Patents

Literature

953results about "Thermal wood treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

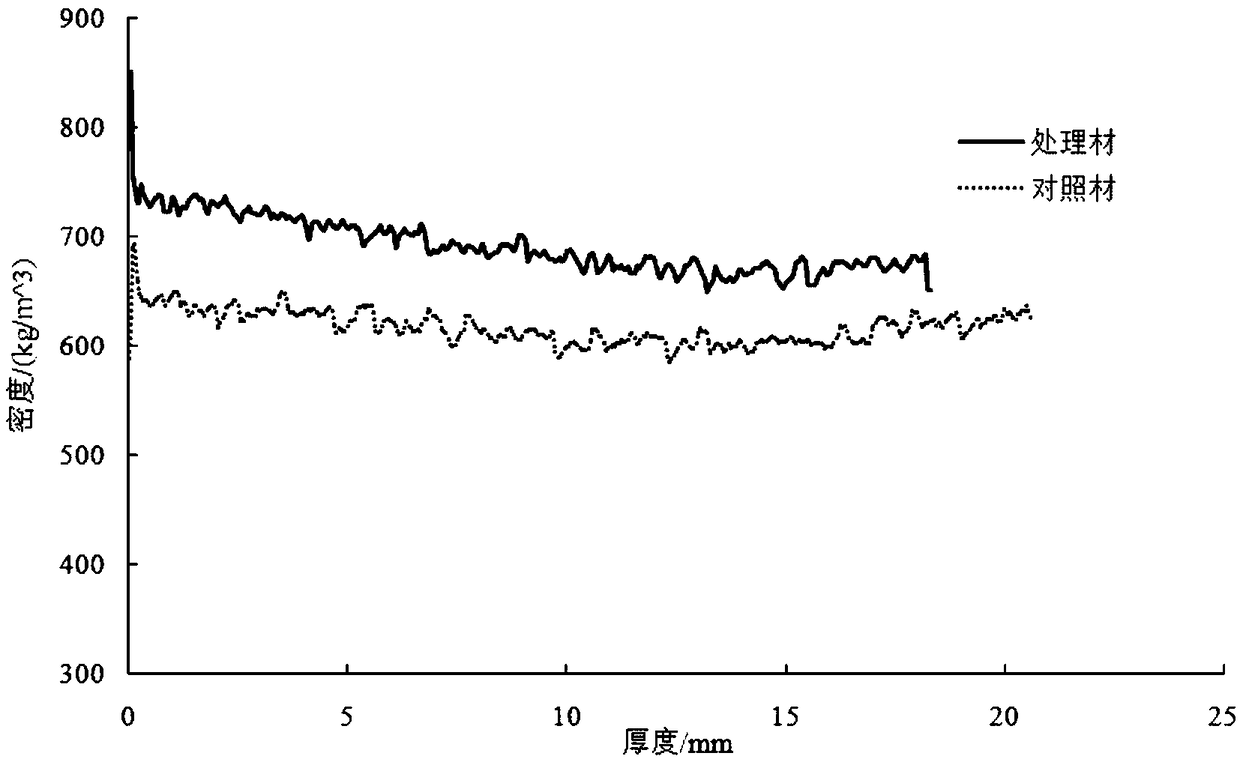

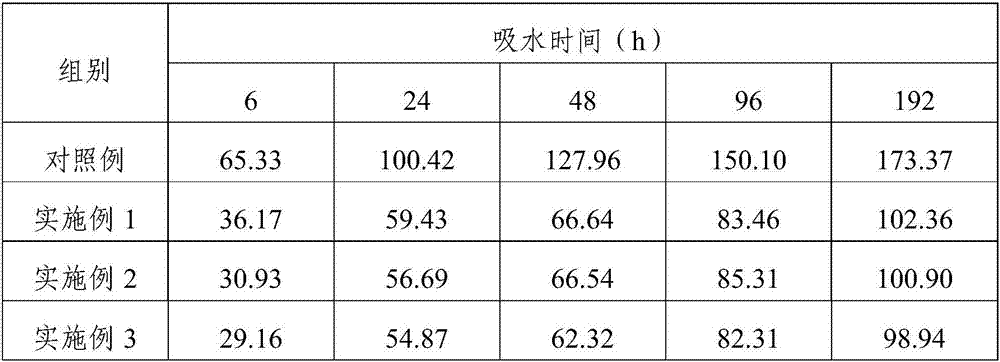

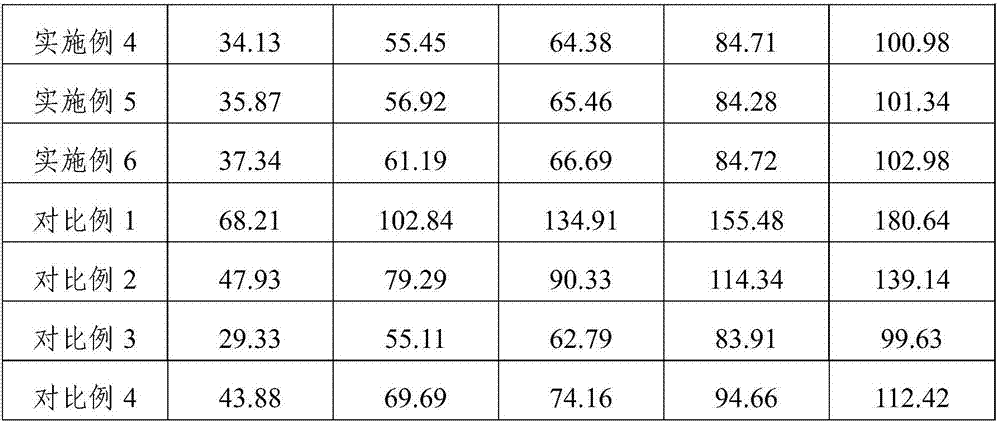

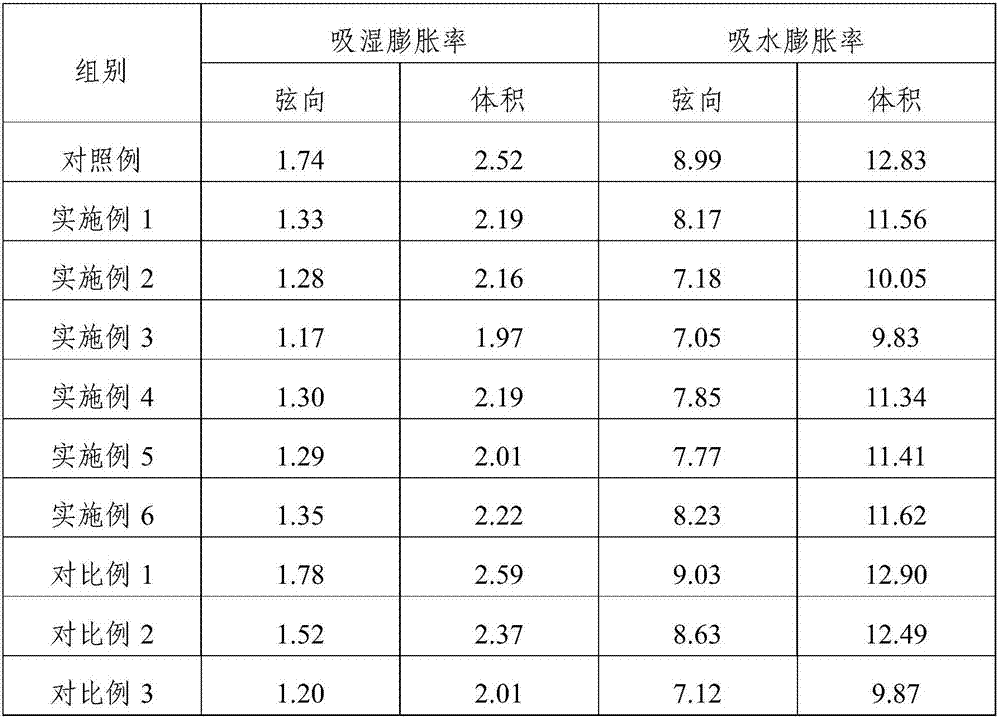

Enhanced high-temperature heat treated wood and manufacturing method thereof

InactiveCN104985657AGood dimensional stabilityReduce moisture absorptionWood treatment detailsThermal wood treatmentPulp and paper industryResin adhesive

The invention discloses enhanced high-temperature heat treated wood and a manufacturing method thereof. The manufacturing method comprises the following steps that 1, high-temperature heat treatment is performed, wherein man-made forest wood serves as raw materials, and high-temperature heat treatment is performed on the man-made forest wood to obtain heat treated wood; 2, impregnation enhancing treatment is performed, wherein the heat treated wood obtained by the step 1 is impregnated in resin adhesives to obtain impregnated wood; 3, solidification forming treatment is performed, wherein solidification forming treatment is performed on the impregnated wood obtained by the step 2 to obtain the enhanced high-temperature heat treated wood. According to the manufacturing method, not only can the mechanical properties of the wood be improved, but also the size stability of the wood can be improved, green and environmental protection are achieved, and the prepared enhanced high-temperature heat treated wood takes the man-made forest wood as the raw materials and is high in mechanical strength and good in size stability.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

Method for Treating Wood and Wood-Based Materials, and Wood and Wood-Based Materials Obtainable Therewith

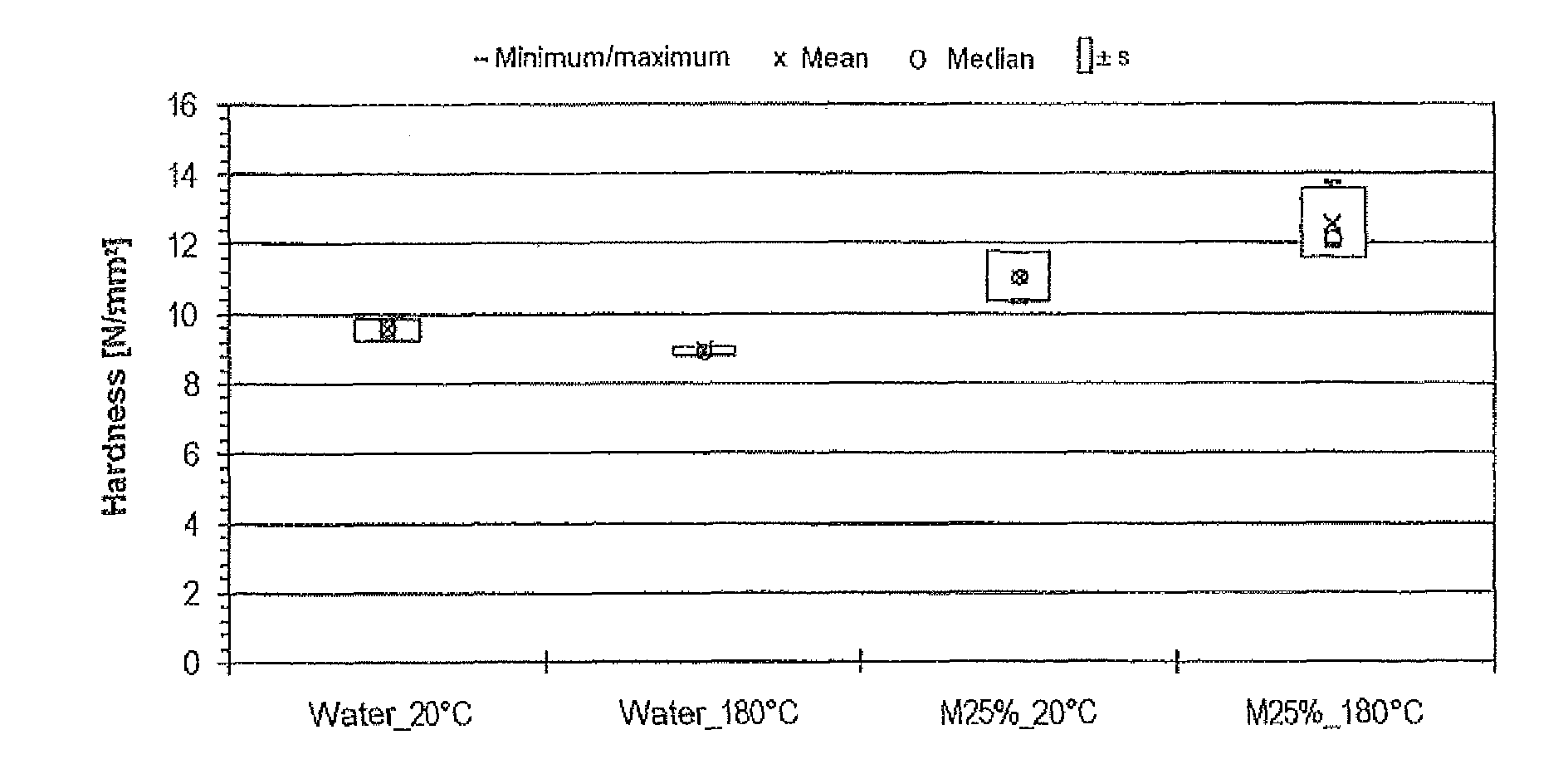

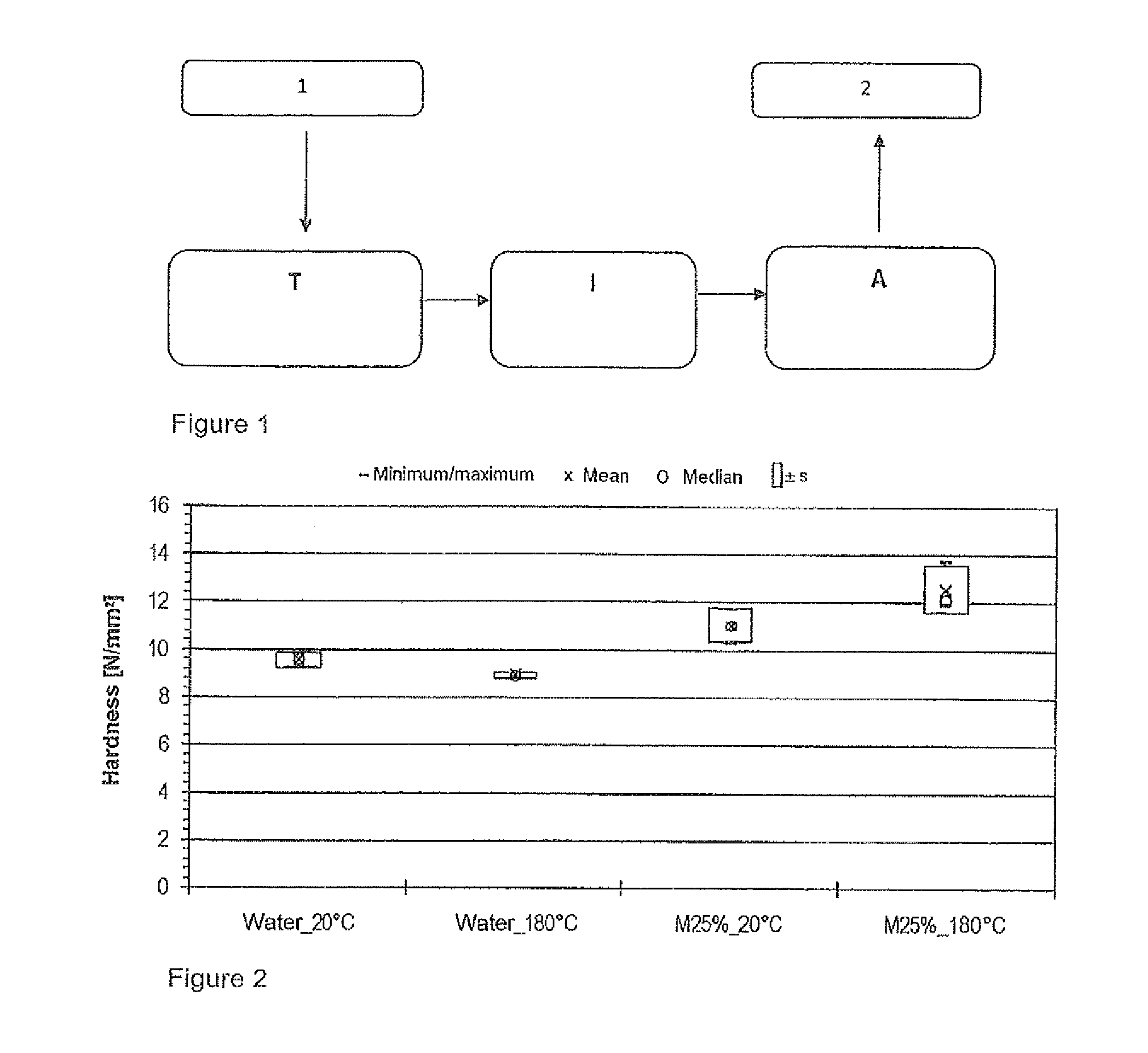

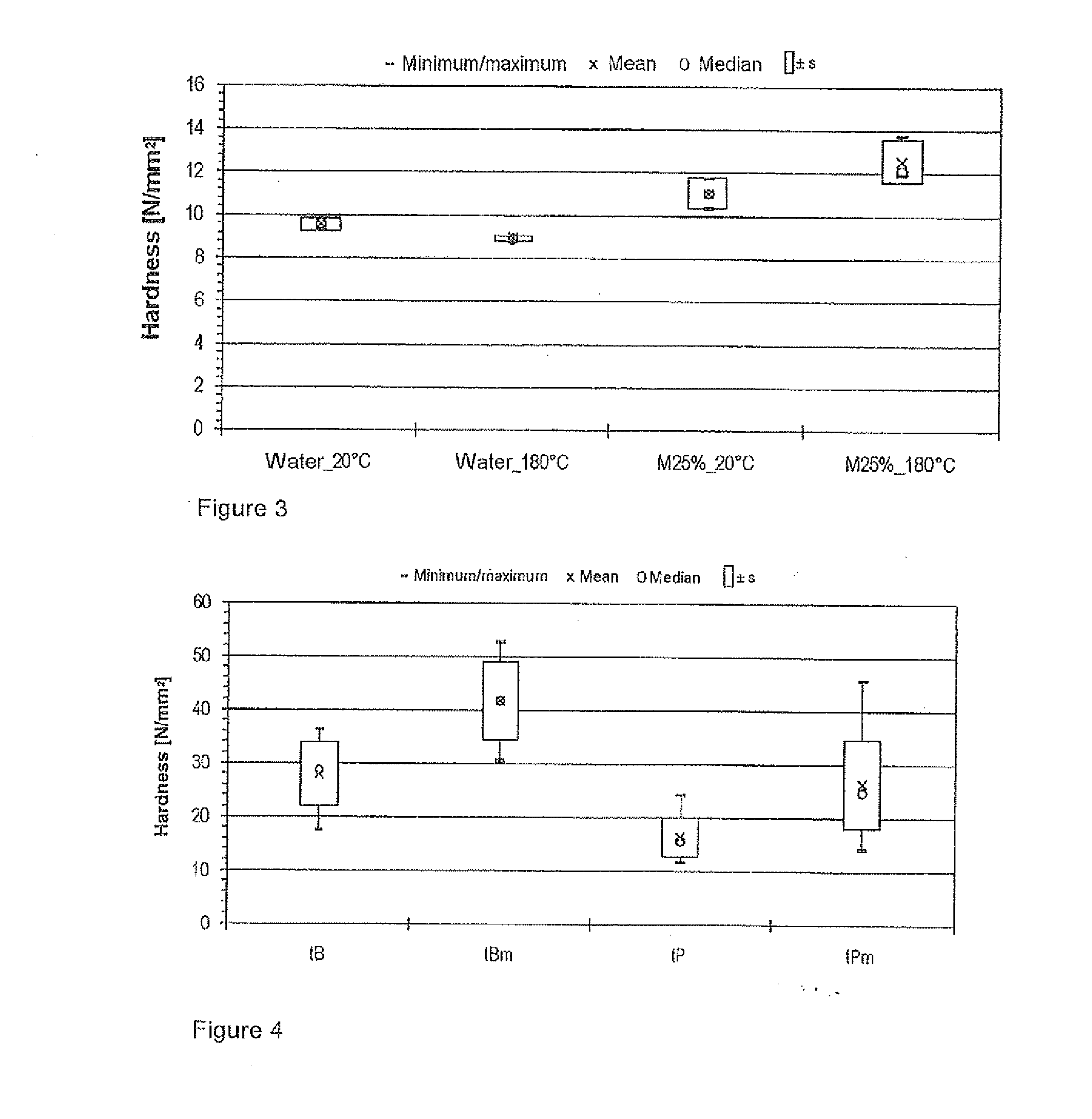

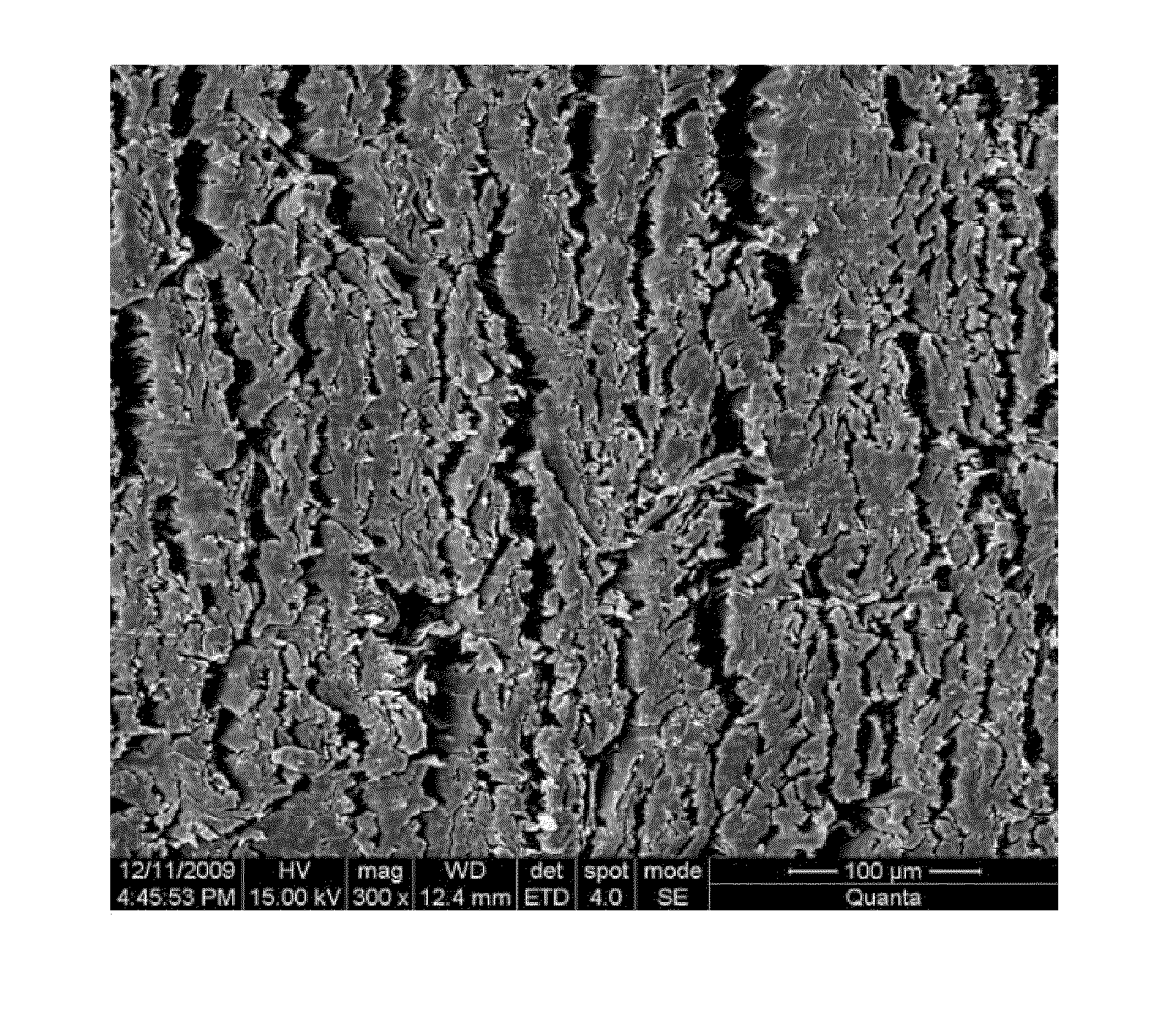

InactiveUS20130298814A1Improve propertiesImprove stabilityNon-magnetic metal hullsHull decksHardnessMelamine

The present application relates to a method for treating wood and wood-based materials for enhancing dimensional stability and surface properties and also for preventing cracking and extending durability. More specifically the invention for the treatment of wood and wood-based materials is directed to a method wherein the wood or wood-based material is subjected to a thermal treatment and the wood or wood-based material is at least partly impregnated with a melamine-containing resin. Subsequently the wood or wood-based material thus impregnated is cured with hot steam at not more than 125° C. preferably up to a maximum of 120° C. In a further aspect the present application includes the thermally treated wood or wood-based material, impregnated with melamine resin and cured, that is obtainable from the method of the invention. The present invention lastly provides for the use of melamine-containing resin for impregnating wood and wood-based materials which are or have been thermally modified, for the purpose of increasing the hardness and reducing the dimensional change through thermal modification. The material produced in accordance with the invention can be used as a substitute for teak.

Owner:GEORG AUGUST UNIVERSITAT GOTTINGEN STIFTUNG OFFENLICHEN RECHTS +1

Type of wood section material and its manufacturing method

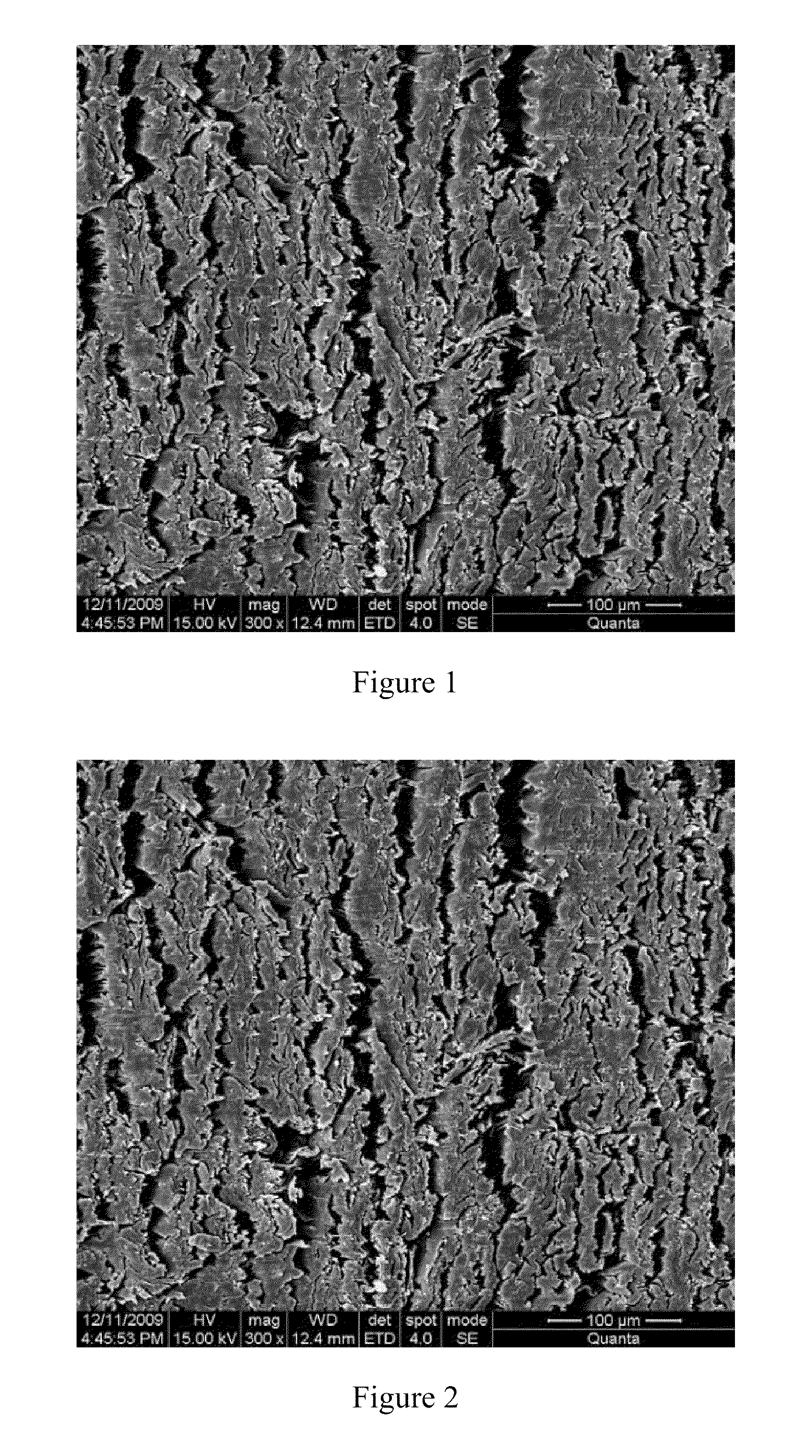

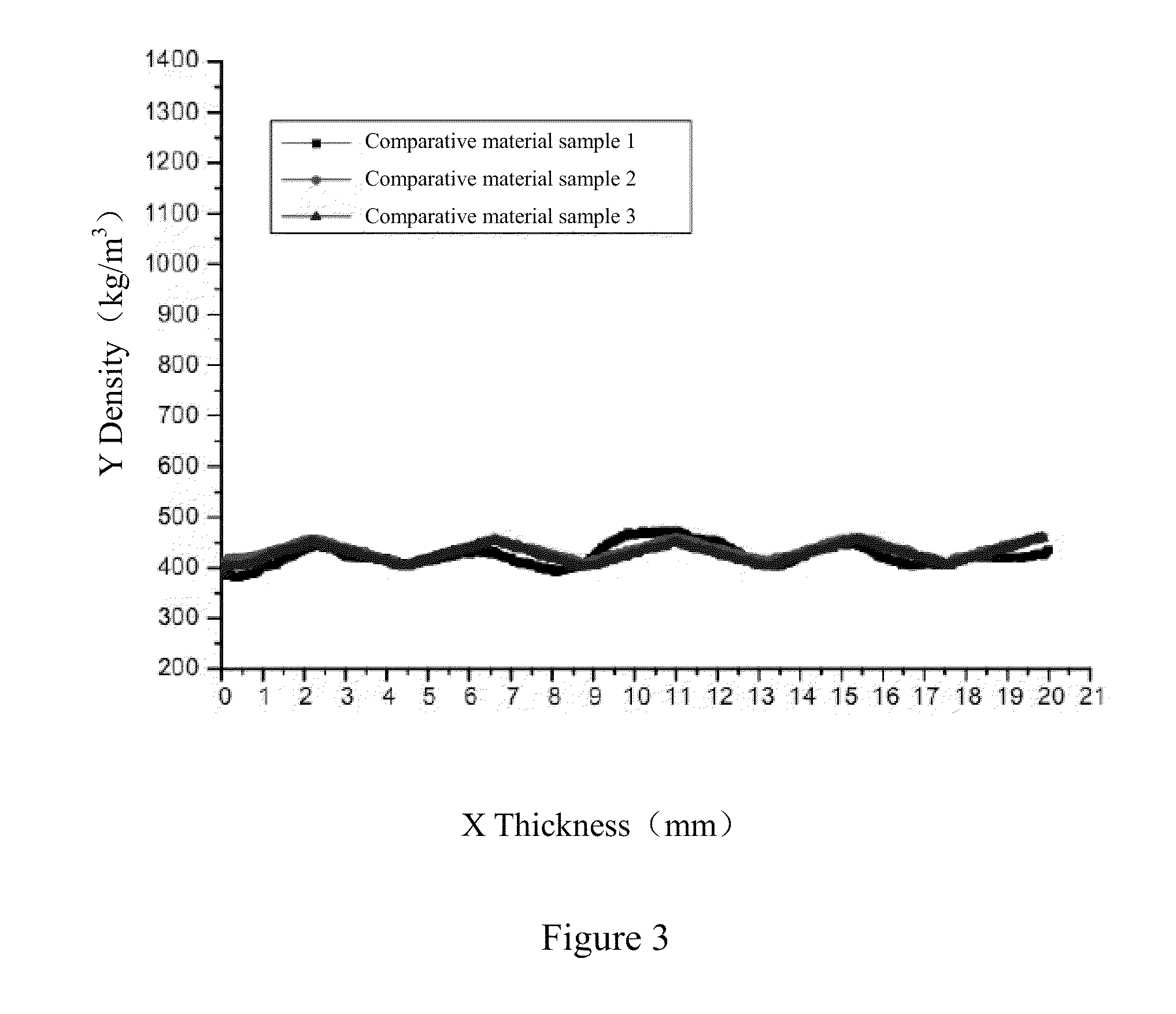

ActiveUS20110262727A1Easy to useLow densityThermal wood treatmentWood layered productsWood machiningCarbonization

The present invention relates to a type of wood section material manufacturing method, especially with respect to soft wood section material and its manufacturing method. It belongs to wood processing field. This invention is achieved by the following technical plans: a type of wood section material manufacturing method includes the following steps: (1) wood preparation; (2) drying; (3) Polishing; (4) Hot pressing, which is to use two hot pressing boards with 140-200° C. to firmly press two surfaces of panel blank material; (5) Pre-carbonization, which pre-carbonize the panel blank material under 160° C. and 200° C.; (6) Carbonization, which carbonize the panel blank material between 200° C. and 225° C.; (7) Cooling; and (8) Moisture content control. This invention is particularly suitable to make wooden floor boards and office furniture.

Owner:TU DENGYUN +1

Processing technology for moso bamboo for bamboo-woven basket

InactiveCN105904556AHigh strengthImprove toughnessPressure wood treatmentWood treatment detailsFiberHigh pressure

The invention provides a processing technology for moso bamboo for a bamboo-woven basket. The processing technology comprises the following steps that the moso bamboo freshly cut is placed into a refrigeration house with the temperature ranging from 10 DEG C to 15 DEG C to be frozen; the frozen moso bamboo is taken out and subjected to high-temperature processing for 30-60 min, the processing temperature ranges from 120 DEG C to 150 DEG C, and then the moso bamboo is placed in a closed pressure processing tank to be subjected to high-pressure processing; and the root of the moso bamboo subjected to high-pressure processing is cut away, bamboo breaking is conducted through a bamboo breaking machine, a bamboo skin is formed and tailored according to the specification of a needed bamboo-woven product, then, the tailored bamboo skin is dried, and the water content of the bamboo skin is not larger than 4%. The operation of the processing technology is easy to achieve. The moso bamboo processed through the processing technology is used for weaving the bamboo-woven product, the mould proof, high-temperature resisting and severe cold resisting capability and the anti-yield strength of the bamboo-woven product can be greatly improved, and the connection strength of bamboo fiber is obviously improved.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

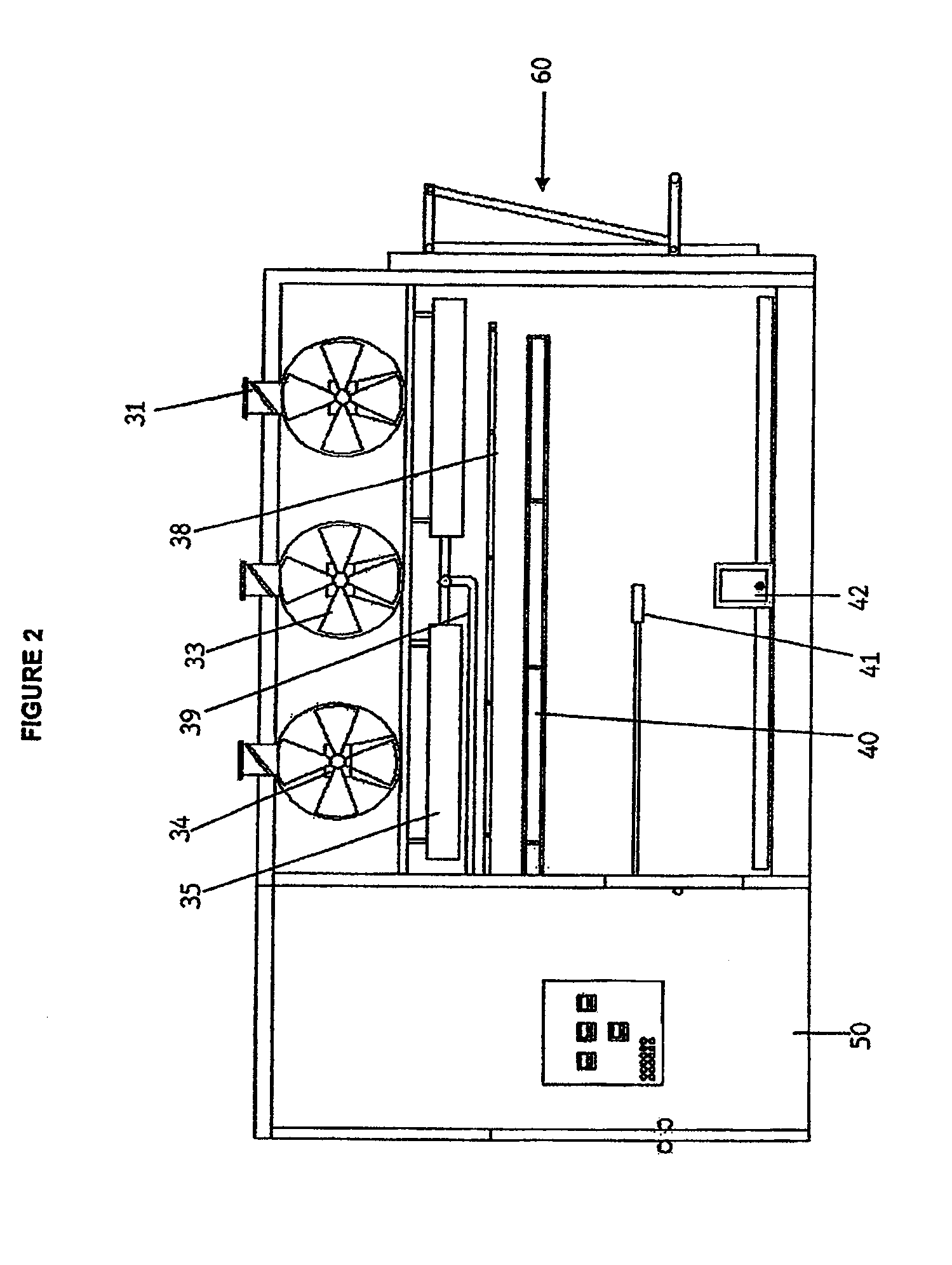

High temperature lumber treatment system

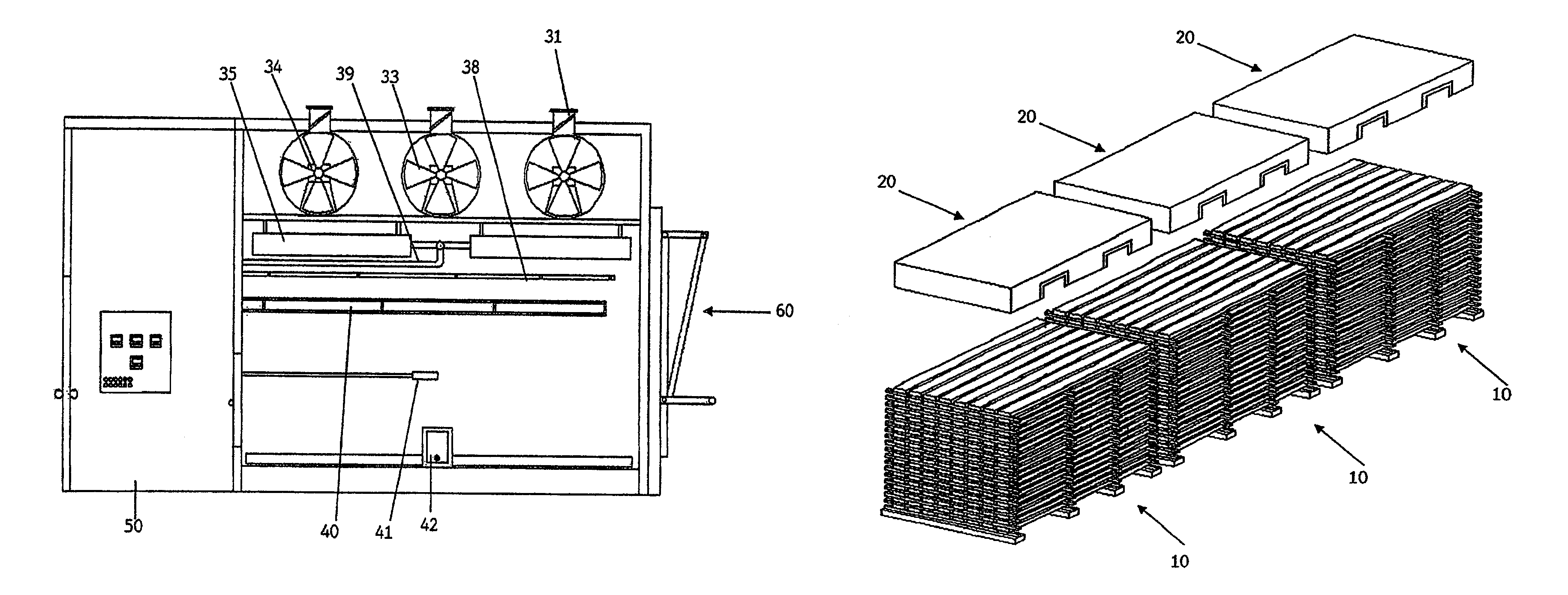

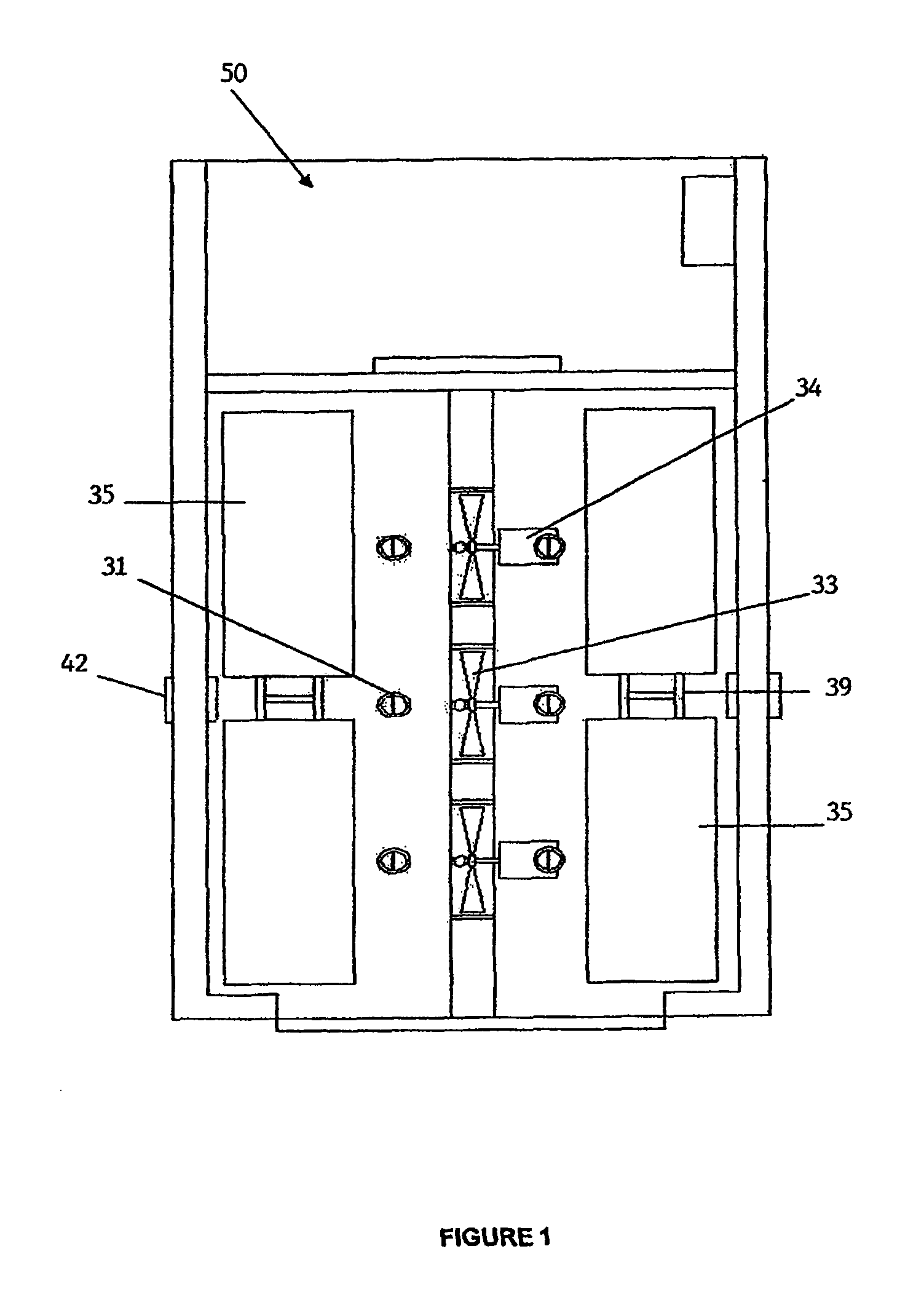

ActiveUS8397400B2Minimize build-upShorten the timeAgriculture tools and machinesDrying using combination processesProcess engineeringEquilibrium moisture content

High-temperature method for the treatment of lumber, the method comprising the steps of providing stacks (10) of lumber, restraining those stacks, subjecting the stacks to a first conditioning phase, drying the stacks in an air stream at a temperature of not less than 120° C., cooling the stacks and subsequently subjecting the stacks to a second conditioning phase, and further cooling the dried stacks in ambient temperature air stream. A kiln for use in the high-temperature lumber treatment method of this invention, comprises a chamber (30) for receiving stacks of lumber, heat supply means to produce and supply heated air and steam for drying and conditioning the stacks, heat exchange means (35) to provide and maintain a stable and sustained temperature environment within the chamber, humidification means to provide and maintain a predetermined equilibrium moisture content within the chamber, air stream generation means (33, 34) to provide a sustained and uniform flow of air within the chamber, and control means for monitoring and controlling various drying parameters within the chamber.

Owner:FOREST RES INST MALAYSIA FRIM

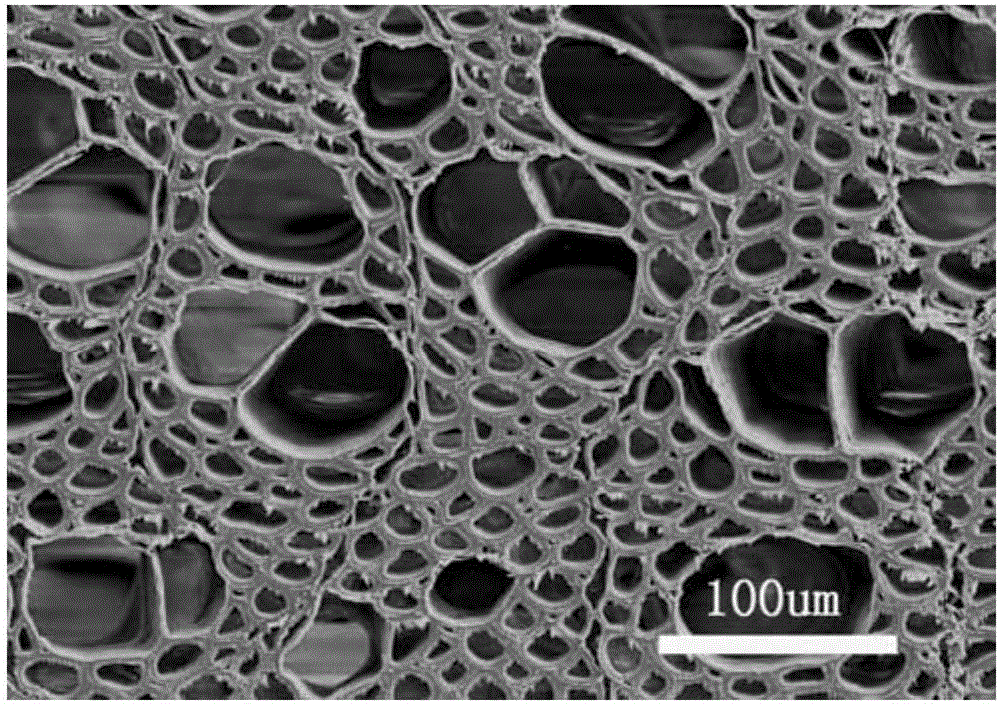

Production method of compressed compact carbonized wood

InactiveCN106493815AEasy to operateHigh strengthPressure wood treatmentWood compressionCelluloseCarbonization

A production method of compressed compact carbonized wood relates to wood modification methods and mainly solves the problem that existing wood modification methods cannot improve the mechanical strength and the waterproof dimensional stability of wood. The method comprises, I, wood softening pretreatment including immersing and heating wood in a pretreatment solution and then washing the wood to obtain softened wood, II, softened wood compression, and III, high-temperature wood carbonization. The production method of the compressed compact carbonized wood can solidify compressed deformation of wood, avoid resilience and reinforce cellulose framework structures to strengthen wood. Wood modified through the method obtains obvious enhancement in mechanical strength and dimensional stability. The production method of the compressed compact carbonized wood is applied to wood modification.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

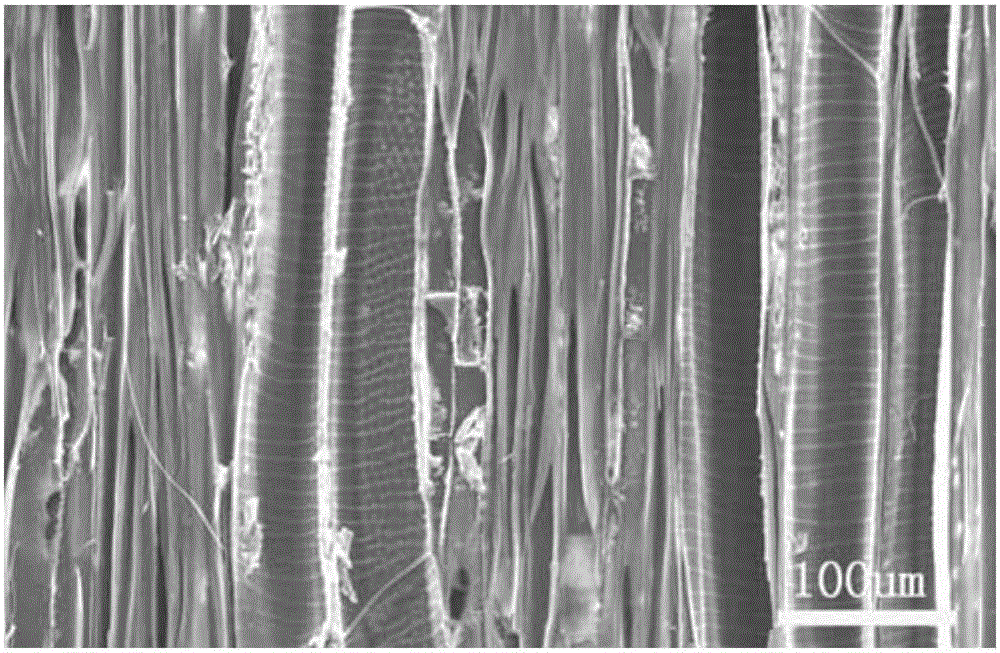

Wood compression-in-situ pressured heat treatment integrated method and compressed wood prepared through method

ActiveCN108582377AAvoid bubblingUniform temperature distributionPressure wood treatmentWood compressionPulp and paper industryDouble stage

The invention discloses a wood compression-in-situ pressured heat treatment integrated method and compressed wood prepared through the method. The method comprises the first step of the drying stage,the second step of pavement, the third step of heating, the fourth step of double-stage pressure compression treatment, the fifth step of heat treatment, the sixth step of stress relief and the seventh step of unloading. By means of the wood compression-in-situ pressured heat treatment integrated method and the compressed wood prepared through the method, the integral compression quality of the wood can be greatly improved, compression rebound of the wood can be controlled, the treated wood flatness is improved, no chemical pollution exists in the treatment process, the production cost is low,operation is simple and convenient, and the beneficial effects of high efficiency, environment friendliness and the like are achieved. Integral compression and deformation perpetual fixing of wood are achieved. By means of the method, the mechanical performance and size stability of the wood can be improved, and meanwhile the defects that anti-bending strength and screw holding force of wood subjected to heat treatment are poor are overcome.

Owner:GUANGXI NANNING QIAOSHENG WOOD

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for treating preservative-treated wood

ActiveUS7246452B1Avoid leachingDrying using combination processesDrying gas arrangementsPreservativePulp and paper industry

There is provided a method for treating preservative-treated wood such that the preservative is substantially prevented from leaching. The treatment comprises drying of the preservative-treated wood until the moisture content of the wood is below a level capable of supporting the diffusion of the preservative.

Owner:ROY JACQUES

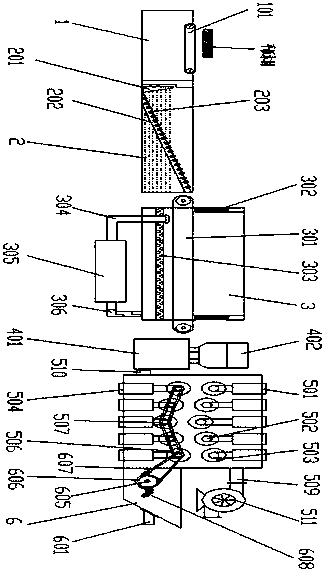

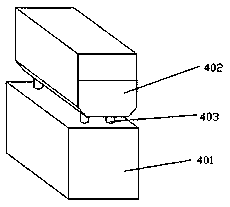

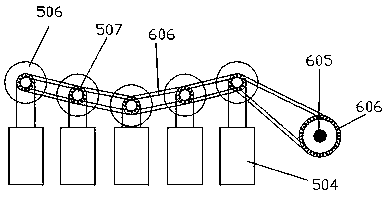

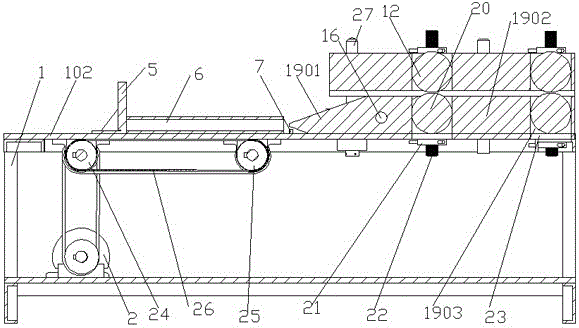

Multi-deflection bending shaping device and bending shaping method for furniture wood processing

InactiveCN110271069AImprove accuracyAvoid deformationPressure wood treatmentWood treatment detailsClamp connectionDrive shaft

The invention discloses a multi-deflection bending shaping device for furniture wood processing. The device is composed of a material inlet platform, a soaking tank, a fumigation box, a heat-preservation levelling platform, a bending shaping box and a material outlet platform, the material inlet platform is provided with a first conveyer belt, a second conveyer belt is obliquely arranged in the soaking tank, a third conveyor belt and a steam spray pipe are arranged in the fumigation box, and the heat-preservation levelling platform is composed of a base seat, lifting rods and a lifting platform; the interior of the bending shaping box is connected with each first hot pressing roller through one corresponding first hydraulic rod and is connected with each second hot pressing roller through one corresponding second hydraulic rod, driven gears of the second hot pressing rollers are connected with a driving gear chain of a driving shaft, and the bending shaping box communicates with a hot air fan; and a slide groove of a bottom plate in the material outlet platform is in clamp connection with a T-shaped supporting foot of a motor, and the motor is connected with a horizontal push rod. The device provided by the invention realizes a bending shaping method of soaking, steam fumigation, low-pressure levelling, repeated hot roll bending and repeated hot roll shaping, is suitable for wood with different deflection, and has high bending and shaping efficiency, and high accuracy, and the shaped wood is not easy to deform.

Owner:利辛县爱侣家俱加工有限公司

Mouldproof and mothproof treatment method for wood

ActiveCN104441130AReduce moisture contentImprove mildew resistanceWood treatment detailsThermal wood treatmentHuman bodyAfter treatment

The invention relates to a mouldproof and mothproof treatment method for wood. The mouldproof and mothproof treatment method comprises the following steps: (1) processing wood at 85-90 DE C for 3 hours under the condition that the relative humidity is 48%-50%; (2) fumigating the wood with a 35% acetate solution at 1-1.5MPa and 105 DEG C for 30-45 minutes; (3) preparing a treating fluid; (4) soaking the wood treated in the step (2) with the treating fluid at 35 DEG C for 2 hours; (5) treating the wood surface treated in the step (4) with quick lime; and (6) treating the wood processed in the step (5) at 78 DEG C for 3 hours under the condition that the relative humidity is 25%-38%. The mouldproof and mothproof treatment method for the wood provided by the invention is simple; heavy metal is not used in the treatment process; no components which pollute a human body or the environment are generated after treatment; pollution is avoided; meanwhile, the treatment time is shortened to a few hours; and the treatment efficiency is greatly improved.

Owner:阜南佳利工艺品股份有限公司

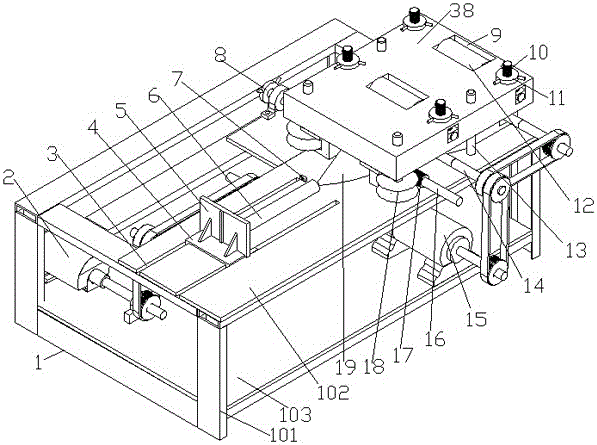

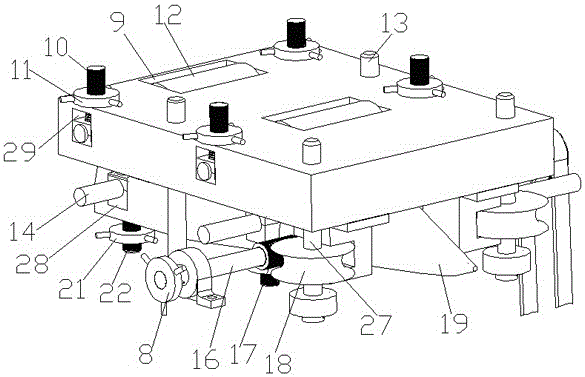

Moso bamboo extrusion-flattening processing device and method

ActiveCN106272768ASolve the problem of serious decline in physical and mechanical propertiesHigh technology contentWood treatment detailsCane mechanical workingElectric machineryDrive motor

The invention relates to a moso bamboo extrusion-flattening processing device and a moso bamboo extrusion-flattening processing method. The moso bamboo extrusion-flattening processing method comprises the following steps: segmenting fresh moso bamboos, removing inner and outer joints, notching, soaking in hot water, softening by baking at high temperature, and sending into a moso bamboo extrusion-flattening device to prepare a large-breadth extrusion-flattened bamboo board. The moso bamboo extrusion-flattening processing device comprises a machine frame, a feeding device and an extrusion-flattening device, wherein the machine frame comprises a frame body, a machine table and a platform; the extrusion-flattening device comprises an extrusion-flattening tongue plate, a driving motor and a lifting platform; the front end of the extrusion-flattening tongue plate is a conical part; the back end of the extrusion-flattening tongue plate is a flattening part; lower pressing rolls are arranged inside the flattening part; upper pressing rolls matched with the lower pressing rolls are arranged inside the lifting platform; lower pressing roll rotating shaft at one ends of the lower pressing rolls are in belt or chain transmission with the output shaft of the driving motor; the feeding device is positioned in front of the extrusion-flattening tongue plate. Through the moso bamboo extrusion-flattening processing device and the moso bamboo extrusion-flattening processing method, the problems that in the current bamboo flattening processing process, the flattened bamboo board is small in breadth size and serious in decline in physical and mechanical properties are solved, and the scientific and technological content in the bamboo product industry and the added value of a product are comprehensively increased.

Owner:FUJIAN AGRI & FORESTRY UNIV

Board softening and mould proofing method

InactiveCN106182286AGuaranteed flexibilityNatural colorRadiation/waves wood treatmentWood treatment detailsSodium bicarbonateFiber

The invention discloses a board softening and mould proofing method. Softening and mould proofing are carried out at the same time, the treatment period is short, the method is simple, the working efficiency is improved by 15.3%, batch treatment can be carried out, softening and mould proofing are carried out through three steps, the effect is durable, traces are not left, and the cost is saved by 14.2%. A board is soaked with fermentation liquor, generated micromolecule matter can change the organization structure, fibers are initially softened, restraining on growth of infectious microbes is achieved, and deep pigments are dissolved; the board is soaked with a Chinese drug solution, rapid permeability is achieved, outside-to-inside even antibiosis is achieved, the using amount is small, antibacterial treatment can be carried out after diluting with water, safety and high efficiency are achieved, the cost is low, and the effect is durable; the board is subject to ultrasonic soaking with a sodium bicarbonate solution, antibiosis and disinfection are carried out, blots are removed, mould proofing and moth proofing are carried out, and the fibers are softened; and the board is dried in a low-temperature and low-humidity room, so that the pliability of the board is kept, preparation is facilitated, the fracture rate is reduced by 6%, the color and luster of the board can be kept natural, even and new, and color and luster treatment in the later period is facilitated.

Owner:阜南县创发工艺品有限公司

Production and treatment process of solid wood furniture

InactiveCN106976142AImprove product qualityNo cracking deformationWood treatment detailsThermal wood treatmentSolid woodWax

The invention discloses a production and treatment process of solid wood furniture. The process comprises cutting, mildewproof treatment, wax boiling, finish polishing, painting assembly and aftertreatment; the cutting is to cut furniture logs into multiple assembly blocks according to the shape and the structure of the furniture; the mildewproof treatment is to treat assembly blanks by a mildewproof process and to dry to reach the water content of lower than 10%; the pressure planing and tenoning step is to use a pressure planing machine for polishing the dried blanks to produce mortise-tenon joint structures; the blanks are polished to become concentrates; after a primer is sprayed on the surfaces, the concentrates are cooled for drying; and the concentrates are assembled as a product. The process is reasonable; and the produced solid wood furniture is excellent in product quality, is not deformed by cracking, reinforces the mildewproof capacity, and is stable in performance and long in service life.

Owner:张强

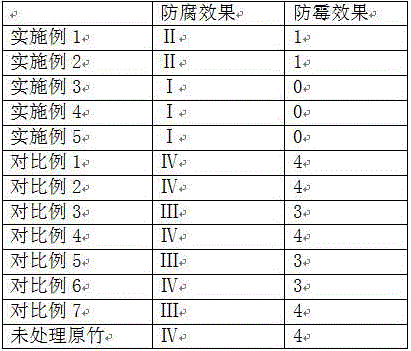

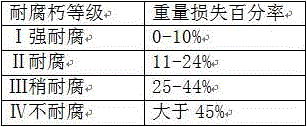

Antiseptic and mildewproof treatment technology for bamboo

ActiveCN106671234AIdeal Saturation Injection EffectExtended stayPressure wood treatmentWood treatment detailsVacuum pressureEngineering

The invention belongs to the field of bamboo treatment and relates to an antiseptic and mildewproof treatment technology. The technology comprises the following steps that (1), the fresh bamboo is dried to be with the water content of 12-15%; (2), the dried bamboo is put into a vacuum pressure tank, the vacuum degree of the vacuum pressure tank is controlled to be over 0.08 MPa, and the treatment time ranges from 35 min to 50 min; (3), a protective agent is added to the vacuum pressure tank; (4), a vacuum pump is closed, a pressure pump is started, the pressure is made to be in the range of 1.2-1.8 MPa, and treatment is conducted for 50-70 min under the condition of keeping the pressure; and (5), the pressure is relieved, and the protective agent is drained. According to the antiseptic and mildewproof treatment technology for the bamboo, for the characteristic of the bamboo, the technological processes of drying, high-pressure, vacuum, pressurization and vacuum are adopted, in combination with the protective agent special for the bamboo, the protective agent can be effectively permeated into the bamboo from bamboo inner rings (inner of the bamboo) with the high nutrient content and the low density, the ideal protective agent saturation injection effect is achieved, the protective agent stays in the bamboo for a long time and is not easy to drain, and the long-term protective effect can be played.

Owner:安吉竹境竹业科技有限公司

Method for dyeing rattans with plant-based black dye

ActiveCN107336314AImprove permeabilityImprove surface activityRadiation/waves wood treatmentElectric wood treatmentActive agentWarm water

The invention discloses a method for dyeing rattans with plant-based black dye. The method is characterized by comprising the steps that (1), softening is performed, wherein the rattans are soaked in warm water firstly and then soaked in a softener solution to be subjected to ionization treatment; (2), dyeing is performed, wherein the rattans are soaked in an active agent solution for 2-3 h, and then dyeing and drying are performed and repeated for 3-4 times; (3), color protection treatment is performed, wherein the rattans are subjected to atomization treatment with a color fixative; (4), fixation is performed, wherein the fixation treatment is conducted on the rattans needing color protection by ultraviolet light and mixed mud; and (5), air-drying is performed, wherein the dye-fixed rattans are dried to the moisture content of 7%-10%, and then the rattans are coated with paraffin oil and air-dried. Compared the rattans produced through the method with a control group, the content of the dye in the rattans is increased by 61.5 mg / 100 g, the discoloration test time is prolonged by 55 h, and the bending rate is increased by 7.8%.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Processing method for bamboo strip

InactiveCN104400848AAvoid deformationImprove stabilityWood treatment detailsReed/straw treatmentDrugs solutionThermal treatment

A related processing method for a bamboo strip comprises the following steps: (1) bundling up bamboo strips; (2) preparing a processing solution; (3) putting the bamboo strip bundle prepared in the step (1) into the processing solution for processing, keeping the temperature of the processing solution to be 75-90 DEG C and processing for 1-2 h; and (4) performing heat treatment. The provided processing method for the bamboo strip prevents deformation in the processing process, improves the anticorrosion performance and mildew resistance of the bamboo strip by using a drug solution for processing, and improves the stability and the anticorrosion performance of the bamboo strip through heat treatment.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Preparation method of functional wood material with photocatalytic activity

ActiveCN107803900AWide variety of sourcesReduce manufacturing costRadiation/waves wood treatmentPhysical/chemical process catalystsProtonationUltraviolet lights

The invention provides a preparation method of a functional wood material with a photocatalytic degradation function. The preparation method solves the problems that a wood material is easily polluted, color change under ultraviolet light is large, and the catalyzing efficiency of photocatalytic degradation of organic dyestuff through a single catalyst is low. The preparation method comprises thesteps that first, surface activation is conducted on the wood material through a sodium hydroxide solution; g-C3N4 after being subjected to protonated treatment is loaded on the surface of the wood material through a vacuum impregnation method; and taking ammonium fluorotitanate and urea as raw materials, TiO2 is grown on the surface of the wood material which is loaded with the g-C3N4, and the functional wood material with the photocatalytic activity is obtained through the steps of heat preservation, cleaning and the like. The degradation rate of rhodamine B and a methylene blue solution with the mass concentration being 2 mg / L and under ultraviolet illumination within four hours can reach to 95% or above through the functional wood material, change in color difference of the surface ofthe wood material after being subjected to ultraviolet light aging can be effectively reduced, color stability of the surface of the wood material is greatly improved, and the preparation technology has the advantages that the technology is simple, operation is easy, the cost is low, and the environment-friendly effect is achieved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for manufacturing modified wood

InactiveUS6667429B2Simplified processing stepsShort timeElectrophonic musical instrumentsDrying using combination processesChemical treatmentHornbeam

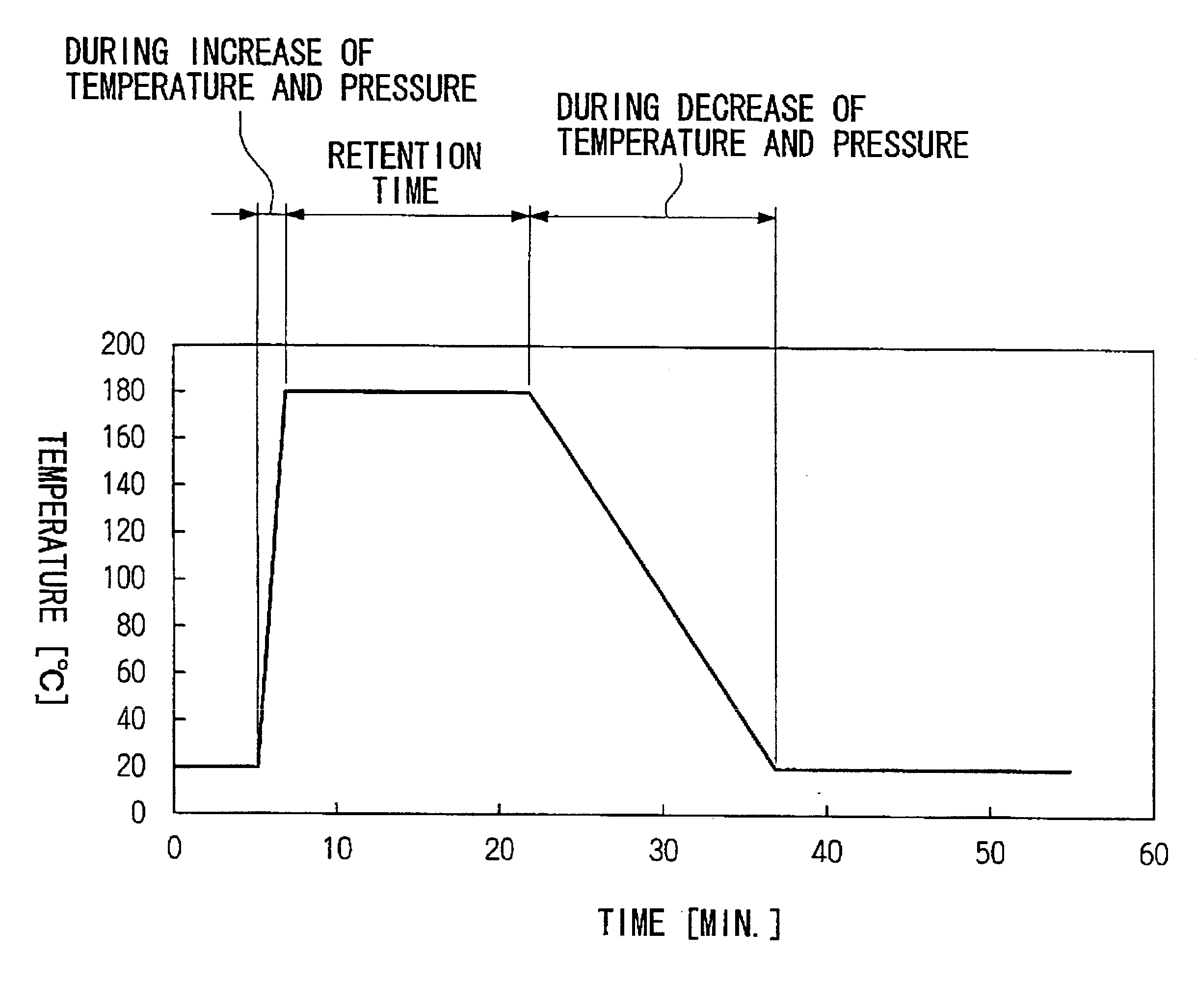

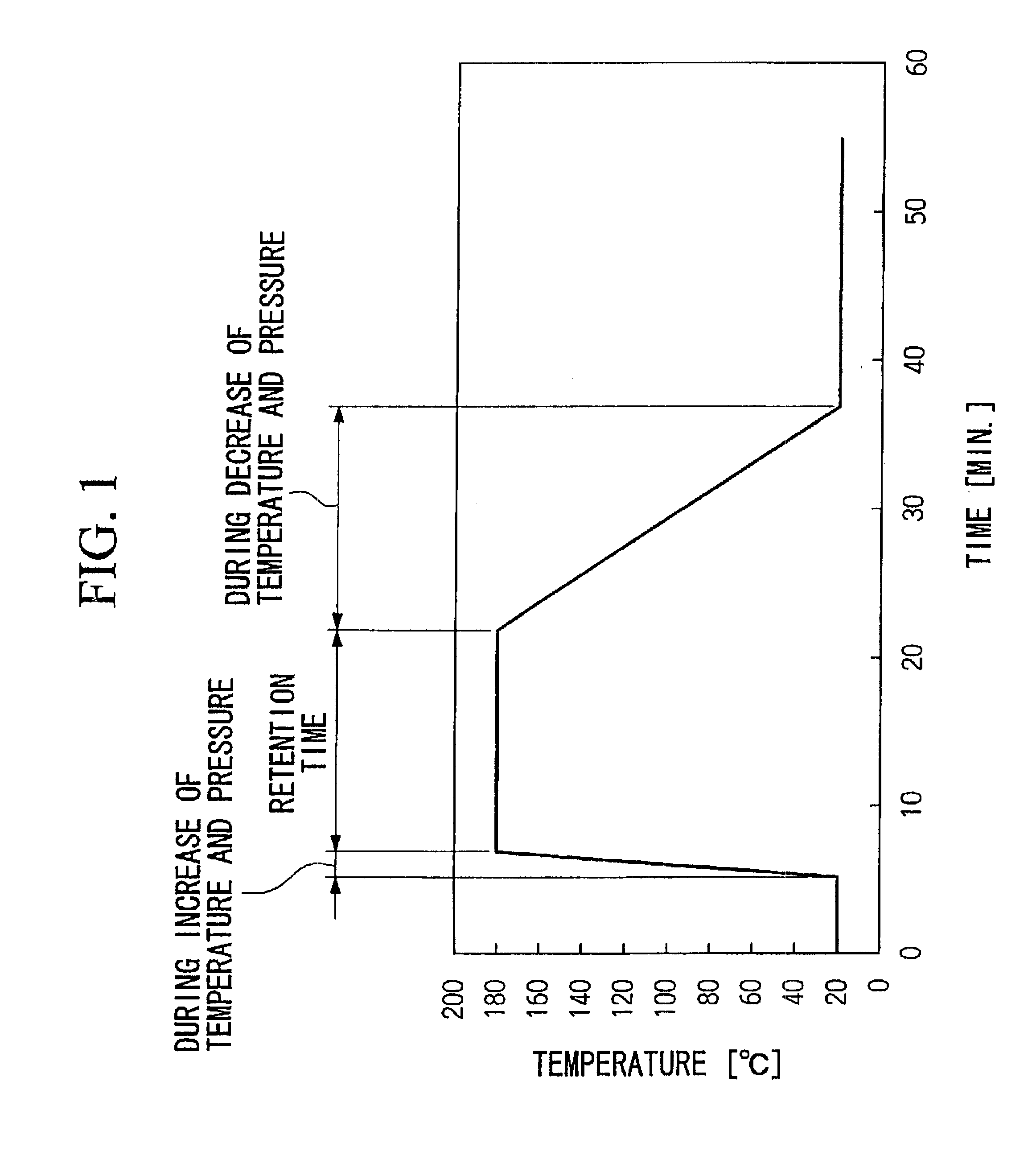

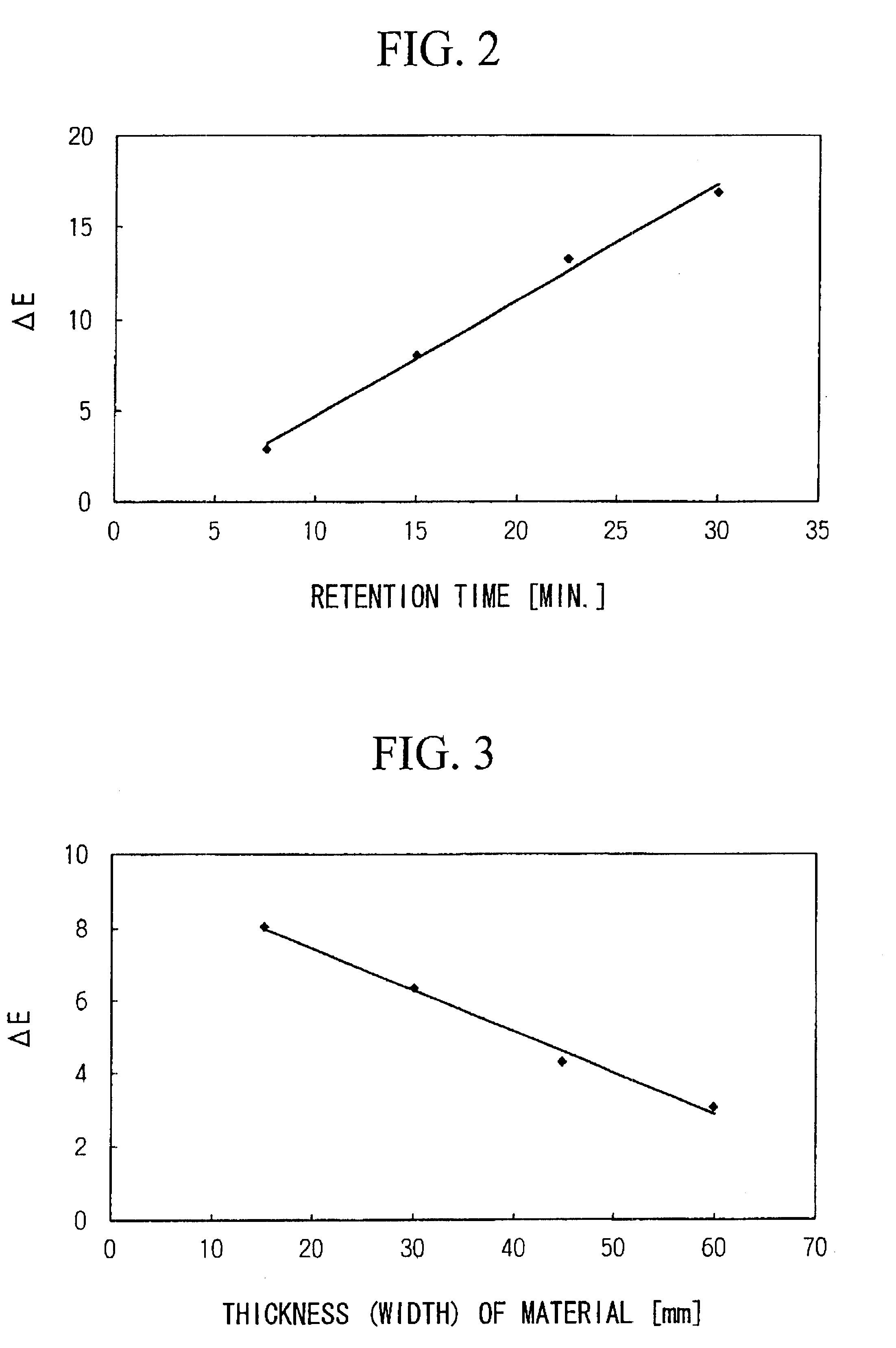

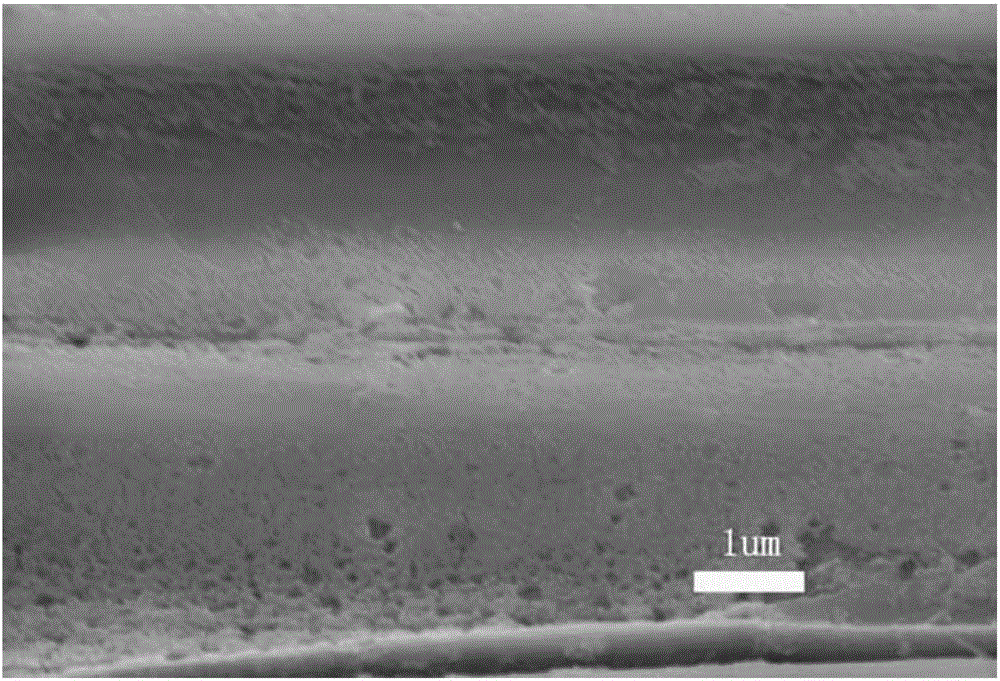

Wood such as spruce, maple, and hornbeam are retained in high pressure steam of pressure 0.2 to 1.6 MPa at 120 to 200° C. for 1 to 60 minutes, and subsequently, cooled and dried to obtain a modified wood having superior acoustic properties and old wood-like appearance due to a change to a deep color tone. Since the conventional modification methods by chemical treatment using chemicals such as resorcin and formaldehyde are not used, the treatment steps are simple and a modified wood used as a material for musical instruments is obtained at low cost.

Owner:YAMAHA CORP

Treatment method for bamboo weaving raw materials before weaving

InactiveCN107186845AImprove weaving propertiesHigh strength propertiesWood treatment detailsCane mechanical workingUltimate tensile strengthMaterials science

The invention discloses a method for pre-weaving bamboo weaving raw materials, which comprises the following steps: (1) raw material selection treatment, (2) high-temperature cooking treatment, (3) soaking treatment, (4) modification treatment, (5) dry weaving treatment . The invention carries out multi-process special treatment operations before bamboo weaving, which effectively improves the weaving characteristics of bamboo, enhances the softening performance, ensures the yield of weaving products, and at the same time enhances the overall strength characteristics of the weaving products and improves the quality of use , prolong the service life, and have good promotion and application value.

Owner:安徽宏润工艺品有限公司

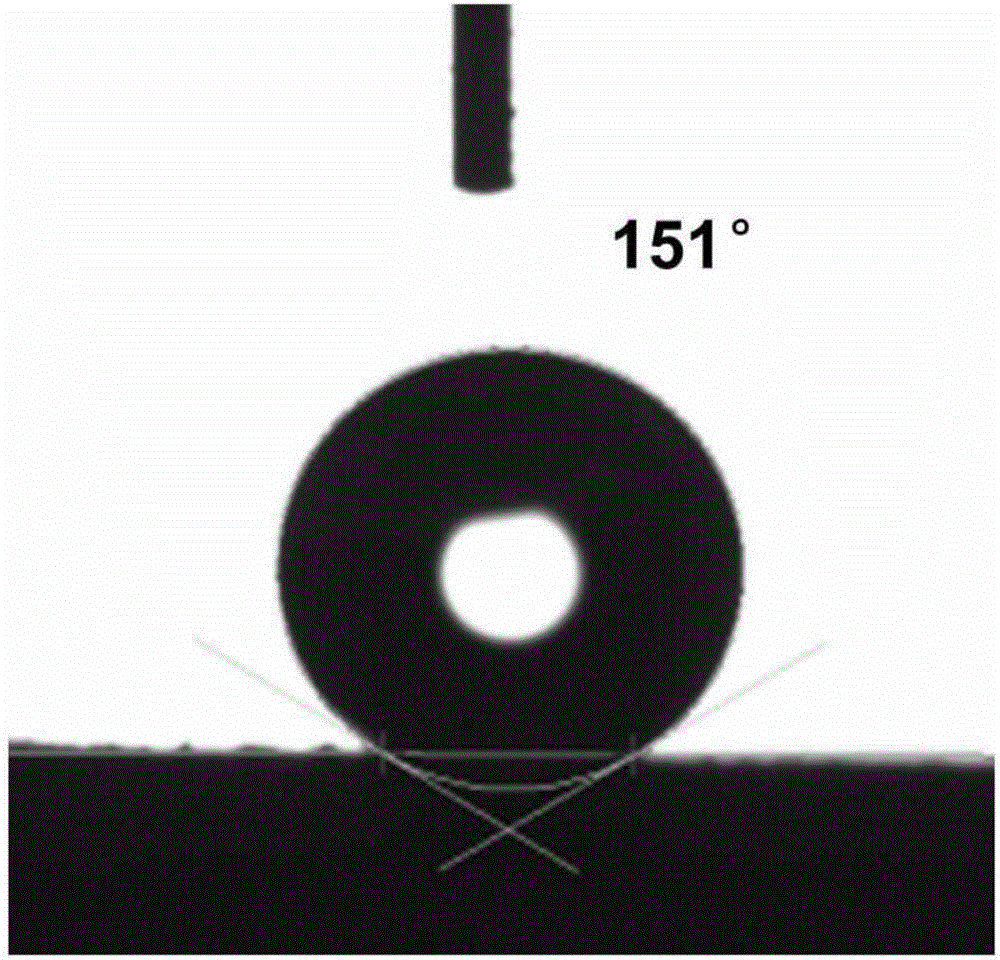

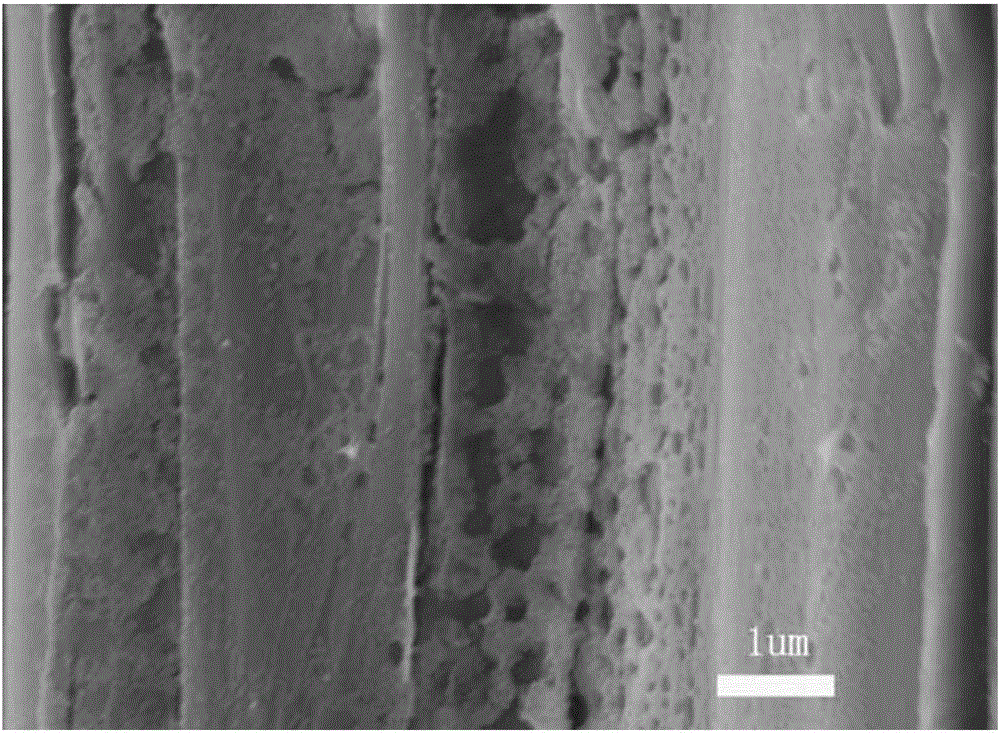

Preparation method for carbonized wood with super waterproof sterilization self-cleaning function

InactiveCN106493813AEasy to operateLow costWood treatment detailsThermal wood treatmentAlcoholNanoparticle

The invention discloses a preparation method for carbonized wood with a super waterproof sterilization self-cleaning function and relates to a wood modification method. The preparation method for the carbonized wood with the super waterproof sterilization self-cleaning function aims at solving the problems that existing carbonized wood does not have the waterproof and anti-corrosion functions. The method includes the steps that firstly, nanoparticle impregnation for wood treatment is performed, wherein the wood is placed into a nanoparticle / ethyl alcohol-water mixed solution subjected to supersonic treatment and is placed in a pressurizing device for impregnation, pressure is unloaded and returns to a normal pressure, then the wood is taken out, the surface of the wood is wiped clean, and the wood is placed in room temperature for standby use; secondly, hydrophobic treatment is performed, wherein the wood is placed in a fluorine-containing ethyl alcohol solution, a sealing reaction is performed, the wood is taken out, liquid on the surface of the wood is wiped thoroughly, and then the hydrophobic treatment is completed; and thirdly, carbonizing treatment is performed, and then the carbonized wood with a super hydrophobic sterilization self-cleaning function is obtained. The method is easy to operate, environment-friendly, low in cost and capable of integrating the super waterproof function and the sterilization function. The preparation method is used for modifying wood.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

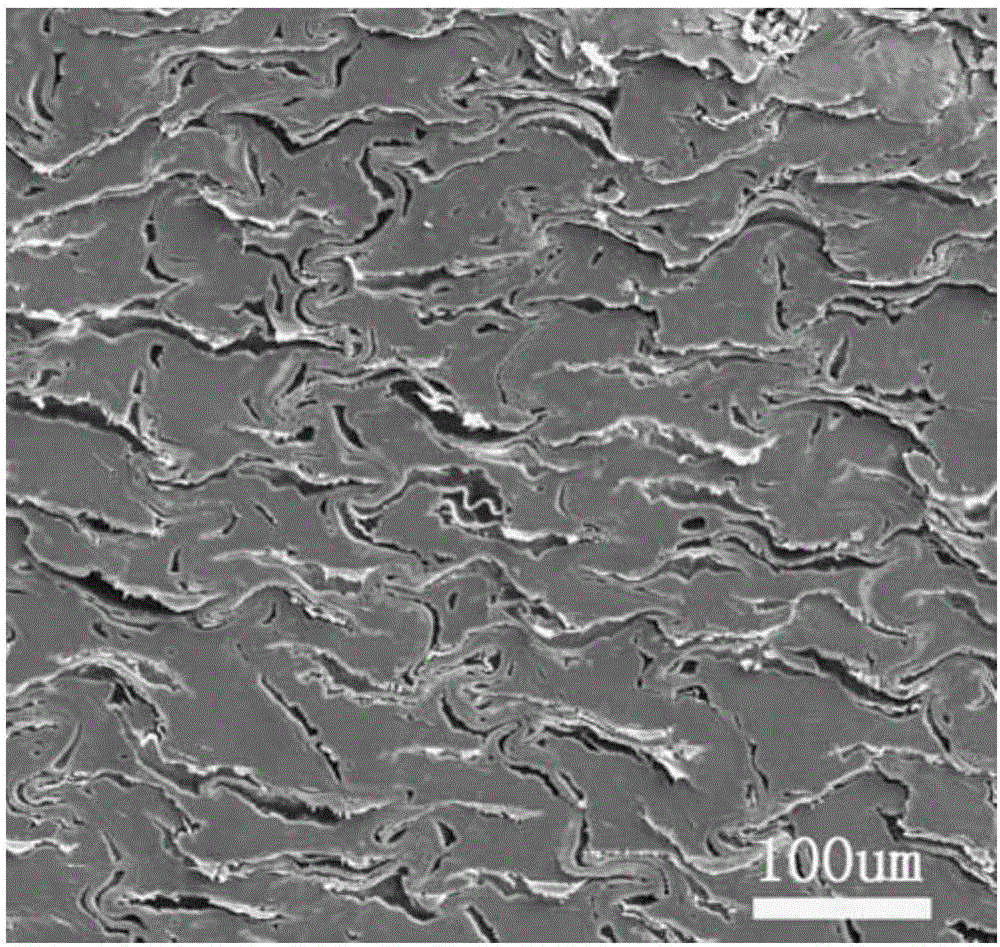

Method for preparing modified wood by compounding heat treatment based on alkali lignin

InactiveCN107972144AImprove waterproof performanceOvercome crackingWood treatment detailsThermal wood treatmentCompound aHeat treated

The invention relates to a method for preparing modified wood by compounding heat treatment based on alkali lignin. The method comprises the following steps: (1) soaking the wood treated in vacuum ina 1,4-dioxane solution with alkali lignin, adjusting the pressure to 0.2-0.8MPa and retaining the pressure for 50-90 minutes; and (2) taking the wood soaked in the step (1) out, drying the wood, putting the wood under the condition at the temperature of 120-200 DEG C, and carrying out heat treatment for 1.5-4 hours to obtain the modified wood. The method is used as a non-toxic and long-acting woodmodification manner with low cost and simple process; the modified wood with high water resistance and high size stability is prepared by compounding a heat treatment method; the defects of high possibility of cracking and high possibility of deformation of the fast-growing wood can be effectively overcome; the bottleneck problem of utilization of the fast-growing wood at present can be solved.

Owner:BEIJING FORESTRY UNIVERSITY

Sympodial bamboo integration profile manufacturing method

ActiveCN103737692AHigh densityImprove the bactericidal effectPressure wood treatmentWood treatment detailsCarbonizationHigh pressure

The invention discloses a sympodial bamboo integration profile manufacturing method. The method is characterized by including the following steps: S1, soaking bamboo filaments of sympodial bamboo which are subjected to green planing and yellow removing in water for high-temperature stewing at temperature of 100-120 DEG C for at leat four hours, wherein the water contains, by mass, 5-10% of hydrogen peroxide and 0.5-1% of sodium hydroxide; S2, disposing wet bamboo filaments in a carbonization furnace for carbonizing at temperature of 130-15o DEG C and at pressure of 3-4 MPa for 4-6 hours; S3, drying for the first time, dipping in glue, and drying for the second time after glue dipping; S4, performing high-pressure forming at pressure of being not less than 1.2 t / cm2; S5, performing thermosetting for more than 10 hours at temperature of 80-150 DEG C under the condition that the pressure of being not less than 1.2 t / cm2 is maintained. By the sympodial bamboo integration profile manufacturing method, sympodial bamboo integration profiles meeting structural profile requirements can be manufactured.

Owner:SHENZHEN KANGER BAMBOO & WOOD

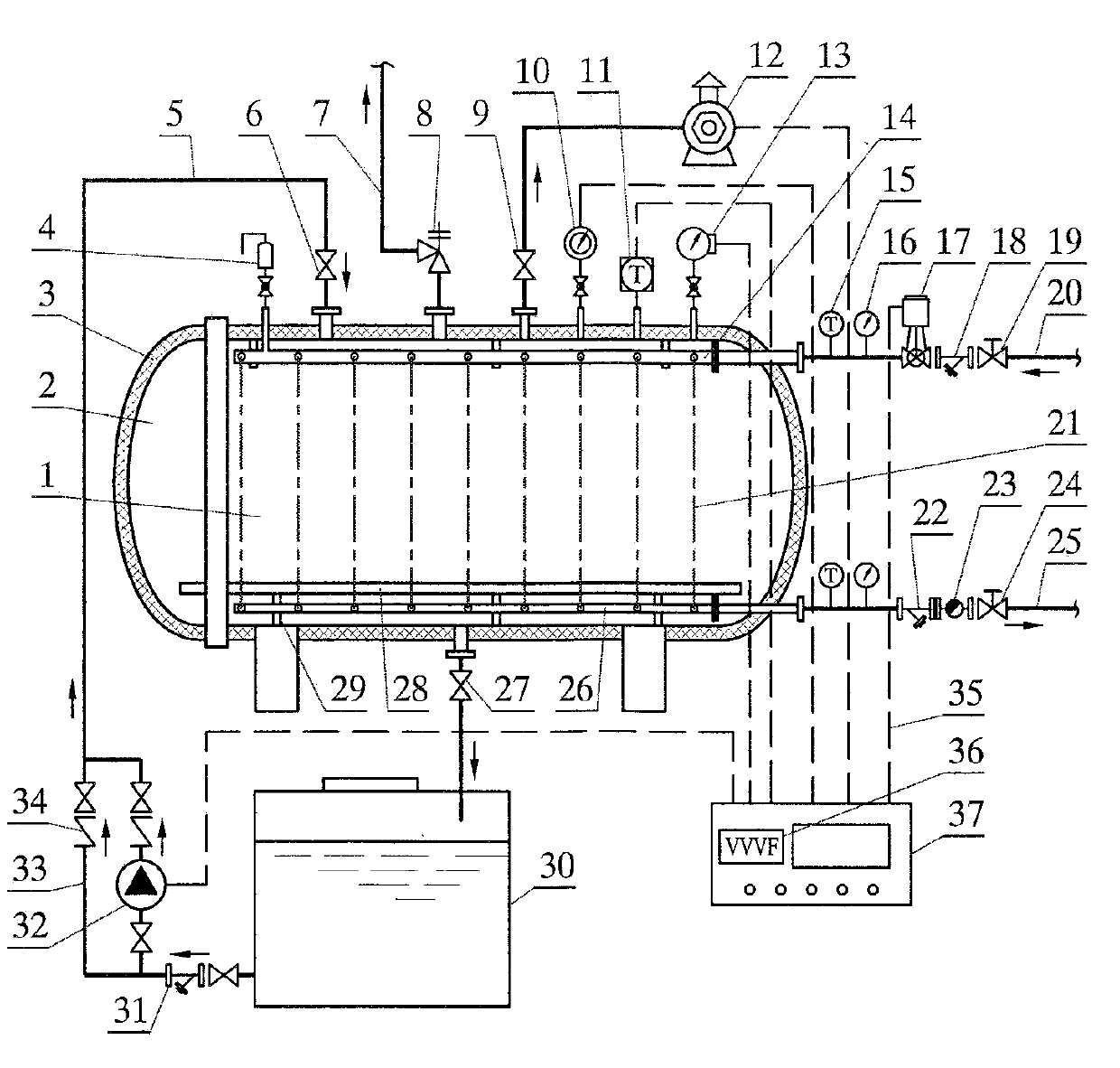

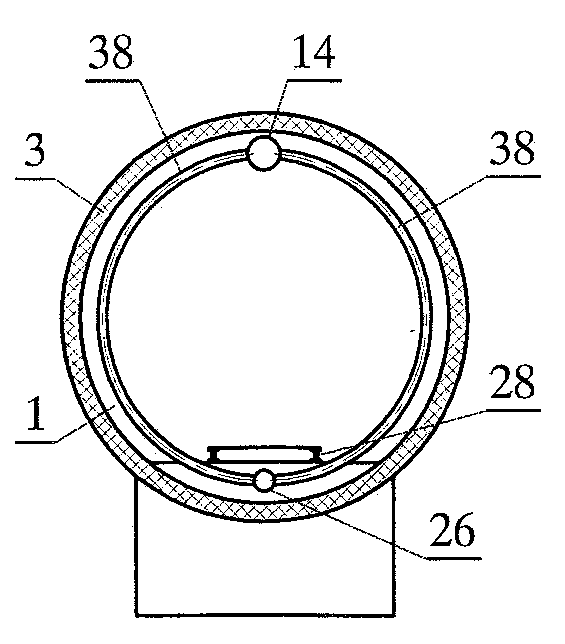

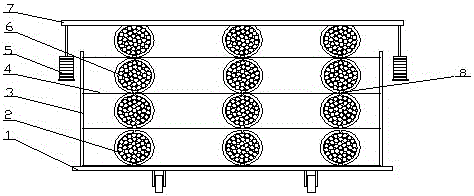

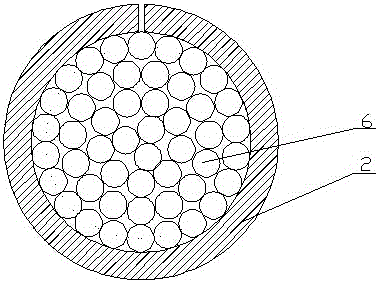

Wood dipping heat treatment pressurization device

InactiveCN104647493ASuitable for flame retardantEnergy savingWood treatment detailsThermal wood treatmentInlet valveEngineering

The invention discloses a wood dipping heat treatment pressurization device, which is mainly composed of a pressurized tank, a pressurized tank door, a vacuum pump, a liquid storage box, a pressurization pump and a control cabinet. The pressurized tank and the pressurized tank door cooperate to form a horizontal sealed pressurized container, heat exchange coil pipes and a sliding guide rail are installed in the pressurized tank, the top of the pressurized tank is provided with a liquid inlet and a liquid inlet valve, the liquid inlet and the liquid inlet valve are connected to the liquid storage box through a liquid inlet pipe, the pressurization pump is disposed on the liquid inlet pipe between the liquid storage box and the liquid inlet valve, the pipeline between the pressurization pump and the liquid storage box is provided with a filter, a by-pass pipe bypasses the pressurization pump, and a check valve is arranged on the by-pass pipe. The top of the pressurized tank is also equipped with a vacuum valve, a vacuum control instrument, a temperature sensor and a pressure detection instrument, and the vacuum valve is connected to the vacuum pump through a pipeline. The wood dipping heat treatment pressurization device provided by the invention has the advantages of energy saving, convenient use, easy control and the like, can be well suitable for modification treatment of wood flame retardance, corrosion protection, enhancement and the like, and the effect is good.

Owner:QINGDAO TONGCHUANG ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

Fragrance-adding treating process for yellow pear wood

ActiveCN104290157AGood persistence of aromaGood insect repellent and antibacterial propertiesWood treatment detailsThermal wood treatmentSurface finishPEAR

Owner:徐州博创建设发展集团有限公司

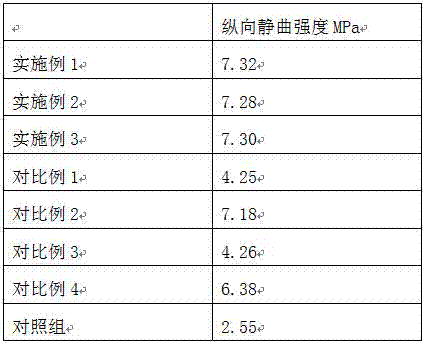

Antiseptic treatment technology for woodware

InactiveCN107398971AImprove anti-corrosion performanceImprove longitudinal static bending strengthRadiation/waves wood treatmentWood treatment detailsCancer researchStatic bending

The invention discloses an antiseptic treatment technology for woodware, and relates to the technical field of woodware treatment. The technology comprises the first step of surface treatment, the second step of pre-preg treatment and the third step of resin impregnation. According to the provided antiseptic treatment technology for woodware, the antiseptic performance of the woodware is effectively improved, meanwhile, the longitudinal static bending intensity of the woodware can be effectively improved, and accordingly the mechanical performance of the woodware is improved.

Owner:FUNAN NATURE ARTS & CRAFTS

Old rattan treatment process

InactiveCN106378846AThe color and oil volume are as newRestore resiliencePressure wood treatmentWood treatment detailsFiberNitrogen

The invention provides an old rattan treatment process. The old rattan treatment process comprises the following steps of soaking old rattan for four hours with a modified toughening solution, and conducting ventilation for airing; then putting the rattan in a closed container full of nitrogen, conducting pressure-maintaining treatment for one hour; spraying Shaoxing rice wine to the rattan, then putting the old rattan in the burning sun to insolate the old rattan for four days, and thoroughly cleaning the old rattan with deionized water; soaking the old rattan which is thoroughly cleaned for 24 hours with biogas slurry generated through anaerobic fermentation, thoroughly cleaning the rattan with deionized water, and then drying the old rattan with a draying machine, so that the water content of the old rattan is not greater than 2%; then, conducting fumigation for one hour under steam, and after fumigation is ended, spraying glycerinum to the old rattan; then wrapping and covering the old rattan with baijiu vinasse, and putting the old rattan in a constant temperature box for heat preservation; and putting the old rattan in the drying machine for drying. The treatment process is used for treating the old rattan and can restore toughness of the rattan, kill worm eggs in the rattan and remove worm holes in the rattan, so that wood fibers of the rattan are connected more tightly; and distortion-resistant strength and tensile strength are greatly enhanced.

Owner:FUNAN COUNTY TIANYI CRAFTS

Flattening method for bamboo tubs in high-temperature tank

ActiveCN105856367AFast growthBreeding is easyWood treatment detailsCane mechanical workingEngineeringRound bar

The invention provides a flattening method for bamboo tubes in a high-temperature tank. The flattening method comprises the following technological steps that (1) pretreatment is conducted on the fresh bamboo tubes; (2) the bamboo tubes are stacked; (3) high-temperature self-flattening is conducted on the circular bamboo tubes in the tank; and (4) post-treatment is conducted after bamboo chips are flattened. The fresh bamboo tubs are subjected to rapid heating and heat-moisture treatment through high-temperature steam in the high-temperature saturated steam tank at the temperature of 130-160 DEG C, and the temperature of the bamboo tubes is made to reach the softening point of lignin, cellulose and hemicellulose. In this way, the circular bamboo tubes with saw kerfs are flattened through round bar steel in the bamboo tubes under the dead-weight action of weights such as external iron blocks, the treatment temperature in the bamboo tube flattening process is decreased, the labor intensity in the operating process of workers is relieved, and the severe environment is improved. The manufactured flattened bamboo tubes are better in physical and mechanical performance and other performance, attractive in color and suitable for art work fabrication, furniture fabrication and house decoration. An optimal processing method is provided for the bamboo industry.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com