Carbon nanotube/nanosulfur/polyaniline composite electrode, preparation method and application

A technology of carbon nanotubes and composite electrodes, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as poor performance of carbon-sulfur materials, poor cycle performance, and affecting the application range of materials, so as to increase the absorption Liquid retention capacity, good power performance, and the effect of inhibiting the dissolution and loss of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

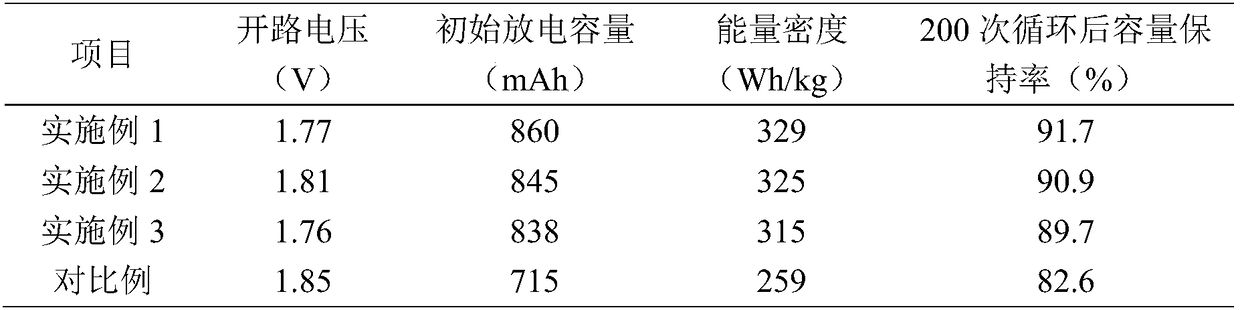

Embodiment 1

[0032] The carbon nanotube / nanosulfur / polyaniline composite electrode is obtained by electrochemically depositing polyaniline on the surface of the base electrode formed of carbon nanotube / nanosulfur composite material, and the preparation steps are:

[0033] 1) Preparation of basic electrode

[0034] Add 15.8g sodium thiosulfate and 3g polyvinylpyrrolidone into 100mL water and mix well, then add 5mL concentrated hydrochloric acid, stir and react for 3h to form a nano-sulfur particle suspension, centrifuge to discard the supernatant, wash and dry to obtain nano sulfur;

[0035] Mix 30g of nano-sulfur, 5g of calcium bicarbonate and 150mL of carbon nanotube conductive liquid with a concentration of 6%, then coat the copper foil, and sinter it at 180℃ for 2h, remove the copper foil and pulverize to obtain carbon nanotubes / Nano-sulfur composite materials;

[0036] Weigh 94g carbon nanotube / nanosulfur composite material, 2g conductive agent SP, 3g polyvinylidene fluoride and 100g N-methy...

Embodiment 2

[0041] The carbon nanotube / nanosulfur / polyaniline composite electrode is obtained by electrochemically depositing polyaniline on the surface of the base electrode formed of carbon nanotube / nanosulfur composite material, and the preparation steps are:

[0042] 1) Preparation of basic electrode

[0043] Add 15.8g sodium thiosulfate and 3g polyvinylpyrrolidone into 100mL water and mix well, then add 5mL concentrated hydrochloric acid, stir and react for 3h to form a nano-sulfur particle suspension, centrifuge to discard the supernatant, wash and dry to obtain nano sulfur;

[0044] Weigh 10g of nano-sulfur, 1g of calcium bicarbonate and 100mL of carbon nanotube conductive liquid with a concentration of 5%, then coat copper foil, and sinter at 150℃ for 1h, remove the copper foil and pulverize to obtain carbon nanotubes / Nano-sulfur composite materials;

[0045] Weigh 90g of carbon nanotube / nanosulfur composite material, 3g of conductive agent carbon black, 3g of sodium alginate and 100g o...

Embodiment 3

[0050] The carbon nanotube / nanosulfur / polyaniline composite electrode is obtained by electrochemically depositing polyaniline on the surface of the base electrode formed of carbon nanotube / nanosulfur composite material, and the preparation steps are:

[0051] 1) Preparation of basic electrode

[0052] Add 15.8g sodium thiosulfate and 3g polyvinylpyrrolidone into 100mL water and mix well, then add 5mL concentrated hydrochloric acid, stir and react for 3h to form a nano-sulfur particle suspension, centrifuge to discard the supernatant, wash and dry to obtain nano sulfur;

[0053] Mix 50g of nano-sulfur, 10g of calcium bicarbonate and 200mL of carbon nanotube conductive liquid with a concentration of 8%, then coat the copper foil, and sinter at 200℃ for 3h, remove the copper foil and pulverize to obtain carbon nanotubes / Nano-sulfur composite materials;

[0054] Weigh 95g of carbon nanotube / nanosulfur composite material, 1g of conductive agent acetylene black, 5g of polytetrafluoroethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com