Manufacturing method of color-variable spraying material

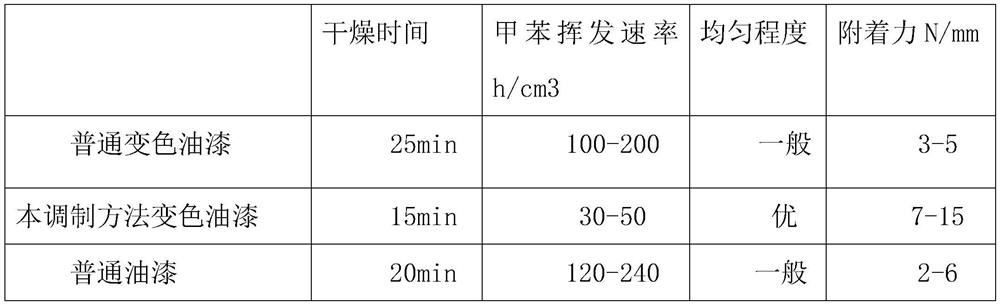

A technology of spraying materials and colors, applied in the direction of coating, etc., can solve the problems of poor surface brightness, poor adhesion of discoloration paint, etc., and achieve the effects of reducing drying time, improving adhesion, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

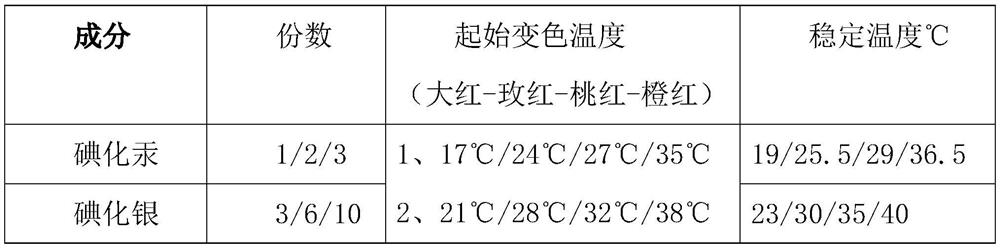

Embodiment 1

[0029] A variable-color spraying material, comprising the following raw materials in parts by weight: 15 parts of vegetable oil; 5 parts of wood wax oil; 10 parts of olive oil; 8 parts of acrylic resin; 10 parts of epoxy resin; 5 parts of silicone resin; 1 part of mercury iodide; 3 parts of silver iodide; 3 parts of methyl methacrylate; 3 parts of ethyl acetate; 4 parts of diatom mud; 3 parts of n-butyl acetate; 3 parts of ethyl acetate; 2 parts of n-butyl ester; 4 parts of ethanol 3 parts of benzene; 3 parts of xylene; 5 parts of mica powder; 5 parts of cinnabar powder; 5 parts of zinc chloride; 10 parts of thermal powder; appropriate amount of pure water for use.

[0030] A variable color spraying material, comprising the following steps:

[0031] Step 1: 5 parts of cinnabar powder, 5 parts of mica powder, 5 parts of zinc chloride, 10 parts of temperature sensitive powder, 1 part of mercury iodide, 3 parts of silver iodide, 3 parts of methyl methacrylate, stirring speed at 3...

Embodiment 2

[0042] A variable-color spraying material, comprising the following raw materials in parts by weight: 23 parts of vegetable oil, 7.5 parts of wood wax oil; 15 parts of olive oil; 12 parts of acrylic resin; 15 parts of epoxy resin; 10 parts of silicone resin; 2 parts of mercury iodide; 6 parts of silver iodide; 5 parts of methyl methacrylate; 5 parts of ethyl acetate; 7 parts of diatom mud; 4.5 parts of n-butyl acetate; 4.5 parts of ethyl acetate; 4 parts of n-butyl ester; 5.5 parts of benzene; 5.5 parts of xylene; 7.5 parts of mica powder; 10 parts of cinnabar powder; 10 parts of zinc chloride;

[0043] A method for producing a variable-color spraying material, comprising the following steps:

[0044] Step 1: 10 parts of cinnabar powder, 7.5 parts of mica powder, 10 parts of zinc chloride, 15 parts of temperature sensitive powder, 2 parts of mercury iodide, 6 parts of silver iodide, 5 parts of methyl methacrylate, stirring speed at 400r / min, stirring The time is 5 minutes, an...

Embodiment 3

[0055] A method for producing a variable-color spraying material, comprising the following steps:

[0056] A variable-color spraying material, comprising the following raw materials in proportion by weight: 15-30 parts of vegetable oil; 10 parts of wood wax oil; 20 parts of olive oil; 16 parts of acrylic resin; 20 parts of epoxy resin; 15 parts of silicone resin 3 parts of mercury iodide; 10 parts of silver iodide; 8 parts of methyl methacrylate; 8 parts of ethyl acetate; 10 parts of diatom mud; 6 parts of n-butyl acetate; 6 parts of ethyl acetate; 6 parts of n-butyl; 10 parts of ethanol; 8 parts of benzene; 8 parts of xylene; 10 parts of mica powder; 15 parts of cinnabar powder; 15 parts of zinc chloride;

[0057] Step 1: 15 parts of cinnabar powder, 10 parts of mica powder, 15 parts of zinc chloride, 20 parts of temperature-sensitive powder, 3 parts of mercury iodide, 10 parts of silver iodide, 8 parts of methyl methacrylate, stirring speed at 500r / min, stirring The time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com