Manufacturing method for waterproof bamboo tea tray

A manufacturing method and technology of bamboo tea, applied in manufacturing tools, flat products, reed/straw treatment, etc., can solve problems affecting the quality stability of bamboo tea trays, reduce the service life of bamboo tea trays, waste bamboo resources, etc., and achieve excellent waterproof and waterproof Mildew effect, solution to water seepage, cracking and mold, effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

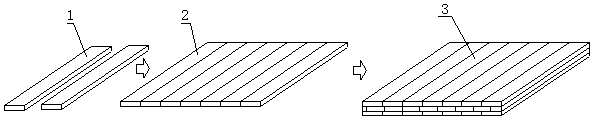

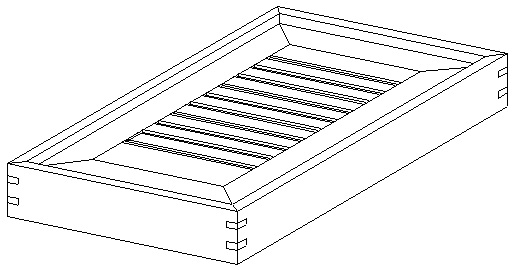

[0029] see Figure 1-2 , a method for manufacturing a waterproof bamboo tea tray, firstly preparing a bamboo chip / dodecyltrimethoxysilane waterproof composite material board, then utilizing the bamboo chip / dodecyltrimethoxysilane waterproof composite material board to prepare a bamboo tea tray and carrying out Sealing and filling are performed to obtain the final finished waterproof bamboo tea tray.

[0030] The preparation method of bamboo chip / dodecyltrimethoxysilane waterproof composite material board is:

[0031] 1) Slices: Moso bamboo slices, length 500-1000 mm, width 3-18 mm, thickness 2-12 mm;

[0032] 2) Planing: planing the bamboo slices on all sides;

[0033] 3) Surface browning: Put the planed bamboo chips in step 2) into a brown surface treatment container for surface browning. The conditions for browning treatment are: steam pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com