourcesLow costLamination ancillary operationsBiochemical fibre treatmentFiberGlycerol

The invention discloses a lasting antibacterial composite fabric based on graphene. The lasting antibacterial composite fabric comprises a skin-friendly layer, a sweat absorption layer, an antibacterial layer and an anti-ultraviolet layer, water-soluble phenolic resin is used for carrying out modification treatment on bamboo fibers, so that the modified bamboo fibers have high specific surface area, and the adsorbability, the antibacterial property, the deodorization property and the ultraviolet resistance of the bamboo fibers are greatly improved; graphene oxide quantum dots are used as a matrix for fixing cerium oxide nano-particles, so that the cerium oxide nano-particles are uniformly distributed on the graphene oxide quantum dot nano-sheets, and the effects of slowly releasing the cerium oxide nano-particles and resisting bacteria for a long time are achieved by adding chitosan and glycerol; and nano zinc oxide and flower-like titanium dioxide are organically combined in the anti-ultraviolet layer, so that UVA and UVB in sunlight ultraviolet rays can be effectively shielded, and the self-cleaning property and the pollution resistance of the fabric are improved.

Owner:江苏江山红化纤有限责任公司

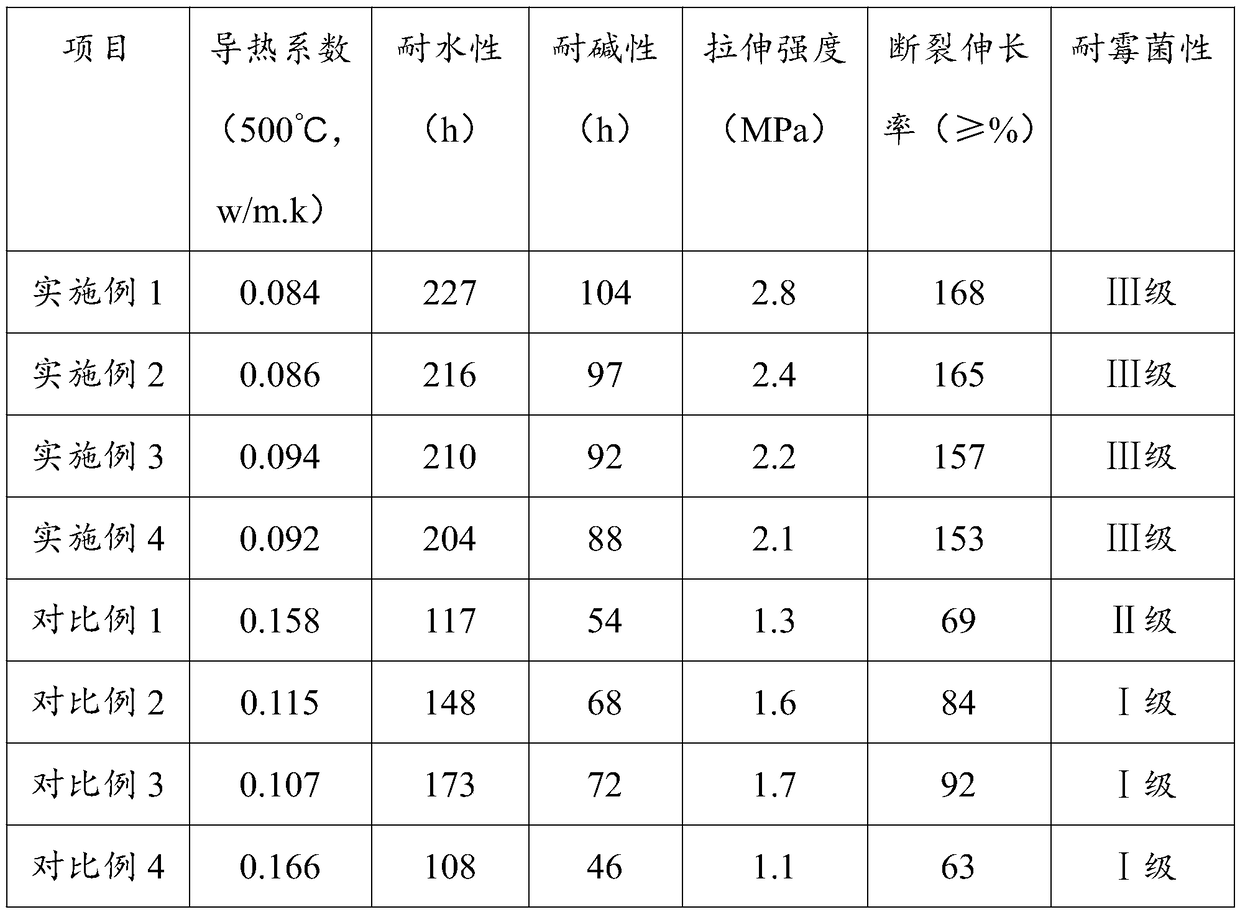

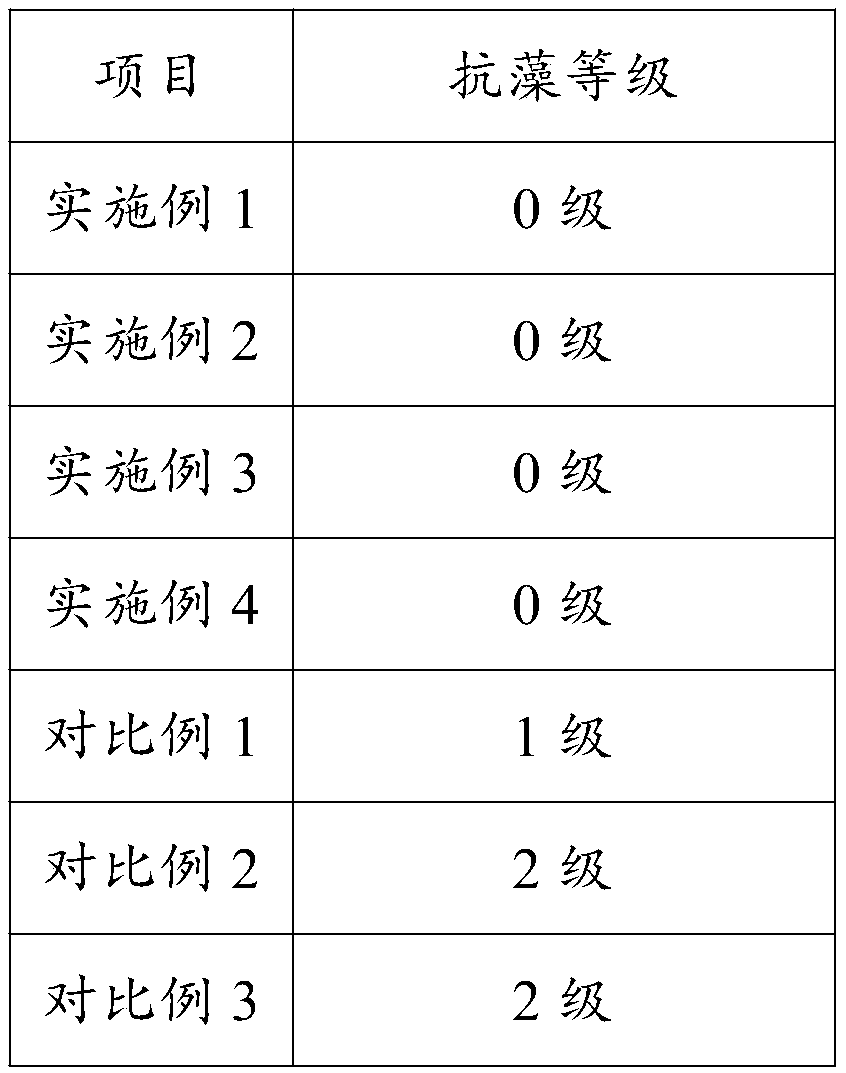

External wall panel insulating coating and preparation method thereof

ActiveCN109233476AImprove hydrophobicityHigh tinting strengthAntifouling/underwater paintsPaints with biocidesSodium BentoniteMicrosphere

The invention discloses an external wall panel insulating coating and a preparation method of the insulating coating. The insulating coating comprises the following ingredients in parts by mass: 100-130 parts of vinyl chloride / vinyl acetate / acrylate copolymerization emulsion, 20-40 parts of silane coupling agent, 6-18 parts of rutile titanium dioxide, 5-10 parts of texanol, 3-7 parts of modified bentonite, 2-5 parts of nano antibacterial high polymer microsphere, 0.1-0.8 parts of curing agent, 0.6-1.3 parts of anti-alga agent and 40-70 parts of tetrahydrofuran. The preparation method comprisesthe steps of emulsion particle preparation, antibacterial and anti-alga mixed solution preparation, mixed emulsion preparation and insulating coating preparation. The external wall panel insulating coating has better hydrophobicity and chemical resistance, and good mold and alga growth inhibition performance after absorbing moisture, and a low heat conductivity coefficient and a heat insulating effect of the coating are kept.

Owner:浙江立盛新型墙体材料有限公司

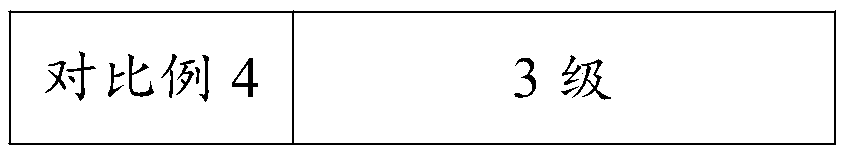

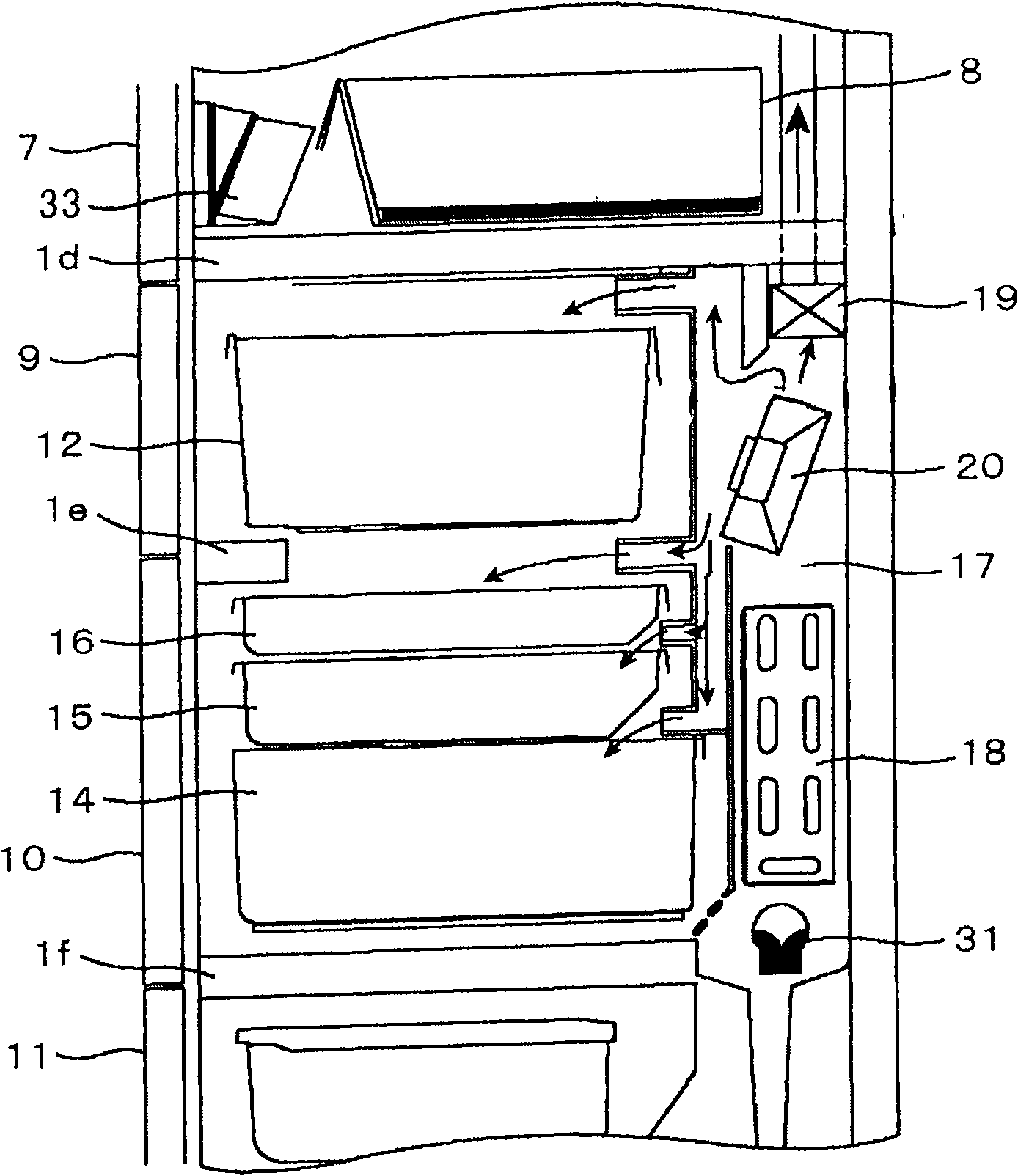

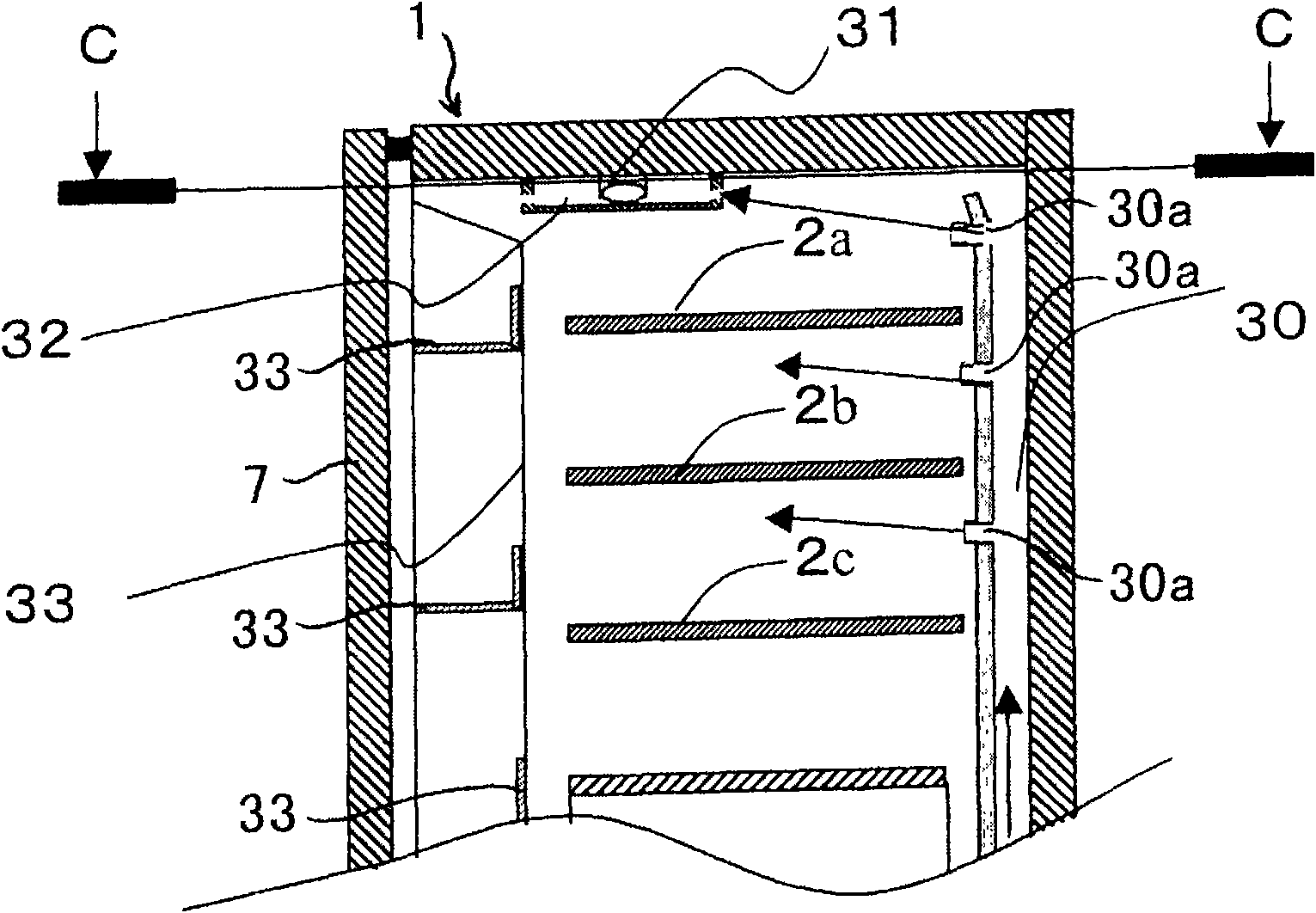

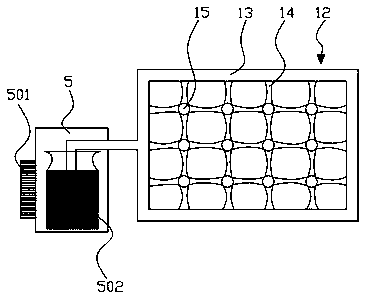

Refrigerator

InactiveCN101988781AImprove deodorizationImprove sterilization effectPhysical/chemical process catalystsDomestic refrigeratorsCold airEngineering

An aim of the invention is to provide a refrigerator with improved deodorization and degerming performance. The refrigerator of the invention is characterized by comprising the following components: a storage chamber which is provided on the refrigerator body; an outlet for conveying cold air to the storage chamber; a visible light emitting type diode which is provided at a place more next to thefront edge compared with the central part in the depth direction at the upper part in the storage chamber and irradiates to the inside; a light-penetrable cover which covers the diode and is providedwith photocatalyst; and a partition which divides the space in the storage chamber and is provided with photocatalyst. The diode irradiates the cover and the partition for performing deodorization tothe cold air discharged from the outlet to the storage chamber.

Owner:HITACHI APPLIANCES INC

Novel antibacterial textile and manufacturing method of series products thereof

InactiveCN101660269AHas antibacterial propertiesImprove antibacterial propertiesFibre treatmentAntibacterial agentAntibacterial property

The invention relates to a novel antibacterial textile and series products thereof. The antibacterial agent formula of the novel antibacterial textile comprises the following components in percentageby weight: 2.3 percent of antibacterial agent SCJ-2000, a proper amount of softening agent, and the balance of water. A process of the novel antibacterial textile comprises the following steps of: (taking the preparation of 100 liters of a treatment fluid as an example) adding 50 kilograms of the SCJ-2000 into 80 liters of the water, stirring the mixture evenly, adding a proper amount of the softening agent, and finally adding the water until the total volume is 100 ligers and stirring the mixture evenly to obtain the treatment fluid; soaking a treated object in the treatment liquid in the bath ratio of 1:10, and then dehydrating and drying the treated object to obtain the finished product; or padding the treated object in the padding ratio of 70 to 80 percent, then drying the treated object (at a temperature of between 80 and 110 DEG C), and stentering the treated object at a temperature of 150 DEG C for 30 seconds, or stentering the treated object at a temperature of between 120 and130 DEG C for 2 to 4 minutes. The antibacterial agent has broad-spectrum efficient antibacterial properties, is nontoxic and tasteless and has no negative effects. The products have the functions of sterilization, bacteriostasis, deodorization, antifogging, itching relieving and convergence, and are washable for above 100 times. The novel antibacterial textile and the series products are suitablefor the antibacterial treatments of the textiles with various materials, colors and deigns and the products of the textiles, and have wide application and high cost performance.

Owner:BEIJING YUJIAMING TRI STATE ION RES INST

Clumped sorbent material

ActiveUS20110084027A1Improve deodorizationImprove sorbencyOther chemical processesSolid sorbent liquid separationNatural productLitter

The present invention pertains to a natural product litter composition as well as methods of preparing and using a natural product litter as a sorbent for liquids. The sorbent contains 1 to 10% by weight Aspen particles and 90 to 99% by weight ground grain byproducts including red dog wheat and wheat middlings. The sorbency of a ground grain litter can be improved by pelletization and crumbling.

Owner:SWHEAT SCOOP LLC

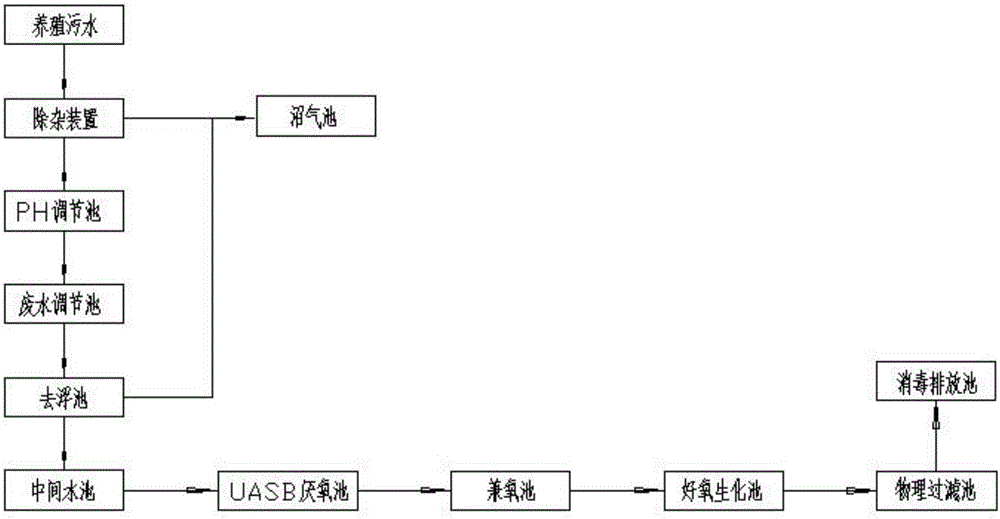

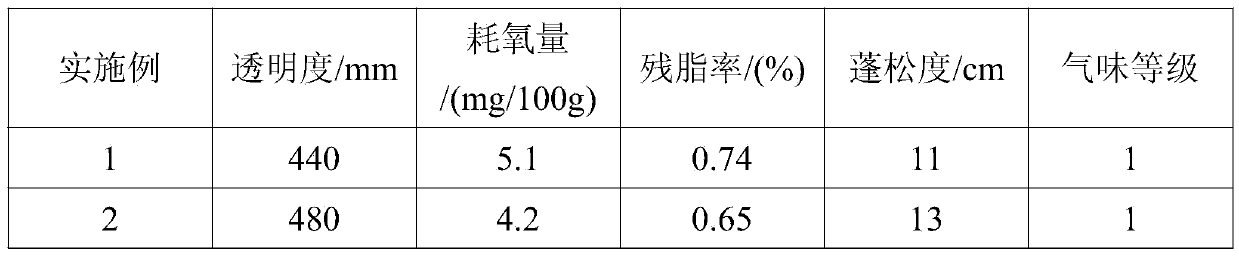

Comprehensive treatment technology for livestock breeding sewage

InactiveCN106186525ALow running costGuaranteed uptimeTreatment using aerobic processesWaste water treatment from animal husbandryLivestock breedingPh regulation

The invention discloses a treatment technology for livestock breeding sewage. The technology comprises the following steps of 1, sewage pretreatment; 2, sewage biochemical treatment; 3, sewage post-treatment, wherein according to sewage pretreatment, an impurity removal device, a pH regulation pond, a regulation pond, a floatation removal pond and a middle pond are mainly included; according to sewage biochemical treatment, an anaerobic tank, an oxygen compatibility pool, an aerobic tank and a physical filter tank are mainly included; sewage is efficiently and easily purified on the basis of reasonable sewage treatment technological process arrangement, the production cost of the sewage purification treatment industry is effectively lowered, and the production efficiency is improved.

Owner:四川天渌环境工程有限公司

Washing agent for raw feather and preparation method thereof

InactiveCN105368600AImprove washabilityEfficient removalNon-ionic surface-active compoundsDetergent compounding agentsEthylenediamine tetraacetateAcetic acid

The invention discloses a washing agent for raw feather and a preparation method thereof and relates to the technical field of a washing agent. The washing agent is prepared from 85-90 parts by weight of polyoxyethylene lauryl ether-7, 3-5 parts by weight of dipropylene glycol methyl ether, 4-6 parts by weight of sec-octyl alcohol, 0.4-0.7 parts by weight of methanol, 0.5-1.5 parts by weight of polyoxyethylene lauryl ester, 0.1-0.3 parts by weight of sodium dodecyl benzene sulfonate, 0.1-0.3 parts by weight of tetrasodium ethylenediamine tetraacetate, 0.03-0.1 parts by weight of Kathon and 1.5-2.5 parts by weight of water. The washing agent has excellent washing effects, can effectively remove dirt and dust on raw feather, can remove odor of raw feather, and can kill bacteria on the feather surface.

Owner:WEST ANHUI UNIV +1

Multifunctional inverter

ActiveCN107276427AImprove ventilationImprove cooling effectAc-dc conversionCooling/ventilation/heating modificationsActivated carbonEngineering

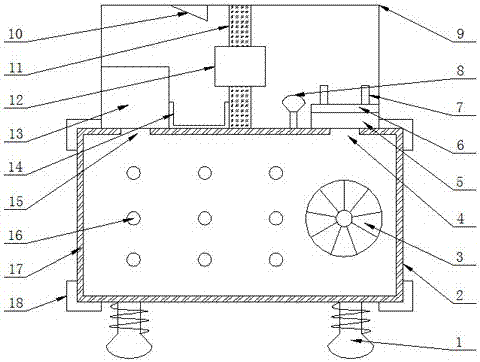

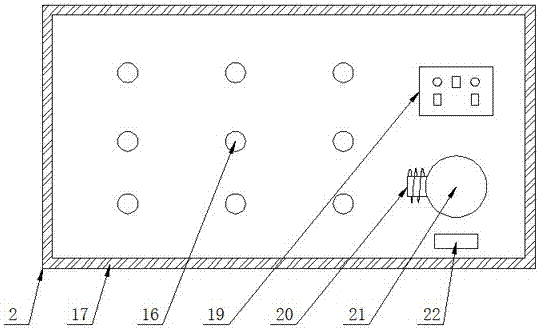

The invention discloses a multifunctional inverter which comprises a damping seat, an inverter body, an ion fan, an air outlet, a activated carbon net, a heat radiation plate, a heat radiation pipe, an ultraviolet sterilization lamp, a dehumidifying hood, an inclined block, a baffle plate, a suction fan, an air heater, a water tank, an air inlet, a hole, a radiation protection lead plate, a corner bead, a multifunctional socket, an electromagnetic coil, a power supply switch and an armature. The inverter body is provided with the hole and is equipped with the corner bead. The inverter body is internally equipped with the radiation protection lead plate. The bottom of the inverter body is correspondingly equipped with the damping seat. One side of the inverter body is equipped with the ion fan, and the other side of the inverter body is equipped with the multifunctional socket. The bottom of the multifunctional socket is equipped with the power supply switch which is equipped with the electromagnetic coil. The top of the inverter body is correspondingly provided with the air inlet and the air outlet. The inverter is safe to use and has the characteristics of cooling and dehumidification.

Owner:江苏谷峰电力科技股份有限公司

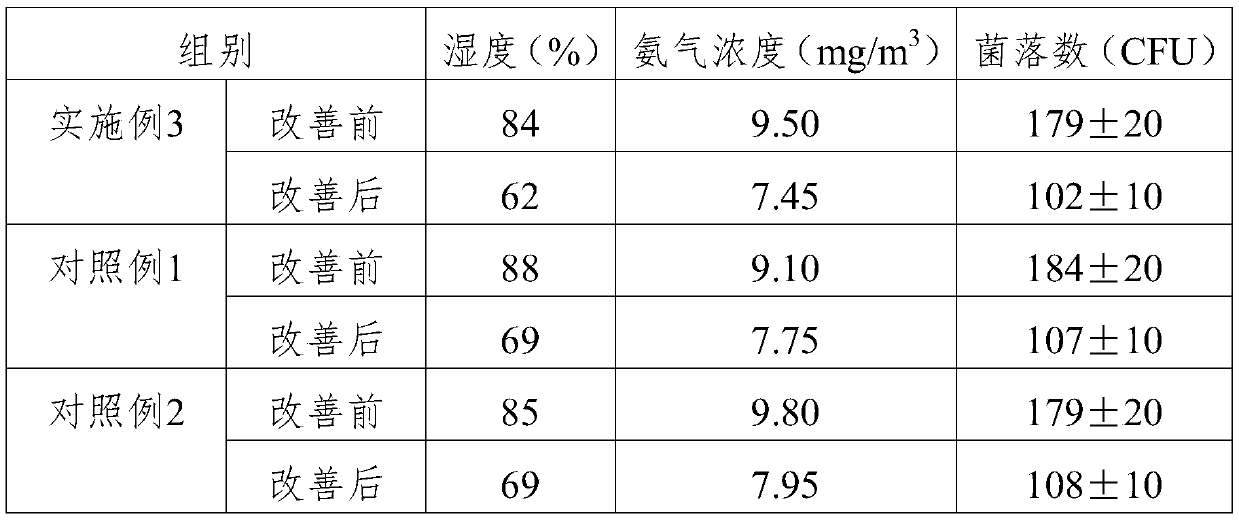

Improver for improving breeding barn environment, preparation method and application of improver

InactiveCN110367193AFast absorptionDry fastGas treatmentDispersed particle separationBiotechnologyMontmorillonite

The embodiment of the invention discloses an improver for improving a breeding barn environment, a preparation method and an application of the improver. The improver is prepared from the following raw materials in parts by weight: 70-75 parts of modified montmorillonite, 8-12 parts of mineral adsorbents, 6-10 parts of plant adsorbents, 1.5-2 parts of titanium dioxide, 4-5 parts of natural plant essential oil and 3-4 parts of pH regulators. The water and ammonia in the barn can be rapidly absorbed through the selection of the raw materials with the specific dosage, the purposes of quickly drying the site and removing peculiar smell can be achieved, and the barn environment can be effectively improved; moreover, the improver is easy to clean without sticking to water through the selection of the specific raw materials; and in addition, the improver can effectively inhibit the growth and spread of bacteria, has no stress reaction on livestock, and is beneficial to improving the health oflivestock.

Owner:北京桃古图新材料有限公司

Composite preparation for producing bio-organic fertilizer from fermented excrements of livestock

InactiveCN107500884AImprove carbon to nitrogen ratioHigh heat production effectBio-organic fraction processingClimate change adaptationChemistryAlkaline protease

The invention discloses a composite preparation for producing a bio-organic fertilizer from fermented excrements of livestock, and the composite preparation can improve fermentation efficiency and deodorization and bacteriostasis effects of the excrements of the livestock. The composite preparation is prepared from the following components in parts by mass: 3-5 parts of alkaline protease, 1-3 parts of lipase, 1-3 parts of cellulase, 1-3 parts of pectinase, 5-10 parts of bacillus subtilis powder, 3-6 parts of bacillus megaterium powder, 3-6 parts of paenibacillus azotofixans GD bacteria powder, 1-3 parts of JF bacillus powder, 3-6 parts of enterococcus faecalis powder, 1-2 parts of candida mycoderma bacteria powder and 1-2 parts of rhodopseudomonas palustris powder, wherein total enzyme activity is at least 0.3 million U / g, and the total number of viable organisms is at least 1012 CFU / Kg.

Owner:DALIAN SANYI ANIMAL MEDICINE CO LTD +1

Deep-seepage deodorizing floor drain

InactiveCN101949168APaste for a long timeReliable and effective removal of accumulated waterSewerage structuresCeramic tilesWater seepage

The invention discloses a deep-seepage deodorizing floor drain, which comprises a body, wherein the upper part of the body is provided with impoundment grooves; a deodorizing bowl is arranged above the impoundment grooves; the lower edge of the deodorizing bowl is immerged into standing water in the impoundment grooves; the lower part of the body is provided with a plug-in mounting part of which a lower end is sealed; the plug-in mounting part is sleeved with connecting pipes connected with a drainage pipeline; the upper part of the connecting pipe is provided with a water-seepage structure for draining the standing water between ceramic tiles and the floor; a water outlet communicated with the drainage pipeline is reserved on a sidewall at the lower end of the plug-in mounting part; and a water seal structure is also arranged in the plug-in mounting part. The deep-seepage deodorizing floor drain has a simple structure, is convenient to mount, can effectively drain the standing water between the ceramic tiles and the floor and effectively prevent water in the floor drain from back-seepage into the floor, improves deodorizing capability, prolongs the lifetime of the water seal and effectively avoids odor in the sewage drainage pipeline overflowing out of the floor drain.

Owner:徐彬

Deodorization and degradation treating agent for garbage leachate and preparation method thereof

InactiveCN107867749AShorten the production cycleEliminate odorWater treatment compoundsSpecific water treatment objectivesPotassiumCarboxylic salt

The invention discloses a deodorization and degradation treating agent for garbage leachate, which is used or carrying out treatment aiming at leachate of garbage from an urban garbage landfill and agarbage power plant, The deodorization and degradation treating agent is prepared from the following components in parts by weight: 7 to 10 parts of ammonium persulfate, 4 to 7 parts of sodium persulfate, 14 to 17 parts of sodium carbonate, 3 to 5 parts of sodium silicate, 8 to 10 parts of sodium cetyl sulfate, 4 to 6 parts of lauroyl aspartic acid, 3 to 5 parts of sodium oleyl sulfate, 6 to 9 parts of sodium stearyl sulfate, 5 to 8 parts of fatty alcohol polyoxyethylene ether, 3 to 5 parts of dilauryl tartrate, 9 to 12 parts of polyglycerol, 5 to 8 parts of potassium carboxylates, 3 to 6 parts of sodium n-alkyl sulfate and 7 to 10 parts of n-butyl polyacrylate. An aqueous solution, with a mass concentration of 0.5 to 0.8 percent, of the treating agent can be used for thoroughly dissolvingsulfur-containing and nitride-containing stinking water within several seconds in a normal-temperature condition to remove a peculiar smell, and can be used for decreasing BOD5 (Biochemical Oxygen Demand 5) in black garbage leachate with a foul smell to 50 percent or below within several minutes. The invention also relates to a preparation method of the deodorization and degradation treating agent for the garbage leachate.

Owner:刘音希

Ventilation device for livestock and poultry breeding shed

InactiveCN109169322AIncrease blood oxygen levelsImprove the immunity of livestock and poultry and the survival rate of livestock and poultryAnimal housingBird housingsFilter windowLivestock

The invention discloses a ventilation device for a livestock and poultry breeding shed, and belongs to the field of livestock and poultry breeding. The device comprises a livestock and poultry breeding shed, wherein the left side of the livestock and poultry breeding shed is provided with a wind guide plate, the right side of the livestock and poultry breeding shed is provided with an exhaust fan,the junction of the exhaust fan and the livestock and poultry breeding shed is provided with a deodorizing device, the livestock and poultry breeding shed at the lateral of the wind guide plate is correspondingly provided with a filter window, the filter window is internally provided with two layers of a screen, and there is hollowed-out filter cotton sandwiched between the two layers. The ventilation device can quickly introduce fresh air into the livestock and poultry breeding shed to remove odor, thereby improving the air quality in the livestock and poultry breeding shed, improving the survival rate of livestock and poultry, and proving a good growth environment for livestock and poultry.

Owner:兰溪市拜瑞珂科技服务有限公司

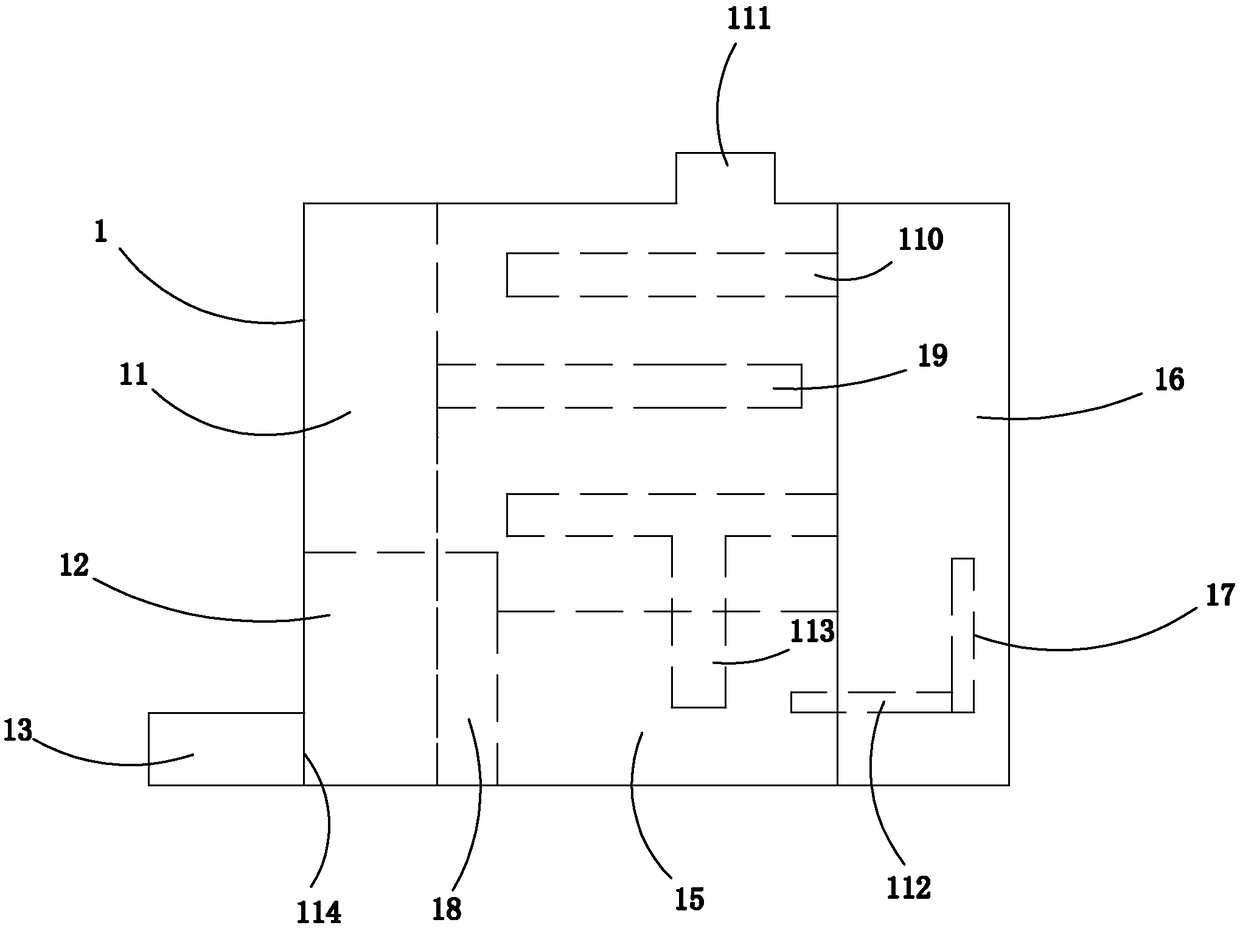

Odor eliminating device in garment dyeing production process

InactiveCN108754948AImprove deodorizationKeep dryLiquid/gas/vapor article treatmentLiquid/gas/vapor removalCooling chamberMechanical engineering

The invention discloses an odor eliminating device in a garment dyeing production process. The odor eliminating device comprises a controller, a bottom plate and a conveying mechanism, wherein the controller and the conveying mechanism are electrically connected; a top plate is arranged above the bottom plate; a front side plate and a back side plate are respectively arranged on the two ends of the bottom plate in the length direction; the two ends of the bottom plate are fixedly connected with the top plate through the front side plate and the back side plate; moving doors are arranged on thetwo ends, vertical to the length direction, of the bottom plate; the moving doors are electrically connected with the controller; an opening matched with the conveying mechanism is formed in each moving door; the upper end of each moving door is connected with the top plate; a work chamber is formed among the bottom plate, the front side plate, the back side plate and the top plate, and comprisesa steam odor eliminating chamber, a drying chamber and a cooling chamber in sequential arrangement in the conveying direction of the conveying mechanism; a moving door is respectively arranged between the steam odor eliminating chamber and the drying chamber and between the drying chamber and the cooling chamber; the conveying mechanism sequentially passes through the steam odor eliminating chamber, the drying chamber and the cooling chamber. The odor eliminating and drying effect on the dyed garments can be effectively improved.

Owner:JIXI YUANDAO AGRI IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com