A kind of preparation method of spinel structure lithium titanate

A technology of structural lithium titanate and spinel, applied in titanate, alkali metal titanate, chemical instruments and methods, etc., can solve the problems of shortening calcination time, low tap density, and reducing particle sintering, etc. The effect of saving energy consumption, low cost and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

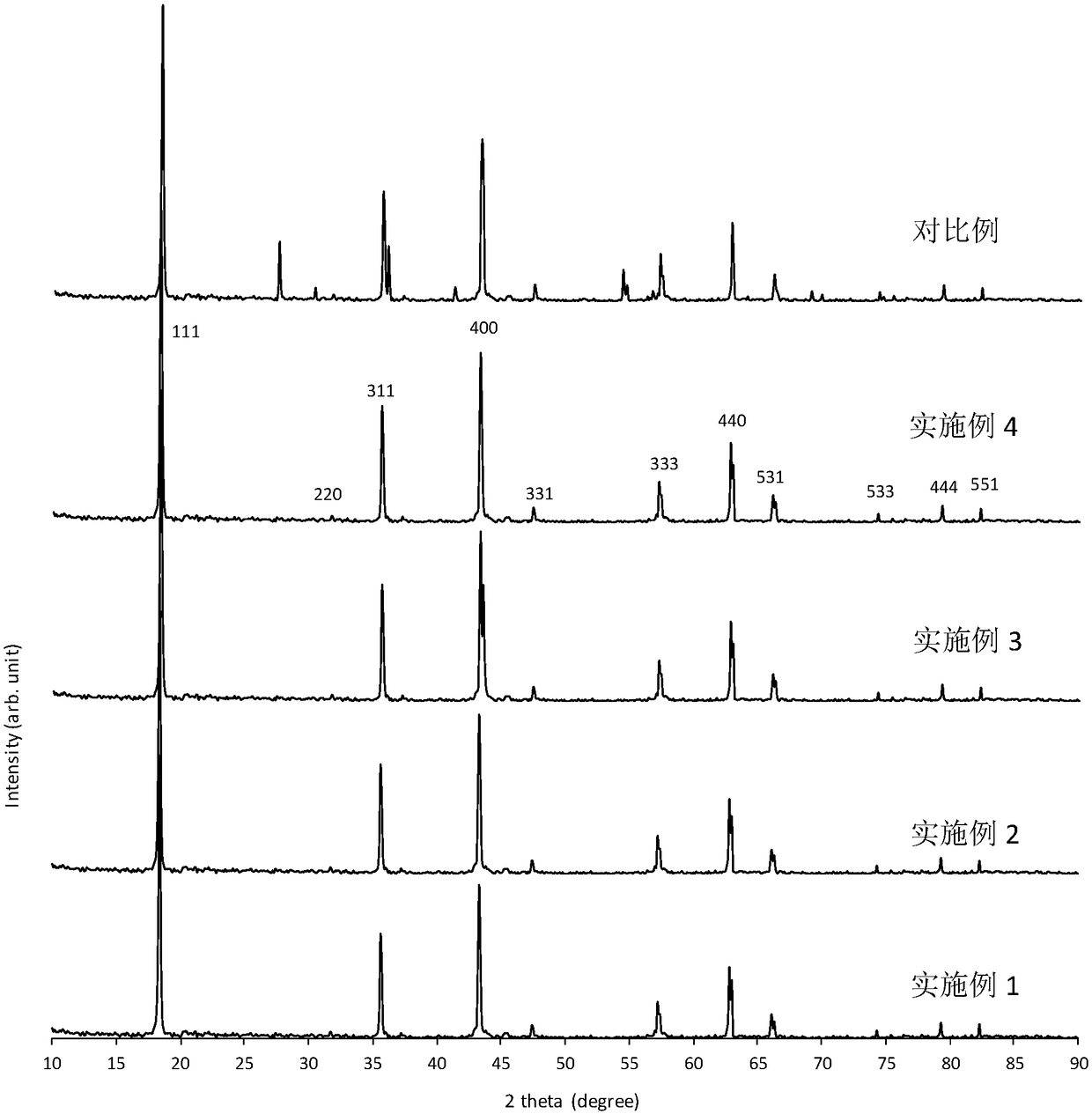

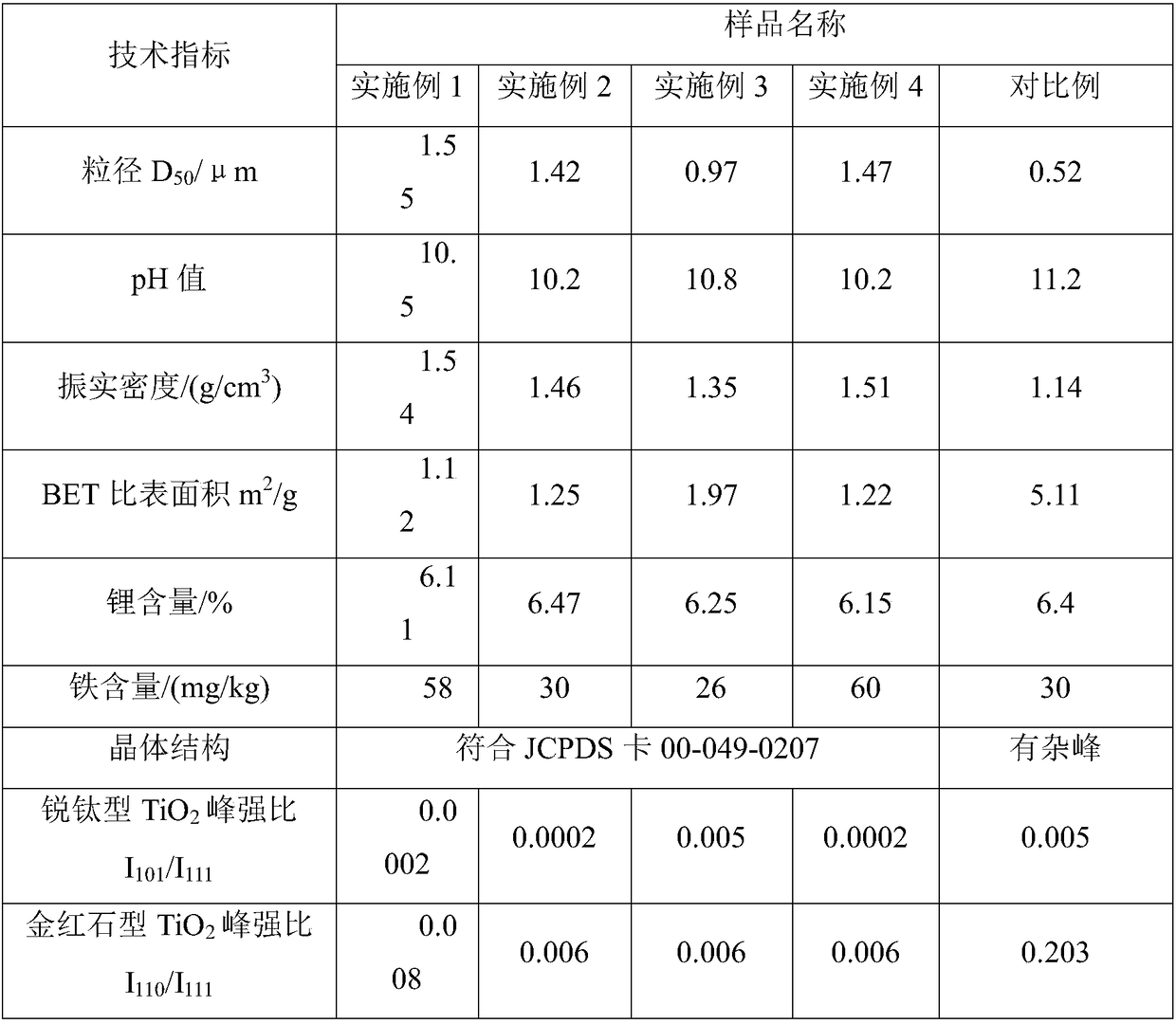

Examples

Embodiment 1

[0031] The preparation of spinel structure lithium titanate includes the following steps:

[0032] (1) Take metatitanic acid with an iron content of 65mg / kg after the second water washing in the sulfuric acid method titanium dioxide production process, and add deionized water to make the concentration 350g / L (with TiO 2 Calculated) of slurry A;

[0033] (2) Take 3.0L slurry A, add 1.05L concentration to 100g / L (with TiO 2 Calculate the calcined seed crystal, stir for 3h, filter and wash with water until the pH value is greater than 1.8, stop washing, add deionized water to filter cake to make 200g / L (with TiO 2 Calculate) the slurry B;

[0034] (3) Add lithium carbonate powder to slurry B according to the ratio of Li / Ti=0.88 (molar ratio), and stir for 6 hours to prepare slurry C;

[0035] (4) The slurry C is sent to a rotary calcining kiln with a specification of φ150x2000 for dehydration, desulfurization and calcination. The control parameters of the rotary kiln are 320°C at the kiln...

Embodiment 2

[0038] The preparation of spinel structure lithium titanate includes the following steps:

[0039] (1) Take metatitanic acid with an iron content of 28mg / kg after the second water washing in the production process of sulfuric acid method titanium dioxide, add deionized water to make the concentration of 500g / L (with TiO 2 Calculated) of slurry A;

[0040] (2) Take 2.0L slurry A, add 0.4L with a concentration of 50g / L (with TiO 2 Calculate the calcined seed crystals), stir for 2h, filter and wash with water until the pH value is greater than 1.8, stop washing, and add deionized water to the filter cake to make 400g / L 2 Calculate) the slurry B;

[0041] (3) In accordance with the ratio of Li / Ti=0.97 (molar ratio), a lithium acetate solution with a concentration of 300g / L (calculated as lithium acetate) was added to slurry B, and stirred for 4 hours to prepare slurry C;

[0042] (4) The slurry C is sent to a rotary calcining kiln with a specification of φ150x2000 for dehydration, desulfur...

Embodiment 3

[0045] The preparation of spinel structure lithium titanate includes the following steps:

[0046] (1) Take metatitanic acid with an iron content of 80mg / kg after the second water washing in the sulfuric acid method titanium dioxide production process, add deionized water to make the concentration 250g / L (with TiO 2 Calculated) of slurry A;

[0047] (2) Take 4.0L slurry A, add 0.8L concentration 250g / L (with TiO 2 Calculate the calcined seed crystals), stir for 2h, filter and wash with water until the pH value is greater than 1.8, stop the water washing, add deionized water to the filter cake to make 200g / L (with TiO 2 Calculate) the slurry B;

[0048] (3) Add lithium sulfate powder to slurry B according to the ratio of Li / Ti=0.82 (molar ratio), and stir for 6 hours to prepare slurry C;

[0049] (4) The slurry C is sent to a rotary calcining kiln with a specification of φ150x2000 for dehydration, desulfurization and calcination. The control parameters of the rotary kiln are 400°C at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com