Patents

Literature

54results about How to "Uniform discoloration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

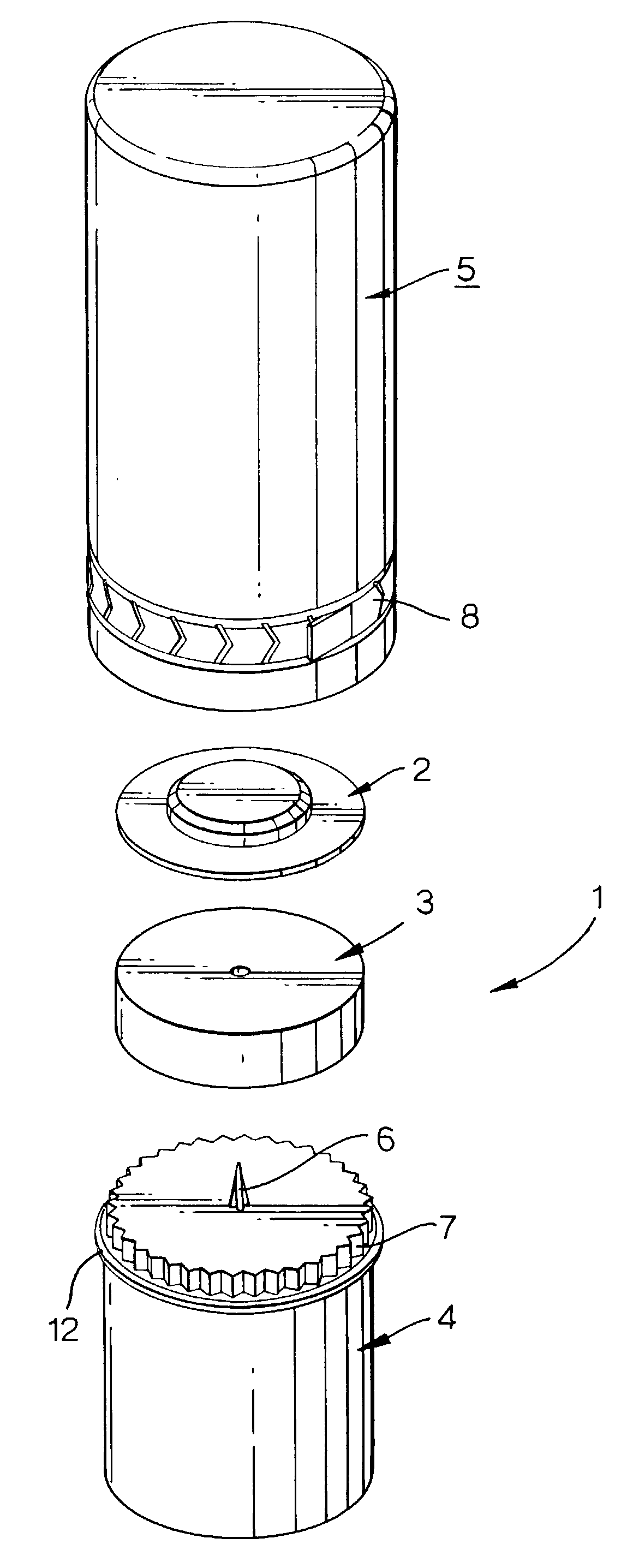

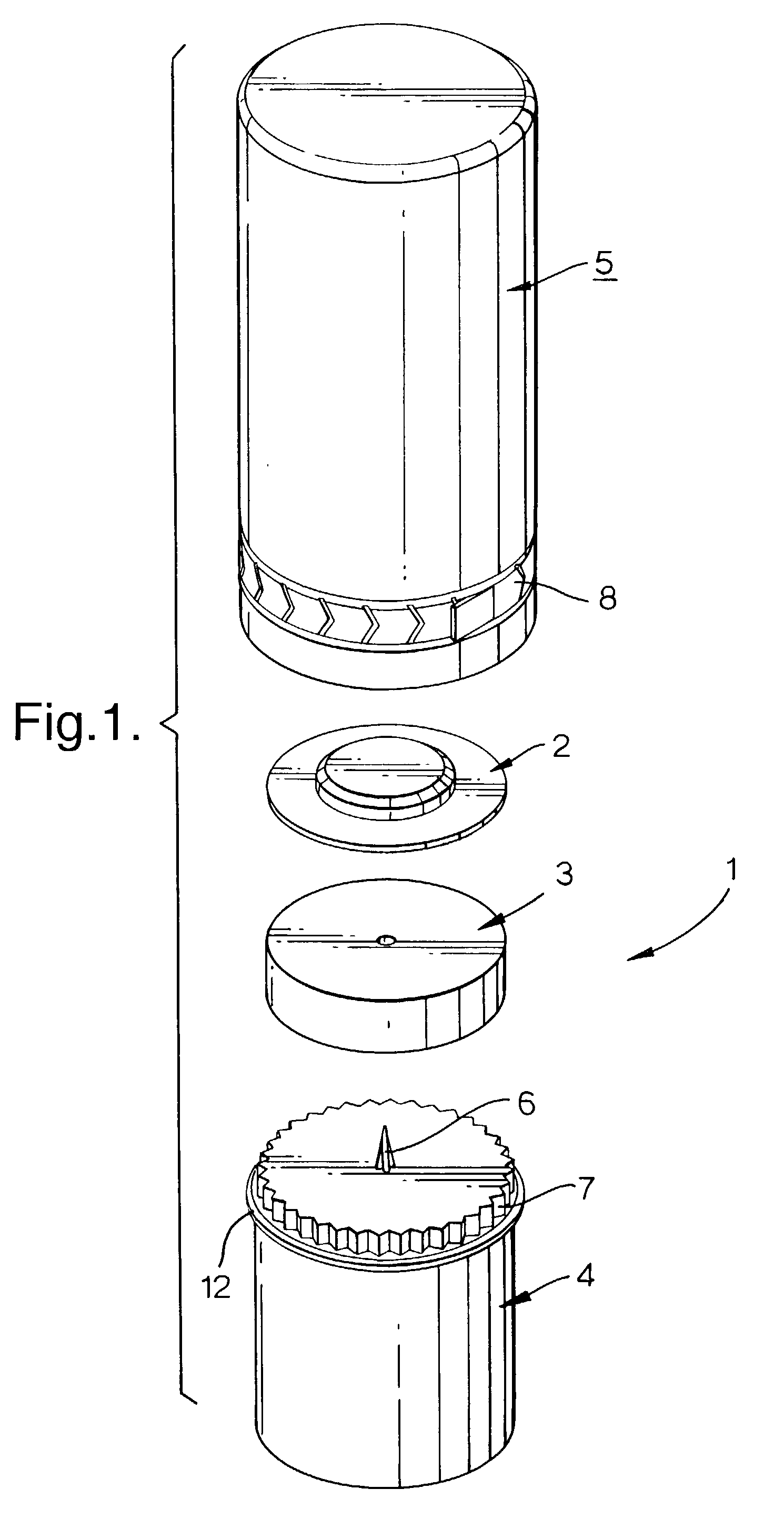

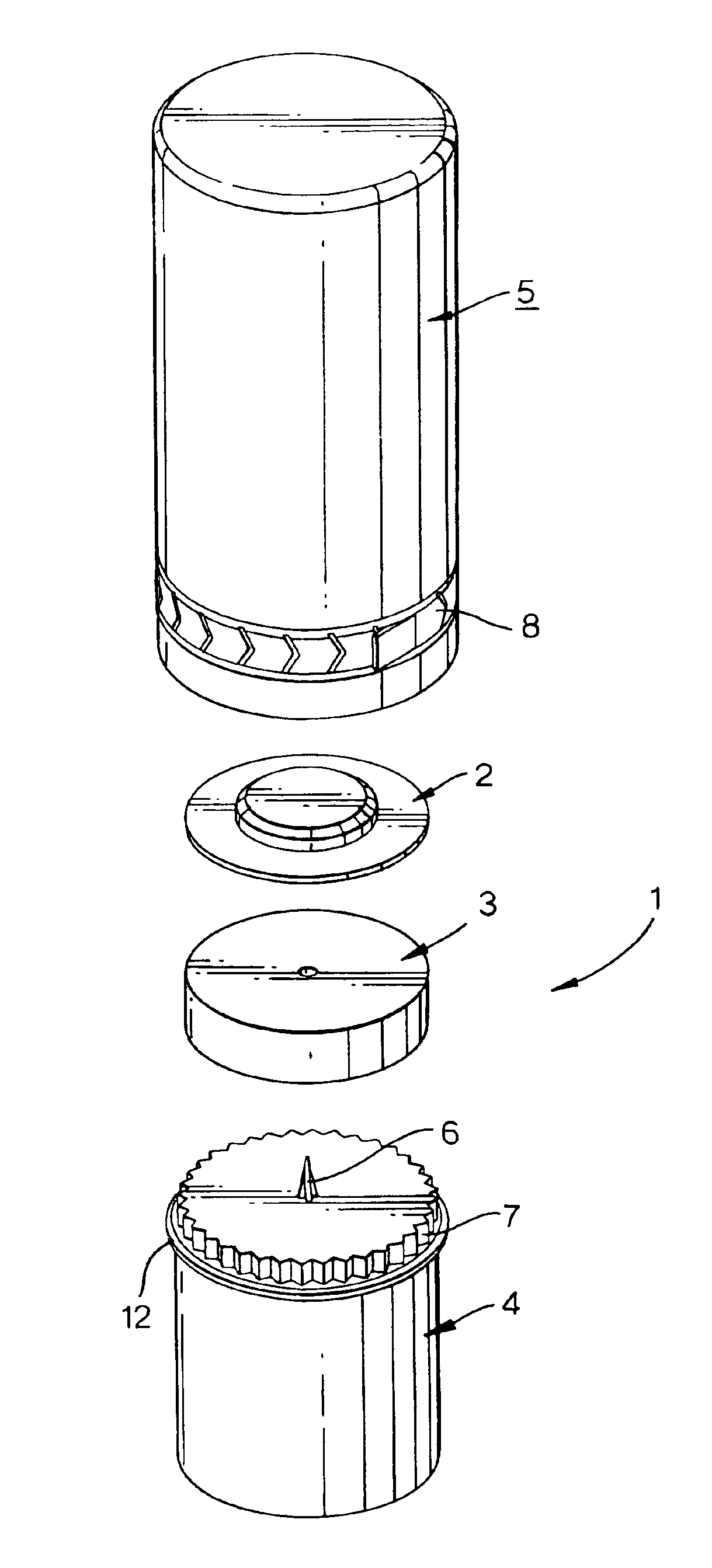

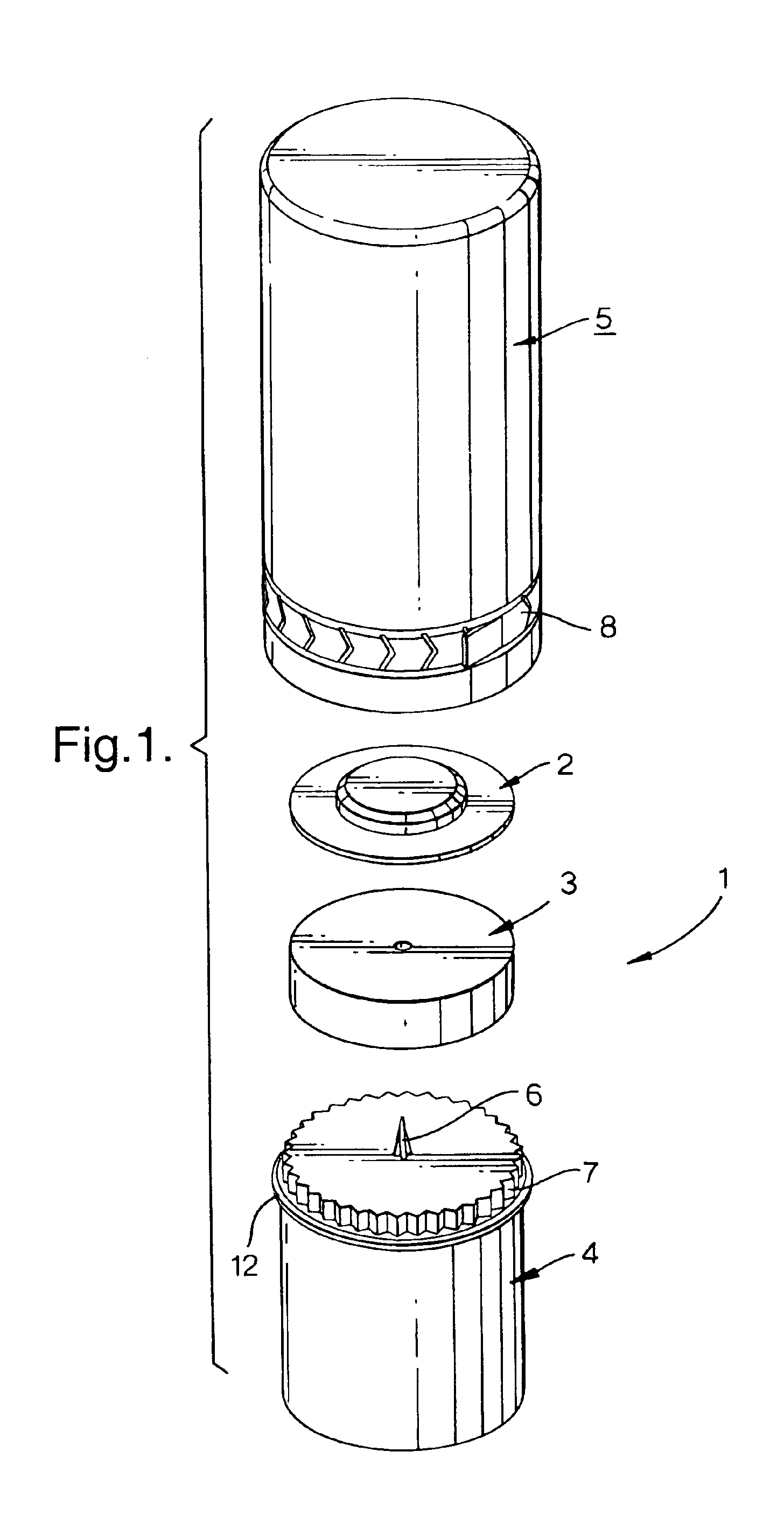

Tamper evident closure

InactiveUS20020195413A1Good miscibilityImprove responseSmall article dispensingCapsAbsorbent PadsBlister pack

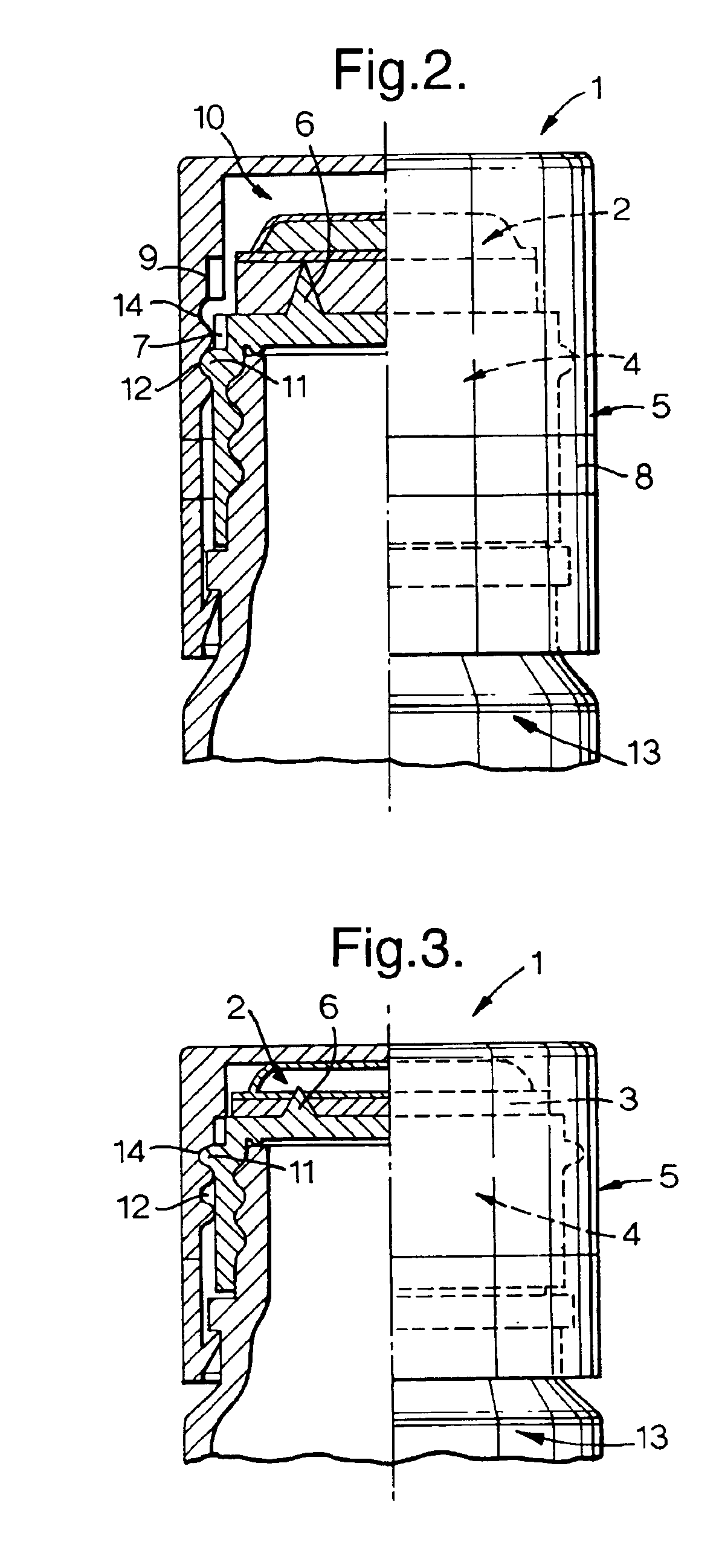

A tamper evident closure (1) includes a housing (5) containing a blister pack (2) and a substrate (3), wherein the blister pack (2) contains a first reagent which is visible prior to first opening and the substrate (3) contains a second reagent. First opening of the closure ruptures the blister pack thereby exposing the first reagent to the second reagent and effecting a reaction that causes a visual change that signals the closure has been opened. The tamper evident closure of the present invention is primarily intended to be used as an anti-counterfeit measure on a spirit or pharmaceutical bottle. In the preferred embodiment, the closure incorporates a liquid that when brought into contact with a reagent chemical contained in an absorbent pad, effects an irreversible color change. This color change will indicate to a consumer the bottle has been previously opened or tampered with. The design makes it very difficult for a counterfeiter to cover up or eradicate the visible effects. In particular, the only way a counterfeiter could do this would be to put in a replacement blister and an absorbent pad. Filling a blister pack with a liquid is a highly specialist task which makes replication very difficult. The ability to control the color change to complement the branded goods provides a way of building up consumer recognition of the product and thereby establishing confidence in those products that carry the tamper evident closure of the present invention.

Owner:ALLIED DOMECQ SPIRITS & WINE BRITISH

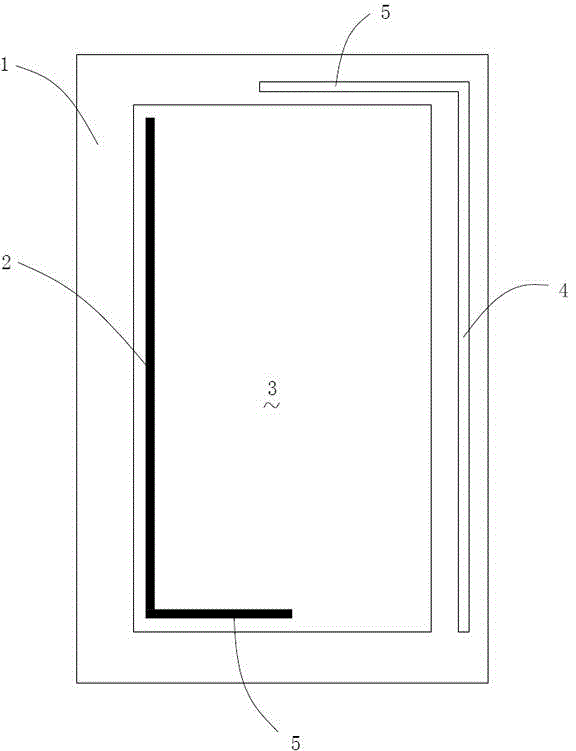

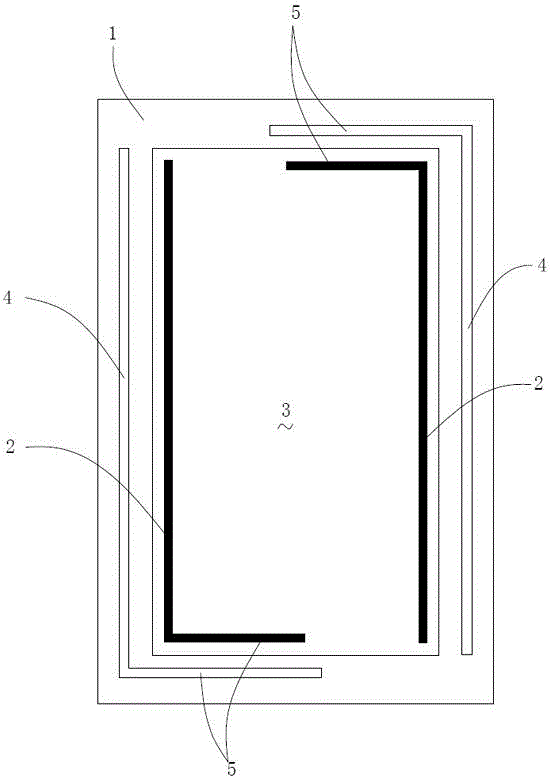

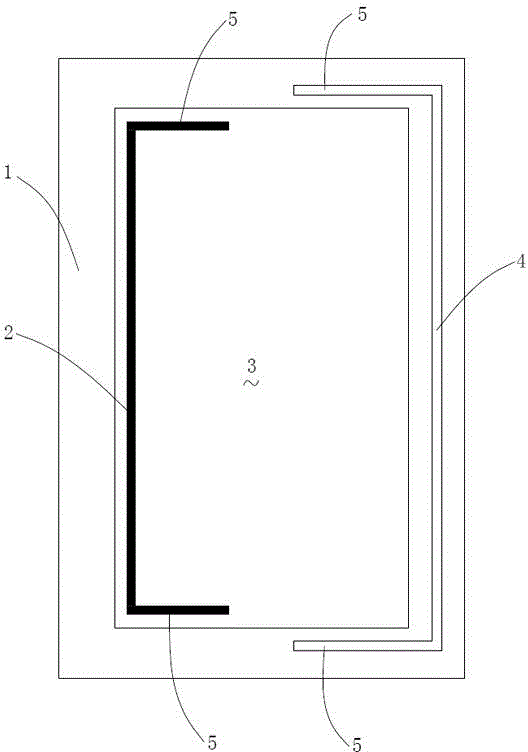

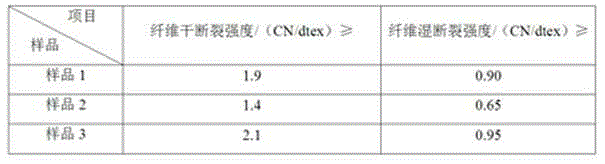

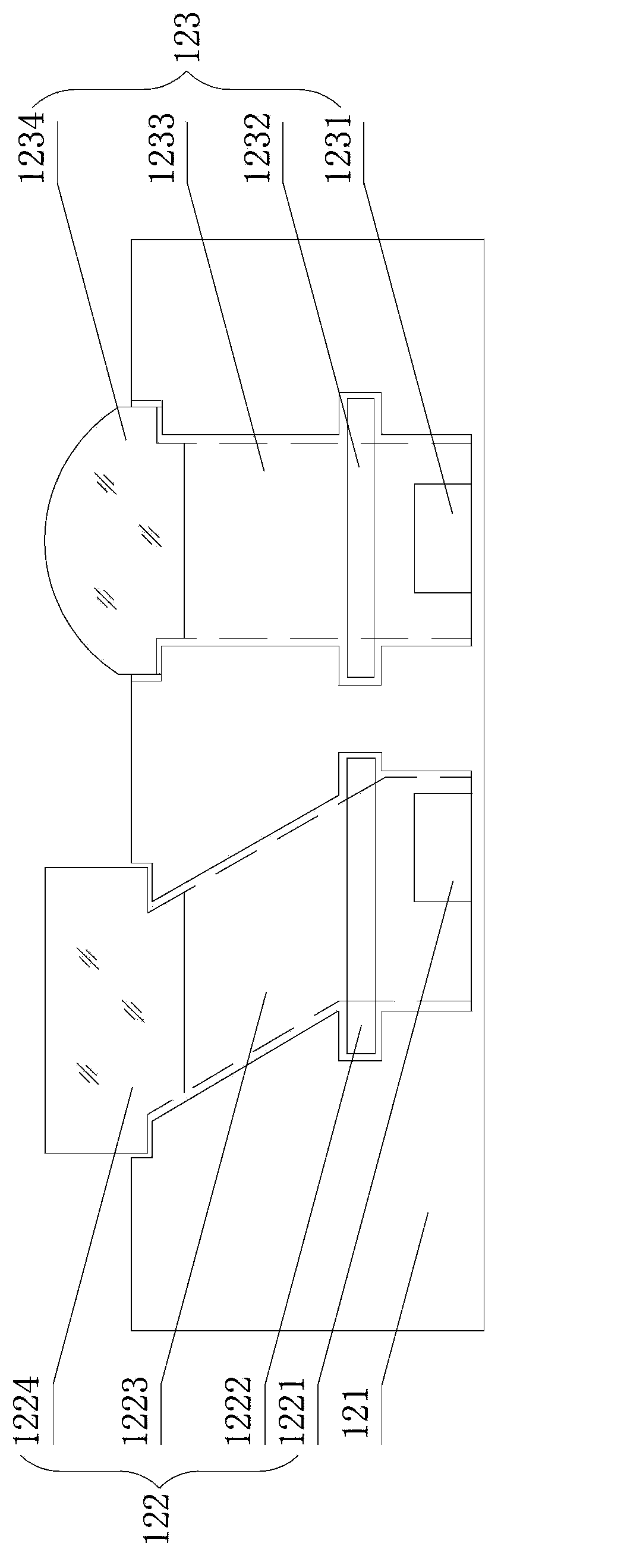

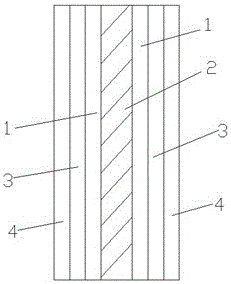

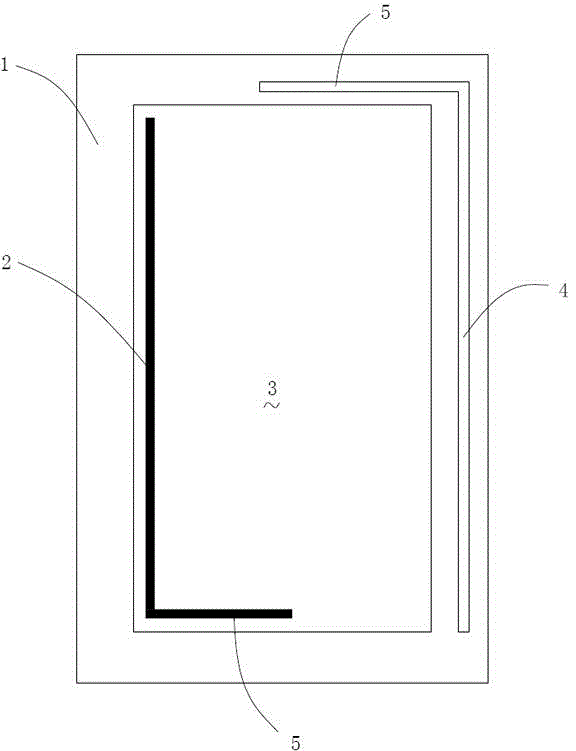

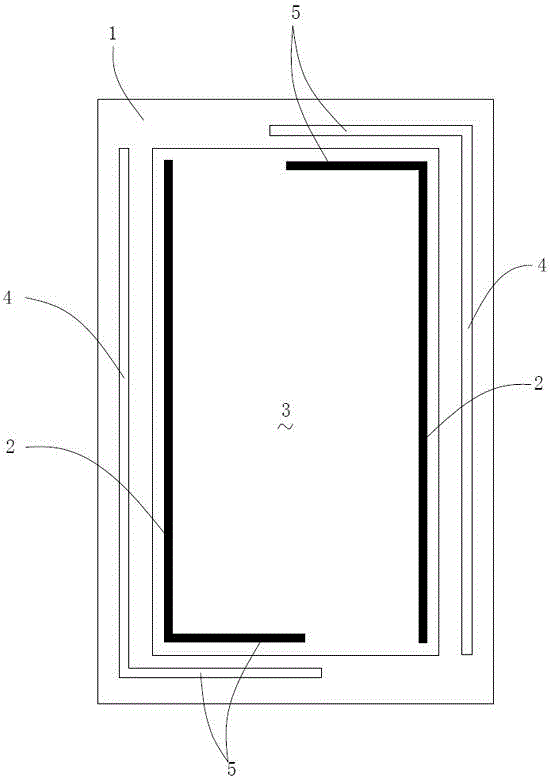

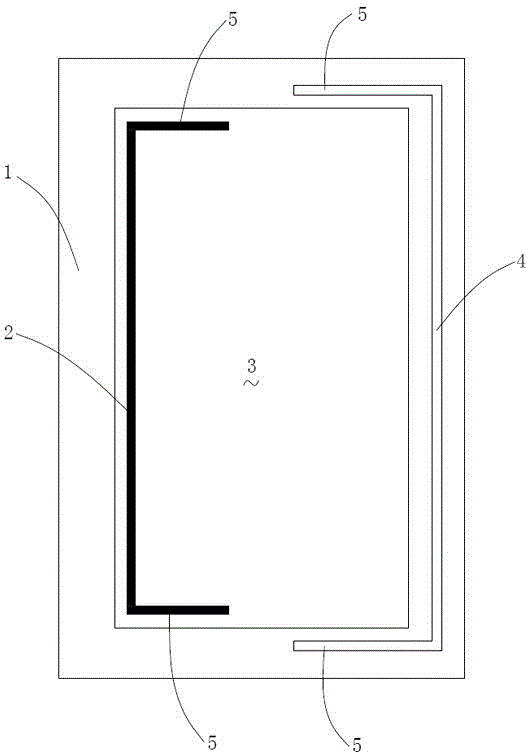

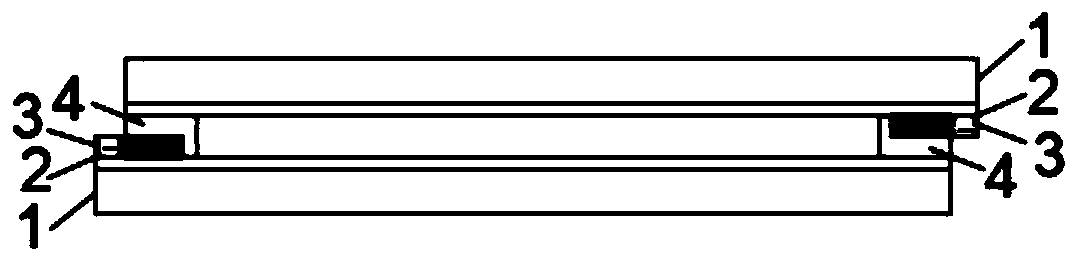

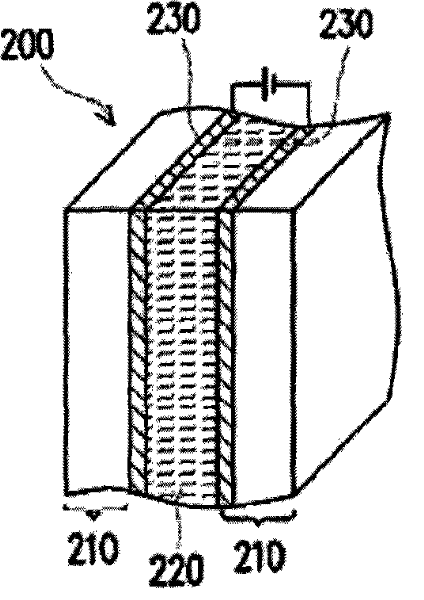

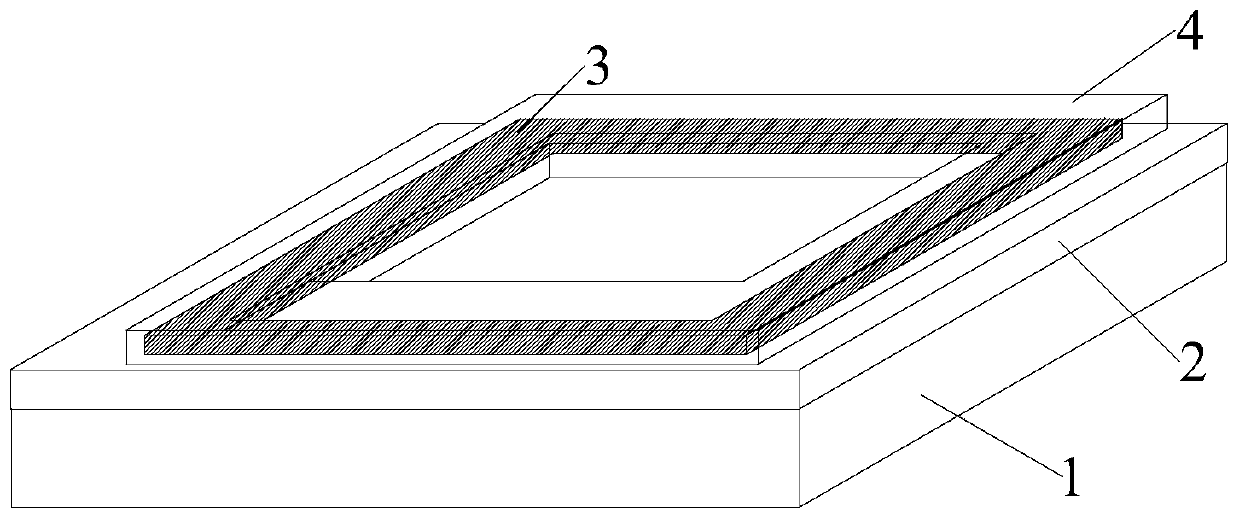

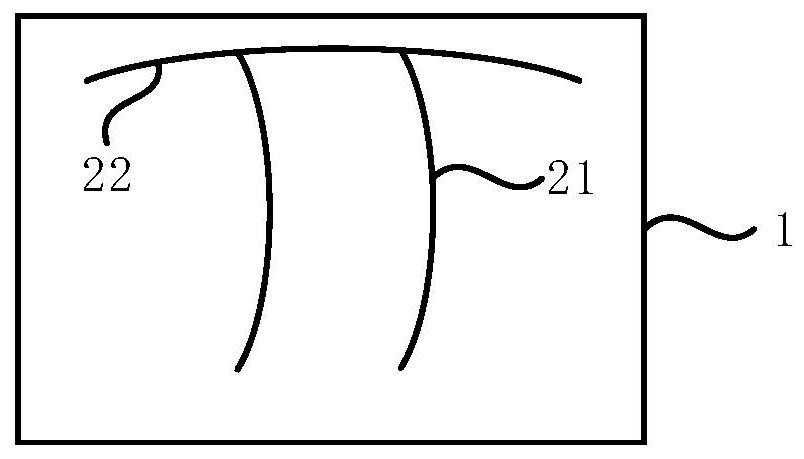

Driving layout structure of electrochromic glass

ActiveCN104898345AShorten the electric effect distanceShorten the timeNon-linear opticsElectricityElectrochromism

The invention relates to a driving layout structure of electrochromic glass, which solves the technical defects that the effective driving voltage on the two sides of large area electrochromic glass is too high, and the effective driving voltage in the middle is not enough, thereby causing uneven discoloring of the electrochromic glass. A lower electrode conductive strip is arranged on a bottom layer conductive layer, an upper electrode conductive strip is arranged on a top layer conductive layer, the upper and the lower electrode conductive strips are respectively arranged on long sides of the two sides of the electrochromic glass, the end portions of conductive strips extend on short sides of the electrochromic glass or / and the numbers of the conductive strips is increased in pair, and electric effect distances between the corresponding upper and the lower electrode conductive strips are reduced, thereby enabling the electric effect distances to be smaller than the lengths of the short sides of the electrochromic glass. The driving layout structure of electrochromic glass can greatly improve distribution of effective driving voltage of the electrochromic glass by changing the shape of the conductive strips or increasing the number of the conductive strips, reducing the electric effect distances between the end portions of the upper and the lower electrode conductive strips, and enabling large area electrochromism to be more uniform.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

Tamper evident closure

Owner:ALLIED DOMECQ SPIRITS & WINE BRITISH

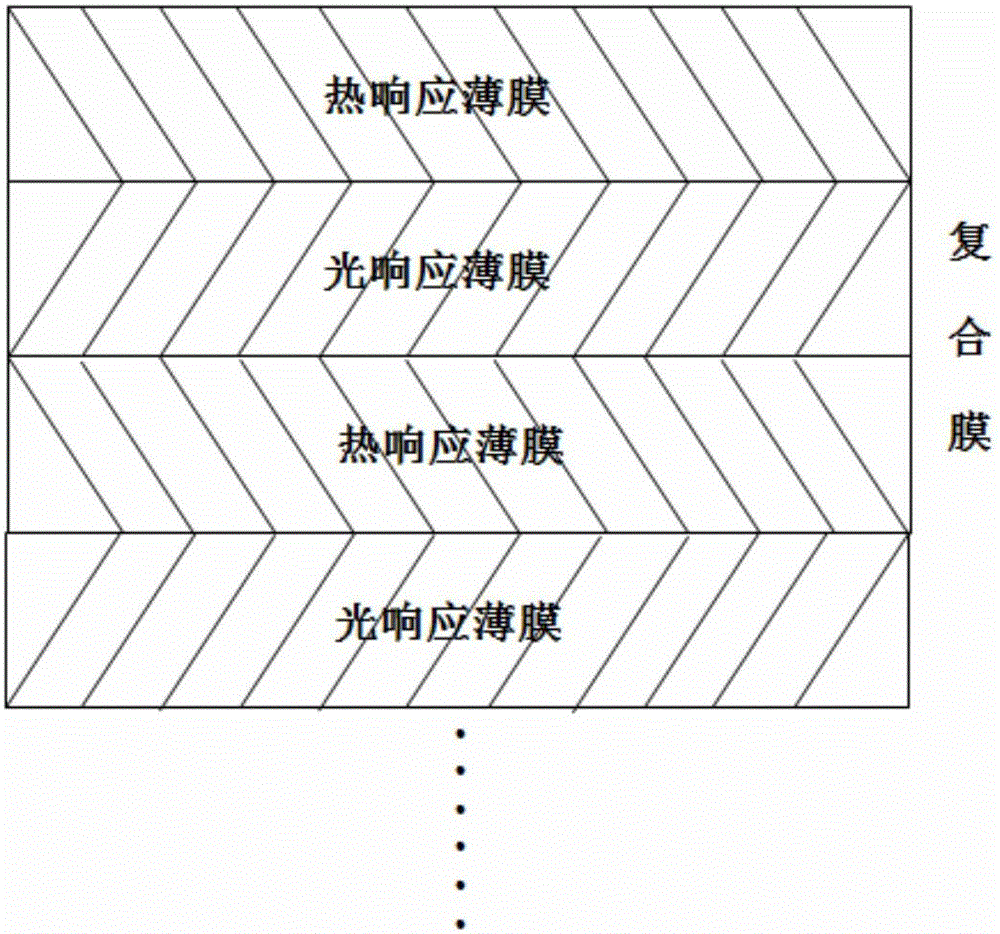

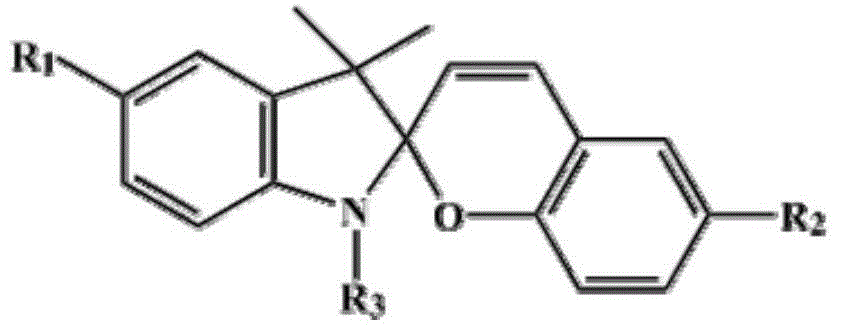

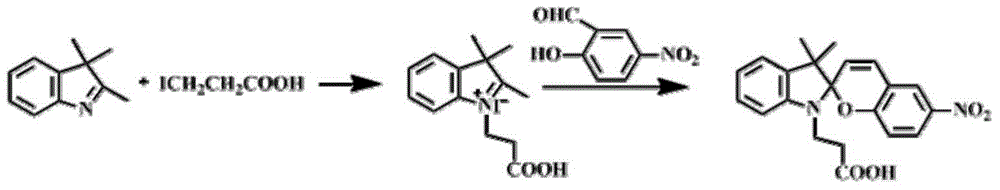

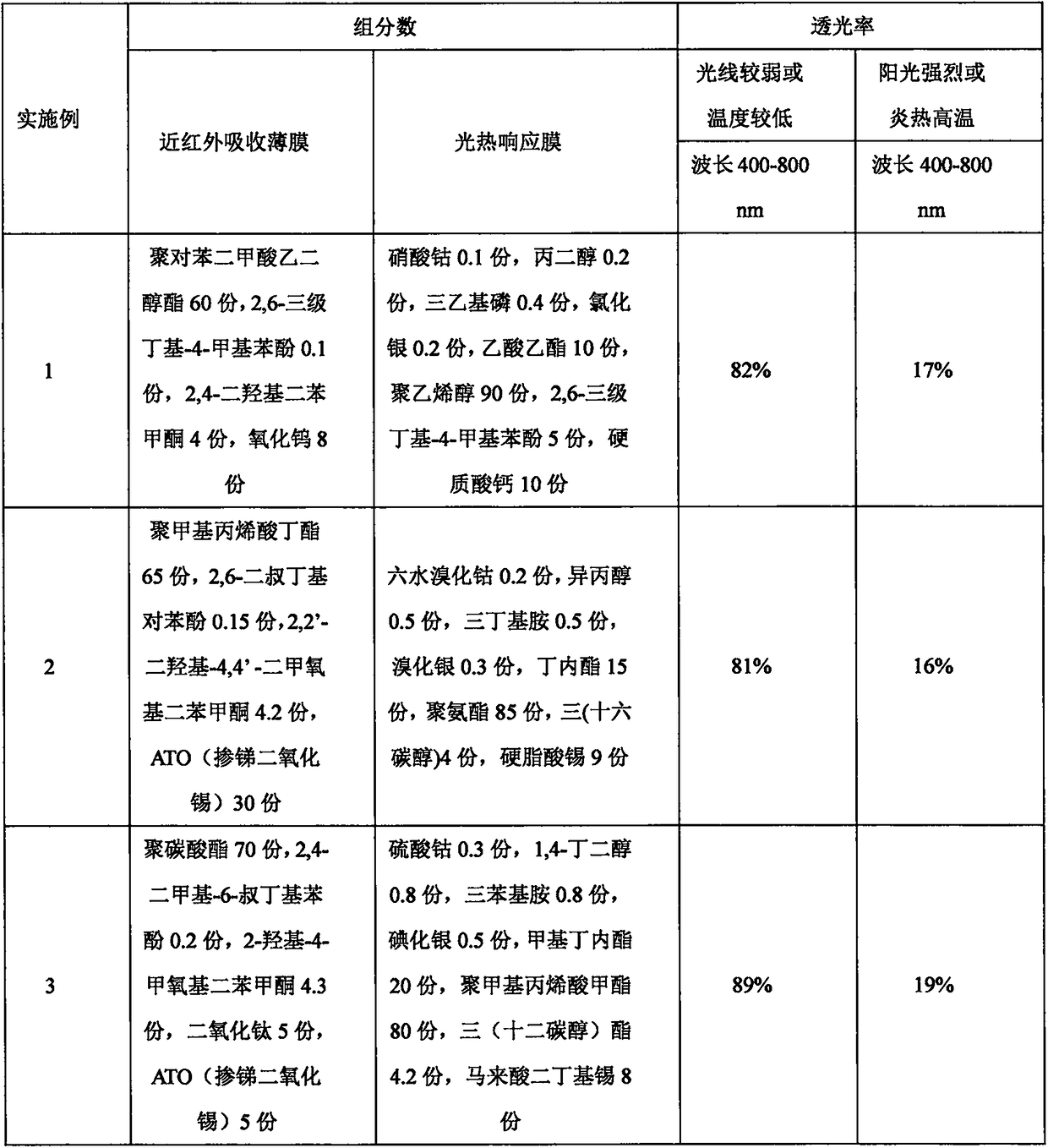

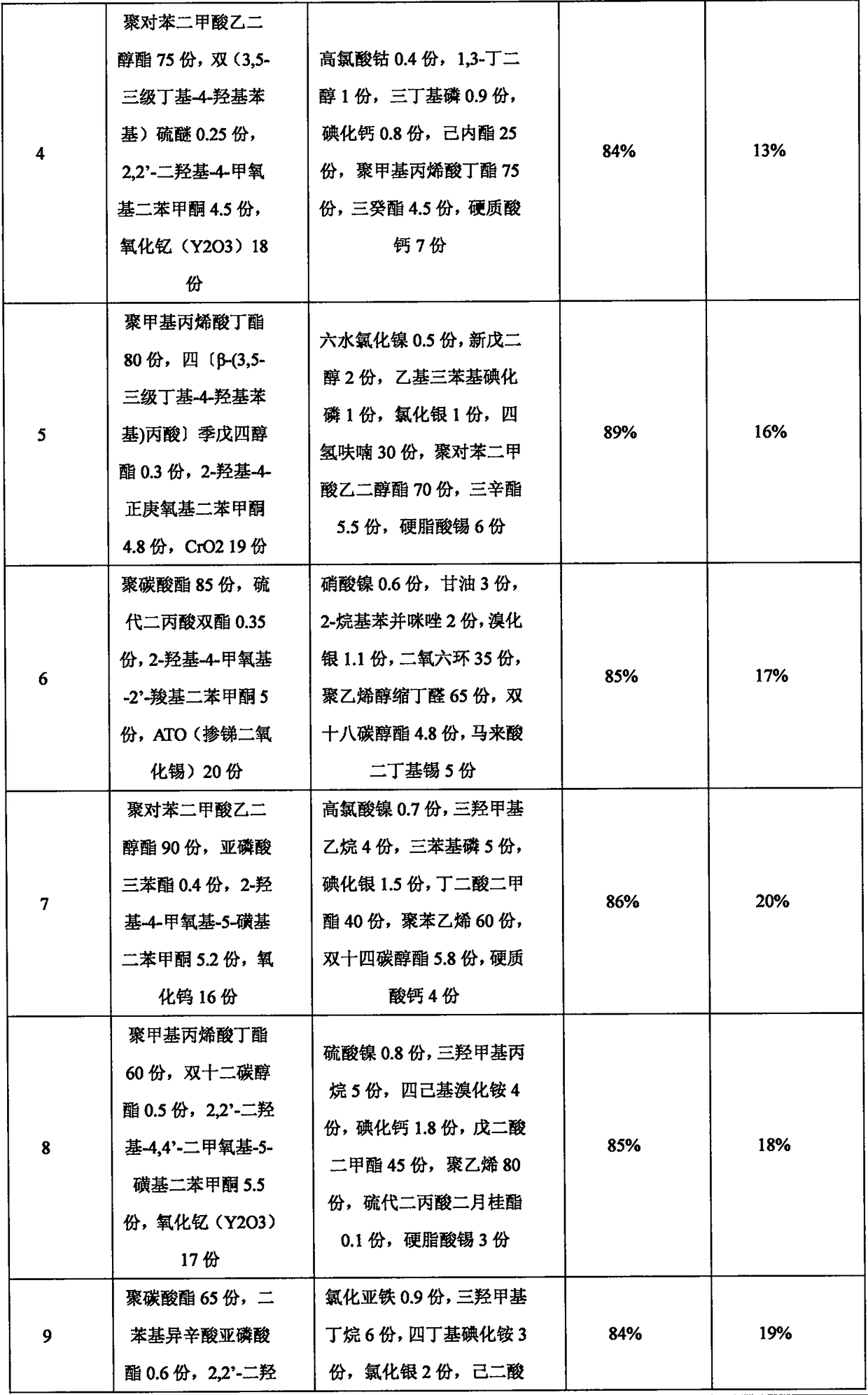

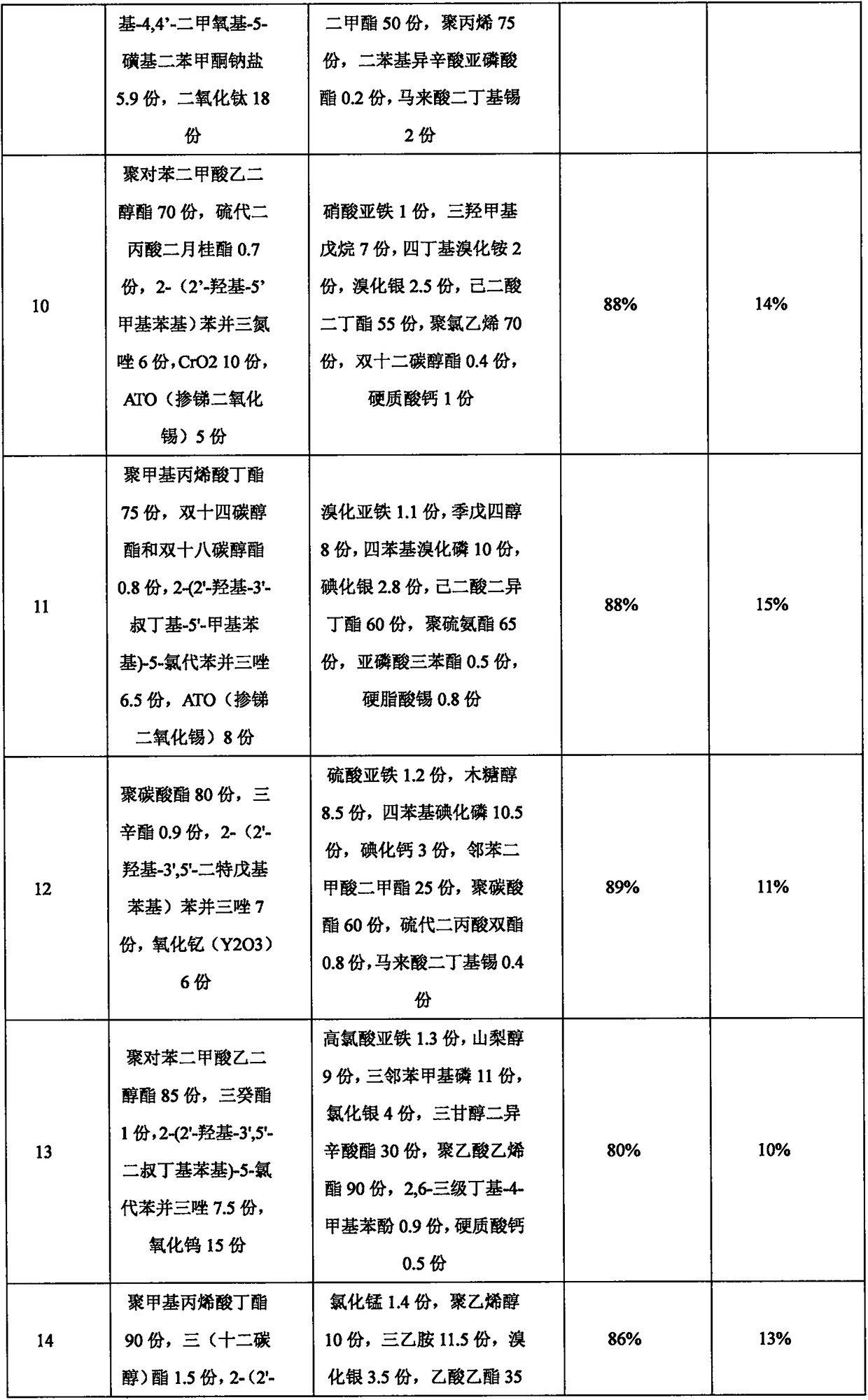

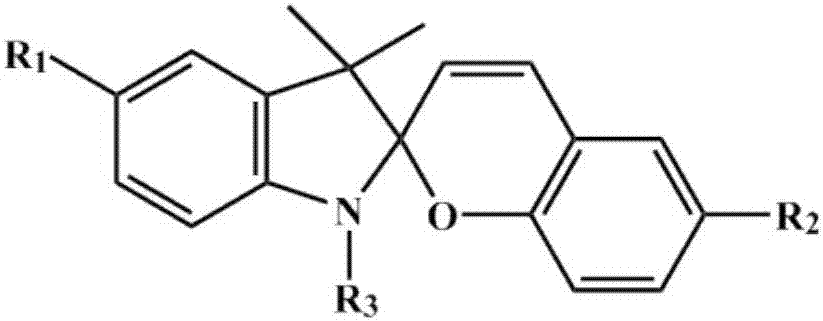

Photothermally responsive smart energy saving composite film

ActiveCN105017698AReduce energy consumptionEmission reductionSynthetic resin layered productsLuminescent compositionsVanadium dioxideThermochromism

The present invention discloses a photothermally responsive smart energy saving composite film, and is comprised of a reversible photochromism containing a spiropyran material and a vanadium dioxide based reversible thermochromism material. The smart energy saving composite film can be used to prepare one or more layers of alternating and composite color-changeable films, and is both decorative and functional, which is suitable for the requirement of energy saving in architecture and can be widely used in spheres like doors and windows of buildings and energy-saving and safe glasses of cars as well as agricultural green house films. The smart energy saving composite film is based on the photothermal response technology, has a good color changing effect, a good anti-aging property and good stability, can reduce the energy consumption and carbon emission, and has a wide market prospect.

Owner:青岛至慧新材料科技有限公司

Color changeable artificial leather, and preparation method and color changing method thereof

InactiveCN104975515AWith color changeThe discoloration effect remains the sameTextile shapingPolymer scienceOrganic solvent

The invention relates to a color changeable artificial leather, including a surface layer. The surface layer is prepared from the following raw materials by weight: 40-50 parts of polyurethane resin, 30-35 parts of an organic solvent, 10-15 parts of a silica powder discoloration powder, 5-10 parts of a matting powder, 0.5-1 part of a leveling agent and 3-5 parts of a PU toner. The invention also relates to a preparation method of the color changeable artificial leather and the color changing method of the color changeable artificial leather. The color changeable artificial leather of the invention under pressure or high temperature can change color and has the advantage of enduring color changing effect.

Owner:FUJIAN POLYTECH TECH CO LTD

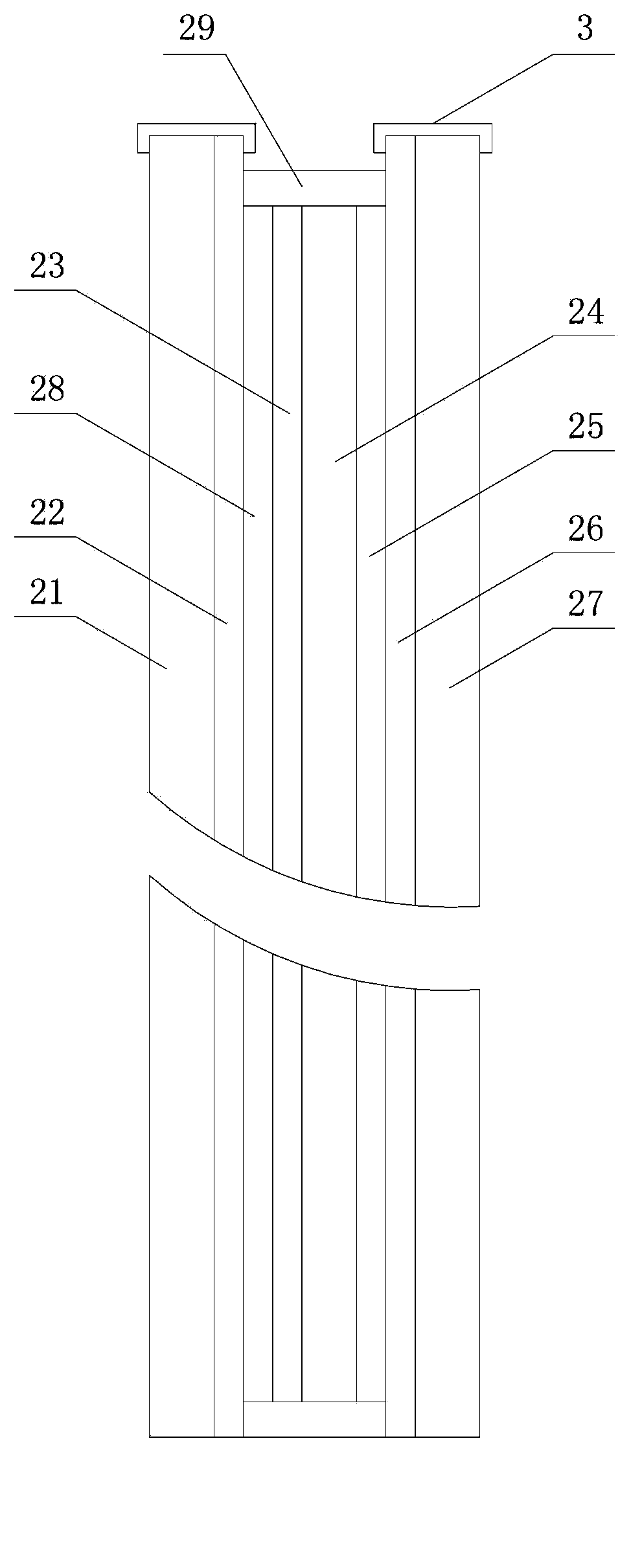

Photochromic viscose fiber and preparation method thereof

ActiveCN104357936AProtect strong baseProtect from strong acidsArtificial filaments from viscoseEmulsionColor changes

The invention relates to a photochromic viscose fiber and a preparation method thereof, belonging to the technical field of textile. The photochromic viscose fiber is prepared from an adhesive, photochromic microcapsules and a fiber reinforced agent, wherein the content of the photochromic microcapsules is 1-20wt%, and the content of the fiber reinforced agent is 0.1-10wt%. The preparation method of the photochromic viscose fiber comprises the following steps: (1) dissolving the photochromic microcapsules and the fiber reinforced agent into water to form dispersed viscose emulsion; (2) feeding the dispersed viscose emulsion into viscose to be spun, and mixing; (3) molding by spinning in an acid bath to obtain a photochromic viscose fiber product. The photochromic viscose fiber is simple and reasonable in components and simple in preparation method; the obtained fiber is uniform in whole color change; the strength of the photochromic viscose fiber reaches or exceeds that of the conventional viscose fiber, so that the demand of fabric manufacture can be met.

Owner:XINXIANG CHEM FIBER

Front-view intelligent anti-glare device of vehicle and manufacturing method of anti-glare mirror thereof

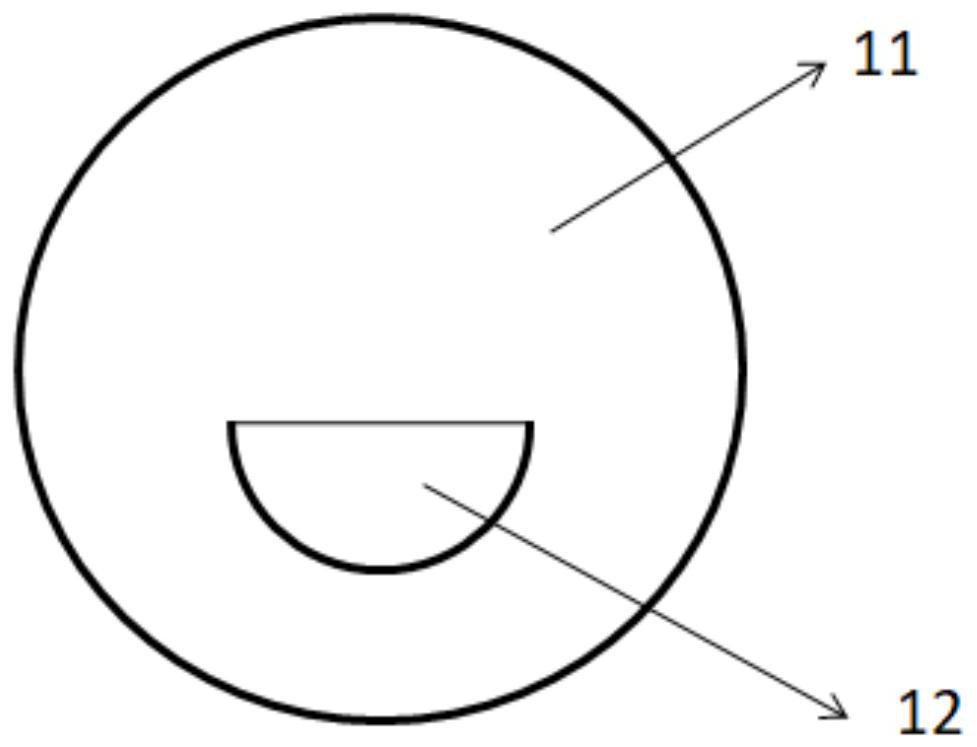

ActiveCN103909868AControl detectionControl Auto SwitchNon-linear opticsOptical viewingEngineeringLight sensing

The invention relates to a front-view intelligent anti-glare device of a vehicle and a manufacturing method of an anti-glare mirror thereof. The front-view intelligent anti-glare device of the vehicle is provided with a control device installed in the support and the anti-glare mirror. The output end of the control device is connected with the input end of the anti-glare device. The control device is provided with an MCU microprocessor, a light sensor, a power supply module and a power supply output control module. The light sensor is provided with a casing and a light sensing mechanism arranged in the casing. The light sensing mechanism is provided with a glare sensor and an environment light sensor. The input end of the MCU microprocessor is respectively connected with the output end of the environment light sensor, the output end of the glare sensor and the output end of the power supply module, and the output end of the MCU microprocessor is connected with the input end of a power supply control module. The output end of the power supply control module is used for being connected with the input end of the anti-glare mirror through an electrode. A monomer molecular coating is added for the anti-glare mirror. The front-view intelligent anti-glare device senses the intensity through the light sensor, the MCU microprocessor receives, processes and sends signals to eliminate glare influence, and the running safety is ensured.

Owner:CHANGZHOU YAPU NEW MATERIALS CO LTD

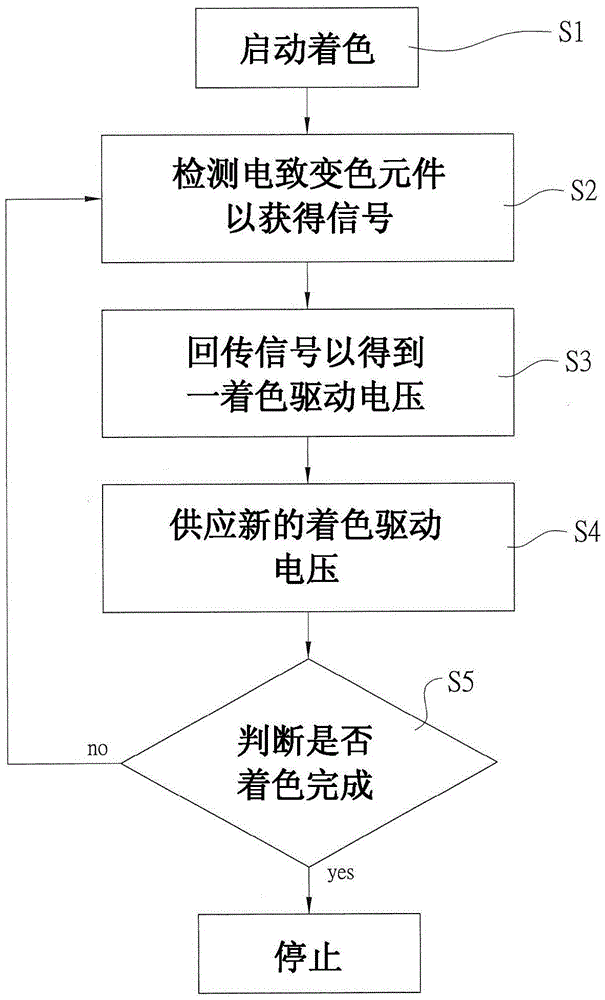

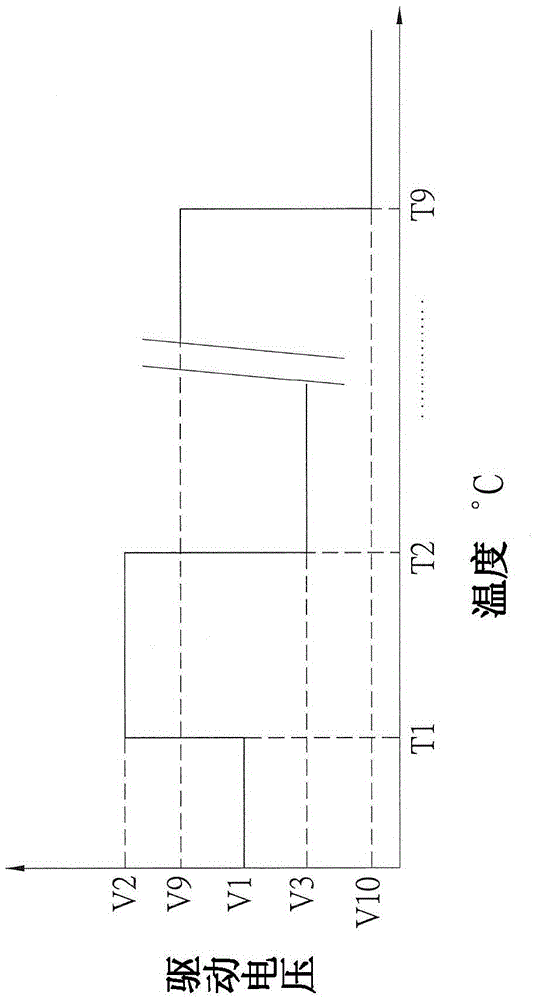

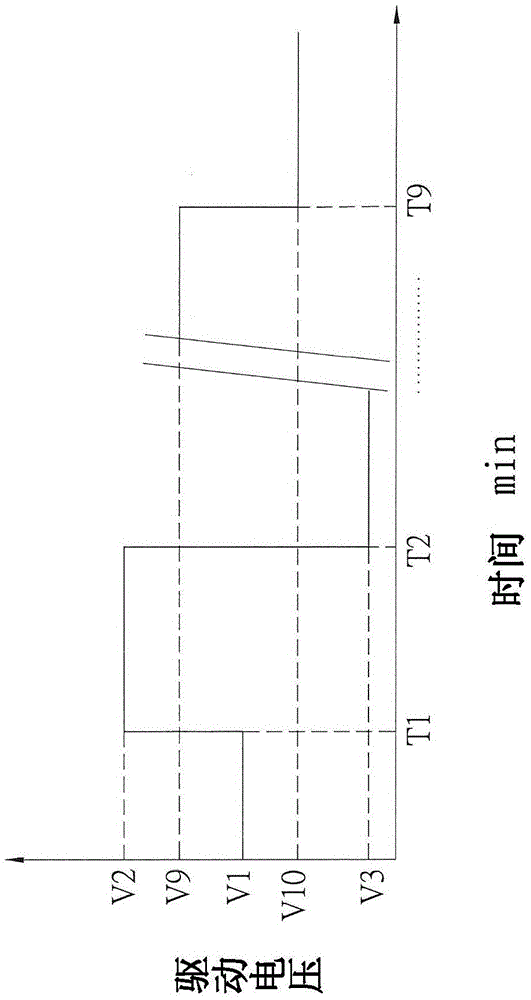

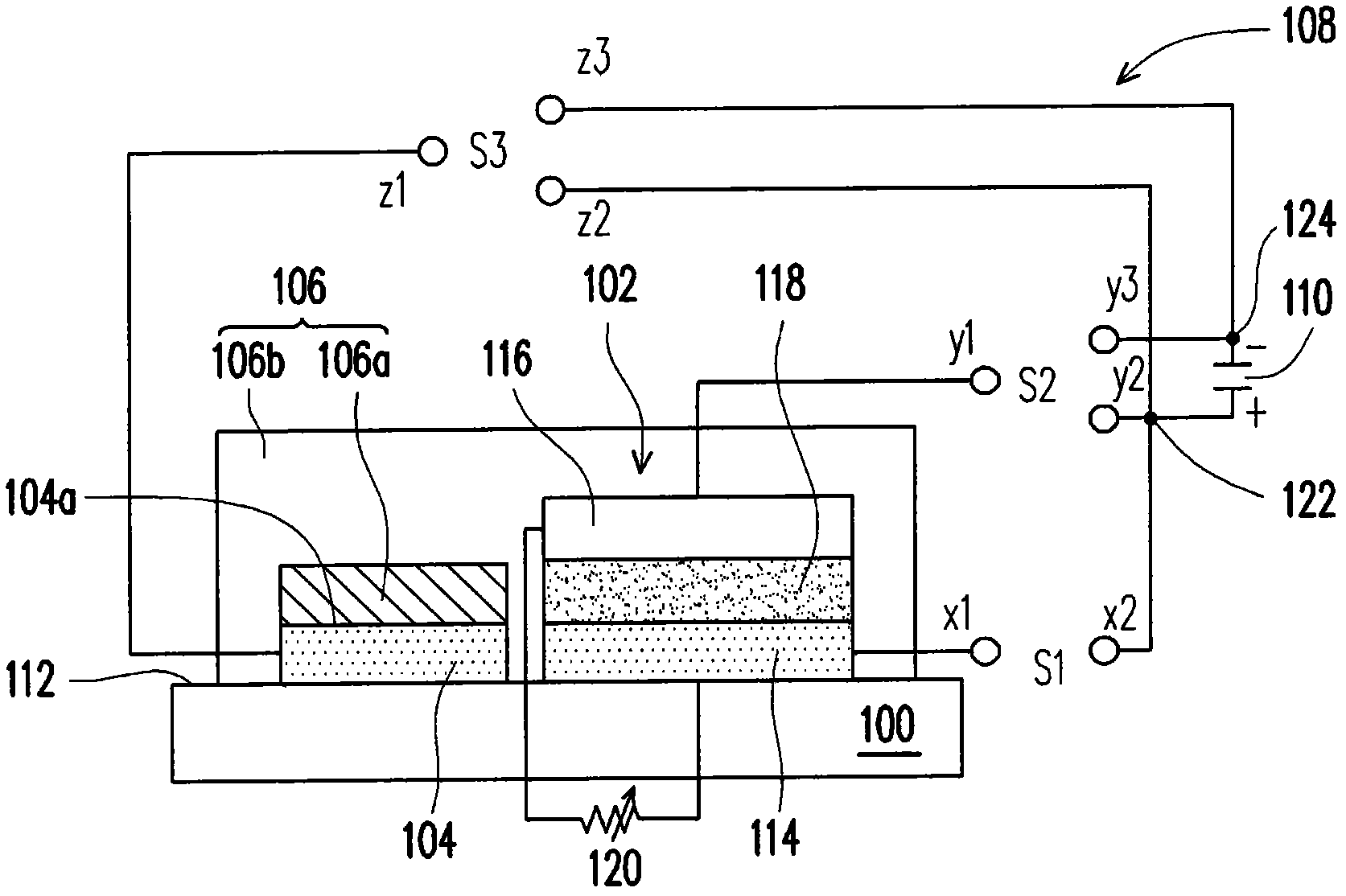

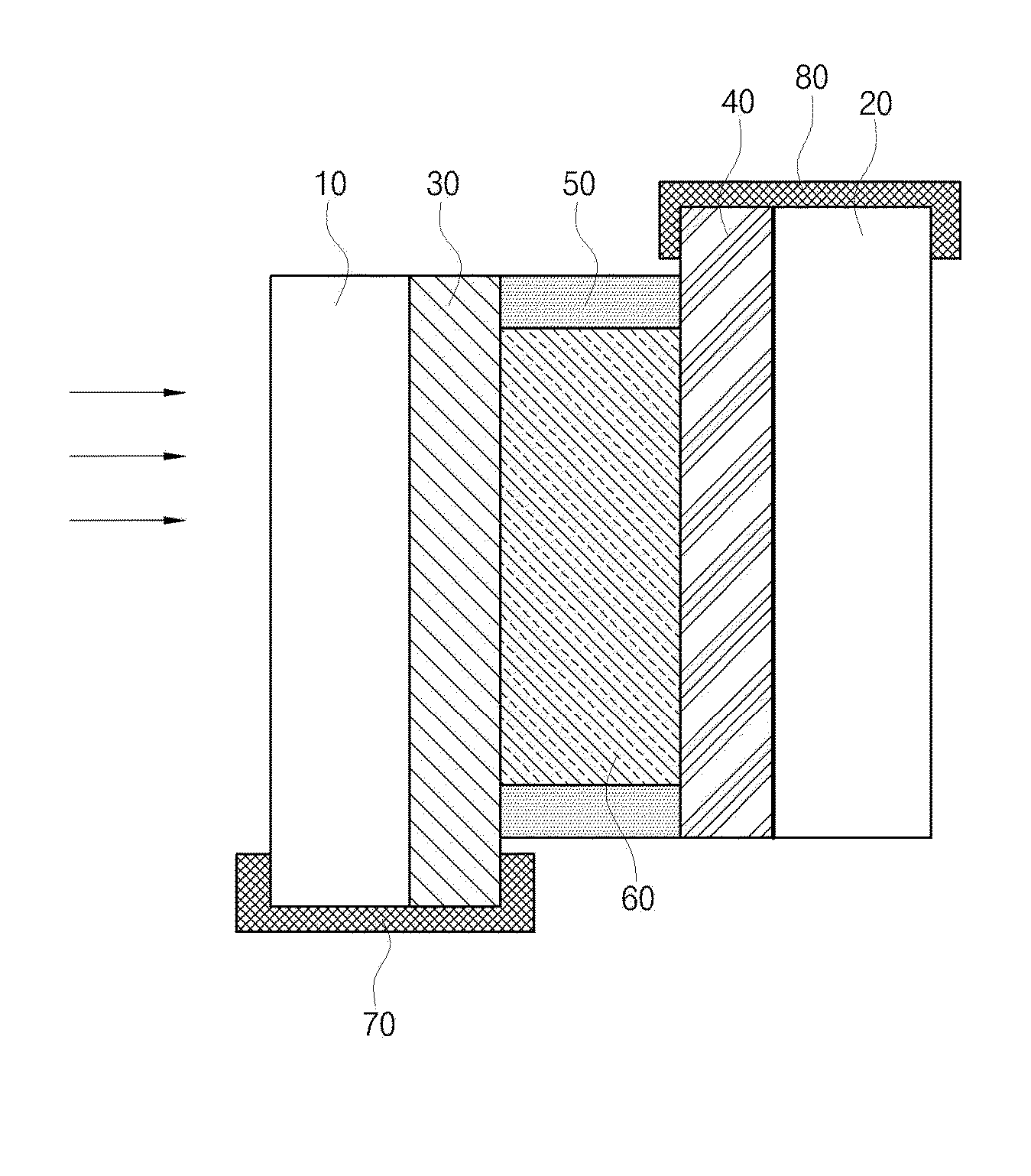

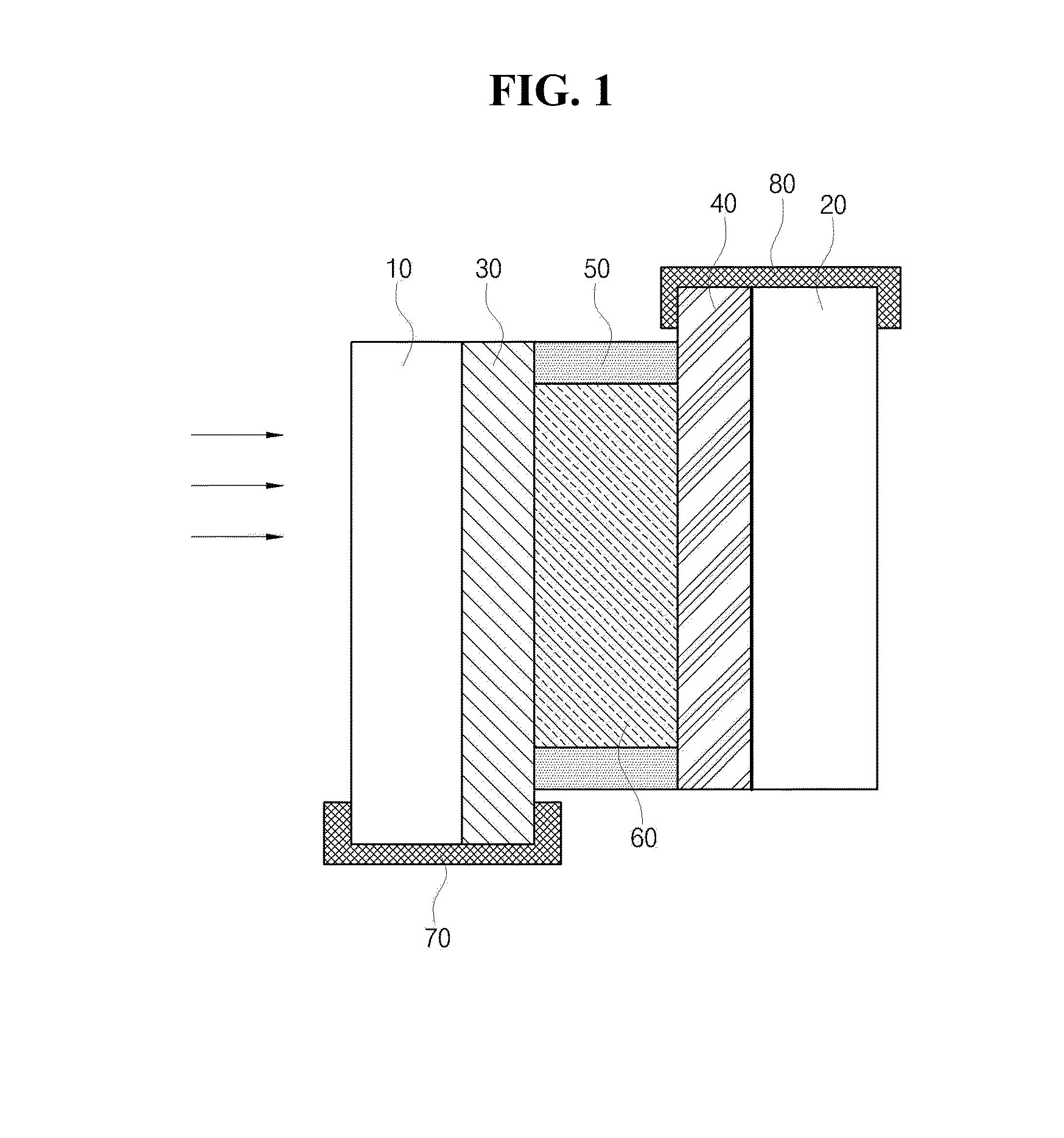

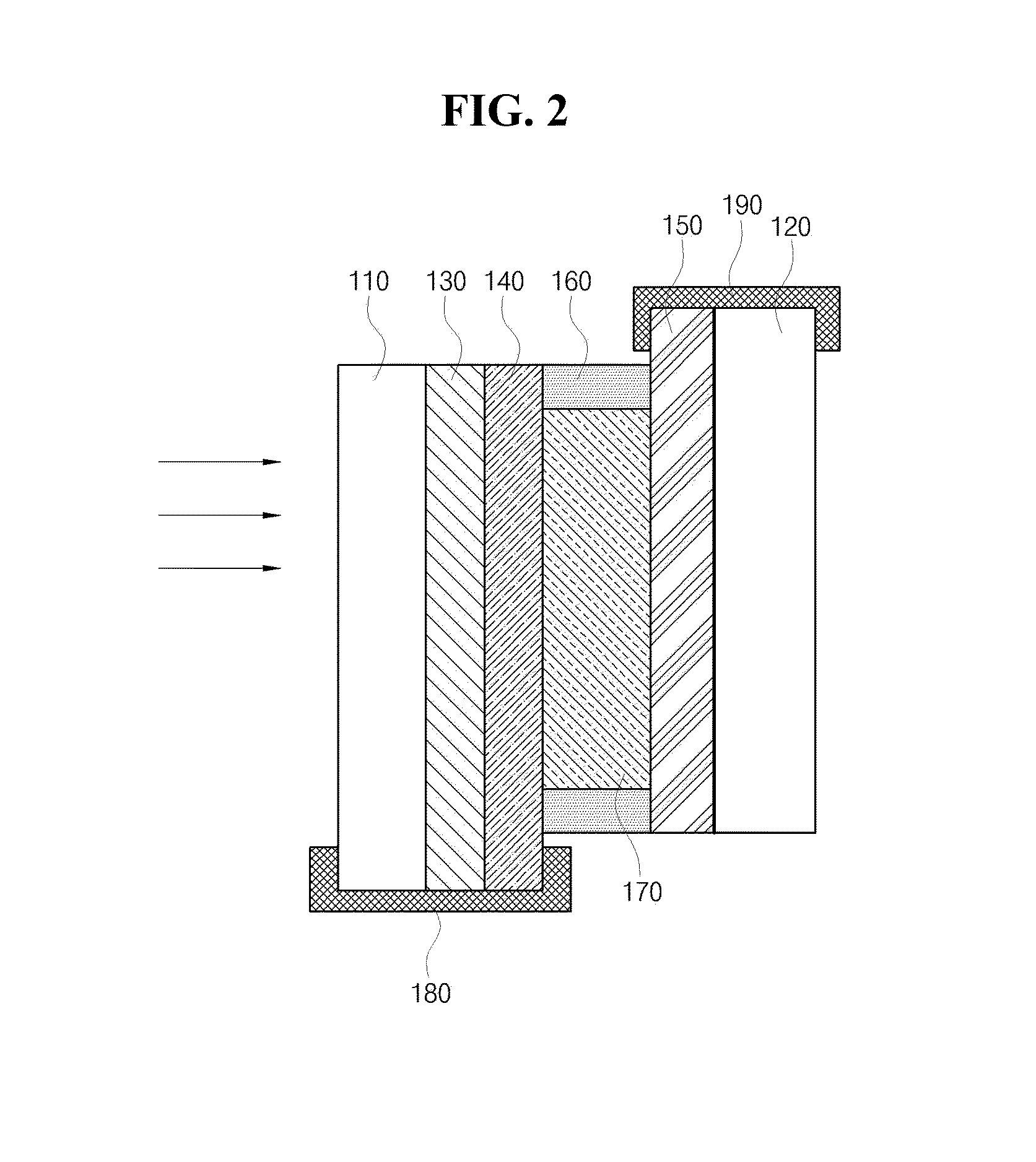

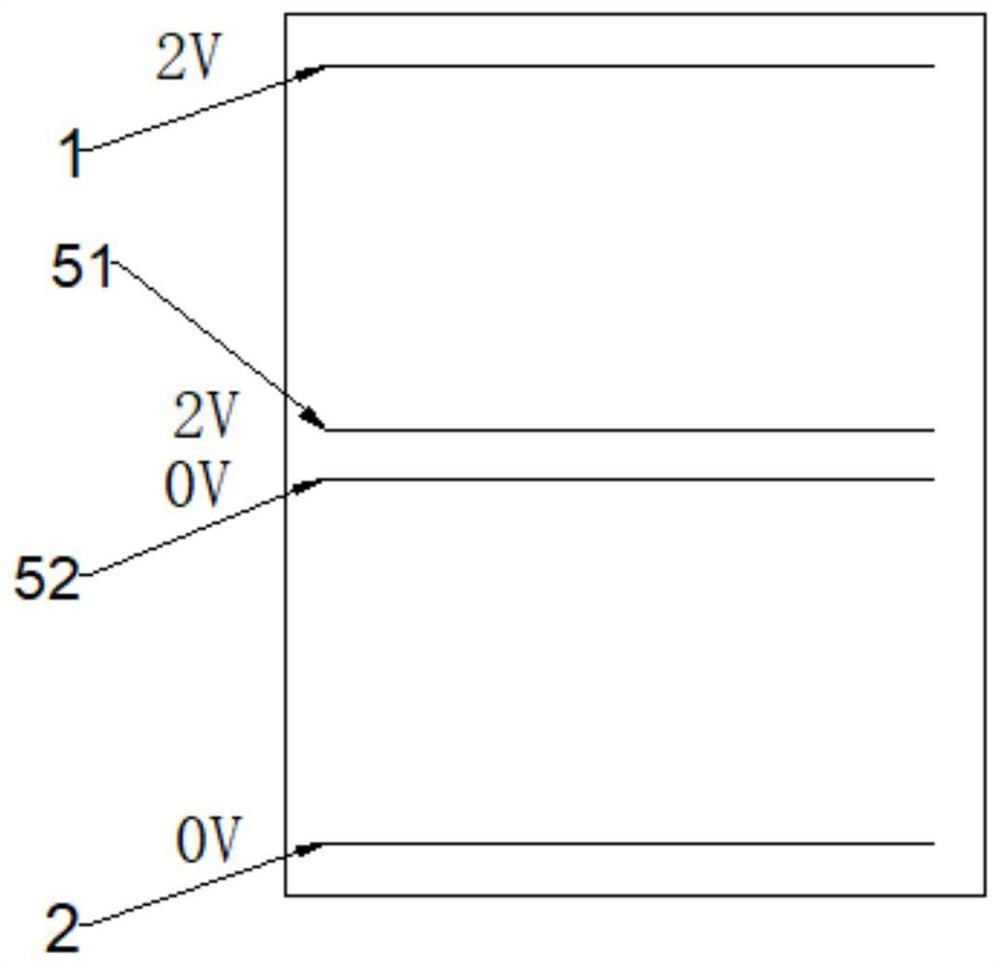

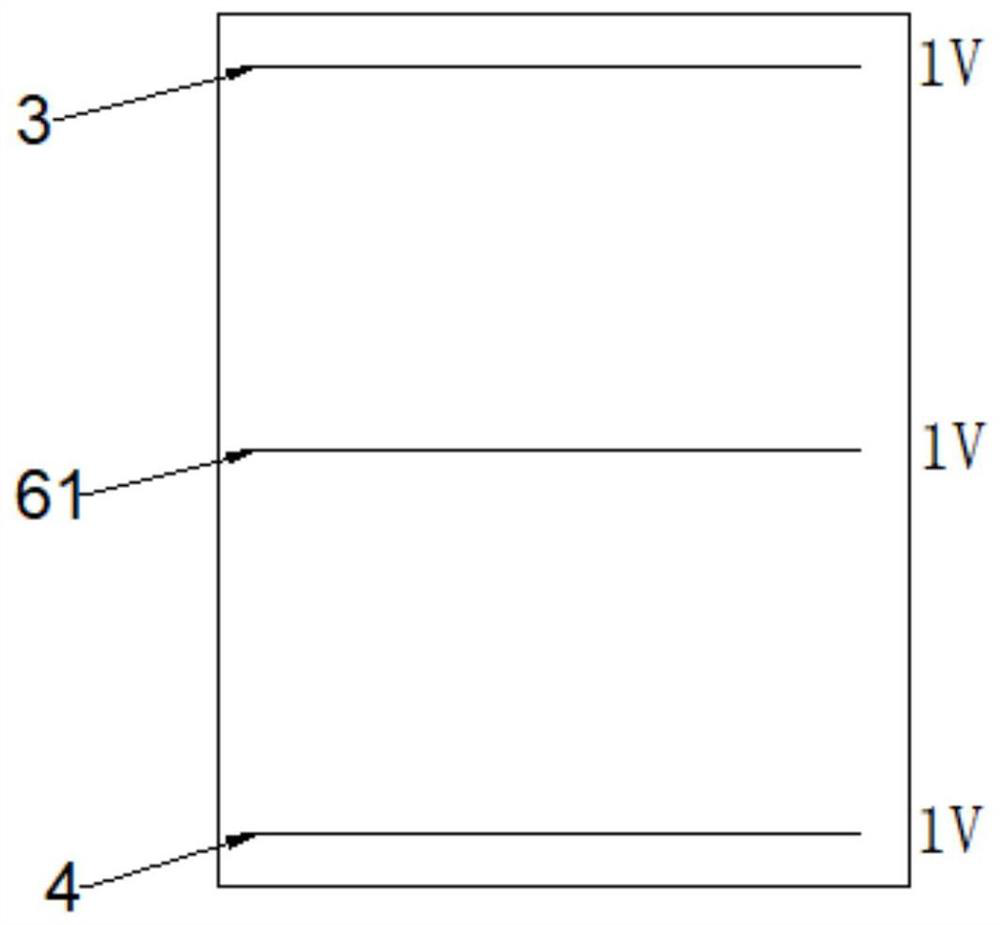

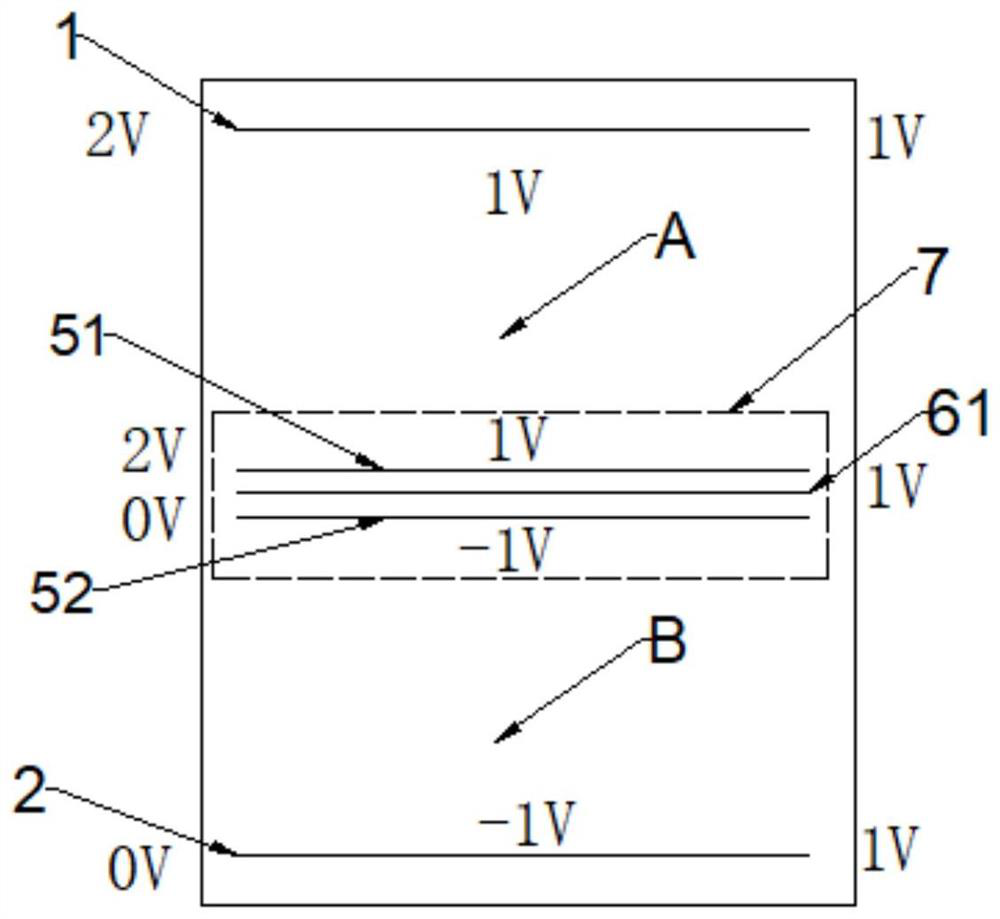

Method of driving electrochromic device

InactiveCN106558294AUniform discolorationExtended service lifeStatic indicating devicesElectricityEngineering

The invention relates to a method of driving an electrochromic device. Through detecting signals (such as temperature, time, power and current values) generated during the electrochromic process of an electrochromic element and driving the voltage value of the electrochromic element according to signal changes, the control mechanism can enable multi-stage voltage driving, and thus, when the electrochromic process of the electrochromic element is controlled repeatedly, the color of the electrochromic element is more uniform, the electrochromic time can be shortened, and the service life of the electrochromic element can be prolonged.

Owner:TINTABLE SMART MATERIAL CO LTD

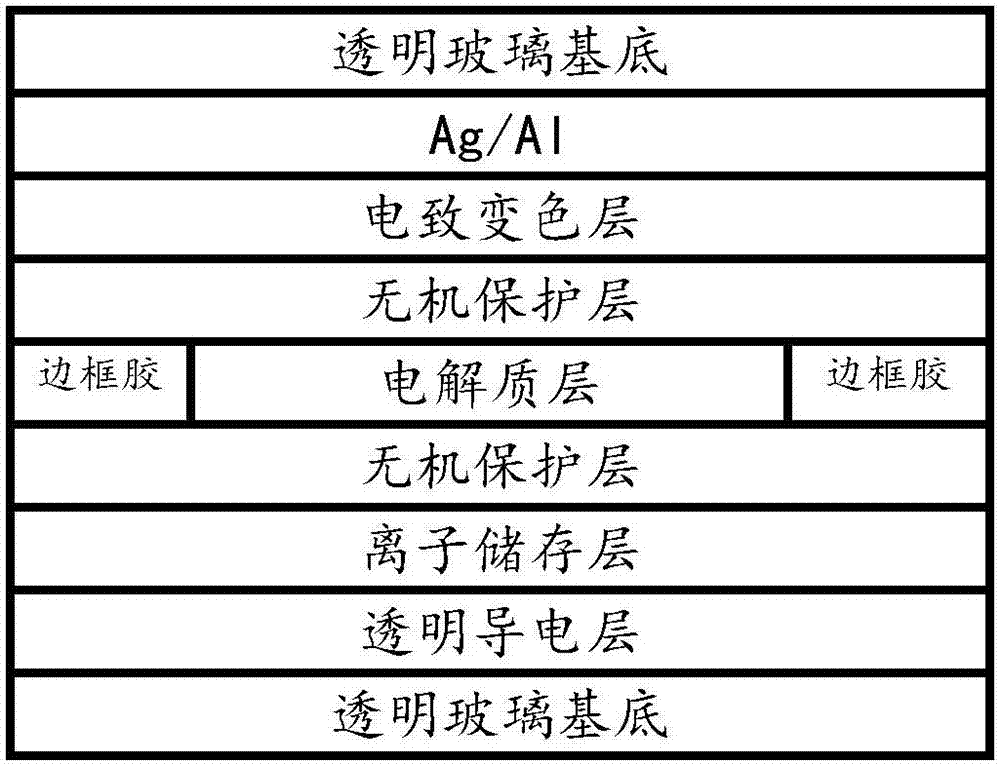

Electrochromic device and application thereof in field of rearview mirror preparation

InactiveCN106896612AResistant to UV radiationUniform discolorationNon-linear opticsOptical viewingChemistryRear-view mirror

The invention relates to the field of electrochromism and particularly relates to an organic silicon modified acrylate based electrochromic device and application thereof in the field of rearview mirror preparation. The electrochromic device comprises an electrolyte layer, and the electrolyte layer is formed by organic silicon modified gel electrolyte available for ultraviolet curing and border adhesives used for packaging devices surrounding the gel electrolyte. The electrochromic device has advantages of cheapness, high conductivity, high response speed, solar radiation resistance, high permeability and the like, and a preparation process is simple. Electrochromic rearview mirrors manufactured by adoption of the electrochromic device are high in electrochromic speed, uniform in electrochromism and high in cycling stability and have a promising application prospect in the field of automobile rearview mirrors.

Owner:JISHENG PHOTOELECTRIC SHENZHEN CO LTD

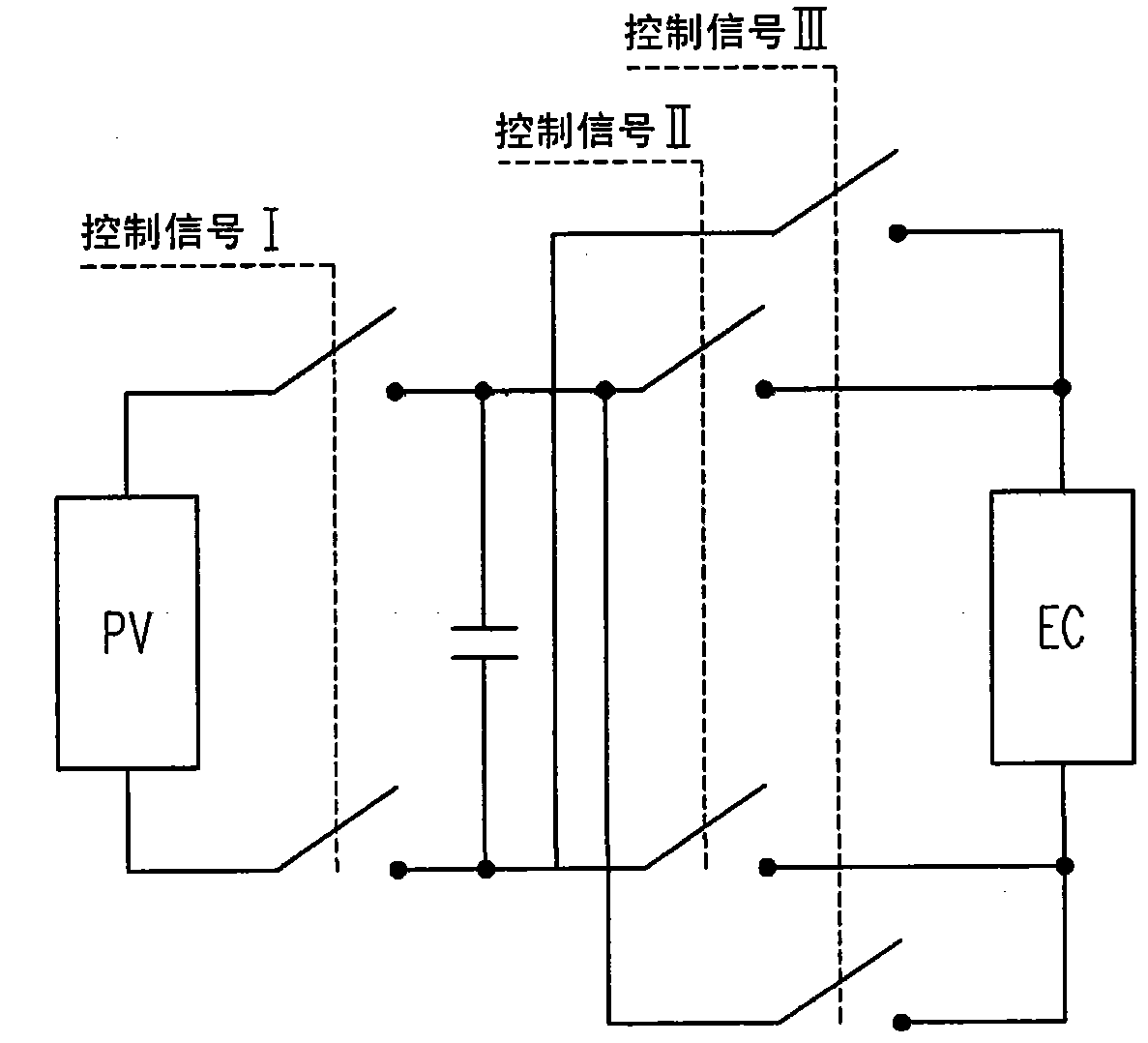

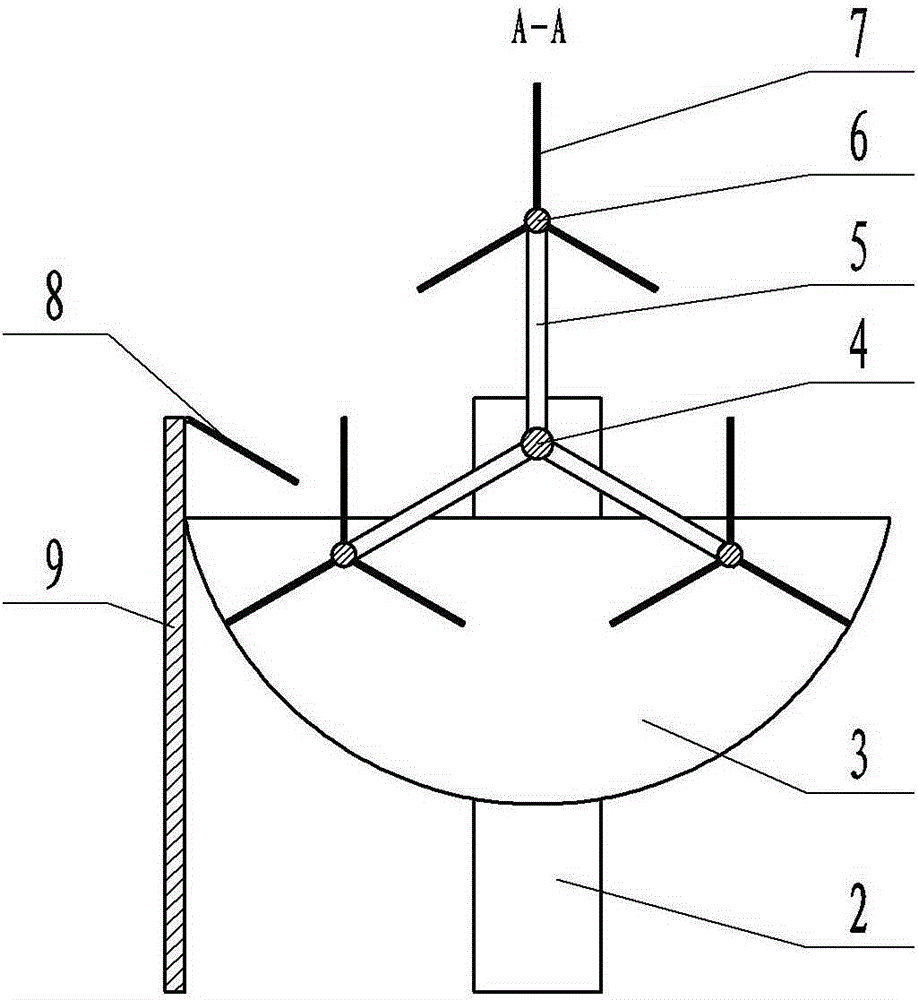

Adjustable Solar Photoelectric Electrochromic Components and Modules

The invention provides a tunable solar photovoltaic electrochromic assembly and module. The assembly comprises a transparent substrate, a thin-film solar cell positioned on the transparent substrate, transparent conductive layers positioned on the transparent substrate beside the thin-film solar cell, an electrochromic material covering exposed surfaces of the transparent conductive layers and the thin-film solar cell, a switching device, and a charge-discharge device coupled to the switching device. The first transparent conductive layer and a cathode layer of the thin-film solar cell respectively serve as an anode and a cathode of the electrochromic material simultaneously. The switching device is electrically connected to a first transparent conductive layer and electrically connected to an anode layer and a cathode layer of the thin-film solar cell, and enters a control mode through a switch control signal.

Owner:IND TECH RES INST

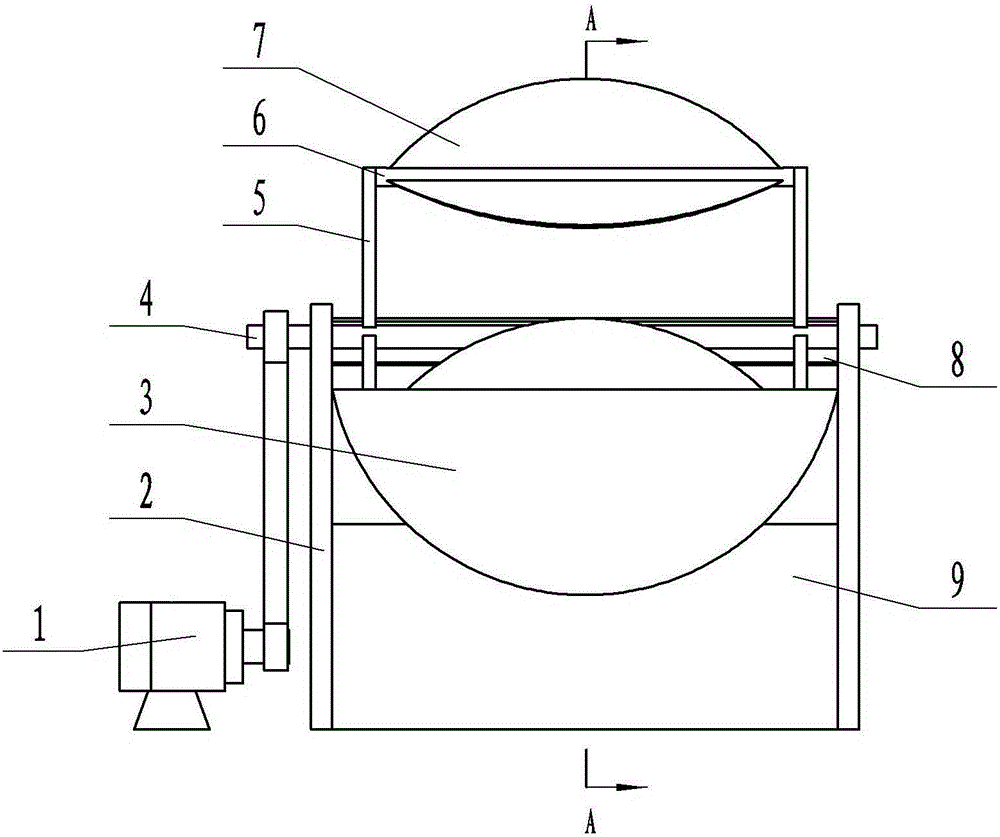

Tea frying device

ActiveCN104171077BContinuous and uniform color changeUniform discolorationPre-extraction tea treatmentRange of motionChange color

The invention discloses a tea frying device, and relates to the technical field of tea processing equipment. The tea frying device comprises a frying pan, and a rotating shaft which is arranged above the frying pan and is driven by a motor, wherein two sides of the frying pan are provided with brackets for supporting the rotating shaft; the brackets at two sides of the frying pan are coaxially provided with two opposite rotating shafts; each rotating shaft is fixedly provided with three support rods evenly; a fixed shaft is connected between every two corresponding support rods on the two rotating shafts, and is connected to the outer end of each support rod; each fixed shaft is evenly provided with three stir-frying brushes; a vertical plate parallel to the rotating shaft is arranged on the side of the frying pan, and is higher than the upper edge of the frying pan; and a cleaning brush which inclines towards the frying pan is fixedly arranged on the upper edge of the vertical plate, and is within the movement ranges of the stir-frying brushes. Compared with the prior art, the tea frying device is high in stir-frying efficiency, and tea is even to change color and not easy to deform.

Owner:WUZHOU ZHONGMING TEA IND CO LTD

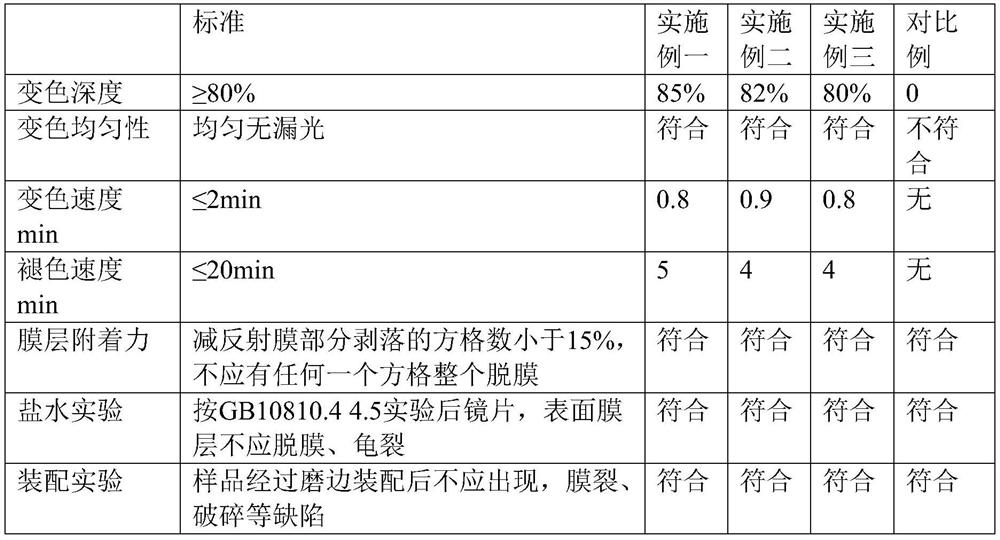

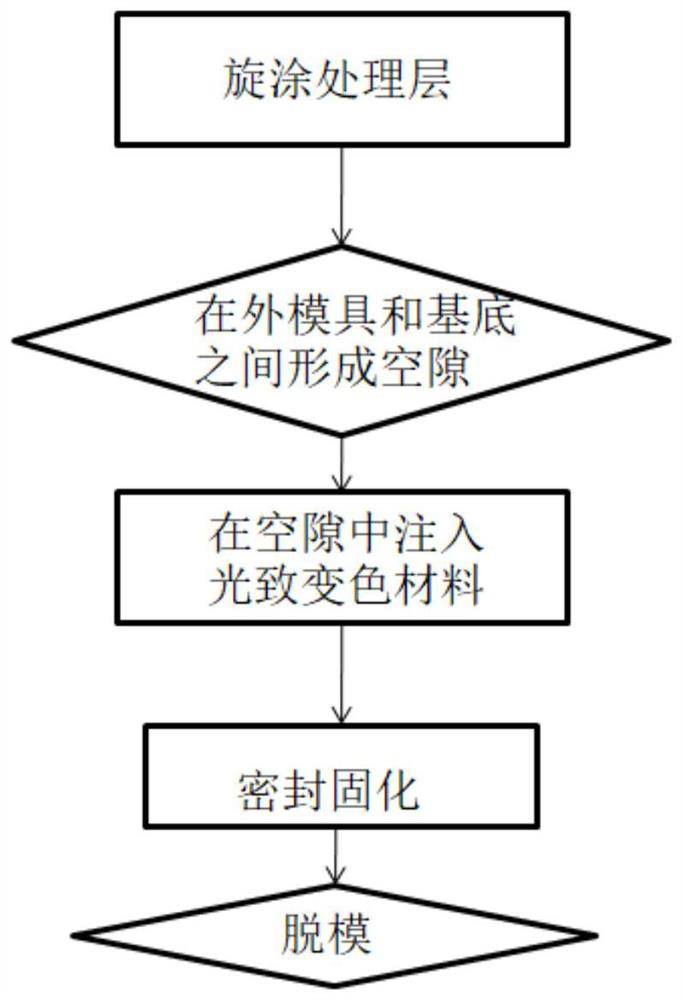

Color changing process for resin lens

InactiveCN105892093AUniform discolorationExtended service lifeOptical partsOptical elementsSpinsColor changes

The invention discloses a color changing process for a resin lens. The color changing process is different from the traditional processes of polymerization and top coating and the like and has obvious advantages. The color changing process comprises the main steps of: (1) pretreating the lens; (2) preparing color-changing hardening liquid and adding a plasticizing agent; (3) spin coating the color changing liquid on the surface of the lens; (4) plating films; (5) checking. The color changing process disclosed by the invention has the advantages that the lens hardening and the color changing are completed in one step; the lens prepared by the process has the advantages that the color change is uniform, the service life is long and the cost is effectively reduced; simultaneously, color changing powder and the plasticizing agent are dispersed in the hardening layer in the form of particles, so that the impact resistance of the lens can be effectively improved.

Owner:ZENNI OPTICAL

Intelligent energy saving composite film

InactiveCN108454200AImprove intelligenceEnsure stabilitySynthetic resin layered productsCoatingsComposite filmNear infrared absorption

The invention discloses an intelligent energy saving composite film. The intelligent energy saving composite film comprises a PET thermal-reflective film layer, at least one near infrared absorption film layer, and at least one optothermal responsive film layer; and coating, spraying, bonding, or extruding combination means are adopted for multi-layer alternative combination of the above layers. The intelligent energy saving composite film is high in intelligent performance, is capable of adjusting shielding coefficient and light transmittance through automatic generated stress-coping behaviors based on external environment change, realizing composite film color change in a set temperature or light intensity range, realizing intelligent adjusting on environment temperature and light, realizing preferable utilization and shielding of solar energy, maintaining environment stability, improving environment comfortableness, reducing energy consumption, and saving energy.

Owner:常州市交通设施有限公司

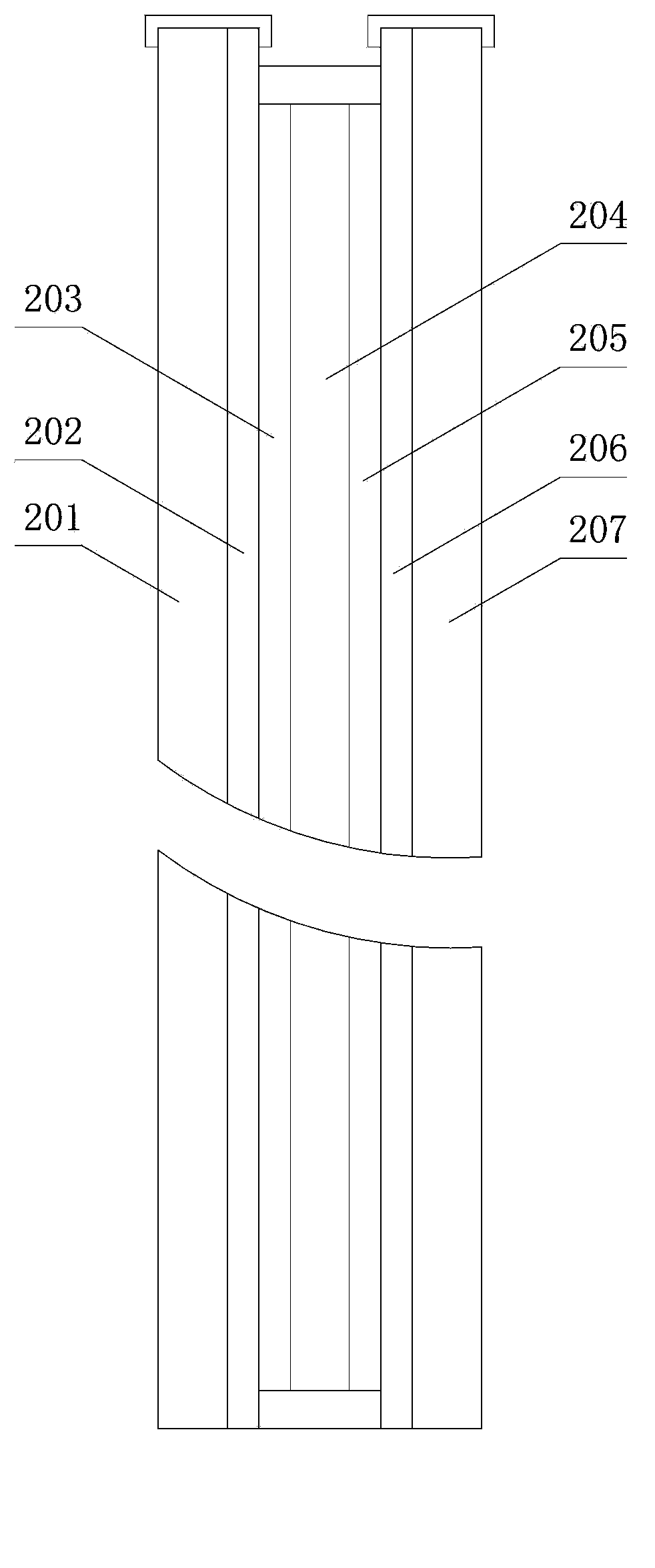

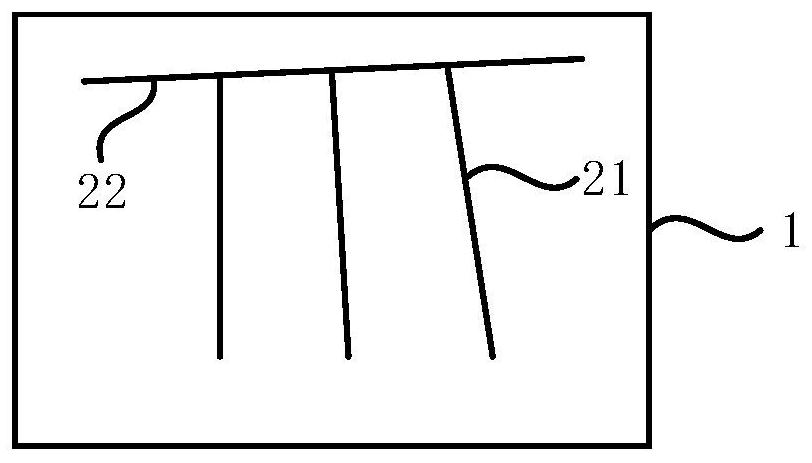

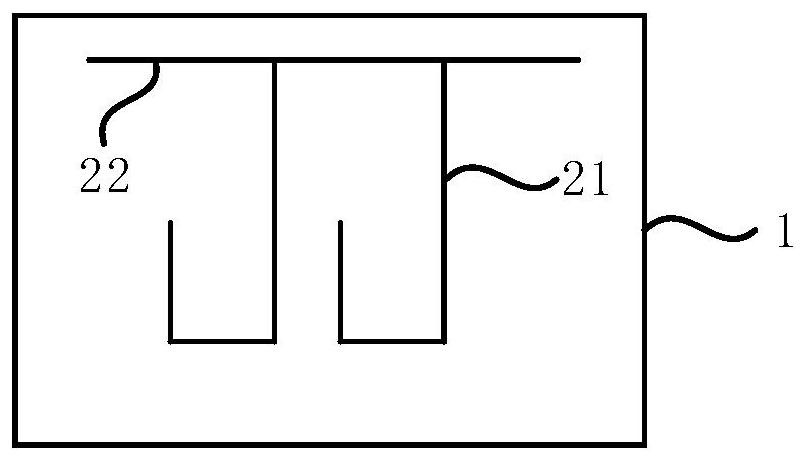

Drive mode of electrochromic glass

ActiveCN104880885AImprove distributionUniform discolorationStatic indicating devicesNon-linear opticsEngineeringElectrochromism

The invention relates to a drive mode of electrochromic glass, solves the technical defects that effective driving voltage of both sides of large-area electrochromic glass is too high and effective driving voltage of the middle of the large-area electrochromic glass is low, thus uneven color of the electrochromic glass occurs in the prior art. The drive mode can be divided into a one-group electrode drive mode and a two-group electrode drive mode according to the number of conductive strips. In the one-group electrode drive mode, direct current is applied to a top electrode conductive strip and a bottom electrode conductive strip to perform driving, at least one end of at least one conductive strip of the two conductive strips is provided with a bent portion. In the two-group electrode drive mode, the direct current is applied to two pairs of conductive strips. By changing the number and shape of the conductive strips, an electric effect distance between the top electrode conductive strip and the bottom electrode conductive strip is shortened during driving, thereby effective driving voltage distribution on the electrochromic glass is improved, color uniformity of the large-are electrochromic glass is achieved, and the color-changing speed is increased.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

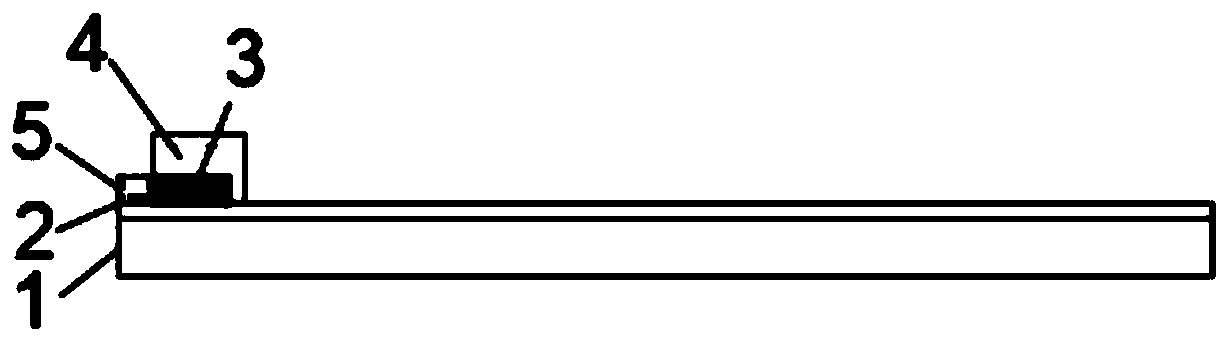

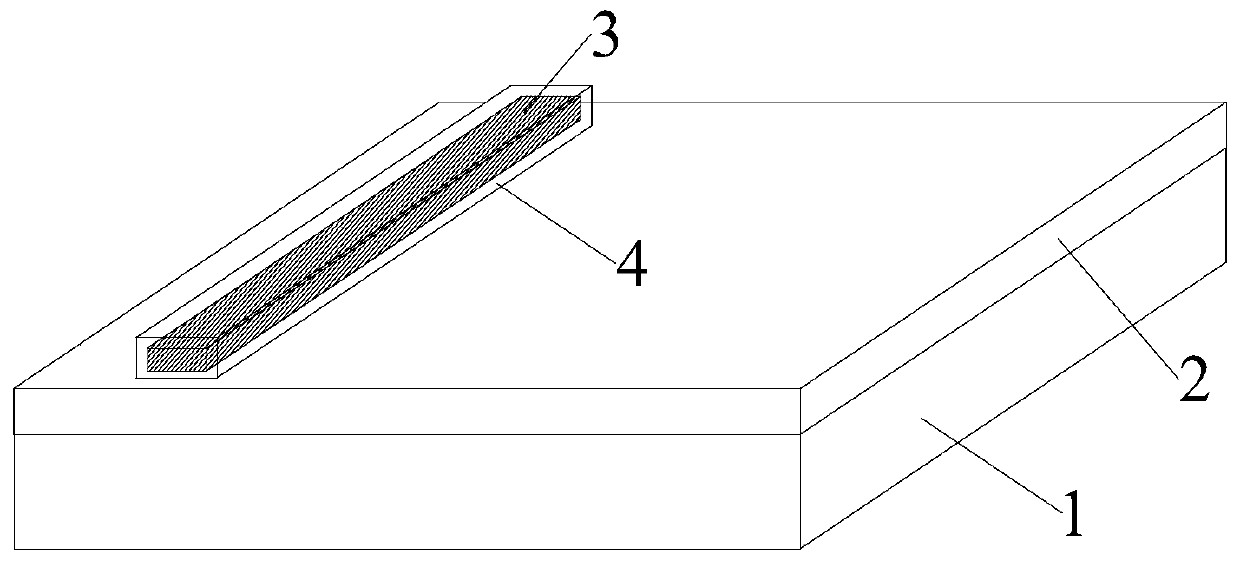

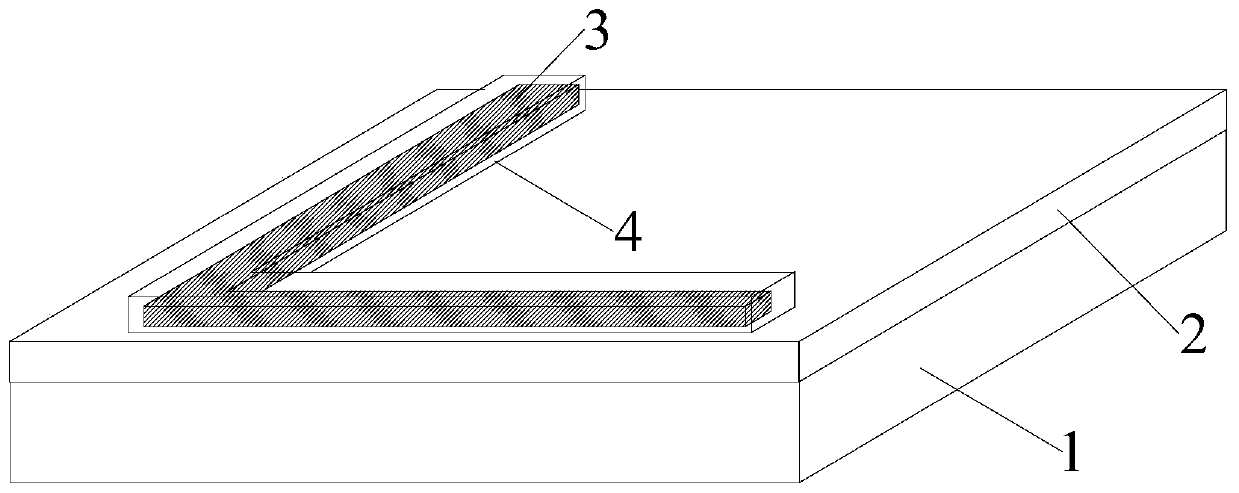

Edge sealing conductive substrate and electrochromic device

The invention relates to an edge sealing conductive substrate and an electrochromic device. The edge sealing conductive substrate comprises a substrate layer, a transparent conductive layer, at leastone conductive part, at least one sealing part and at least one side extraction electrode connected to the conductive part; the transparent conductive layer is laminated on the top surface of the substrate layer; the conductive part is connected to the transparent conductive layer; and the sealing part is connected to the top surface of the transparent conductive layer. The electrochromic device comprises a first conductive layer, a color-changing material layer and a second conductive layer which are sequentially arranged in a stacked mode; and the color-changing material layer is separatelyconnected to the transparent conductive layers of the first conductive layer and the second conductive layer, and the sealing parts of the conductive layers are used for sealing the edge of the color-changing material layer. When the edge sealing conductive substrate provided by the invention is used for arranging the electrochromic device, additional electrode distribution operation is not needed, the influence of water and oxygen in air is avoided, and the obtained electrochromic device has relatively high structural strength.

Owner:SHENZHEN GUANGYI TECH CO LTD

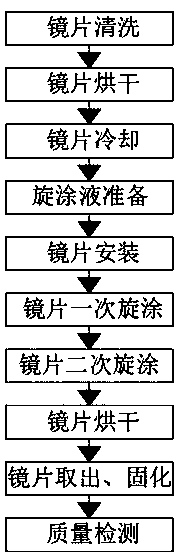

Spin coating production technology of photochromic lens

InactiveCN110314831AImprove wear resistanceGuaranteed hardening effectPretreated surfacesCoatingsAdhesion forcePhotochromic lens

The invention discloses a spin coating production technology of a photochromic lens, and belongs to the technical field of lens production. The spin coating production technology comprises the following steps of, S1, cleaning the lens; S2, drying the lens; S3, cooling the lens; S4, preparing the spin coating solution; S5, mounting the lens; S6, carrying out primary spin coating on the lens; S7, carrying out secondary spin coating on the lens; S8, drying the lens; S9, taking out and cured the lens; and S10, carrying out quality detection. The lens is cleaned through an ultrasonic cleaner, the surface of the photochromic lens is thoroughly cleaned, so that a good foundation is laid for the subsequent soaking technology; and the pre-coated layer infiltrating by the primary spin coating not only makes the surface layer of the lens have very good adhesion force, but also makes excellent adhesion force to be generated between the surface layer and the silicon hardening liquid of the secondary spin coating, so that the hardening effect of the surface of the lens can be ensured, the wear resistance of the lens is improved, the phenomenon that the lens generates stripes during spin coatingis effectively avoided, color change is uniform, the impact resistance of the lens is improved, the production efficiency is improved, and the production cost is reduced.

Owner:江苏新唯尊光学眼镜有限公司

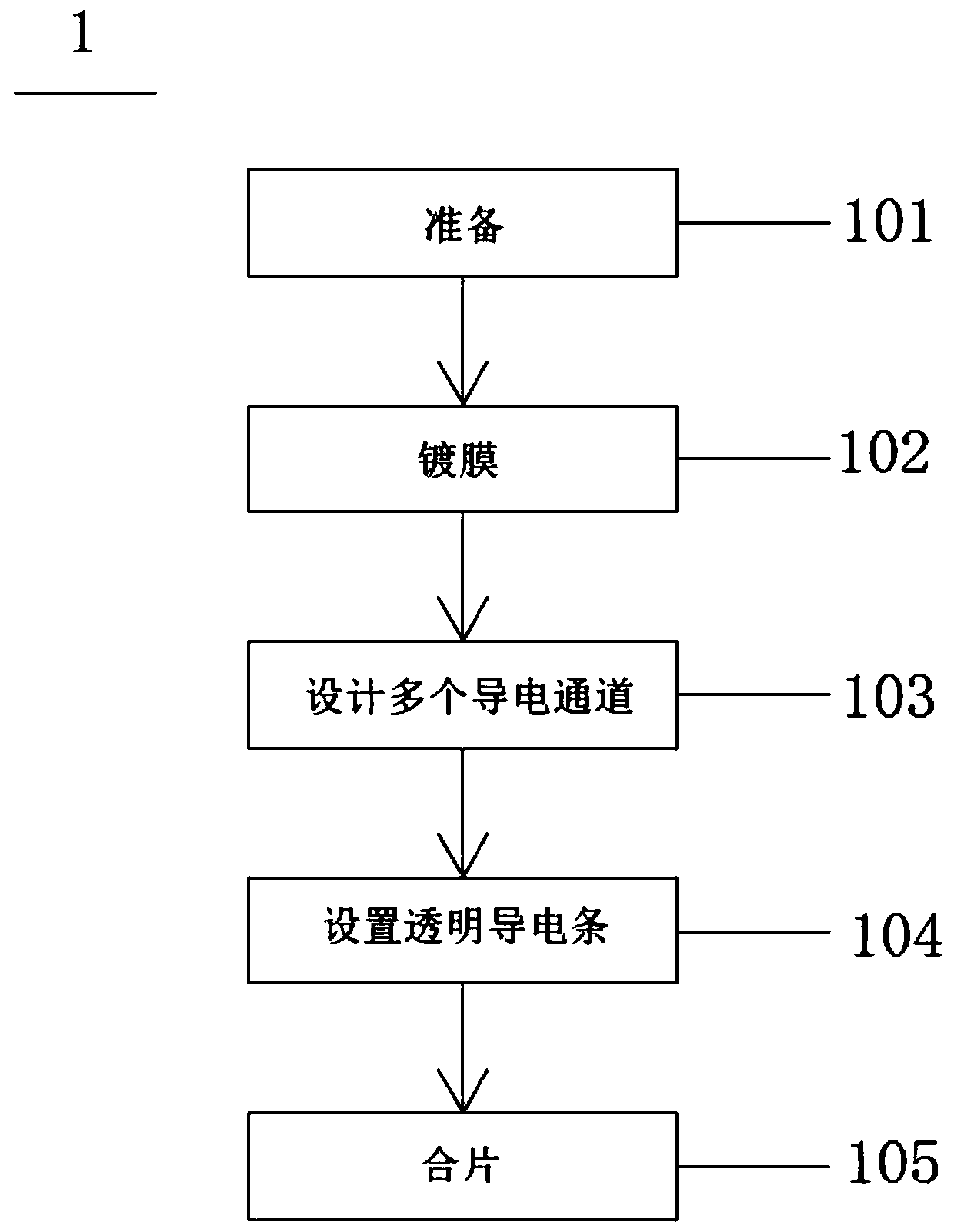

High-efficiency uniformly colored hook face electrochromic transparent element and preparation method thereof

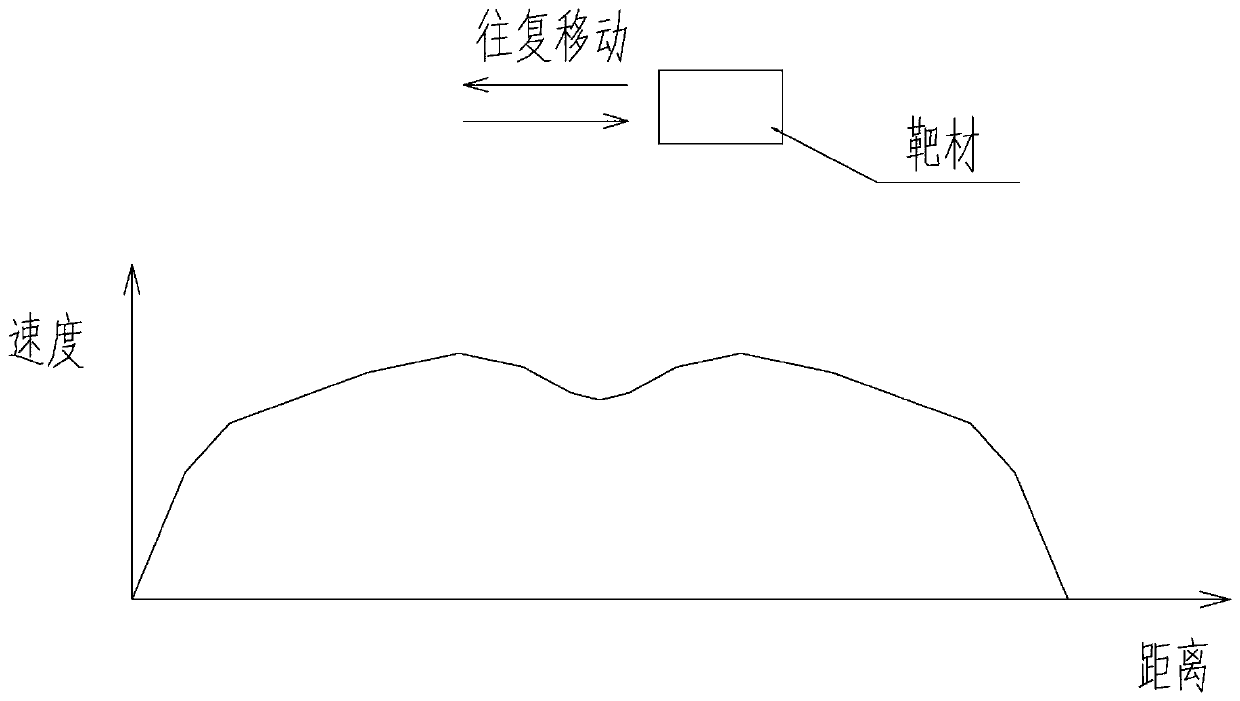

ActiveCN110007539AAchieve uniformity of thicknessAchieve uniformityVacuum evaporation coatingSputtering coatingSputteringChange color

The invention relates to a high-efficiency uniformly colored hook face electrochromic transparent element and a preparation method thereof. The preparation method includes the following steps: a firstsubstrate and a second substrate of the high-efficiency uniformly colored hook face electrochromic transparent element are pretreated and cleanedup through deionized water; surfaces of the first substrate and the second substrate are correspondingly plated with various transparent film layers under a vacuum state when the first substrate and the second substrate enter a vacuum chamber; under thecondition that a circuit works normally, a plurality of conductive channels are designed correspondinglyin the various transparent film layers within the range of a visible area of the high-efficiencyuniformly colored hook face electrochromic transparent element; and transparent conductive strips are correspondingly extended inside the conductive channels. According to the high-efficiency uniformly colored hook face electrochromic transparent element and the preparation method thereof, uniformity of the thickness of the film layers is achieved by setting sputtering process parameters reasonably and controlling the gradient change of the running speed from one side edge to the other side edge when target materials sputter the first substrate and the second substrate, so that the formed high-efficiency uniformly colored hook face electrochromic transparent element changes color evenly.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

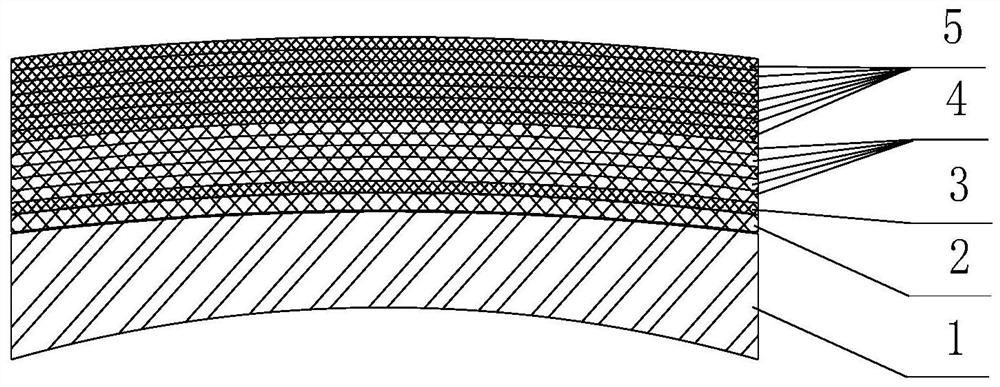

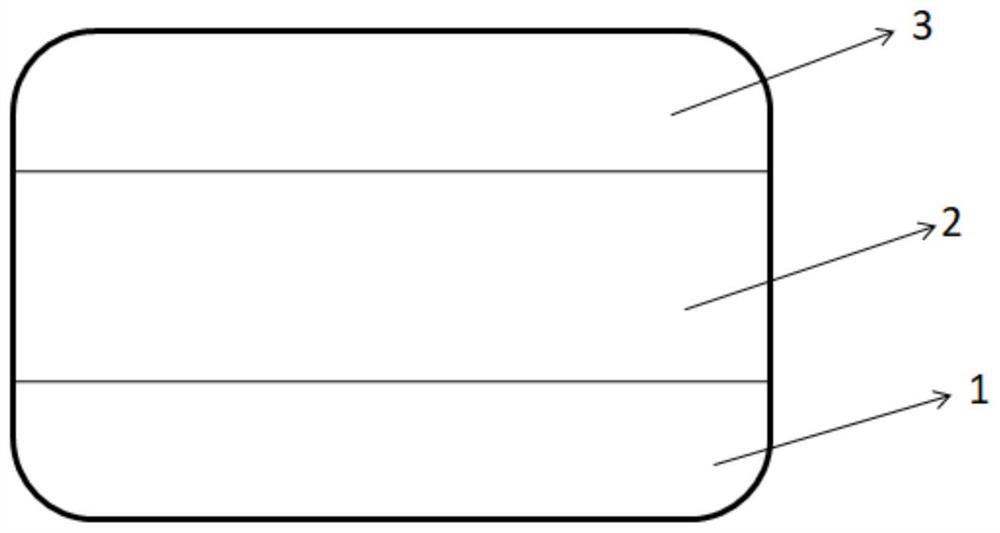

Color-changing resin spectacle lens and preparation method thereof

ActiveCN112649973AUniform discolorationGood depth of discolorationVacuum evaporation coatingSputtering coatingBenzopyranIsolation layer

The invention discloses a color-changing resin spectacle lens and a preparation method thereof. A hardening layer and a vacuum coating color-changing layer are sequentially arranged on the front surface of a resin lens substrate. The vacuum coating color-changing layer sequentially comprises a first isolation layer, second to sixth organic color-changing layers and seventh to thirteenth anti-reflection coating layers from inside to outside. The second to sixth organic color-changing layers are sequentially composed of a benzopyran color-changing layer with the thickness of 130-150 nm, a fulgide color-changing layer with the thickness of 65-80 nm, a benzopyran color-changing layer with the thickness of 100-120 nm, a fulgide color-changing layer with the thickness of 80-95 nm and a benzopyran color-changing layer with the thickness of 180-200 nm from inside to outside. The method is completed by flash evaporation and vacuum spraying.

Owner:ZENNI OPTICAL

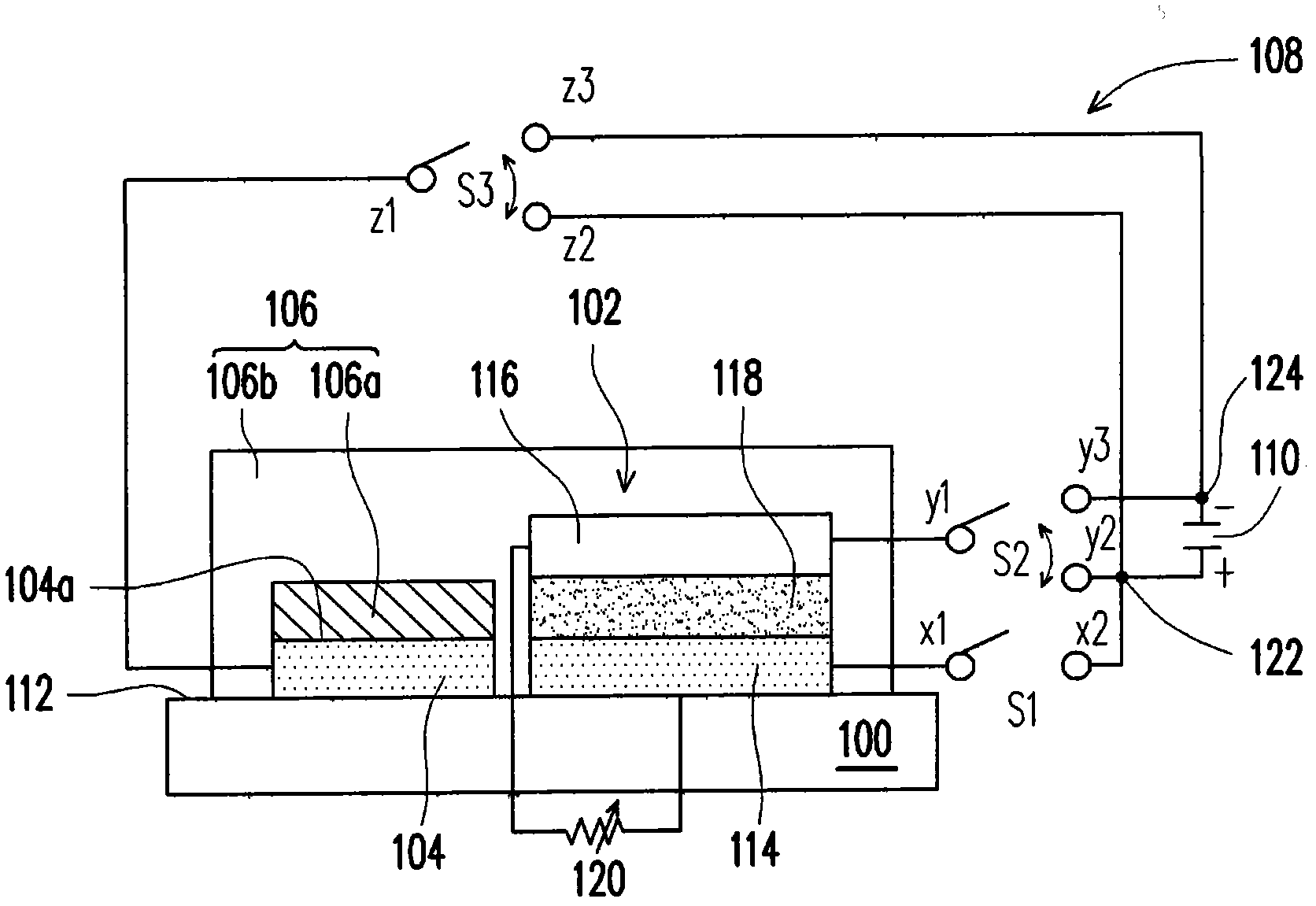

Solar photovoltaic electrochromic device

ActiveCN101673018BReduced demand for electricity generationReduce thicknessPhotovoltaic energy generationNon-linear opticsElectricityElectrical battery

Owner:IND TECH RES INST

Teak discoloration treatment method

InactiveCN107471358ADilute the colorFast discolorationElectric wood treatmentWood treatment detailsLight treatmentLow temperature plasma

The invention discloses a teak discoloration treatment method, and relates to the technical field of wood treatment. The treatment method comprises the steps: (1) surface modification; (2) low-temperature plasma treatment; and (3) light treatment; according to the treatment method disclosed by the invention, teak is soaked in an isocyanato modified solution for treatment, so that auxochromes, such as carbon base, vinyl, methoxyl and carboxyl, in chromophoric groups of the teak surface are effectively reacted physically, and precipitation pigments of the wood surface can be dissolved to a certain extent; and at the same time, black streaks and spots can be removed effectively through active groups in the isocyanato modified solution, and the original color of the wood is diluted.

Owner:安徽三和工艺品有限公司

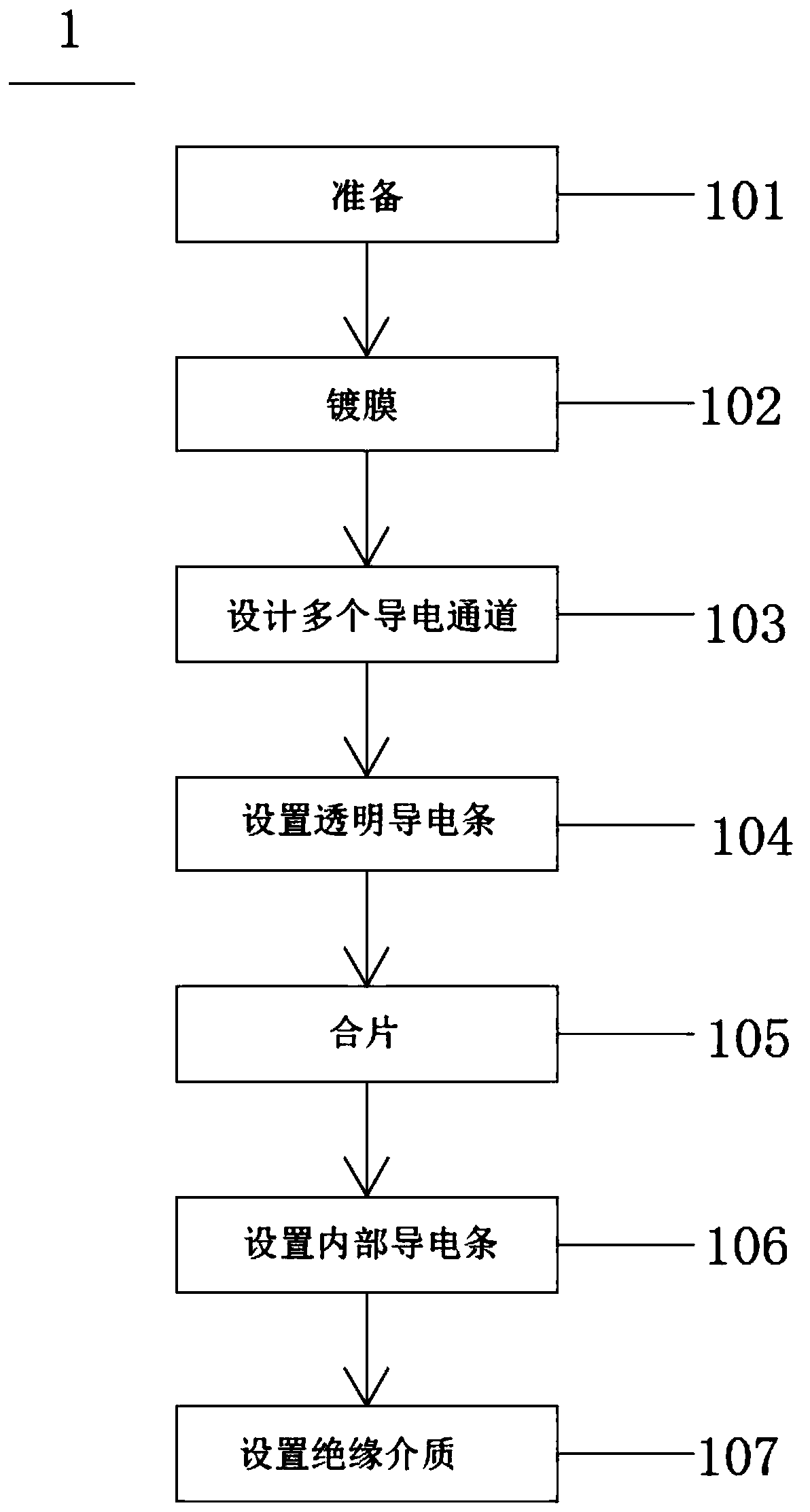

Conductive substrate, preparation method thereof and electrochromic device

InactiveCN111190313AReduced risk of short circuitsNot corrodedNon-linear opticsConductive materialsColor changes

The invention relates to a conductive substrate, a preparation method thereof and an electrochromic device. The conductive substrate comprises a transparent conductive substrate, at least one conductive part and an insulating part coating the conductive part, wherein the transparent conductive substrate comprises a transparent conductive layer and a transparent substrate layer which are stacked insequence; and the conductive part is arranged on the surface of the transparent conductive layer. According to the invention, a traditional electrochromic electrode is improved, and the conductive material is printed on the transparent conductive substrate, so that voltage distribution on the transparent conductive substrate is uniform, and the color changing process of the electrochromic deviceapplying the conductive substrate is uniform; according to the invention, the conductive material is arranged by adopting a printing method with a mature process, the operation difficulty of the preparation method is reduced, the conductive material arranged by the printing method is thinner, and the conductive material can be better attached to an electrode printing area, so that the conductive substrate has certain flexibility.

Owner:SHENZHEN GUANGYI TECH CO LTD

Photochromic PVC plastic and preparation method thereof

InactiveCN103740003AWith UV indicator functionUniform discolorationPlastic materialsRoom temperature

The invention provides a photochromic PVC plastic and a preparation method thereof. The photochromic PVC plastic comprises the following components in parts by weight: 90-95 parts of PVC powder, 0.05-0.3 part of photochromic raw powder and 5-10 parts of stabilizer. The invention also provides a preparation method of the photochromic PVC plastic, which comprises the following steps: adding the photochromic raw powder into the PVC powder according to the weight ratio, adding the stabilizer and mixing uniformly; putting the mixture into a film making machine, and controlling a certain temperature (180-200 DEG C); pulling out the film, and putting the film back into the film making machine, and repeating for 5-6 times; observing whether the film formation and color are uniform; and if the film formation and color are uniform, airing at room temperature. According to the photochromic PVC plastic, the photochromic plastic material can be produced by a method of directly adding the photochromic raw powder into the PVC powder; the photochromic PVC plastic can be widely applied to the market products, is beautiful and novel and has an ultraviolet indication function; and moreover, the photochromic PVC plastic is more durable than the products prepared from a common photochromic coating and realizes a more uniform color change effect.

Owner:TIANJIN UVOS TECH CO LTD

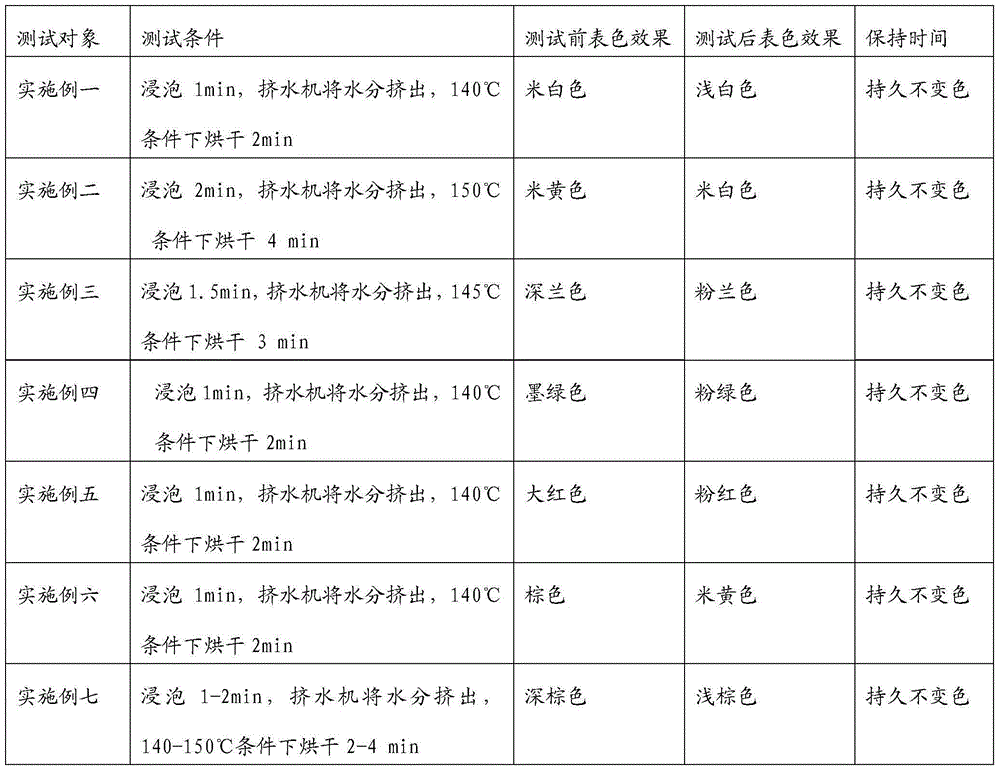

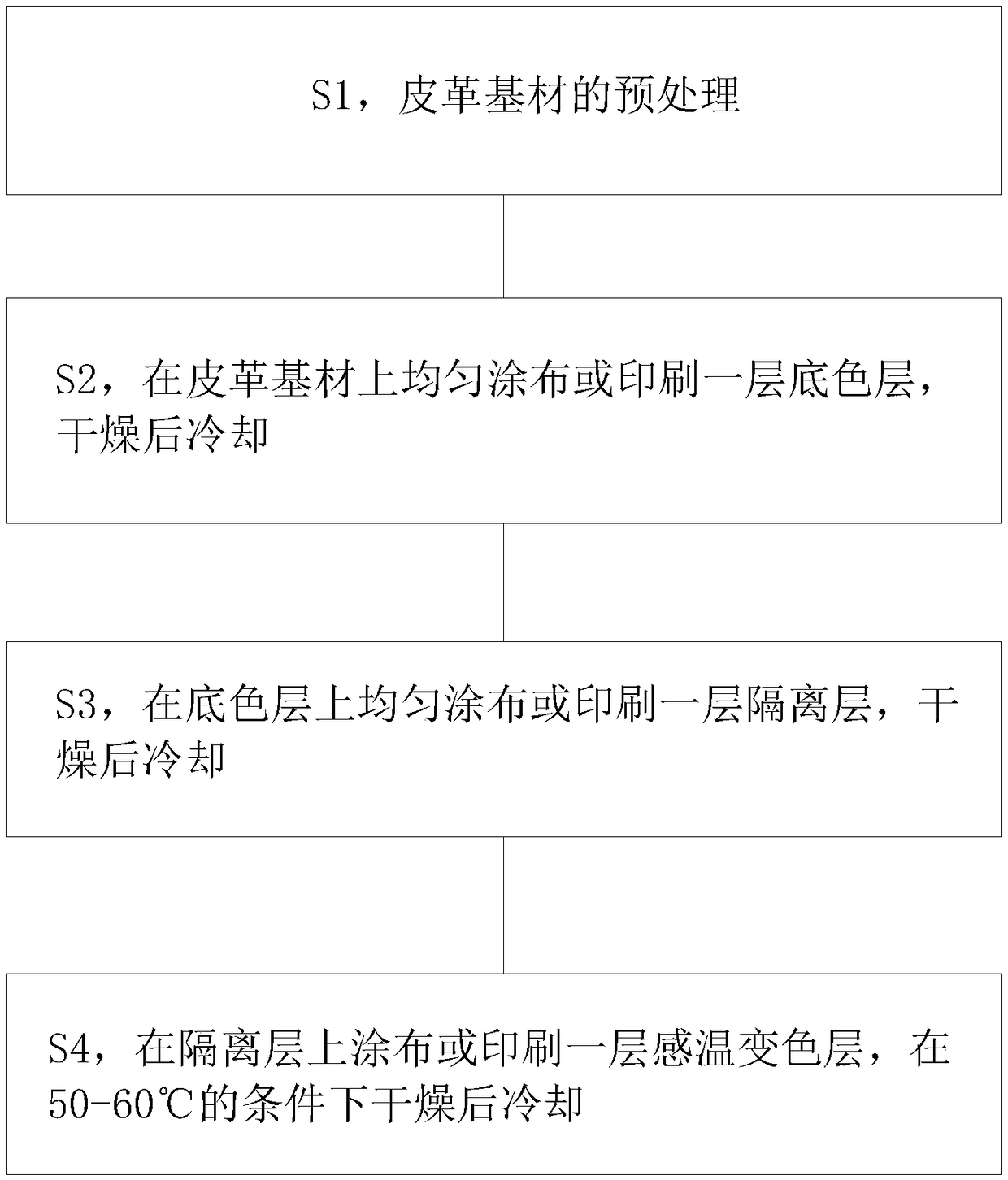

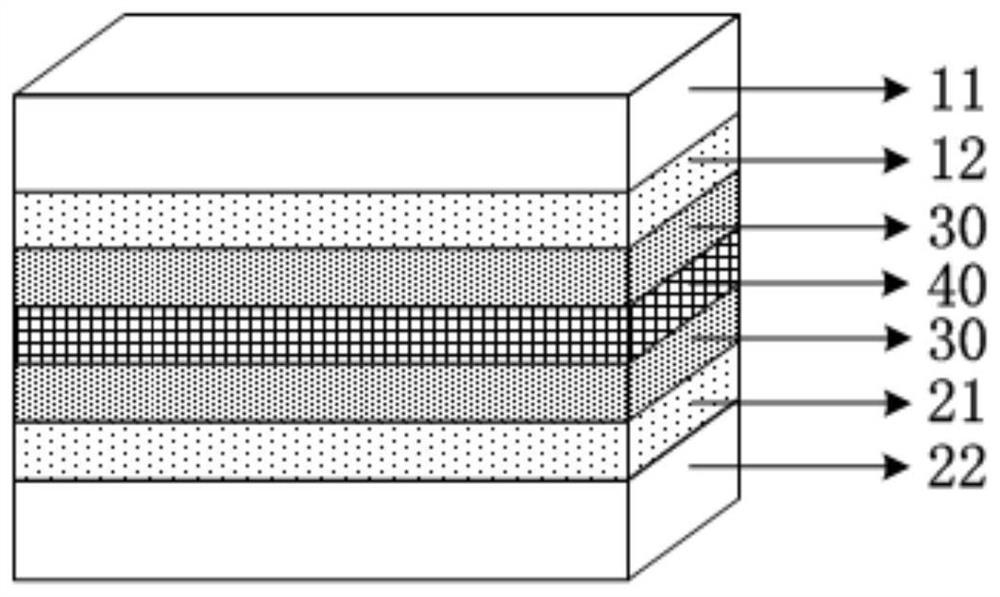

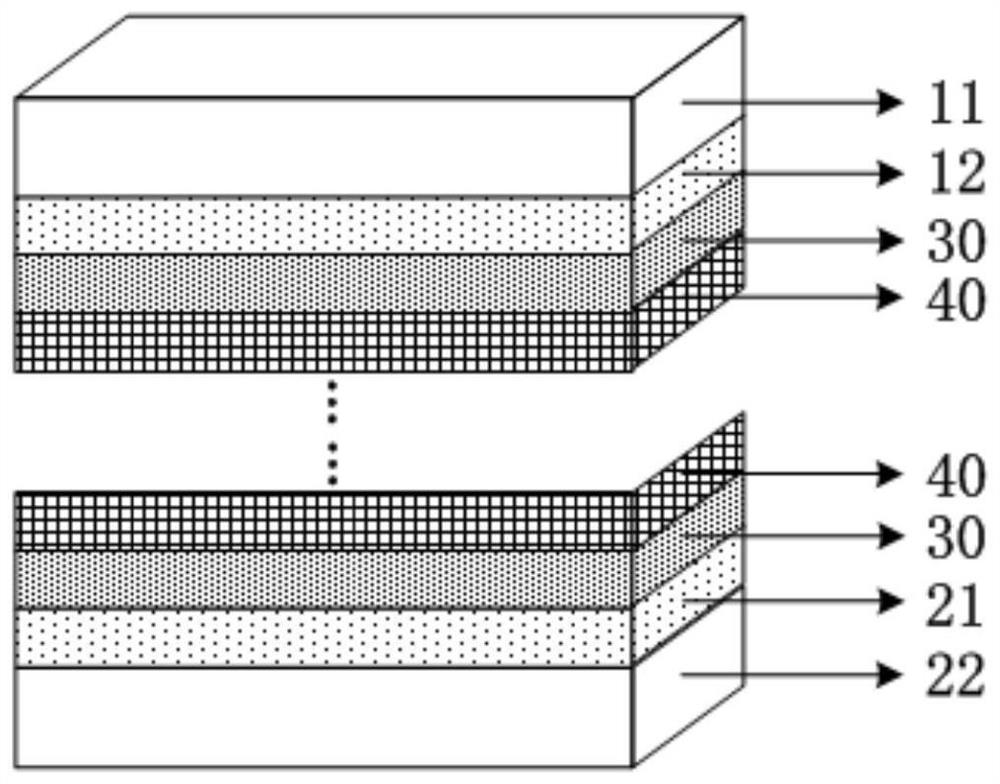

Thermochromic leather as well as production method and application thereof

InactiveCN109440485AUniform discolorationImprove performanceTextiles and paperThermosensitive paintsIsolation layerColor changes

The invention belongs to the technical field of leather, and discloses thermochromic leather as well as a production method and application thereof. The thermochromic leather comprises a leather baselayer, a ground color layer is arranged on the leather base layer, an isolation layer is arranged on the ground color layer, and a thermochromic layer is arranged on the isolation layer. According tothe thermochromic leather, the ground color layer can be coated with a color required by a user, the isolation layer can prevent the color of the ground color layer from floating upwards and can prevent the color of the thermochromic layer from permeating downwards, and the thermochromic layer can show different colors along with the change of the temperature. The thermochromic leather has the advantages of being stable in performance, uniform in color change and wide in application range.

Owner:田祥云

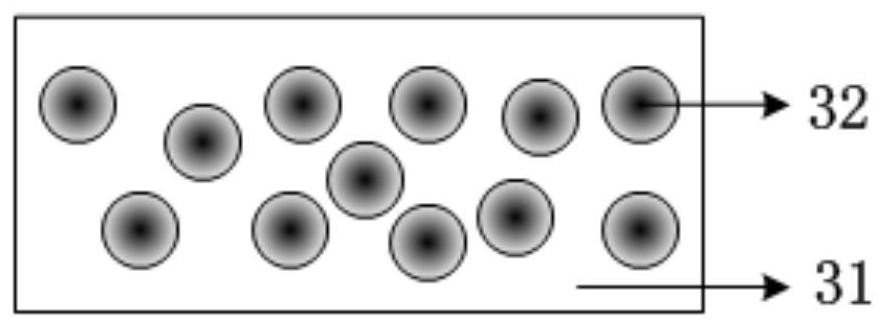

Flexible electrochromic device and preparation method thereof

PendingCN111722449AUniform discolorationGood flexibilityNon-linear opticsColor changesElectrochromism

The invention provides a flexible electrochromic device and a preparation method thereof. The flexible electrochromic device comprises: a first substrate, a first electrode layer arranged on the surface of the first substrate, a second substrate, a second electrode layer arranged on the surface of the second substrate, n functional layers and n-1 barrier layers, wherein the n functional layers andthe n-1 barrier layers are alternately arranged between the first electrode layer and the second electrode layer, the first electrode layer and the second electrode layer are both in contact with thefunctional layers, n is a positive integer larger than or equal to 2, and the functional layers comprise electrolyte and electrochromic particles dispersed in the electrolyte. Therefore, the drivingvoltage of the flexible electrochromic device is relatively low, and the color changing speed is higher so that the color changing of the device is relatively uniform in the color changing process; the electrochromic particles are dispersed in the electrolyte so that the integrity of the electrochromic particles is not damaged when the flexible electrochromic device is bent for multiple times or the bending angle is relatively large, and the safe use of the device is further ensured; and the manufacturing cost of the device is low.

Owner:CHINA LUCKY FILM CORP

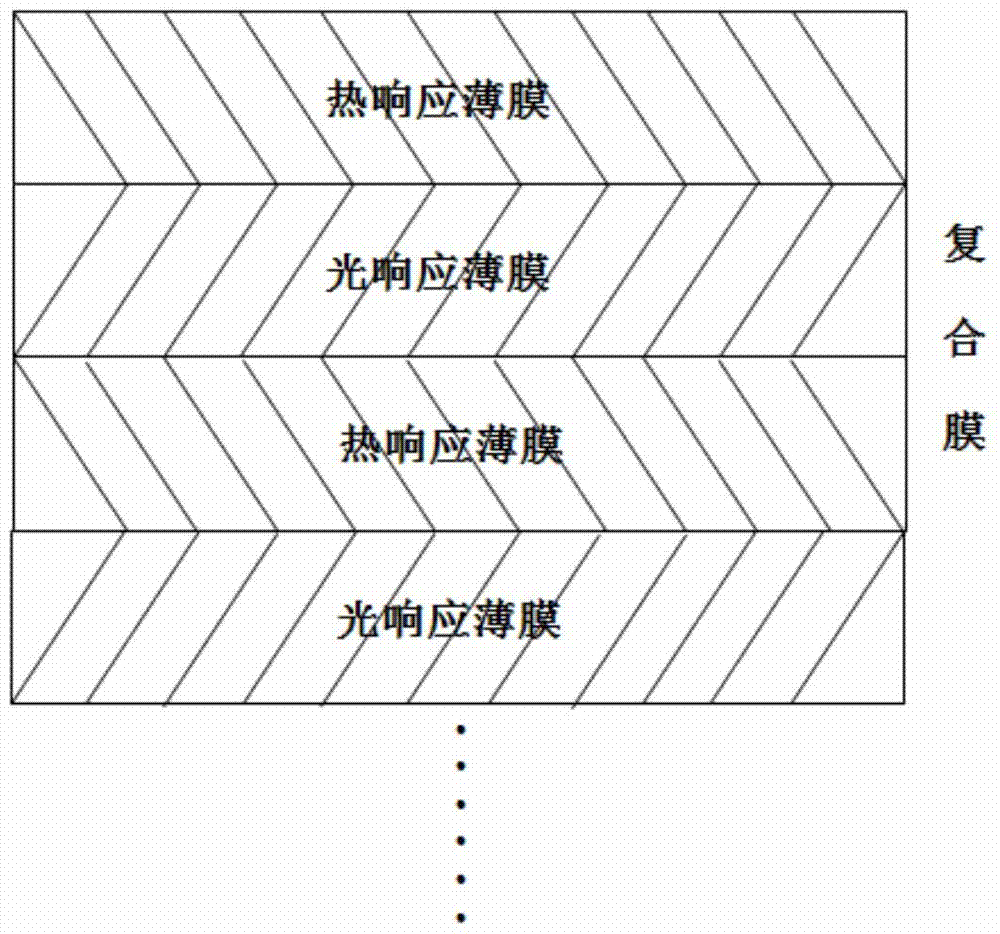

A photothermal responsive intelligent energy-saving composite film

ActiveCN105017698BReduce energy consumptionEmission reductionSynthetic resin layered productsLuminescent compositionsColor effectVanadium dioxide

The invention discloses a photothermal responsive intelligent energy-saving composite film, which is composed of reversible photochromic substances containing spiropyrans and reversible thermochromic substances containing vanadium dioxide bases. The intelligent energy-saving composite film can be used to prepare one or more layers of alternately compounded color-changing films, which integrates functionality and decoration, and is suitable for building energy-saving needs in most areas of my country, and can be widely used in building doors, windows and automobiles. Safety glass and agricultural greenhouse film and other fields. The intelligent energy-saving composite membrane material of the present invention is based on photothermal response technology, has good discoloration effect, good anti-aging performance, good stability, and can reduce energy consumption and carbon emissions, and has a very broad market prospect.

Owner:青岛至慧新材料科技有限公司

Electrochromic device

InactiveUS20140002883A1Uniform decolorizationUniform discolorationStatic indicating devicesNon-linear opticsElectricityOptoelectronics

Provided is an electrochromic device including: two substrates opposed to each other; an electrode and a conductive reflection layer interposed between the two substrates; a first electrochromic coating layer interposed between the electrode and the conductive reflection layer; and an electrolyte layer interposed between the first electrochromic coating layer and the conductive reflection layer, whereby uniform discoloration and decolorization can be performed, the efficiency of power consumption can be enhanced, and a durability of the device and the speed of a decolorization reaction can be improved.

Owner:LG INNOTEK CO LTD

Color-changing device and control method thereof

ActiveCN112558371AAvoid damageAchieve gradientNon-linear opticsStatic indicating devicesElectrically conductiveStructural engineering

The invention provides a color changing device and a control method thereof. The color changing device comprises a first substrate layer, a first conducting layer, a color changing layer, a second conducting layer and a second substrate layer which are sequentially arranged in a stacked mode. The color changing device comprises at least one partition structure, the partition structure comprises atleast two boundary bus bars and at least one partition bus bar located between the two boundary bus bars, and the partition bus bars and the boundary bus bars are located on different conducting layers respectively. The partition structure composed of the partition bus bars and the boundary bus bars is additionally arranged on the conducting layer of the color-changing device, the voltage on thebus bars is regulated and controlled, the color-changing areas of the color-changing device are adjusted according to actual application, meanwhile, the effect of combining gradient and partition is achieved, and device damage caused by current loss is reduced.

Owner:SHENZHEN GUANGYI TECH CO LTD

Preparation process of building decoration material with discoloration function

The invention discloses a preparation process of a building decoration material with a discoloration function, wherein the preparation process comprises the steps: mixing 50 parts by mass of a PVC powder and 30 parts by mass of a plasticizer evenly, to prepare a PVC predipping adhesive; and then drying, coating the surface of the dried product with 10 parts by mass of sulfur aluminosilicate cement, 30 parts by mass of an inorganic adhesive, 60 parts by mass of calcium carbonate, 30 parts by mass of a heat stabilizer, 10 parts by mass of perlite, 2 parts by mass of a discoloring pigment and 10parts by mass of a light stabilizer, then continuing to dry, and baking at the temperature of 150 DEG C for 5 min, to obtain the product. In the preparation, a pre-dispersion method is used, a homogeneous dispersion system which is prepared by adding the discoloring pigment and the additive is prepared, and a homogeneous dispersion system prepared by mixing the PVC powder and the plasticizer is prepared, and then the two homogeneous dispersion systems are mixed to obtain a homogeneous PVC macromolecular coating adhesive, and the prepared building film material is discolored uniformly.

Owner:安徽乐享家装饰设计有限公司

Photochromic lens with double optical film layers and preparation method of photochromic lens

ActiveCN113514963AOvercoming the inhomogeneity of the bi-optical film layerUniform discolorationPolyether coatingsEpoxy resin coatingsPhoto irradiationMaterials science

The invention relates to the technical field of lens manufacturing processes, in particular to a preparation method of a photochromic lens with double optical film layers. According to the technical key points, the photochromic lens with the double optical film layers comprises a substrate, a processing layer and a photochromic layer from inside to outside, and the photochromic layer is cured on the surface of the processing layer through ultraviolet irradiation. According to the preparation method of the photochromic lens with the double optical film layers, a bioptical lens is adopted as the lens substrate, and a photochromic technology and a bioptical technology are combined, so that the defect of nonuniformity of the double optical film layers caused by a spin-coating method is overcome, the photochromic layer can be uniformly attached to the surface of the lens substrate, and the photochromic lens is uniform in color change and excellent in performance; and the surface shape luminosity of the bioptical lens substrate can be ensured not to be influenced.

Owner:JIANGSU MAAT OPTICAL CO LTD

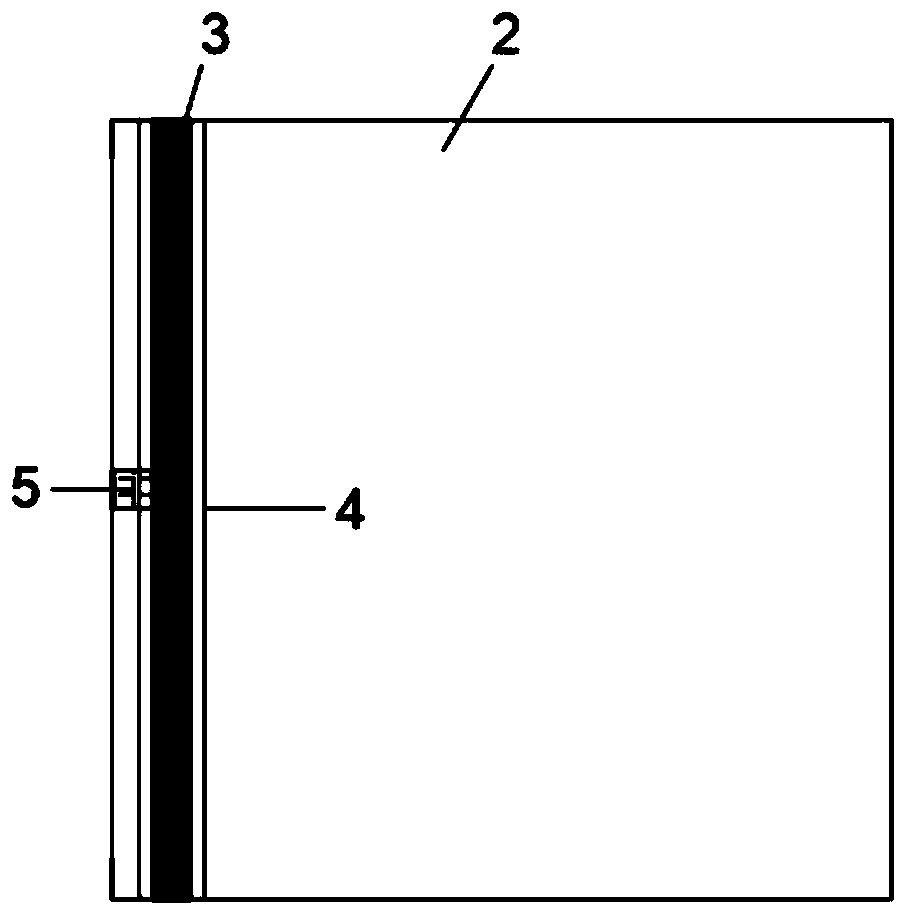

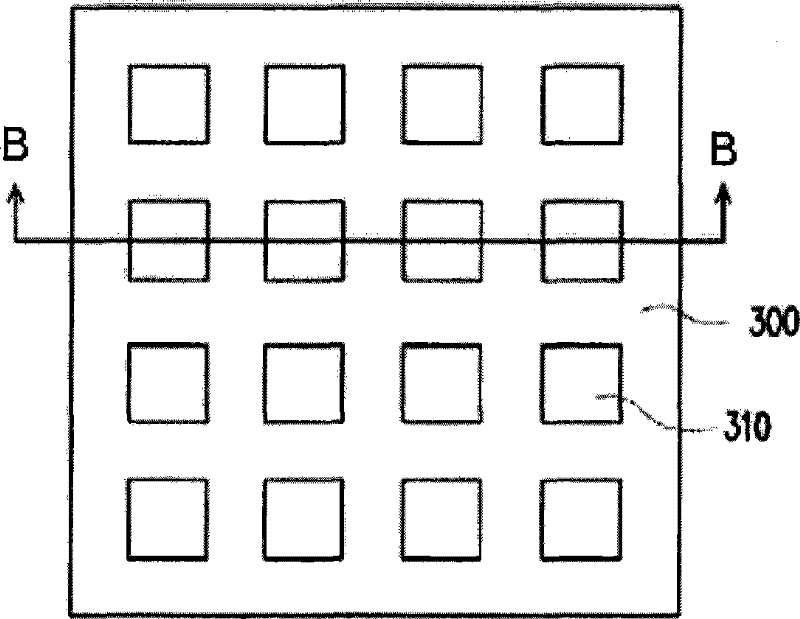

Conductive substrate and electrochromic device

ActiveCN112363358AReduce potential differenceReduce halo phenomenonNon-linear opticsPotential differenceElectrical connection

The embodiment of the invention discloses a conductive substrate and an electrochromic device. The conductive substrate comprises a substrate layer, a conductive layer and a wiring layer; the conductive layer is arranged on the substrate layer; the wiring layer is arranged on the conductive layer and comprises a first conductive circuit arranged in a first direction and a second conductive circuitarranged in a second direction, the first conductive circuit extends inwards from the edge of the conductive layer, the second conductive circuit is arranged on the edge of the conductive layer, andthe first conductive circuit is electrically connected with the second conductive circuit. According to the technical scheme provided by the embodiment of the invention, the potential difference between the edge and the center of the conductive substrate is reduced when the conductive substrate is electrified, so that when the conductive substrate is applied to the electrochromic device, the halophenomenon is weakened, a more uniform color changing process is realized, and meanwhile, especially for the electrochromic device with a relatively large area, a relatively high color changing speedis ensured.

Owner:SHENZHEN GUANGYI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com