Hemp degumming and softening synchronous treatment process

A simultaneous processing and degumming technology, applied in the direction of producing bast fiber by chemical method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

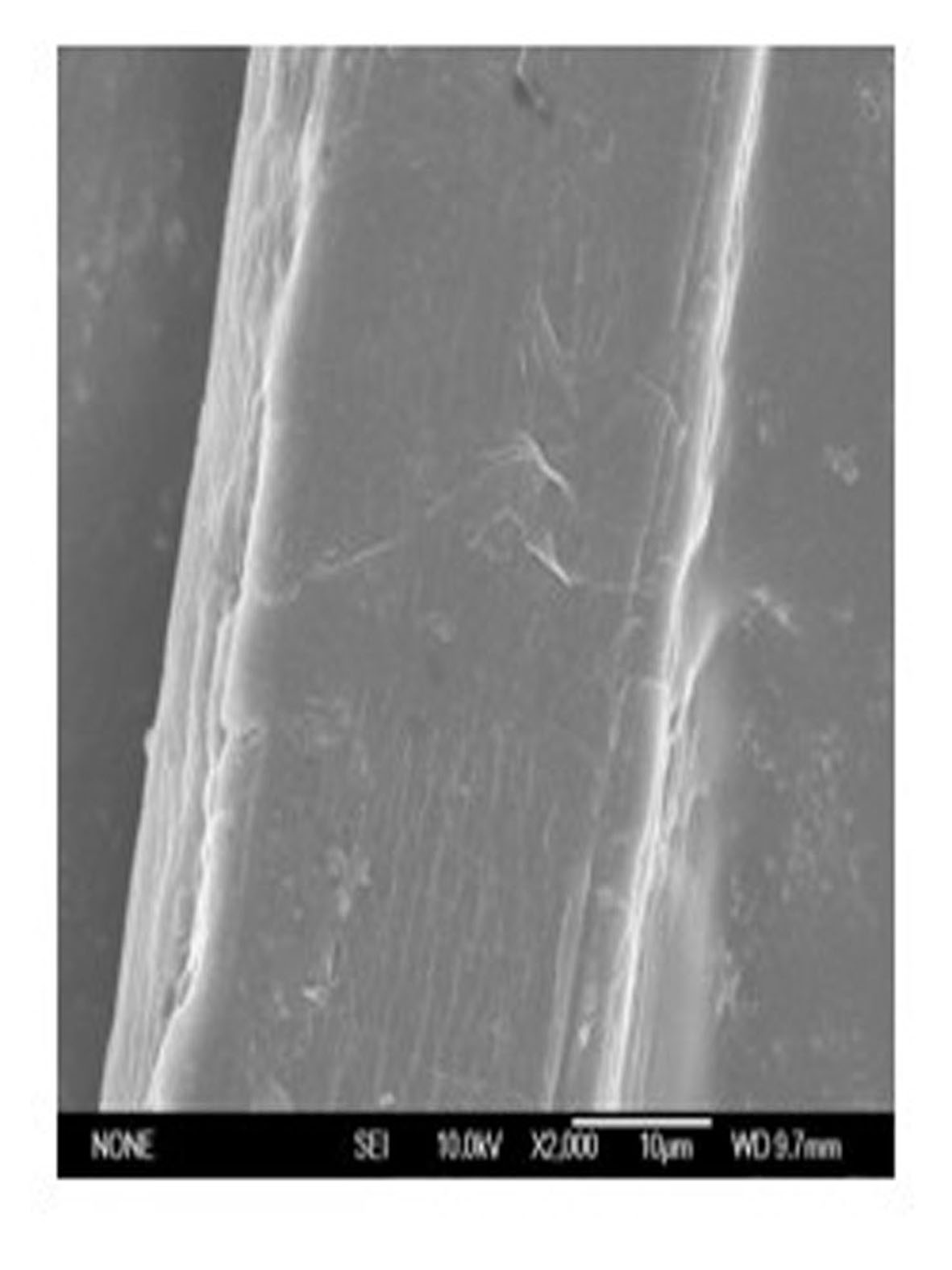

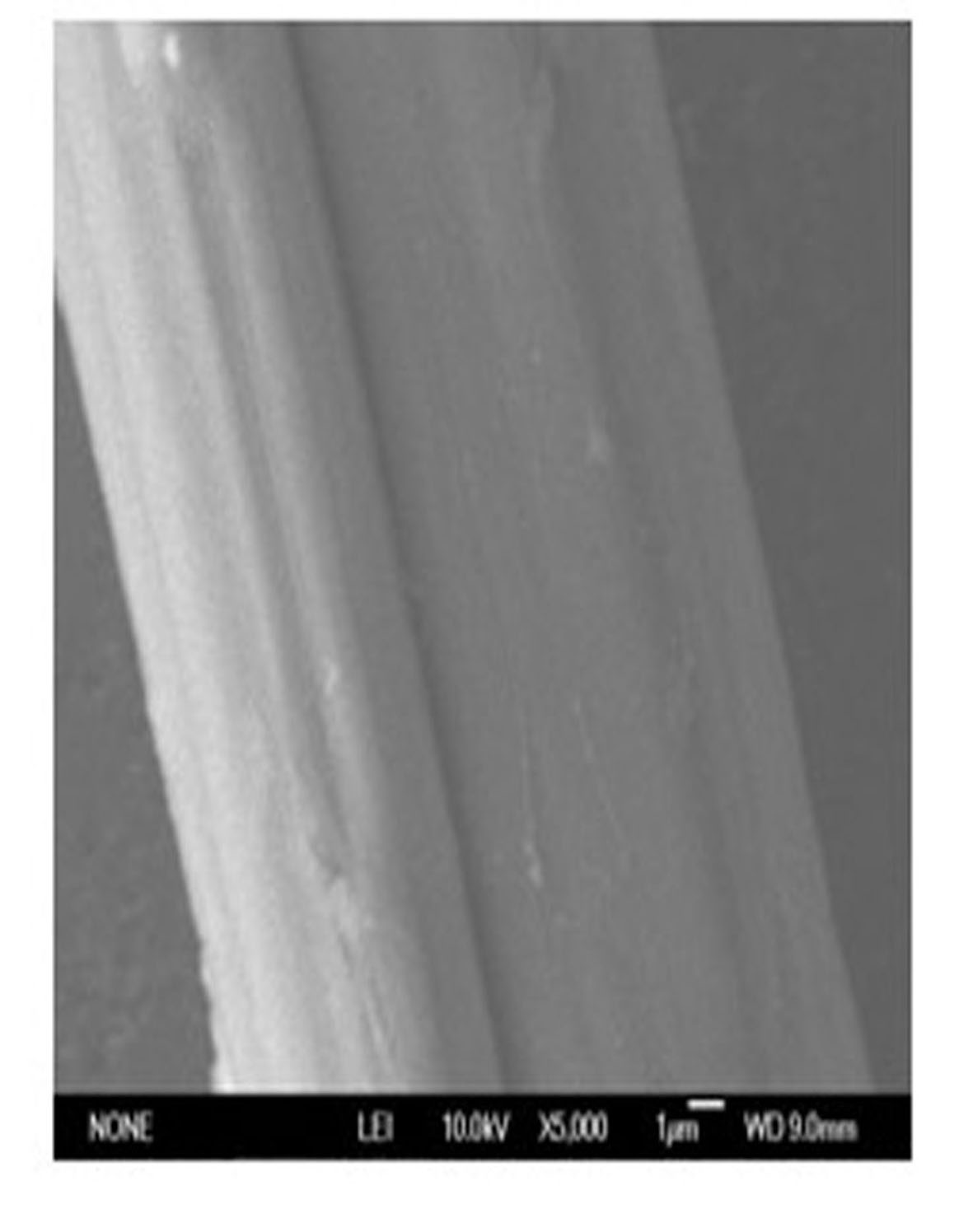

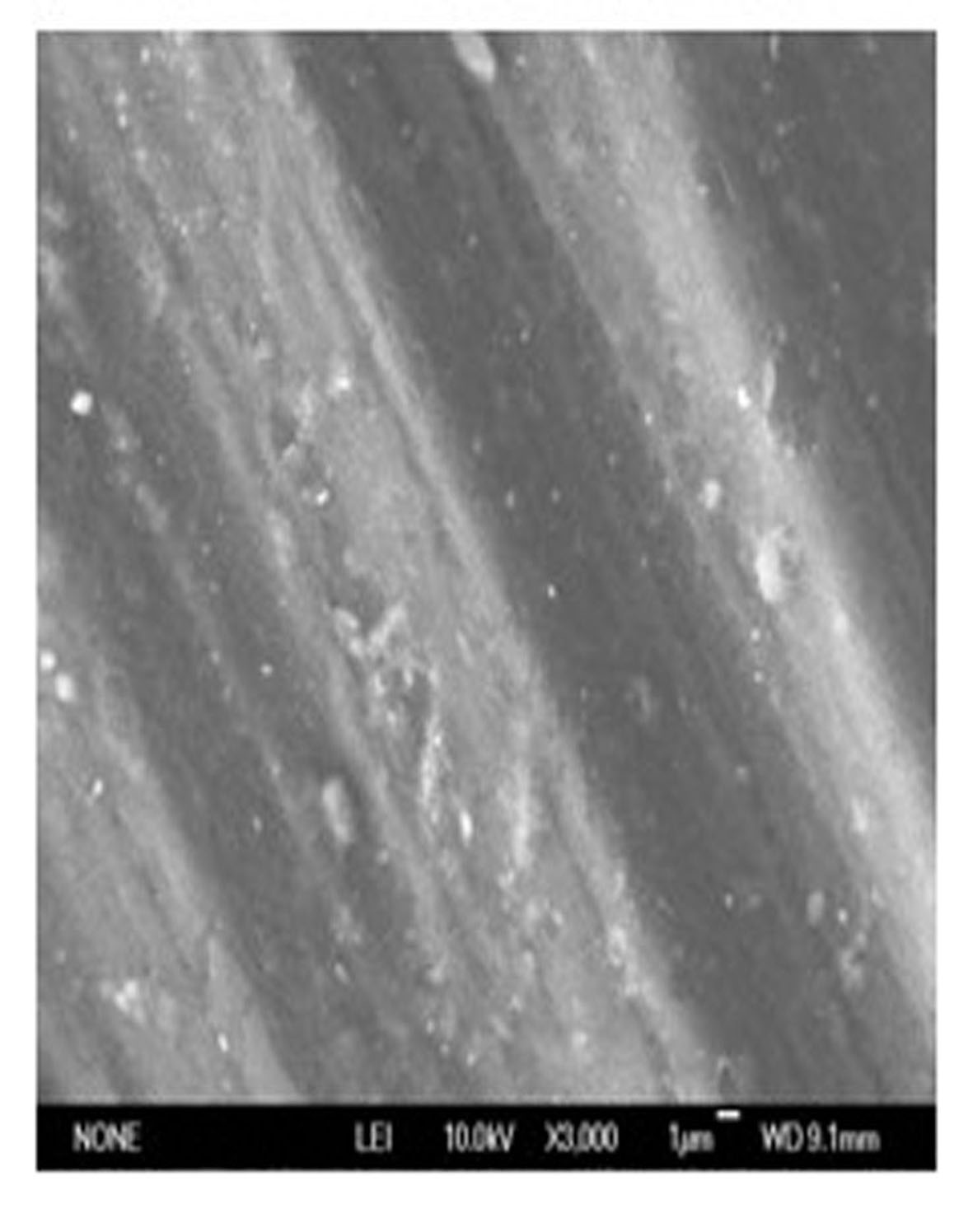

Image

Examples

Embodiment approach 1

[0029] Implement a kind of hemp fiber degumming treatment process and supple treatment process of the present invention, its process step is as follows:

[0030] (1) The epidermis of the hemp stalk was stirred by pre-water at 70°C for 60 minutes, alternately stirred clockwise / counterclockwise every 20 minutes, and the bath ratio of fiber to deionized water was 1:12. Water treatment cleans the dust, dust and other impurities on the surface of the fiber, and can also soften the fiber;

[0031] (2) Put the fibers treated in the water bath into the ultrasonic processor and vibrate for 15 minutes. Ultrasound makes the fibers soft and initially sheds the glue;

[0032] (3) Pre-acidify the fiber after pre-water treatment at 50°C for 20 minutes, the mixed solution is 0.7g / L sulfuric acid, 0.5g / L acetic acid, 1.0g / L sodium nitrate, 1.0g / L sodium hypochlorite, Agitate cis / reverse alternately for 20 minutes, and the bath ratio of fiber to solution is 1:12. Acid treatment can chemicall...

Embodiment approach 2

[0041] According to the process method of embodiment 1, the difference of embodiment 2 is:

[0042] (1) The epidermis of the hemp stalk was stirred by pre-water at 75°C for 70 minutes, and alternately stirred clockwise / counterclockwise every 25 minutes;

[0043] (2) The shock processing time in the ultrasonic processor is 20 minutes;

[0044] (3) Wash the fiber after ultrasonic treatment with deionized water, and soak it in a mixed solution composed of 0.8g / L sulfuric acid, 0.6g / L acetic acid, and 1.2g / L sodium hypochlorite at a temperature of 55°C. / Stir alternately for 25min;

[0045] (4) When irradiated under ultraviolet light, the concentration of hydrogen peroxide is 0.35mol / L, the concentration of sodium hydroxide is 0.3mol / L, the concentration of sodium silicate is 0.003mol / L, and the concentration of magnesium sulfate is 0.02mol / L. The concentration of sodium polyphosphate is 0.005mol / L, the wavelength of ultraviolet light is 300nm, and the radiation time is 40 minut...

Embodiment approach 3

[0050] According to the process method of embodiment 1, the difference of embodiment 3 is:

[0051] (1) The epidermis of the hemp stalk was stirred by pre-water at 80°C for 80 minutes, and alternately stirred clockwise / counterclockwise every 30 minutes;

[0052] (2) The shock processing time in the ultrasonic processor is 20 minutes;

[0053] (3) Wash the fiber after ultrasonic treatment with deionized water, and soak it in a mixed solution composed of 1.0g / L sulfuric acid, 0.7g / L acetic acid, and 1.4g / L sodium hypochlorite at a temperature of 60°C. / Stir alternately for 30min;

[0054] (4) When irradiated under ultraviolet light, the concentration of hydrogen peroxide is 0.4mol / L, the concentration of sodium hydroxide is 0.35mol / L, the concentration of sodium silicate is 0.005mol / L, and the concentration of magnesium sulfate is 0.03mol / L. The concentration of sodium polyphosphate is 0.010mol / L, the wavelength of ultraviolet light is 350nm, and the irradiation time is 50 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com