Color changeable artificial leather, and preparation method and color changing method thereof

A color-changing and artificial leather technology, which is applied to textiles, papermaking, and fabric surface trimming, can solve the problems of artificial leather not being able to obtain permanent discoloration effects and unstable discoloration performance of artificial leather, and achieve the effect of simple method, easy application and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

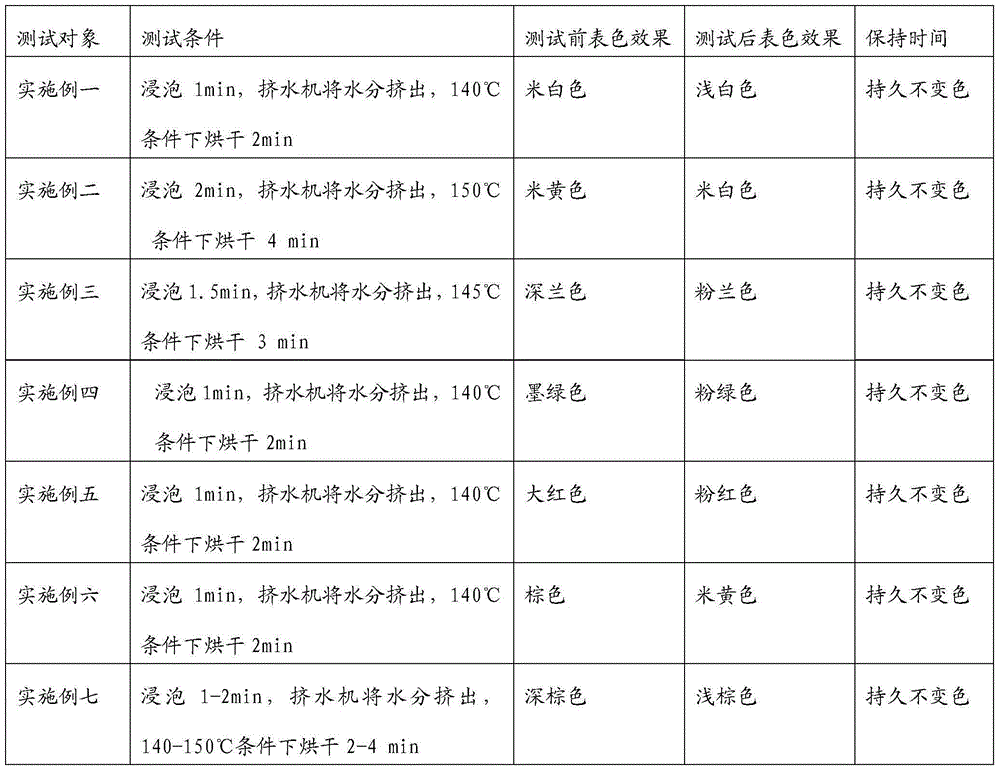

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the above-mentioned color-changing artificial leather, which includes a surface layer forming step. The surface layer forming step is: mixing the surface layer raw materials to form a surface layer slurry, and coating the surface layer slurry On the release paper, after drying at 130-160°C for 40-50S, the surface layer is obtained.

[0030] The beneficial effect of the preparation method of the variable color artificial leather of the present invention is:

[0031] The drying conditions of the surface layer are: 130-160°C, 40-50S. Through the setting of the above drying conditions, the moisture content of the obtained artificial leather surface layer tends to be within the optimum range, thus providing a good foundation for the discoloration effect on the one hand. On the one hand, the product stability of artificial leather is guaranteed.

[0032] Further, it also includes an inner layer forming step, the inne...

Embodiment 1

[0042] A color-changing artificial leather of the present embodiment comprises a surface layer, an inner layer and a foaming layer in order from top to bottom, and the surface layer is prepared from the following raw materials in parts by weight: 40 parts of polyurethane resin, 30 parts of organic solvent, 10 parts of silicon dioxide discoloration powder, 5 parts of matting powder, 0.5 parts of leveling agent and 3 parts of PU toner; the inner layer comprises the following raw materials in parts by weight and is prepared: 98 parts of polyvinyl chloride resin, phthalate di 60 parts of octyl ester, 10 parts of filler, 2 parts of heat stabilizer and 5 parts of PVC color paste; the foam layer is prepared from the following raw materials in parts by weight: 98 parts of polyvinyl chloride resin, dioctyl phthalate 70 parts, 60 parts of filler, 3 parts of stabilizer, 2 parts of foaming agent and 4 parts of PVC color paste. The organic solvent is dimethylformamide (DMF), toluene (TOL) ...

Embodiment 2

[0046] A color-changing artificial leather of the present embodiment comprises a surface layer, an inner layer and a foaming layer sequentially from top to bottom, and the surface layer is prepared from the following raw materials in parts by weight: 50 parts of polyurethane resin, 35 parts of organic solvent, 15 parts of silicon dioxide discoloration powder, 10 parts of matting powder, 1 part of leveling agent and 5 parts of PU toner; the inner layer comprises the following raw materials in parts by weight and is prepared: 102 parts of polyvinyl chloride resin, phthalic acid di 70 parts of octyl esters, 120 parts of fillers, 3 parts of heat stabilizers and 10 parts of PVC color paste; the foam layer is prepared from the following raw materials in parts by weight: 102 parts of polyvinyl chloride resin, dioctyl phthalate 90 parts, 80 parts of filler, 4 parts of stabilizer, 4 parts of foaming agent and 8 parts of PVC color paste. The organic solvent is dimethylformamide (DMF), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com