Drive mode of electrochromic glass

An electrochromic glass and driving method technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of insufficient intermediate effective driving voltage, high effective driving voltage, uneven discoloration of electrochromic glass, etc., to achieve effective improvement. The effect of driving voltage distribution, shortening the required time, and improving the distribution of the effective driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

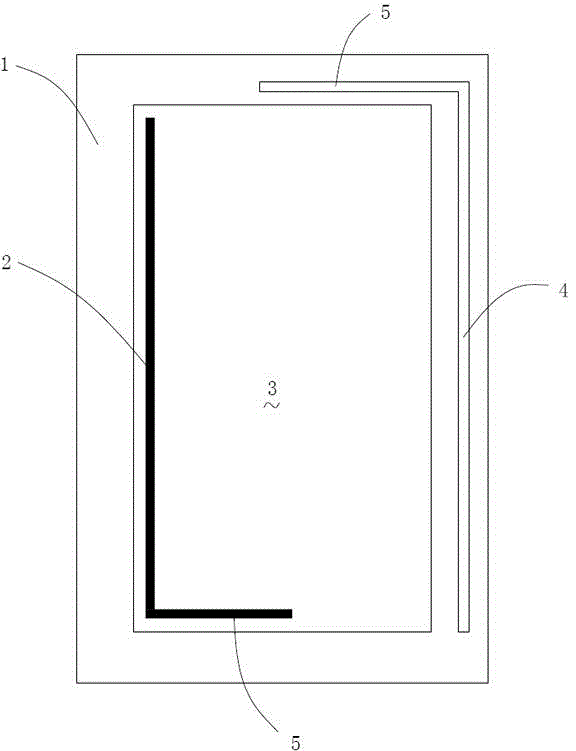

[0028] Embodiment 1: A driving method of electrochromic glass (see attached figure 1 ), the lower electrode conductive strip 4 is set on the bottom conductive layer, and the upper electrode conductive strip 2 is set on the top conductive layer. On the long sides of both sides of the electrochromic glass, the length of each conductive strip can cover the entire long side, or can be arranged along the long side from one end of the glass to 4 / 5 of the long side. An extension section is provided at one end of each conductive strip close to the short side of the electrochromic glass, and the extended section is a bending portion 5 perpendicular to the main body of the conductive strip, so that the conductive strip is L-shaped as a whole. The length of the bent portion is greater than 1 / 3 of the length of the short side of the electrochromic glass and less than 4 / 5 of the length of the short side of the electrochromic glass. In this embodiment, the length of the bent portion of the ...

Embodiment 2

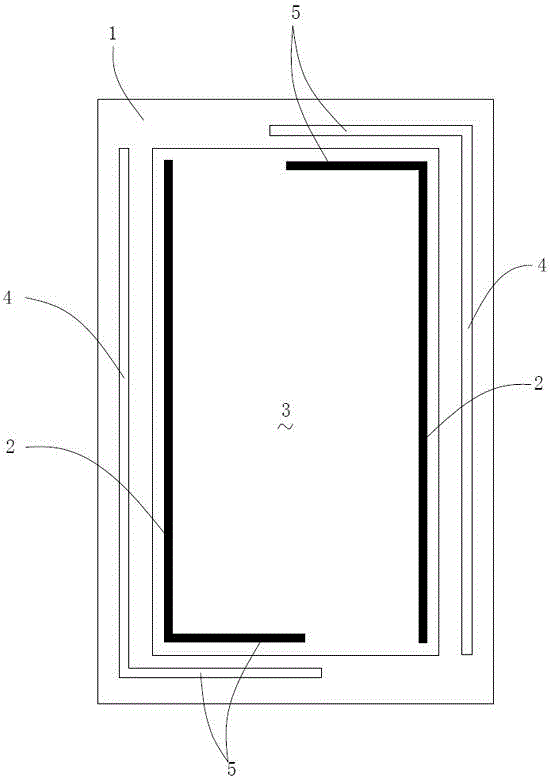

[0030] Embodiment 2: A driving method of electrochromic glass (see attached figure 2 ), the bottom conductive layer leads the lower electrode conductive strip 4 through indium tin welding, and the upper electrode conductive strip 2 is obtained by pasting copper conductive strips on the top conductive layer, and the two conductive strips are respectively arranged on different long sides of the two sides of the electrochromic glass superior. The conductive strips in this embodiment are four in total and divided into two groups, each group includes an upper electrode conductive strip and a lower electrode conductive strip, and the upper electrode conductive strip and the lower electrode conductive strip of the same group are respectively arranged on the electrochromic On different long sides on both sides of the glass, different groups of upper electrode conductive strips and lower electrode conductive strips are arranged on the long side of the same side of the electrochromic g...

Embodiment 3

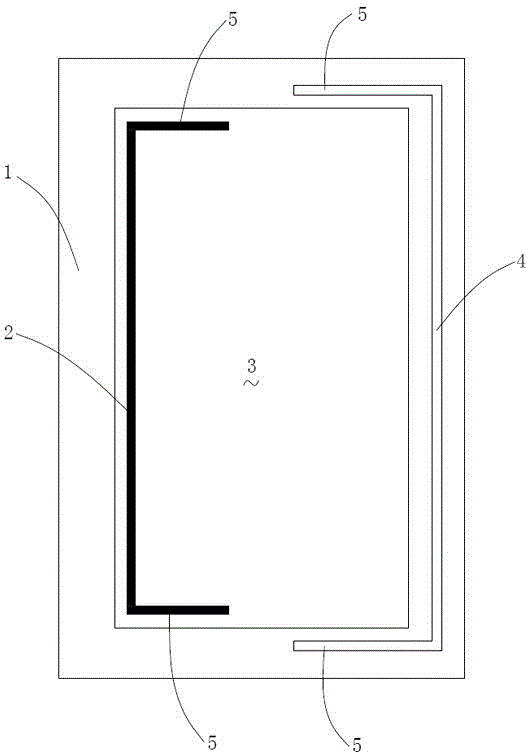

[0032] Embodiment 3: A driving method of electrochromic glass (see attached image 3 ), the lower electrode conductive strip 4 is pasted and welded on the bottom conductive layer, the upper electrode conductive strip 2 is pasted and welded on the top conductive layer, and the two conductive strips are respectively pasted and welded on different long sides of the two sides of the electrochromic glass. Both ends of the strip have extensions, and the extensions are the bending parts 5 of the vertical conductive strips, so that the conductive strips as a whole are in a right-angled C shape, and the two opposite bending parts of the upper electrode conductive strip and the lower electrode conductive strip The distance between the parts is less than 1 / 2 of the length of the short side of the electrochromic glass and greater than 1 / 5 of the length of the short side of the electrochromic glass. In this embodiment, the distance between the ends of the opposite two bending parts is 2 / 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com