Water-based yangbuck with lustring effects and method for preparing water-based yangbuck

A kind of Yangba leather, water-based technology, applied in the field of garment leather production, to achieve the effect of good velvet feeling, strong leather feeling and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

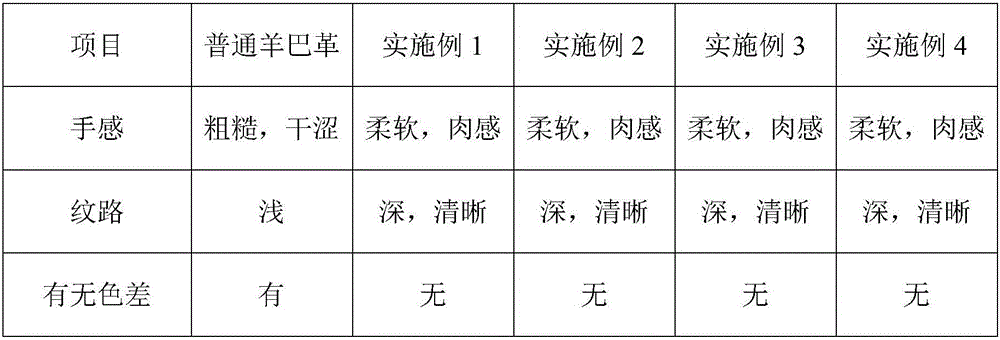

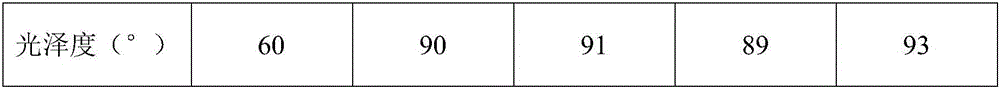

Examples

Embodiment 1

[0041] (1) To prepare water-based wet bass slurry, take 80kg water-based polyurethane (Hefei Ketian KT631), 12kg lignocellulose, 0.5kg sodium dodecylsulfonate, 0.5kg water-based thickener (RM2020), and use a high-speed mixer Stir and foam to 1.2 times the original volume.

[0042] Scrape the water-based wet base slurry on the base fabric, the thickness of the water-based wet base slurry is 300um, and then transport it to the coagulation tank for solidification at room temperature, so that the water-based wet base slurry is completely combined with the base fabric , and then placed in an oven to dry and cool to prepare the water-based bass.

[0043] (2) Preparation of water-based yangbuck material: take 90 parts of water-based polyurethane resin (Hefei Ketian KT727), 3 parts of yangbuck powder (TX-909, particle size 18-20um), 3kg of water-based color paste, 0.6kg of water-based thickener agent (RM2020), add it to the mixer, and stir until the slurry is evenly dispersed.

[00...

Embodiment 2

[0050] (1) Prepare water-based wet bass slurry, take 80kg water-based polyurethane (Hefei Ketian KT631), 15kg lignocellulose, 1kg sodium dodecylsulfonate, 0.8kg water-based thickener (RM2020), and stir with a high-speed mixer , foamed to 1.3 times the original volume.

[0051]Scrape the water-based wet base slurry on the base fabric, the thickness of the water-based wet base slurry is 300-400um, and then transport it to the coagulation tank for solidification at room temperature, so that the water-based wet base slurry and the base fabric Completely combined, then placed in an oven to dry, cooled, and prepared to obtain water-based bass.

[0052] (2) Prepare water-based yangbuck material: take 90kg water-based polyurethane resin (Hefei Ketian KT727), 5kg yangbuck powder (particle size 18-20um), 5kg water-based color paste, 0.8kg water-based thickener (RM2020), add In a mixer, stir until the slurry is evenly dispersed.

[0053] Coat the water-based yangbuck material on the re...

Embodiment 3

[0059] (1) Prepare water-based wet bass slurry, get 80kg water-based polyurethane (Hefei Ketian KT631), 17kg lignocellulose, 1kg sodium dodecyl sulfonate, 1kg water-based thickener (RM2020), stir with a high-speed mixer, Foam to 1.4 times the original volume.

[0060] Scrape the water-based wet base slurry on the base fabric, the thickness of the water-based wet base slurry is 350um, and then transport it to the coagulation tank for solidification at room temperature, so that the water-based wet base slurry is completely combined with the base fabric , and then placed in an oven to dry and cool to prepare the water-based bass.

[0061] (2) Prepare water-based yangbuck material: take 90kg water-based polyurethane resin (Hefei Ketian KT727), 7kg yangbuck powder (particle size is 15-18um), 7kg water-based color paste, 1 part of water-based thickener (RM2020), add In a mixer, stir until the slurry is evenly dispersed.

[0062] Coat the water-based yangbuck material on the releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com