Patents

Literature

128results about "Electric wood treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for high-strength antibacterial mould-proof bamboo plywood

InactiveCN105773740AImprove wettabilityImprove antibacterial propertiesElectric wood treatmentWood treatment detailsResin adhesiveUltimate tensile strength

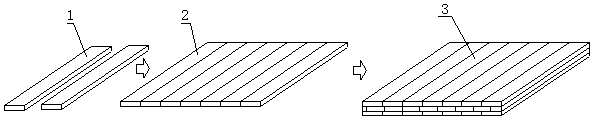

The invention discloses a preparation method for high-strength antibacterial mould-proof bamboo plywood. The preparation method comprises the steps that a bamboo sheet is manufactured, specifically, the bamboo sheet is dried to be 8-15% in moisture content, and then the bamboo sheet is subjected to plasma processing to obtain a material A; the material A is added into an antibacterial agent to be soaked for 30-45 min, and then is dried to be 8-15% in moisture content to obtain a material B; the material B is soaked in a phenolic resin adhesive for 100s-120s, and then is dried to be 10-15% in moisture content to obtain a material C; the material C is assembled to obtain a work board; the work board is subjected to hot-pressing consolidation to obtain a substrate; and the substrate is aged to obtain the high-strength antibacterial mould-proof bamboo plywood. The preparation method for the high-strength antibacterial mould-proof bamboo plywood has the advantages of being simple in process, mild in condition and low in cost; and the obtain bamboo plywood is high in strength, good in corrosion resistance and excellent in antibacterial and mould-proof performance.

Owner:安徽福佳竹木日用品有限公司

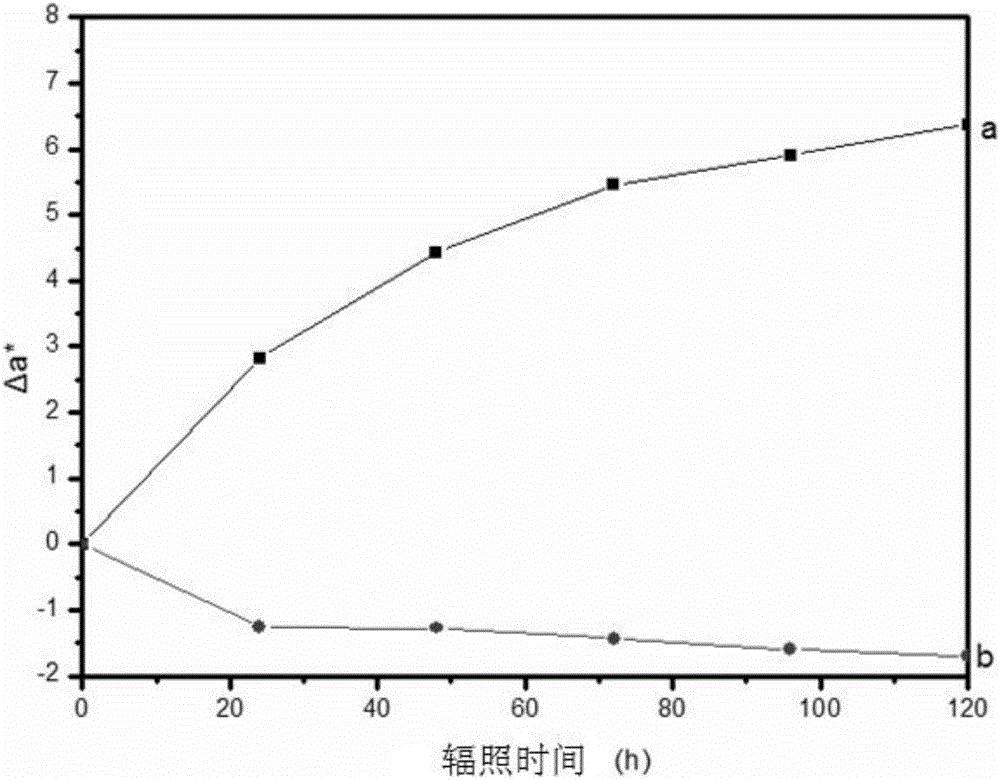

Method for dyeing rattans with plant-based black dye

ActiveCN107336314AImprove permeabilityImprove surface activityRadiation/waves wood treatmentElectric wood treatmentActive agentWarm water

The invention discloses a method for dyeing rattans with plant-based black dye. The method is characterized by comprising the steps that (1), softening is performed, wherein the rattans are soaked in warm water firstly and then soaked in a softener solution to be subjected to ionization treatment; (2), dyeing is performed, wherein the rattans are soaked in an active agent solution for 2-3 h, and then dyeing and drying are performed and repeated for 3-4 times; (3), color protection treatment is performed, wherein the rattans are subjected to atomization treatment with a color fixative; (4), fixation is performed, wherein the fixation treatment is conducted on the rattans needing color protection by ultraviolet light and mixed mud; and (5), air-drying is performed, wherein the dye-fixed rattans are dried to the moisture content of 7%-10%, and then the rattans are coated with paraffin oil and air-dried. Compared the rattans produced through the method with a control group, the content of the dye in the rattans is increased by 61.5 mg / 100 g, the discoloration test time is prolonged by 55 h, and the bending rate is increased by 7.8%.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Preparation method of high-thermal-conductivity graphene floor heating floor

ActiveCN108177225AIncrease productivityNo pollution in the processElectric wood treatmentWood treatment detailsCell cavitySingle plate

The invention relates to a preparation method of a high-thermal-conductivity graphene floor heating floor. The method comprises the following steps of 1 single plate pretreating, 2 air drying at roomtemperature, 3 plasma treating, 4 dipping, 5 drying, 6 single plate blank matching and 7 hot pressing. According to the preparation method, a graphene-metal composite material is dissolved into a dipping solution, dipping modification is conducted on wood, the graphene-metal composite material is evenly distributed in wood cell cavities, therefore, the thermal conductivity of the wood can be greatly improved, and the density and the stability of the wood can be enhanced. The modified wood is made into the high-thermal-conductivity graphene floor heating floor by being taken as a veneer layer,a middle layer and a substrate, the thermal conductivity of the floor is effectively improved, and the functions of saving energy and reducing consumption and being uniform in thermal dissipation, stable in structure and the like of the floor heating floor are achieved.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

Wood preservative treatment method

InactiveCN107283567ASimple anti-corrosion treatment processReduce energy consumptionElectric wood treatmentWood treatment detailsPreservativeHigh pressure

The invention relates to the technical field of wood processing, in particular to a wood antiseptic treatment method, in which wood of an appropriate size is selected, sent into an expansion chamber, expanded, immersed in a diluted quaternary ammonium copper solution, and combined with a high-voltage pulse electric field during treatment treatment, and finally, drying the processed wood. The wood antiseptic treatment process of the present invention is simple, low energy consumption, good permeability of the preservative, effective combination with wood, and low loss rate in the later antiseptic process.

Owner:FUNAN YONGXING ARTS & CRAFTS

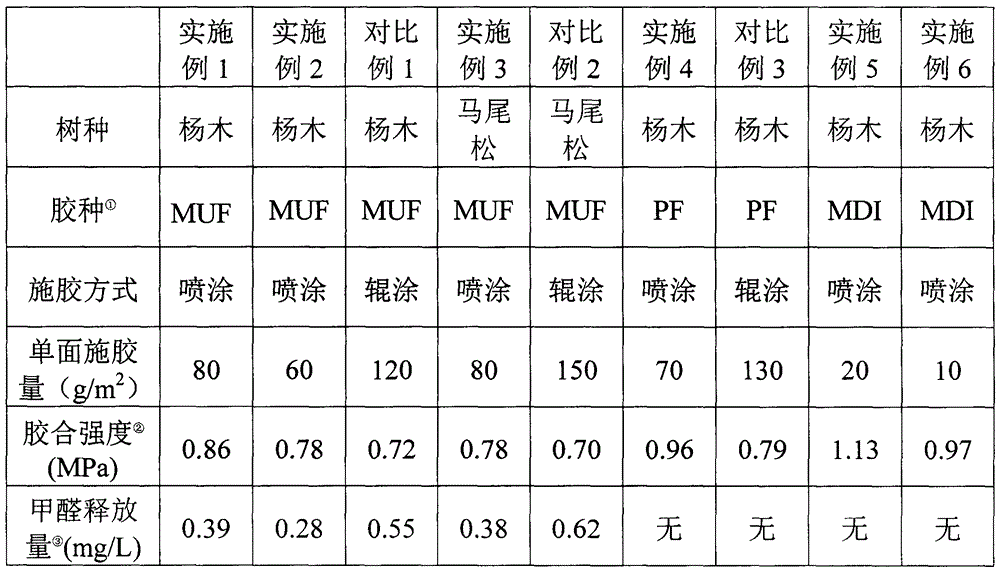

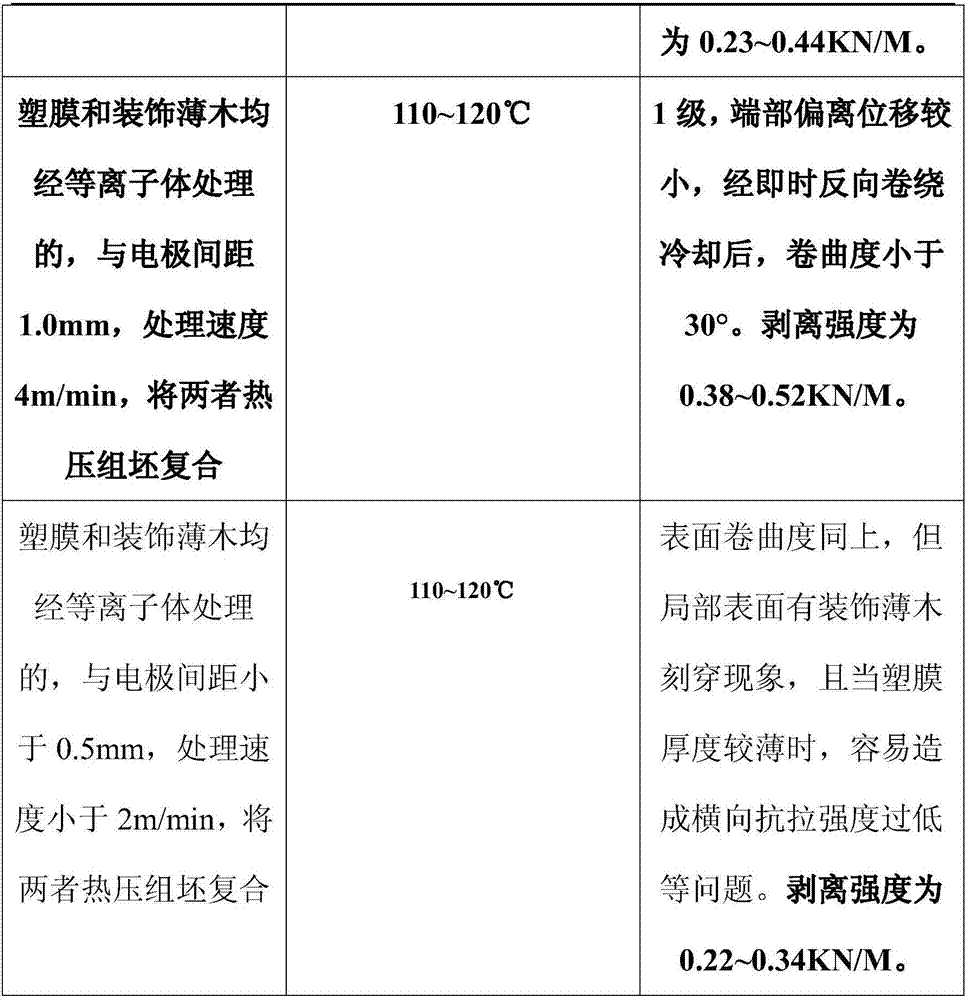

Manufacturing method of low-glue environmental protecting plywood

ActiveCN105818225AImprove qualityReduce manufacturing costElectric wood treatmentWood treatment detailsFiberWood veneer

The invention discloses a manufacturing method of low-glue environmental protecting plywood, and belongs to the technical field of manufacturing of artificial boards. The process comprises the following steps: a wood section is rotationally cut to 1-3 mm wood veneers; the wood veneers are dried to adjust the water content to 2-15%; the normal-pressure and low-temperature plasma modifying treatment is performed for two surfaces of the veneers; through ultrasound and cyclone synergistic effect, adhesive is atomized as particles with a diameter of smaller than 40 microns to spray the surfaces of the veneers; the applying quantity of the adhesive on one surface is controlled within 10-80 g / m2; the veneers are assembled to a blank by perpendicular fiber grain directions of the veneers on adjacent layers; and the blank is hotly pressed to prepare the low-glue environmental protecting plywood. The performance of the product prepared by the method accords with the national plywood standard requirement; the formaldehyde emission reaches the E0-grade requirement; the adhesive dosage is reduced by 30-70% compared with a traditional gluing mode; the product quality is prominently promoted; and the production cost is obviously reduced. In addition, the method is energy-saved and environment-friendly in production process; and production equipment is convenient for operation, high in efficiency, excellent in controllability and capable of realizing continuous automatic operation.

Owner:NANJING FORESTRY UNIV

Method for utilizing dendrocalamus affinis leaves to process zongzi wrapping leaves

ActiveCN106142268ACultivation is simpleHigh economic valueLiquid surface applicatorsWrappersFood safetyCopper

The invention discloses a method for utilizing dendrocalamus affinis leaves to process zongzi wrapping leaves. Dendrocalamus affinis leaves are adopted as a processing material for zongzi wrapping leaves. The method comprises the technological processes of dendrocalamus affinis leaf picking, green color protecting through a green-preserving agent, sorting and stacking, ultralow temperature freezing treatment, drying, and discharging and dampening, wherein the green color protecting technology comprises the steps of placing the leaves in sodium copper chlorophyllin to be soaked for 20 min, and then, placing the soaked leaves into an electrochemical device to be subjected to electrochemical treatment. According to the method, the dendrocalamus affinis leaves can be utilized to supplement the zongzi wrapping leaf resource, and the contradiction between supply and demand is relieved; the green color of the zongzi wrapping leaves is achieved through utilizing the sodium copper chlorophyllin, and the food safety problem is avoided; and the reaction is promoted through adopting an electrochemical manner.

Owner:CHONGQING ACADEMY OF FORESTRY SCI

Production process for formaldehyde-free multiply plywood

InactiveCN106945137AIncrease roughnessHigh bonding strengthOther plywood/veneer working apparatusElectric wood treatmentCross-linkCohesive strength

The invention discloses a production process for formaldehyde-free multiply plywood. The production process mainly includes the following steps of cold plasma processing, double-sided gluing of single boards, assembly, hot-press molding, contact calibrating, gluing and veneering, veneer hot pressing, edge sawing, sanding and finished product obtaining. According to the production process, under a high-temperature hot-pressing action of the boards, after isocyanate modified soy protein adhesive is unblocked, the activity of -NCO radials of isocyanate is recovered, and the -NCO radials carry out a cross-linking reaction with degraded soy protein and wood, so that a uniform space mesh structure is formed, the cohesion strength is improved, formation of stable chemical bonds on the surface of the soy protein and the surface of the wood can be facilitated, and thus water resistance of the soy protein based adhesive is improved.

Owner:ANHUI FUYANG QINGLIN WOOD PROD CO LTD

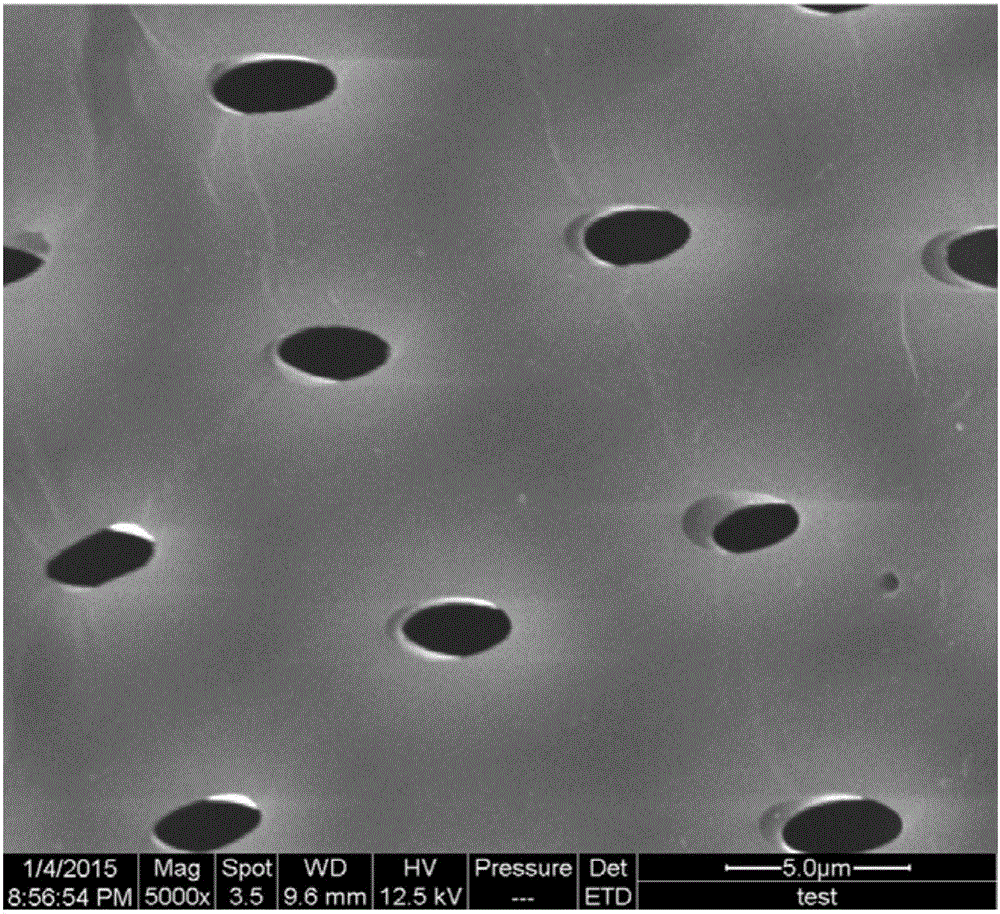

Manufacturing method for bamboo wood surface loaded nanometer titania material

InactiveCN107139298AEasy to produceEasy to operateGas treatmentPhysical/chemical process catalystsAqueous solutionNanometre

A manufacturing method for a bamboo wood surface loaded nanometer titania material. The method comprises the following steps that firstly, sulfonation treatment of nanometer titania is conducted, and a TIO2 nano material is prepared into a water solution with the set mass fraction to be used later; secondly, cold plasma processing is conducted on bamboo wood; and thirdly, preparing of bamboo-base nanometer titania composite materials is conducted, wherein the process comprises the following steps that cold plasma processing is conducted, the bamboo wood is then immersed in the nano TIO2 water solution obtained after sulfonation treatment, and then the bamboo-base nanometer titania composite material is prepared. The manufacturing method for the bamboo wood surface loaded nanometer titania material uniform in titanium dioxide distribution, easy to operate, large in load amount and firm in combination with wood is provided.

Owner:ZHEJIANG FORESTRY ACAD

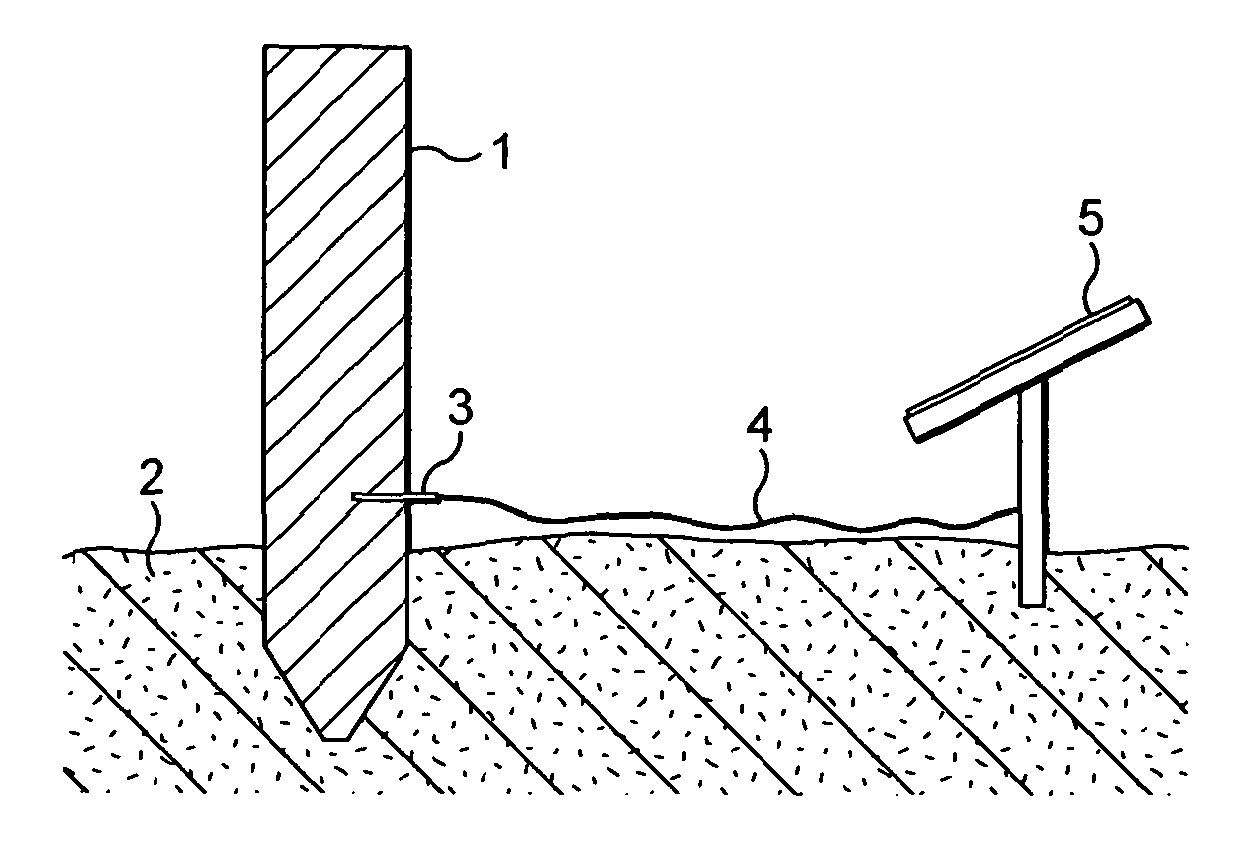

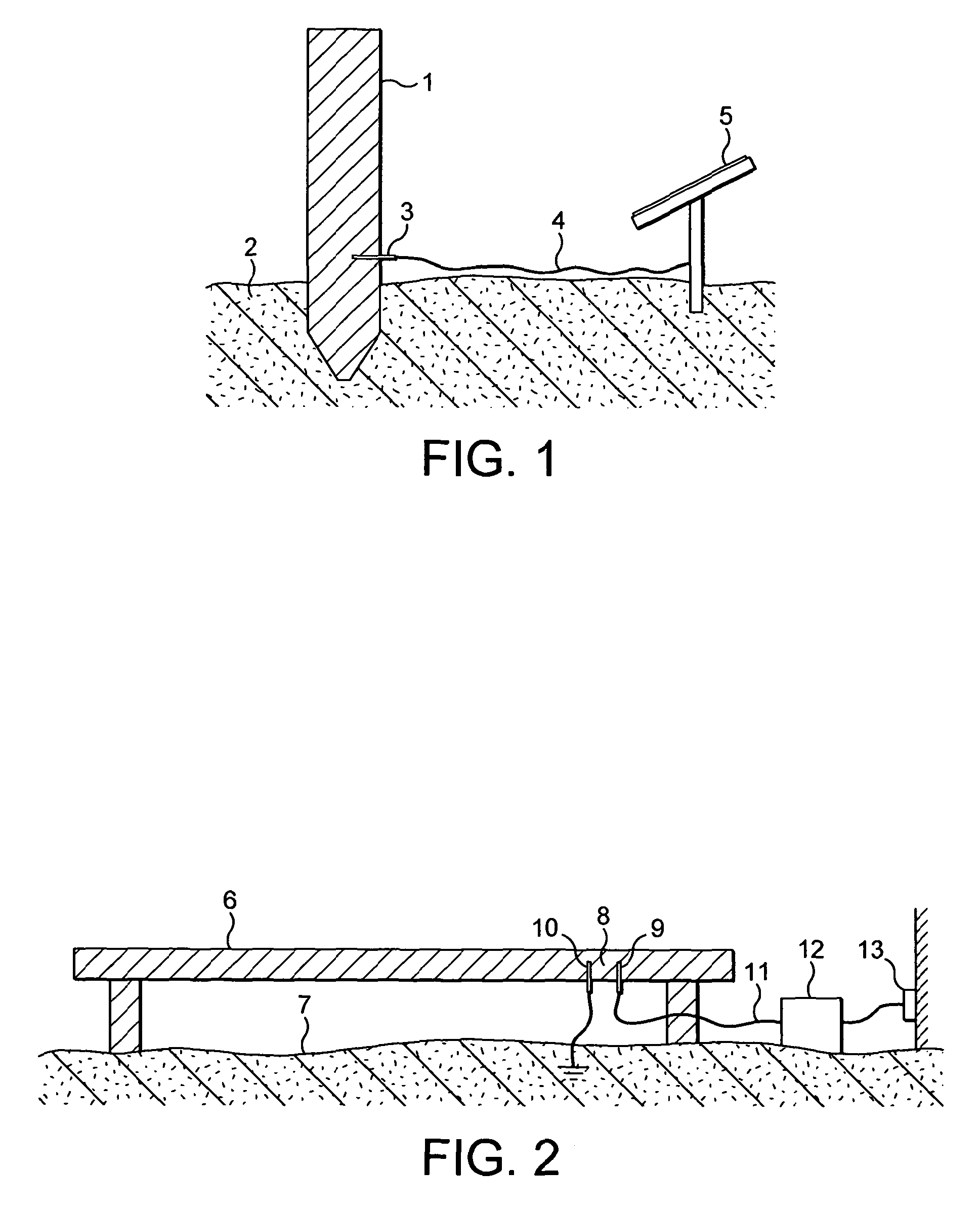

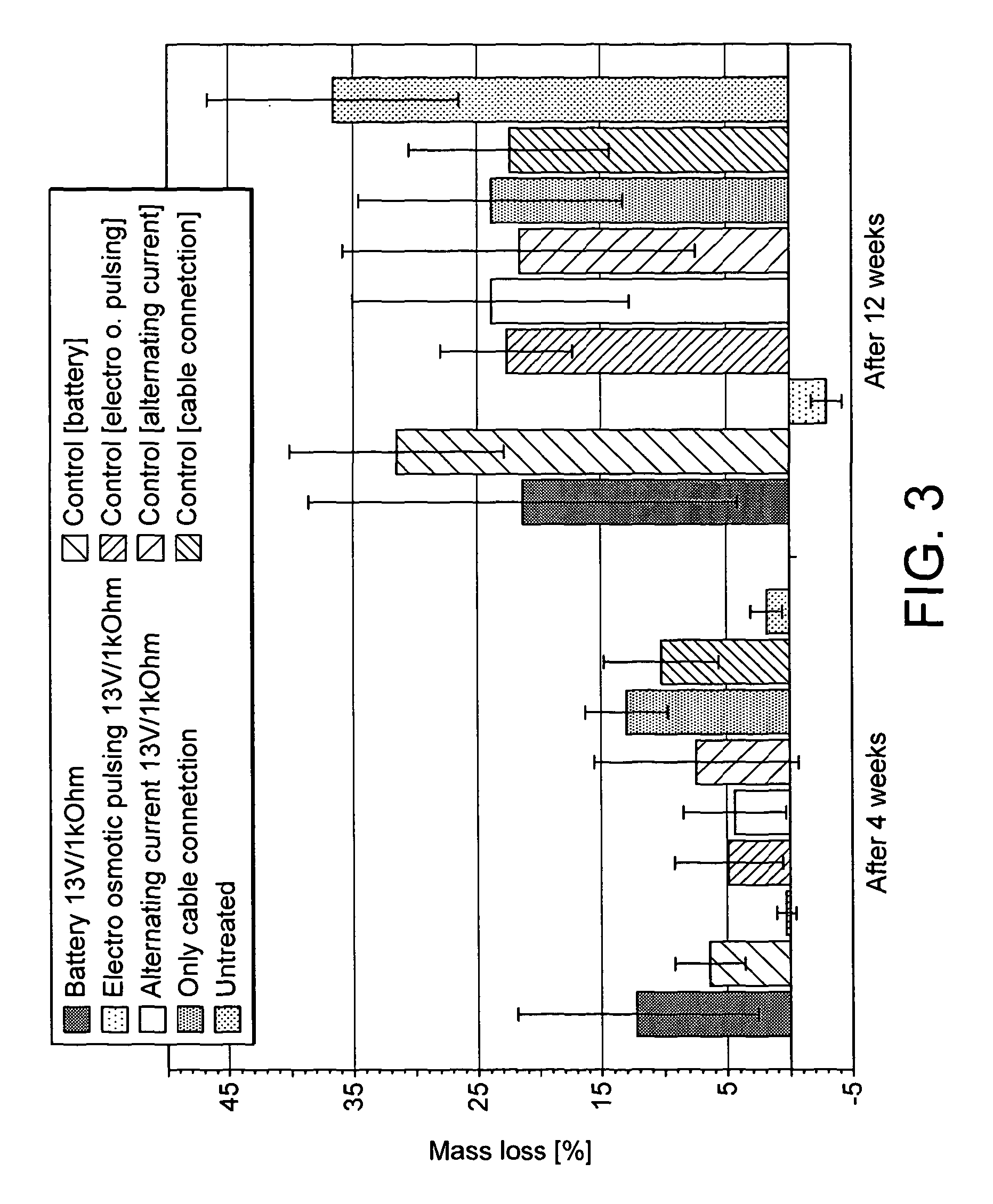

Method of treatment of cellulosic objects

InactiveUS20120273358A1Extended maintenance periodBenefiting environmentElectric wood treatmentVolume/mass flow measurementCelluloseEngineering

The invention provides a method of inhibiting biological damage to a cellulosic structural element exposed to environmental moisture, said method comprising applying a pulsed asymmetric electrical voltage to a decay-prone region of a said element over a prolonged time period.

Owner:MILJOTEKNOLOGI

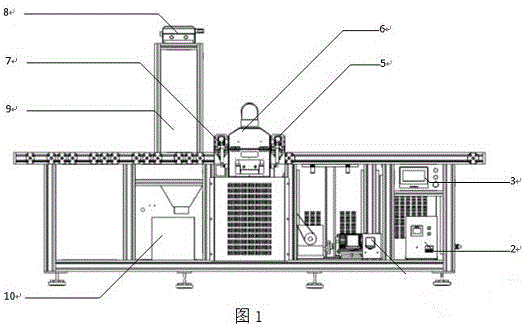

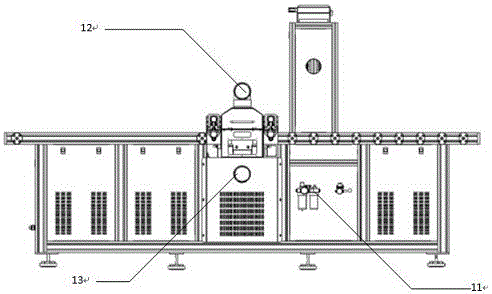

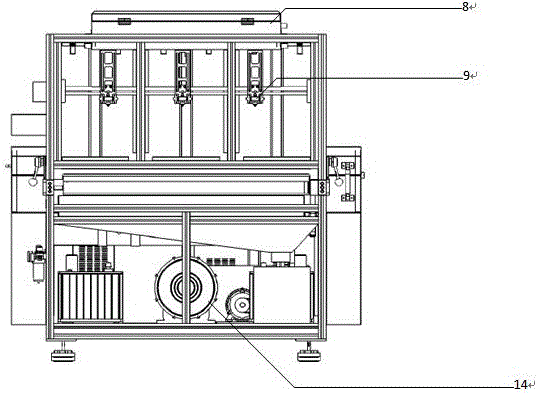

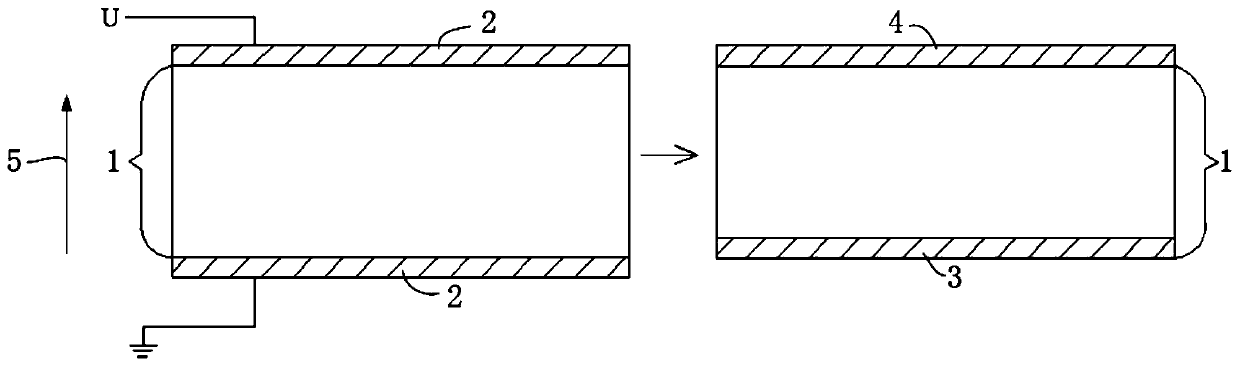

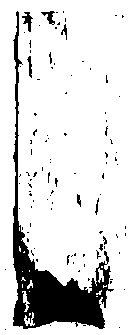

Low-glue-application-amount wood single composite low-temperature plasma processing equipment and operation method

InactiveCN106142265AReduce processing costsSimple and fast operationElectric wood treatmentWood treatment detailsEnvironmental resistanceEngineering

The invention discloses low-glue-application-amount environment-friendly wood single composite normal-pressure and low-temperature plasma processing equipment and an operation method thereof. According to the equipment, a machine body is formed by assembling profile frames; a low-temperature plasma electrode base station is mounted between a belt type conveying platform and a roller type conveying platform; the belt type conveying platform is mounted at the front end of the machine body and fixed on the profile frames; the roller type conveying platform is mounted at the tail end of the machine body and fixed on the profile frames; a trace glue application device is mounted on the profile frames, is located at the back end of the low-temperature plasma electrode base station and is located above the roller type conveying platform; a cooling fan is further arranged, is located in the machine body and is located below the low-temperature plasma electrode base station; an upper metal air collecting cover and a lower metal air collecting cover are further arranged outside the machine body; and a power device is further arranged. The invention further provides an operation method. The equipment is simple to operate, high in controllability and low in treatment cost.

Owner:NANJING SUMAN PLASMA TECH CO LTD

Processing method for improving hardness of cedar craft

ActiveCN107322721AImprove insect repellent effectGood antibacterial effectElectric wood treatmentMagnetic wood treatmentWater contentFood science

The invention discloses a processing method for improving the hardness of a cedar craft. The method comprises the following steps of (1) activating treatment, wherein a cedar product is immersed in a hormone solution and a plant alkaloid solution respectively to be subjected to immersion treatment; (2) antibacterial immersion, wherein the activated product is immersed in a sterilization solution to be subjected to vacuum steaming; (3) ionization treatment, wherein on-load voltages of 120-130 V and 150-156 V are used for ionization respectively, and two cycles of ionization treatment are carried out in the conditions of 92-97 DEG C and 115-120 DEG C; (4) magnetizing curing, wherein the ionized product is immersed in an alkaloid solution to be subjected to magnetizing treatment at the frequencies of 1-2 MPa and 3-4 MPa respectively; (5) drying, wherein the product is dried to the water content of 6-8% at 60-65 DEG C. According to the cedar craft processed by the method, the Rockwell hardness is improved by 116 HR, the tensile strength is improved by 29 MPa, the absorptive performance is reduced by 13.8%, and the flame retardance is improved by 25 S.

Owner:FUNAN NATURE ARTS & CRAFTS

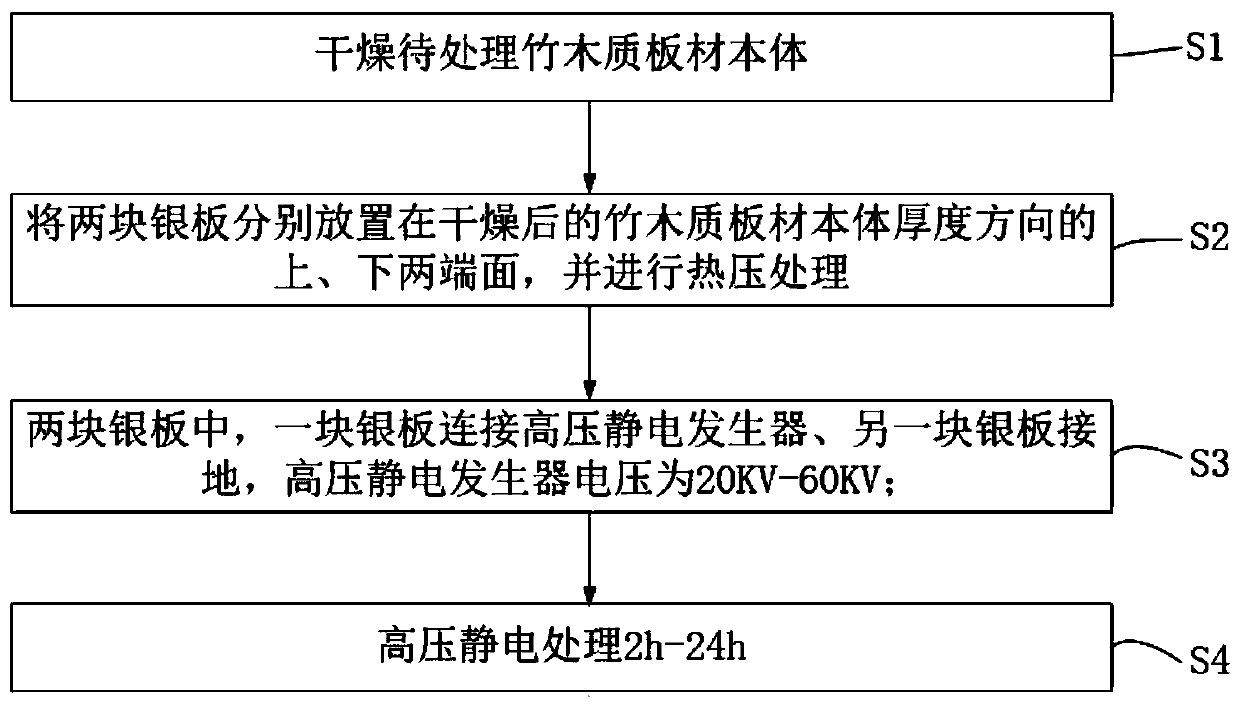

Bamboo material modifying method and bamboo plate

ActiveCN110202649AHigh modification treatment depthModification treatment is easy to operateLamination ancillary operationsElectric wood treatmentSilver plateHigh pressure

The invention discloses a bamboo material modifying method and a bamboo plate and belongs to the field of wood materials. According to the bamboo material modifying method, under the action of a 20-60KV high-voltage electrostatic field, high-voltage electrostatic treatment is carried out on a bamboo plate body with silver plates fitting on the upper and lower end faces. The bamboo plate after modified treatment sequentially comprises a nano-silver element permeation layer, a bamboo plate body, and a nano-silver element deposition layer / nano-silver element permeation layer in the thickness direction of the plate. The bamboo material after high-voltage electrostatic modified treatment has larger anti-corrosive and mildewproof treatment depth; the permeation depth of the nano-silver elementin the plate is 0.05-1mm; and the modified bamboo material is higher in anti-corrosive and mildewproof effect.

Owner:NANJING FORESTRY UNIV

Non-formaldehyde waterproof plastic film reinforced flexible decorative veneer and preparation method thereof

ActiveCN106272804AReduce heat stressLower bonding temperatureElectric wood treatmentSynthetic resin layered productsEngineeringPlastic film

The invention discloses a non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. Composting faces of a rotary cut or sliced decorative veneer and a plastic film are subjected to low-temperature plasma modification treatment, the treated composite faces of the decorative veneer and the plastic film are stacked to form composite blanks, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer is obtained through hot-press gluing. The invention further discloses a preparation method of the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. The product prepared by adopting the method releases no formaldehyde, no adhesive or gluing procedure is omitted, the production cost is lowered, the product suppleness is good, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer has the enough transverse tensile strength, will not cause glue penetration, is good in water resistance, saves energy, and is environmentally friendly, easy and convenient to operate and high in efficiency.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

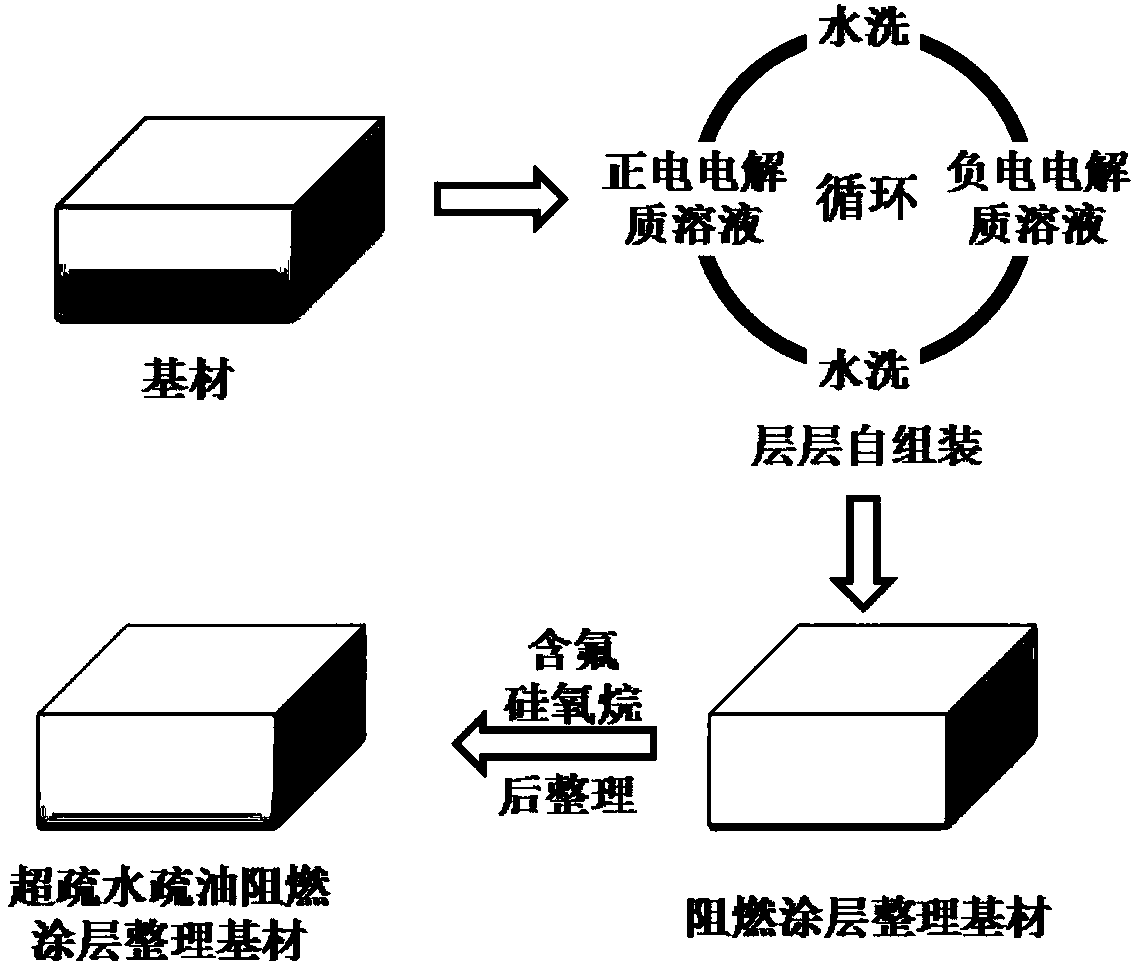

Method of super hydro-oleophobic flame retardant coating finishing base material

ActiveCN108505323AImprove flame retardant performanceNo negative effects of its own natureElectric wood treatmentWood treatment detailsSiloxanePolymer chemistry

The invention discloses a method of a super hydro-oleophobic flame retardant coating finishing base material. The method comprises the following steps: firstly, preparing a base material modified by 2to 30 bilayers by using a layer-by-layer self-assembly mode; secondly, carrying out after finishing on the treated base material by using a fluorine-containing siloxane solution and drying, thus obtaining a super hydro-oleophobic flame retardant coating on the surface of the base material. The base material finished by the method has the advantages of super hydro-oleophobic properties and excellent flame retardancy; the defects such as poor water resistance of an existing layer-by-layer self-assembly coating, damage to an internal structure of the material by a traditional flame retardant method and the like are overcome; the method of the super hydro-oleophobic flame retardant coating finishing base material is suitable for the super hydro-oleophobic flame retardant modification of materials such as fabrics, wood, foam and plastics.

Owner:UNIV OF SCI & TECH OF CHINA

Mouldproof modification treatment method of maize straws

ActiveCN106182250AImprove drying efficiencyTight organizationPressure wood treatmentElectric wood treatmentPre treatmentBiology

The invention discloses a mouldproof modification treatment method of maize straws. The method comprises the steps of: (1) pretreatment of the straws; (2) modification; and (3) drying. The method is scientific and reasonable in step matching; the treated maize straws are excellent in comprehensive performance; and compared with the prior art, the mould and insect preventing time of the maize straws is prolonged by 20-25%, the water absorption is reduced by 30% or above, the fire resisting temperature is increased by 30-40 DEG C, and the use stability and the life are better.

Owner:阜南县猛发工艺品有限公司

Anti-cracking treatment method for rattan

InactiveCN106393369APrevent peelingAvoid breakingElectric wood treatmentWood treatment detailsWarm waterLow temperature plasma

The invention discloses an anti-cracking treatment method for a rattan. The method comprises the following steps: treating the rattan in a dark environment of which the humidity is 65% to 68% and the temperature is 8 to 10 DEG C, and irradiating twice; subsequently soaking the rattan in warm water and putting in cold storage; dissolving chitosan in a saturated carbon dioxide water solution to prepare a solution for soaking the rattan; and treating the rattan by utilizing low-temperature plasma generated by dielectric barrier discharge at atmospheric pressure. In comparison with an existing rattan treatment method, the method disclosed by the invention has the advantages that a knitted product made from the rattan treated by the method disclosed by the invention is not deformed, free of cracks and very comfortable to skin in use; the bearing capacity is increased; the dimensional stability is good; decrustation of the rattan can be effectively prevented; after the rattan is knitted, the strength of the rattan is gradually restored and is increased by 2% to 3% in comparison with the original strength; the treated rattan is quite good in corrosion prevention effect, good in rattan softening effect and harder to mildew and damage in use; the knitted product prepared by the rattan treated by the method disclosed by the invention is free of mildew and worm damages and can be kept in the original color within at least 8 years.

Owner:阜南县环宇柳木工艺制品有限公司

Making-old treatment method for wooden product

ActiveCN106182263AGood removal effectEasy to operateElectric wood treatmentWood treatment detailsMedicinePre treatment

The invention discloses a making-old treatment method for a wooden product. The method comprises the first step of wooden product pretreatment, the second step of making-old treatment and the third step of drying quality keeping treatment. The method is overall simple and high in treatment efficiency, and the making-old treatment can be finished in one day. Compared with the traditional treatment manners in which the making-old treatment is finished in at least one week and even in one month, the work efficiency is greatly improved, and the manufacturing cost is reduced. The surface of the wooden product subjected to making-old treatment is smoother and more compact, the humidity resistance is better, and the water absorbing rate is reduced by about 15%. During using, the cracking rate is reduced by about 20%, the durable duration of the wooden product is prolonged by 10% or more, and the using value is high.

Owner:阜南县猛发工艺品有限公司

Preparation method for outdoor anticorrosive bamboo plate

InactiveCN108818870AAnti-corrosion and anti-mildew effectEffective colorNon-macromolecular adhesive additivesElectric wood treatmentAdhesiveWater resistant

The invention belongs to the technical field of anticorrosive bamboo plate processing, and specifically relates to a preparation method for an outdoor anticorrosive bamboo plate. The preparation method comprises the steps of carrying out impregnation treatment on acquired fresh bamboo materials, then drying the acquired fresh bamboo materials in an airtight environment, carrying out carbonizationtreatment, preparing a compound adhesive solution, and preparing the plate. Compared with the prior art, the preparation method has the following advantages: a boric acid aqueous solution or a boric acid aqueous solution containing ammonium polyphosphate is utilized for carrying out treatment under the action of a pulse current, so that the treatment time is greatly shortened, and anticorrosive and mold-proof effects in the strip bamboo materials are also achieved; and high-temperature carbon dioxide is utilized for drying intermediate materials, and then impregnation is carried out in the compound adhesive solution, so that the adhesive impregnation quality is ensured, the obtained bamboo plate is stable in quality and high in density, and has high water-resistant, anti-insect, mold-proofand weather-proof effects, the service life of the bamboo plate reaches 10 years and above in the case of being laid outdoors, and the mechanical property and the mold-proof effect of the bamboo plate cannot be influenced even if screws are used, so that the use range of the bamboo plate is expanded.

Owner:ANHUI HUOSHAN LONGXING BAMBOO IND MFR

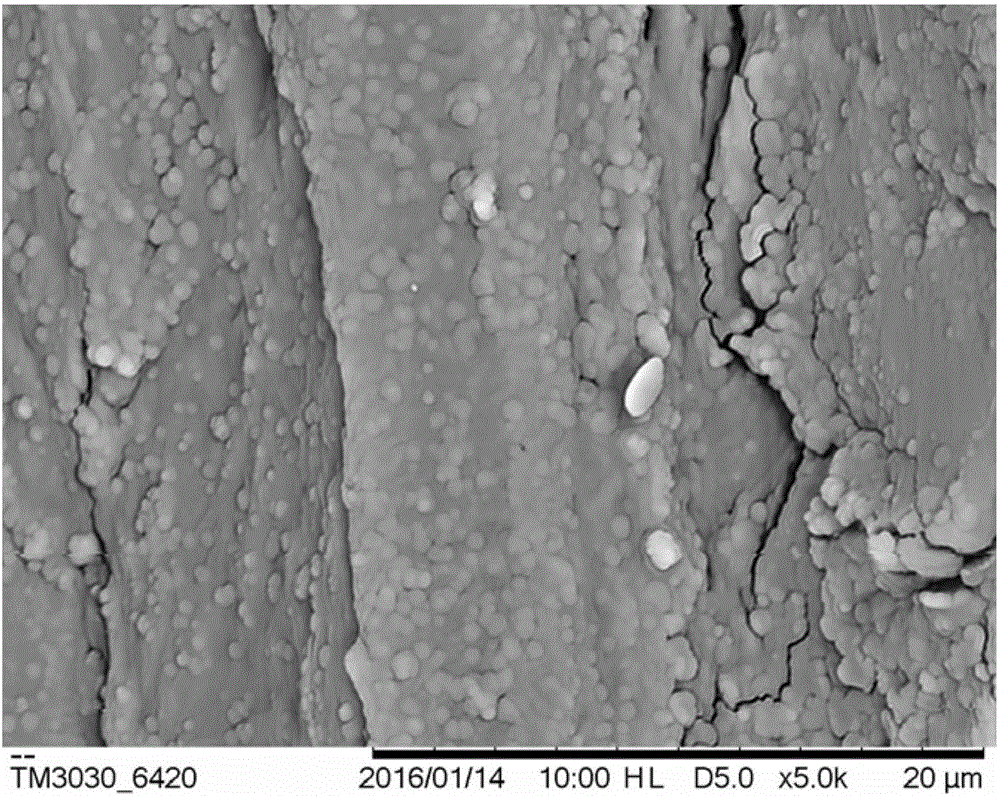

High-strength antibacterial wood preparation method and high-strength antibacterial wood

ActiveCN110253703AIncreased nanovoidsImprove adsorption capacityWood compressionElectric wood treatmentSulfite saltMildew

The invention discloses a high-strength antibacterial wood preparation method and a high-strength antibacterial wood. During the use, the mildew of wood is serious, such that the performances of the material are reduced, and the service life is shortened. According to the method, lignin and hemicellulose are removed from wood, the obtained wood is infiltrated with polyaniline, and the polyaniline-containing pretreated wood is placed in an electroplating solution and is electroplated to obtain a metal-plated wood complex; and the metal-plated wood complex is placed in a hot pressing machine, and is subjected to hot pressing. According to the present invention, lignin and hemicellulose are removed from wood by using a sodium sulfite solution so as to substantially increase the nanometer gaps inside the wood and improve the adsorption capacity of the wood; polyaniline is uniformly distributed inside the wood, such that the wood has electrical conductivity; and the hot pressing drying technology promotes the internal moisture of the wood to move to the outside.

Owner:HANGZHOU DIANZI UNIV

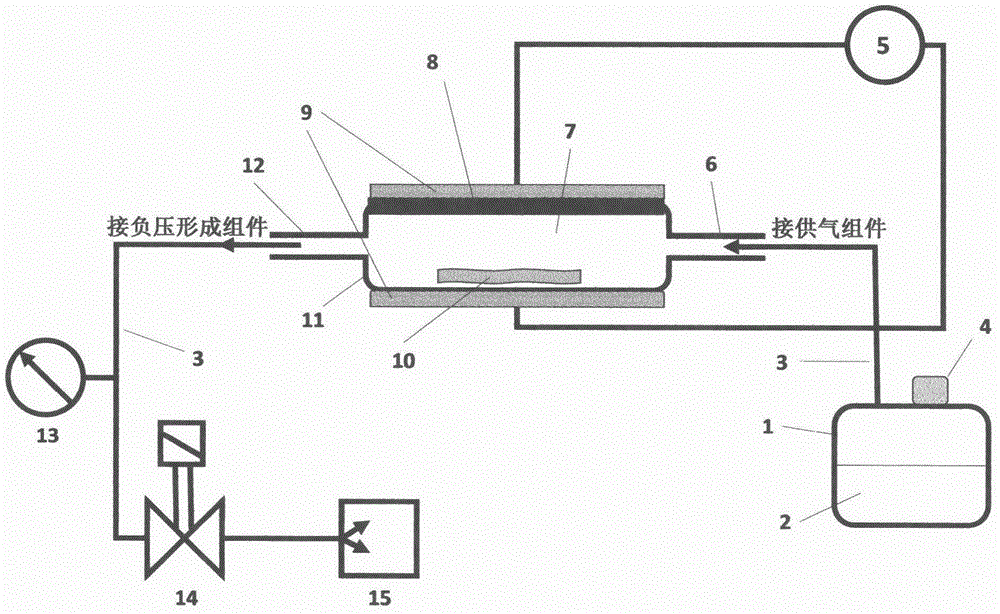

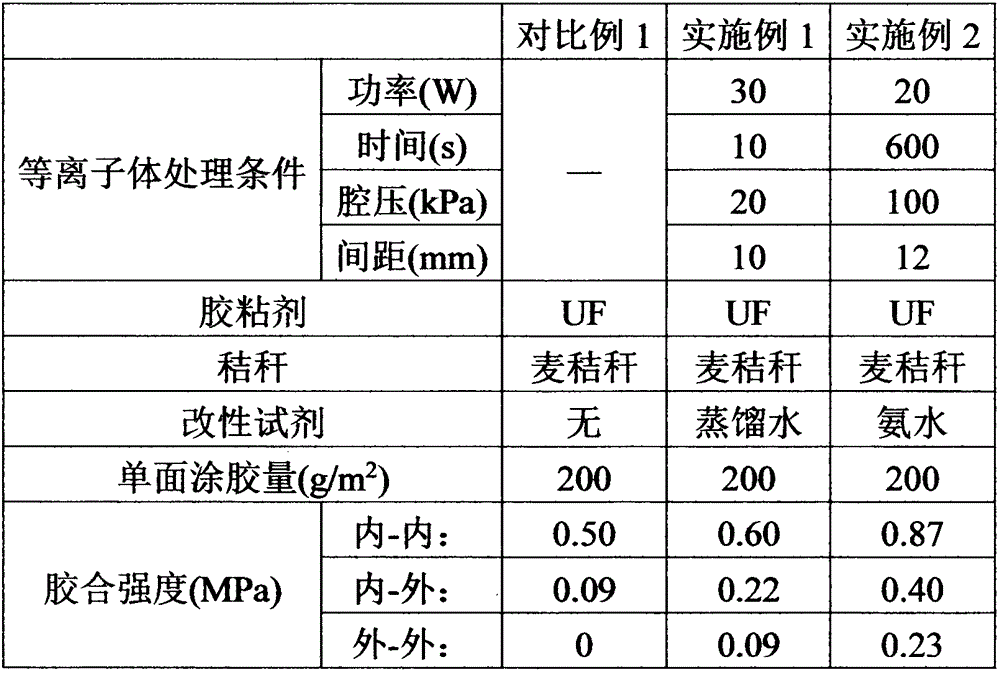

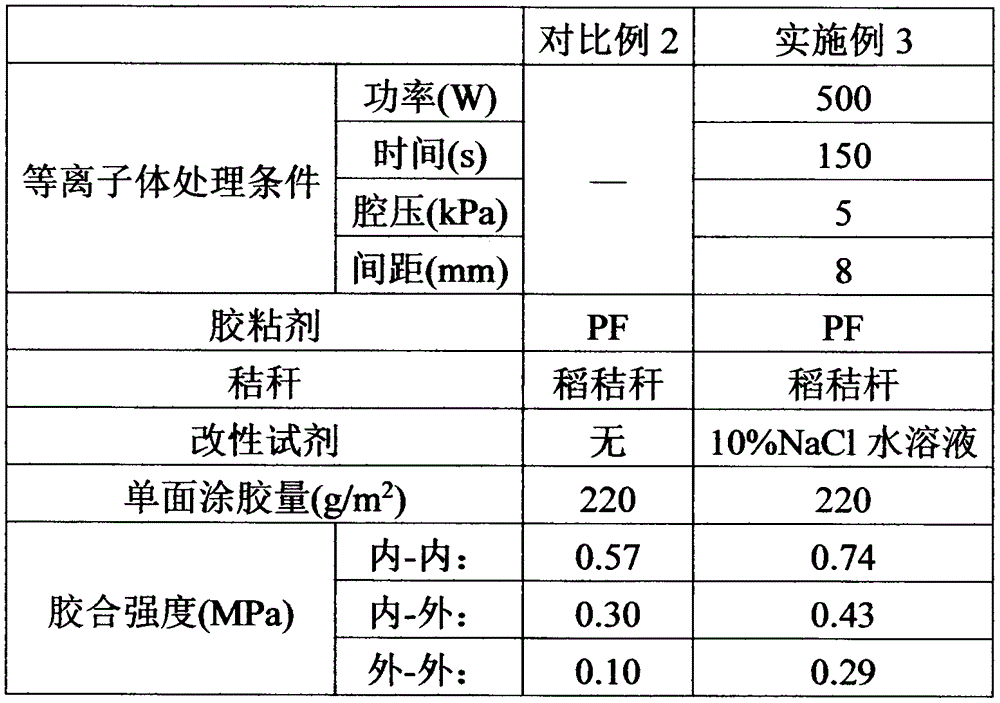

Method for enhancing bonding performance of crop straw through water vapor dielectric barrier discharge plasma

InactiveCN106079012ALow discharge powerImprove stabilityPressure wood treatmentElectric wood treatmentManufacturing technologyAdhesive

The invention relates to a method for enhancing the bonding performance of crop straw through water vapor dielectric barrier discharge plasma and belongs to the technical field of artificial board manufacturing. The process comprises the steps that leaves, sheaths and branch knots of the straw are removed, the straw is cut to be 2-30 cm long and subjected to softening and drying treatment, the moisture content is adjusted to be 6%-10%, and the straw is put into a quartz reaction cavity of special water vapor dielectric barrier discharge plasma for processing the straw; gas containing water vapor is introduced into the reaction cavity, the pressure inside the cavity is controlled to be 5-100 kPa through a vacuum pump, a plasma power source is started, the discharge power is adjusted to be 20-500 W, and the electrode interval is adjusted to be 5-12 mm, so that water vapor among electrodes is triggered and discharges electricity to generate the low-temperature plasma, and the surface of the straw is processed for 10-600 s continuously; and adhesives are applied to the surface of the processed crop straw and are curved after being subjected to hot pressing to reach the bonding strength. The method can remarkably improve the bonding performance between the inner surface and the inner surface of the straw, between the inner surface and the outer surface of the straw as well as between the outer surface and the outer surface of the straw and improve the quality of straw board products, and the equipment is simple, easy to operate, capable of saving energy, efficient, environmentally friendly and free of pollution.

Owner:NANJING FORESTRY UNIV

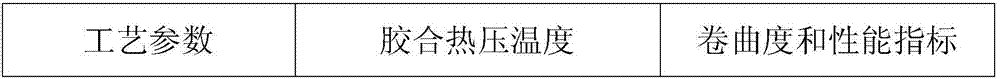

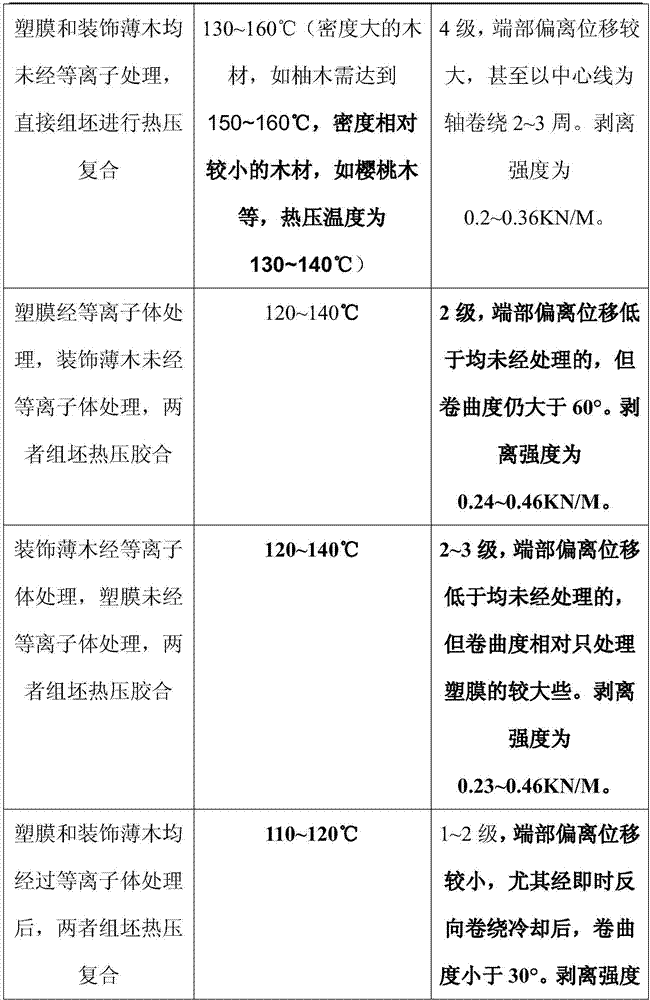

Method for improving interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification

ActiveCN107030802AResolve curlSolve discolorationLayered product treatmentElectric wood treatmentAdhesiveEngineering

The invention discloses a method for improving the interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification. The method sequentially comprises the following technology steps that surface pretreatment of the decorative veneer, low-temperature plasma treatment of the surface of the decorative veneer, low-temperature plasma treatment of the surface of a plastic film, assembly and hot pressing of the decorative veneer and the plastic film, and facing hot-pressing of the plastic-film-reinforced flexible decorative veneer. By the adoption of the method for improving the interface bonding performance between the composite flexible decorative veneer and the surface facing through plasma modification, woodwork surface facing is conducted through the plastic-film-reinforced flexible decorative veneer manufactured through plasma modification treatment, an adhesive is not needed, the procedure of applying the adhesive can be omitted, the bonding strength of the facing surface of the product can be improved by 10%-70%, the adhesive force of a paint film can be improved by 20%-40%, the production cost can be reduced by 10%-50%, energy is saved, environmental friendliness is achieved, operation is easy and convenient, and efficiency is high.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Antique finishing treatment method for date wood

InactiveCN106272783ADoes not affect internal structural strengthLess corrosiveElectric wood treatmentWood treatment detailsPulp and paper industryLow temperature plasma

The inventiondiscloses an antique finishing treatment method for date wood. The method comprises the steps as follows: primary surfacetreatment, immersion, painting of a photocatalyst, secondary surfacetreatment, low-temperature plasma treatment and stability enhancement. The antique finishing treatment method for the date wood adopts a multi-step treatment process and can efficiently perform antique finishing on the date wood, antique finishing is uniform, the antique finishing effect is natural, treatment is more deep and thorough, the quality is high, and the antique finishing treatment time can be shortened and is shortened by 35% or more compared with a common antique finishing treatment method for the date wood. With the adoption of the treatment method, by the aid of immersion and coordination of the components, the antique finishing effect can be improved, andthe corrosion resistance of wood can be improved; the surface of the date wood is coated with the photocatalyst, and a plasma arc lamp is adopted for uniformly irradiating the surface of the date wood, the primitive simplicity of the surface of the date wood can be improved, uniform and natural texture can be formed on the surface of the date wood, the treated date wood surface is uniform and natural, and more significantly, the color sense and the hand feel after antique finishing can be enhanced.

Owner:安徽三和工艺品有限公司

Preparation method of high-strength bamboo shoot shell packing materials

InactiveCN108214725AHigh adsorption activityHigh bonding strengthFlexible coversWrappersAdhesiveCorona discharge

The invention relates to a preparation method of high-strength bamboo shoot shell packing materials and belongs to the technical field of packing material preparation. According to the preparation method, firstly through a molecular sieve dewaxing principle, the surface of a bamboo shoot shell is subjected to dewaxing treatment, molecular sieve powder absorbing bamboo wax, lemon juice and bacterial suspension liquid are mixed for fermentation, then fermentation products and nickel boride are mixed and react in a high-pressure reaction kettle to obtain a reinforced material, and then the reinforcing material, urea resin and starch paste are utilized to prepare an adhesive. Then the surface of the dewaxed bamboo shoot shell is subjected to corona treatment, after the adhesive is applied, hotpressing is conducted, and thus the high-strength bamboo shoot shell packing paper is obtained. According to the preparation method, the surface of the bamboo shoot shell is subjected to corona treatment, corona discharge is utilized, low-temperature plasma is generated, thus free radicals are generated on the surface of the bamboo shoot shell, so that crosslinking occurs, the surface of the bamboo shoot shell is coarsened, the wettability to the modified adhesive is improved, the free radicals generated on the surface of the bamboo shoot shell can generate intermolecular adsorption and hydrogen bond adsorption with active groups in the modified adhesive, and the mechanical strength of a plate is improved.

Owner:黄旭东

Wood surface hydrophobic treatment method

ActiveCN107379179AImprove corrosion resistanceEffective combinationRadiation/waves wood treatmentElectric wood treatmentMicrowaveWorking life

The invention discloses a wood surface hydrophobic treatment method and relates to the technical field of wood treatment. The wood surface hydrophobic treatment method comprises the following steps: (1) pre-treatment; (2) microwave treatment; (3) vacuum impregnation; (4) low-temperature plasma treatment; when wood is treated through the wood surface hydrophobic treatment method disclosed by the invention, not only can the hydrophobic properties of wood surfaces be effectively improved, but also the corrosion resistance of the wood surfaces can be effectively improved, so that the application range and the working life of the wood can be effectively improved.

Owner:安徽嘉美工艺品有限公司

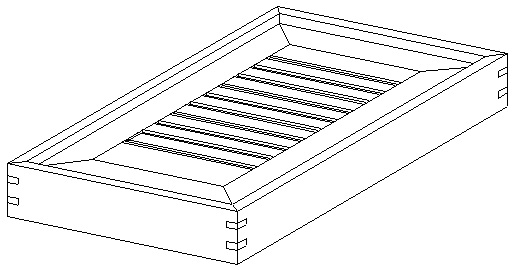

Manufacturing method for waterproof bamboo tea tray

ActiveCN108568884AExtended service lifeImprove qualityElectric wood treatmentBio-packagingEpoxyEcological environment

The invention discloses a manufacturing method for a waterproof bamboo tea tray. Firstly, a bamboo sheet / dodecyltrimethoxysilane water resistance composite material board is prepared, and then a bamboo tea tray is prepared and is subjected to sealing and filling treatment, and finally, a finished product of the waterproof bamboo tea tray is obtained; a bamboo sheet is soaked in a dodecyltrimethoxysilane water resistance solution for dipping to make the bamboo sheet have the excellent effect of water resistance and mildew resistance. Tenons and mortises of tea tray members are coated with hydroxymethyl resorcinol and mono-component moisture curing polyurethane glue to achieve sealing treatment of the end face of the bamboo tea tray; a connection gap between the members and unevenness of a board surface are filled with bamboo powder with 160-240 meshes and AB epoxy glue with surface dry of 30 minutes; and therefore, the problem of easy water seepage, cracking and mildewing of the bambootea tray in a current market can be effectively solved, the quality of the bamboo tea tray is improved, the service life of the bamboo tea tray is prolonged, the waste of bamboo wood resources is avoided, the added value of bamboo wood is raised, a forest and ecological environment are protected, and economic, social and ecological benefits are good.

Owner:FUJIAN AGRI & FORESTRY UNIV

Teak discoloration treatment method

InactiveCN107471358ADilute the colorFast discolorationElectric wood treatmentWood treatment detailsLight treatmentLow temperature plasma

The invention discloses a teak discoloration treatment method, and relates to the technical field of wood treatment. The treatment method comprises the steps: (1) surface modification; (2) low-temperature plasma treatment; and (3) light treatment; according to the treatment method disclosed by the invention, teak is soaked in an isocyanato modified solution for treatment, so that auxochromes, such as carbon base, vinyl, methoxyl and carboxyl, in chromophoric groups of the teak surface are effectively reacted physically, and precipitation pigments of the wood surface can be dissolved to a certain extent; and at the same time, black streaks and spots can be removed effectively through active groups in the isocyanato modified solution, and the original color of the wood is diluted.

Owner:安徽三和工艺品有限公司

Processing technology of fireproof and heat insulation pine solid door

ActiveCN107139303AImprove mildew resistanceExtended service lifeElectric wood treatmentWood treatment detailsSolid woodPulp and paper industry

A processing technology of a fireproof and heat insulation pine solid door comprises the following steps that (1) after pine is processed to the corresponding shape and dimension according to the boundary dimension of the solid door, clear water is used for washing away wood bits and other impurities, and a solid door blank is obtained; (2) the solid door blank is put into an electrolyte to be subjected to electrolytic treatment; (3) the solid door blank obtained after electrolytic treatment in the step (2) is put into a vacuum dryer to be subjected to drying treatment; (4) the outer surface of the solid door blank obtained after drying treatment in the step (3) is coated with an inner coating; (5) after the inner coating is naturally aired, coating of a middle layer is achieved; and (6) after the middle layer is naturally aired, coating of an outer coating is achieved, and the pine solid door is obtained. The pine solid door manufactured through the processing technology is long in service life and smooth in surface, and the coatings are not prone to sliding off.

Owner:广东煜丰实业(集团)有限公司

Manufacturing method of nanometer titania formaldehyde-reduced bamboo plywood

InactiveCN107984574APhotocatalytic degradation of formaldehydeAnti-corrosionMaterial nanotechnologyElectric wood treatmentMelaminePolyresin

A manufacturing method of nanometer titania formaldehyde-reduced bamboo plywood includes the following steps of (1) sulfonation treatment of nanometer titania, (2) cold plasma treatment of bamboo veneers, (3) preparation of the bamboo veneers with the surfaces loaded with the nanometer titania, and (4) preparation of the nanometer titania formaldehyde-reduced bamboo plywood, specifically, the prepared bamboo veneers with the surfaces loaded with the nanometer titania are cut into a certain size according to requirements, single-face gluing is conducted by adopting urea resin or melamine urea-formaldehyde resin, longitudinal and transverse crossing laying is conducted according to the laying requirements of common plywood, the veneers are displayed for 10-30 min after laying, and then the veneers are subjected to hot pressing by being placed in a hot pressing machine, so that the nanometer titania formaldehyde-reduced bamboo plywood is obtained. According to the manufacturing method ofthe nanometer titania formaldehyde-reduced bamboo plywood, the titania is distributed evenly, operation is simple, the loading quantity is large, and the titania is firmly combined with wood and bamboo materials.

Owner:ZHEJIANG FORESTRY ACAD

Pollution-free treatment method for improving weathering resistance and amphiphobic performance of wood

ActiveCN106426447AImprove the efficiency of weathering performance treatmentReduced sputtering process timeElectric wood treatmentWood treatment detailsOctadecyltrichlorosilaneOxygen

The invention provides a pollution-free treatment method for improving the weathering resistance and the amphiphobic performance of wood, relates to a wood surface treatment method, and solves the problem that a conventional method for improving the weathering resistance and the amphiphobic performance of wood is long in using period, and organic raw materials have toxicity. The treatment method comprises the following steps that 1, plasma cleaning is conducted on the wood; 2, the cleaned wood is placed in a magnetron sputtering apparatus for pre-sputtering; 3, oxygen and argon are introduced, after elemental titanium is oxidized into titanium dioxide ions in the glow state, the wood is sputtered at the power of 300-400 W, the power is adjusted to 100-150 W, and ion sputtering treatment is continued to obtain wood sputtered with a titanium dioxide layer; and 4, the sputtered wood is soaked in an octadecyltrichlorosilane solution, and the soaked wood is dried finally. The sputtering material, namely elemental titanium, is nontoxic, the whole sputtering treatment time is shortened greatly, and the weathering resistance treatment efficiency of the wood is improved.

Owner:WENZHOU UNIV OUJIANG COLLEGE

Method for processing wood fibers by plasma for reinforcing interface bonding capacity of fiber plate

InactiveCN107009478AReduce processing powerShort processing cycleElectric wood treatmentWood treatment detailsEnvironmental resistanceWood fibre

The invention provides a method for processing wood fibers by plasma for reinforcing the interface bonding capacity of a fiber plate, relates to a method for preparing the fiber plate by blending and hot pressing, and mainly solves the problems that a conventional manufacturing method of wood fiber products harms the environment, and is high in cost and inadequate in processing. The method comprises the following steps of I, drying the wood fibers until the water ratio of the dried wood fibers is 8%-15%; II, placing the dried wood fibers in a reaction kettle, turning on a plasma generator, and adjusting the working parameters of a plasma power source to be 50-60V and 10-25Hz; III, performing gaseous medium surface treatment, and controlling the injecting capacity of gaseous mediums to be 2-3L / h; IV, maintaining the stable plasma state for 2.5-5min; V, turning off the plasma generator, and opening the reaction kettle; and VI, taking out the wood fibers from the reaction kettle, so as to obtain a finished product, wherein high mechanical properties between the finished product and xylogen are obtained, and the bonding capacity of the finished product and the xylogen is improved by about 30%. According to the method disclosed by the invention, the plasma is adopted to process wood fibers so that the interface bonding capacity is reinforced; no chemical preservative is added; the technology is succinct; and the product is green and pollution-free, and is beneficial to environmental protection.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com