Patents

Literature

134results about How to "Good combination fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Traditional Chinese medicine inclusion compound with antibacterial effect and textile finishing method of traditional Chinese medicine inclusion compound

InactiveCN102605630AImprove the immunityOvercome the single defect of antibacterial effectFibre treatmentBiotechnologyCyclodextrin

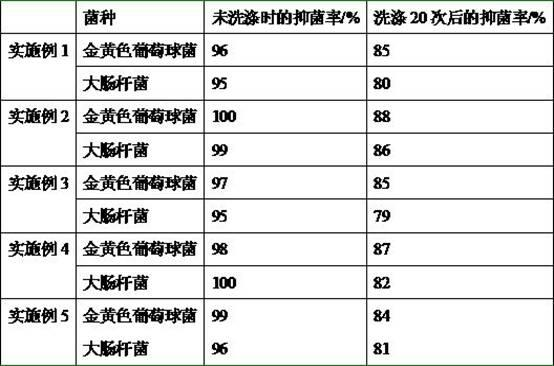

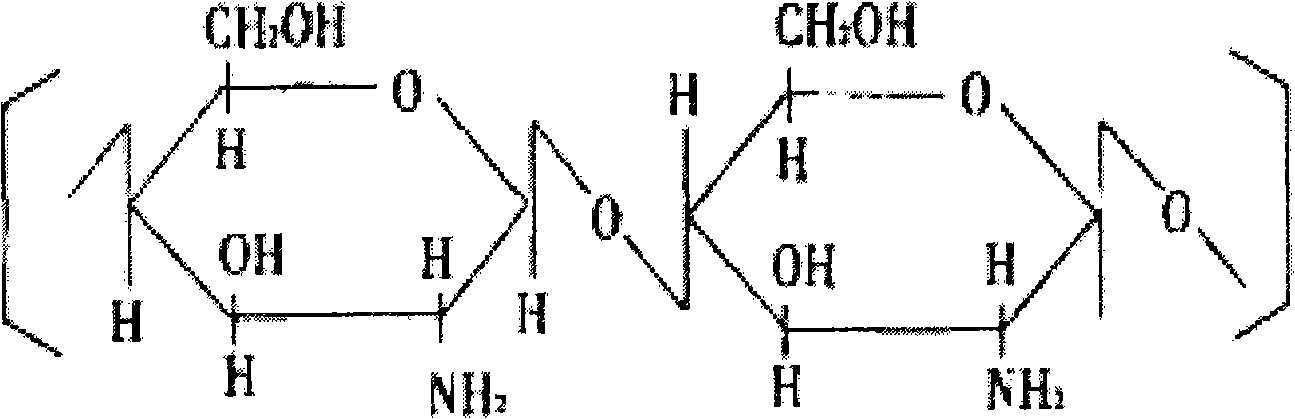

The invention discloses a traditional Chinese medicine inclusion compound with an antibacterial effect and a textile finishing method of the traditional Chinese medicine inclusion compound. The traditional Chinese medicine inclusion compound is prepared from traditional Chinese medicine extract liquid with the total ingredient percentage being 100 percent and beta-cyclodextrin through a saturated water solution method, wherein the traditional Chinese medicine extract liquid comprises the following ingredients in percentage by mass: 25 percent to 60 percent of honeysuckle, 15 percent to 50 percent of folium Artemisiae argyi, 20 percent to 35 percent of liquorice and 5 percent to 15 percent of scutellaria baicalensis. The traditional Chinese medicine inclusion compound and cross linking agents are added into chitosan acetic acid solution to be prepared into antibacterial finishing liquid. A simple rolling baking process is adopted for carrying out antibacterial finishing on the cellulose fiber, the process is simple, the finished textile has the broad-spectrum antibacterial performance on common germs such as staphylococcus aureus, escherichia coli and the like, and in addition, the water washing resistance performance is good.

Owner:NANTONG JIAYUSI TEXTILE GROUP

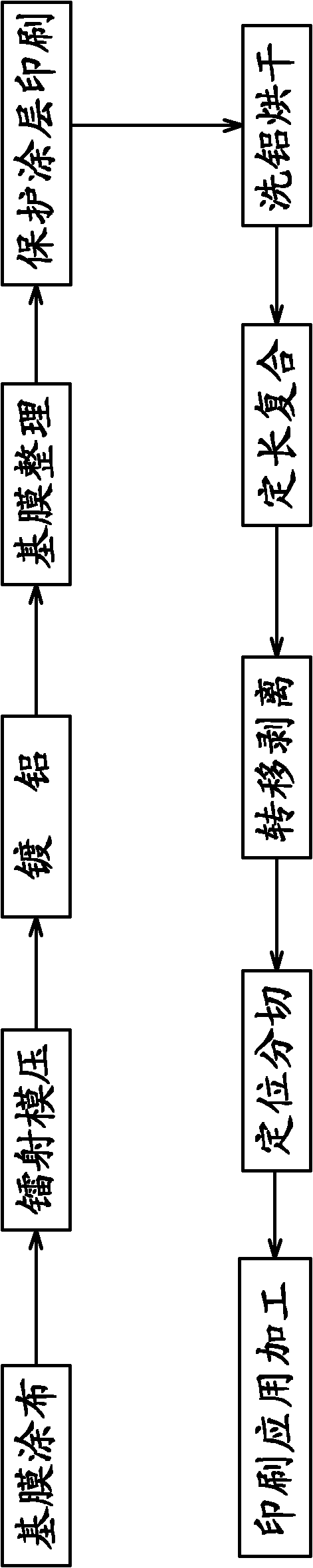

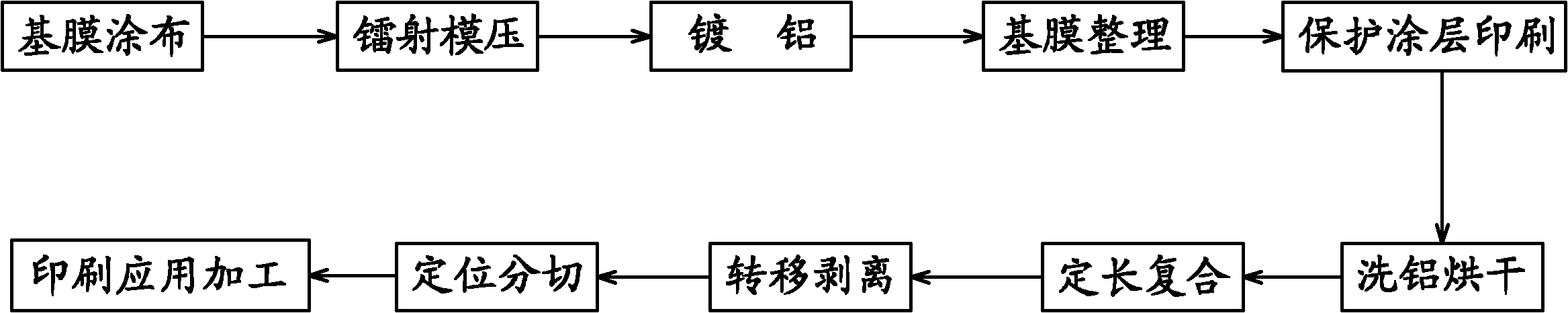

Process for producing cigarette label by replacing large-area hot stamping with local dealuminization transfer

ActiveCN102152678AAvoid implementation difficultiesGood qualityPattern printingOther printing apparatusHot stampingProcess engineering

The invention discloses a process for producing a cigarette label by replacing large-area hot stamping with local dealuminization transfer. Currently, the large-area hot stamping cigarette label producing process has the problems of large equipment investment, high requirement on elasticity of a hot stamping film adhesive layer, difficulty in realization and the like. The invention adopts the technical scheme that the process for producing the cigarette label by replacing large-area hot stamping with local dealuminization transfer comprises procedures of coating a base film, carrying out laser die pressing, aluminizing, neatening the base film, printing a protection coating, dealuminizing and drying, carrying out fixed-length compound, carrying out transfer stripping, carrying out position slitting and carrying out printing application processing sequentially. The process is used for replacing a large-area hot stamping process, so that the realization difficulty of a large-area bottom hot stamping printing product is avoided. The process has high quality. Even a dot laser pattern can be realized. Meanwhile, the combination firmness of the pattern on paper is improved and the grade of the product is promoted. The investment level of equipment is reduced. The production cost is greatly reduced.

Owner:ZHEJIANG MINONG CENTURY GRP

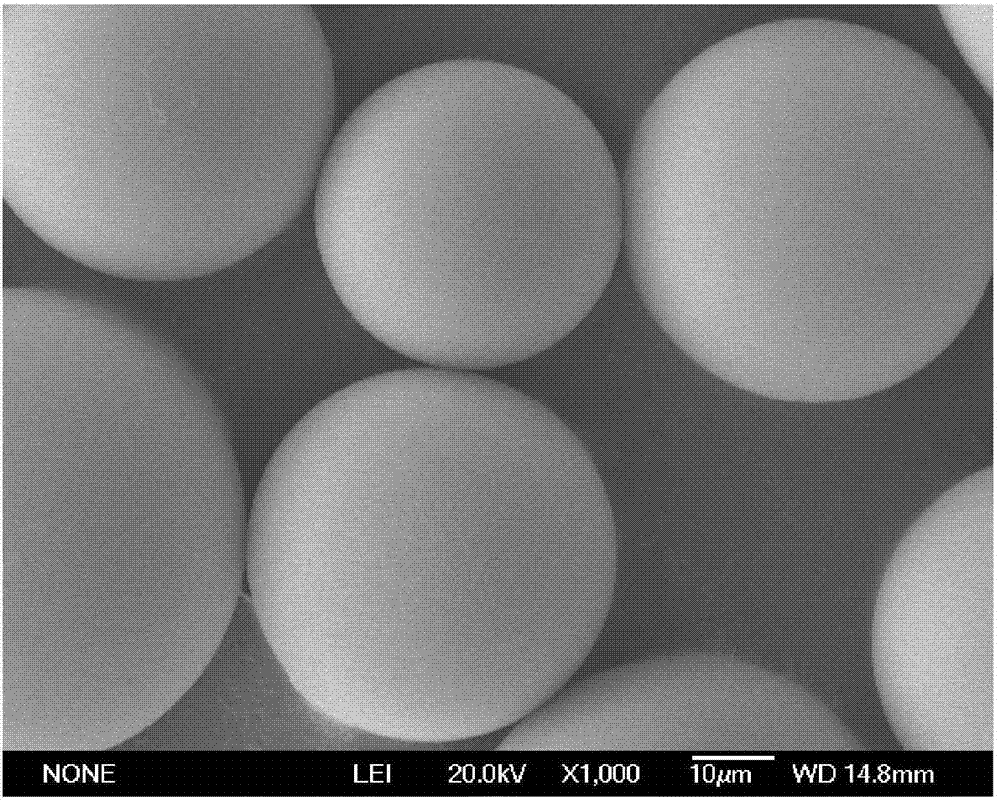

Method for preparing nano silver and titanium dioxide thin films on surfaces of hollow glass beads

ActiveCN103007931AImprove photocatalytic activityHigh fluorescence intensityMetal/metal-oxides/metal-hydroxide catalystsChemical platingPhotocatalytic degradation

The invention discloses a method for preparing nano silver and titanium dioxide thin films on the surfaces of hollow glass beads, which comprises the following steps of: I, firstly coating a nano silver thin film on the surface of a hollow glass bead by using a chemical plating method; and II, then directly coating a layer of nano titanium dioxide thin film on the surface of the hollow glass bead coated with the nano silver thin film by using a hydrothermal method. The method disclosed by the invention has the advantages of raw material saving, simplicity and convenience in operation, good binding strength, higher photocatalytic activity and the like, and endows hollow glass beads with a photocatalytic degradation property for dyes and organic pollutants.

Owner:JIAXING HENENG TECH CO LTD

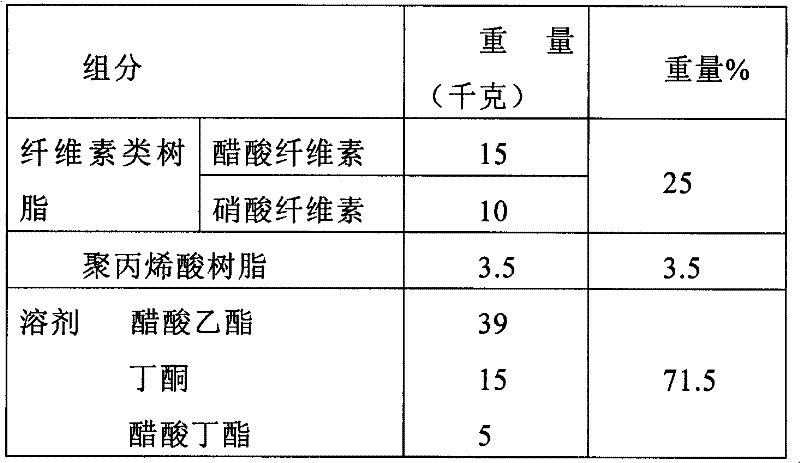

Shifted Al-plating paint for offset printing, preparation method and application thereof

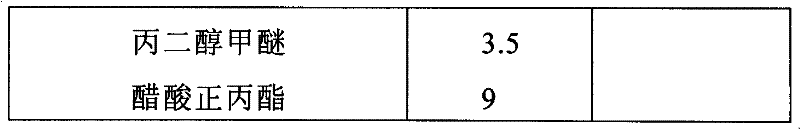

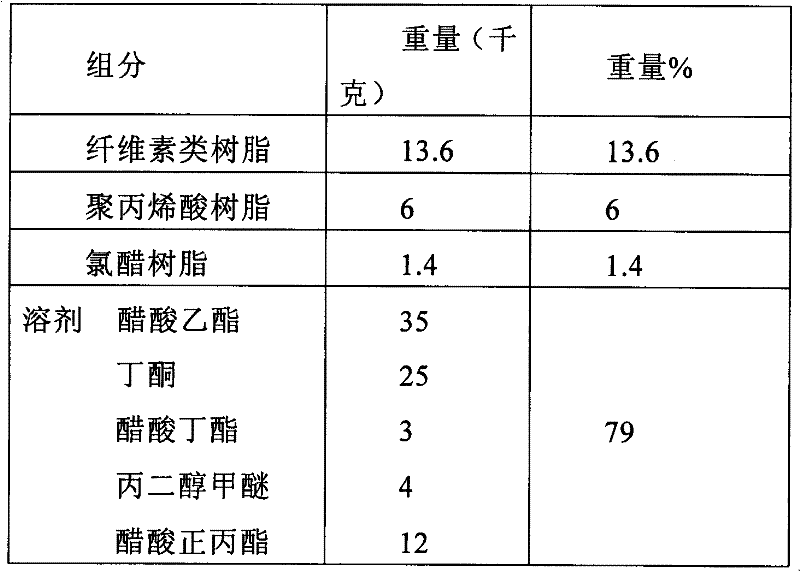

The invention relates to a shifted Al-plating paint for offset printing, a preparation method and application thereof. The paint provided by the invention comprises the following components of: by weight, 5-25 parts of cellulosic resin, 3-12 parts of polyacrylic resin, 0-5 parts of Vinyl chloride-acetate copolymer, 0-0.5 parts of an auxiliary agent and 70-86 parts of a solvent. The prepared shifted Al-plating paint can be used in the offset printing technology. In comparison with the prior art, the shifted Al-plating paint can be directly used for offset printing without the varnishing process, has excellent adhesive fastness with offset printing ink; the preparation method provided by the invention has advantages of simple technology and high production efficiency; the paint also has excellent peeling performance and good bonding fastness with an aluminium layer and a printing ink layer, and the PET basal lamina can be repeatedly used; in addition, the solvent used in the preparation of the paint contains no industrial forbidden solvent such as BTX, is safe and environmentally-friendly, and is beneficial for sustainable development.

Owner:SHANGHAI WEIKAI CHEM +1

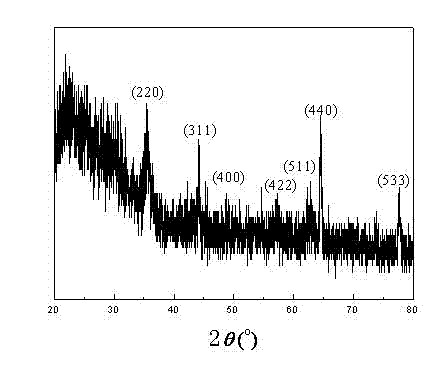

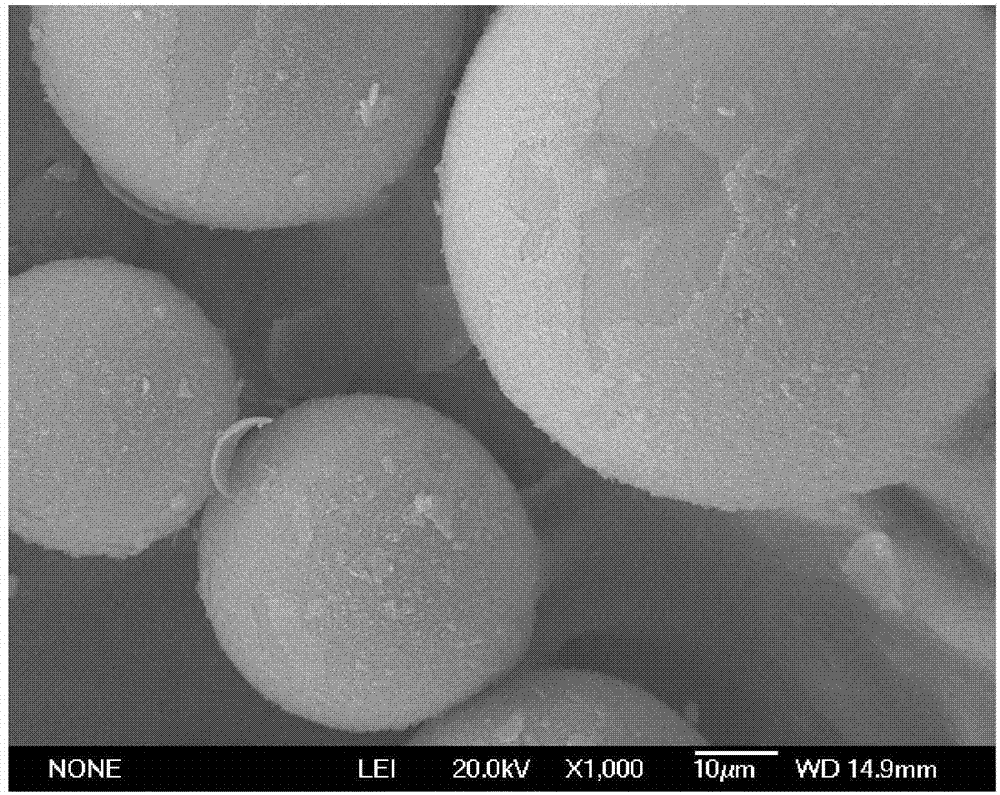

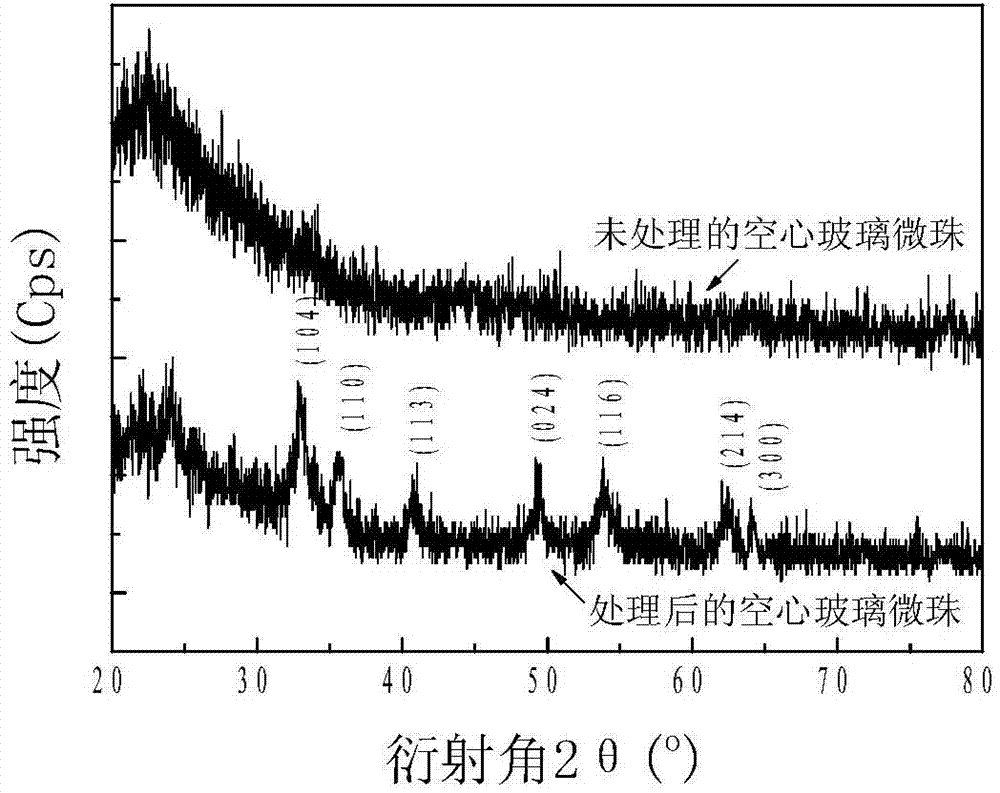

Method for modifying hollow glass microspheres by chemical precipitation process

The invention discloses a method for modifying hollow glass microspheres by a chemical precipitation process. The method comprises the following steps: firstly weighing the hollow glass microspheres with mass-volume concentration of 10-20g / L into a deoiling liquid, stirring for reacting at the temperature of 80-100 DEG C for 20-30 minutes, filtering and washing the hollow glass microspheres, and then drying at the temperature of 110 DEG C for 1-2 hours; and then coating a ferroferric oxide magnetic nanoparticle film on the surfaces of the hollow glass microspheres by adopting ferrous chlorideand ferric trichloride. In the method, while the ferroferric oxide magnetic nanoparticles are prepared by the chemical precipitation process, a ferroferric oxide magnetic nanoparticle film layer is directly coated on the surfaces of the hollow glass microspheres so that the hollow glass microspheres have magnetic properties. The method is economical in raw materials and is simple and convenient in operation. Test results show that the hollow glass microspheres modified by the ferroferric oxide magnetic nanoparticles have the advantages of excellent magnetic properties and certain bonding firmness, thus meeting the actual demand.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Polyurethane foam forming mould and manufacturing method of mould cavities

The invention discloses a polyurethane foam forming mould and a manufacturing method of mould cavities. The mould comprises a mould frame, mould cavities, filling layers between the mould frame and the mould cavities, a locking device and a mould opening and closing device; the mould cavities are made of crystalline resin materials; an exhaust hole is arranged on the lower mould cavity; spew grooves are respectively arranged on the upper mould cavity and the lower mould cavity; and a blade parting surface and an upper and lower mould cavity positioning surface are respectively arranged on the upper mould cavity and the lower mould cavity. The mould cavities are made of the crystalline resin materials, and the manufacturing method of the mould cavities comprises the following steps: firstly designing the mould cavities by using a computer three-dimensional design software and then manufacturing the mould cavities by adopting the CNC numerical control processing, the injection-moulding processing, the rapid forming processing and the vacuum moulding processing methods. The invention solves the technical problems that a mould cavity parting line between an aluminum alloy casting mould and an epoxy resin mould has worse matching, the mould cavities are required to be coated with mould release agents, and formed products are easy to generate flash edges, so that the forming processing efficiency of similar products is improved, thereby reducing the production cost and improving the availability of resources.

Owner:黄吉力

Ink-jet oil painting canvas and manufacturing method thereof

The invention discloses an ink-jet oil painting canvas. The oil painting canvas comprises a base material, a bottom coating layer and a surface coating layer from bottom to top in sequence, wherein the bottom coating layer comprises the following components in parts by weight: 35-45 parts of filler, 1-3 parts of polyvinyl alcohol, 30-40 parts of a bonding agent, 0.5-2 parts of an additive and 10-30 parts of water; the surface coating layer comprises the following components in parts by weight: 10-15 parts of silicon dioxide, 1-3 parts of polyvinyl alcohol, 30-40 parts of a special bonding agent, 0.5-2 parts of an additive, 1-5 parts of an anti-bleeding agent, and 30-50 parts of water. The ink-jet oil painting canvas disclosed by the invention has the advantages that the matching and the bonding strength of the ink-jet oil painting canvas with latex used in Latex ink are good, and when the Latex ink is used for ink-jet printing, the ink can be cured on the surface coating layer at low temperature, and high color fastness can be obtained; simultaneously, the extra anti-bleeding agent is added into the surface coating layer, so that the bleeding of ink can be prevented, the edges of a painting are clear and the color expressiveness is excellent.

Owner:JIANGSU GEMEIGAO DEV CO LTD +1

High-content aqueous polyurethane latex and preparation method thereof

The invention discloses high-content aqueous polyurethane latex and a preparation method thereof. (A) hydrogenated diphenylmethane diisocyanate, (B) fatty group diamino sulfonic acid sodium salt, (C) linear bihydroxyalkyl siloxane, (D) dimer acid polyester dibasic alcohol; (E) 2-methyl-2, 4 pentanediol, (F) 1, 3 cyclohexanediol, (G) chain extender, (H) fatty alcohol-polyoxyethylene ether TO7, and (J) deionized water are used for preparing the high-content aqueous polyurethane latex through a prepolymerization reaction, a chain-extending reaction and an emulsion reaction. The invention has the advantages of low production cost, 55% of solids content, good water pressure resistance, fastness, abrasion resistance, favorable washability and aqueous environmental protection.

Owner:郯城县华晨涂料有限公司

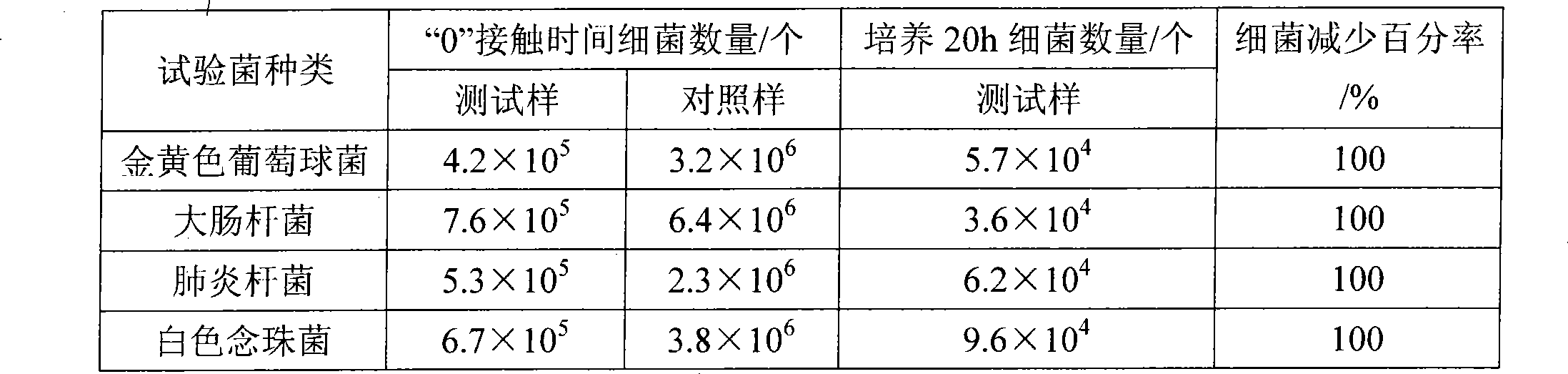

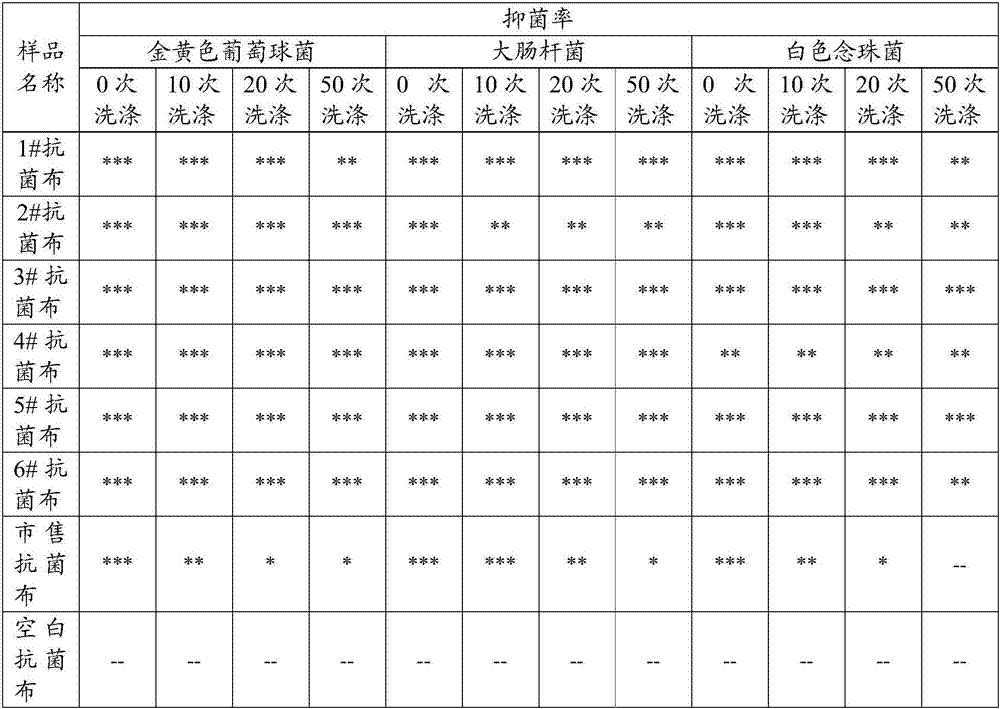

Antibacterial cotton cloth and preparation method

InactiveCN101392454AGuaranteed permeabilityGood combination fastnessVegetal fibresLiquid/gas/vapor textile treatmentCelluloseCotton gauze

Owner:LOGISTICS UNIV OF CAPF

Preparation method of magnetic nano ferroferric oxide modified hollow glass microsphere

ActiveCN102993781AHigh saturation magnetizationGood combination fastnessOther chemical processesPigment treatment with macromolecular organic compoundsIonNanometre

The invention discloses a preparation method of a magnetic nano ferroferric oxide modified hollow glass microsphere. The method comprises the steps of removing oil of a hollow glass microsphere; soaking the hollow glass microsphere with oil removed in a coarsening solution to react, filtering and subsequently washing, and drying; dipping the hollow glass microsphere in a coupling agent solution to react, filtering and subsequently washing, drying and baking; dipping the hollow glass microsphere in a chitosan solution, stirring and filtering, subsequently prebaking and baking; soaking the dried hollow glass microsphere in a sodium hydroxide solution, filtering and then washing; and finally dipping the hollow glass microsphere in a ferrous chloride mixture solution, transferring to a high-pressure reaction kettle, sealing and then carrying out insulation treatment, and filtering the hollow glass microsphere after finishing reacting; and washing respectively by using absolute ethyl alcohol and deionized water and drying. The preparation method saves the raw material and is easy and simple to operate; through the modification on the surface of the hollow glass microsphere, the problems of no magnetism, poor coating fastness, weak magnetism and the like of the hollow glass microsphere are solved.

Owner:JIAXING HENENG TECH CO LTD

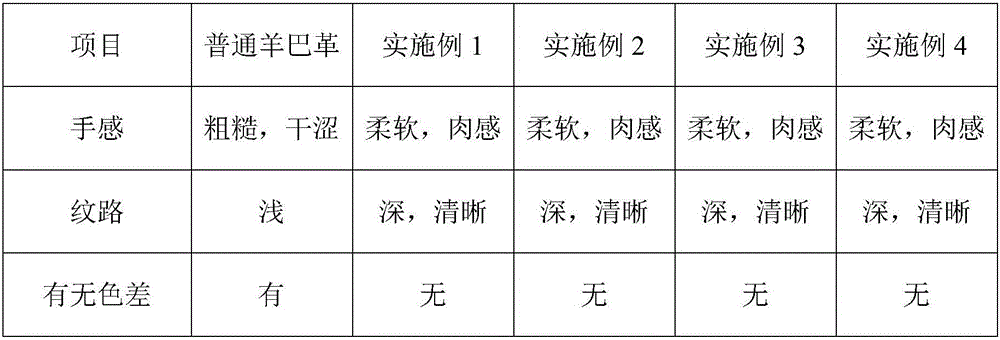

Water-based yangbuck with lustring effects and method for preparing water-based yangbuck

ActiveCN106436337AStrong sense of hierarchyClear texturePolyurea/polyurethane coatingsTextiles and paperWater basedEngineering

The invention provides a method for preparing water-based yangbuck with lustring effects. The method includes steps of 1), coating and scraping water-based wet base slurry on base cloth, transporting the base cloth into a coagulating tank, coagulating the base cloth and drying the base cloth by means of baking to obtain water-based base; 2), coating water-based yangbuck materials on release paper, drying the water-based yangbuck materials and the release paper to form yangbuck clinging surfaces, adhering the water-based base onto the yangbuck clinging surfaces, then drying the yangbuck clinging surfaces by means of baking, cooling the yangbuck clinging surfaces and peeling the release paper to obtain artificial leather by means of preparation; 3), placing the artificial leather in a baking oven and foaming the artificial leather at the high temperature to obtain yangbuck by means of preparation; 4), carrying out color change treatment on the yangbuck by the aid of a printing machine; 5), preparing lustring materials, adding the lustring materials into the printing machine and carrying out lustring treatment on the yangbuck. The method has the advantages that the surfaces of the water-based yangbuck are high in leather feeling and good in velvet feeling and feel soft, and the excellent lustring effects can be realized; the surfaces of the yangbuck are bulky, thick, smooth, straight and bright and have plump pile after lustring treatment is carried out on the yangbuck, and market requirements on high-grade yangbuck can be met.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

Solder resist ink with low-energy ultraviolet curing performance

InactiveCN103571265AHigh glossKeep dryInksPhotosensitive materials for photomechanical apparatusAcrylic resinUltraviolet

The invention relates to solder resist ink with low-energy ultraviolet curing performance. The solder resist ink comprises the following components in percent by weight: 50%-70% of polyurethane modified acrylic resin, 5%-25% of epoxy acrylic resin, 5%-20% of a reaction diluent, 5%-10% of a photoinitiator, 7%-15% of filler, 0.5%-3% of organic pigment. A printed circuit board prepared by the formula is high-temperature resistant, free of discoloring and dropping and smooth in appearance. An LED (Light-Emitting Diode) UV (Ultraviolet) light source is adopted, so that energy consumption is lowered, ozone is not produced, and processing benefits and environment-friendly performance of the circuit board are improved.

Owner:上海麟多祈化工科技有限公司

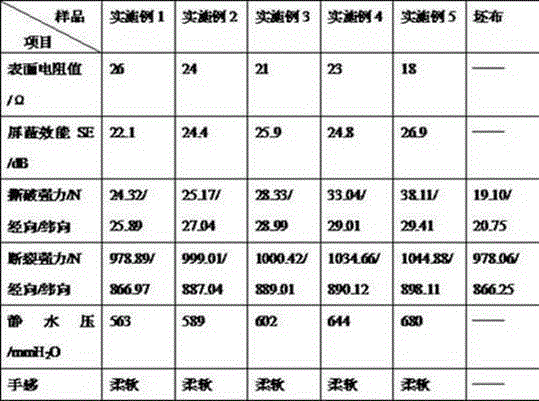

Preparation method of multifunctional conducting fabric based on photocuring technology

InactiveCN107059415AReduce energy consumptionImprove efficiencyPolyurea/polyurethane coatingsTextiles and paperUltraviolet lightsEngineering

The invention relates to a preparation method of a multifunctional conducting fabric based on a photocuring technology. The method comprises the following steps of (1) preparing graphene / titanium dioxide water dispersion liquid; (2) preparing a waterborne photocuring multifunctional fabric sorting agent; (3) sorting the sorting liquid onto the fabric; performing drying and ultraviolet light curing. After the process, a multifunctional sorting layer can be formed on the surface of the fabric, so that the fabric has good conductivity, antibacterial performance, uvioresistant performance, self cleaning performance and mechanical property. The photocuring technology is used for bonding the graphene onto the surface of the fabric; the process is simple; the durability is high; in addition, the conducting layer has the excellent toughness and intensity; the combination firmness with the base cloth is high; the original hand feeling cannot be influenced; the method belongs to a green energy-saving simple convenient and efficient conducting fabric preparation method.

Owner:SAINTYEAR HLDG GROUP +1

Coated mist release paper

InactiveCN102704333AGood film formingGood combination fastnessNon-fibrous pulp additionCoatings with pigmentsBenzoyl peroxidePolyvinyl alcohol

The invention discloses coated mist release paper which is obtained by coating a matte lamination release agent on raw paper. According to a material formula, the matte lamination release agent consists of 15-70% of polyvinyl alcohol aqueous solution, 20-65% of emulsion type organosilicon release agent, 6-12% of stabilizer, 0.3-2% of emulsifier, 1.2-4.5% of catalyst, 0.5-3.5% of crosslinking agent and 2-10% of matting filler. The stabilizer is at least one of agar, gelatin and water-soluble starch; the emulsifier is at least one of sodium polyphosphate, Twain 80 and tributyl phosphate; the catalyst is platinum catalyst or benzoyl peroxide; and the crosslinking agent is methyl hydrogen polysiloxane oil. The coated mist release paper is simple in production technology flow, low in cost and convenient in operation.

Owner:斯迪克新型材料(江苏)有限公司

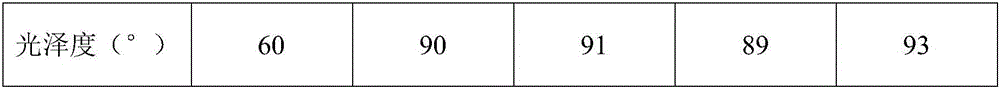

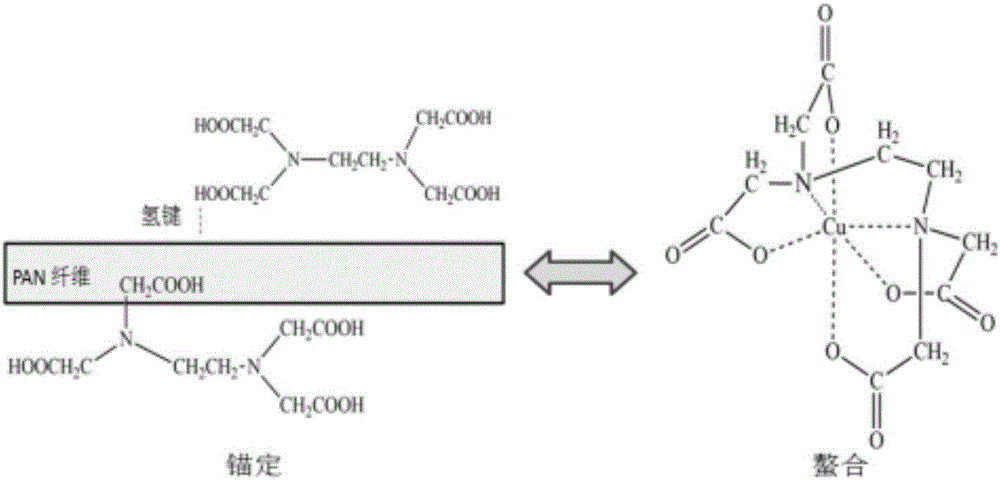

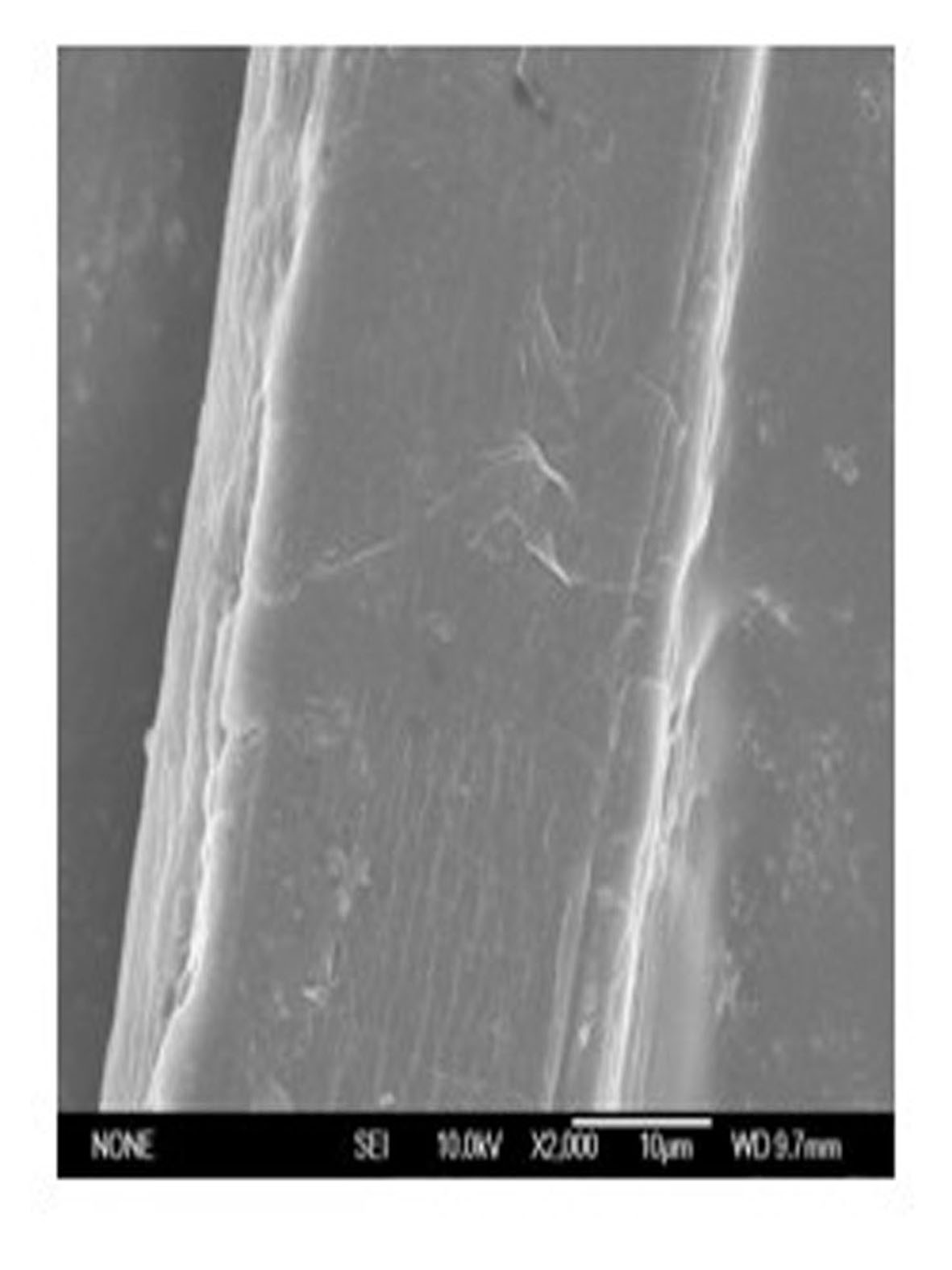

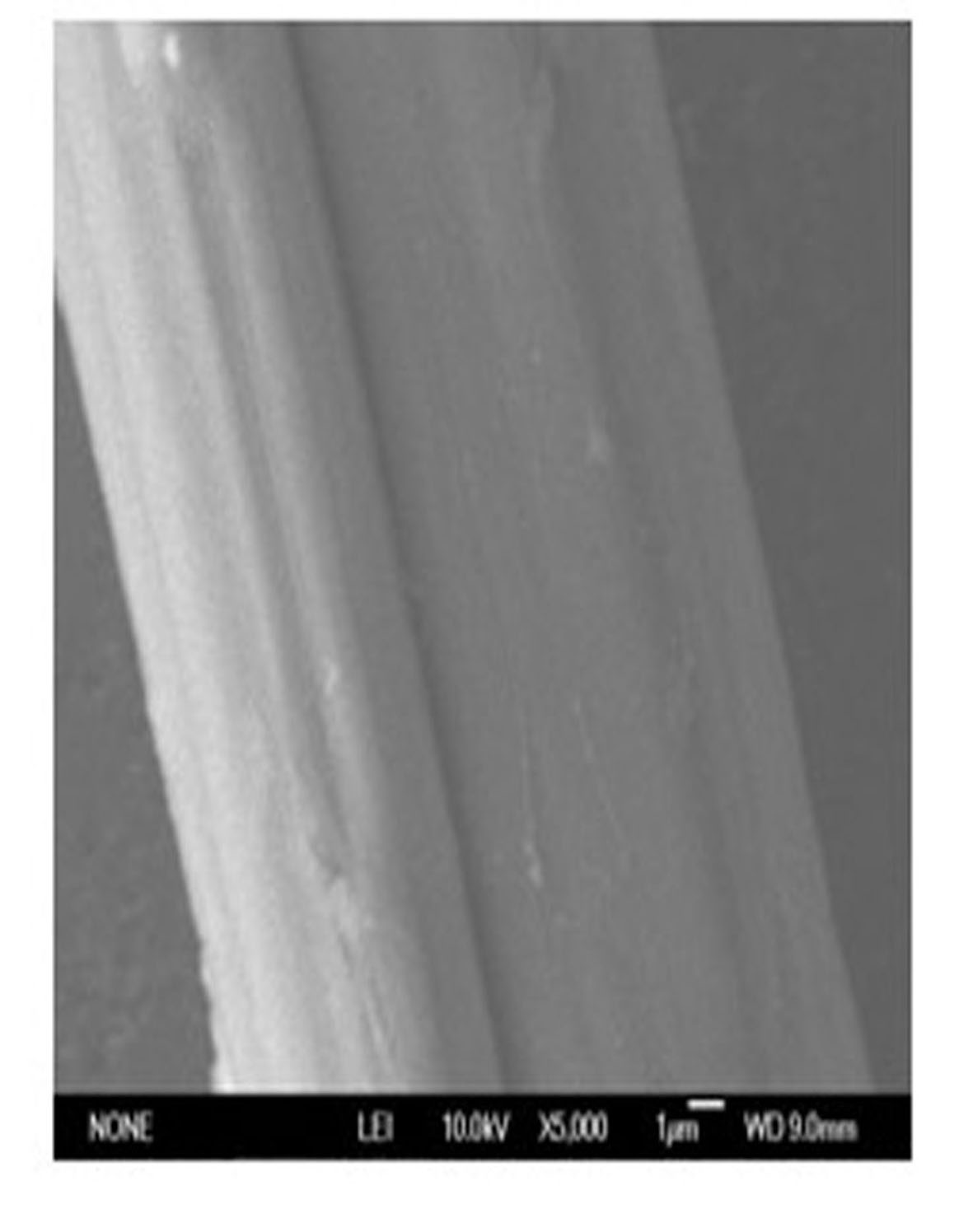

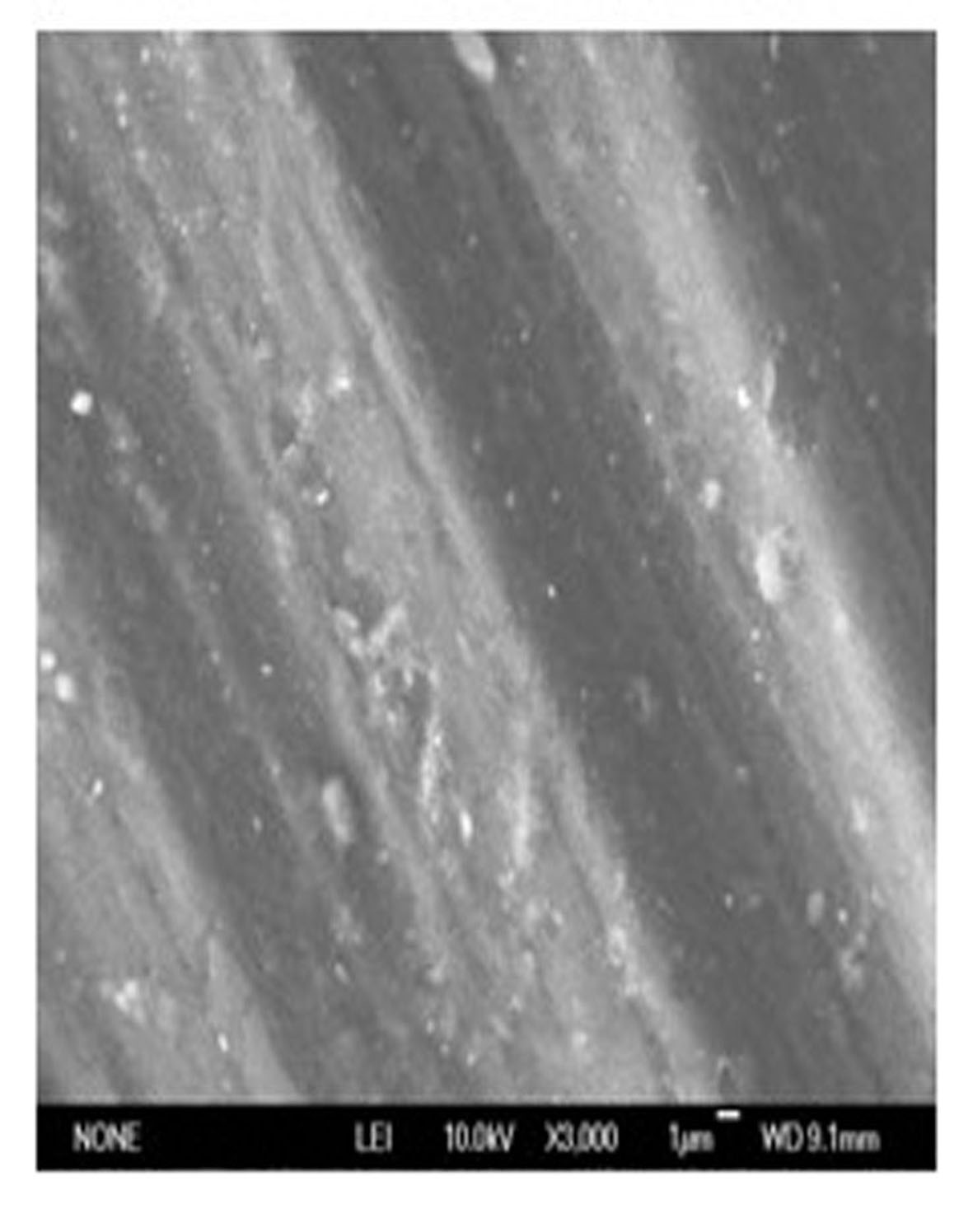

Preparation method of anti-microbial conductive acrylic fiber/copper sulphide complex fiber

InactiveCN106758148ALarge specific surface areaFacilitate depositionFibre typesWater bathsPolymer science

The invention relates to a preparation method of an anti-microbial conductive acrylic fiber / copper sulphide complex fiber. The preparation method comprises the steps of pretreating acrylic fiber; immersing the pretreated acrylic fiber into a copper sulfate solution, stirring, keeping in water bath with the temperature ranging from 40 to 80 DEG C for 1 to 2h, then adding a chelating agent solution, immersing and drying for three times, then adding the obtained acrylic fiber into a sodium sulfide solution, reacting at room temperature for 10 to 30min, cleaning, and drying to obtain the anti-microbial conductive acrylic fiber / copper sulphide complex fiber. The anti-microbial conductive acrylic fiber / copper sulphide complex fiber prepared by the invention not only has favorable antibacterial property, electrical conductivity, binding strength, washing fastness and the like, but also is moderate in preparation conditions, simple in process and low in cost.

Owner:DONGHUA UNIV

Hemp degumming and softening synchronous treatment process

InactiveCN102330158AImprove solubilityPlay the role of preliminary degummingFibre treatment to obtain bast fibreWater bathsSURFACTANT BLEND

The invention provides a hemp degumming and softening synchronous treatment process. The hemp degumming and softening synchronous treatment process comprises the following steps of: after dipping, stirring and ultrasonically treating hemp fiber in a solution with bath ratio of 1:12, washing the hemp fiber; next, dipping the washed hemp in a mixed solution again, radiating the hemp by using ultraviolet rays, and adding a cooking additive to the hemp and mixing the mixture; repeating the steps and adding a softening agent; and finally, adding the cooking additive to the treated hemp fiber and then dipping the hemp fiber in a constant temperature water bath to be cooked; meanwhile, adding the softening agent to the hemp fiber, and stirring, washing, scotching, oiling, deoiling and drying thehemp fiber so as to obtain the synchronously degummed and softened hemp. According to the invention, the softening agent is added to the hemp during cooking and then the hemp is dipped and stirred sothat the softening is synchronously carried out; the alkali boiled hemp fiber is placed under strong ultraviolet rays to be radiated again so that the cracks on the surface of the fiber are increased; and the softening agent immediately enters the interior to be grafted and better bonding effect of the softening agent is obtained under the radiation of a coupling agent, a surfactant and ultraviolet rays so as to realize synchronous degumming and softening treatment of the hemp fiber.

Owner:TAIYUAN UNIV OF TECH

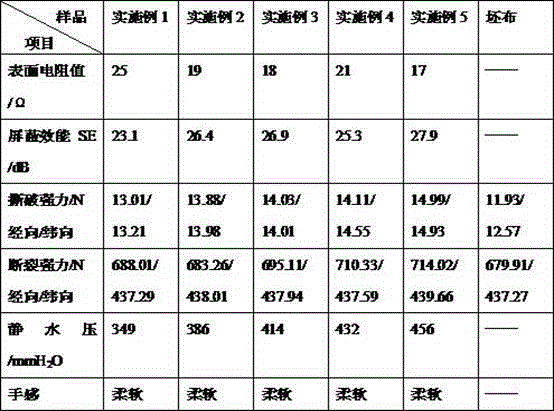

Anti-electromagnetic radiation fabric coating adhesive and preparation method thereof

ActiveCN104452298AShort production processSimple and fast operationVegetal fibresIsooctyl acrylatePolyester

The invention discloses an anti-electromagnetic radiation fabric coating adhesive and a preparation method thereof. The anti-electromagnetic radiation fabric coating adhesive is prepared from the following raw materials in parts by weight: 8-10 parts of sodium dodecyl benzene sulfonate, 5-6 parts of fatty alcohol-polyoxyethylene ether, 25-30 parts of butyl acrylate, 85-90 parts of 2-ethylhexyl acrylate, 9-10 parts of cyclohexyl methacrylate, 3.5-4 parts of acrylamide, 4-5 parts of acrylic acid, 1.5-2 parts of trimethylolpropane triacrylate, 10-20 parts of styrene, 1.5-2 parts of glycidyl methacrylate, 1.0-1.6 parts of ammonium persulfate and 250-330 parts of deionized water. The method comprises the following steps: synthesizing an emulsion by emulsification and initiated polymerization; and adding a mixed liquid of 3-6 parts of conductive polyaniline and 15 parts of N,N-dimethyl formamide, 30-35 parts of a carbon nanotube dispersion liquid and 3-4 parts of an associative polyurethane flatting rheological agent, and compounding, so as to obtain the anti-electromagnetic radiation fabric coating adhesive. The anti-electromagnetic radiation fabric coating adhesive is suitable for pure cotton and polyester fabrics, and has good conductive property, anti-electromagnetic radiation property, binding strength, water-fastness, tearing strength, breaking strength, hydrostatic pressure resistance and hand feeling.

Owner:DANDONG UNIK TEXTILE

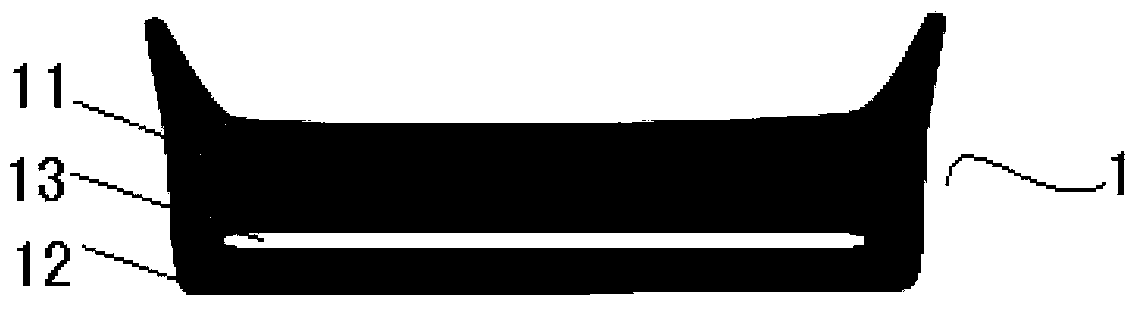

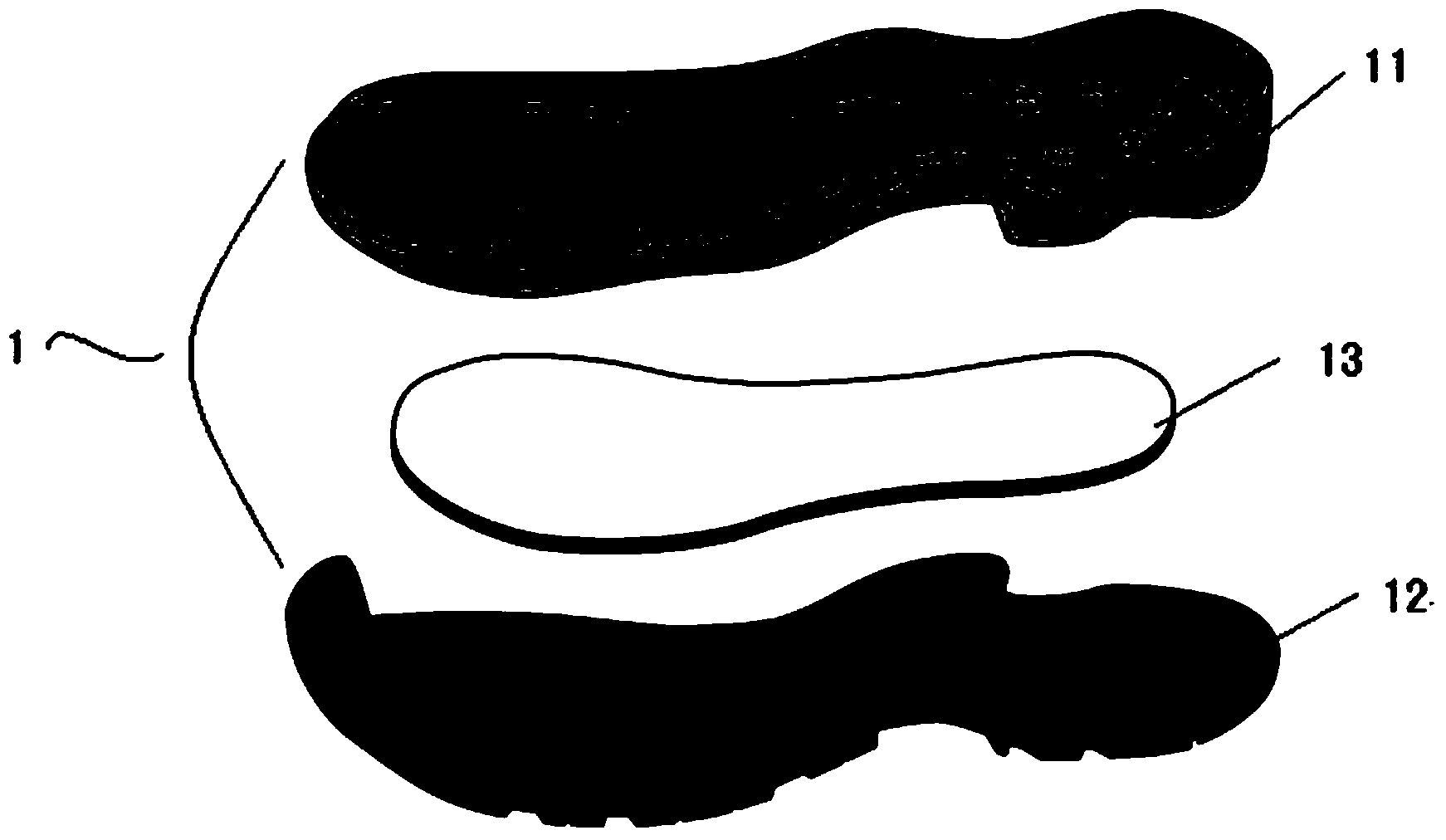

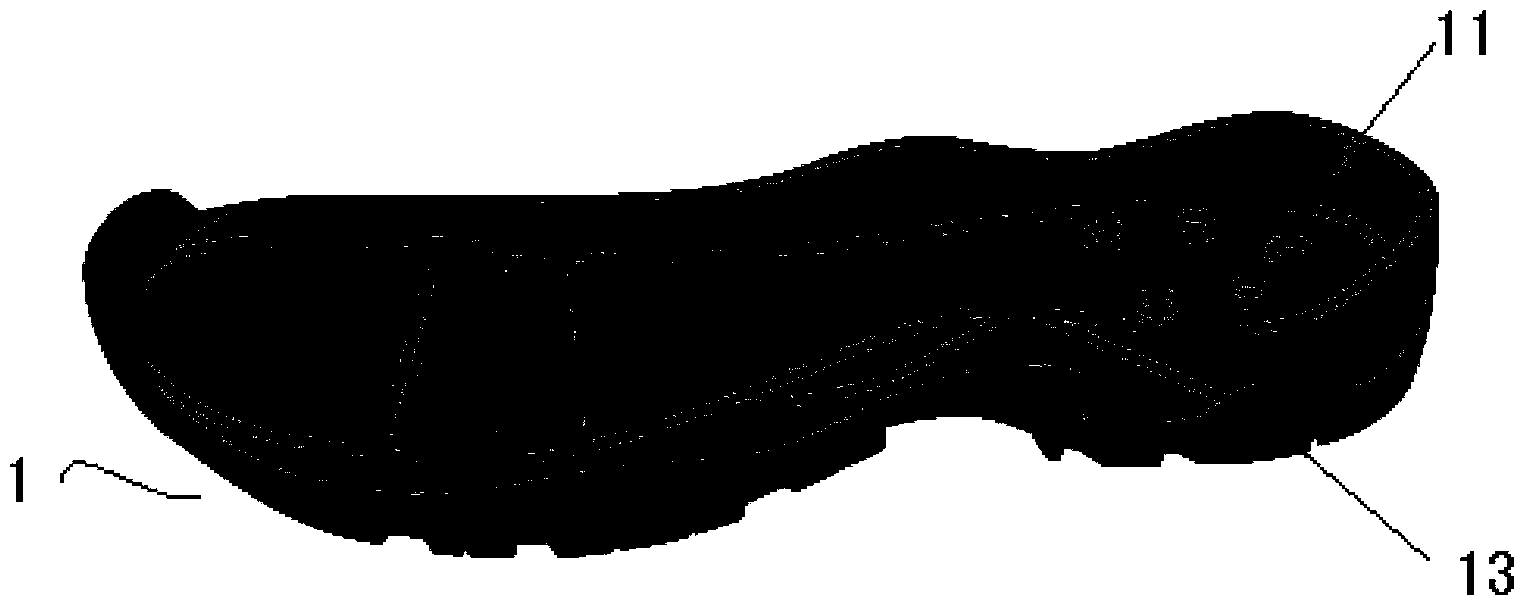

Anti-puncture combined shoe sole and manufacturing method thereof

The invention relates to an anti-puncture combined shoe sole and a manufacturing method thereof. The anti-puncture combined shoe sole is characterized by comprising a foamed EVA (Ethylene-Vinyl Acetate) middle sole and a rubber outer sole, wherein an anti-puncture middle cloth layer which is matched with the top shape of the rubber outer sole is further arranged between the foamed EVA middle sole and the rubber outer sole; an EVA rubber film is arranged between the top of the anti-puncture middle cloth layer and the foamed EVA middle sole; a layer of EVA rubber film is further arranged between the bottom of the anti-puncture middle cloth layer and the top of the rubber outer sole; the foamed EVA middle sole, the anti-puncture middle cloth layer and the rubber outer sole are jointed into a whole by hot pressing; the anti-puncture middle cloth layer comprises over three layers of anti-puncture compact fabrics; a layer of EVA rubber film is arranged between every two adjacent anti-puncture compact fabrics; all layers of anti-puncture compact fabrics are jointed integrally by hot pressing. The sole and the method can be widely applied to the manufacturing process of shoes made by a bonding process.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Wool-blown hollow bag yarn

The invention discloses a wool-blown hollow bag yarn. The main body of the yarn is a filament yarn made of terylene or nylon, or a composite yarn formed by the filament yarn and a staple fiber yarn made of other raw materials; wool refers to at least one of sheep wool, paco wool, acrylic staple fiber, polyester staple fiber and nylon staple fiber. The yarn has fluffy and soft handfeel, and is 20-30 percent higher than a worsted yarn of the same count in strength; a fabric made of the wool-blown hollow bag yarns is 8-20 percent lighter than a fabric of the same thickness made of the worsted yarns of the same count, and is better in heat-insulating effect.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

MXenes-AgNPs synergistic antibacterial cotton fabric and preparation method thereof

ActiveCN112941899AEasy reunionSustained antibacterial effectBiochemical fibre treatmentLight resistant fibresCovalent InteractionAntibacterial activity

The invention provides an MXenes-AgNPs synergistic antibacterial cotton fabric. Through the synergistic antibacterial effect of MXenes and AgNPs, the cotton fabric has excellent antibacterial activity and lasting antibacterial ability. AgNPs are uniformly loaded on the surface of the MXene two-dimensional nanosheet through covalent interaction, so that the MXenes nanocomposite loaded with AgNPs is formed. The surface of the cotton fabric is uniformly coated with the AgNPs-loaded MXenes nano composite material through covalent interaction. In addition to the antibacterial property, the cotton fabric prepared by the invention further has multiple functions of ultraviolet resistance, electromagnetic radiation resistance, conductivity and the like, the additional value of the cotton fabric is greatly improved, and the application range of the cotton fabric is greatly widened.

Owner:SUZHOU INST OF TRADE & COMMERCE

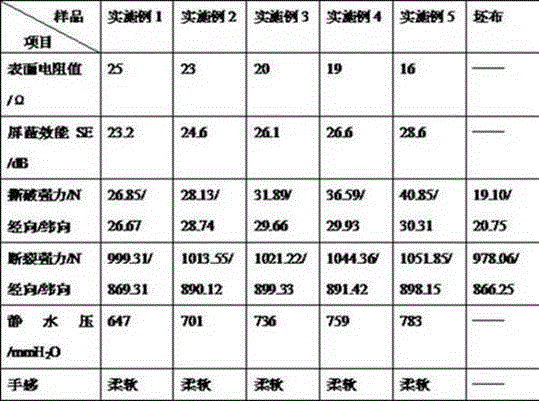

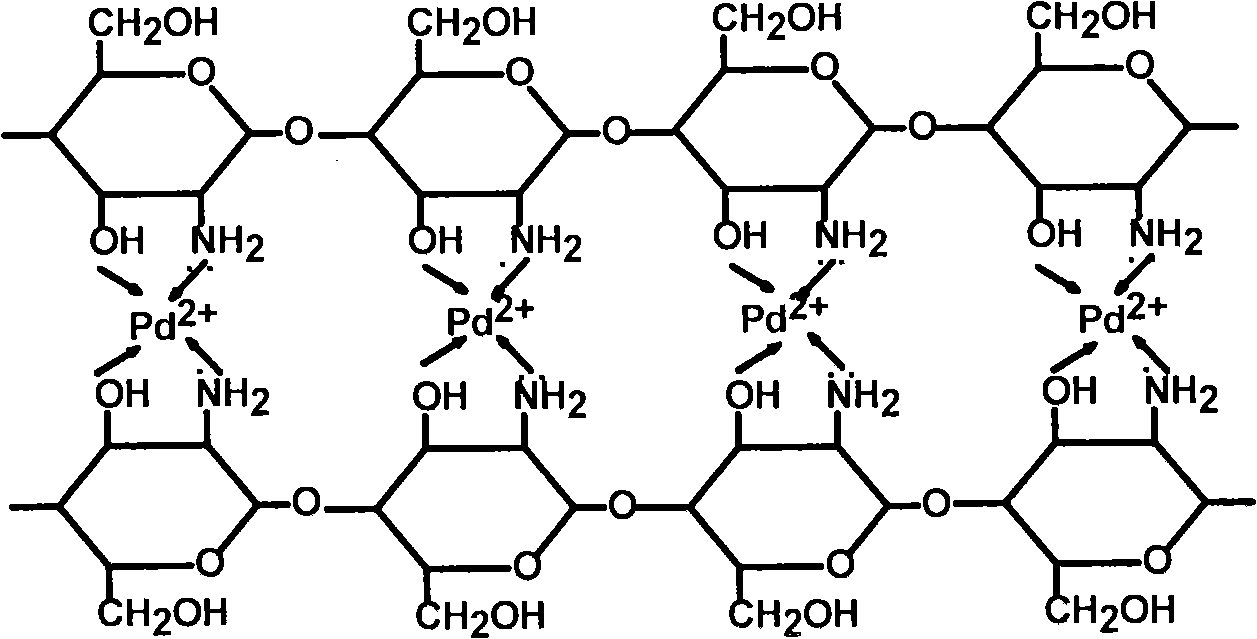

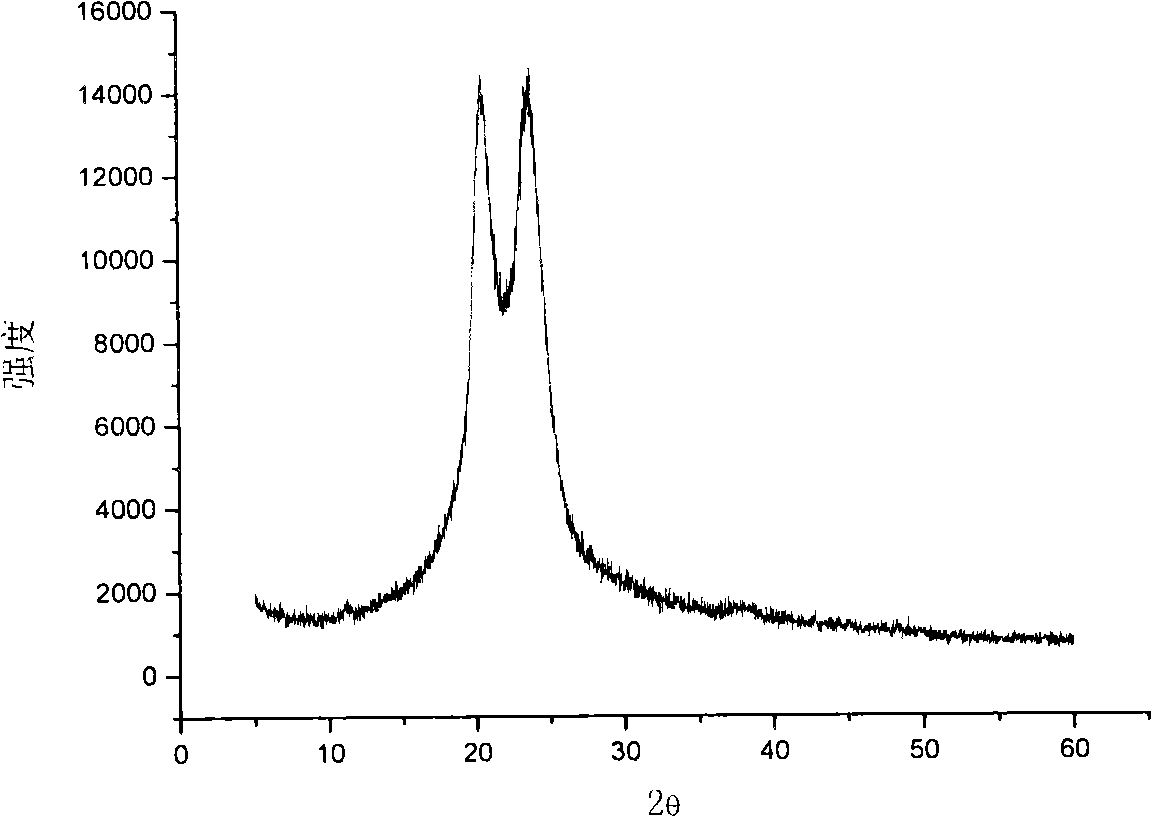

Activation method before flexible backing material chemical plating based on numerator self-assembly technique

InactiveCN101319315AGood combination fastnessNot easy to fall offLiquid/solution decomposition chemical coatingActivation methodChemical plating

The invention provides a molecular self-assembly technique based method for pre-activating a flexible base material before chemical plating, comprising the following steps of: 1. placing a crosslinking agent and chitosan or derivative thereof into a weak acidic aqueous solution, with electromagnetical stirring and keeping the solution stand to obtain a chitosan finishing liquid; 2. impregnation method: impregnating a fabric in the chitosan finishing liquid with electromagnetical stirring; cleaning the fabric with deionized water and drying the fabric; a padding method: impregnating the fabric in the chitosan finishing liquid, and carrying out impregnating and padding twice with a padder as well as pre-drying and baking to the fabric; 3. placing the fabric in an activation solution with palladium chlonde; route 1: activating, cleaning with the deionized water and drying; route 2: stirring electromagnetically or keeping stand, and baking. The method has the advantages of improving friction performance, ensuring all mechanical properties and even distribution of the activated layer on the surface of the fabric, improving the problems of severe environment pollution caused by the prior activation process and having stronger catalytic activity, wide application, simple operation, low cost and excellent activation effect, and has an important practical meaning for preparing flexible electromagnetic shielding materials.

Owner:DONGHUA UNIV

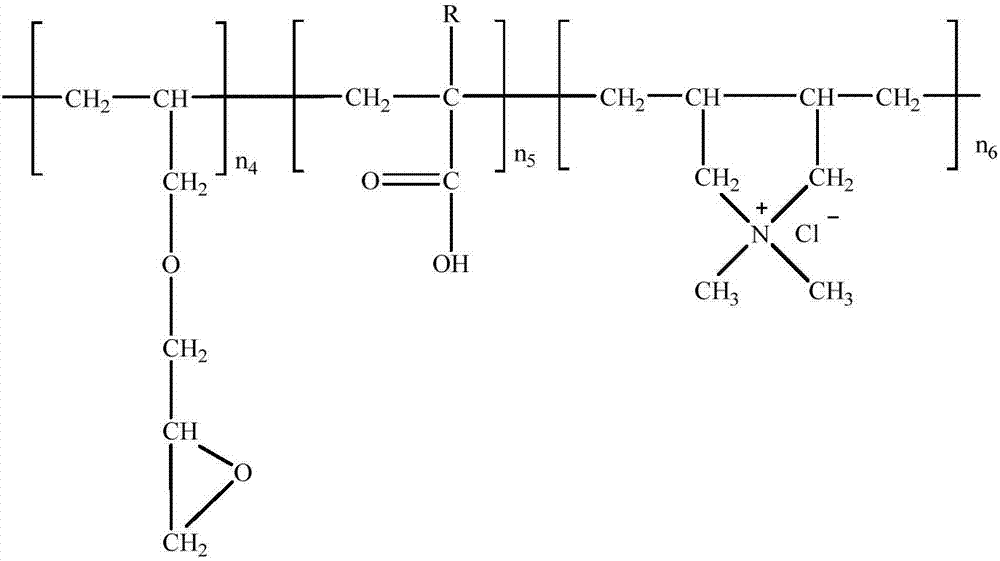

Antibacterial finishing method of cotton fabrics

ActiveCN107287899AFlexible dosage adjustmentMeet needsBiochemical fibre treatmentVegetal fibresPolymer solutionPolymer composites

The invention relates to an antibacterial finishing method of cotton fabrics. The finishing method comprises the following steps: preparing a nano zinc oxide complex solution, preparing a quaternary ammonium salt polymer solution; mixing the nano zinc oxide complex solution and the quaternary ammonium salt polymer solution to obtain a zinc oxide-quaternary ammonium salt polymer composite antibacterial agent; mixing the zinc oxide-quaternary ammonium salt polymer composite antibacterial agent with water to obtain an antibacterial finishing solution with a concentration of 50 to 500 g / L; using the antibacterial finishing solution to carry out a dip padding treatment on cotton fabrics, and finally drying the cotton fabrics after the dip padding treatment. The adopted antibacterial finishing agent is a complex of quaternary ammonium salt polymer and nano zinc oxide. The cotton fabrics processed by the provided antibacterial finishing method have a good antibacterial performance. The using amounts of two antibacterial agents can be flexibly adjusted according to the actual needs; the local antibacterial effect is enhanced, at the same time, the binding strength between the antibacterial finishing agent and cotton fabrics is strong, the cotton fabrics are resistant to washing, and the antibacterial effect is long-lasting.

Owner:科凯精细化工(上海)有限公司

Preparation method of rear earth europium doped hollow nano TiO2 glass micro beads

InactiveCN104069847AModification process is simpleSave raw materialsMetal/metal-oxides/metal-hydroxide catalystsNitrateSulfate

The invention discloses a preparation method of rear earth europium doped hollow nano TiO2 glass micro beads. The preparation method of the rear earth europium doped hollow nano TiO2 glass micro beads comprises the following steps: firstly, coating surfaces of hollow glass micro beads with magnetic nano Fe3O4 by ferric sulfate, sodium thiosulfate, urea, polyethylene glycol-1000; then coating a SiO2 intermediate layer with tetraethoxysilane, and finally coating a europium doped nano TiO2 photocatalyst by titanous sulfate, the urea, polyvinylpyrrolidone and europium nitrate, so as to obtain the rear earth element doped hollow magnetic photocatalysis glass micro beads with core-shell structures. By adopting the preparation method, the rear earth europium doped hollow nano TiO2 glass micro beads has the excellent magnetic performance on the premise of not reducing the photocatalysis activity of TiO2.

Owner:XI'AN POLYTECHNIC UNIVERSITY

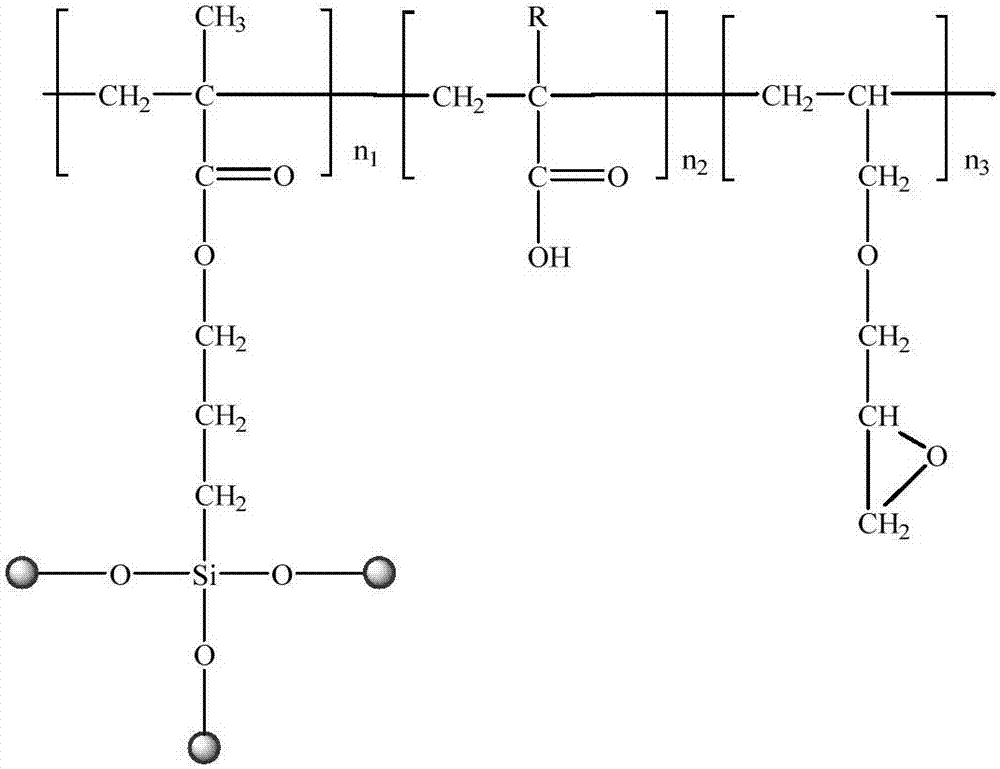

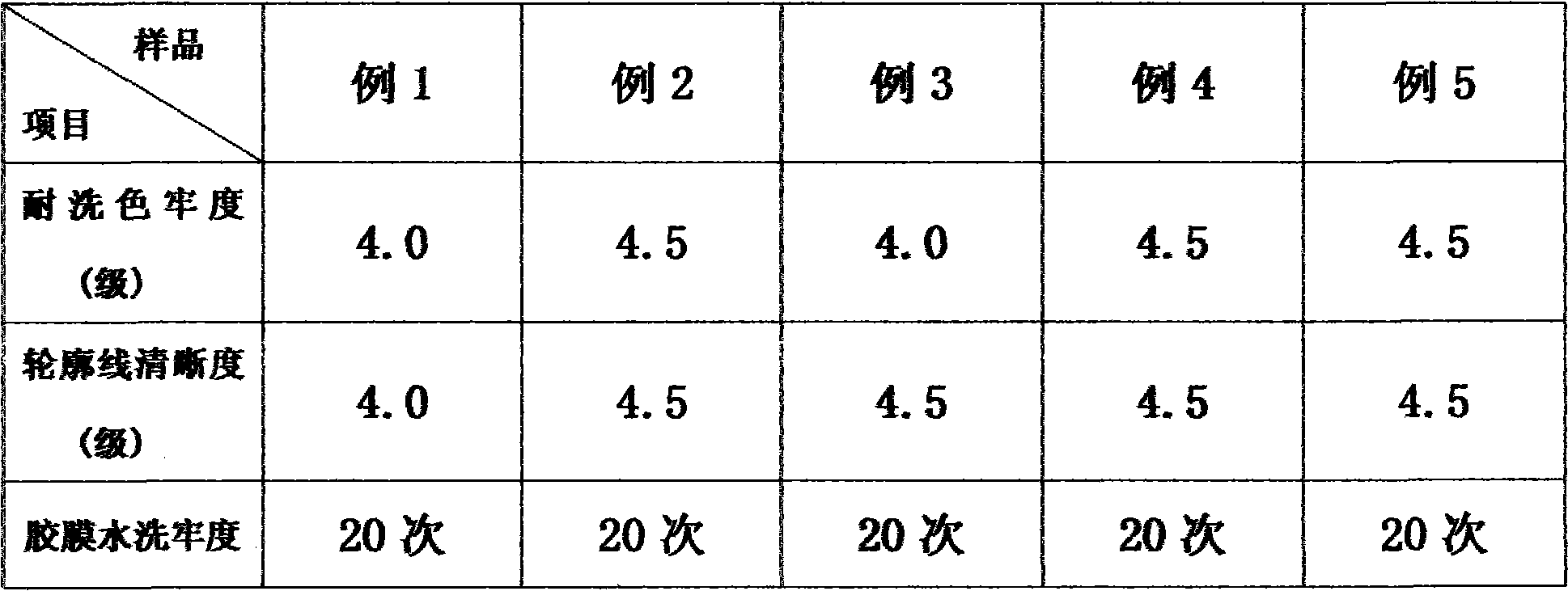

Ink-jet printing coating adhesive for fabrics and preparation method

InactiveCN101613940AImprove washing fastnessImprove adsorption capacityFibre treatmentDyeing processGlycidyl methacrylatePolymer science

The invention discloses an ink-jet printing coating adhesive for fabrics and a preparation method. The preparation method comprises the following steps: using methyl methacrylate, n-butyl methacrylate, glycidyl methacrylate, allyl methacrylate, chlorinated methacrylic acid trimethyl ammonia ethyl ester, fatty alcohol-polyoxyethylene ether XL90, cetyltrimetheylammonium bromide, 2,2-azobis (2-methyl propionamidine) hydrochloride, deionized water, nanometer SiO2 and associative polyurethane leveling rheological agent WT-203 as raw materials; and forming the coating adhesive through four-step processes of emulsification, induced polymerization, nanometer SiO2 dispersion and thickening complex. The invention has simple and convenient production method, and is applied to the coatings on various natural fibers and synthetic fiber fabrics with good firmness, the printing color is not dissolved in water, and the line profile is clear without diffusion.

Owner:LIAONING FIXED STAR FINE CHEM

Method of wrapping hollow glass bead by virtue of dye-sensitized nanometer ferric oxide

InactiveCN103566977AImprove bonding fastnessImprove photocatalytic activityWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsAminationNanotechnology

The invention discloses a method of wrapping a hollow glass bead by virtue of dye-sensitized nanometer ferric oxide. The method concretely comprises the following steps: 1) pretreating the hollow glass bead to obtain a clean hollow glass bead; 2) preparing a modification treatment liquid, and carrying out enriched amination modification treatment on the surface of the hollow glass bead after pretreatment in the step one by virtue of the modification treatment liquid; 3) carrying out dye sensitization treatment on the hollow glass bead after amination modification in the step two; 4) wrapping the surface of the hollow glass bead after dye sensitization in the step three by virtue of the dye-sensitized nanometer ferric oxide. By adopting the method of wrapping the hollow glass bead by virtue of the dye-sensitized nanometer ferric oxide, the problems that the binding fastness of the nanometer ferric oxide and the hollow glass bead is weaker, and the photocatalytic activity is weak are solved, and the generation and wrapping of the nanometer ferric oxide are finished in one step.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Inorganic nano SiO2 hybrid organic silicon fluoride-free waterproof agent and preparation method thereof

ActiveCN111910439AImprove wash resistanceGuaranteed long-term effectLiquid repellent fibresGrip property fibresEpoxySide chain

The invention discloses an inorganic nano SiO2 hybrid organic silicon fluoride-free waterproof agent and a preparation method thereof. The preparation method comprises the following steps of introducing a long carbon chain group and a reactive amino group into an organic silicon side chain by adopting an alkaline equilibrium reaction to prepare cross-linked long-chain alkyl / amino co-modified organic silicon; putting nano SiO2 into methylbenzene for ultrasonic treatment, and performing modifying by using a silane coupling agent to prepare epoxy modified nano SiO2; enabling the prepared cross-linked long-chain alkyl / amino co-modified organic silicon and epoxy modified nano SiO2 to react in solvent isopropanol, so as to obtain inorganic nano SiO2 hybrid long-chain alkyl organic silicon; and emulsifying the inorganic nano SiO2 hybrid long-chain alkyl organic silicon with water to obtain the inorganic nano SiO2 hybrid organic silicon fluoride-free waterproof agent. The preparation method provided by the invention is clear in route and simple, can be used for preparation without special and complex equipment, is used for waterproof finishing of cotton fabrics, enables the fabrics to be soft in hand feeling, can enable the fabrics to have an excellent waterproof effect, and has relatively good durability.

Owner:科凯精细化工(上海)有限公司

Preparation method for intelligent trademark cloth base material applicable to RFID technology

ActiveCN107938380AIncrease coverageImprove flatnessHeating/cooling textile fabricsRecord carriers used with machinesPolyesterYarn

The invention discloses a preparation method for an intelligent trademark cloth base material applicable to an RFID technology, wherein the preparation method includes weaving of greige cloth, desizing and water washing, heat setting treatment, coating, and rewinding and slitting. Composite yarns formed by wrapping polyester with chinlon are used as greige cloth yarns. The chinlon component is slightly dissolved in a methanol-calcium chloride nylon system and is bonded with nylon resin in a coating glue. The coating glue and the greige cloth are combined firmly, and the washable performance isgood. The greige cloth subjected to pretreatment and polyamide coating layer finishing can be well bonded with an RFID chip. Modified kaolin subjected to high temperature calcination and hydrophobictreatment is used as a filler of a coating layer, the whiteness is increased, the mechanical properties are improved, the coating layer is prevented from absorbing moisture, the failure of the RFID chip is prevented, and a large number of microporous networks of the modified kaolin make the coating layer have excellent printing adaptability. The intelligent trademark cloth base material is suitable for both thermal transfer printing and RFID technology, so as to facilitate logistics management of trademark logos and products attached with the trademark logos.

Owner:HUZHOU SINY LABEL MATERIAL

Wall coating for buildings

InactiveCN104497750AEffective antibacterialGood combination fastnessAntifouling/underwater paintsPaints with biocidesOrganic solventAcrylic resin

The invention relates to the technical field of coatings, in particular to a wall coating for buildings. The wall coating for the buildings contains following constituents of, based on weight parts, 30-50 parts of aqueous acrylic resin, 10-20 parts of aqueous acrylic modified epoxy resin, 10-20 parts of dimethyl silicone polymer, 18-27 parts of organic solvent, 3-5 parts of kaolin, 3-5 parts of ferric oxide, 2-5 parts of nanometer titania, 5-10 parts of water hyacinth additives, 1-2 parts of cuprous sulfate, 1-3 parts of butyl and amidogen formic acid iodination allylene ester and 5-10 parts of modified hydroxyapatite. The wall coating for the buildings can effectively resist bacteria, prevents a wall surface from being affected with damp and mildewing, and thereby keeps the wall surface smooth and clean.

Owner:QUZHOU UNIV

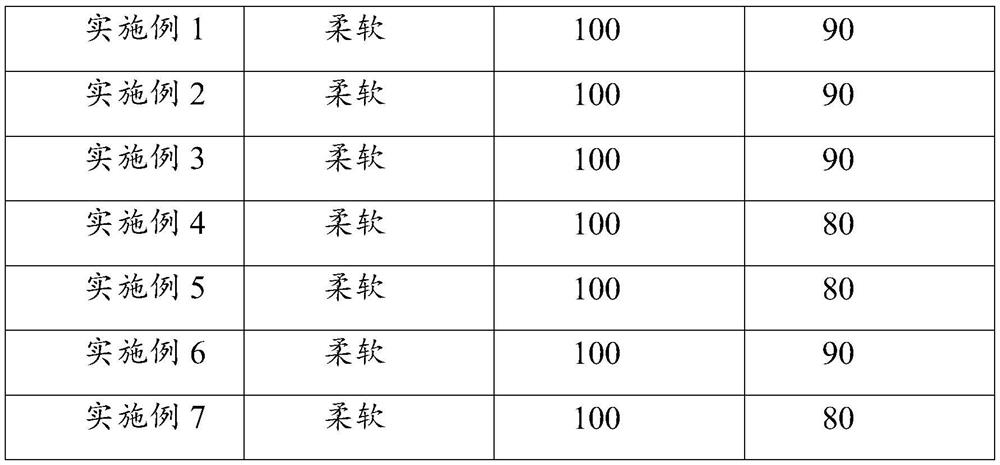

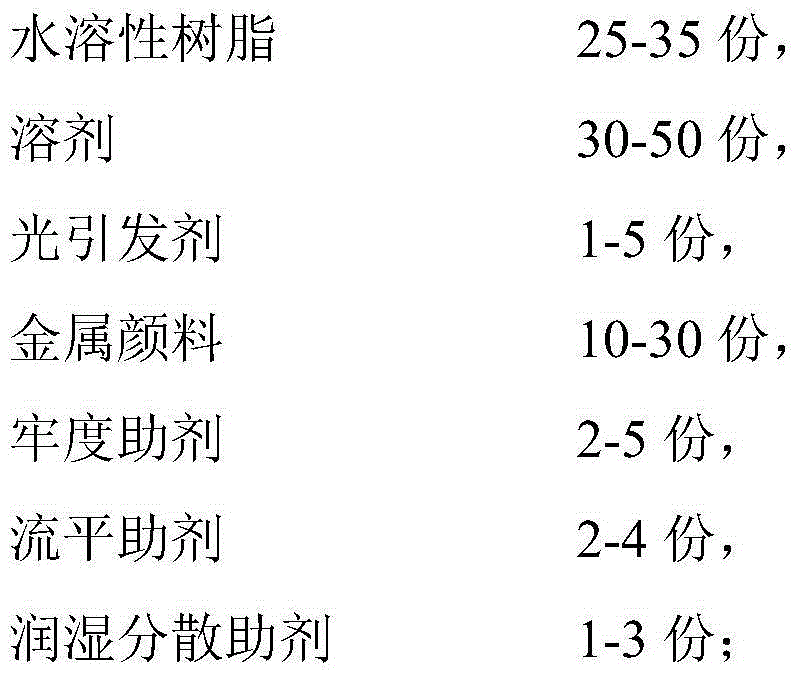

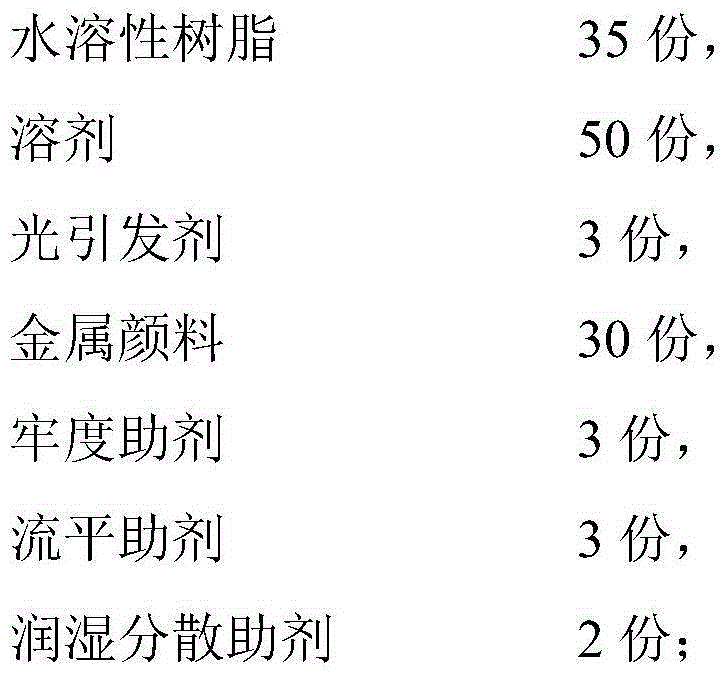

Water-based metal ink for UV offset ink and preparation method thereof

The invention relates to a water-based metal ink for UV offset ink and a preparation method thereof. The water-based metal ink comprises the following components by weight: 25-35 parts of water soluble resin, 30-50 parts of a solvent, 1-5 parts of a photoinitiator, 10-30 parts of a metallic pigment, 2-5 parts of a fastness assistant, 2-4 parts of a leveling assistant and 1-3 parts of a wetting and dispersing assistant. Specifically, the solvent is a mixed solvent of deionized water and ethanol in a mass ratio of 1:1, the metallic pigment is bronze powder or aluminum silver powder. The preparation method includes: firstly fully mixing the metallic pigment with the solvent evenly, then adding water soluble resin, the photoinitiator and assistants in order, stirring the materials fully till uniform dispersion, then carrying out filling, sealing and packaging, and performing aluminum foil sealing, thus obtaining the water-based metal ink finished product. Compared with the prior art, the water-based metal ink provided by the invention is green and environment-friendly, has the advantages of good binding fastness with UV offset ink, difficult fall, simple preparation process, good finished product stability, and production cost saving, and is suitable for industrial scale and high efficiency production.

Owner:SHANGHAI HUIBAI FINE CHEM CO LTD

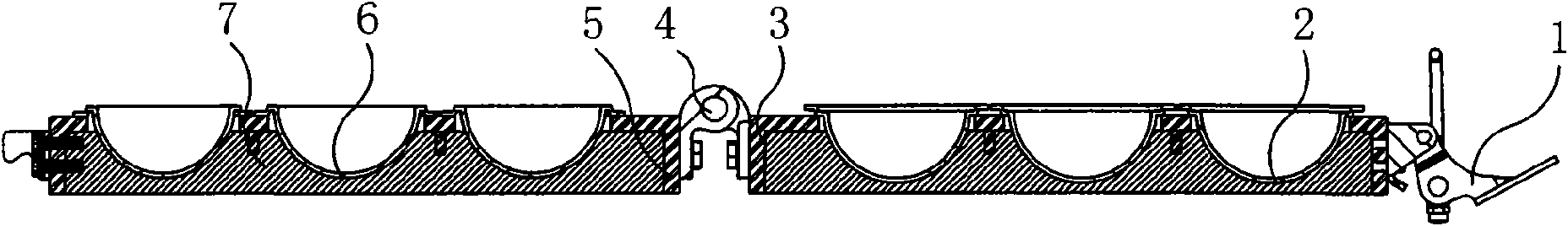

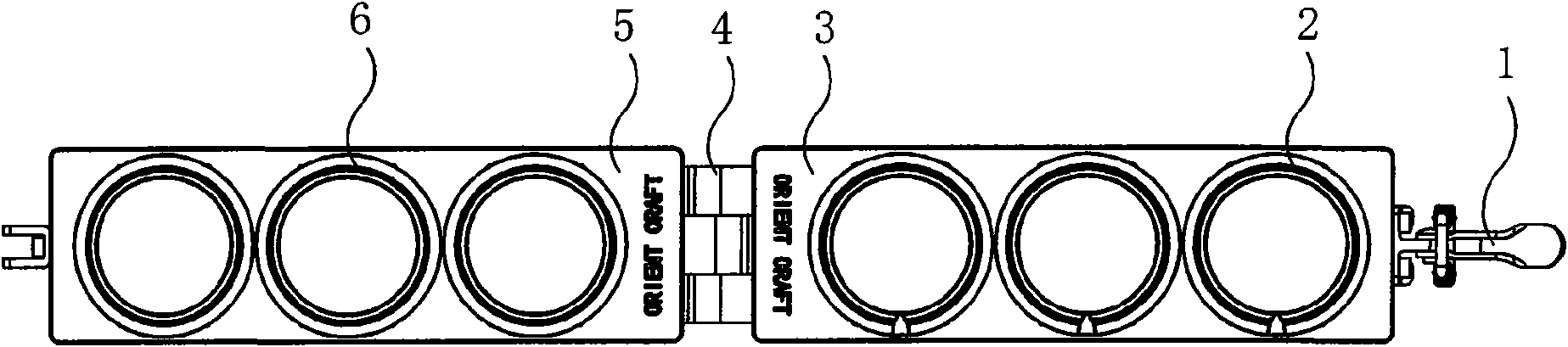

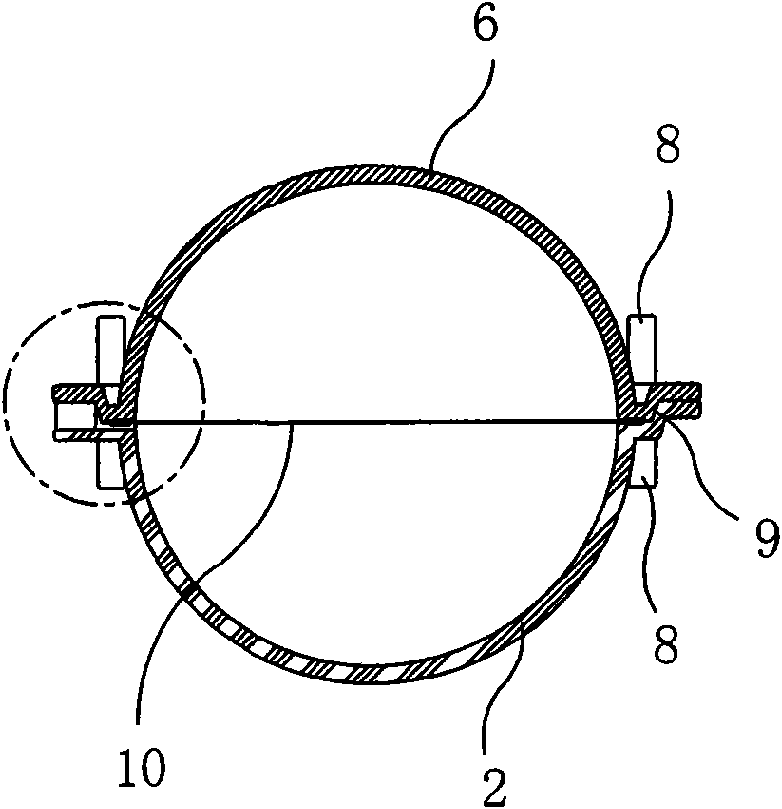

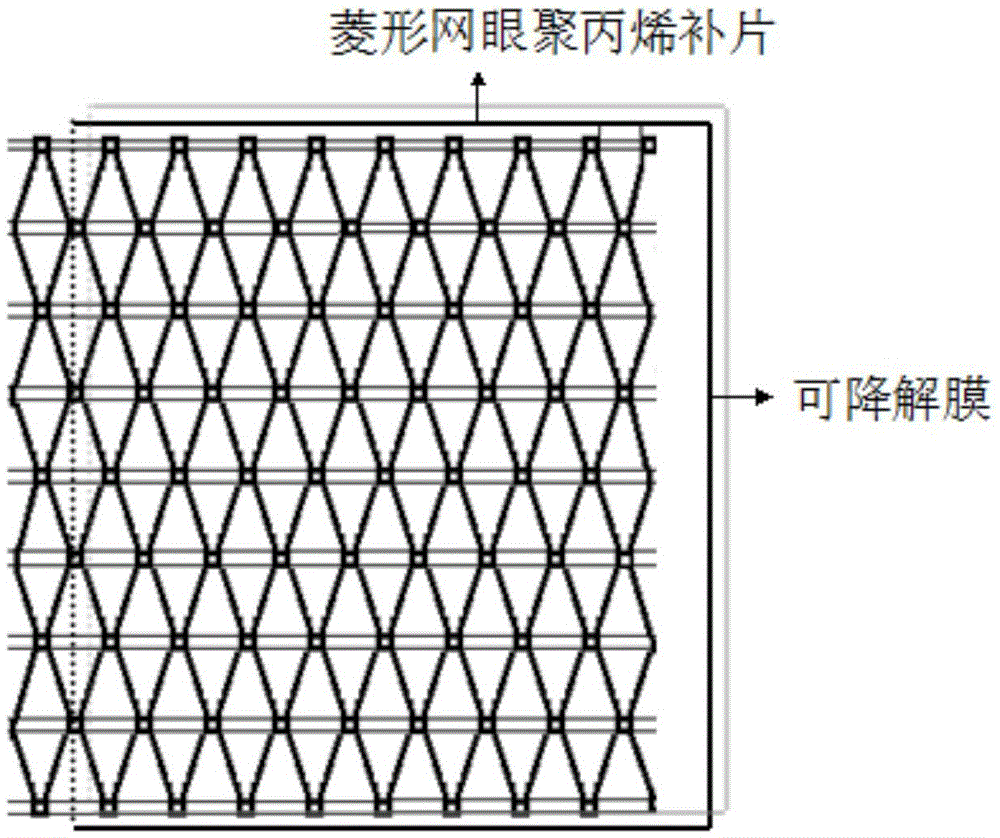

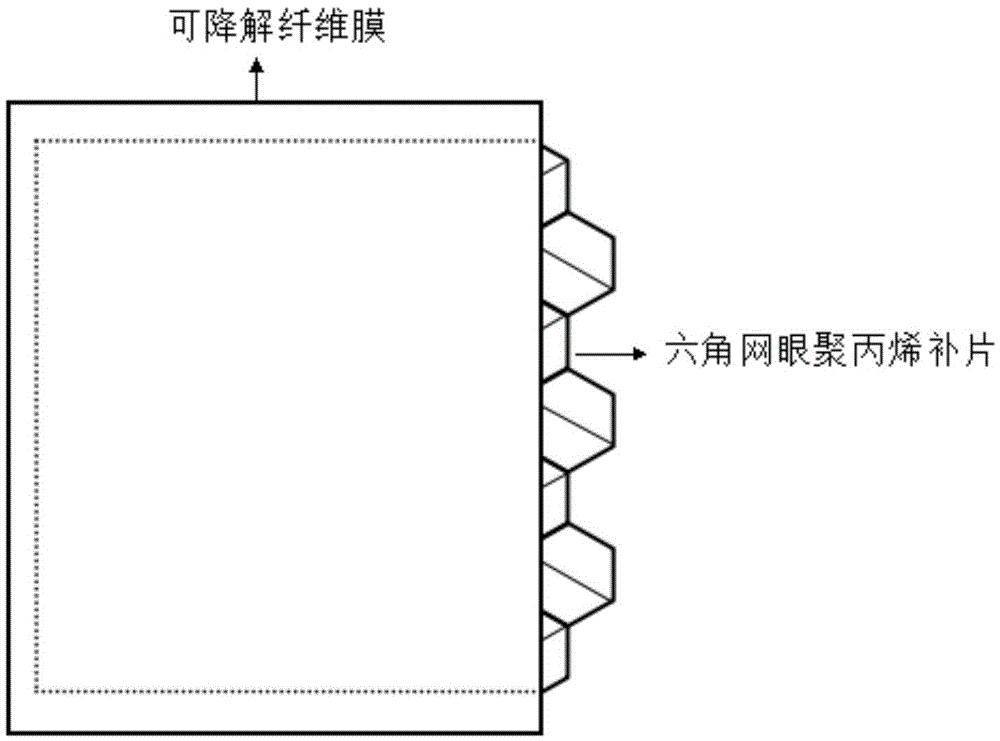

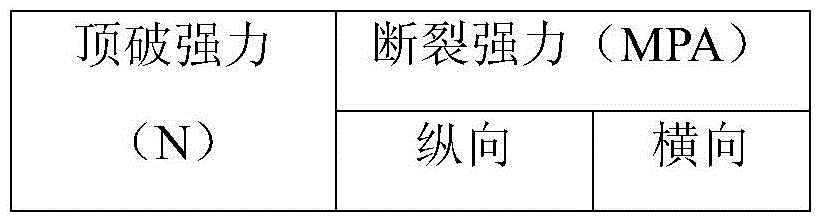

Polylactic acid/polycaprolactone/polypropylene composite pelvic floor patch and preparation method thereof

InactiveCN105536071ADoes not cause thickness changesHigh porosityTissue regenerationProsthesisPolymer sciencePelvic diaphragm muscle

The invention relates to a polylactic acid / polycaprolactone / polypropylene composite pelvic floor patch and a preparation method thereof. The composite pelvic floor patch is a three-layer coated patch consisting of an upper coating layer, a lower coating layer and a middle support layer, wherein the coating layers are degradable films, and the support layer is a warp-knitted mesh patch. The preparation method comprises the following steps: knitting polypropylene monofilaments to obtain a polypropylene warp-knitted mesh patch, washing and naturally air-drying the polypropylene warp-knitted mesh patch at room temperature, and then performing heat setting, cooling and cutting; mixing polylactic acid and polycaprolactone, dissolving the mixture in a solvent, and performing heating and stirring to obtain a mixed solution; impregnating the polypropylene warp-knitted mesh patch in the mixed solution, taking out and horizontally arranging the polypropylene warp-knitted mesh patch, and performing volatilization and sterilization to obtain the polylactic acid / polycaprolactone / polypropylene composite pelvic floor patch. According to the composite pelvic floor patch and the preparation method thereof, an absorbable material is combined with a nonabsorbable material, and an impregnation and coating forming process is utilized, so that the prepared coated patch has the advantages of small thickness, strong strength, high flexibility and biocompatibility and the like. The method is simple and convenient to implement, and use of an adhesive is not required.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com