Patents

Literature

49results about How to "Strong adsorption properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste willow artwork branch recycling method

ActiveCN107142119AHigh carbonation rateQuality improvementOther chemical processesBiofuelsEnvironmental engineeringPre treatment

The invention discloses a waste willow artwork branch recycling method. The waste willow artwork branch recycling method comprises the following steps: (1) preprocessing the branch; (2) removing a surface coating; (3) processing at high temperature and high pressure; (4) processing by using an acid-base solution; (5) modifying; (6) carbonizing. The waste willow artwork branch material is processed in a targeted manner, the surface and the inner organizational structure of the branch are changed, the content and the proportion of the internal substance are regulated, the process parameters in the carbonizing are controlled, so that the overall carbonation ratio is effectively improved, the carbonation quality is improved, the carbonation ratio of the branch is finally more than 99.5%, the specific surface area of the prepared bio-carbon is not less than 3500 m<2> / g and increased by more than 20% in comparison with the prior art, the proportion of micropores in the prepared bio-carbon is more than 96.5%, a quite excellent adsorption characteristic is shown, and the use value is very high.

Owner:阜南县永盛工艺品有限公司

Modified nanometer bamboo charcoal mask and manufacturing method thereof

InactiveCN104041963ALow costHigh adsorption propertiesFibre typesProtective garmentWoven fabricPolymer chemistry

Provided are a modified nanometer bamboo charcoal mask and a manufacturing method thereof. The modified nanometer bamboo charcoal mask comprises an inner mask and an outer mask, wherein the inner mask is provided with a dismounting opening, and a filer layer is arranged in the dismounting opening. The inner mask and the outer mask of the mask and a filer layer base plate are made of an electrets melt-blowing polypropylene fiber non-woven fabrics, the filer layer uses chitosan as a capsule wall material, microcapsules are made from modified nanometer bamboo charcoal powder, beewax is used as an adhesive for arranging the microcapsules on the non-woven fabrics. The modified nanometer bamboo charcoal powder are modified by adopting nanometer titanium dioxide. The modified nanometer bamboo charcoal mask is green, environment-friendly, safe and efficient, has the broad-spectrum antibacterial effect and has good washability due to the fact that the beewax is used as the adhesive to arrange the microcapsules on the non-woven fabrics.

Owner:广州市威普复合材料有限公司

Succinic anhydride modified polymine grafting medium, preparation method and application thereof

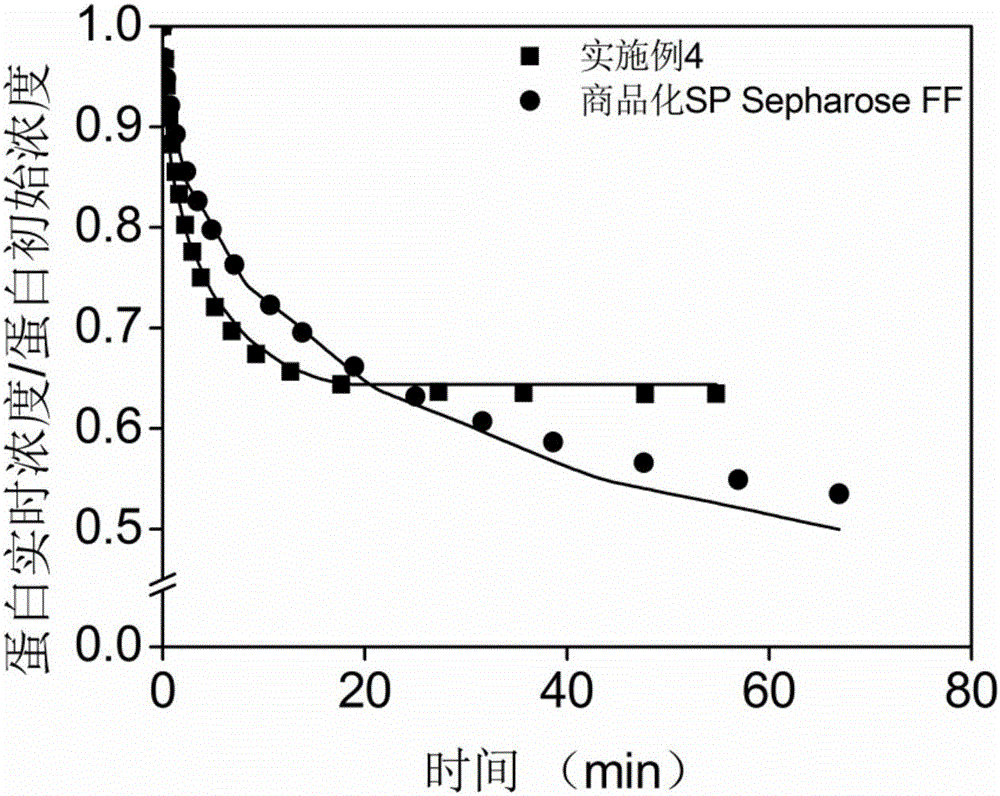

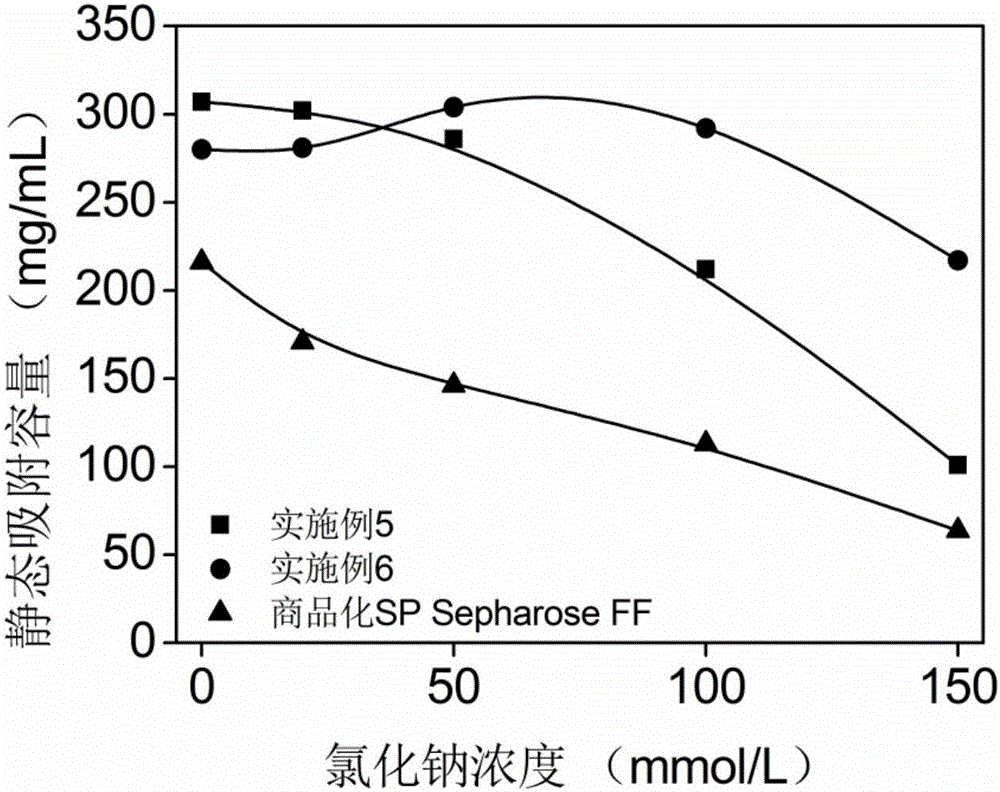

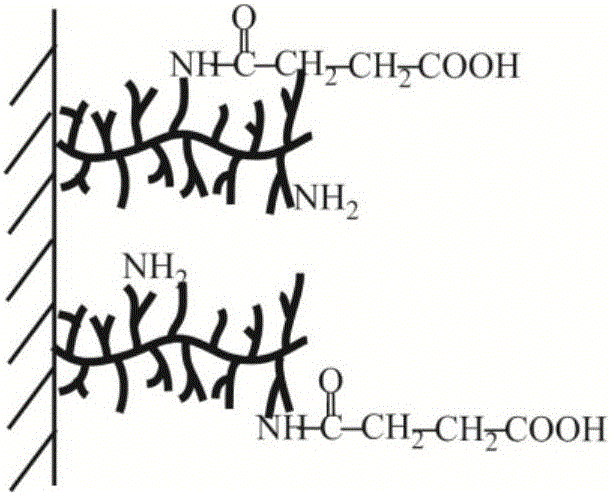

InactiveCN106000364AFast adsorption rateHigh static adsorption capacityChromatographic cation exchangersCation exchanger materialsIon exchangeBiocompatibility Testing

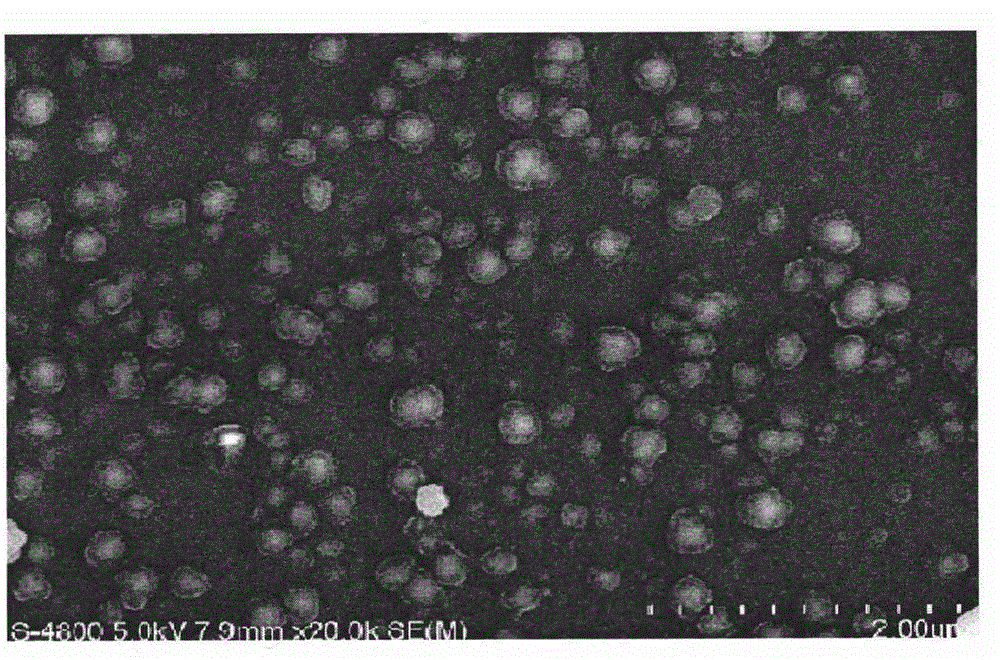

The invention relates to a succinic anhydride modified polymine grafting medium, a preparation method and application thereof. The sepharose gel particle with average grain diameter of 50-170mu m is taken as a chromatography medium of the succinic anhydride modified polymine grafting medium; polymine grafting chain is introduced to the surface through an epoxy group spacer arm; the amino group on the polymine grafting chain is combined with succinic anhydride, so that the succinic anhydride modified polymine grafting medium with carboxyl ion exchange capacity being 150-970mmol / L is obtained. The succinic anhydride modified polymine grafting medium provided by the invention has higher adsorption rate to protein or strong adsorption property to protein, higher static adsorption capacity and excellent tolerance to salt concentration. The medium is conveniently cleaned and sterilized and is easy to regenerate; the biocompatibility is excellent; the preparation method is simple and the cost is low; the medium has wide application prospect in protein separation and purification.

Owner:TIANJIN UNIV

MoS2-enhanced heterogeneous Fenton photocatalyst and preparation method thereof

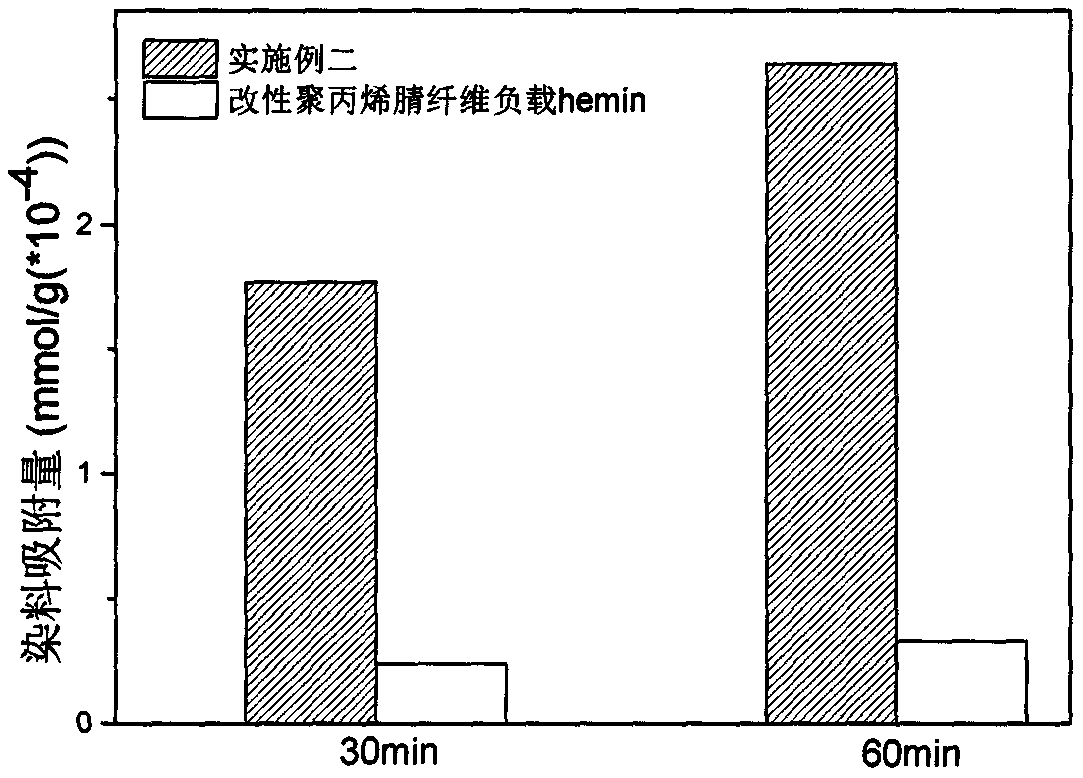

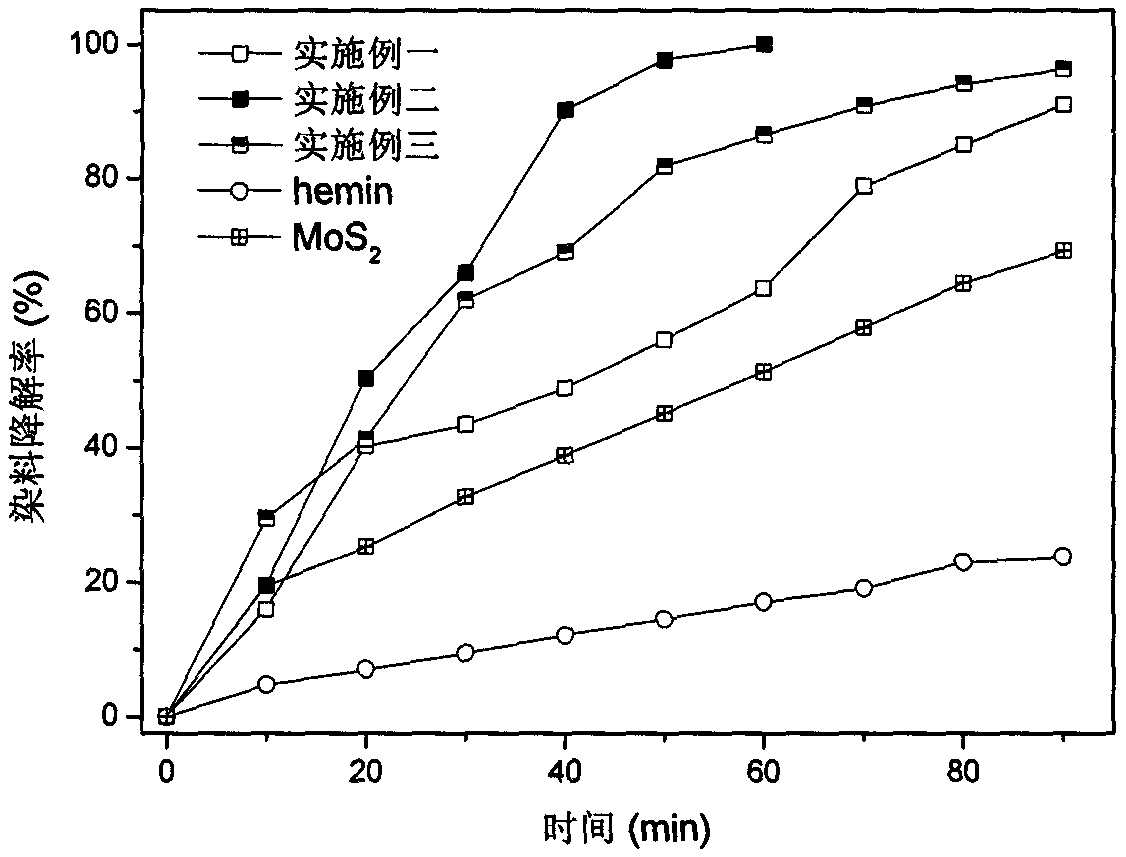

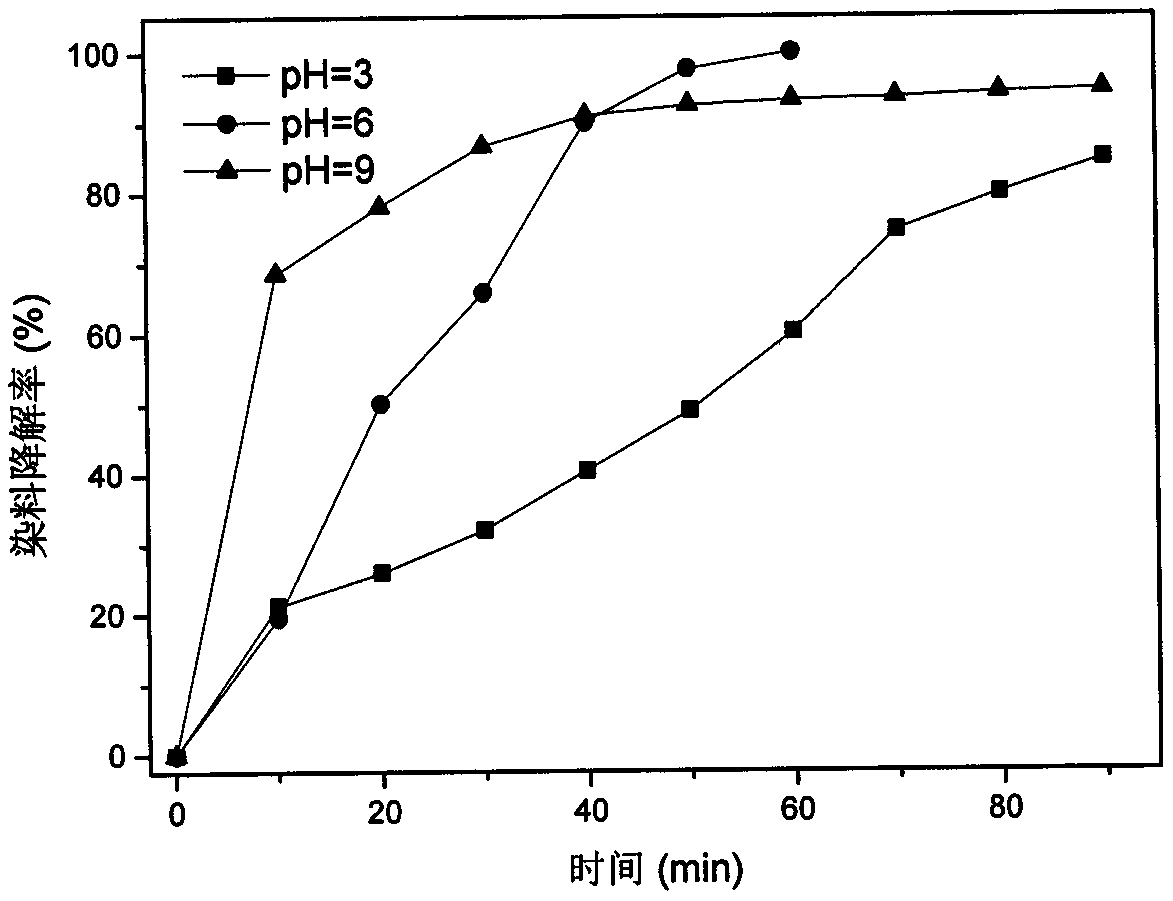

ActiveCN109590027AQuick conversionOvercome the bottleneck of the loopWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAmmonium tetrathiomolybdateHemin

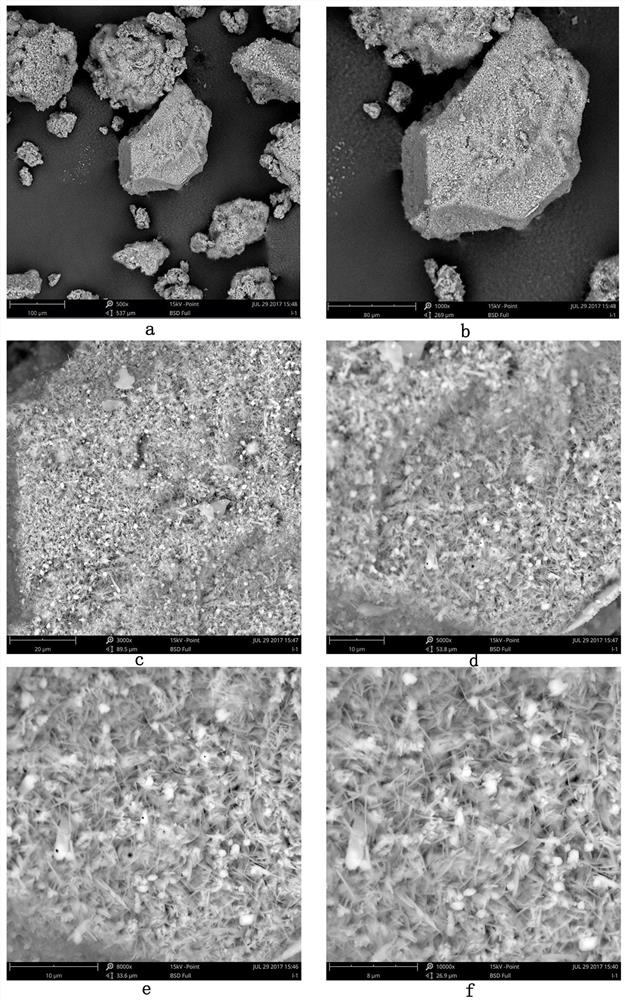

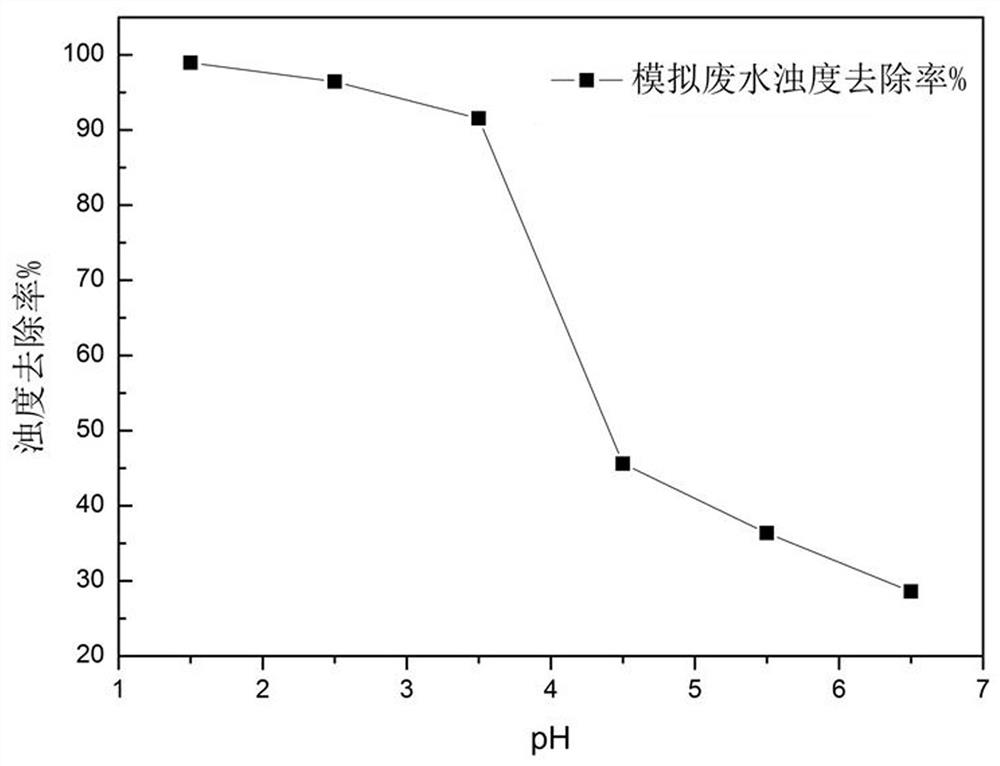

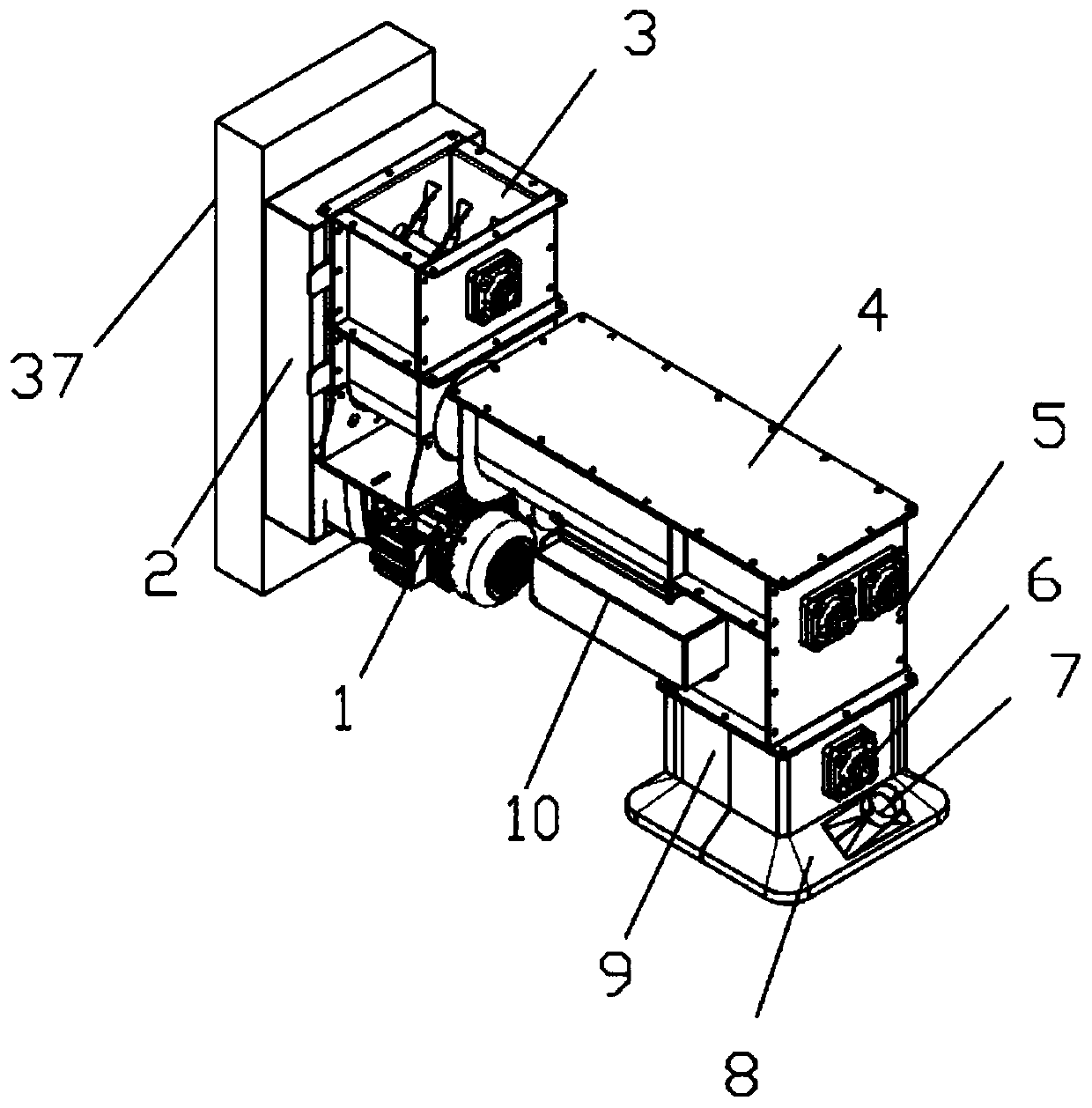

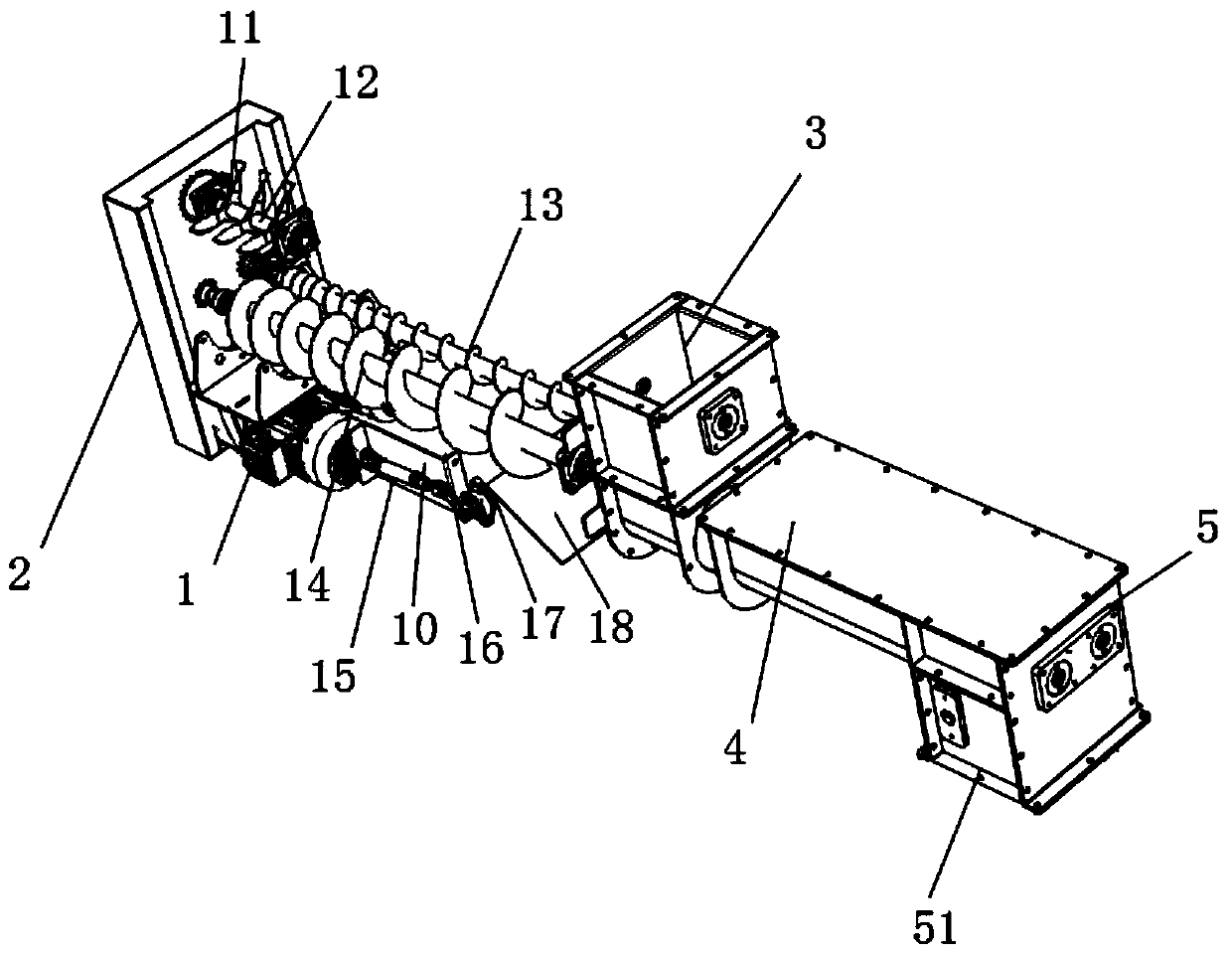

The invention relates to an MoS2-enhanced heterogeneous Fenton photocatalyst and a preparation method thereof. The catalyst has a fibrous appearance and is prepared by taking modified polyacrylonitrile fiber as a carrier and loading MoS2 and chlorhematin (hemin). The preparation method comprises the steps: firstly, making the modified polyacrylonitrile fiber containing an amidoxime group react with a DMF / water mixed solution of hemin, then, making the obtained fiber react with ammonium tetrathiomolybdate serving as a molybdenum source under an acidic condition to obtain the MoS2-enhanced heterogeneous Fenton photocatalyst. The catalyst disclosed by the invention is suitable for an oxidative degradation reaction of organic pollutants in water such as dyes; and compared with the prior art, MoS2 introduced to the MoS2-enhanced heterogeneous Fenton photocatalyst can be used for remarkably improving the adsorption property and visible light catalytic activity of the heterogeneous Fenton photocatalyst to organic pollutants.

Owner:TIANJIN POLYTECHNIC UNIV

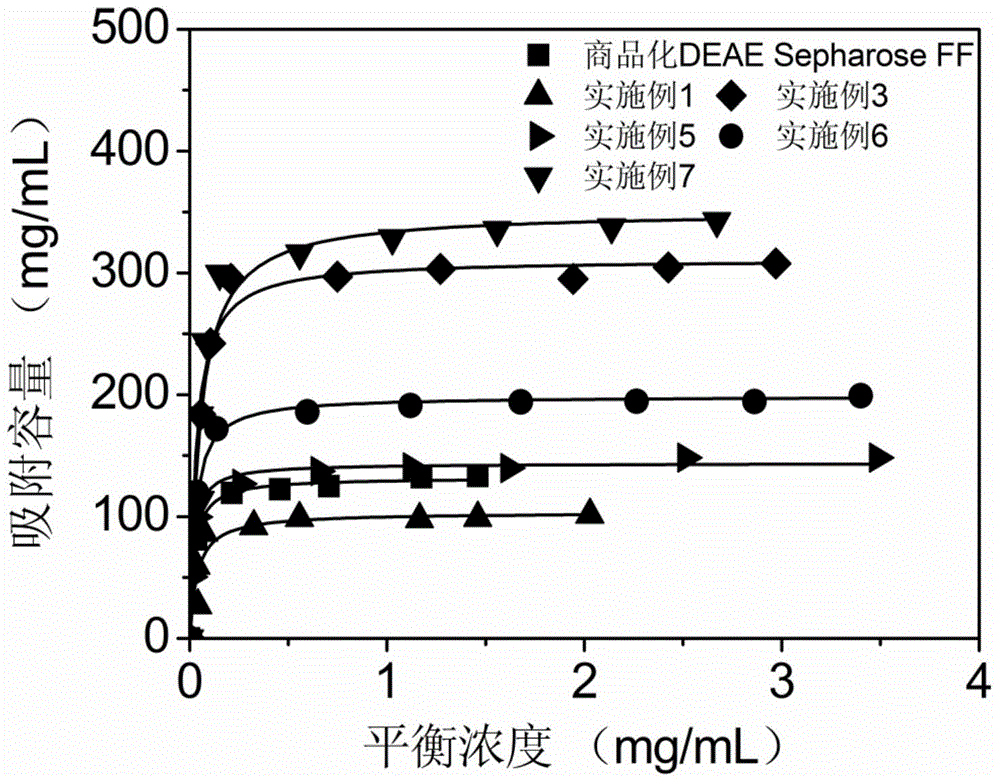

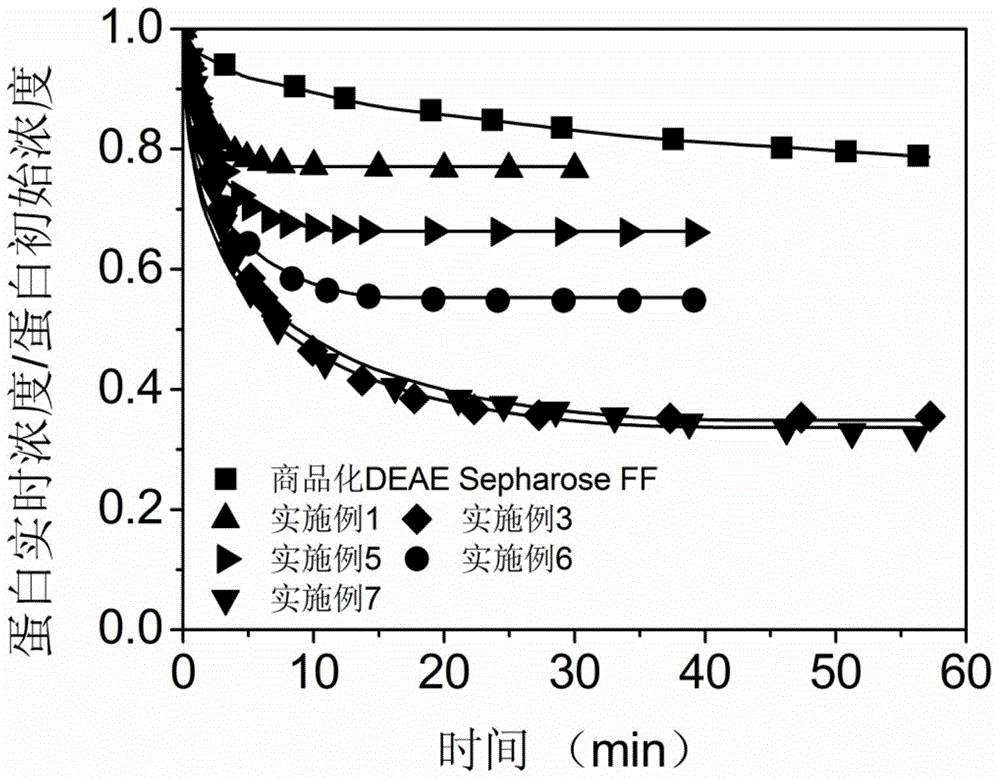

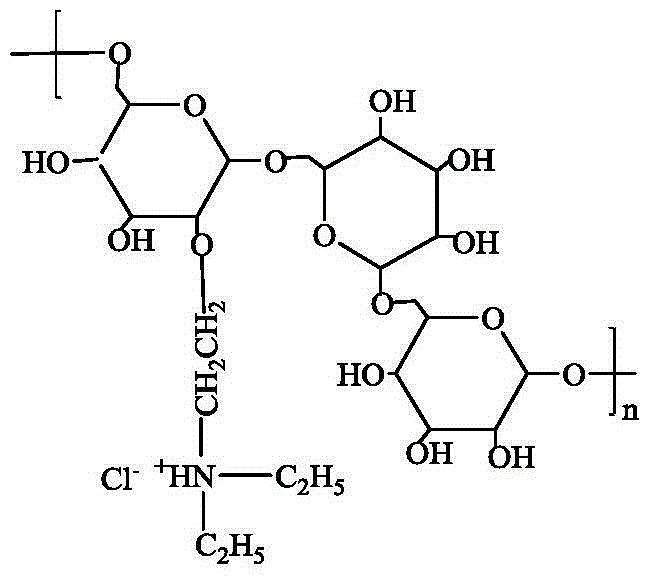

DEAE dextran-modified agarose gel-based chromatography medium and preparation method and application thereof

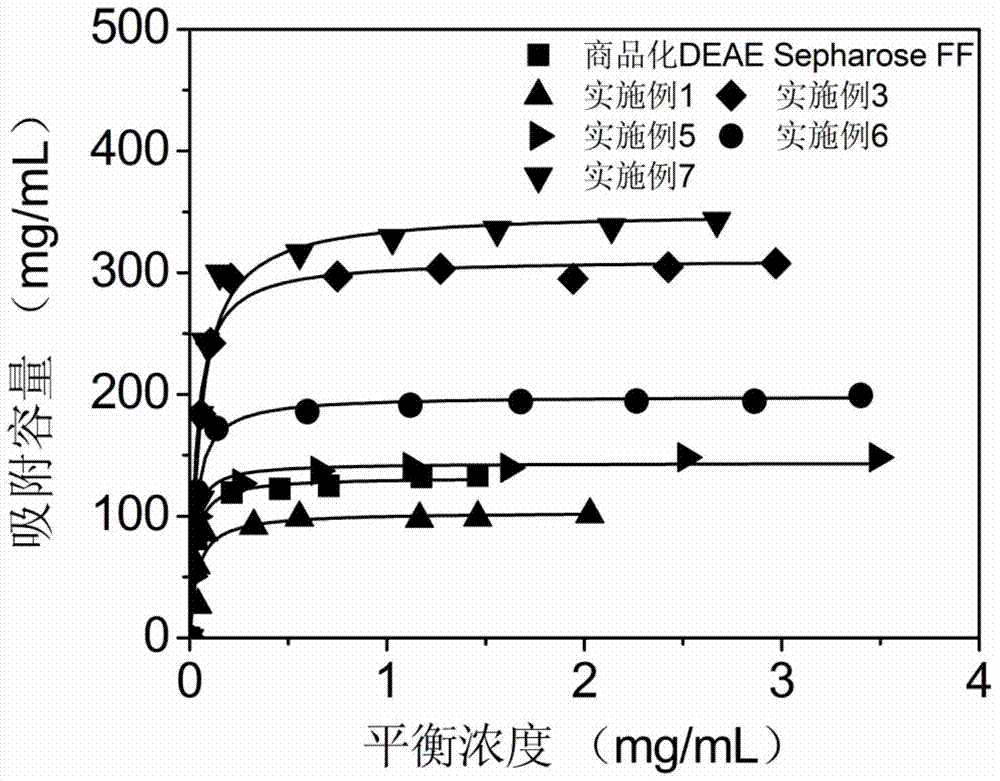

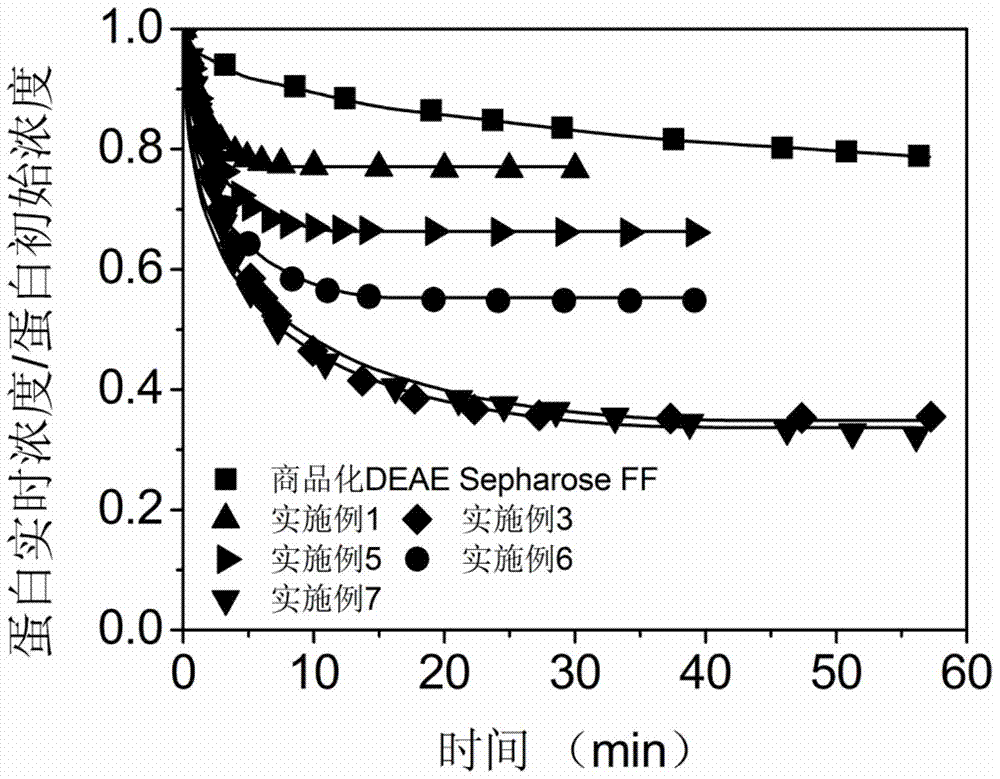

ActiveCN105195115AImprove adsorption capacityIncrease the adsorption rateOther chemical processesPeptide preparation methodsGel basedBiocompatibility Testing

The invention relates to a DEAE dextran-modified agarose gel-based chromatography medium and a preparation method and application thereof. The method includes the steps that first, the molecular weight of DEAE Dextran for grafting is selected; next, the concentration of a DEAE Dextran aqueous solution is controlled; then, the time of diffusion before DEAE Dextran coupling is determined; finally, the reaction time of coupled DEAE Dextran and the concentration and volume of sodium hydroxide are determined. The DEAE dextran-modified agarose gel-based chromatography medium has a strong adsorption property for protein under different modification densities, shows a high adsorption capacity and a high adsorption rate and improves separation efficiency. The medium is convenient to clean and degerm, easy to regenerate and good in biocompatibility. The preparation method is simple and harmfulless and has broad application prospects in efficient and rapid separation and purification of protein.

Owner:TIANJIN UNIV

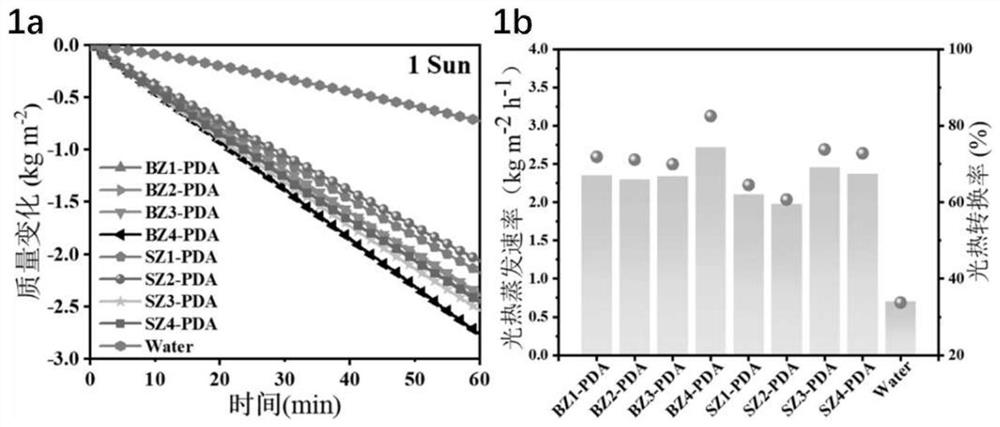

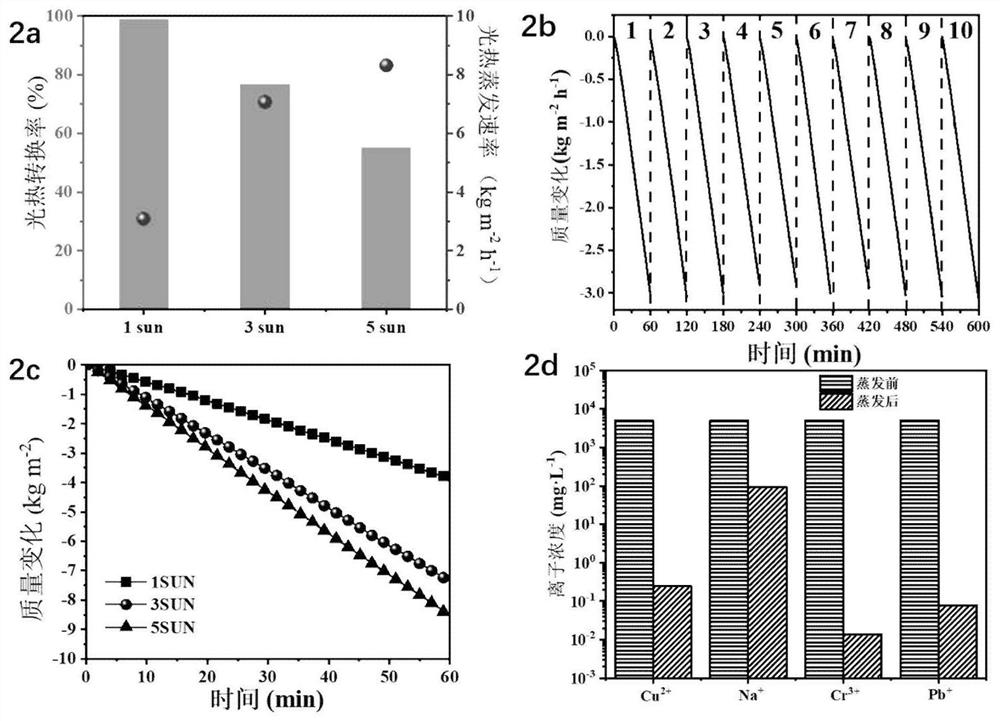

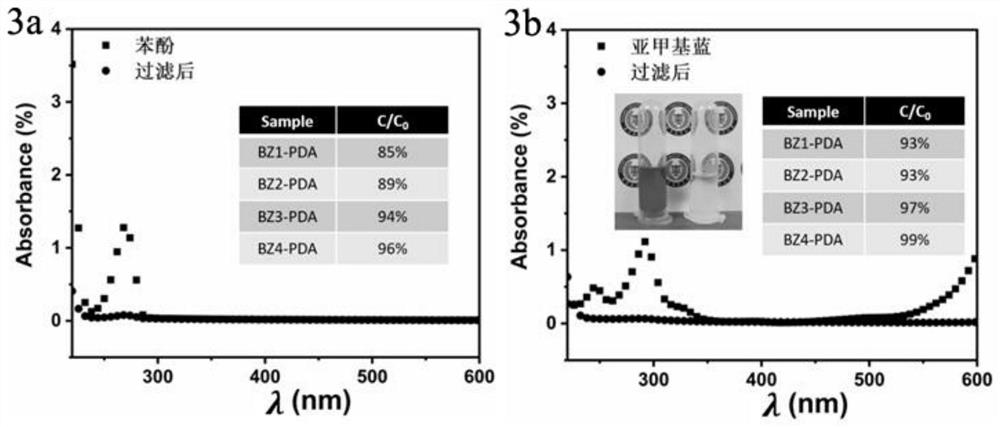

Wood-based composite material for photo-thermal purification of sewage as well as preparation method and application of wood-based composite material

ActiveCN113815072AStrong adsorption propertiesAchieve adsorptionGeneral water supply conservationWood treatment detailsMetal-organic frameworkPhotothermal conversion

The invention discloses a wood-based composite material for photo-thermal purification of sewage as well as a preparation method and application of the wood-based composite material, and belongs to the technical field of photo-thermal conversion. According to the method, after wood is subjected to vacuum impregnation through an MOF precursor solution, a metal organic framework material grows in wood pore channels, and the wood-based composite material for photo-thermal evaporation and heavy metal ion removal is prepared. The polydopamine photo-thermal material in the composite material can convert a solar spectrum into heat energy, so that purified water evaporation is efficiently carried out; the wood substrate can effectively reduce heat conduction loss, heat concentration is achieved, and the photo-thermal conversion efficiency is improved; in addition, the hydrophobic property of the wood accelerates the transmission and evaporation of water; the porous MOF nano material can adsorb pollutant ions. The aim of removing ions in the sewage is fulfilled. The composite material provided by the invention is low in preparation raw material cost, simple and convenient in process, high in repeatability and easy for large-scale production, and has a wide application prospect in multidisciplinary crossing fields such as seawater desalination and sewage purification.

Owner:NANJING FORESTRY UNIV

Environment-friendly bamboo charcoal mask and manufacturing method thereof

ActiveCN104055246AStrong adsorption propertiesHigh adsorption propertiesProtective garmentPolymer scienceEngineering

The invention provides an environment-friendly bamboo charcoal mask and a manufacturing method thereof. The mask comprises an inner mask body and an outer mask body, the inner mask body is provided with a detachment opening, a filtering layer is arranged in the detachment opening, the inner mask body, the outer mask body and the filtering layer are all made of electret melt-blown polypropylene fiber non-woven fabrics, chitosan serves as a capsule wall material of the filtering layer, nanometer bamboo charcoal powder serves as a core material to be made into micro capsules, and the microcapsules are arranged on the non-woven fabrics through beewax serving as adhesive agents. The chitosan, the bamboo charcoal powder and the beewax are all natural materials, the obtained product is environmentally friendly, safe and efficient and has a broad-spectrum antibacterial function, the microcapsules are arranged on the non-woven fabrics through the beewax serving as the adhesive agents, and good washability is achieved.

Owner:维尼健康(深圳)股份有限公司

Preparation method of straw biomass charcoal coated slow release fertilizer

InactiveCN107353169ALarge specific surface areaIncrease floor area ratioCarbon compoundsClimate change adaptationCation-exchange capacitySludge

The invention discloses a preparation method of a straw biomass charcoal coated slow release fertilizer. A small amount of sludge is added to straws, and volatile gases in the sludge escape with the rising of the temperature, so the sludge plays a role in etching to form active carbon having a porous structure, thereby the specific surface area and the volumetric ratio of straw charcoal are increased, and the physical adsorption performance of the charcoal material are improved; the quantity of -OH and -CHO functional groups on the surface of the prepared charcoal is greatly improved, and the surface is partially slightly oxidized after the slow release fertilizer prepared by using the charcoal as a film material exists in soil for a certain time in order to form carbonyl groups and phenolic groups, so the increase of the cation exchange capacity of the soil is facilitated, and the soil has strong adsorption to NH<4><+> and NO<3><->, thereby the nitrogen element in the soil is conserved, the volatilization of ammonia in farmland soil is effectively reduced, and the raining loss of nitrogen nutrients in the soil is effectively controlled.

Owner:安徽华联肥业有限公司

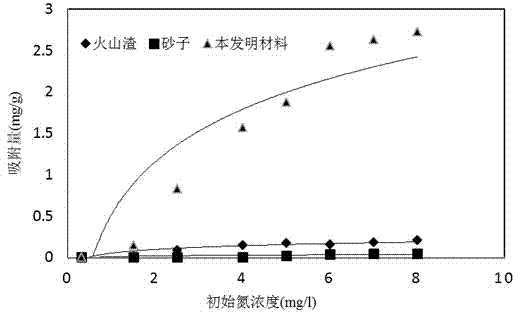

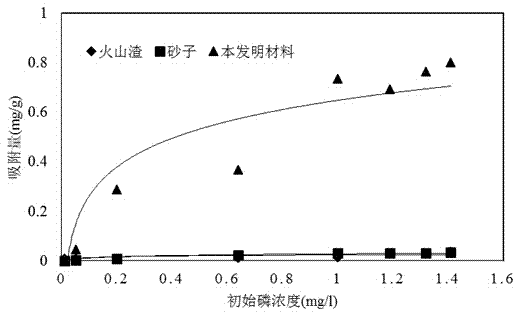

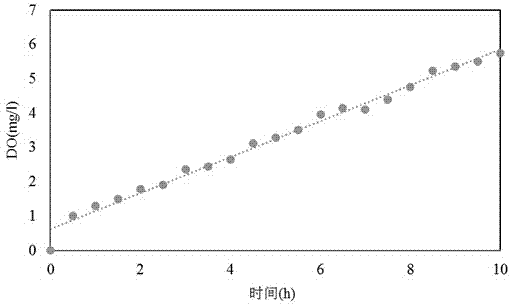

A filler for artificial wetland water treatment and preparation method thereof

InactiveCN104229999BGood removal effectImprove effluent qualitySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandRare earth

The invention relates to filler used for constructed wetland water treatment and a preparation method of the filler. The invention aims at providing a novel constructed wetland filler which is capable of realizing slowly releasing oxygen and reinforcing nitrogen and phosphorus removal and a preparation method of the filler. The filler used for constructed wetland water treatment is volcanic cinder particles which are loaded with a rare-earth nitrogen and phosphorus adsorbent and a slow-release oxygen material, and have particle diameters of 5-15mm. The filler can be used for increasing the sewage purifying capacity of the constructed wetland. And the preparation method has the characteristics of simple process, sufficient raw materials, low cost, and the like.

Owner:NANJING COLLEGE OF CHEM TECH +2

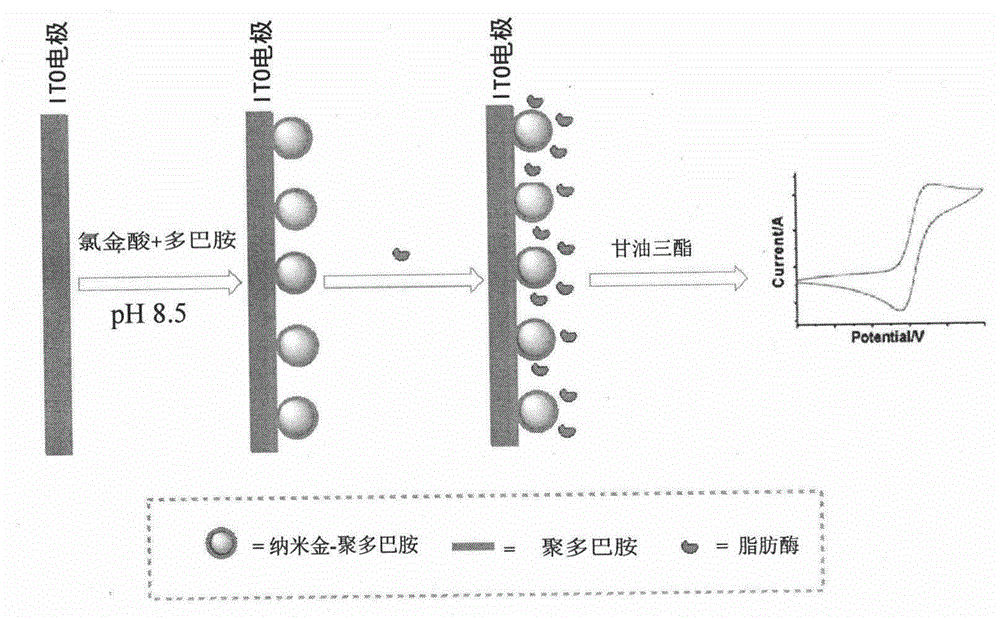

Method for detecting triglyceride in serum

ActiveCN104597100AMove quicklyStrong adsorption propertiesMaterial electrochemical variablesTriglyceridePhysical chemistry

The invention belongs to the field of bio-analytical chemistry, and relates to an electrochemical method for detecting triglyceride in serum. According to the present invention, the characteristic that dopamine is automatically polymerized under a weakly alkaline condition to form polydopamine is utilized, wherein the formed polydopamine is used for immobilizing enzyme molecules, chloroauric acid is subjected to in situ reduction to produce nanometer gold so as to be adopted as the signal amplifying element, and the cyclic voltammetry (CV) is adopted as the electrochemical detection method; and the developed electrochemical sensing strategy for detecting the triglyceride in the serum has advantages of high sensitivity, simple operation and the like, and is suitable for promotion and application.

Owner:NANJING TECH UNIV

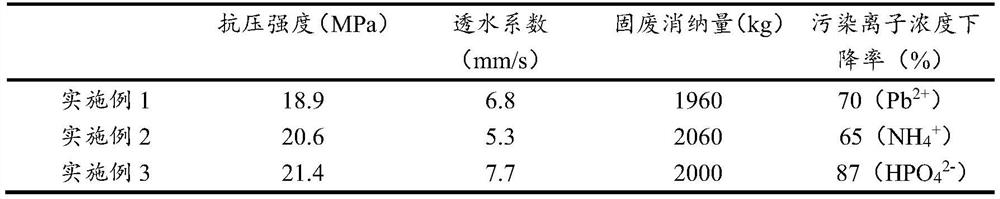

Water purification type solid waste pervious concrete

The invention provides water purification type solid waste pervious concrete, wherein the cementing material of the pervious concrete is a geopolymer and is prepared by mixing a solid waste material mainly containing silicon and aluminum, high-alkalinity red mud and a small amount of an alkali activator. The pervious concrete disclosed by the invention overcomes the defects of high production energy consumption and large environmental pollution of traditional pervious concrete, has the advantages of consuming a large amount of solid wastes, reducing exploitation of natural resources, reducingthe cost and the like, and also has the functions of purifying water and effectively protecting underground water resources.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

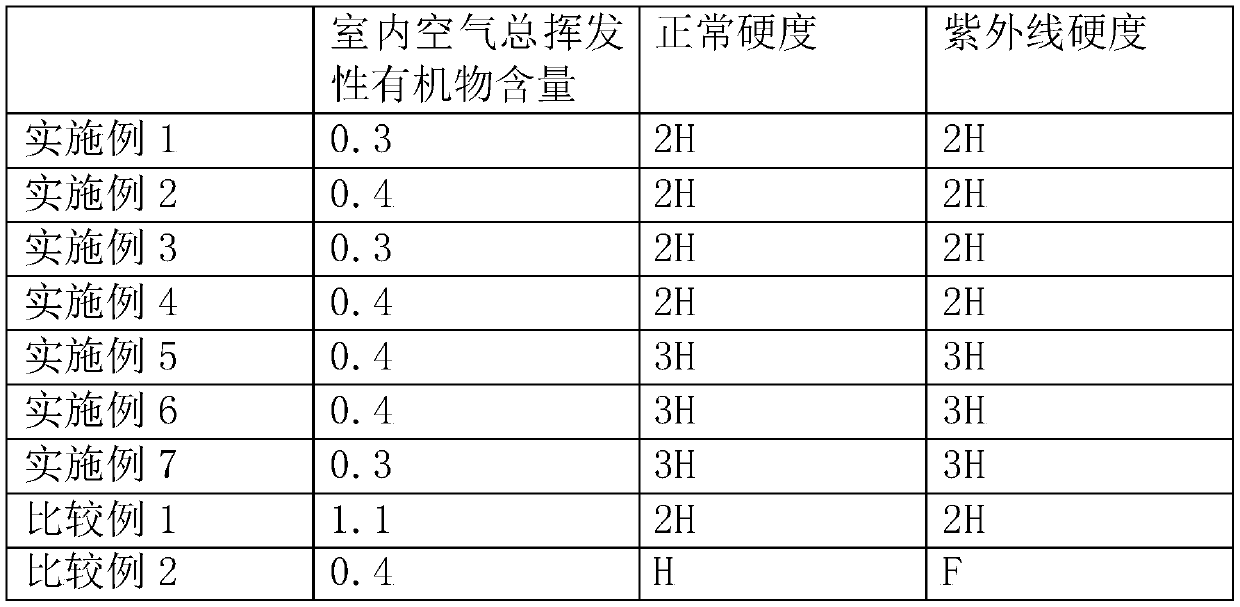

Environment-friendly indoor wall finishing method

ActiveCN109898765AHas adsorption capacityImprove adsorption capacityCovering/liningsDispersed particle separationSalicylic acidHuman health

The invention relates to the field of wall finishing methods, and provides an environment-friendly indoor wall finishing method for the problem that as for a wall coating, harmful gas is not prone toemitting. The environment-friendly indoor wall finishing method includes the following steps that S1, an environment-friendly coating is prepared; S2, the environment-friendly coating is uniformly painted to the outer surface of the wall surface; and S3, the environment-friendly coating is scraped, and the environment-friendly coating is prepared from the following components in parts by mass: 8-10 parts of nano-micropore activated silica, 0.1-0.5 part of a silane coupling agent, 50-70 parts of calcium carbonate, 70-80 parts of cement, and 8-10 parts of salicylic acid. By adding the nano-micropore activated silica, the nano-micropore activated silica has the ability to adsorb various substances, especially for formaldehyde, toluene and other indoor harmful gas, the high adsorption capacityof the nano-micropore activated silica is achieved, as for the indoor wall surface, the harmful gas is not prone to emitting and consequently the human health is affected, and meanwhile, adsorption of the harmful gas emitted by oil paints and coatings on other indoor furniture or components is further facilitated.

Owner:GUANGZHOU NO 4 DECORATION CO LTD

Eutrophication deep treatment method for landscape water body

InactiveCN108314271AMaintain normal pH rangeImprove anaerobic conditionsWater treatment parameter controlWater contaminantsEutrophicationNitrogen

The invention discloses a eutrophication deep treatment method for a landscape water body. The eutrophication deep treatment method particularly specifically comprises the following steps of 1), firstly, uniformly putting a microbial inoculum agent into the landscape water body, wherein the microbial inoculum agent passes through a dispenser placed on in a self sinking type flying-saucer-shaped water decanter; 2), adding a novel compound agent into the landscape water body which is treated for one week; 3), through arranging and planting multifarious aquatic plants on the self sinking type flying-saucer-shaped water decanter and being capable of arranging multiple layers of mutually alternant microbial medium oxidizers and a packing layers on the self sinking type flying-saucer-shaped water decanter, acting together with the aquatic plants to remove, together with the aquatic plants, nitrogen and phosphorus in the water body. The eutrophication deep treatment method can be used for effectively combining existing multifarious treatment methods, and can be used for effectively removing an organic matter and ammonia nitrogen in the water body, and through the novel compound agent isinnovated.

Owner:ANHUI MEIZIRAN ENVIRONMENTAL TECH

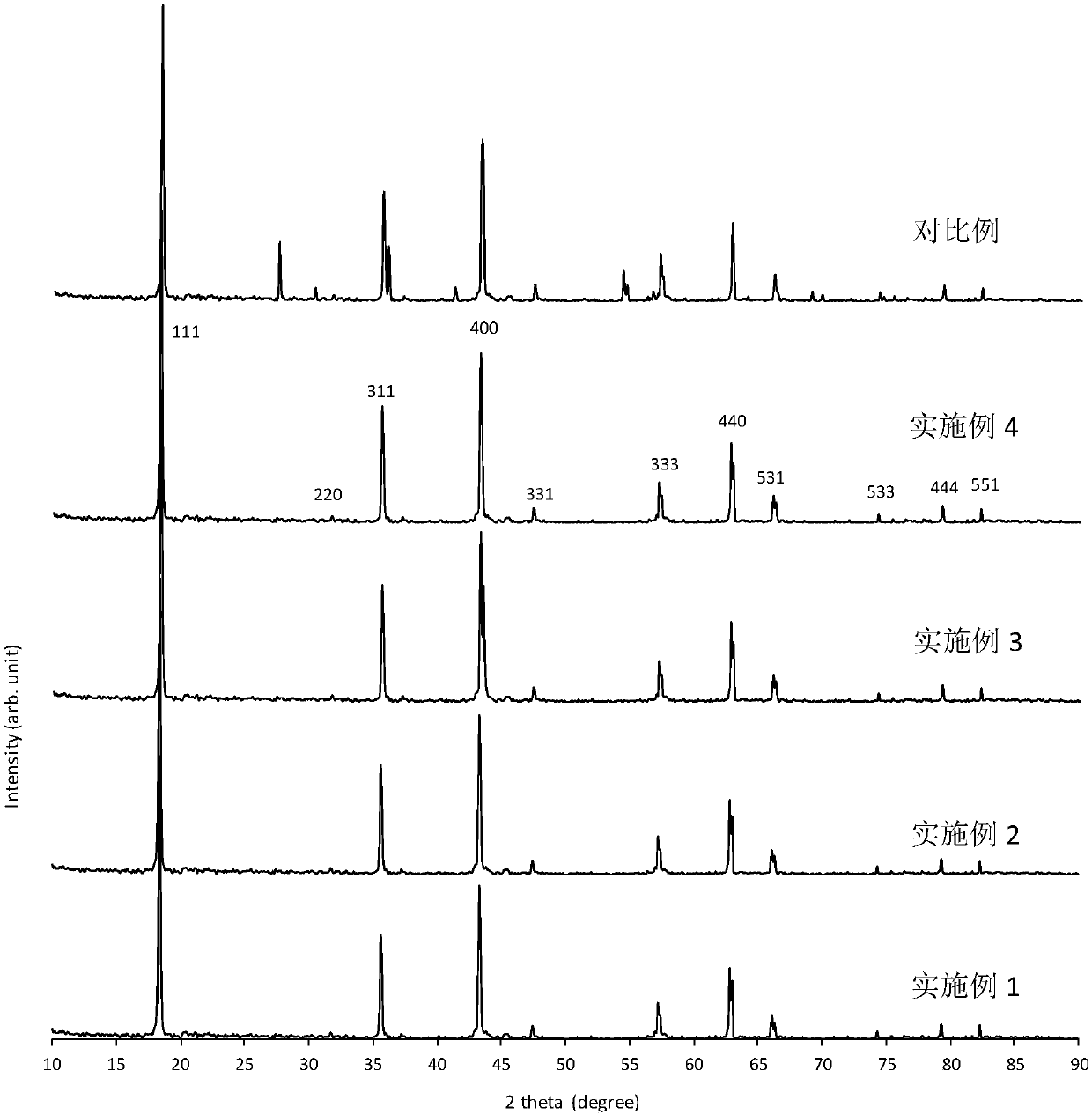

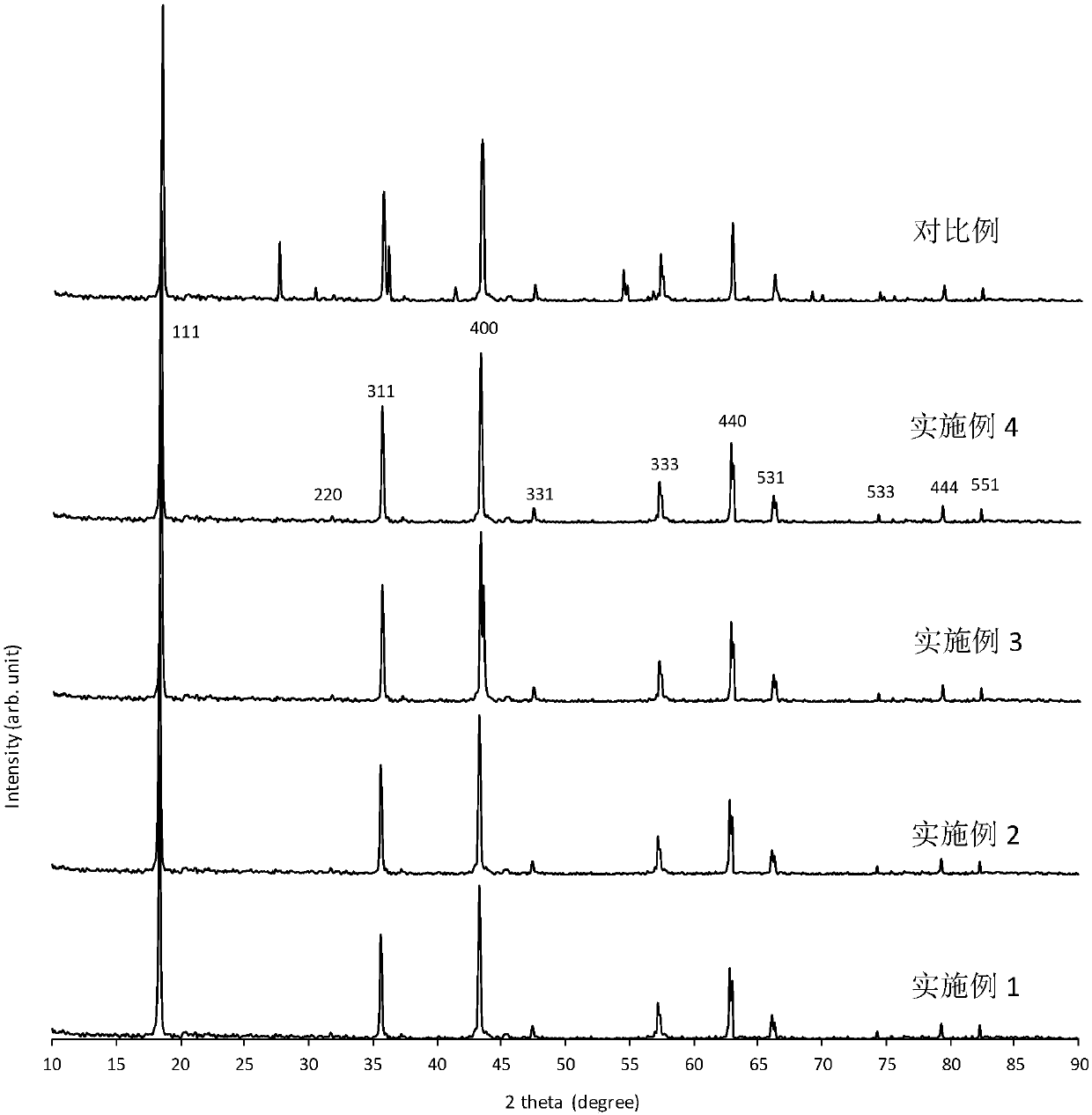

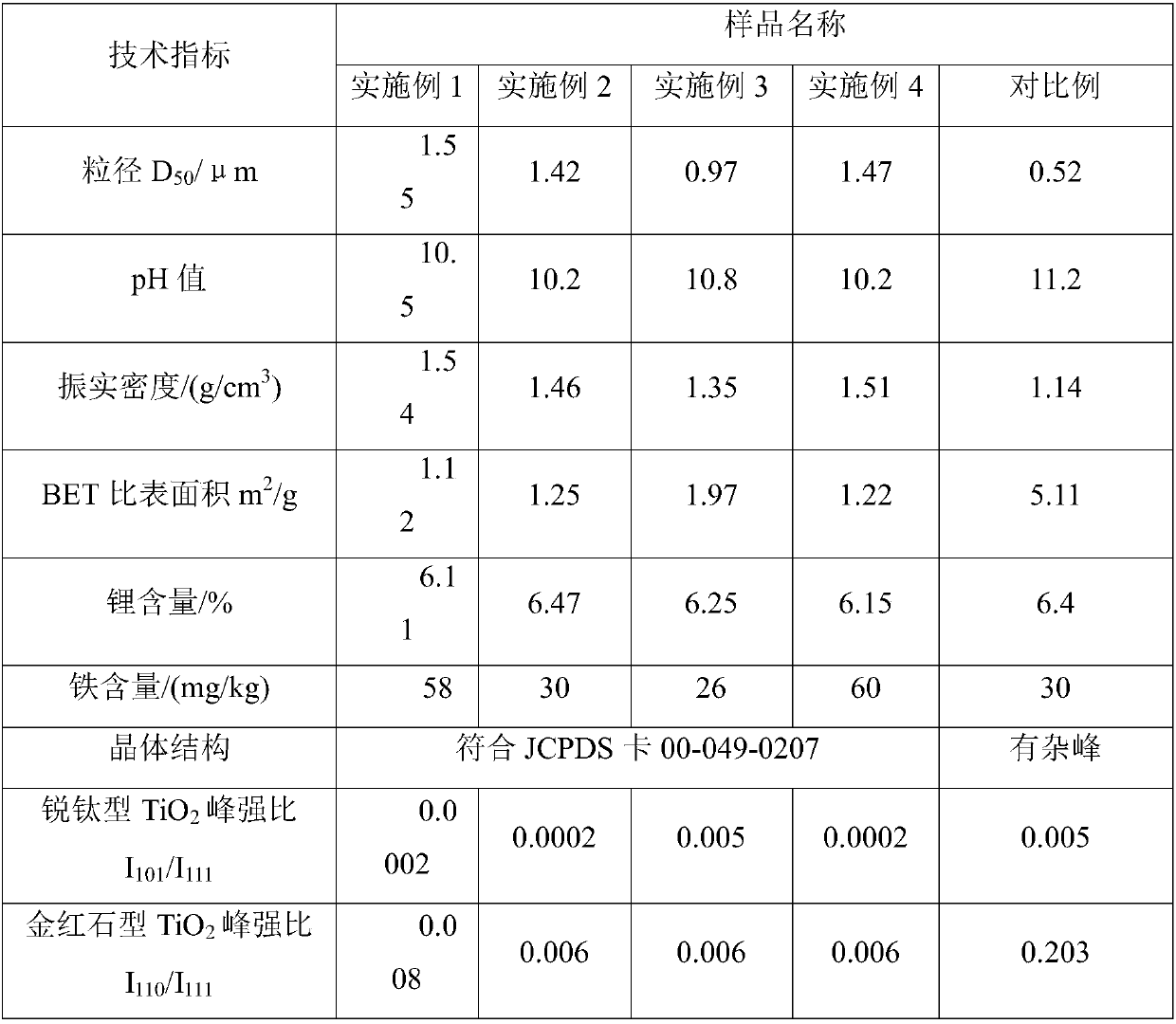

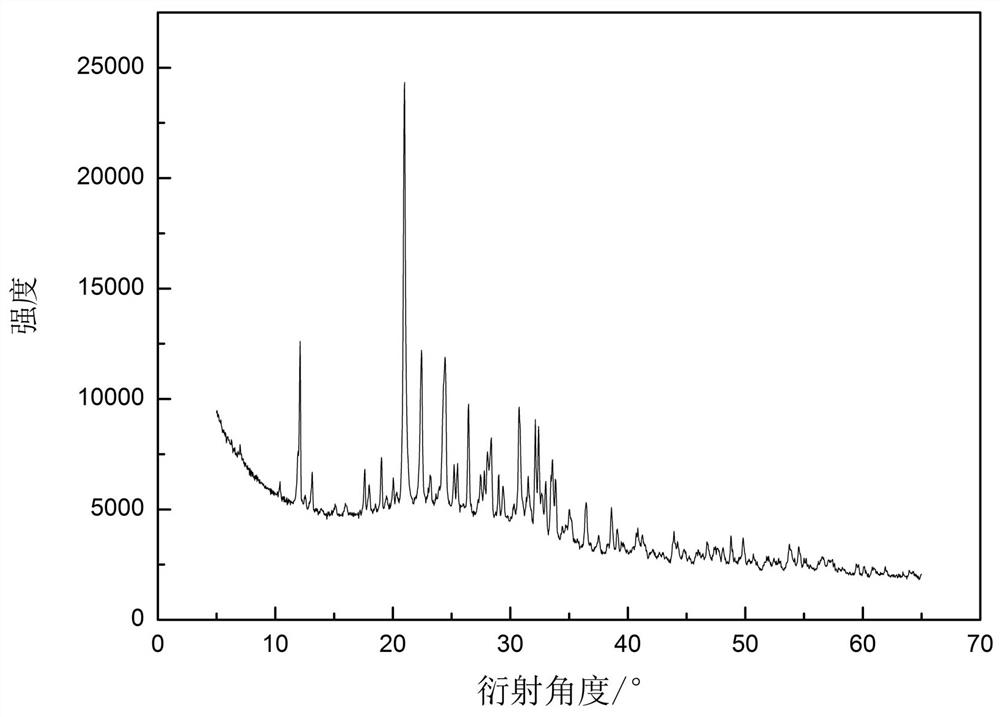

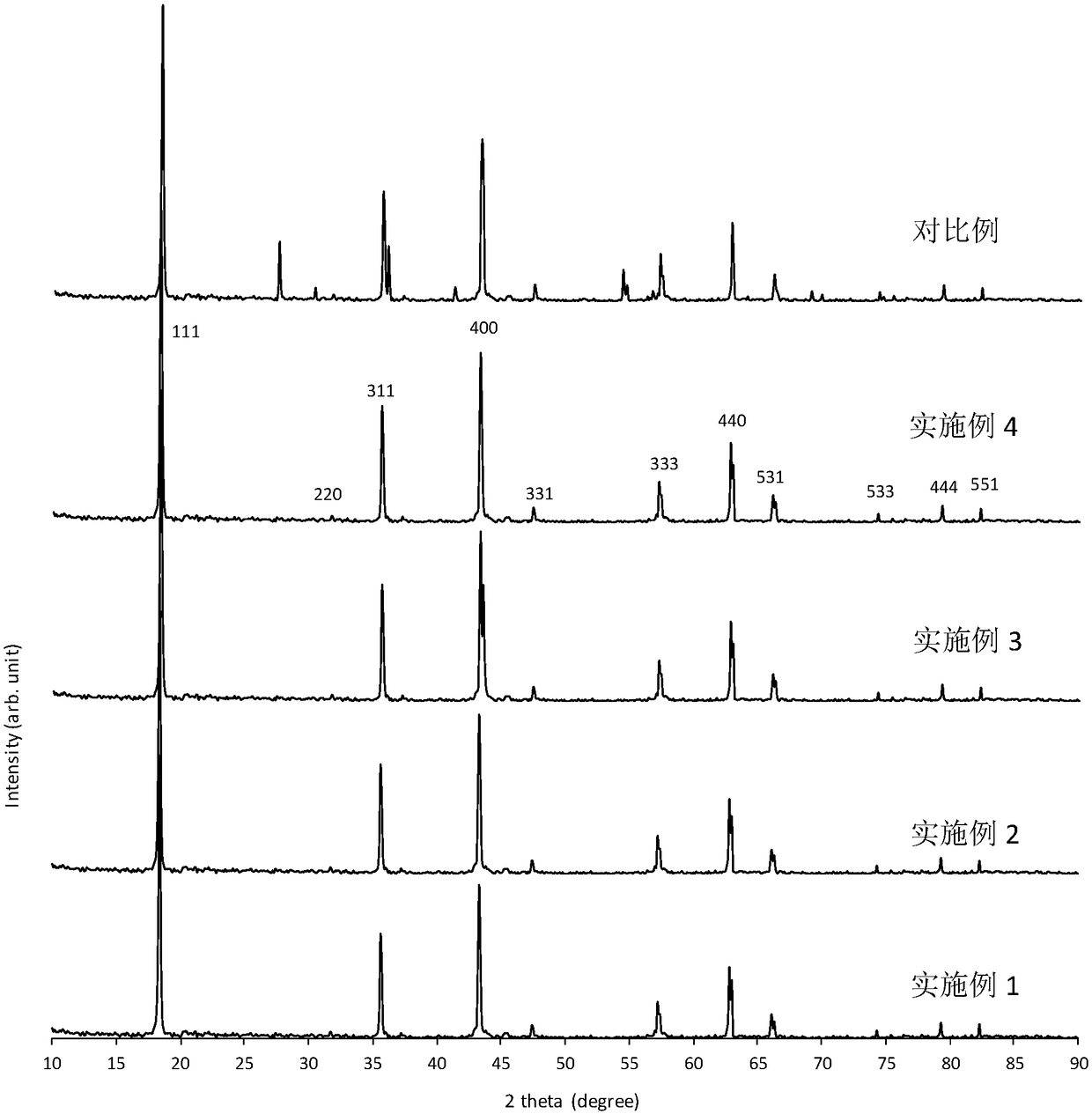

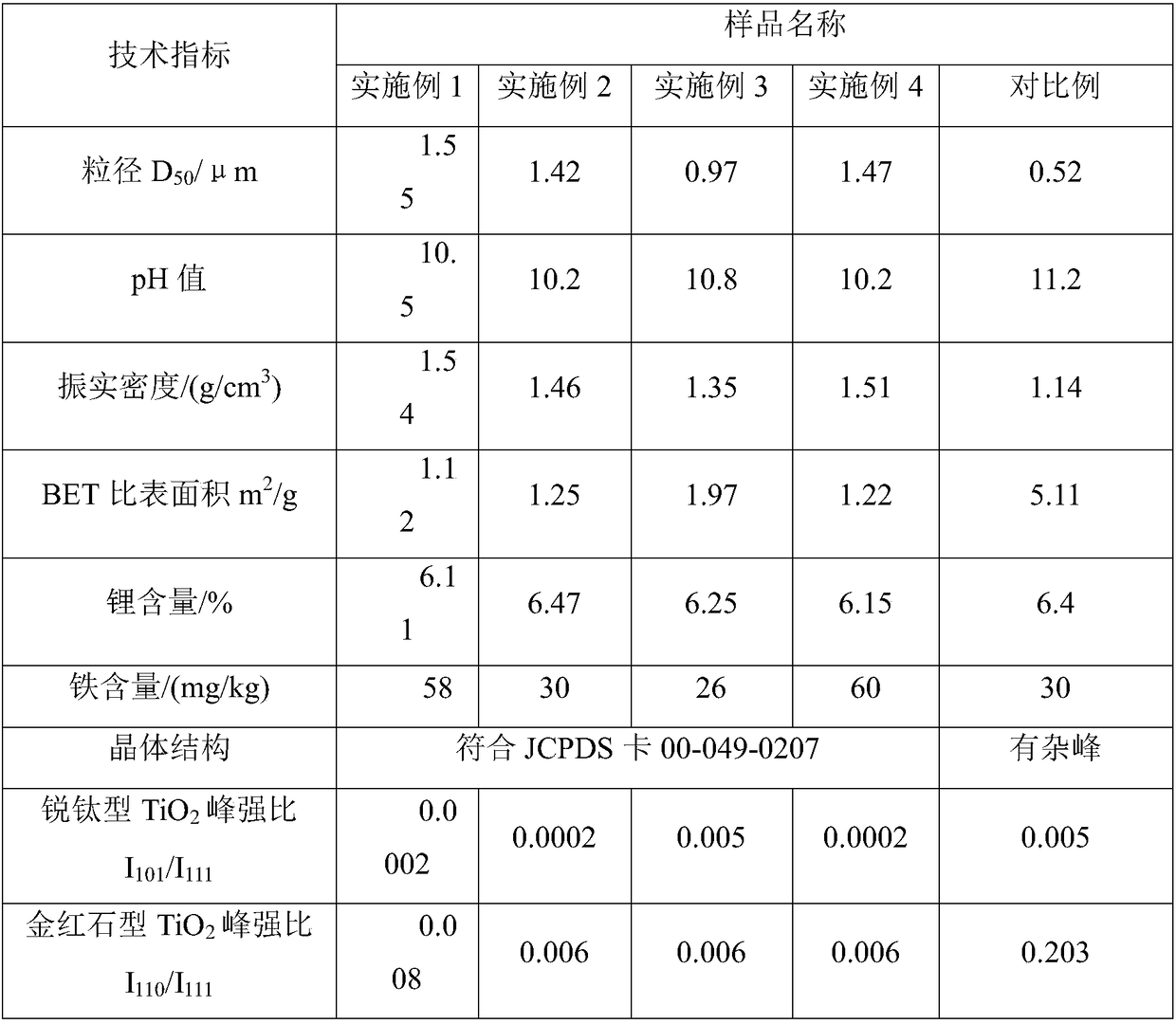

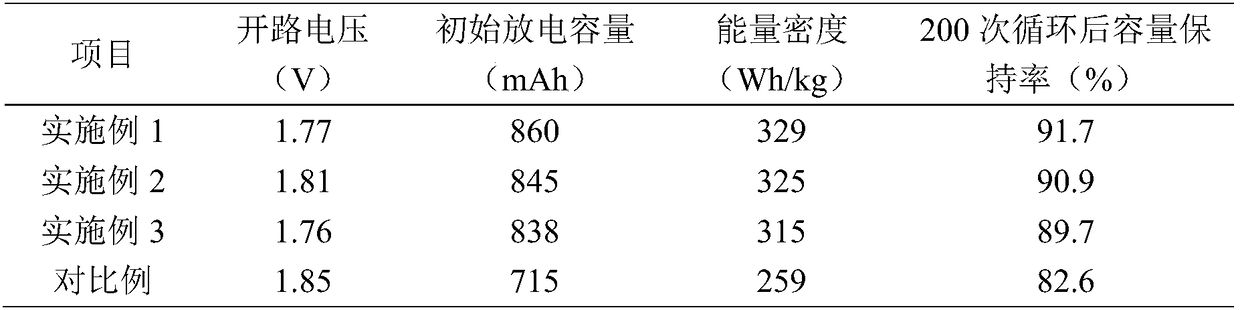

Preparation method of spinel-structure lithium titanate

ActiveCN106698501AImprove utilization efficiencyReduce lithium consumptionAlkali titanatesRotary kilnFilter cake

The invention provides a preparation method of spinel-structure lithium titanate. The preparation method comprises the following steps: 1, taking metatitanic acid produced in a process of producing titanium dioxide with a sulfuric acid method; preparing the metatitanic acid into slurry A with de-ionized water; 2, adding calcining seed crystals, which are widely used in a process of producing rutile-type titanium dioxide with the sulfuric acid method, into the slurry A, wherein the mass ratio of TiO2 in the calcining seed crystals to TiO2 in the slurry A is (2 to 20) to 100; after uniformly stirring, filtering and washing with water; stopping water washing when the pH (Potential of Hydrogen) value is greater than 1.8; adding de-ionized water into a filter cake to prepare slurry B with the TiO2 concentration of 200g / L to 400g / L; 3, adding a lithium source into the slurry B according to the mole ratio of Li to Ti of 0.82 to 0.97; sufficiently and uniformly stirring to obtain slurry C; 4, conveying the slurry C into a rotary kiln; heating and calcining to finish dehydration, desulfurization and crystal form transformation to prepare the spinel-structure lithium titanate. According to the preparation method provided by the invention, all the methods are slurry processes, and dry-method crushing and grinding do not need to be carried out before the crystal form transformation is finished by heating so that energy consumption is low; a titanium source is cheap and easy to obtain.

Owner:YUNNAN GANG FENG NEW MATERIAL CO LTD

A kind of preparation method of boropolysilicate aluminum iron-chitosan composite flocculant

ActiveCN108002504BGood flocculation effectSolve residualWater/sewage treatment by flocculation/precipitationIron sulfateSilicic acid

Owner:ZHENGZHOU UNIV

Antibacterial durable PE composite particle

InactiveCN111234355AStrong adsorption propertiesHigh adsorption propertiesSievingScreeningManganeseAntibacterial agent

According to the antibacterial durable PE composite particle disclosed by the invention, carbon black and an inorganic metal antibacterial agent are replaced by nano-modified bamboo charcoal plastic particles, so that the PE composite particle has good anti-aging and antibacterial properties and is more durable; the nano modified bamboo charcoal plastic particles are prepared from the nano titanium dioxide-zinc dioxide composite powder and the nano bamboo charcoal powder, and the bamboo charcoal is rich in potassium, sodium, calcium, aluminum, manganese and other metal elements and carbides thereof, especially calcium carbide, so that the nano modified bamboo charcoal plastic particles have favorable ultraviolet resistance. Titanium dioxide and zinc oxide are two common inorganic ultraviolet shielding agents, but the shielding capacities of the two inorganic shielding agents are different, the UVB blocking effect of nano titanium dioxide is very good, but the UVA shielding effect is poor; and the shielding effects of the nano zinc oxide are opposite. Therefore, the nano-modified bamboo charcoal plastic particles have triple anti-ultraviolet effects.

Owner:界首市通达塑业有限公司

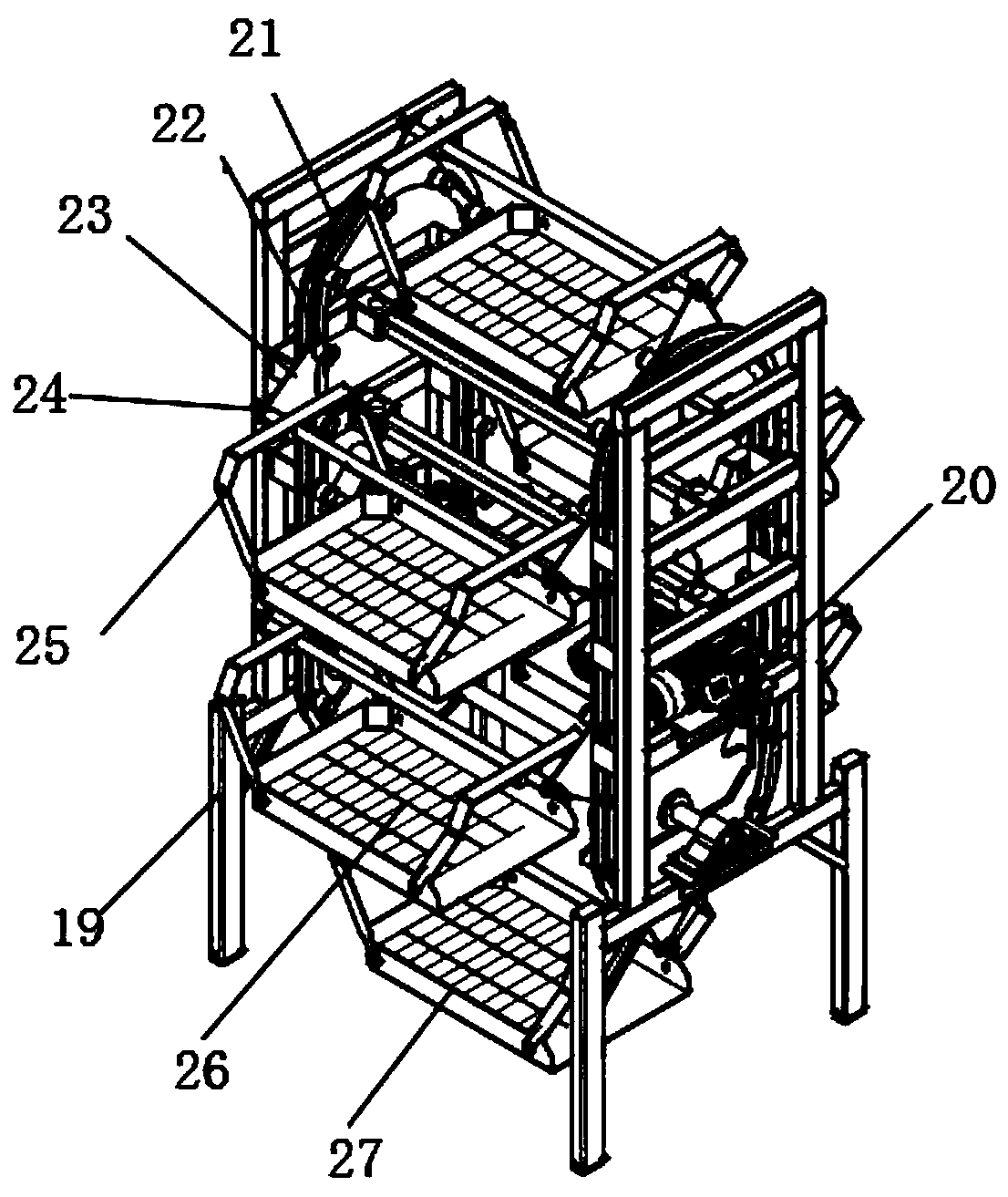

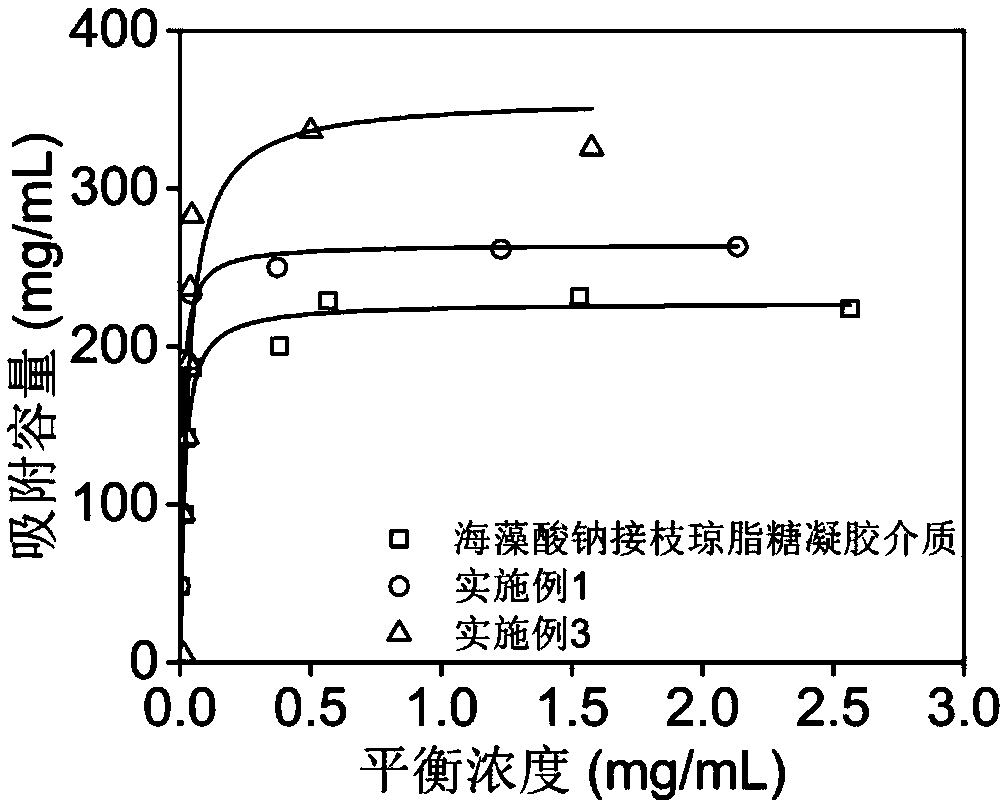

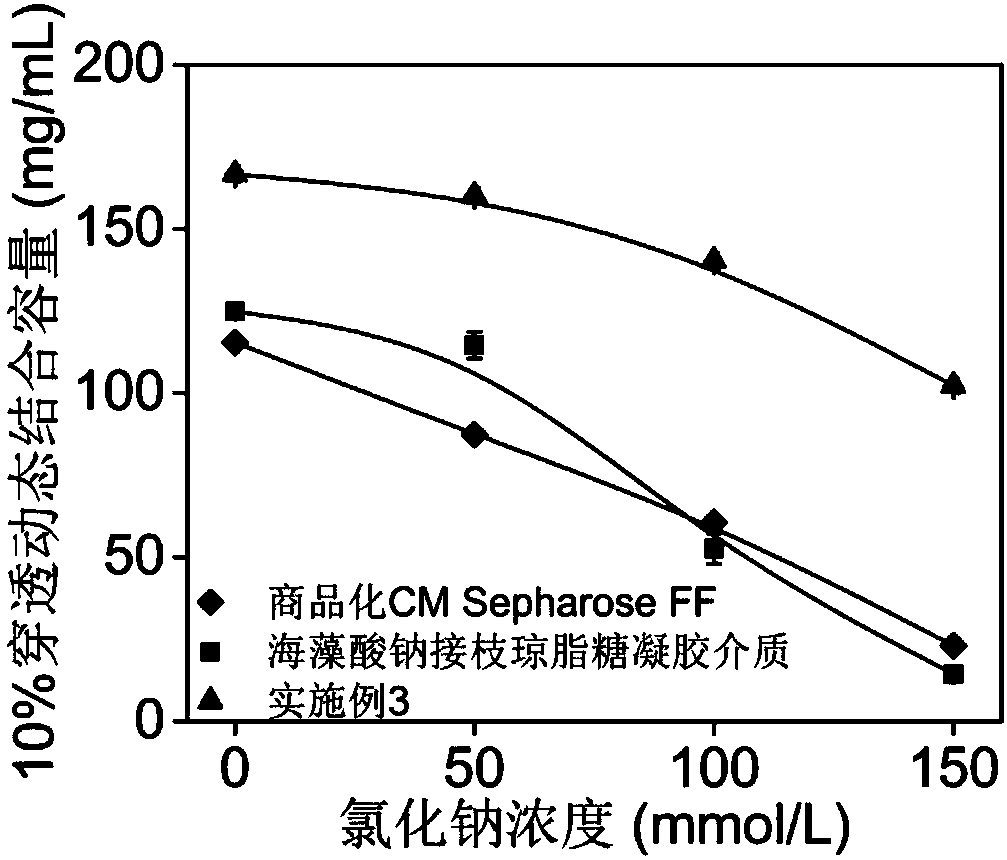

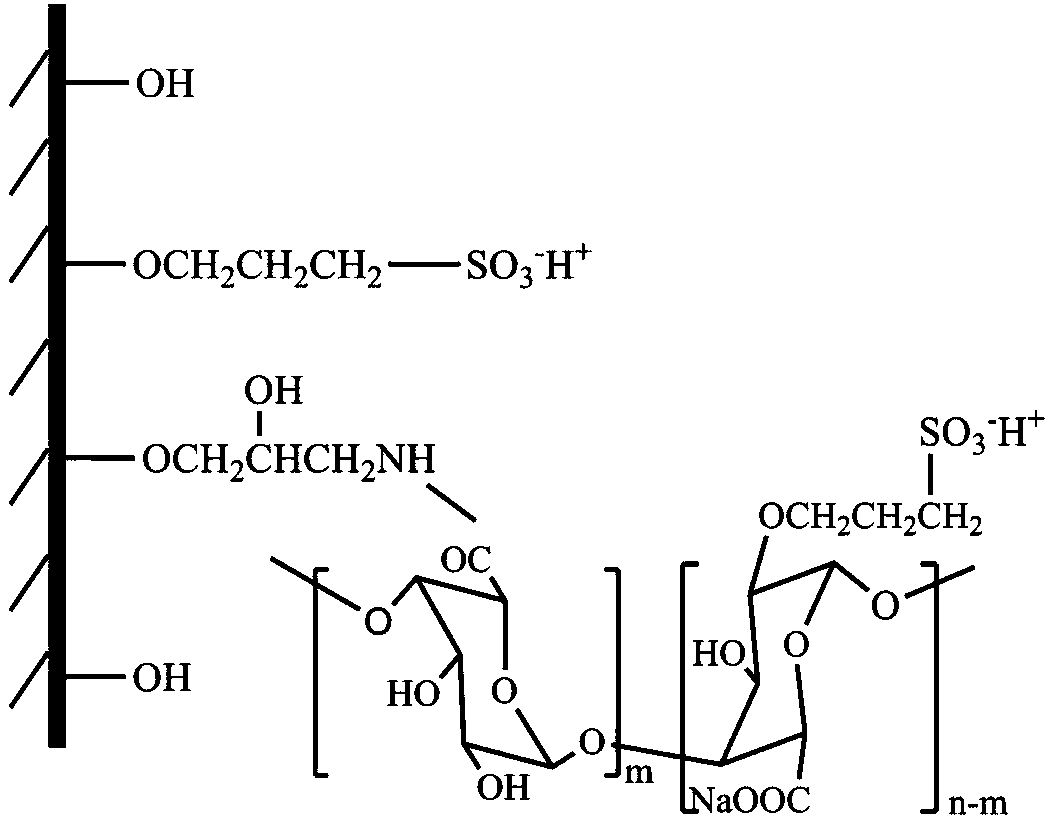

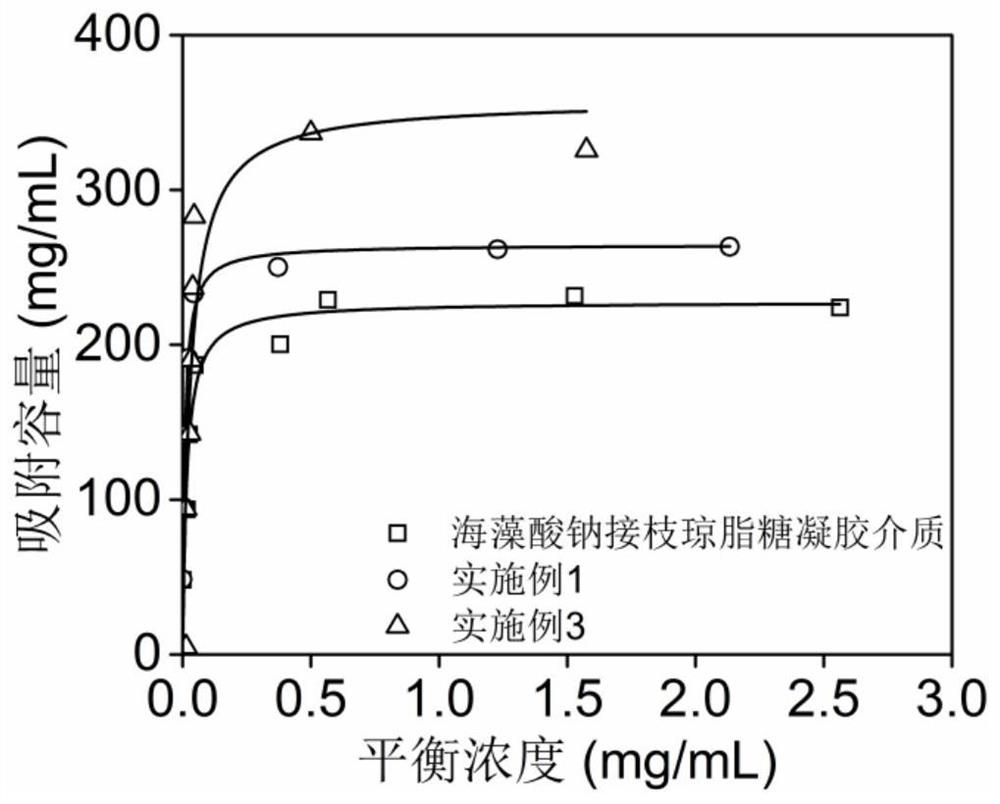

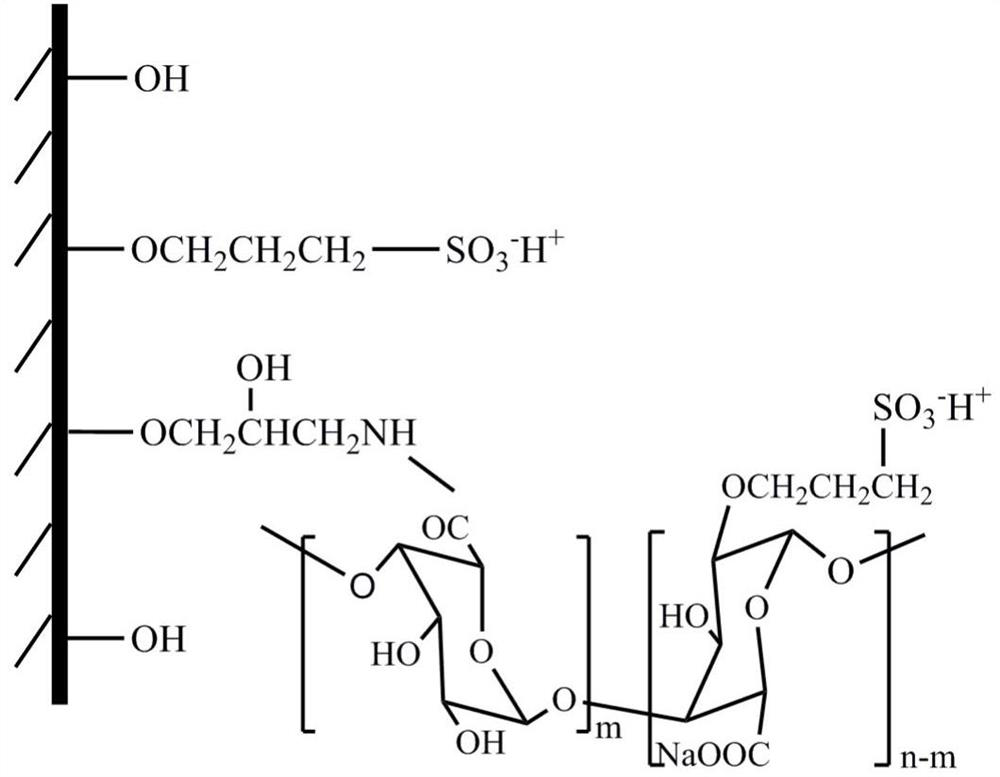

Sulfonated sodium alginate grafted agarose gel chromatographic medium as well as preparation method and application

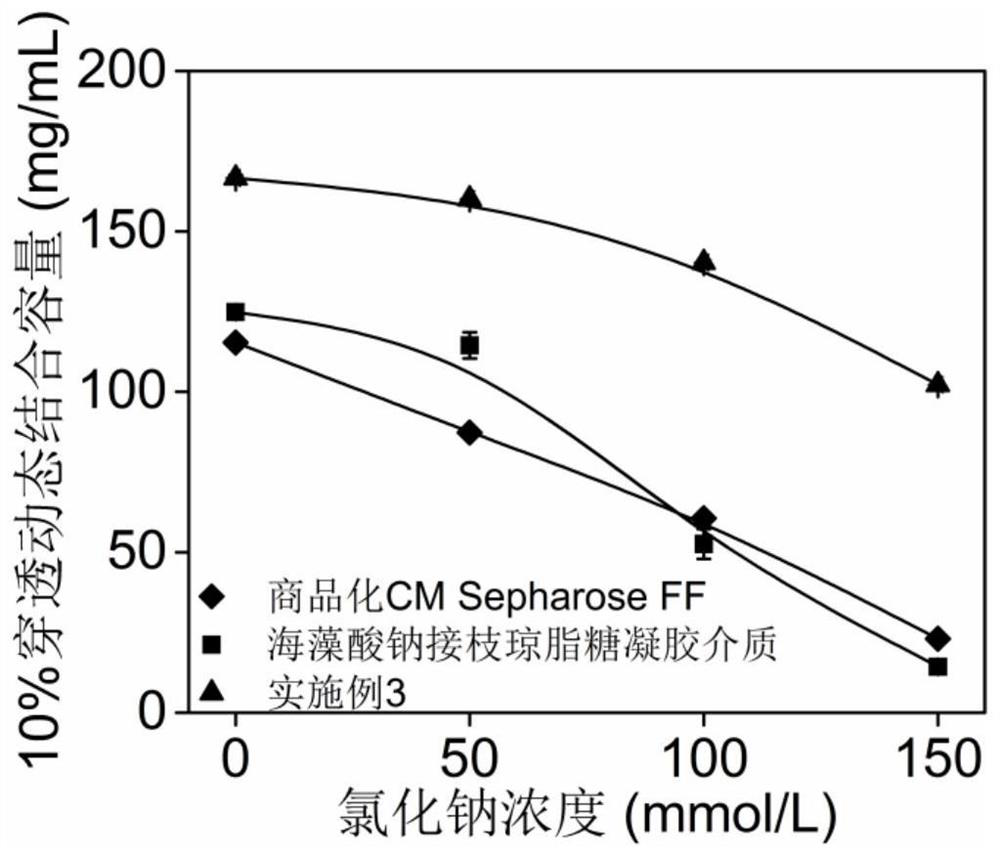

InactiveCN108246273AHigh ion exchange capacityImprove adsorption capacityOther chemical processesPeptide preparation methodsHydrogenIon exchange

The invention relates to a sulfonated sodium alginate grafted agarose gel chromatographic medium as well as a preparation method and application. The preparation method comprises the following steps:firstly, selecting the sodium alginate grafted agarose gel chromatographic medium with a suitable ion exchange capacity as a basic medium for carrying out sulfonic group modification; secondly, controlling the concentration of sodium hydroxide in an allyl bromide activation process; finally, determining the concentration of sodium pyrosulfite and determining the pH (Potential of Hydrogen) value ofthe solution and sulfonation time. According to the sulfonated sodium alginate grafted agarose gel chromatographic medium provided by the invention, the static saturated adsorption capability on lysozyme can reach 358mg / mL and the lowest dynamic binding capacity under a 10 percent penetration condition is also 100mg / mL or more. The medium has the advantages of simple preparation method and low cost, and has a wide application prospect in efficient separation and purification of protein.

Owner:TIANJIN UNIV

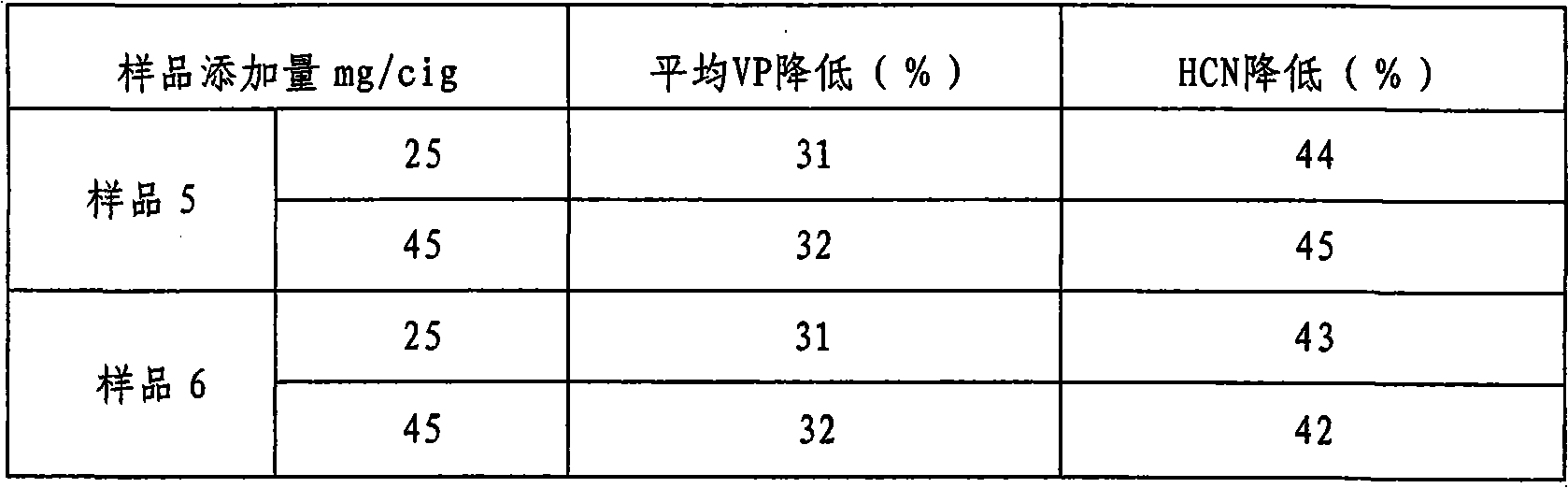

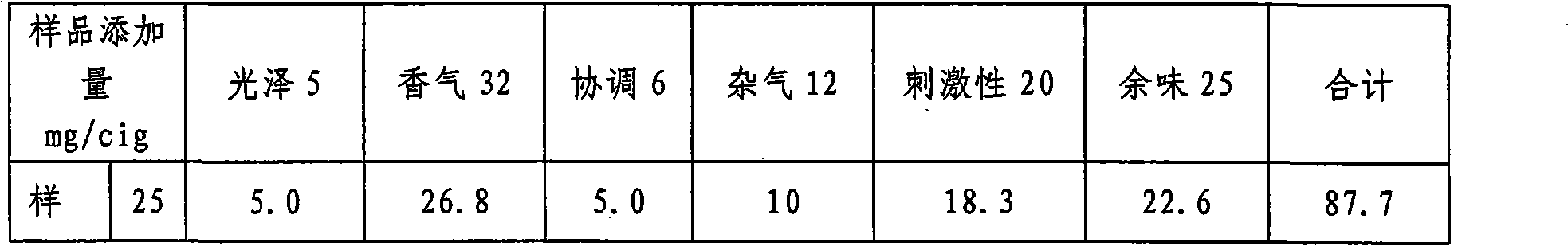

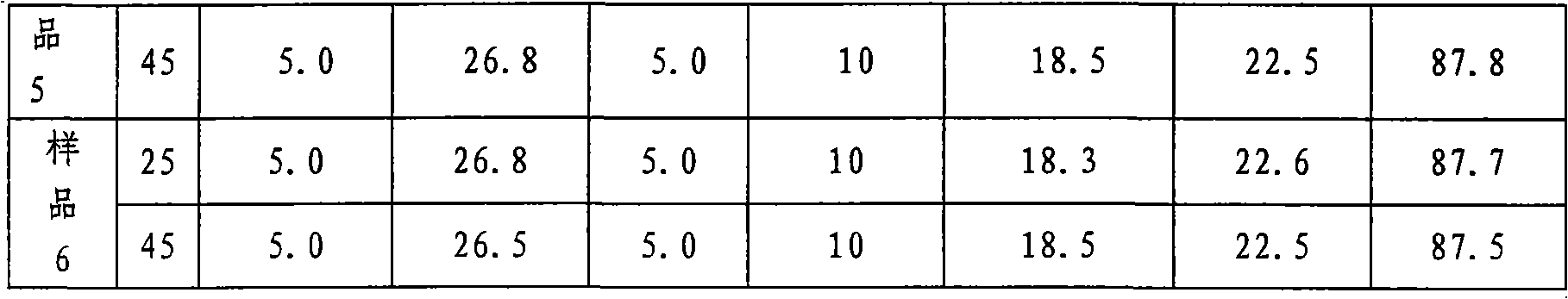

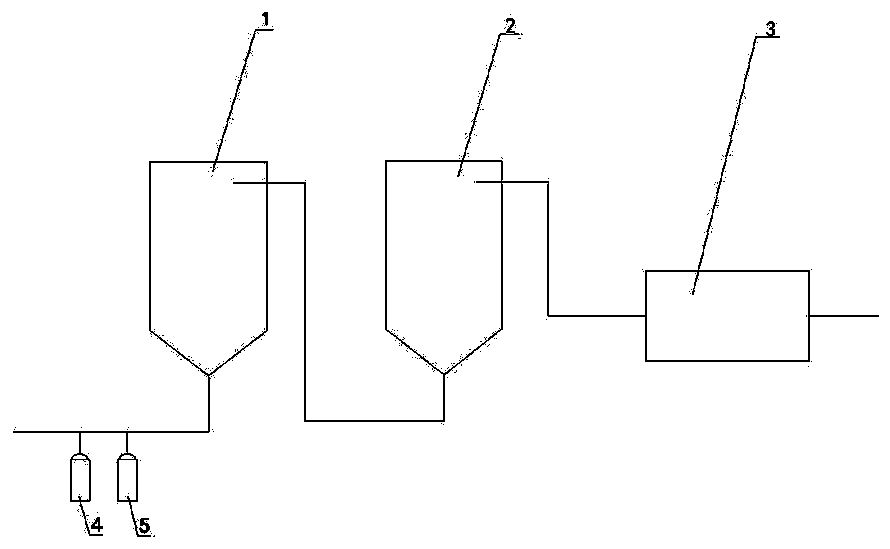

Filter additive for reducing content of hydrocyanic acid in smoke of cigarette and preparation method thereof

InactiveCN101524186BReduce HCN contentImprove adsorption capacityTobacco smoke filtersFlavorAcetic acid

The invention discloses a filter additive for reducing the content of hydrocyanic acid in the smoke of a cigarette and a preparation method thereof. The preparation method comprises the following steps: mixing starch and transitional metallic salts, dipping the mixture with buffer solution of acetic acid, carrying out enzymolysis with diastatic enzyme, drying, crushing and screening to obtain metal dipping modified porous starch particles, namely the needed filter additive. When being applied to the filter of the cigarette, the particles not only have better selective removing for HCN, but also have no adverse influence on reduction of other harmful gases. As the amount of added metal is little, the filter additive has less influence on the flavor of the cigarette. The adsorption efficiency of the product is not reduced obviously after being stored for six months, even longer time. The invention has simple and convenient preparation technique, reliable quality and very stable attachment of transitional metallic ions, and can be applied to all the filters of the cigarettes with known forms.

Owner:YUNNAN RES INST OF TOBACCO SCI

Method for removing heavy metal ions from wastewater of thermal power plant

InactiveCN108328800AStrong adsorption propertiesWater contaminantsTreatment involving filtrationWater contentIon

The invention belongs to the field of treatment of wastewater of thermal power plants, and particularly relates to a method for removing heavy metal ions from wastewater of a thermal power plant. Application of the method for removing the heavy metal ions from the wastewater of the thermal power plant is finished before desulfurization wastewater is introduced into recovery treatment, and the method comprises the following specific steps of: (1) introducing the desulfurization wastewater into a first fluidized bed from the bottom of the first fluidized bed which is filled with a quartz sand filter material, connecting the bottom of the first fluidized bed with a NaOH solution tank and a KMnO4 solution tank, and introducing a NaOH solution and a KMnO4 solution together into the first fluidized bed from the bottom of the first fluidized bed while the desulfurization wastewater is introduced into the first fluidized bed from the bottom; and controlling the pH value in the first fluidizedbed between 7.5 and 11 according to a conventional method. Through the method, the density of mud produced by the process can reach 2.5-3.0 kg / L, and the water content is less than 20% after dehydration is conducted; and when the method is compared with a traditional chemical precipitation method, the amount of the mud produced through the fluidized bed method is less than 25%.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

Microemulsion multifunctional nano oil displacement agent as well as preparation method and application thereof

ActiveCN114437695AImproving the effect of enhanced permeability floodingHigh activityGroup 4/14 element organic compoundsGeneral water supply conservationDodecaneActive agent

The invention provides a micro-emulsion multifunctional nano oil displacement agent as well as a preparation method and application of the micro-emulsion multifunctional nano oil displacement agent. The microemulsion multifunctional nano oil displacement agent is prepared from 10 to 35 parts of nano silicon dioxide, 30 to 50 parts of diphenyl ether gemini surfactant, 10 to 20 parts of isothiazolinone derivative, 1 to 5 parts of permeation enhancer, 1 to 3 parts of stabilizer, 30 to 40 parts of dodecane, 20 to 35 parts of tetradecane and 50 to 80 parts of water. The microemulsion multifunctional nano oil-displacing agent provided by the invention has very high permeability-increasing and oil-displacing capabilities and excellent stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A kind of preparation method of spinel structure lithium titanate

The invention provides a preparation method of spinel-structure lithium titanate. The preparation method comprises the following steps: 1, taking metatitanic acid produced in a process of producing titanium dioxide with a sulfuric acid method; preparing the metatitanic acid into slurry A with de-ionized water; 2, adding calcining seed crystals, which are widely used in a process of producing rutile-type titanium dioxide with the sulfuric acid method, into the slurry A, wherein the mass ratio of TiO2 in the calcining seed crystals to TiO2 in the slurry A is (2 to 20) to 100; after uniformly stirring, filtering and washing with water; stopping water washing when the pH (Potential of Hydrogen) value is greater than 1.8; adding de-ionized water into a filter cake to prepare slurry B with the TiO2 concentration of 200g / L to 400g / L; 3, adding a lithium source into the slurry B according to the mole ratio of Li to Ti of 0.82 to 0.97; sufficiently and uniformly stirring to obtain slurry C; 4, conveying the slurry C into a rotary kiln; heating and calcining to finish dehydration, desulfurization and crystal form transformation to prepare the spinel-structure lithium titanate. According to the preparation method provided by the invention, all the methods are slurry processes, and dry-method crushing and grinding do not need to be carried out before the crystal form transformation is finished by heating so that energy consumption is low; a titanium source is cheap and easy to obtain.

Owner:YUNNAN GANG FENG NEW MATERIAL CO LTD

Carbon nanotube/nanosulfur/polyaniline composite electrode, preparation method and application

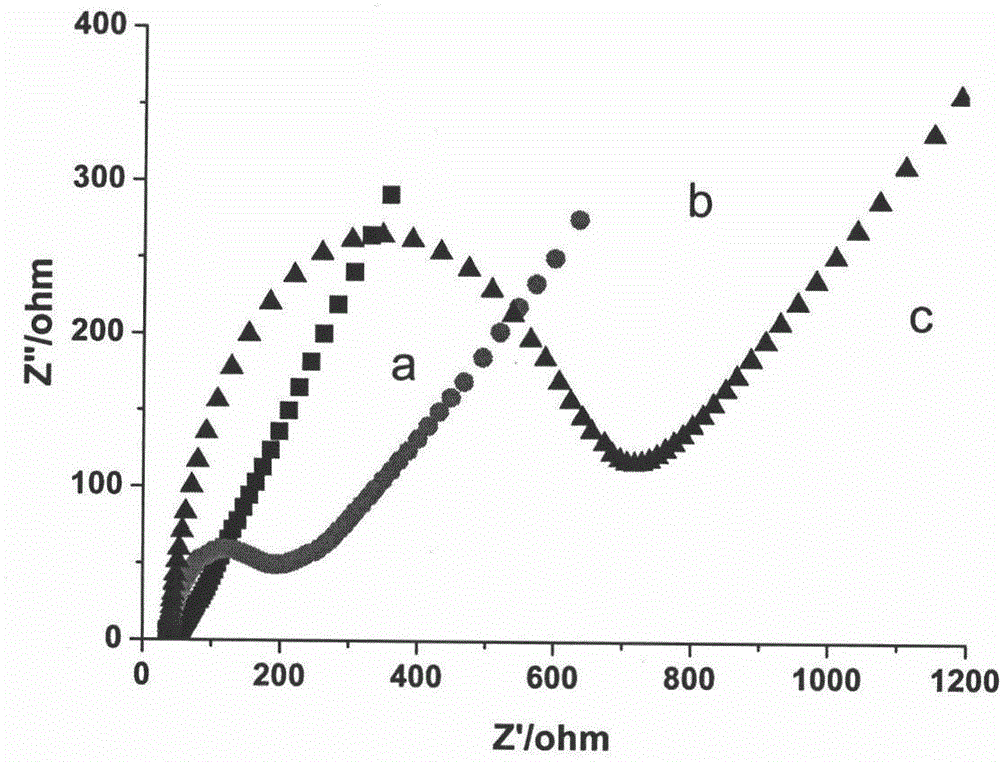

ActiveCN106058151BInhibition of dissolutionReduce expansionSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrochemical responseNew energy

The invention discloses a carbon nanotube / nano sulfur / polyaniline composite electrode, and a preparation method and an application thereof, and belongs to the technical field of electrochemistry and new energy products. The composite electrode has a core-shell structure, an inner core is a carbon nanotube / nano sulfur composite material, an outer shell is uniform and dense polyaniline formed by cyclic voltammetry electrodeposition, and the composite electrode has the characteristics of high electric conductivity, high specific capacity, strong electrochemical stability and the like. Nano-scale carbon nanotubes and a conductive polymer can effectively improve poor conductivity defect of elemental sulfur and an electrochemical reaction product thereof, and the conductive ability of an active substance is greatly improved. At the same time, the nano material has a certain adsorption effect on the intermediate product of a discharge reaction, and the sulfur dissolution loss during the charge / discharge processes can be effectively inhibited. Moreover, the carbon nanotube / nano sulfur inner core having a porous structure plays a buffer role on volume change of sulfur in the charge / discharge processes, can reduce the self swelling rate of the material, increases the liquid absorption and preserving abilities, and improves the cycle performance of the electrode.

Owner:深圳博磊达新能源科技有限公司

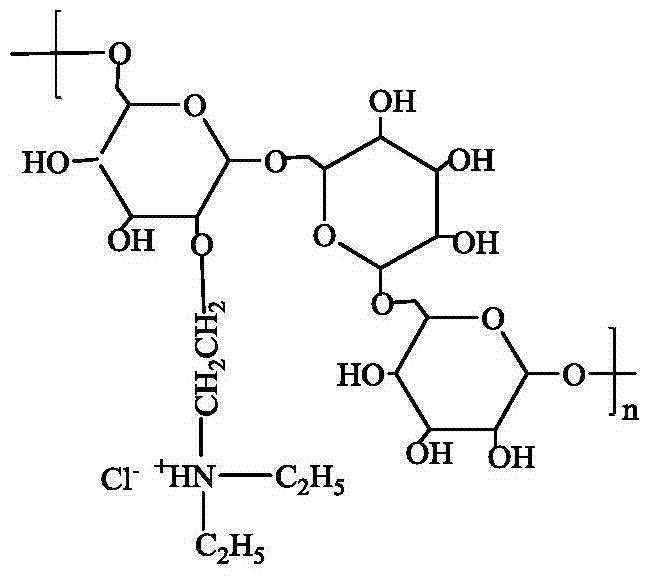

Diethylaminoethylated dextran modified agarose gel-based chromatographic medium, preparation method and application

ActiveCN105195115BStrong adsorption propertiesImprove adsorption capacityOther chemical processesPeptide preparation methodsGel basedBiocompatibility Testing

The invention relates to a chromatographic medium based on agarose gel modified by diethylaminoethylated dextran and its preparation method and application; firstly, the selection of the molecular weight of DEAE Dextran for grafting; secondly, the control of the concentration of DEAE Dextran aqueous solution; thirdly, , Determination of the diffusion time before coupling DEAE Dextan; finally, determination of the reaction time and sodium hydroxide concentration and volume of coupling DEAE Dextran. The DEAE Dextran-modified chromatographic medium based on agarose gel of the present invention has strong adsorption characteristics for proteins at different modification densities, exhibits high adsorption capacity and adsorption rate, and improves separation efficiency. The medium is easy to clean and sterilize, easy to regenerate, has good biocompatibility, has a simple preparation method and low toxicity, and will have broad application prospects in efficient and rapid separation and purification of proteins.

Owner:TIANJIN UNIV

Sulfonated sodium alginate grafted agarose gel chromatographic medium and its preparation method and application

InactiveCN108246273BHigh ion exchange capacityImprove adsorption capacityOther chemical processesPeptide preparation methodsSodium metabisulfiteIon exchange

Owner:TIANJIN UNIV

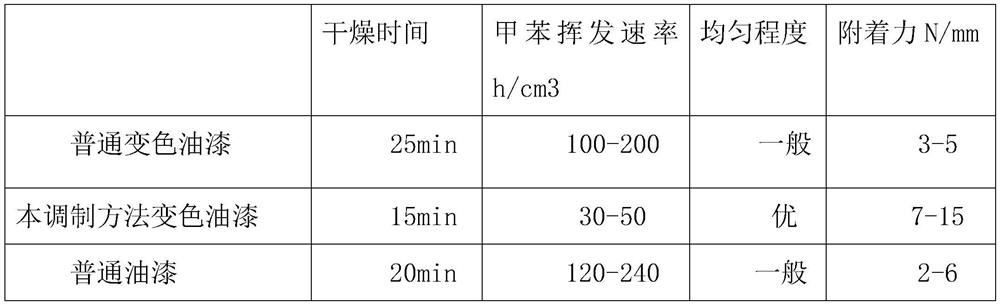

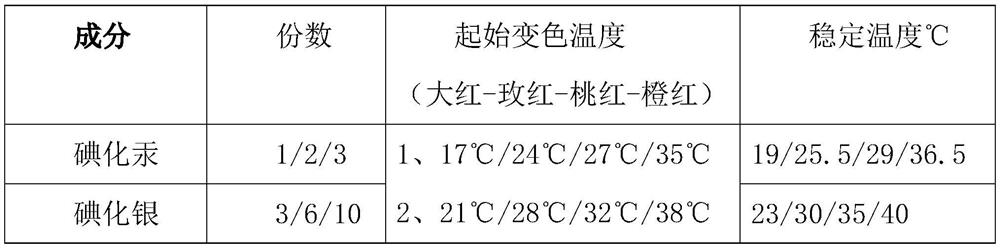

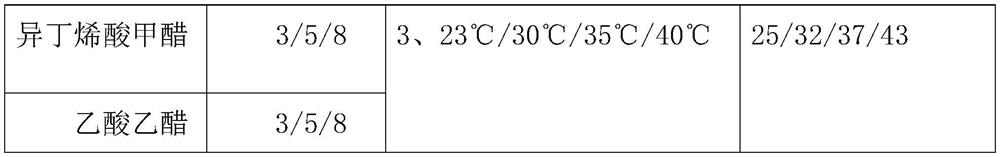

Manufacturing method of color-variable spraying material

The invention discloses a manufacturing method of a color-variable spraying material. The color-variable spraying material comprises the following raw materials in parts by weight: 15-30 parts of vegetable oil; 5-10 parts of wax oil; 10-20 parts of olive oil; a proper amount of purified water for later use; 8-16 parts of acrylic resin; 10-20 parts of epoxy resin; 5-15 parts of silicon resin; a proper amount of purified water for later use; 1-3 parts of mercury iodide; 3-10 parts of silver iodide; 3-8 parts of methyl methacrylate vinegar; 3-8 parts of ethyl acetate; 4-10 parts of diatom ooze; and a proper amount of purified water for later use. In the using process of the color-changing paint, the overall color-changing degree is more uniform and the drying time of the paint is effectivelyshortened; through effective combination of acrylic resin and epoxy resin and mixing of vegetable oil, an effective protective oil film is attached to the surface of the paint, so that the color-changing effect is improved. Therefore, the whole adhesive force of the paint can be well improved, and the decolorization of the paint is reduced after the paint is used for a long time.

Owner:德清品高新材料有限公司

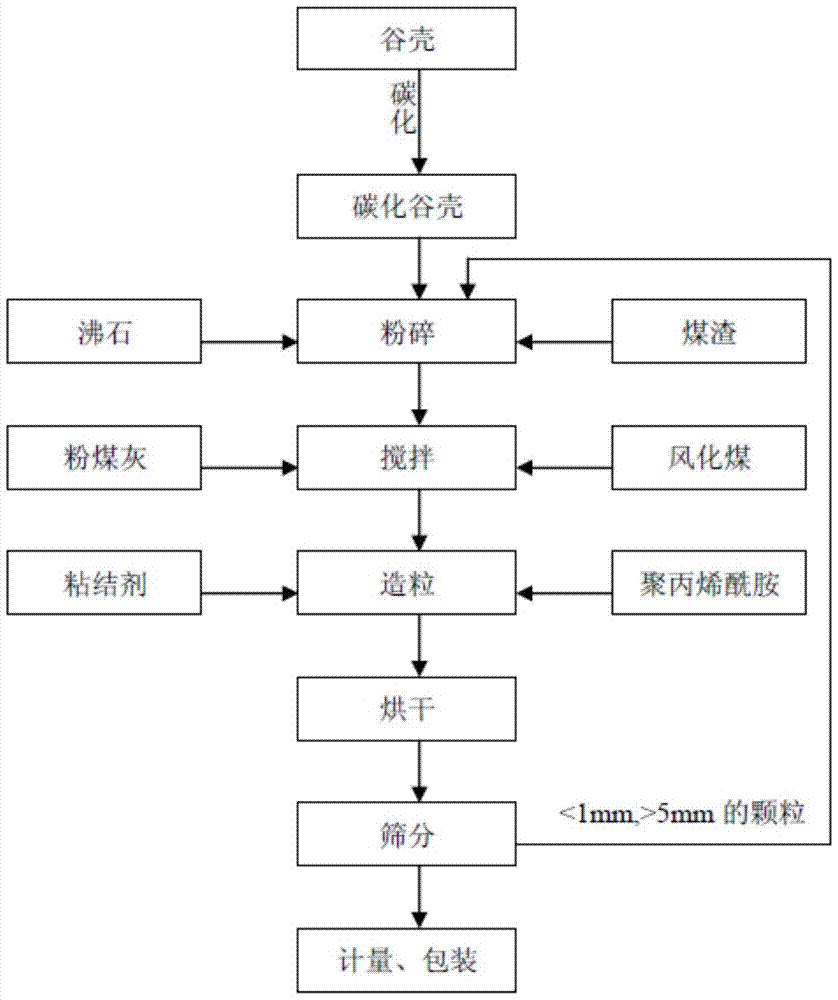

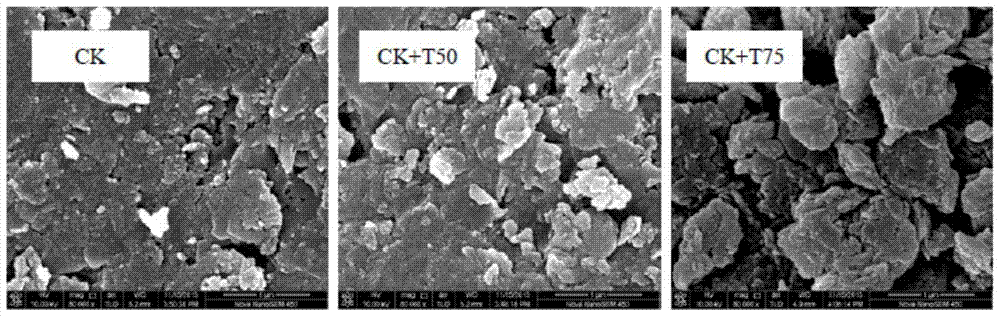

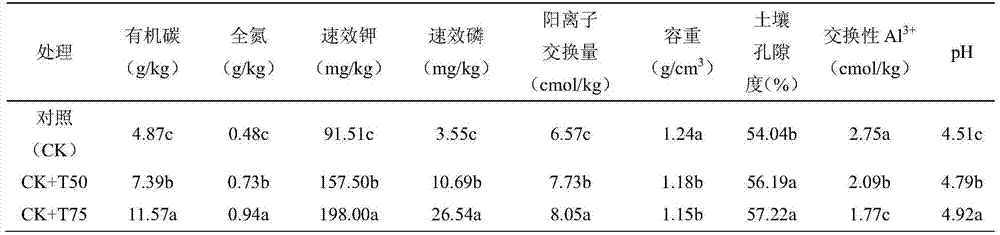

A kind of south red soil dry land nutrient expansion conditioner and preparation method thereof

ActiveCN105037014BIncrease exchange volumeImprove adsorption capacityFertilizer mixturesHuskRed soil

The invention provides a preparing method of south red soil dry land nutrient dilatation conditioner. The conditioner is prepared from, by weight, 25-35% of raw material zeolite, 10-15% of coal cinder, 14-20% of carbonizational husks, 12-17% of coal ash, 17-23% of decomposed coal and 3-8% of polyacrylamide in a blending and pelleting mode. By means of the prepared conditioner, the adsorption capacity of soil to nutrients can be greatly increased, the adsorption ability of soil to nutrients can be enhanced, the physical structure of soil can be obviously improved, the soil acidiy can be adjusted, contradiction among soil water, air and nutrient substances is coordinated, and the conditioner can be widely applied to south red soil dry land and provide a good basis for the high and stable yield of crops.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

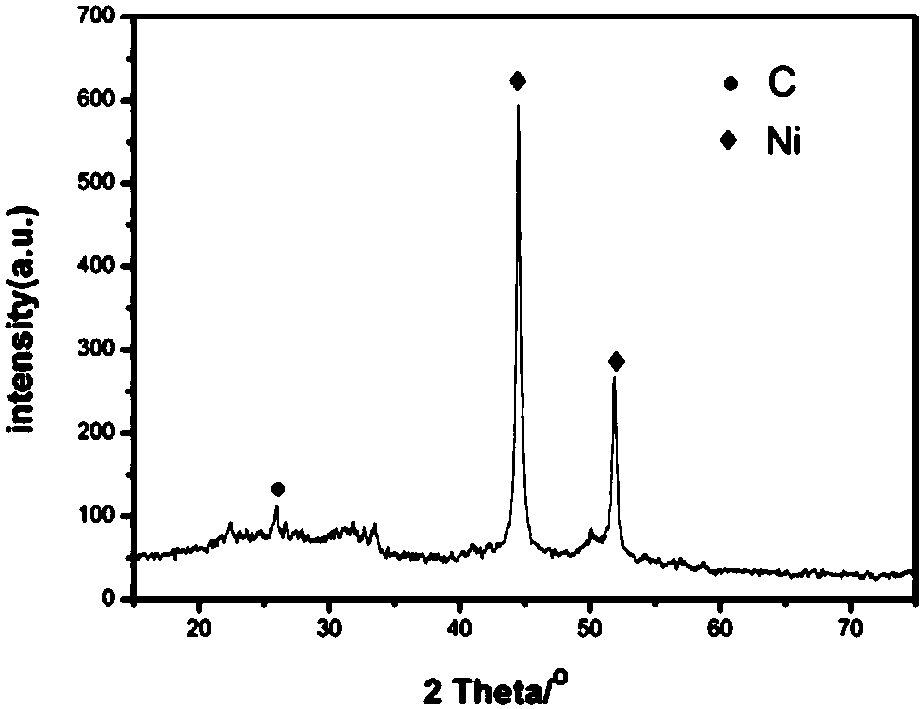

A preparation method of porous carbon-loaded graphene-coated nano-nickel particle absorbing material

ActiveCN106563816BRich pore structureAbundant specific surface areaOther chemical processesTransportation and packagingNickel saltFreeze-drying

A method for preparing a porous carbon-loaded graphene-coated nano-nickel particle wave-absorbing material, using algae as a carbon source, soaking it in a nickel salt solution, so that nickel ions enter the algae cells. After freeze-drying, it is subjected to low-temperature heat treatment, and the algae are converted into carbon, and the metal nickel salt is oxidized to nickel oxide; then the temperature is raised to continue high-temperature heat treatment, so that the nickel oxide is reduced to nickel, and the coating on the nickel nanometer is realized during the heat treatment process. The granular amorphous carbon is catalyzed and graphitized, and finally a composite material of porous carbon-supported graphene-coated nano-nickel particles is obtained. The invention uses algae as a carbon source, which is economical and practical, and uses the characteristics of rich pores in natural algae plants to uniformly disperse nickel on the carbon material; after heat treatment, a porous carbon material with a network structure is obtained, and the nickel particles coated with graphene are dispersed in the porous carbon material. The surface of the carbon material makes the material have excellent microwave absorption properties.

Owner:SHAANXI UNIV OF SCI & TECH

Wind power blade ice melting and inhibiting agent based on exothermic reaction and preparation method thereof

PendingCN113943549AHighly corrosiveGood ice melting effectOther chemical processesSodium acetateSolid component

The invention discloses a wind power blade ice-melting and ice-inhibiting agent based on exothermic reaction and a preparation method thereof. The ice-melting and ice-inhibiting agent comprises a solid component A and a liquid component B. The solid component A comprises sodium hydroxide powder and activated carbon; the liquid component B comprises acetic acid and ethylene glycol (glycerol). Sodium hydroxide and acetic acid are mainly utilized to react to generate sodium acetate and water, and a large amount of neutralization heat is released; wherein the reaction product sodium acetate has a good ice melting effect, the freezing point is reduced, the ice melting efficiency is improved, and the sodium acetate is small in erosion and corrosivity to soil and metal, easy to biodegrade, free of damage to a surface coating of the wind turbine blade and friendly to the surrounding environment.

Owner:XIAN THERMAL POWER RES INST CO LTD

Garment fabric and processing process thereof

InactiveCN108085834AHas a microporous structureStrong adsorption propertiesWoven fabricsYarnFiberCarbon fibers

The invention relates to garment fabric and a processing process thereof. The garment fabric is woven by warps and wefts, wherein the warps are blended by photochromic resin and corn fibers, the photochromic resin is the mixture of photochromic dye monomer particles and thermoplastic resin, and the wefts are blended by bamboo carbon fibers and flame-retardant fibers. The garment fabric is simple in process, soft, comfortable and excellent in flame retardance, fatigue resistance and color changing performance.

Owner:黛玛诗时尚服装有限公司

Modified nano bamboo charcoal mask and preparation method thereof

InactiveCN104041963BStrong adsorption propertiesHigh adsorption propertiesFibre typesProtective garmentPolymer scienceAdhesive

Provided are a modified nanometer bamboo charcoal mask and a manufacturing method thereof. The modified nanometer bamboo charcoal mask comprises an inner mask and an outer mask, wherein the inner mask is provided with a dismounting opening, and a filer layer is arranged in the dismounting opening. The inner mask and the outer mask of the mask and a filer layer base plate are made of an electrets melt-blowing polypropylene fiber non-woven fabrics, the filer layer uses chitosan as a capsule wall material, microcapsules are made from modified nanometer bamboo charcoal powder, beewax is used as an adhesive for arranging the microcapsules on the non-woven fabrics. The modified nanometer bamboo charcoal powder are modified by adopting nanometer titanium dioxide. The modified nanometer bamboo charcoal mask is green, environment-friendly, safe and efficient, has the broad-spectrum antibacterial effect and has good washability due to the fact that the beewax is used as the adhesive to arrange the microcapsules on the non-woven fabrics.

Owner:广州市威普复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com