A filler for artificial wetland water treatment and preparation method thereof

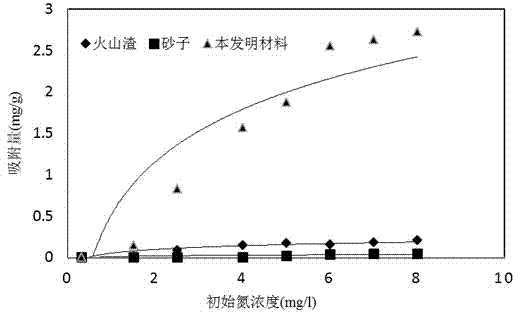

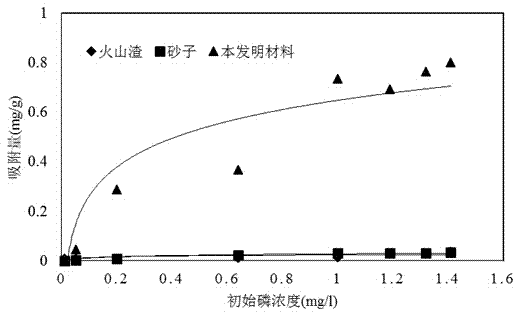

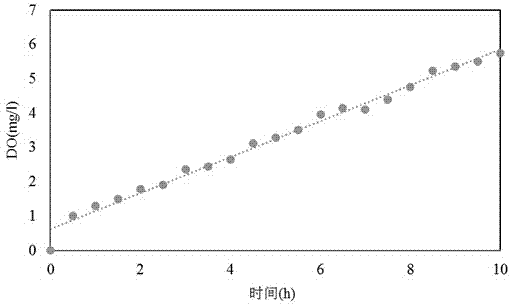

A constructed wetland and water treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., to achieve the effects of improving effluent water quality, promoting removal, and enhancing denitrification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for fillers for artificial wetland water treatment, comprising the following steps:

[0031] (1) Mix volcanic slag and sodium hydroxide evenly, and the mass ratio of soda to ash is 1.0. Put the mixture in a muffle furnace and roast it at 500°C for 2 hours, then cool it to room temperature, grind it and add water, silicon aluminum Adjust the ratio to 5, place it on a magnetic stirrer at room temperature, heat up to 90°C for 2 hours, then heat up to 95°C for 2 hours, filter and wash until the pH value is 7, put it in an oven at 80°C and dry Dry for 4 hours to get the best nitrogen adsorbent.

[0032] (2) Gradually adjust the pH value of the solution with a lanthanum ion concentration of 0.5% to 10, add the best nitrogen adsorbent prepared in step 1 according to 1:50 (solid-to-liquid ratio), soak for more than 16 hours, filter the filter cake in Dry at 110°C, place in a muffle furnace and bake at 450°C for 1 hour, grind and sieve to 120 mesh as the be...

Embodiment 2

[0037] (1) Mix volcanic slag and sodium hydroxide evenly, and the mass ratio of soda to ash is 1.2. Put the mixture in a muffle furnace and roast it at 700°C for 2 hours, then cool it to room temperature, grind it and add water, silicon aluminum Adjust the ratio to 6, place it on a magnetic stirrer at room temperature, heat up to 90°C for 2 hours, then heat up to 95°C for 2 hours, filter and wash until the pH value is 7, and put it in an oven for drying at 80°C Dry for 4 hours to get the best nitrogen adsorbent.

[0038](2) Gradually adjust the pH value of the solution with a lanthanum ion concentration of 0.5% to 10, add the best nitrogen adsorbent prepared in step 1 according to 1:50 (solid-to-liquid ratio), soak for more than 16 hours, filter the filter cake in Dry at 110°C, place in a muffle furnace and bake at 470°C for 1 hour. After grinding and sieving, 120 mesh is the best nitrogen and phosphorus adsorbent.

[0039] (3) Put the limestone into a muffle furnace and roas...

Embodiment 3

[0043] (1) Mix volcanic slag and sodium hydroxide evenly, and the mass ratio of soda to ash is 1.5. Put the mixture in a muffle furnace and roast it at 900°C for 2 hours, then cool it to room temperature, grind it and add water, silicon aluminum Adjust the ratio to 8, place it on a magnetic stirrer at room temperature, heat up to 90°C for 2 hours, then heat up to 95°C for 2 hours, filter and wash until the pH value is 7, put it in an oven at 80°C and dry Dry for 4 hours to get the best nitrogen adsorbent.

[0044] (2) Gradually adjust the pH value of the solution with a lanthanum ion concentration of 0.5% to 10, add the best nitrogen adsorbent prepared in step 1 according to 1:50 (solid-to-liquid ratio), soak for more than 16 hours, filter the filter cake in Dry at 110°C, place in a muffle furnace and bake at 500°C for 1 hour. After grinding and screening, 120 mesh is the best nitrogen and phosphorus adsorbent.

[0045] (3) Put the limestone into a muffle furnace and roast it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com