Material for multifunctional shoe pad and preparation method thereof

A technology of insole and function, applied in the field of insole materials and preparation thereof, can solve the problems of difficulty in effectively preventing foot odor, inability to inhibit bacteria, limited moisture absorption, etc., and achieve the effects of improving life quality, long time and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

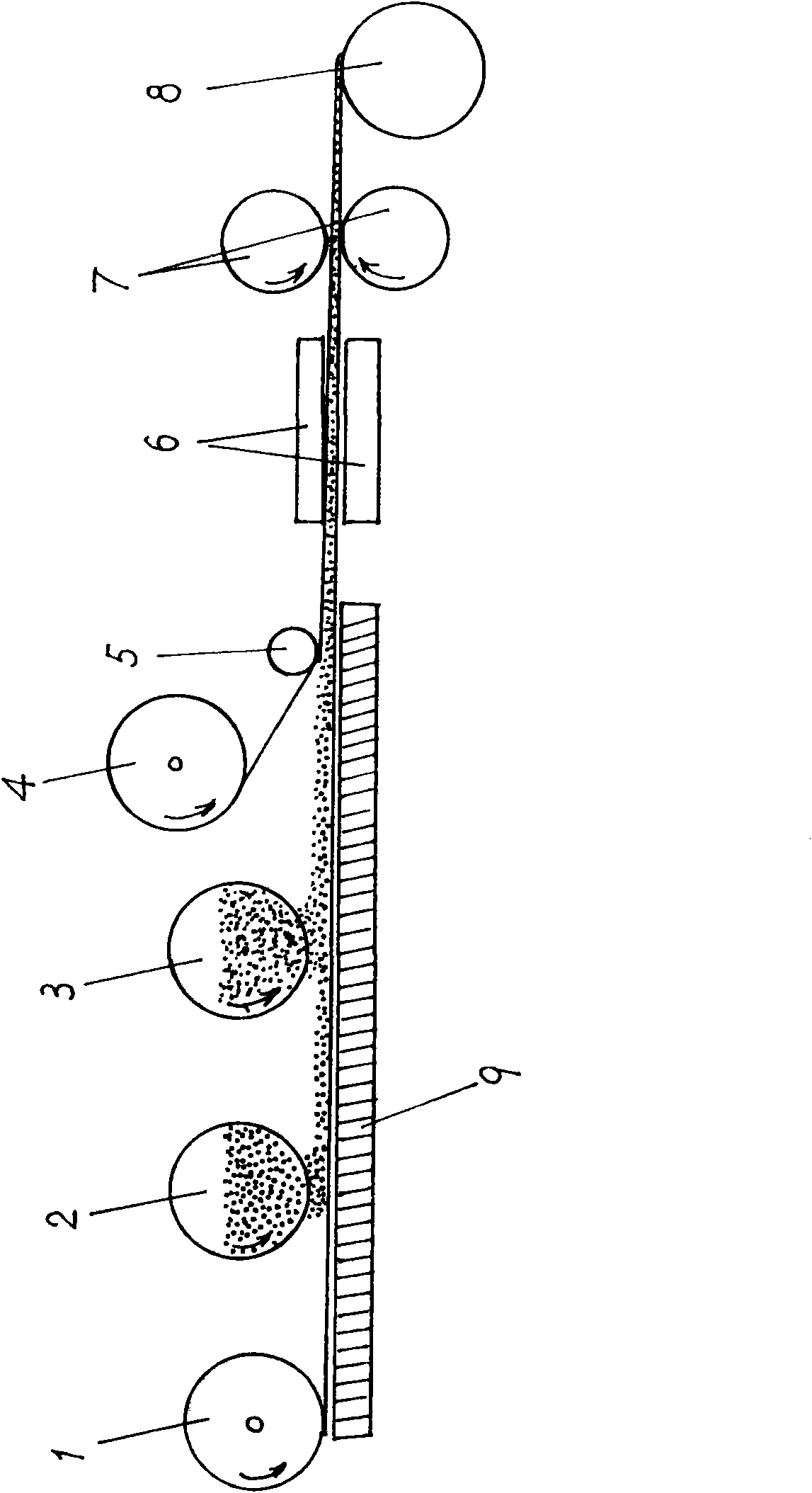

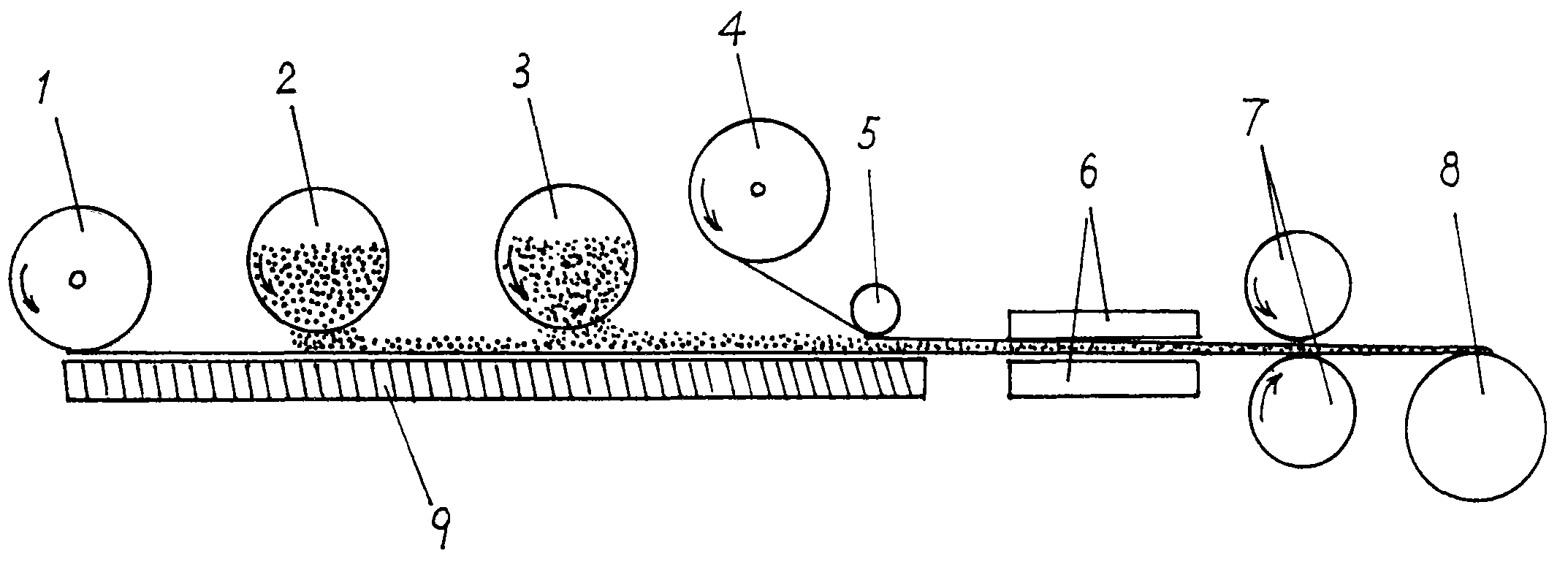

Method used

Image

Examples

Embodiment 1

[0040] (1) Antibacterial agent coated on the surface of superabsorbent resin

[0041] Weigh 10 kg of superabsorbent resin, pour it into a high-speed blender, then weigh 200 grams of nano-silver inorganic antibacterial agent, pour it into a high-speed blender, and stir for 5 to 10 minutes at a speed of 1600 rpm. When the high-speed blender indicates that the temperature is When the temperature is 107-150°C (depending on the melting point of the resin used), the stirring is stopped and the coating is completed;

[0042] (2) Hard microbeads coated with hot melt adhesive

[0043] Weigh 10 kg of glass microspheres, first heat them in an oven, and keep them warm at 110°C for 15-20 minutes. Stir for 5 to 10 minutes at a high speed. Since the surface temperature of the glass beads is the melting point of the EVA hot melt adhesive powder, the EVA hot melt adhesive will melt and cover the surface of the glass beads.

[0044] The following steps are carried out step by step according t...

Embodiment 2

[0046] (1) Antibacterial agent coated on the surface of superabsorbent resin

[0047] Take by weighing 10 kilograms of superabsorbent resin, pour it into a high-speed mixer, then weigh 300 g of nano-silver inorganic antibacterial agent, and pour it into a high-speed mixer, and all the other processes are the same as in Example 1 (1);

[0048] (2) Hard microbeads coated with hot melt adhesive

[0049] Weigh 10 kg of plastic microbeads, first heat them in an oven, and keep them warm at 100°C for 5 to 10 minutes. After taking them out, they are poured into a high-speed mixer equipped with 800g of chlorinated polypropylene hot melt adhesive, and the rest of the process is the same. Example 1(2).

[0050] The following steps are carried out step by step according to the steps of the preparation method of the present invention.

Embodiment 3

[0052] (1) Antibacterial agent coated on the surface of superabsorbent resin

[0053] Weigh 10 kilograms of superabsorbent resin, pour it into a high-speed mixer, then weigh 400 g of nano-silver-zinc inorganic antibacterial agent, and pour it into a high-speed mixer, and the rest of the process is the same as in Example 1 (1);

[0054] (2) Hard microbeads coated with hot melt adhesive

[0055] Weigh 10 kg of metal microbeads, first heat them in an oven, and keep them warm at 180°C for 20 minutes. With embodiment 1 (2).

[0056] The following steps are carried out step by step according to the steps of the preparation method of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com