Cold-hot film process

A cold-foil film and process technology, applied in printing, copying/marking methods, etc., can solve the problems of high price of imported cold-foil film and cold-foil glue, lack of development of cold-foil technology, long supply cycle, etc., and achieve short plate-making cycle, The effect of wide application range and reduced plate making cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

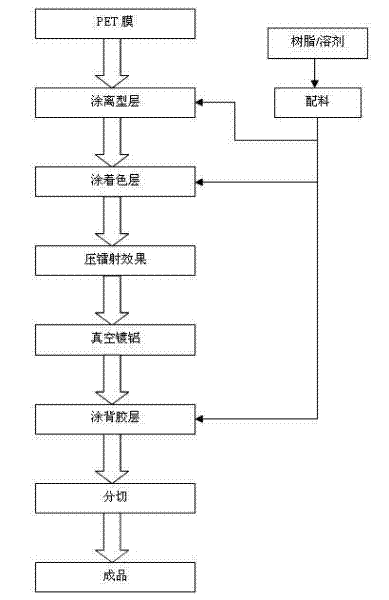

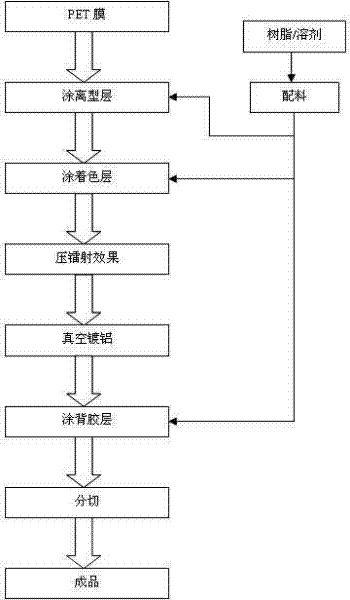

[0023] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

[0024] Process of the present invention such as figure 1 As shown, the release layer is mainly coated on the PET film, and then the coloring layer is coated on the release layer. The effect of the laser layer is molded on the coloring layer. The laser layer is vacuum-plated with aluminum, and then the adhesive is coated. Finally cut into finished products.

[0025] Among them, the coating release layer: additives (silicon oil, water wax, OP wax, polytetrafluoroethylene, oxidized polyethylene, cellulose acetate, etc.) can be dissolved: firstly weigh the methyl ethyl ketone: toluene solution in a ratio of 1:1 , placed in a heating insulation bucket, heated and kept warm to ≥40°C; then weigh the additive and dissolve it in a toluene solution ≥40°C; finally pour the dissolved additive into the mixed solution in the insulation bucket. (Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com