Patents

Literature

473results about How to "Strong sense of hierarchy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

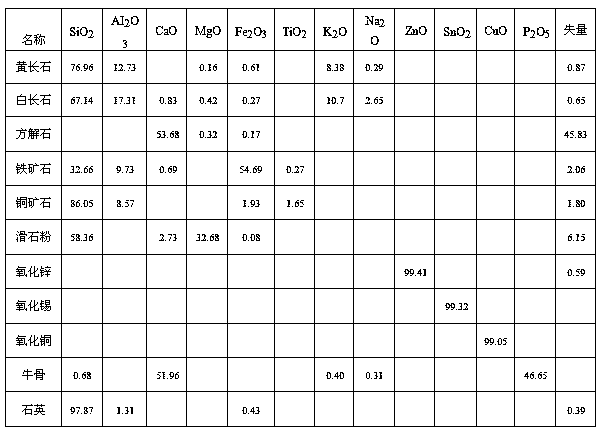

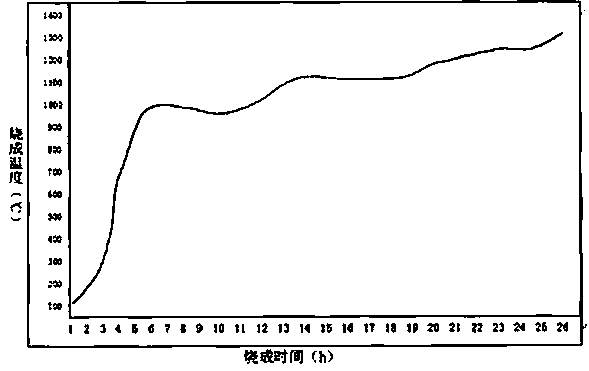

Novel tang-dynasty jun porcelain glaze and manufacturing process thereof

The invention discloses novel tang-dynasty jun porcelain glaze. Yellow feldspar, white feldspar, calcite, quartz, copper ore and iron core are used as glaze raw materials; the yellow feldspar, the white feldspar, the calcite, the quartz, the talcum powder, the copper ore, the zinc oxide, the tin oxide, the copper oxide and ox bone are used as ground coat raw materials; the burnt jun porcelain glaze satisfies the requirement of the tang-dynasty jun porcelain glaze technology, so that the glaze color is natural and variable.

Owner:JIA COUNTY RENSHI CERAMIC IND CO LTD

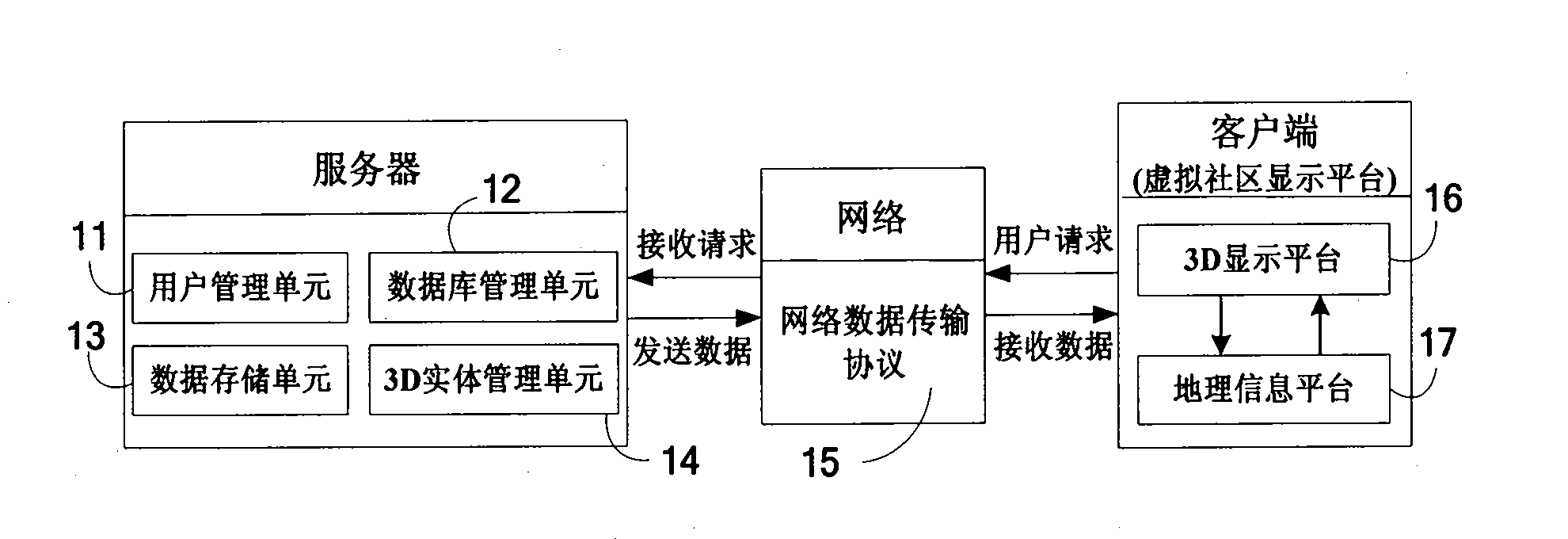

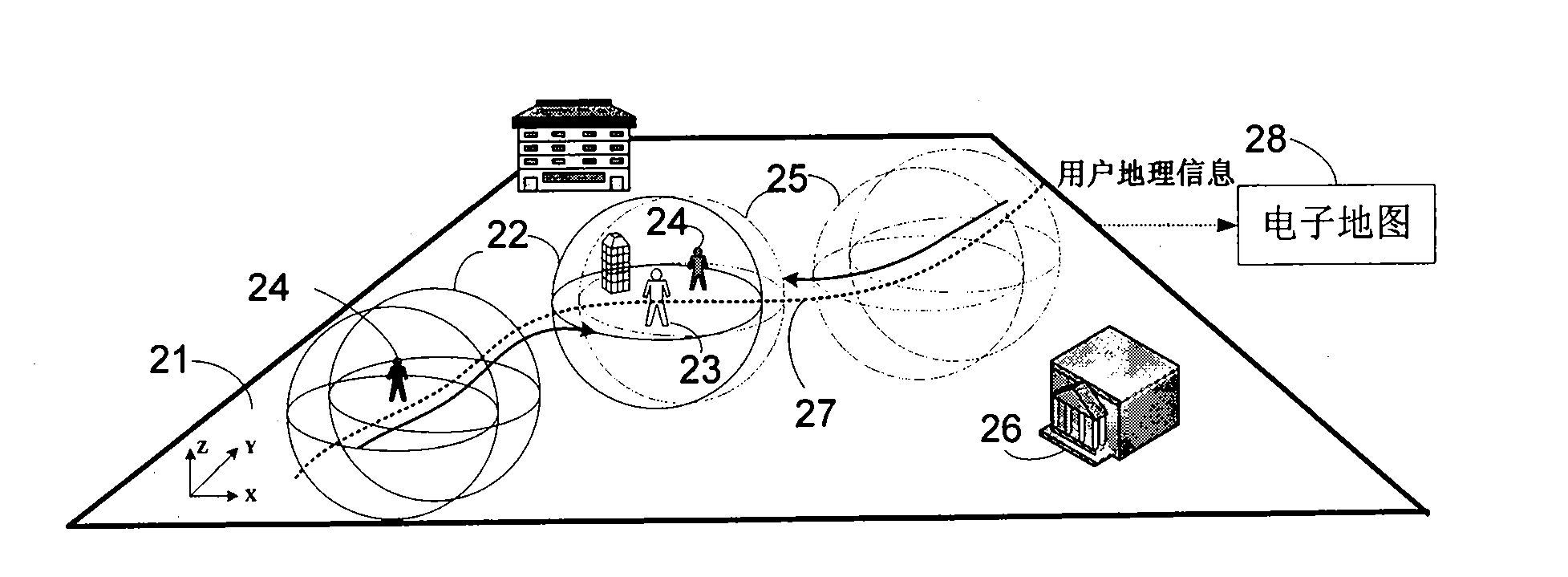

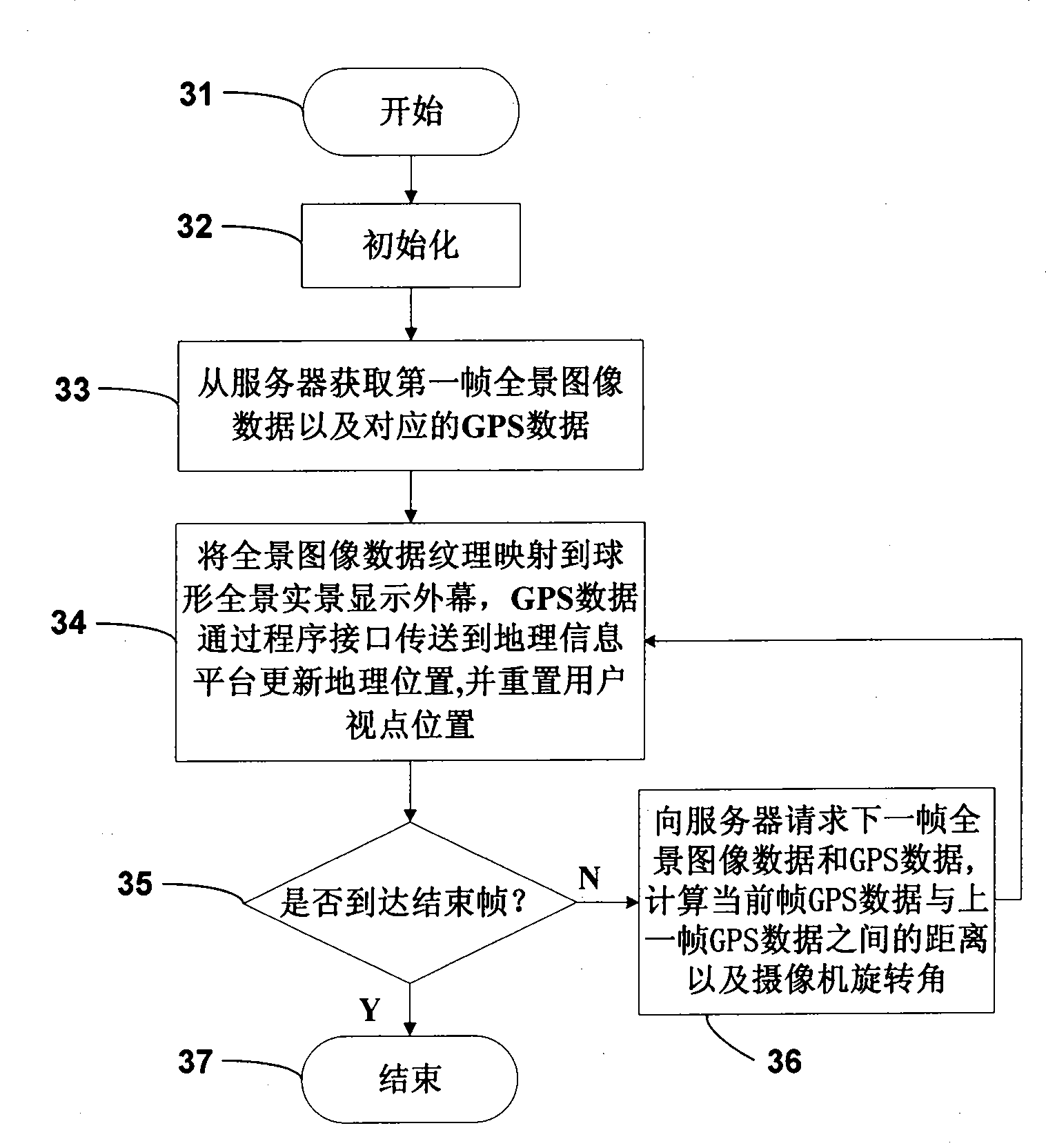

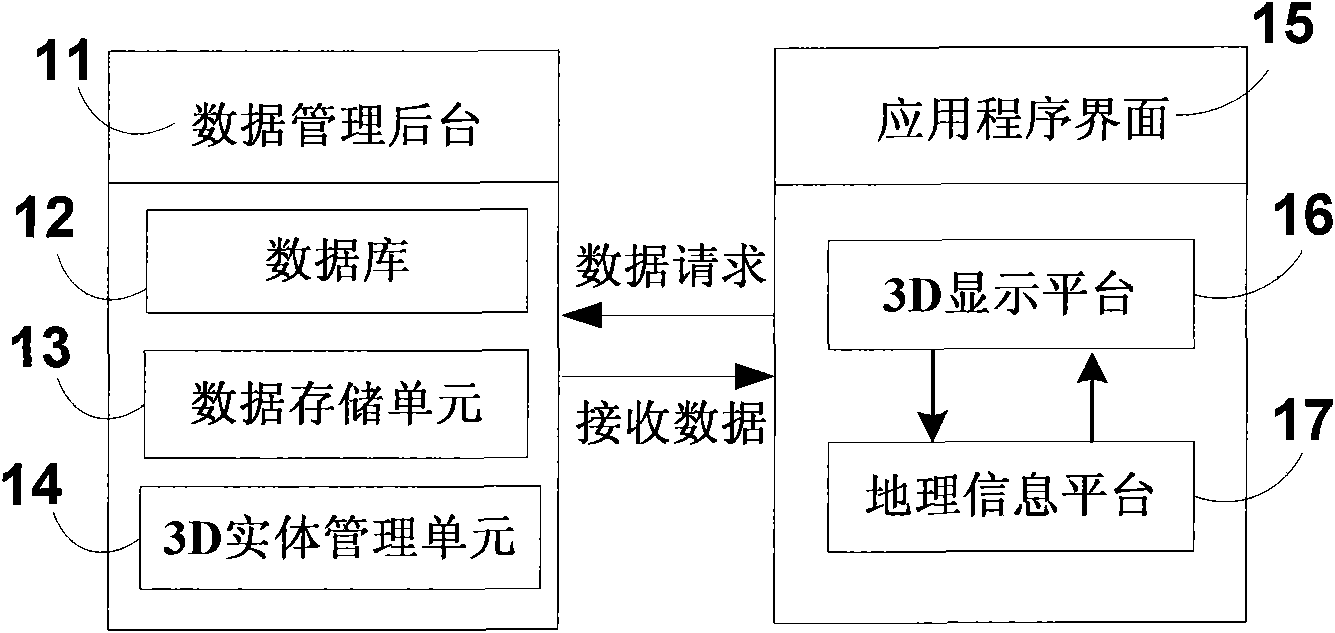

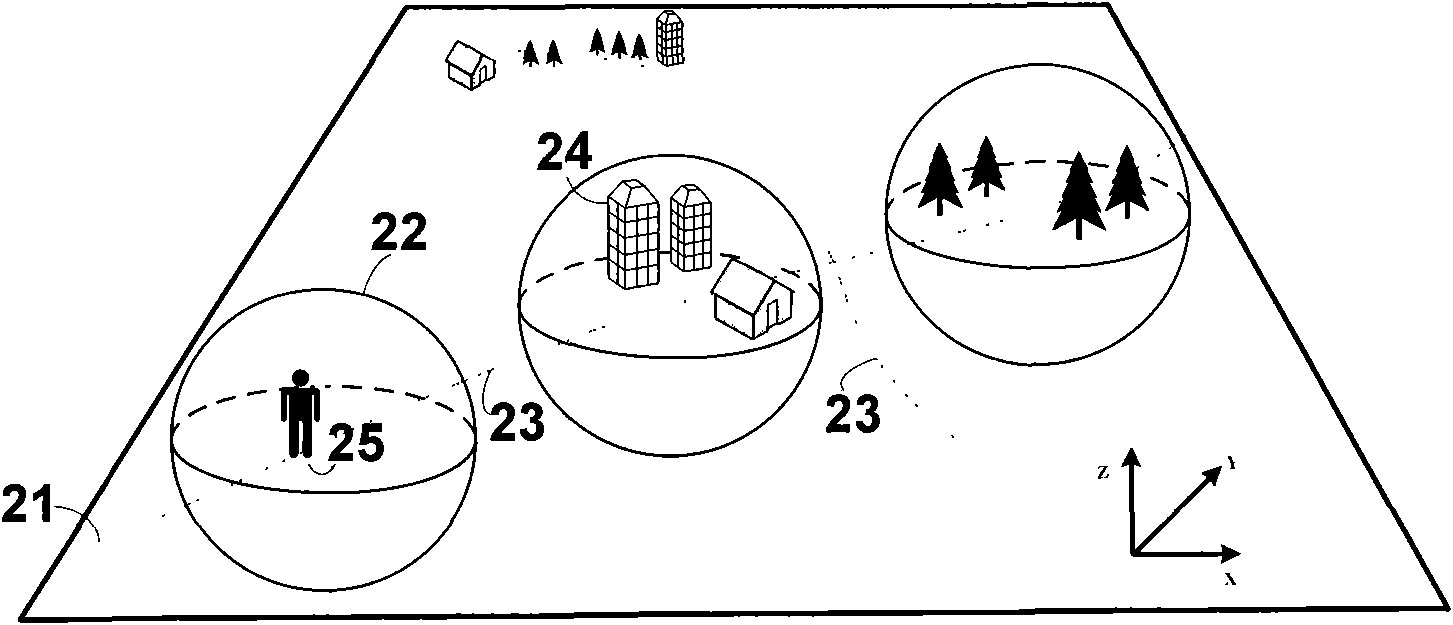

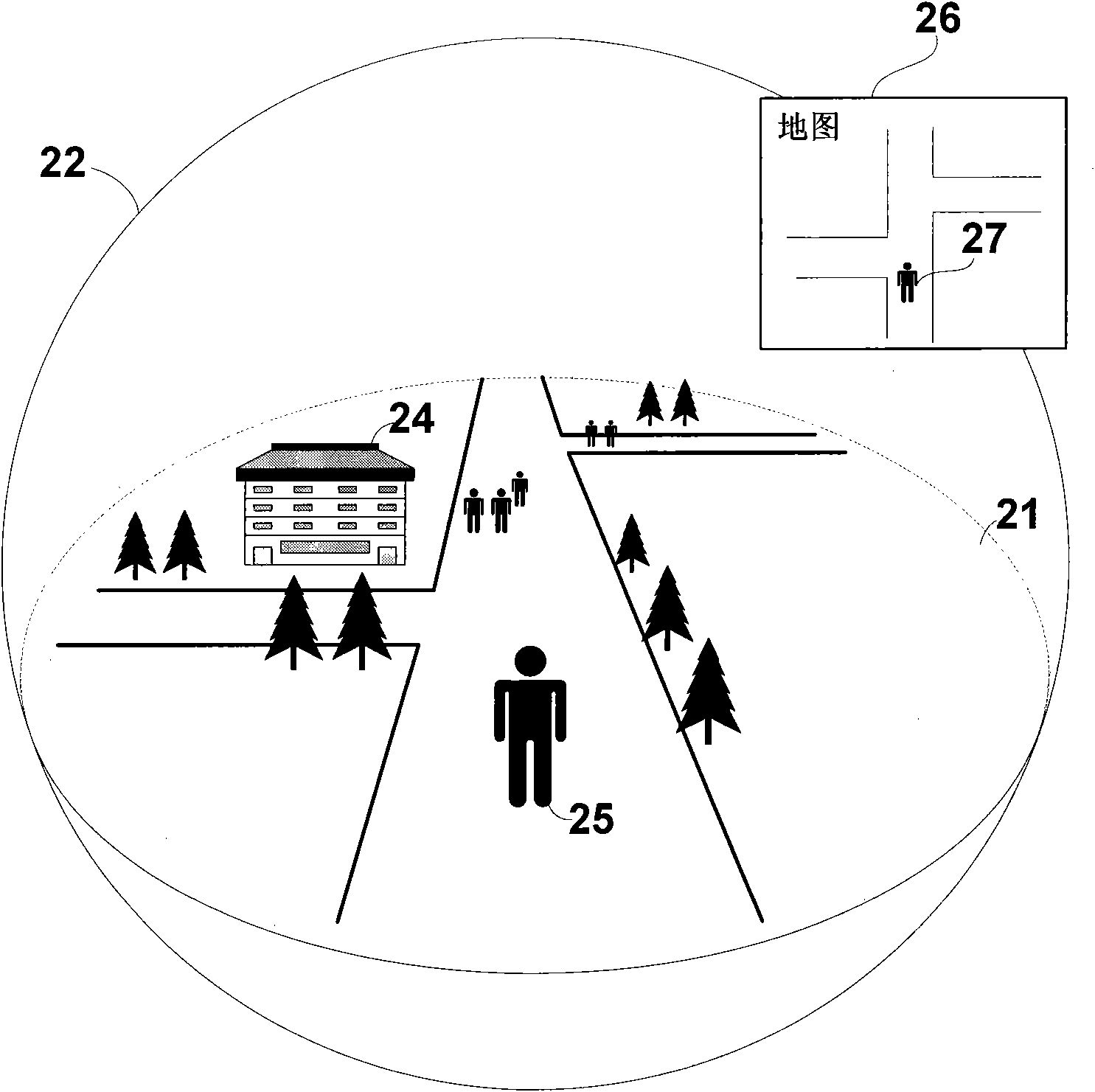

3D virtual community construction method based on panoramic and real image and geographic information

InactiveCN102054289ABuild suitable forAvoid Manual ModelingAnimationTransmissionGeographic siteVirtual space

The invention relates to a 3D virtual community construction method based on panoramic and real image and geographic information. The method comprises the following steps: establishing a virtual community structure; establishing a virtual community display platform through three procedures, including the first procedure of creating a virtual space based on a scene display outer curtain, creating a virtual ground and setting a wandering mode of a user on the virtual ground; the second procedure of adding a 3D entity on the virtual ground and the third procedure of synchronizing the virtual space and the geographic information of the real world; obtaining a virtual community based on panoramic and real image and geographic information; and enabling the environmental interaction of users in the virtual community and the interaction of a current user and other users. The inventive method increases the virtual community scene construction efficiency, improves the realistic effect, ensures the scene of the virtual community consistent to the scene of the real community, allows the user in the virtual space to not only enjoy the environment of the real world but also know the current geographical location, and enhances the realistic effect of the virtual community.

Owner:沈阳迅景科技有限公司

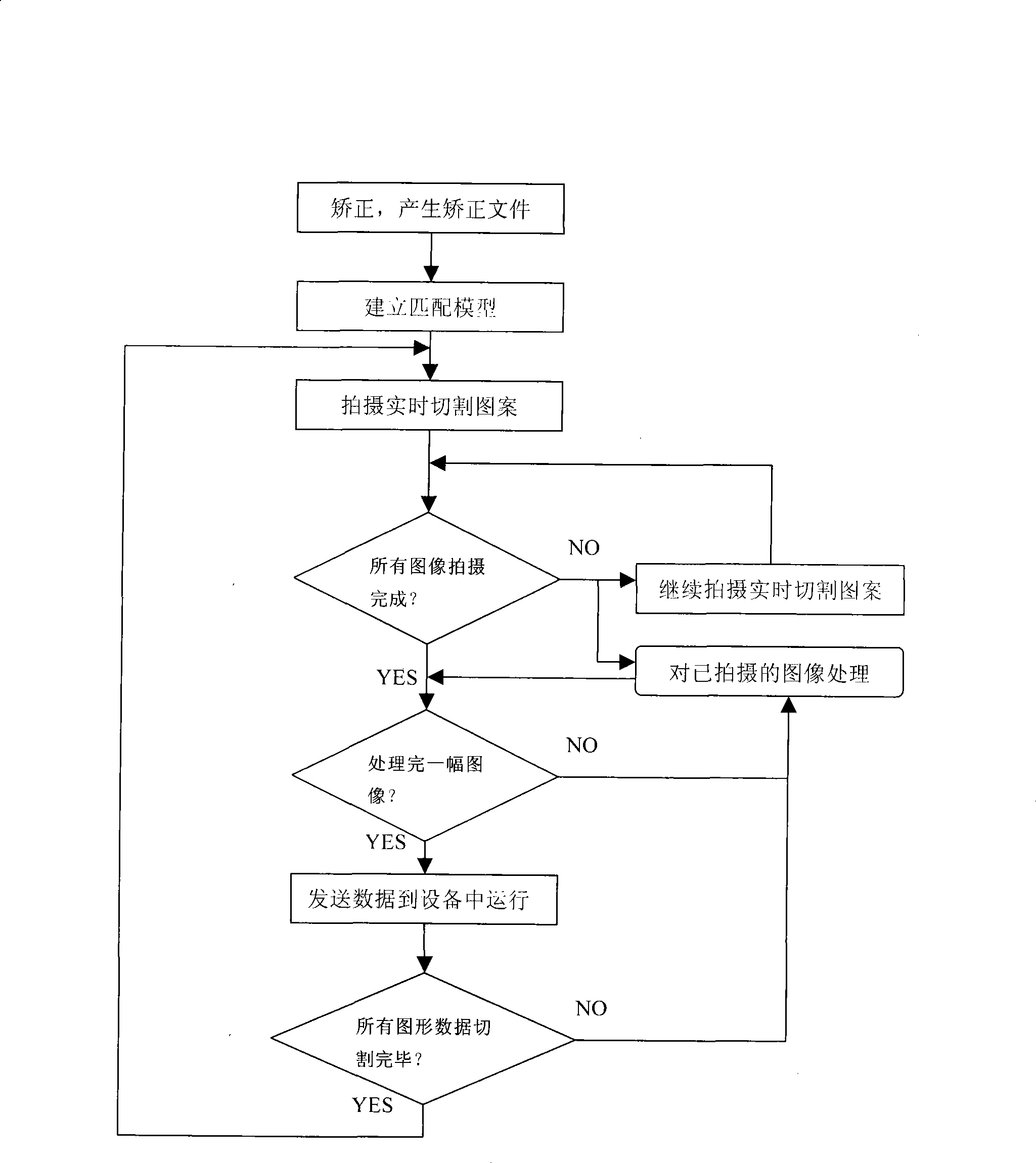

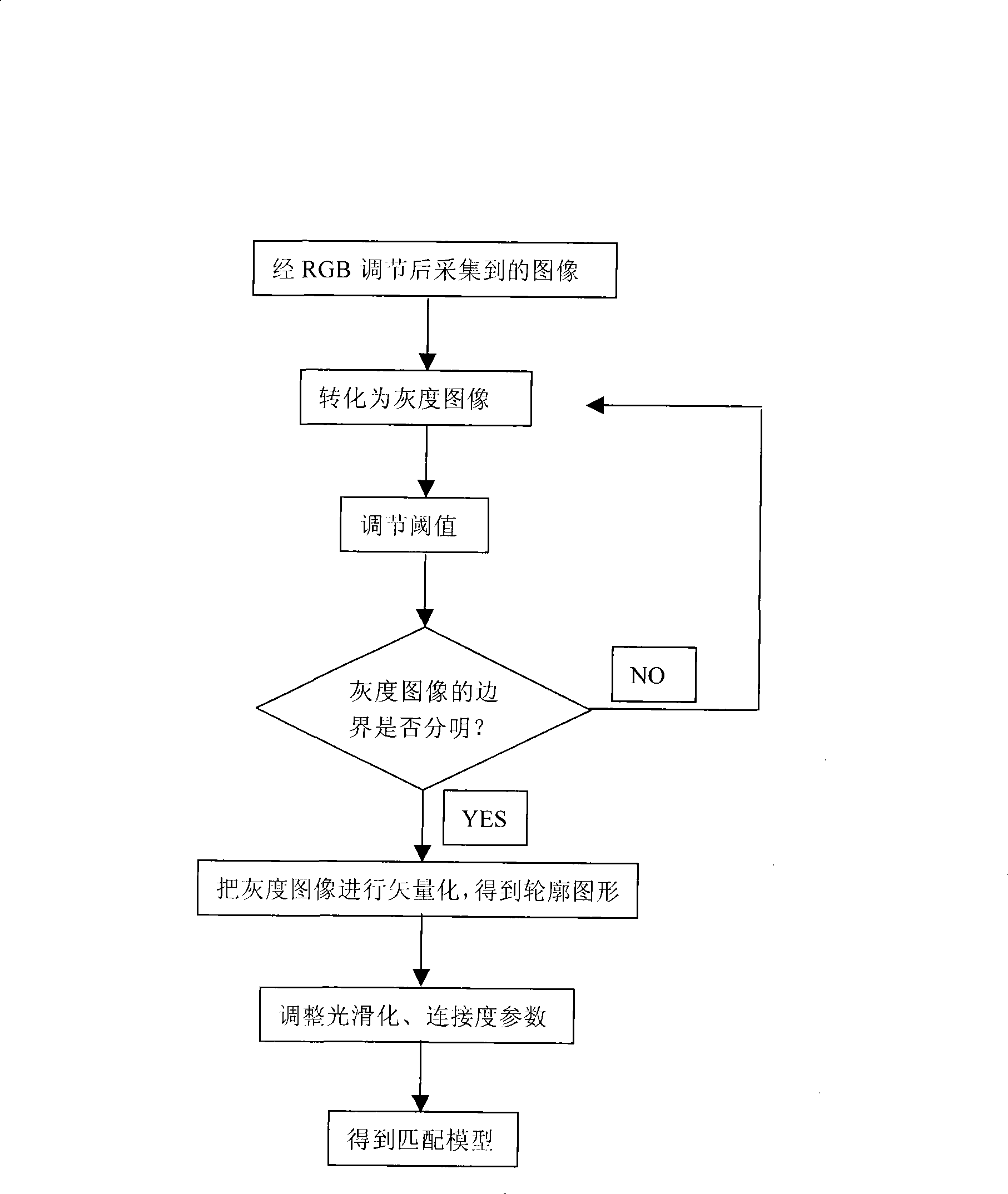

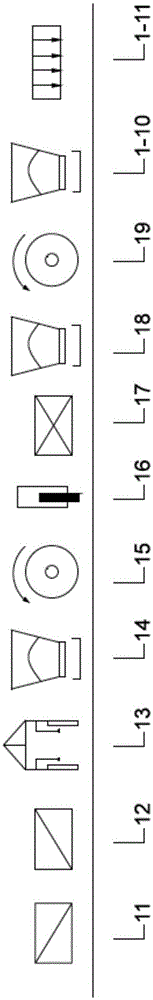

Cutting method along boundary of laser cutting equipment

InactiveCN101363188AAchieve precise cuttingReduce waiting timeSevering textilesLaser beam welding apparatusGraphicsPattern recognition

The invention discloses an edge finding cutting method of a laser cutting device which is characterized in that images of an object needing to be cut are collected through a camera. A correcting document is used for the correction to generate a contour graph. Then, based on the contour graph, a matching model is constructed. Then, the patterns cut in real time are collected through the camera according to set parameters. The vectorization treatment is implemented on the collected images to generate graphs. The graphs are compared with the matching model according to the set similarity. An image satisfying the set similarity is the successful matching image. To the successful matching image, cutting data are generated according to the contour graph of the actually paragraphed image. Finally, the cutting data are sent to the laser cutting device to be cut. The cutting method is characterized by automatically adapting to the cut image differences within certain similarity scope and realizing the precise cutting of images.

Owner:瑞安市博业激光应用技术有限公司

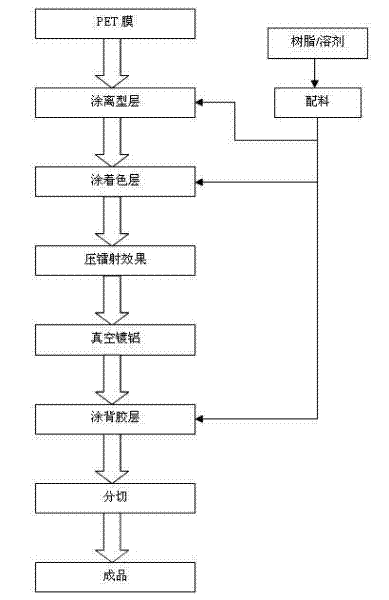

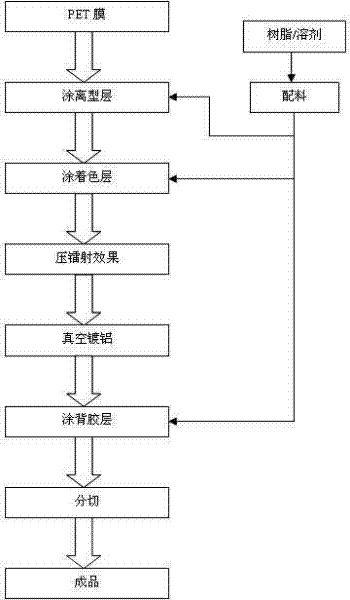

Cold-hot film process

ActiveCN102442098AReduce pollutionFast stamping speedDuplicating/marking methodsPolyethylene terephthalateLaser

The invention mainly discloses a cold-hot film process which comprises the following steps of: firstly, cutting a needed PET (polyethylene terephthalate) film, and coating a releasing layer on the PET film; secondly, coating a coloring layer on the releasing layer, stamping a laser layer effect on the coloring layer, performing vacuum-plating of aluminum above the laser layer, and coating a back glue; and finally, cutting the prepared finished product. The process disclosed by the invention has the advantages of high thermo-printing speed, high accuracy, and short production cycle; and the final product can embody a gradual changing effect and has strong stereovision.

Owner:绍兴虎彩激光材料科技有限公司

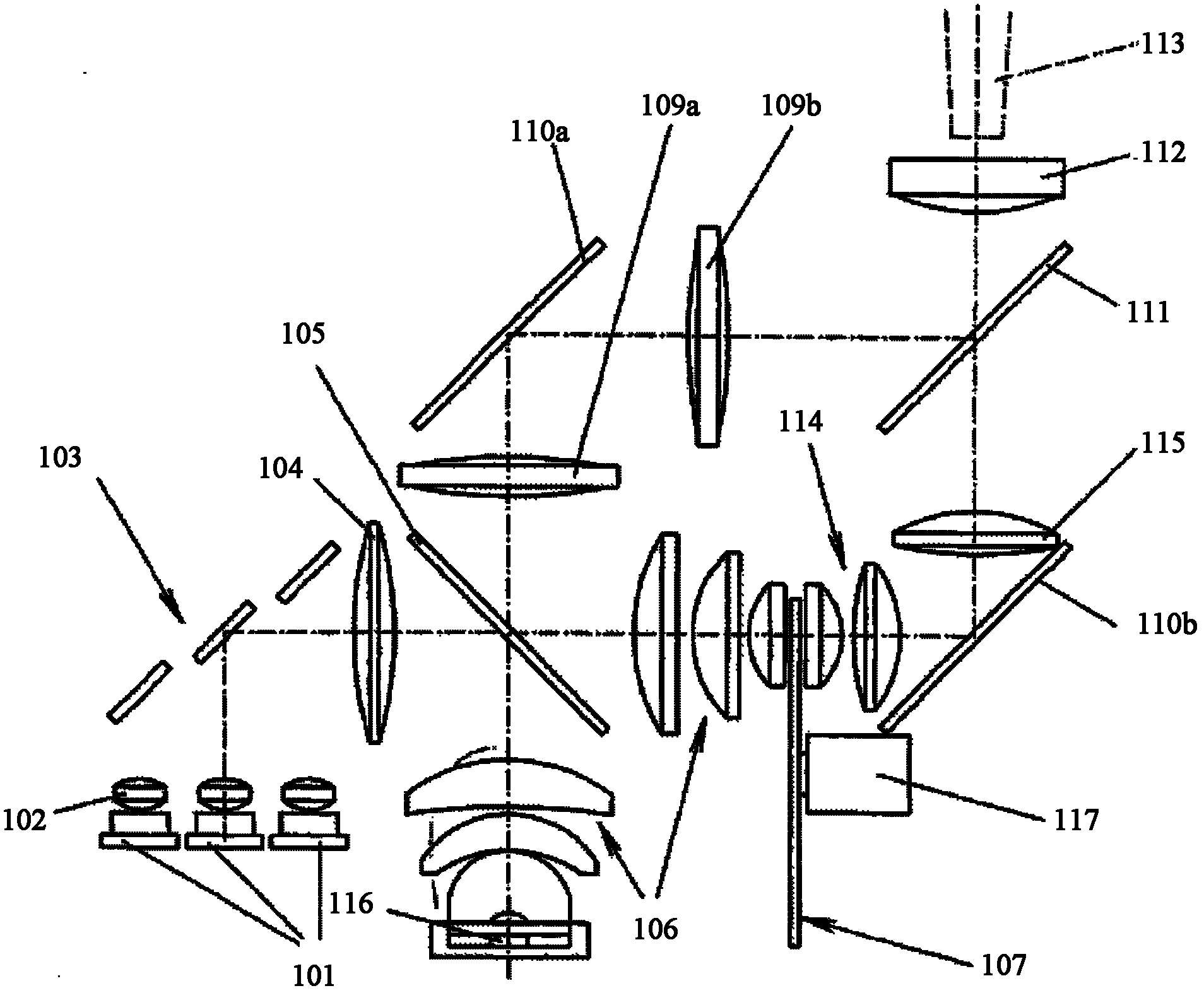

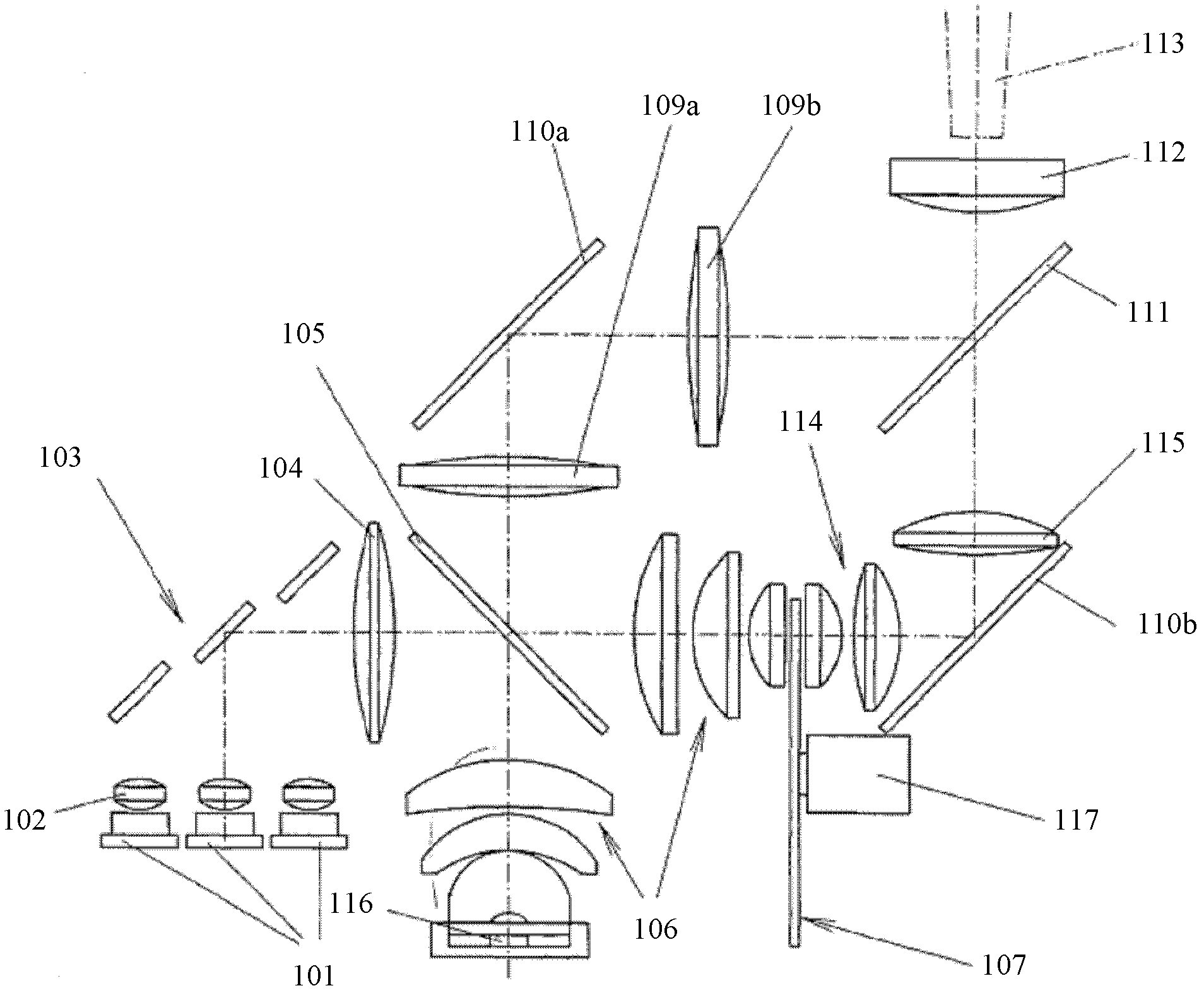

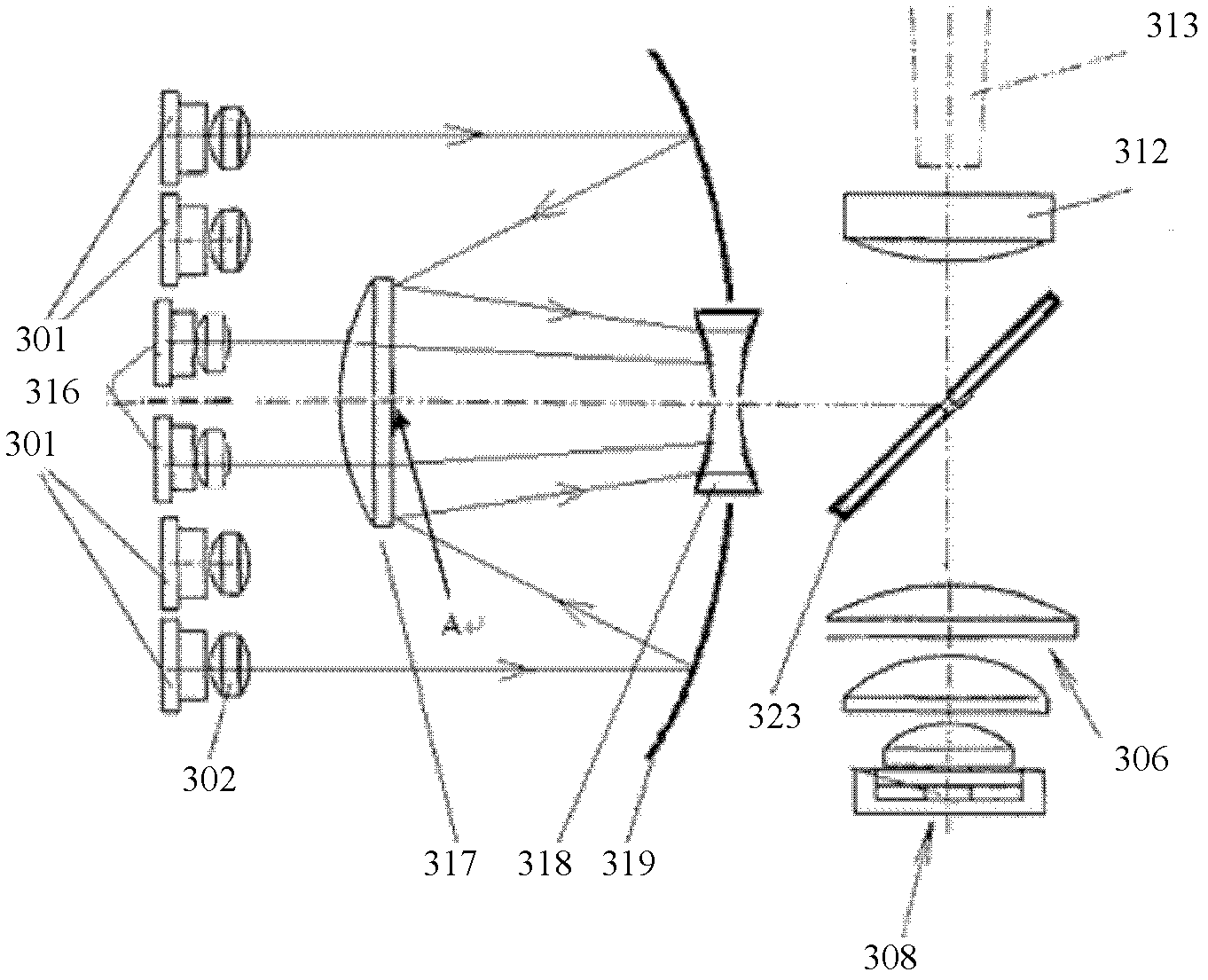

Light source device, light source generation method and laser projection machine comprising light source device

ActiveCN102591120AReduce in quantityReduce lossProjectorsLighting device detailsLength waveLaser projection

The invention discloses a light source device, a light source generation method and a laser projection machine comprising the light source device. The light source device comprises light sources, wherein the light sources comprise a first light source, a second light source and a third light source with different wavelengths; the light source device further comprises a collimating part, a reflecting part, a converging and reflecting part and a converging part, wherein the collimating part is positioned at the ejection side of the first light source, the second light source and the third light source and is used for carrying out collimation processing on the received light sources; the reflecting part is used for reflecting the first light source and the second light source to the converging and reflecting part; the converging and reflecting part is used for carrying out reflection processing on the first light source and the second light source reflected by the reflecting part and carrying out convergence processing on the third light source after collimation processing; and the converging part is used for carrying out convergence processing on the first light source, the second light source and the third light source received so as to enable the first light source, the second light source and the third light source to enter to a light receiving part along the same direction. According to the invention, the quantity of parts in the light source device can be effectively reduced, the light path is simplified, the energy utilization ratio is increased, and the installation and the maintenance are simple.

Owner:HISENSE

Construction method of panoramic/realistic hybrid reality platform

InactiveCN102054290AHigh degree of simulationStrong three-dimensional senseAnimation3D modellingComputer graphics (images)Original data

The invention discloses a construction method of a panoramic / realistic hybrid reality platform, which comprises the following specific steps: acquiring panoramic picture data, geographic information data and other original data required for constructing a hybrid reality platform, and storing in a data storage unit of a data management background; then, creating a hybrid reality panoramic / realistic display curtain, creating a virtual ground and adding 3D entities to construct a hybrid reality space based on panoramic pictures; and finally, synchronizing the hybrid reality space with the geographic information of the real world. By organically combining the real scene with the 3D entities in the virtual space, the invention enables users to have strong space reality feeling and immersion feeling in the process of roaming in the hybrid reality space.

Owner:欧思徕(北京)智能科技有限公司

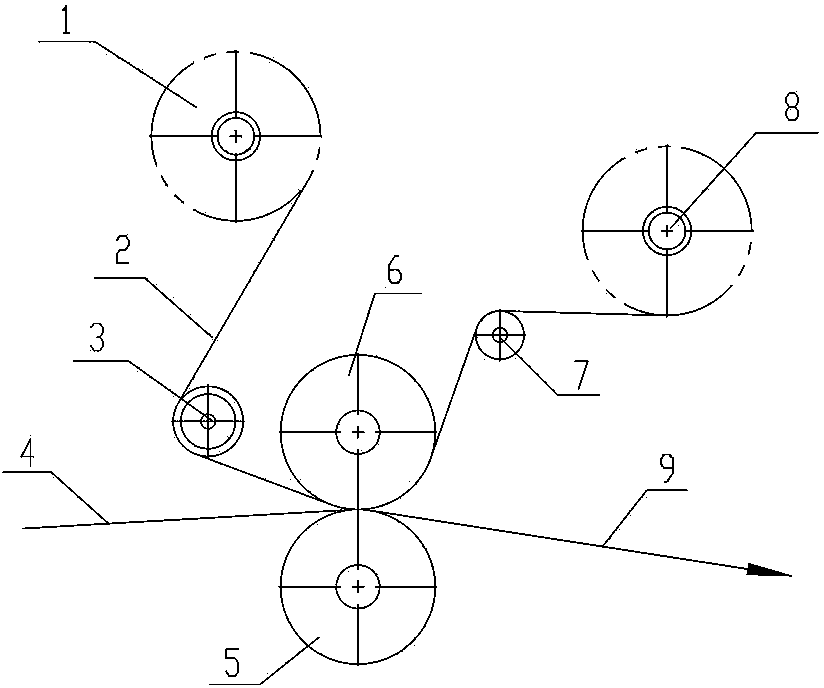

Ceramic polished brick and production method and production line of ceramic polished brick

ActiveCN105328782ASmooth transitionClear and smooth textureCovering/liningsCeramic shaping plantsYarnBrick

The invention discloses a ceramic polished brick and a production method and a production line of the ceramic polished brick. The production line comprises a range-shaped texture forming set, a material block forming set, an atomization spraying system, a third material distributing device, a first roll pressing device, a cutting device, a gorge-shaped texture forming set, a sixth material distributing device, a second roll pressing device, a seventh material distributing device and a press device, all of which are sequentially connected through a belt. According to a preparing method, color attaching pulp is attached to a micro powder stack jointly formed by material blocks formed by a range-shaped texture material belt subjected to the action of a texture manufacturing device and tooth roller crushing, the poking operation and super-through line material filling procedures are carried out on pressed powder through two sets of different mechanical arm combinations, wherein the pressed powder is formed through material supplementing, prepressing and cutting and edge removing. The polished brick obtains the polished brick decoration texture jointly composed of the range-shaped texture, the lava-shaped texture and the gorge-shaped texture. The range-shaped texture is smooth and natural, the edge of the lava-shaped texture has color lines fine like silk yarn, the texture is infinitely close to the difference texture of natural stone, and the stone imitating effect is extremely good.

Owner:GUANGDONG WINTO CERAMICS +3

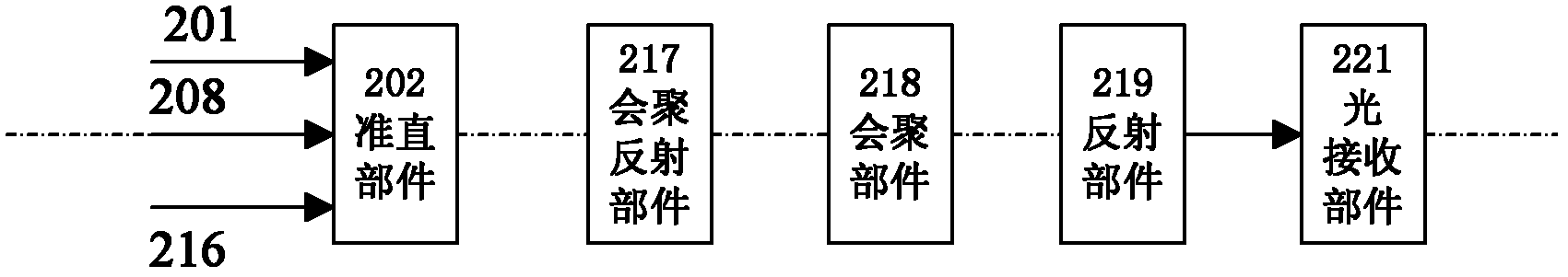

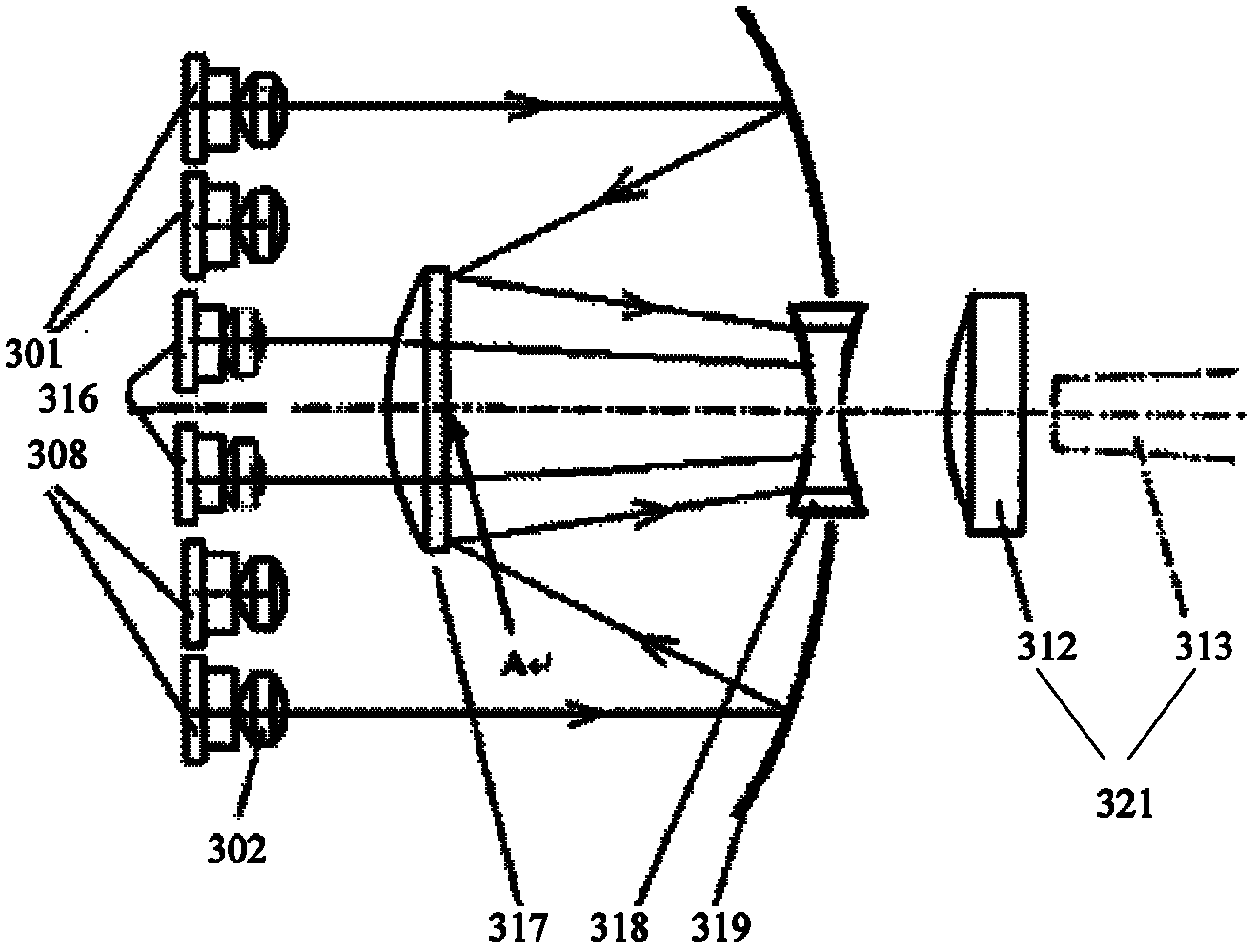

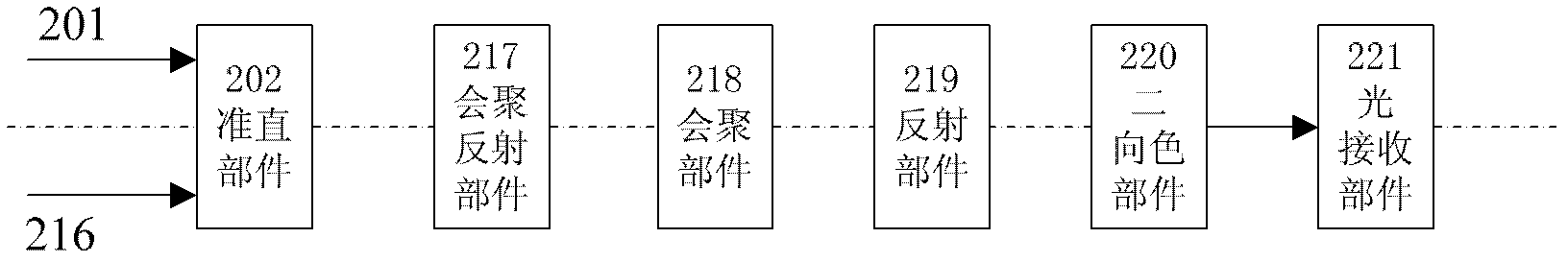

Light source device, light source generation method and laser projector comprising light source device

ActiveCN102540679AReduce in quantityReduce lossProjectorsLighting device detailsLength waveLaser projector

The invention discloses a light source device, a light source generation method and a laser projector comprising the light source device. The light source device comprises light sources comprising a first light source, a second light source and a third light source which are provided with different main wavelengths; the light source device further comprises collimation part, a reflection part, a convergency and refection part, a convergency part and a dichroic part, wherein the collimation part is positioned on emergent sides of the first and the third light sources and is used for aligning the received light sources; the reflection part is used for reflecting the aligned first light source to the convergency and refection part; the convergency and refection part is used for reflecting the first light source reflected by the reflection part and converging the aligned third source; the convergency part is used for converging the first and the third light sources; and the dichroic part is used for leading the second light source plus the first and the third light source from the convergency part to be incident into a light receiving part in the same direction. By adopting the light source device, the number of parts in the light source device can be effectively reduced, a light path is simplified, the energy utilization rate is increased, and the mounting and the maintenance are simple.

Owner:HISENSE

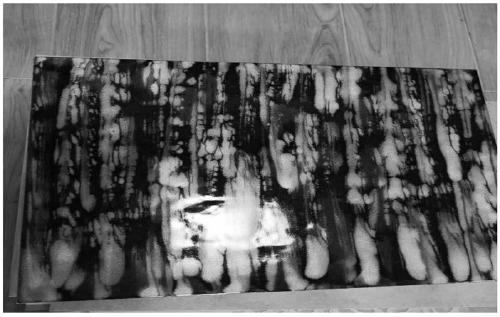

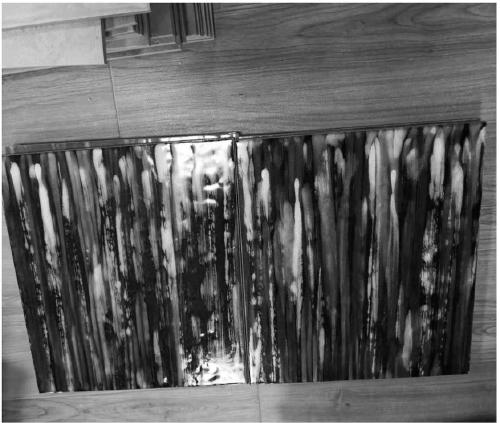

Production processing method of colored crystal glass

ActiveCN102582300AStrong sense of hierarchyFull of abstractionOther printing apparatusPrinting inkEngineering

The invention discloses a production processing method of colored crystal glass, wherein the colored crystal glass is prepared by the steps of cutting, edge processing, high temperature colored crystal printing and low temperature colored crystal printing, a double-layer screen printing manner is utilized in the high temperature colored crystal printing procedure, the mesh number of a second screen layer is more than that of a first screen layer, an included angle alpha of a radial line of the first screen layer and a radial line of the second screen layer is more than 0 degree and less than 900 degrees, a high temperature printing ink layer is fully merged in a glass substrate after the colored crystal glass is dried twice and tempered twice, so that the patterns have strong stereoscopic impression and stereovision, and sufficient abstract feeling, and look noble, elegant and upscale; besides, the printing ink is firmly combined with the glass substrate, so that the printing ink cannot be stripped by a cleaning cloth or other acidic and alkaline substances if being used as a refrigerator door panel. The back surface of the glass is processed by low temperature printing ink printing, thereby the procedures are fewer, the processing technique is simple, and the cost is low.

Owner:焦作飞鸿安全玻璃有限公司

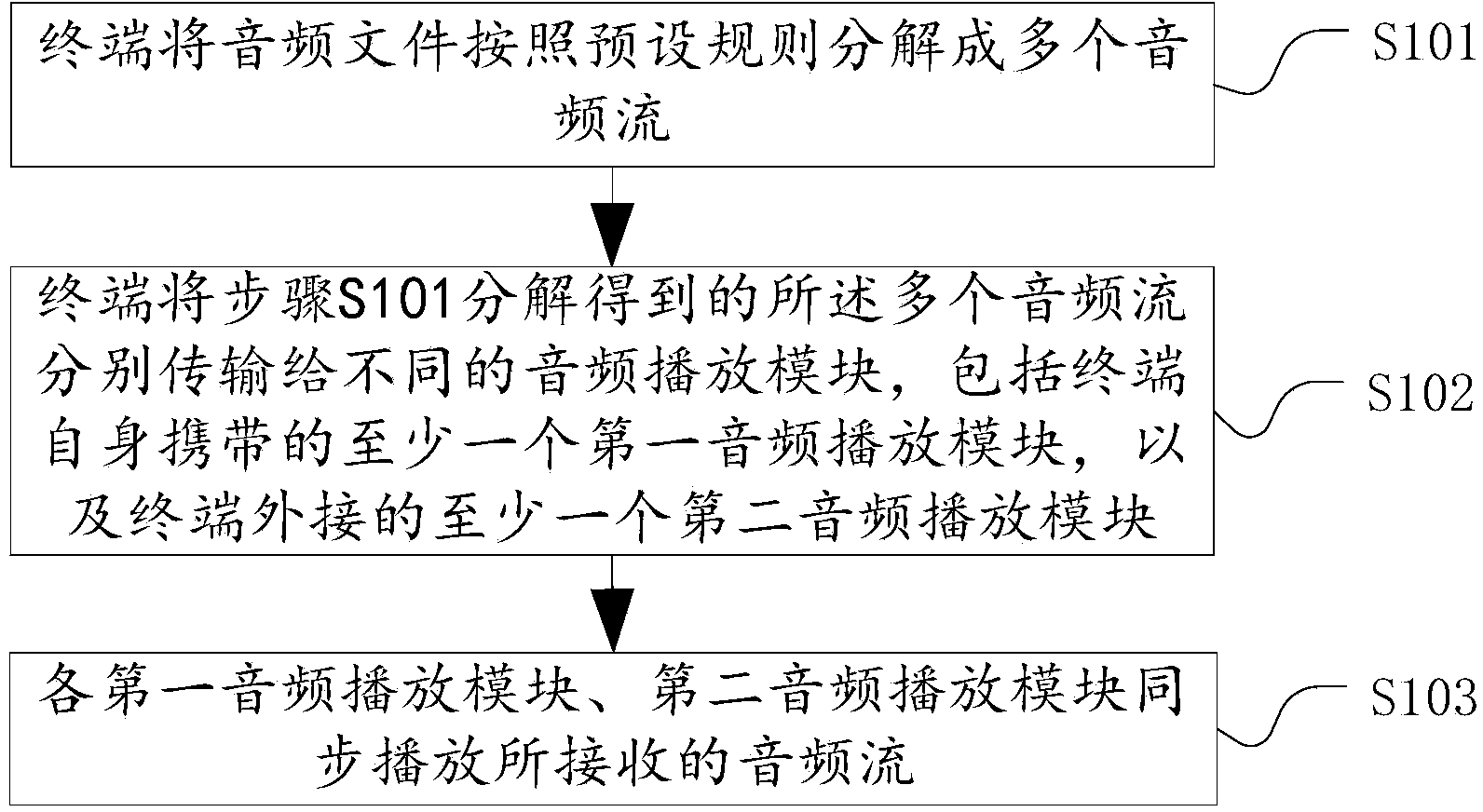

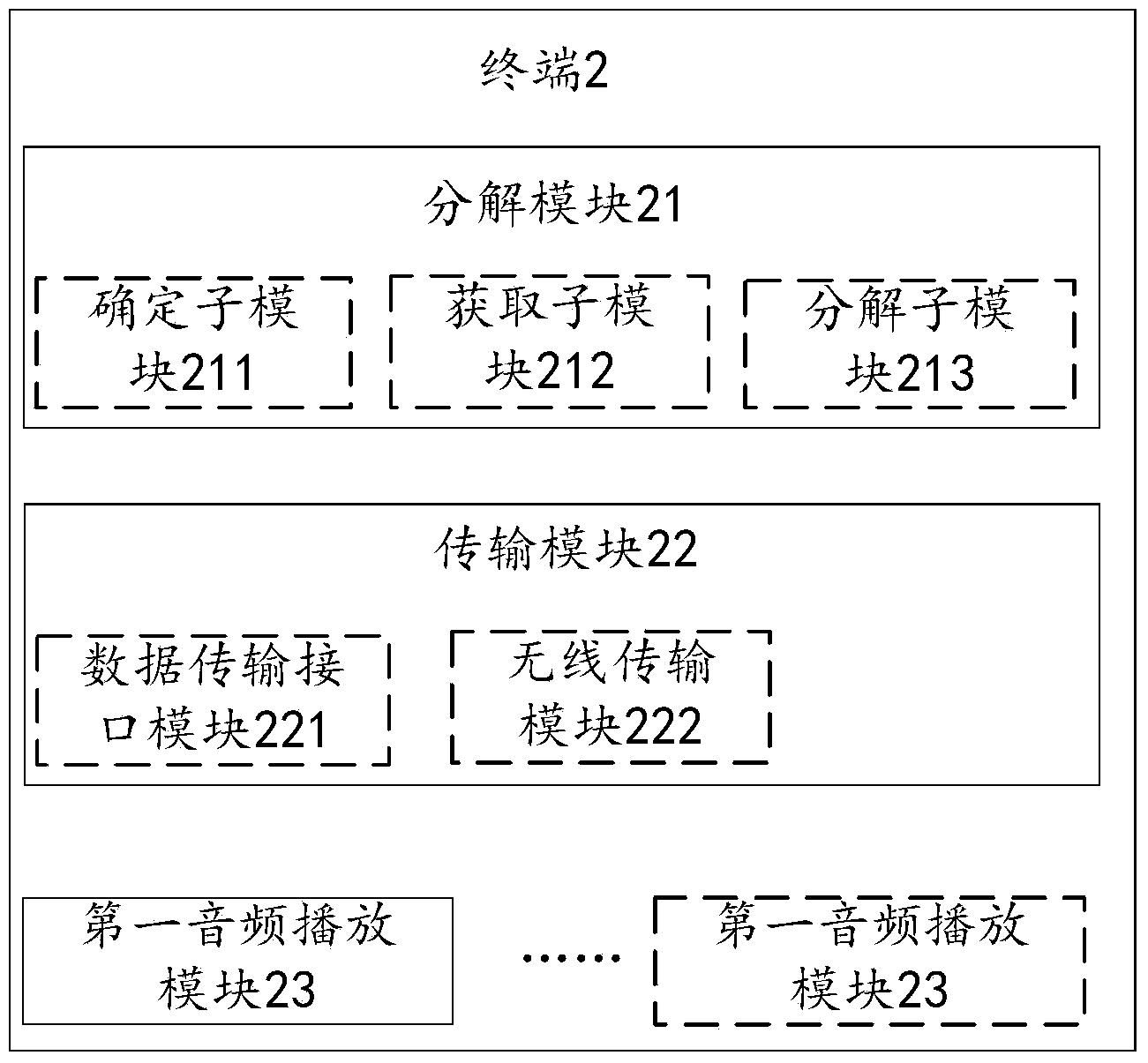

Terminal and stereophonic playing system and method

InactiveCN103841498AImprove experienceStrong sense of hierarchyStereophonic arrangmentsComputer terminalStereophonic sound

The invention discloses a terminal and a stereophonic playing system and method. The terminal decomposes an audio file into a plurality of audio streams according to preset rules and transmits the decomposed audio streams to different audio playing modules respectively. The audio playing modules include at least one first audio playing module carried by the terminal and at least one second audio playing module, wherein the terminal is externally connected with the second audio playing module. Each first audio playing module and each second audio playing module synchronously play the received audio streams. Through the technical scheme, the terminal solves the problems that an existing terminal does not make the most of the audio playing function of its own and needs to carry out stereophonic playing with the external audio playing modules.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

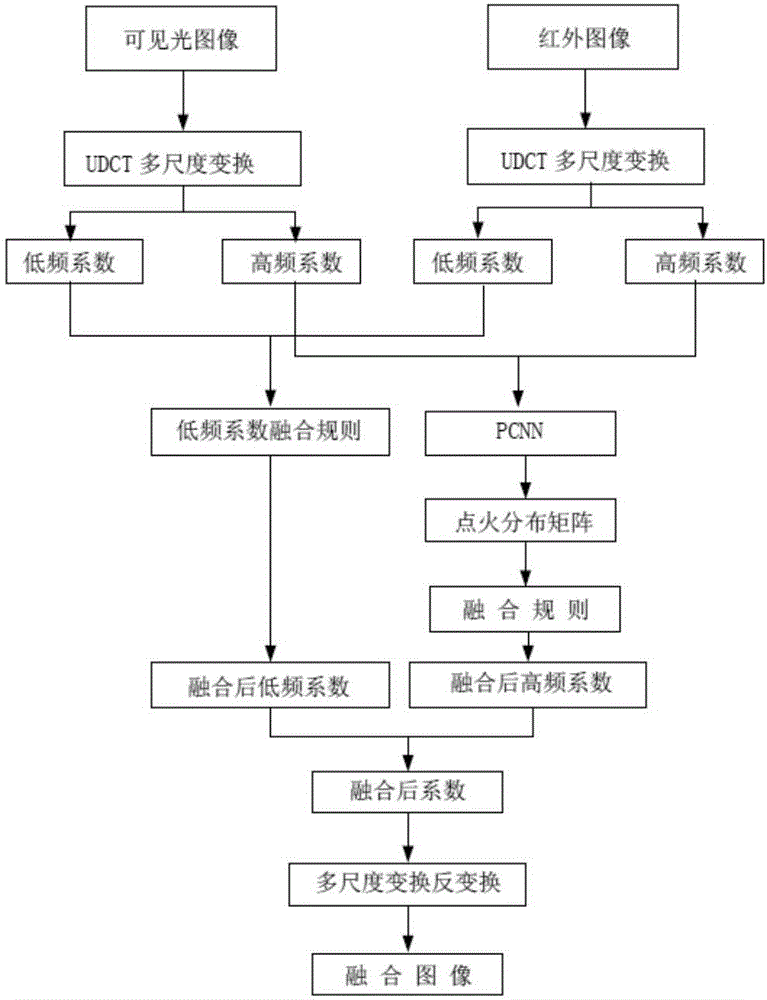

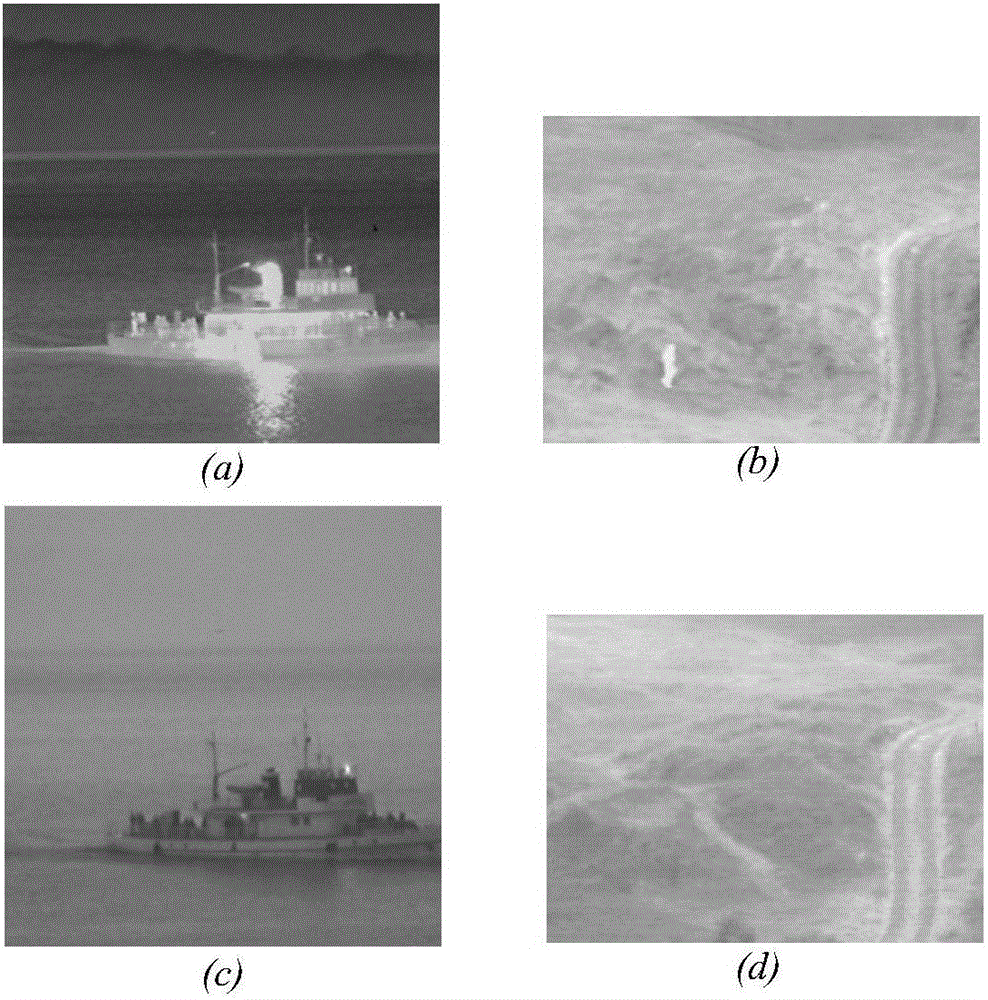

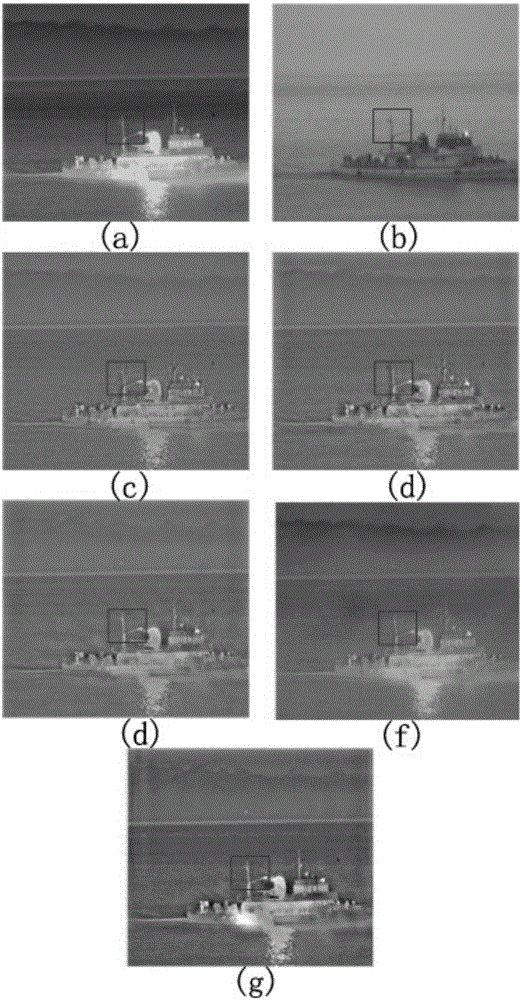

Visible light and infrared image fusion algorithm based on UDCT (Uniform Discrete Curvelet Transform) and PCNN (Pulse Coupled Neural Network)

ActiveCN106327459ARich in detailsSignificant neighborhood characteristicsImage enhancementImage analysisImaging processingDecomposition

The invention discloses a visible light and infrared image fusion algorithm based on UDCT (Uniform Discrete Curvelet Transform) and a PCNN (Pulse Coupled Neural Network), which relates to the technical field of image processing and solves the technical problems that the fused image is not clear and details are unobvious as the similarity of low-frequency information of a to-be-fused image can not be judged in the prior art, and the detail richness degree of a source image can not be judged. The algorithm of the invention mainly comprises steps: (1) after source images of the visible light image and the infrared image are subjected to UDCT decomposition, UDCT subband coefficients with different scales in different directions can be obtained, and the UDCT subband coefficients comprise low-frequency and high-frequency UDCT coefficients; and (2) according to a specific rule, a different mode is adopted for each scale layer for fusion processing, a low-frequency coefficient fusion rule is adopted for the low-frequency coefficients, a high-frequency coefficient fusion rule is adopted for the high-frequency coefficients, and finally, the UDCT coefficient for each layer after fusion can be acquired; and a reconstructed image obtained after inverse transforma on the UDCT coefficient for each layer after fusion is the fused image.

Owner:SICHUAN UNIV

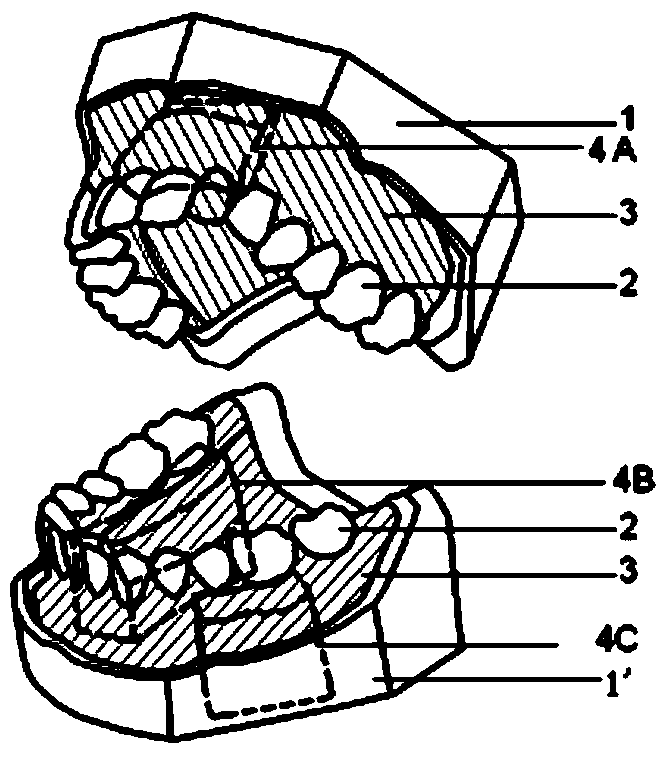

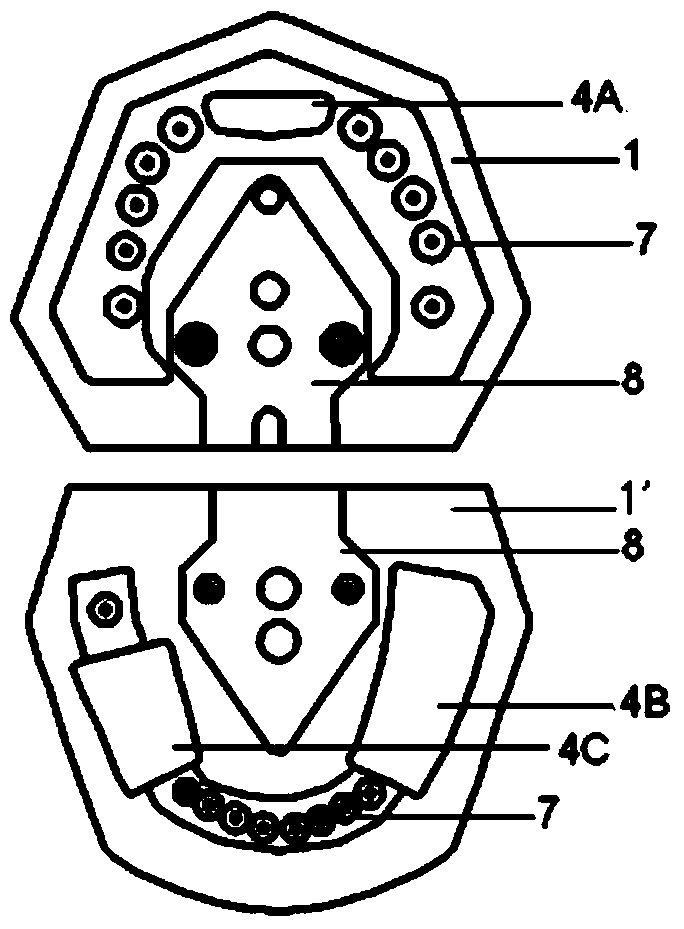

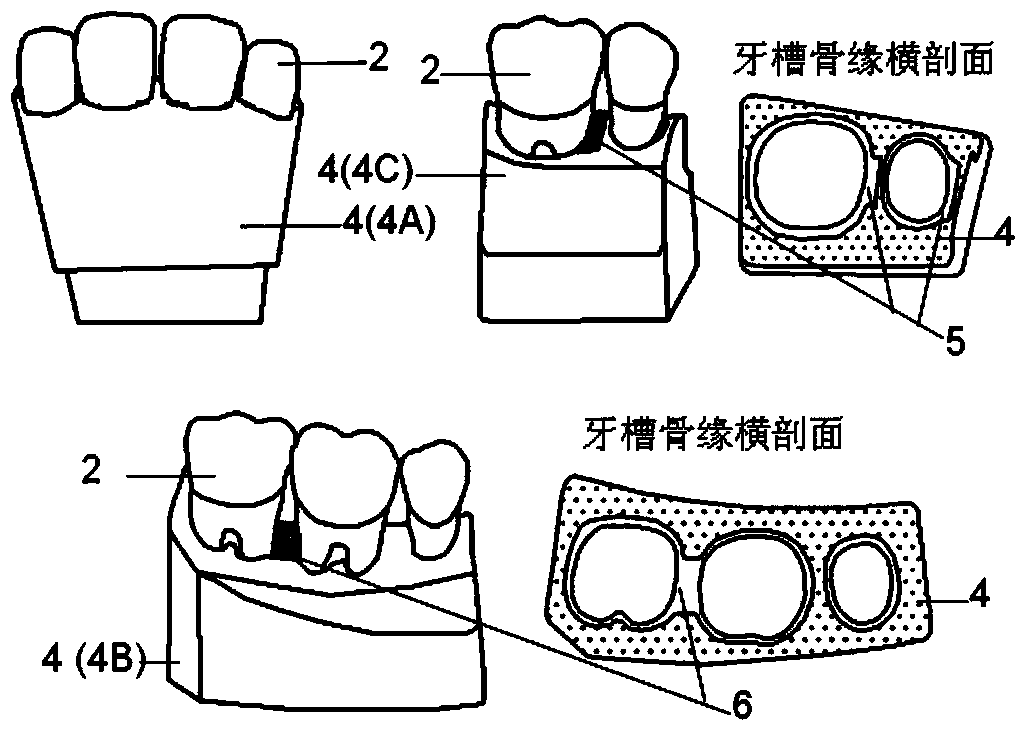

Periodontal operation teaching model

InactiveCN104183181AImprove practicalityReduce teaching costsEducational modelsPeriodontal surgeryMedical institution

The invention discloses a periodontal operation teaching model. The periodontal operation teaching model comprises a model base, an alveolar bone block, gingivae and artificial teeth. The model base comprises an upper jaw base and a lower jaw base. The alveolar bone block comprises an upper jaw alveolar bone block, a lower jaw right side alveolar bone block and a lower jaw left side alveolar bone block. The alveolar bones which have the periodontitis characteristics and the teeth which have the periodontitis characteristics are combined with the artificial gingivae, so that the implementation process of a periodontal operation is simulated to the maximum extent through the teaching model, and meanwhile teaching cost is reduced; the gingivae are made of imported polyurethane rubber, so that the simulation effect is good, the price is relatively low, and the gingivae are suitable for medical colleges and medical institutions; the clinic periodontal lesion structure and the operating hand feeling of the periodontal operation are simulated, the layering sense is good, and practicability is high; the operation body can be replaced, basic skill excise can be repeated, and popularization and application are facilitated.

Owner:ZHEJIANG UNIV

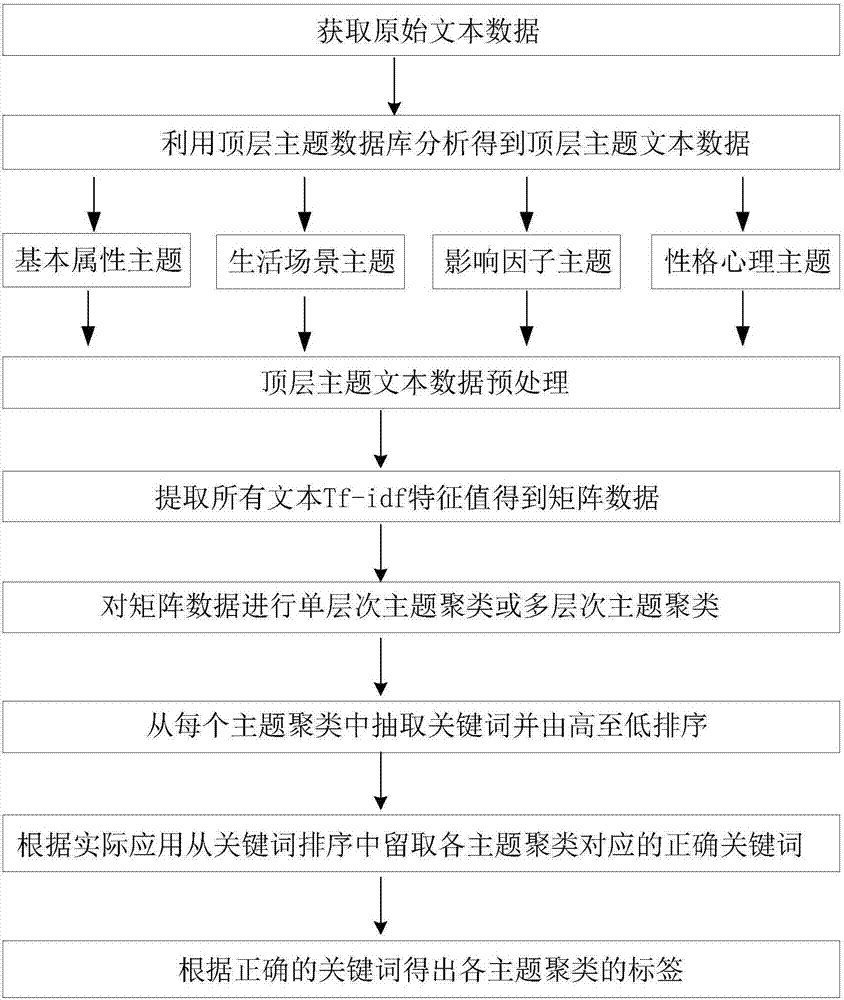

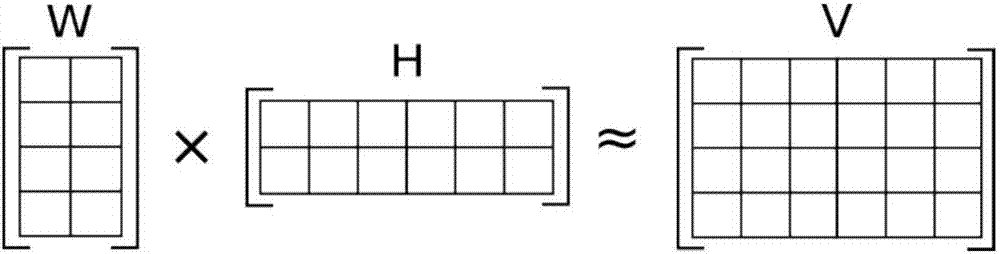

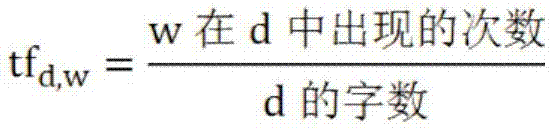

Data tag generation method and apparatus

ActiveCN107301199AAccurate content divisionEasy to useSpecial data processing applicationsInformative contentThe Internet

The invention discloses a data tag generation method and apparatus, and relates to the field of internet data. The method comprises the steps of obtaining original text data; performing analysis by utilizing a top-layer subject database to obtain multiple pieces of top-layer subject text data; preprocessing the top-layer subject text data to obtain preprocessed top-layer subject text data; extracting Tf-idf eigenvalues of all documents in the preprocessed top-layer subject text data to obtain matrix data; performing subject clustering on the matrix data to obtain a plurality of different subject clusters; sorting keywords in each subject cluster from high to low; correcting a keyword sorting table according to an actual application, and reserving the keywords closely related to and correctly expressing contents of the corresponding subject clusters; and obtaining a tag of each subject cluster according to a new keyword sorting table. According to the method, massive data can be subjected to subject clustering quickly and efficiently; and the obtained tag is complete in system structure, rich in content, closer to the actual application and convenient for users to use.

Owner:北京融数云途科技有限公司

Printing technology of PVC (polyvinyl chloride) plastic coiled material floor patterns

The invention discloses a printing technology of PVC (polyvinyl chloride) plastic coiled material floor patterns. The printing technology of the PVC plastic coiled material floor patterns comprises the following steps: firstly, imprinting and coating a releasing agent on the surface of a transfer basement membrane, then printing an ink pattern layer and an adhesive according to design patterns, and drying so as to obtain a transfer membrane; conveying a coiled material floor base material and a transfer membrane together to be between a rubber roller and a mirror surface roller of a printer, and bonding the adhesive on the surface of the ink pattern layer of the transfer membrane and the surface of the coiled material floor basement material sufficiently, wherein ink patterns on the transfer membrane are bonded on the surface of the coiled material floor basement material by the adhesive; the transfer membrane is separated and coiled after changing into a transfer base membrane; the surface of the coiled material floor base material with ink patterns is pasted with a transparent membrane and then is subjected to calendering or embossing treatment so as to obtain a coiled material floor finished product. The printing technology of the PVC plastic coiled material floor patterns, which is provided by the invention, have the advantages that patterns are printed on the surface of the transfer membrane in advance, and then are transferred to the surface of the coiled material floor base material through heating and compression, thereby obtaining floor patterns which are beautiful and vivid in color and intense in layering; the grade of the PVC plastic coiled material floor patterns is improved greatly; meanwhile, the technology is simple, and the production cost is low.

Owner:ZHENGZHOU SANLIAN PLASTIC PROD

Manufacturing process of shell

InactiveCN104626448ARealize sinter-free glazingHas natural stain resistanceLiquid/solution decomposition chemical coatingSuperimposed coating processCopper platingInjection moulding

The invention discloses a manufacturing process of a shell. The manufacturing process of a shell comprises the following steps: (1) providing a plastic and carrying out injection moulding to form a plastic workpiece of the shell; (2) forming a conductive layer on the surface of the shaped plastic workpiece; (3) soaking the plastic workpiece in a copper plating solution to perform electroplating to form a copper-plated layer on the conductive layer; (4) soaking the plastic workpiece in a nickel plating solution to perform electroplating to form a nickel-plated layer on the copper-plated layer; (5) soaking the plastic workpiece in a metal or alloy plating solution to perform electroplating to form a metal-plated layer or alloy-plated layer on the nickel-plated layer; and (6) spraying inorganic coating or organic coating onto the electroplated plastic workpiece to form an inorganic coating layer or an organic coating layer. The manufacturing process increases shell performances such as rigidity and strength, decreases cost, improves production efficiency and realizes environment protection. The manufacturing process can be combined with different electroplating surfaces and inorganic or organic coating layers to present various products with gorgeous and full colors, strong sense of hierarchies, beautiful and decent appearances, heat-resistant and abrasion-resistant properties, anti-corrosion properties and high rigidities.

Owner:温兵

Flashing light wool-simulating hemp-simulating surfacing material and process technique thereof

InactiveCN101109125AImprove comfortSpecial glossHeating/cooling textile fabricsDyeing processPolyesterPolymer science

The invention discloses a sparkling fur- / hemp-imitated shell fabric and the processing process for the shell fabric. Wherein, a warp and a weft are woven together, the warp takes blend yarn of bamboo fiber and polyester microfiber as raw materials, the weft uses blended yarn of sparkled and various color from modified polyester and viscose as raw materials. The invention is soft, of good drapability, highly resistant to wear, with good air permeability, resistance to static, good resilience and antibiotic property.

Owner:洪桂焕

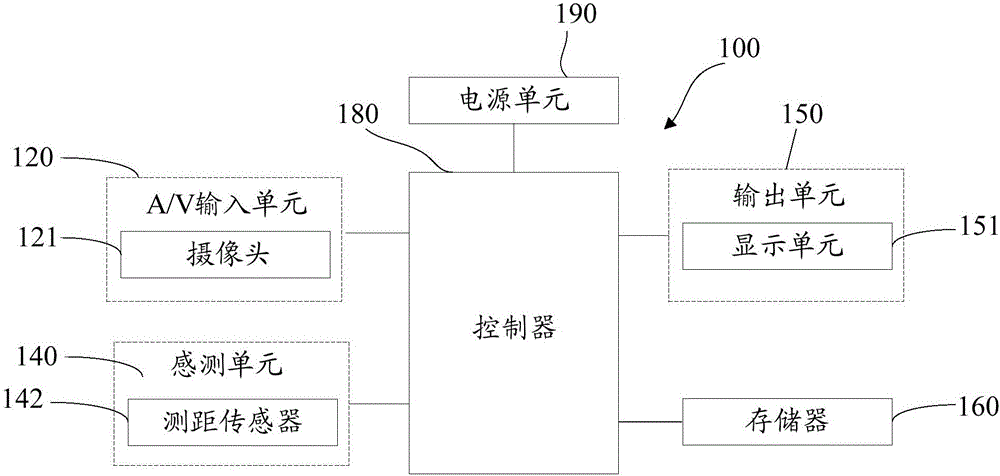

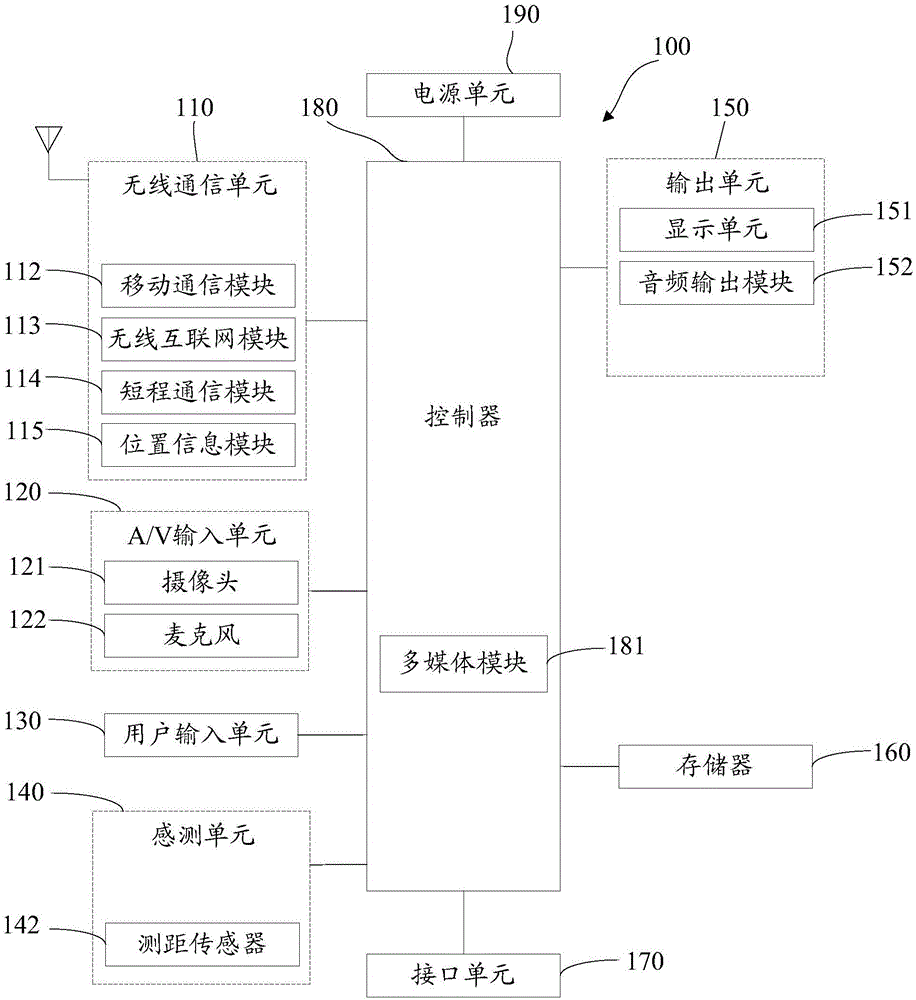

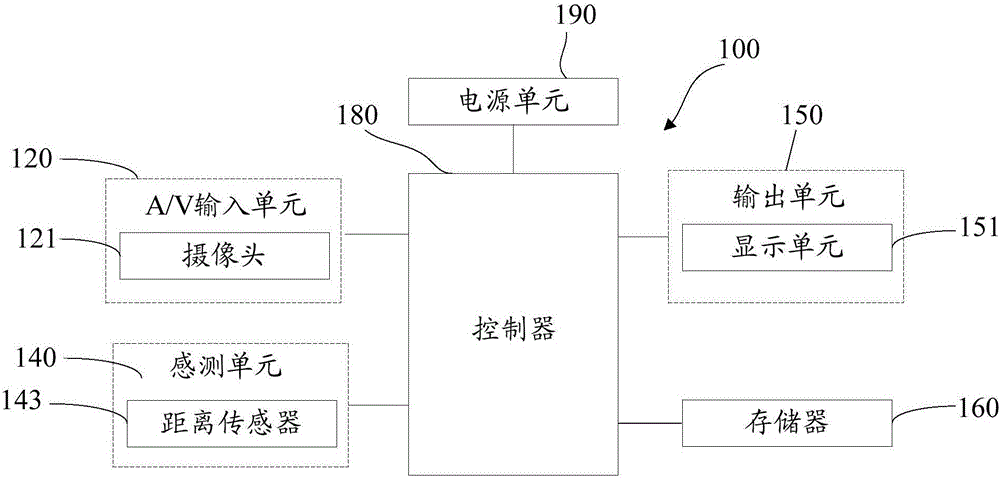

Mobile terminal and focusing method

InactiveCN105827961AImprove experienceStrong sense of hierarchyTelevision system detailsColor television detailsSensing dataImage plane

The present invention discloses a mobile terminal and a focusing method. The mobile terminal comprises a distance measuring sensor used for sensing an object in an environment and outputting the sensing data representing the position of the object in the environment; a controller used for determining an object distance parameter of the object formed relative to a camera based on the sensing data, and determining an image distance parameter used by the camera based on the object distance parameter; the camera used for adjusting the distance between a lens of the camera and an image plane corresponding to the camera under the control of the controller and based on the image distance parameter. According to the present invention, the automatic and rapid focusing of the camera can be realized.

Owner:NUBIA TECHNOLOGY CO LTD

Method for producing multiple color ancient-imitation wood floorings

InactiveCN1903532AWith three-dimensional effectStrong sense of hierarchyPolishing machinesDrying solid materials with heatLacquerDark color

A technology for preparing the pseudo-classical multi-color wooden floor board includes such steps as making raw wooden floor boards, aquatic coloring to have dark color, drying, polishing, aquatically coloring light color, drying, coating priming paint, drying, polishing, coating surface paint, and drying.

Owner:徐建国

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

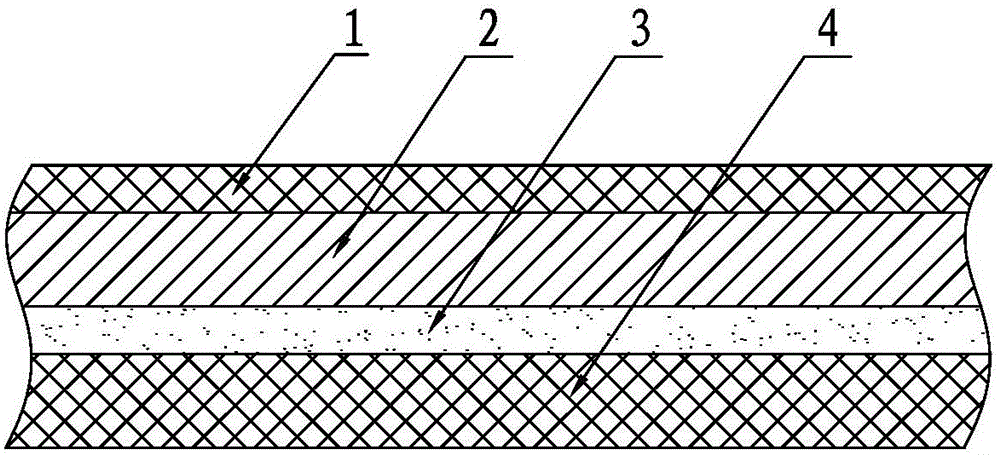

Environment-friendly breathable TPU (Thermoplastic polyurethanes) synthetic leather and preparation method thereof

InactiveCN105966027AReduce pollutionMethod route shortLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesiveAdditive ingredient

The invention discloses an environment-friendly breathable TPU synthetic leather and a preparation method thereof. The environment-friendly breathable TPU synthetic leather comprises a decorative surface layer, a TPU surface layer, an adhesive layer and a base cloth layer. The decorative surface layer is coated on The treatment agent on the upper surface of the TPU surface layer is generated, and the TPU surface layer is combined with the base cloth layer through the adhesive layer. The components and parts by weight of the TPU surface layer are: 30 to 95 parts by weight of TPU particles; 3 to 95 parts by weight of the flame retardant 25 parts by weight; 2-15 parts by weight of pigment; 0-5 parts by weight of light stabilizer; 0-5 parts by weight of anti-scratch agent; 0-20 parts by weight of filler. The adhesive is a water-based polyurethane adhesive; the surface treatment agent is a water-based polyurethane surface treatment agent. Adopting the preparation method of extrusion casting, shaping first, then compounding, and negative pressure embossing, the products are environmentally friendly, non-toxic, low-odor, low-VOC, clear in structure, soft in hand, scratch-resistant, wear-resistant, hydrolysis-resistant, genuine leather Strong features.

Owner:常州三聚塑胶科技有限公司

Sugar alcohol crystal cool sugar-free candy and preparation method thereof

ActiveCN101803663ASolve instabilityImprove stabilityConfectionerySweetmeatsWater bathsFood colouring

The invention provides a sugar alcohol crystal cool sugar-free candy and a preparation method thereof, which can solve the problems of difficult formation and poor mouthfeel caused by easy damaged crystal in the prior art. The technical scheme is that the sugar alcohol crystal cool sugar-free candy comprises a sugar alcohol crystal layer which is prepared from the following components by weight: 50 to 100 percent of xylitol, 0 to 50 percent of sorbitol, 0 to 0.3 percent of flavouring essence, 0 to 0.03 percent of food colour, 0 to 3 percent of fruit juice and 0 to 3 percent of acidity regulator. The invention further provides the preparation method for the candy. The double-layer or three-layer sugar-free candy, which is prepared by melting the xylitol and sorbitol by a heating and boiling method in a water bath of 90 to 98 DEG C so as to prevent crystals of the xylitol and sorbitol from being damaged by over high boiling temperature, is hard, cool and refreshing, and has strong milk or fruit taste.

Owner:SHANDONG FUTASTE

Archaized composite floor and its manufacturing method

ActiveCN1603551AUnique smoky colorObvious ups and downsDecorative surface effectsFlooringColor effectEngineering

The invention discloses in the style of antiquity compound floor and its the preparation method belongs to the compound floor technology, for may solve the traditional compound floor plane effect and the existing in the style of antiquity floor color effect bad, only pauses in the superficial question, the thermo-compression, after the polishing and opens, carries on smokes and scratches, the compound floor which makes has the unique smoking color and the clearer level obvious stereoscopic effect, the form is diverse, and the table board may fully use and so on the merit, in the style of antiquity compound floor which the class invents uses in the house decoration.

Owner:FUSONG QIANQIU WOOD CO LTD

Preparation method of Abbey strong Ale beer

InactiveCN109321394AIncrease bodyGood foaming performanceMicroorganism based processesBeer brewingYeastAlcohol

The invention relates to a preparation method of Abbey strong Ale beer. The preparation method comprises the following steps of (1) mixing malt and water, saccharifying, filtering, boiling, adding hops, and rotationally settling, so as to obtain wheat juice; (2) performing primary fermentation on the wheat juice in a fermenting tank, adding fermentable sugar and dry hops to perform secondary fermentation; after the secondary fermentation is finished, using no production of gas as the endpoint, centrifuging to remove yeast, adding Belgian Kitty candy, inoculating a second type of surface yeast,loading into bottles, putting into a cold storage for tertiary fermentation. The preparation method has the advantages that in the latter stage of the primary fermentation, the fermentable sugar anddry hops are added; after the secondary fermentation is finished, the yeast is removed, the fermentable sugar is added, and the new surface yeast is inoculated to perform the tertiary fermentation. The finally produced beer has the advantages that the degree of alcohol is high, the beer body is mellow, and the fragrance of the malt and the hops and the sweet taste of the beer are highly balanced.

Owner:QILU UNIV OF TECH

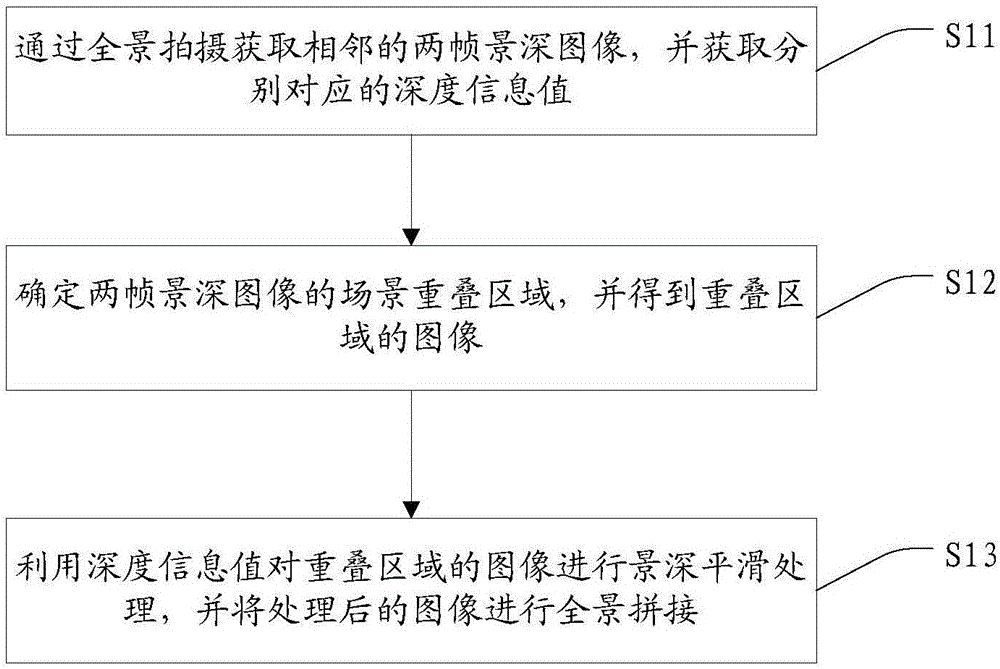

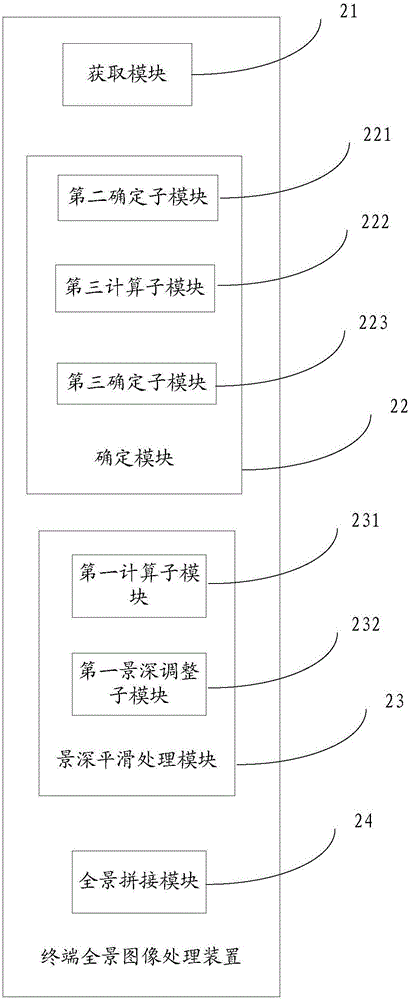

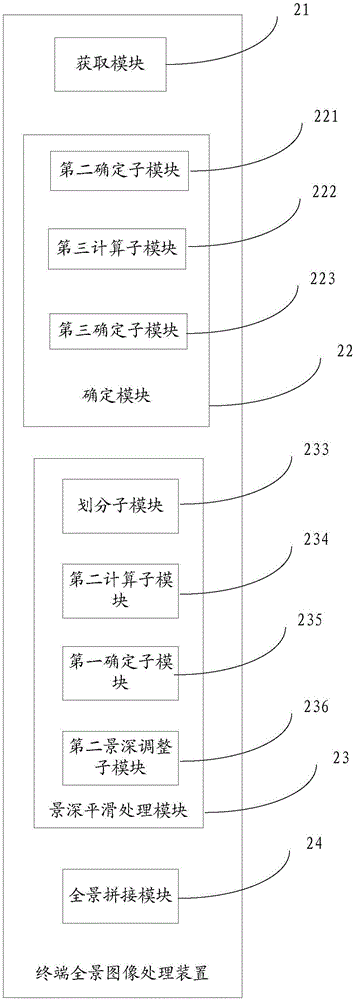

Panoramic image processing method and device for terminal and terminal

InactiveCN106651755AWith bokeh effectStrong three-dimensional senseImage enhancementImage analysisVirtualizationImaging processing

The invention provides a panoramic image processing method and device for a terminal and the terminal. The panoramic image processing method for the terminal comprises the steps of: acquiring two adjacent frames of field depth images by panoramic shooting, and acquiring respective depth information values; determining a scene overlap area of the two frames of field depth images, and obtaining an image of the overlap area; performing field depth smoothing on the image of the overlap area by using the depth information values, and performing panoramic stitching on the processed image. According to the above solution, field depth smoothing is performed on the image of the overlap area by using the respective depth information values of the two adjacent frames of field depth images, so that the obtained panoramic image has a background virtualization effect, and is strong in third dimension and depth sense, prominent in scene focus, natural in stitching transition and good in visual effect.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

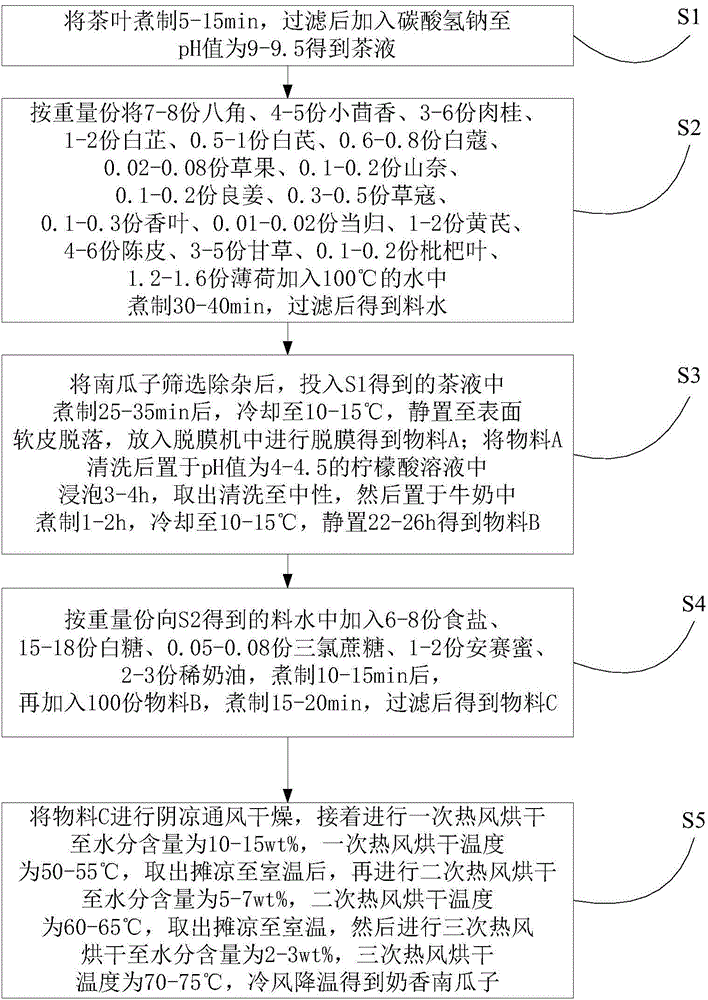

Milk flavored pumpkin seed preparation method

InactiveCN104886666AEasy accessImprove crispnessNatural extract food ingredientsFood dryingSodium bicarbonateAngelica dahurica

The present invention discloses a milk flavored pumpkin seed preparation method which comprises the following steps: boiling tea leaves for 5-15 min, filtering the boiled tea leaves, and adding sodium bicarbonate into the filtrate to obtain the tea liquid; adding star anises, fennel, cinnamomum cassia, angelica dahurica, cynanchum otophyllum, alpinia tonkinensis, amomum tsaoko, rhizoma kaempferiae, alpinia officinarum, alpinia hainanensis, bay leaves, angelica sinensis, astragalus membranaceus, dried tangerine peels, liquorice, eriobotrya japonica leaves, and mentha haplocalyx are added into water to conduct boiling, and filtering the boiled materials to obtain the material filtrate; screening pumpkin seeds and removing impurities of the pumpkin seeds, then putting the impurity removed pumpkin seeds into the tea liquid to conduct boiling, cooling and keeping the boiled pumpkin seeds still until the surface soft skins fall off, then put into a stripping machine for stripping to obtain material A; washing the material A, soaking in a citric acid solution, removing the material A out and washing the material A to be neutral, then placing the material A in milk to conduct boiling and cooling and keeping the boiled material A still for 22-26 h to obtain material B; adding edible salt, white granulated sugar, sucralose, acesulfame and whipping cream into the material filtrate to conduct boiling, then adding the material B to conduct boiling, and filtering the above materials to obtain material C; and air-drying the material C at cool place, and followed by conducting hot air-drying, and cold-air temperature lowering to obtain the flavored pumpkin seeds.

Owner:蚌埠市徽味炒货厂

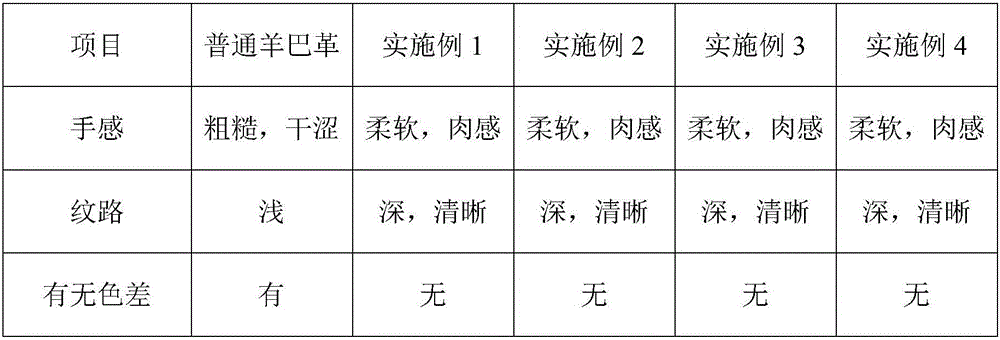

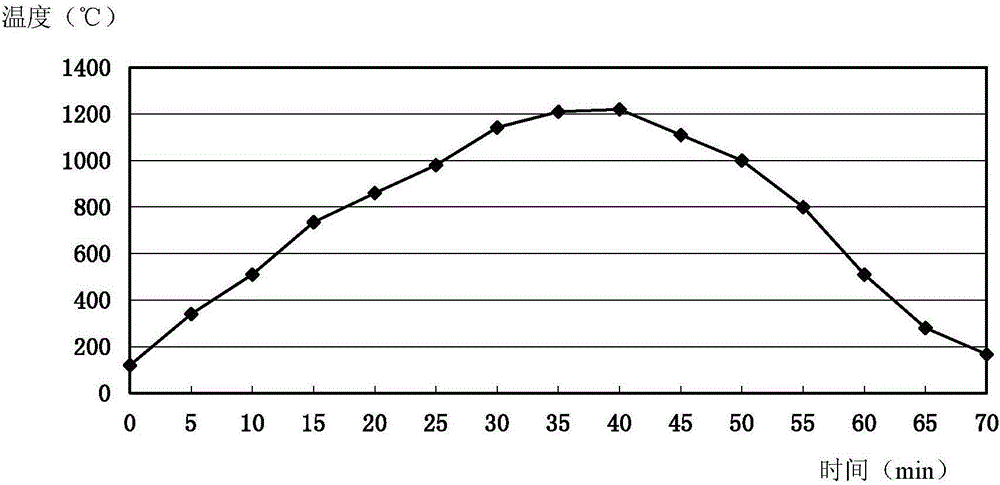

Water-based yangbuck with lustring effects and method for preparing water-based yangbuck

ActiveCN106436337AStrong sense of hierarchyClear texturePolyurea/polyurethane coatingsTextiles and paperWater basedEngineering

The invention provides a method for preparing water-based yangbuck with lustring effects. The method includes steps of 1), coating and scraping water-based wet base slurry on base cloth, transporting the base cloth into a coagulating tank, coagulating the base cloth and drying the base cloth by means of baking to obtain water-based base; 2), coating water-based yangbuck materials on release paper, drying the water-based yangbuck materials and the release paper to form yangbuck clinging surfaces, adhering the water-based base onto the yangbuck clinging surfaces, then drying the yangbuck clinging surfaces by means of baking, cooling the yangbuck clinging surfaces and peeling the release paper to obtain artificial leather by means of preparation; 3), placing the artificial leather in a baking oven and foaming the artificial leather at the high temperature to obtain yangbuck by means of preparation; 4), carrying out color change treatment on the yangbuck by the aid of a printing machine; 5), preparing lustring materials, adding the lustring materials into the printing machine and carrying out lustring treatment on the yangbuck. The method has the advantages that the surfaces of the water-based yangbuck are high in leather feeling and good in velvet feeling and feel soft, and the excellent lustring effects can be realized; the surfaces of the yangbuck are bulky, thick, smooth, straight and bright and have plump pile after lustring treatment is carried out on the yangbuck, and market requirements on high-grade yangbuck can be met.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

Method for producing woolen shiner herringbone

InactiveCN101225567AIncrease color glossImproved flash effectShrinkingLiquid/gas/vapor removalPulp and paper industryHerringbone pattern

The invention relates to a production method for a woolen shiner herringbone cloth, which is characterized in comprising the following steps: 80% 70 yarn count Australian wools and 20% polyamide fibers are adopted to be spun into 20 wool yarns, which are then combined into parallel yarns together with 150D bright terylene shiners and 30D polyamide fiber filaments; then, by means of weaving and post-finishing processes, the intended woolen shiner herringbone is produced. The production method combines woolen yarns and bright shiners to develop a fabric with herringbone-shaped patterns, which is a casual fashion fabric plain in appearance yet fashionable in style, with the excellent qualities, such as soft hand feeling, thinness as well as strong depth perception of the herringbone patterns. Therefore, the woolen shiner herringbone cloth has the advantages of softness and light weight, delicate fabric, strong depth perception, comfortableness for wearing, and easiness for maintenance.

Owner:江阴市天鹅制呢厂有限公司

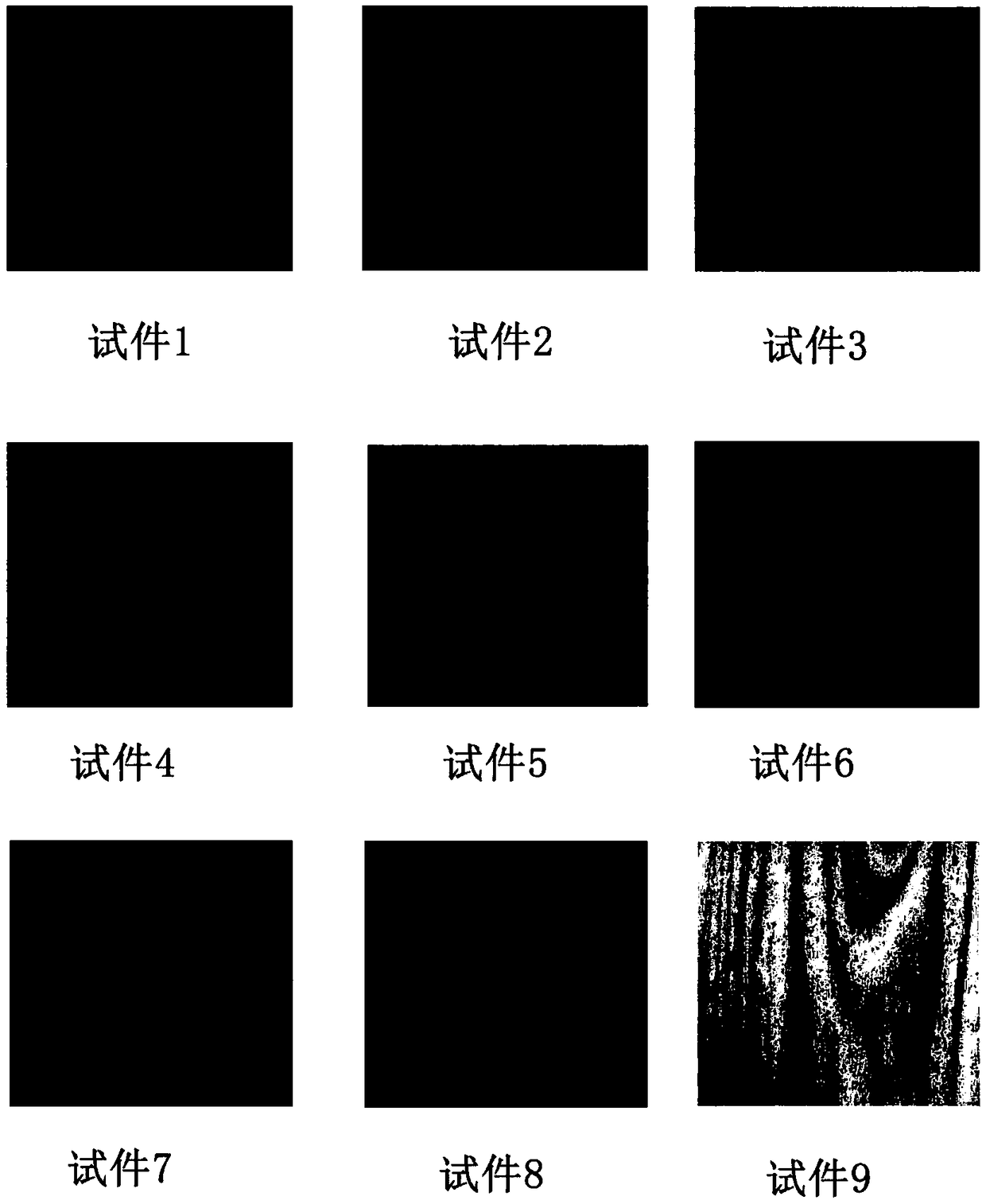

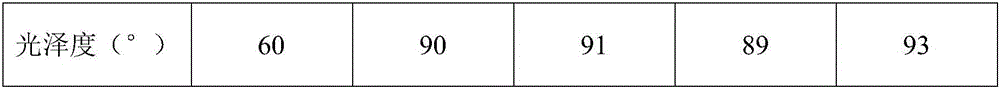

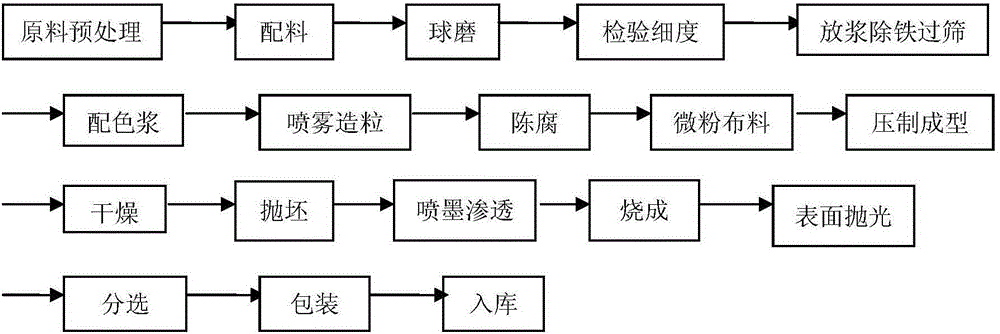

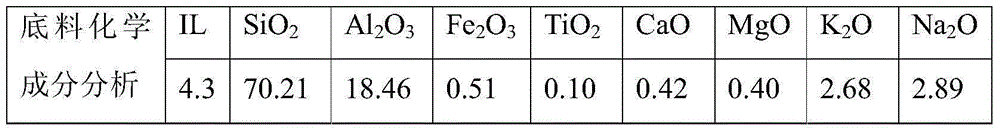

Preparation method of ink-jet permeable micro-powder polished tile

The invention relates to a preparation method of an ink-jet permeable micro-powder polished tile. The preparation method comprises the following steps of preparing a micro-powder blank through micro-powder cloth in a compression forming way; carrying out blank polishing treatment on the micro-powder blank, wherein the blank polishing thickness is 0.6 to 1.0 mm; carrying out ink-jet permeation, firing and surface polishing on a micro-powder cloth blank body which is subjected to the blank polishing treatment to obtain the ink-jet permeable micro-powder polished tile. According to the preparation method of the ink-jet permeable micro-powder polished tile, disclosed by the invention, the advantages of high pattern layering sense of a permeable product, random changing of an ink-jet printing product and the micro-powder cloth polished tile are combined, the stereoscopic impression of a pattern can be stronger, and the texture is more diversified.

Owner:MONALISA GRP CO LTD

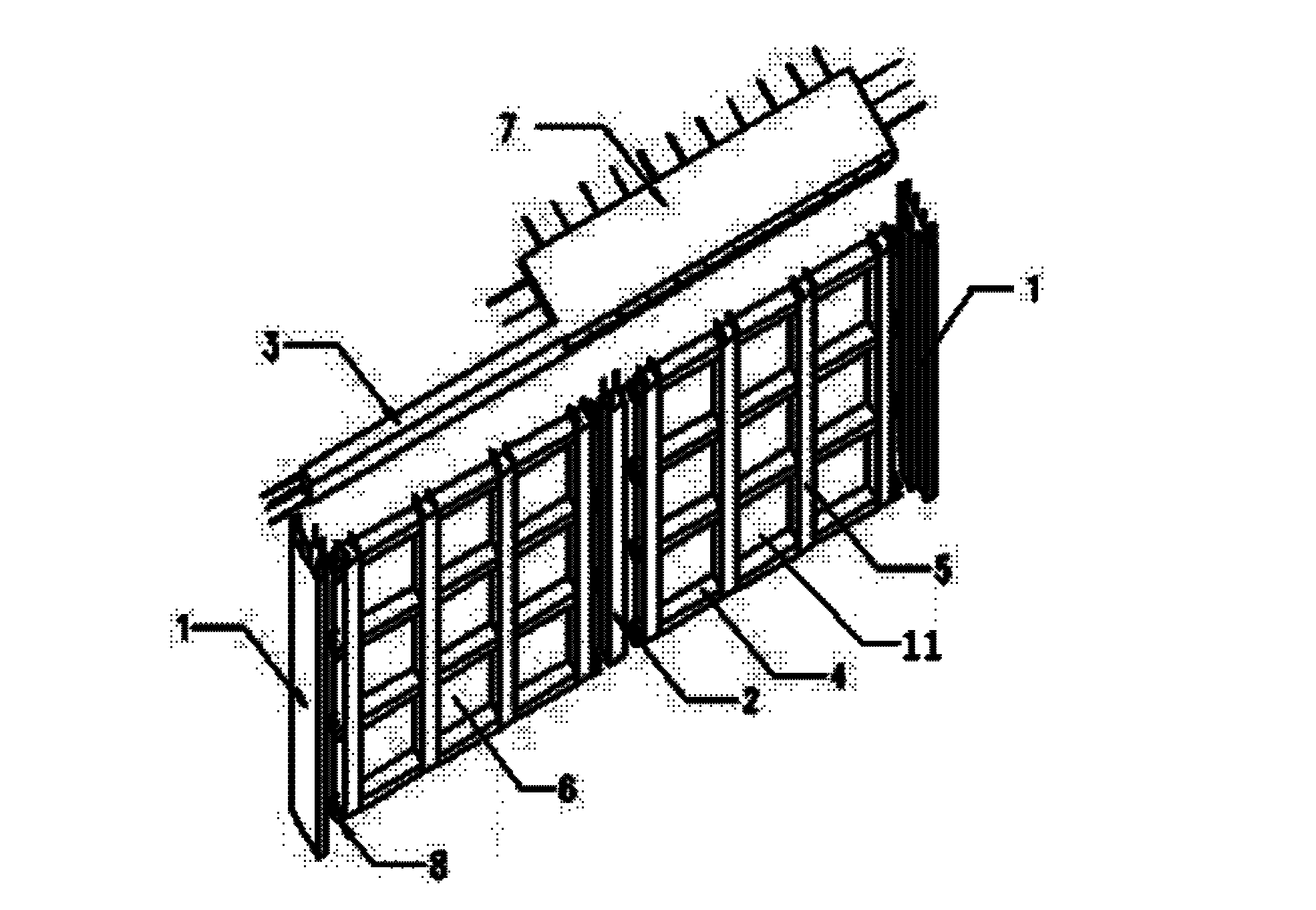

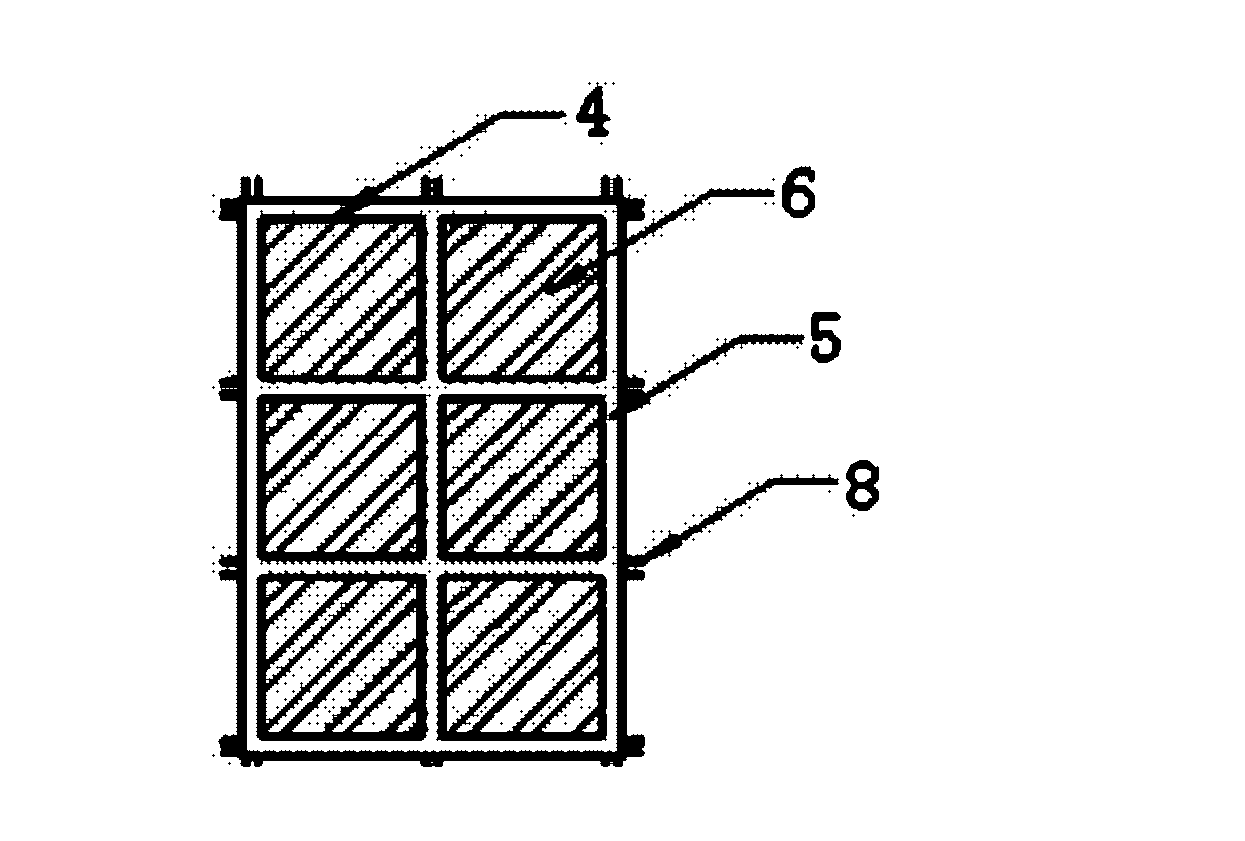

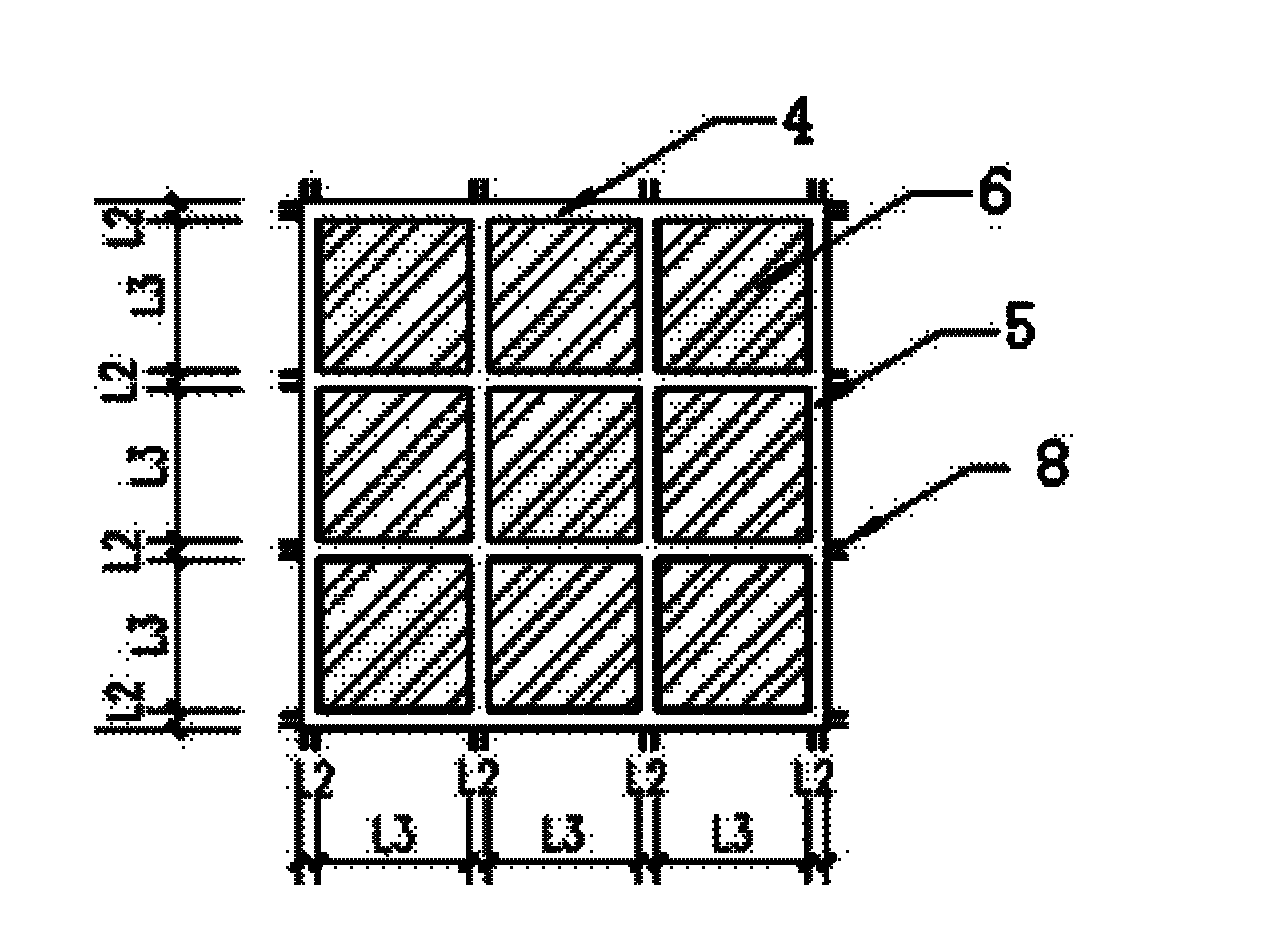

Energy dissipating and shock absorbing system having dense reinforcement structure

The invention discloses an energy dissipating and shock absorbing system having a dense reinforcement structure, which comprises a concealed frame consisting of ending columns, connecting columns and a concealed beam. A floor slab is connected to the concealed beam horizontally, a part of the concealed frame is provided with dense reinforcement composite wall boards with low yield point, and the other part of the concealed frame is provided with light dense reinforcement composite wall boards filled with bricks. The invention provides another energy dissipating and shock absorbing system having a dense reinforcement structure, which comprises a concealed frame consisting of ending columns, connecting columns and a concealed beam, floor slabs are horizontally connected to the concealed beam, and dense reinforcement composite wall boards with low yield points are arranged in the concealed frame fully. Besides, the dense reinforcement composite wall boards with low yield points comprises multiple reinforced beams and reinforced columns which form rectangular grid structures, and steel plates with low yield point are embedded into the grids. The energy dissipating and shock absorbing system having the dense reinforcement structure is simple in structure, high in energy dissipation, stable in in energy dissipation performance and fine in shock absorption.

Owner:XIAN UNIV OF TECH

Flowing color decorative effect ceramic tile and preparation method thereof

The invention relates to a flowing color decorative effect ceramic tile and a preparation method thereof. The preparation method comprises the steps of sequentially applying a ground coat, applying acrystallization cover glaze, applying a crystallization effect glaze on a tile blank, and then firing.

Owner:MONALISA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com