Patents

Literature

263 results about "Silicon fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon Fluoride is a water insoluble Silicon source for use in oxygen-sensitive applications, such as metal production. Fluoride compounds have diverse applications in current technologies and science, from oil refining and etching to synthetic organic chemistry and the manufacture of pharmaceuticals.

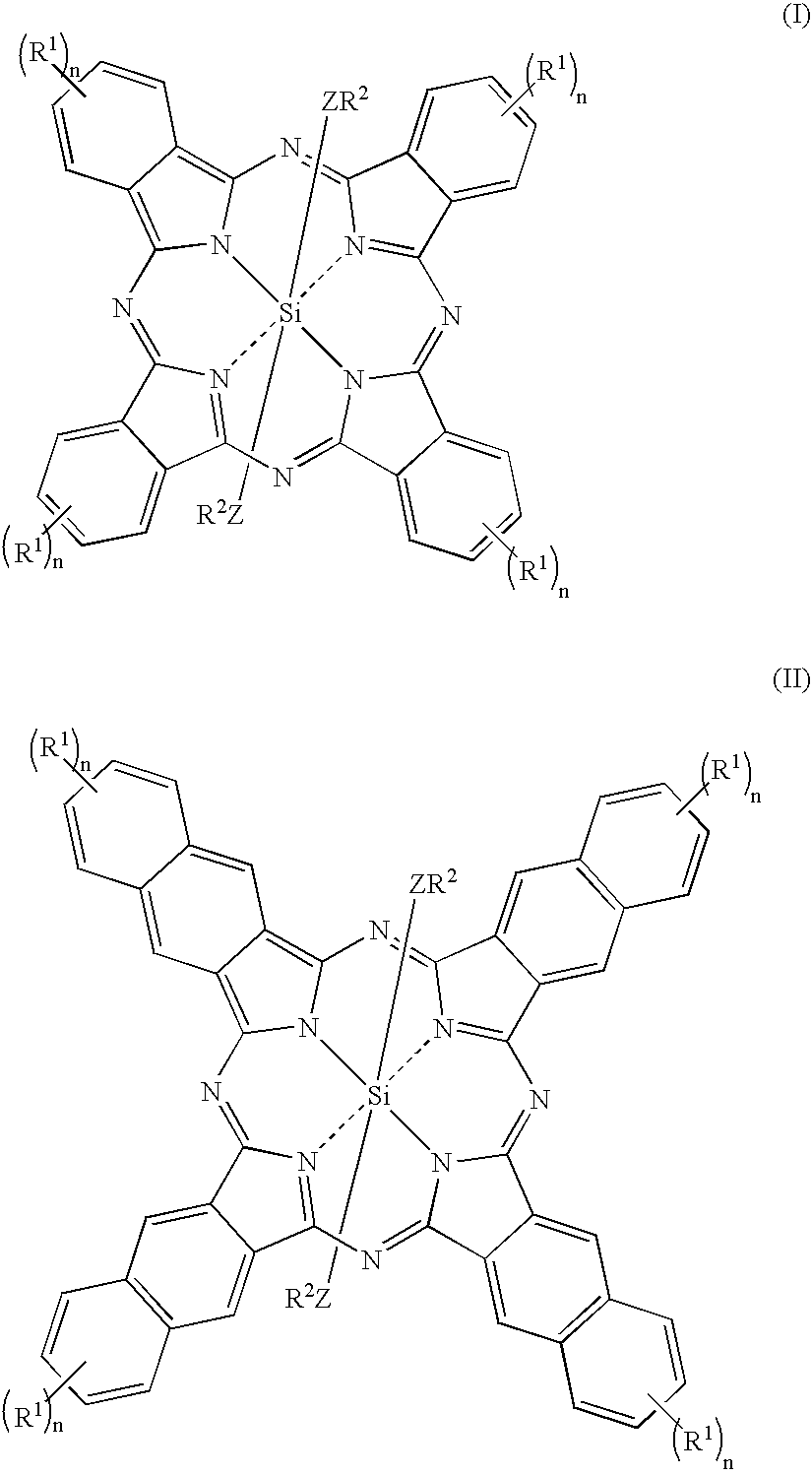

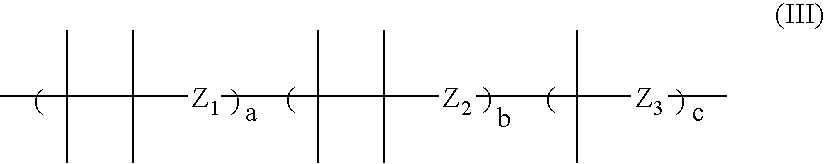

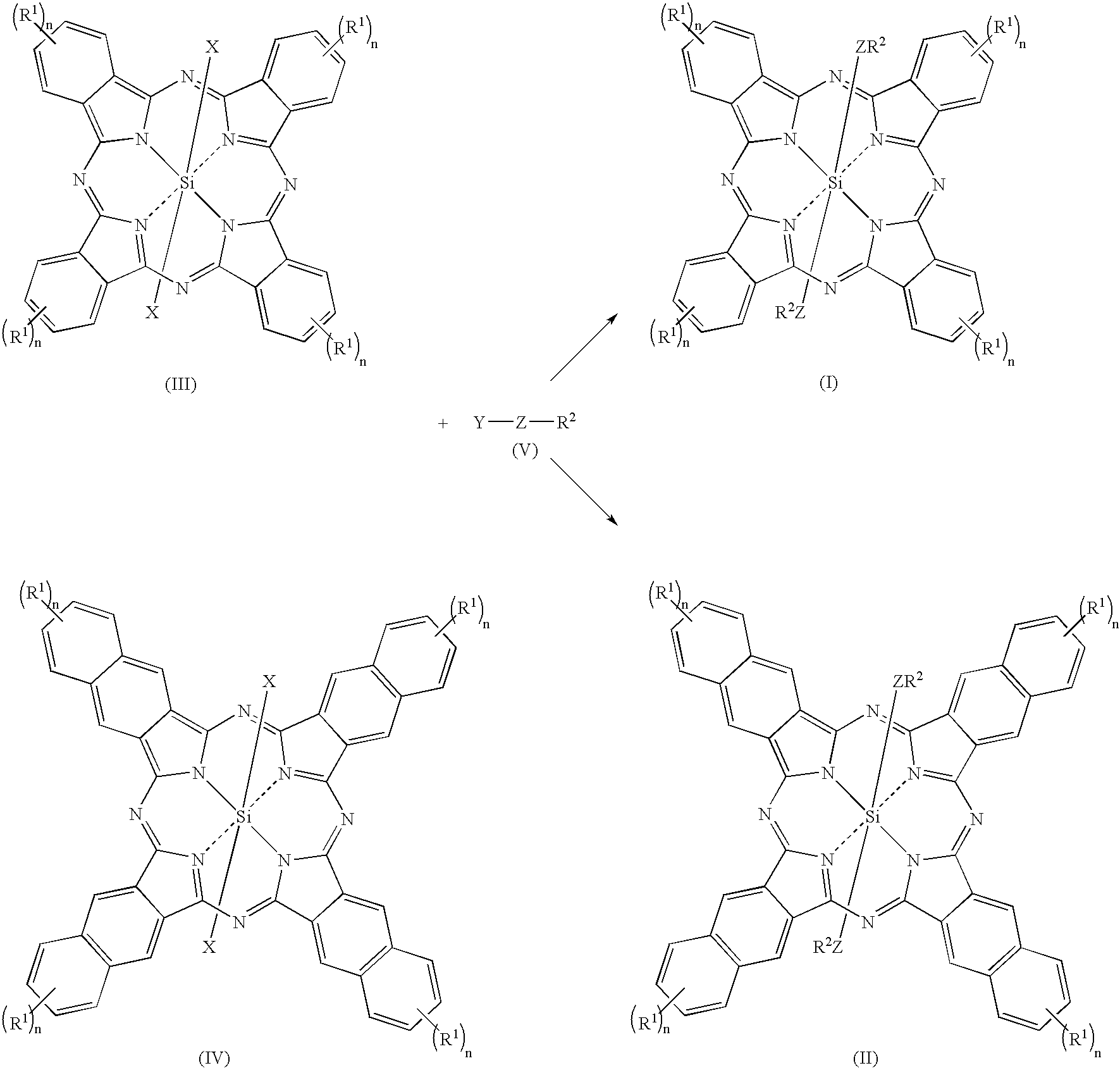

Novel Fluorinated silicon (IV) phthalocyanines and naphthalocyanines for electrophoretic, magnetophoretic or electromagnetophoretic display

This invention relates to stable colorants of high extinction coefficient and high solubility or dispersibility for an electrophoretic, magnetophoretic or electromagnetophoretic display. More particularly, it relates to stable colorants for a microcup-based electrophoretic or electromagnetophoretic display the cells of which are filled with charged and / or magnetic particles dispersed in a halogenated, preferably a fluorinated, solvent. The use of the stable colorants allows the display to be of superior contrast ratio and longevity, and suitable for high-quality imagery applications.

Owner:SIPIX IMAGING INC

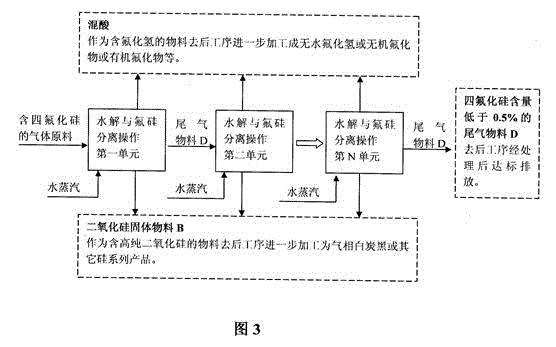

Method of forming silicon-based thin film, silicon-based thin film, and photovoltaic element

InactiveUS7074641B2Improve featuresLow costPolycrystalline material growthFrom solid stateLuminous intensityHydrogen

Owner:CANON KK

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

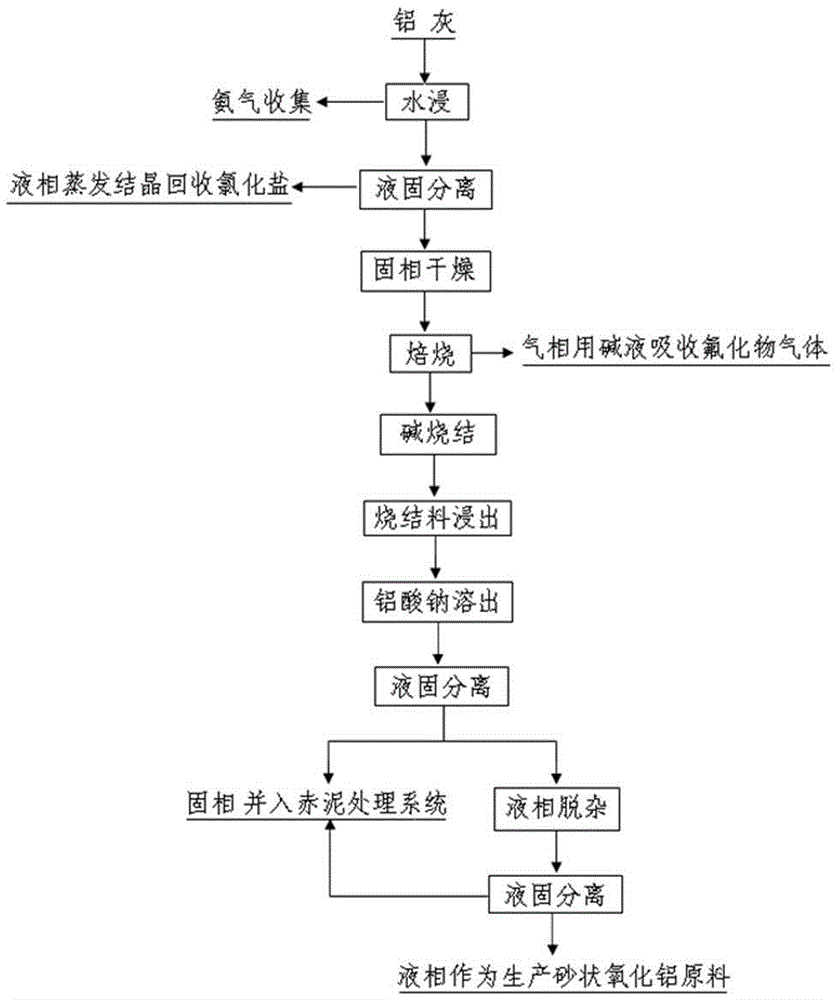

Method for harmless disposal and recycling of aluminum ash

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

Surface treating method for sea water corrosion-resistant metal aluminum or aluminum alloy

InactiveCN101429672AImprove seawater corrosion resistanceEase of industrial applicationAnodisationMetallic aluminumElectrolysis

The invention relates to a method for treating the surface of seawater corrosion resistant metallic aluminum or aluminum alloy. The method comprises the following steps: 1) sand pellets are used to carry out gritting blasting treatment for the surfaces of aluminum and aluminium alloy through a spray gun so as to bring about the concave and convex surface topography in the micron order for aluminium and aluminium alloy; 2 the aluminium and aluminium alloy is cleaned after degreasing and is taken as the anode of an electrolytic bath, and nickel is taken as a cathode; the electrolyte is prepared and is added into the electrolytic bath, and a DC power supply is connected with the anode and the cathode so as to form nanometer holes on the aluminium or aluminium alloy surface; and 3 silicon fluoride is taken to carry out the surface finish of aluminum or aluminium alloy so as to reduce the surface free energy of aluminium or aluminium alloy. The method for adopting silicone fluoride to carry out the surface finish of aluminum or aluminium alloy comprises the following steps: heating up the aluminium or aluminium alloy processed in step 2 to 90 to 120 DEG C, keeping the temperature for 30 to 40 minutes, taking the aluminium or aluminum alloy out and cooling down the aluminium or aluminum alloy to a room temperature, and then carrying out surface finish through a soak method or a vapor plating method. The processed aluminium metal or aluminum alloy has good resistance to seawater corrosion.

Owner:SOUTHEAST UNIV

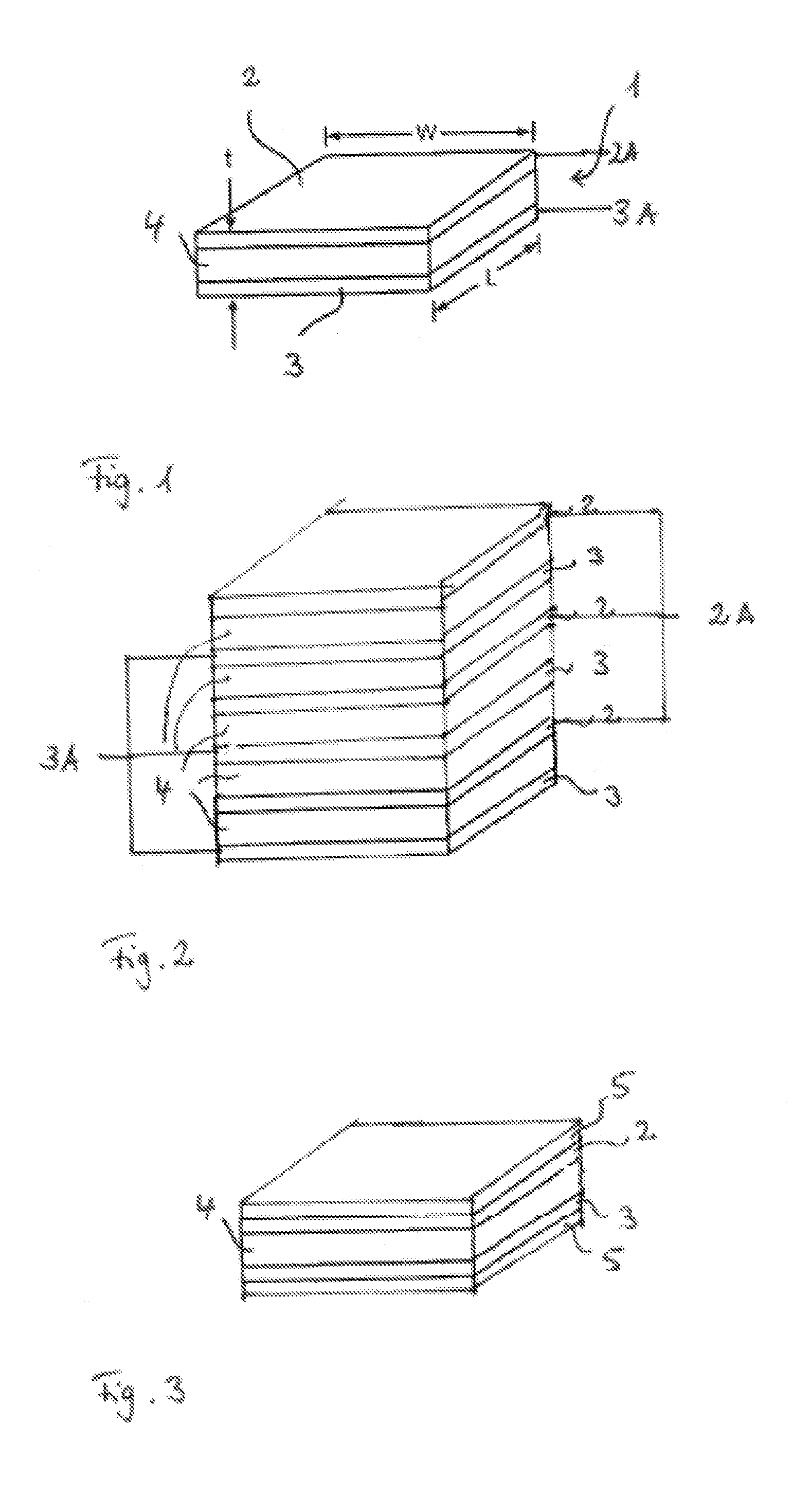

Fluorosilicone-Based Dielectric Elastomer and Method for its Production

InactiveUS20130236730A1Increased dielectric permittivityHigh modulusPiezoelectric/electrostrictive device manufacture/assemblyPlastic/resin/waxes insulatorsPolymer scienceThin membrane

A dielectric elastomer has a film that contains a fluorinated silicone elastomer and has two faces. A coating of a stretchable electrode material is applied to each one of the two faces. The fluorinated silicone elastomer has a modulus of elasticity of maximally 450 kPa. The fluorinated silicone elastomer is a three-dimensionally crosslinked, fluorinated, alkyl group-containing polysiloxane in combination with a fluorinated silicone oil. Alternatively, or in addition, the fluorinated silicone elastomer is a three-dimensional wide-mesh crosslinked, fluorinated, alkyl-group containing polysiloxane whose wide mesh property has been effected by a chain length extension by addition of a chain-shaped silicone molecule containing two Si—H groups to an alkenyl group-containing polysiloxane molecule.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Heat insulation coating

InactiveCN101348639AImprove physical performanceGood weather resistanceReflecting/signal paintsLatex particleCordierite

The invention relates to thermal insulating paint which comprises the following compositions and contents in mass portion: 10.0 to 18.0 portions of water, 0.3 to 1.0 portion of wetting-dispersing agent, 0.3 to 1.0 portion of propanediol, 0.05 to 0.2 portion of a disinfecting agent, 0 to 5.0 portions of French chalk, 2.0 to 10.0 portions of titanium pigment, 1.0 to 5.0 portions of aciform cordierite powder, 5.0 to 15.0 portions of hollow glass bead, 0.1 to 0.2 portion of defoamer, 25.0 to 35.0 portions of modified acrylic acid latex, 0.15 to 0.3 portion of thickening agent, 0.15 to 0.3 portion of a flow agent and 0.1 to 1.0 portion of pH adjusting agent, wherein the modified acrylic acid latex is elastic acrylic acid latex by modifying fluorosilcone monomers and is provided with a core-shell structure and has the silicon fluoride distributed on the surface layer of latex particles. The thermal insulating paint is particularly suitable for forming a decorative surface layer in an external thermal insulating system of an external wall.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Non-stick ceramic paint and coating method thereof

ActiveCN103205201AHigh hardnessImprove temperature resistancePretreated surfacesCoatingsAcetic acidAryl

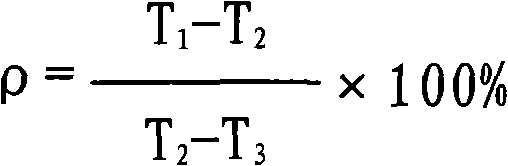

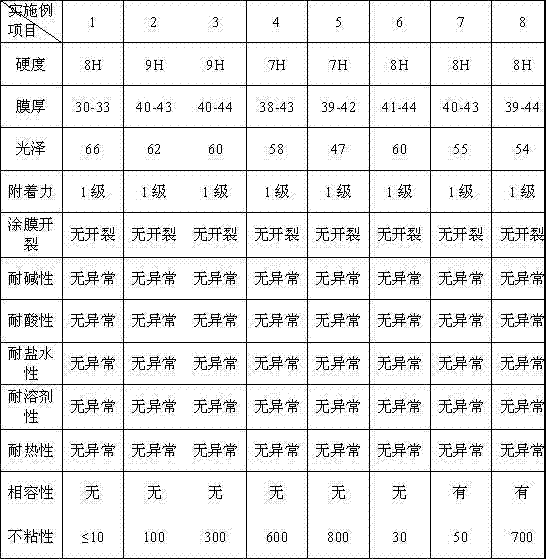

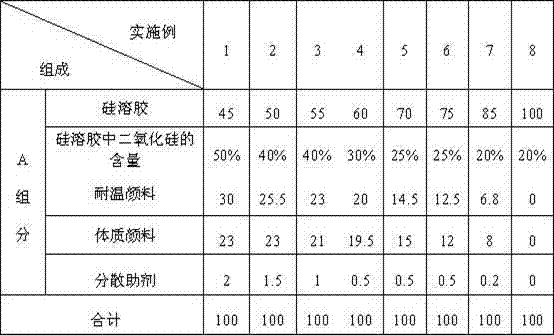

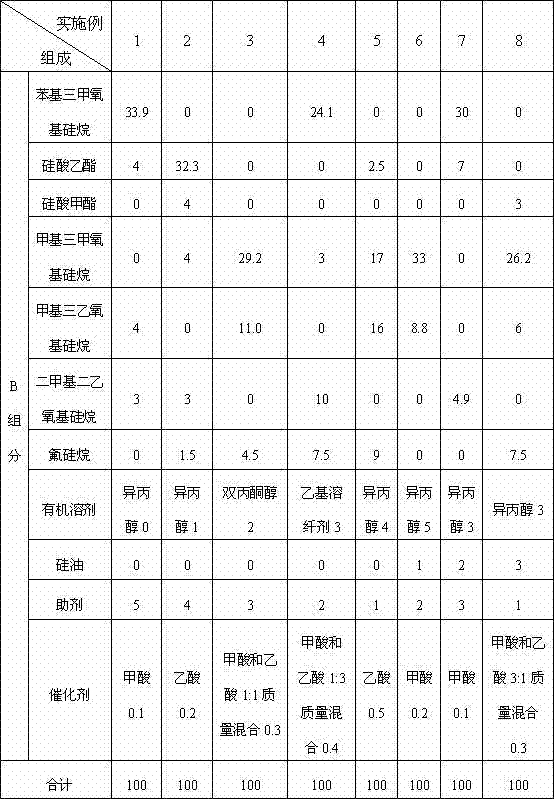

The invention relates to a non-stick ceramic paint and a coating method thereof, belonging to the technical field of a process for coating liquid or other fluids on a surface. The non-stick ceramic paint is prepared by mixing a component A and a component B according to a mass ratio of 2: 0.5-2. The component A comprises, by mass, 45 to 100% of silica sol, 0 to 30% of a pigment, 0 to 23% of a filling material and 0 to 2% of a dispersing aid and is prepared by mixing the above-mentioned components and then grinding the components for more than 2 h. The component B is prepared by mixing the following components by mass: 0.2 to 2% of a catalyst, 3 to 15% of silicon fluoride, 2 to 10% of an auxiliary agent, 0 to 10% of an organic solvent, with the balance being at least one silane, wherein the catalyst is formic acid, acetic acid or a mixture of formic acid and acetic acid. The silane has a general molecular formula as represented by RnSi(OR')4-n, wherein R is an alkyl group, an epoxy group or an aryl group, R' is an alkyl group of C1 to C5, and n is equal to 0, 1 or 2. A coating prepared from the paint does not contain substances like PTFE and PFOA, is environment-friendly and energy-saving and has wear resistance, scratch resistance and excellent non-stick performance.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

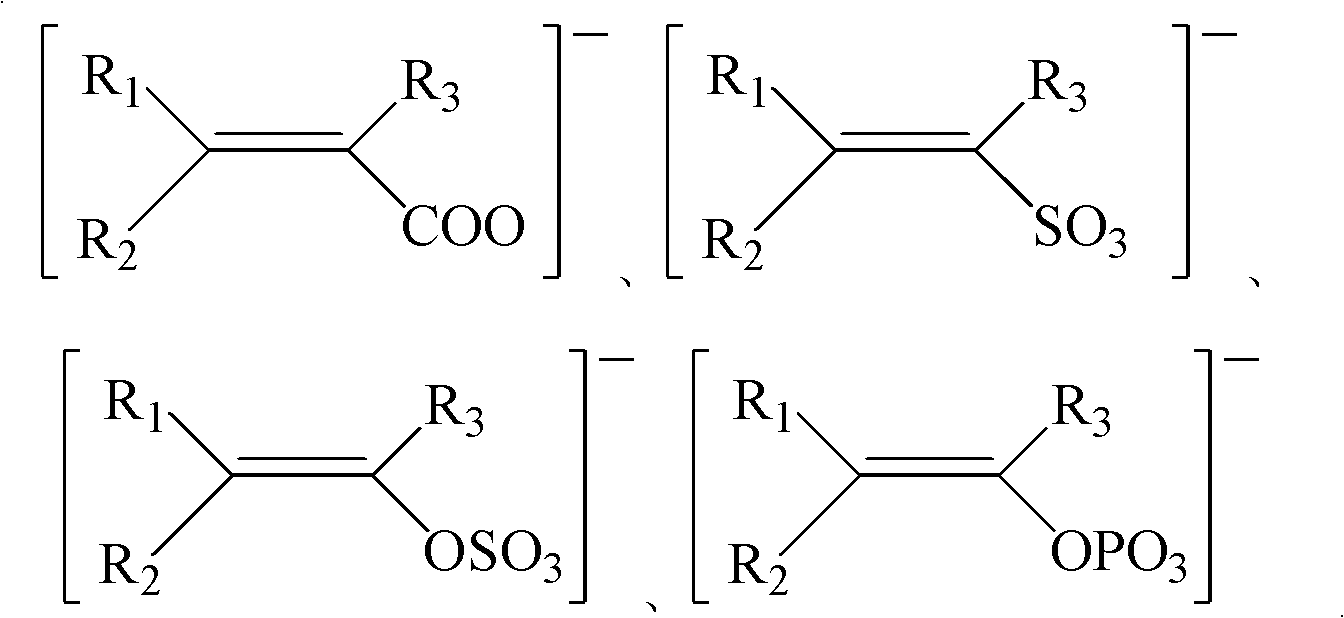

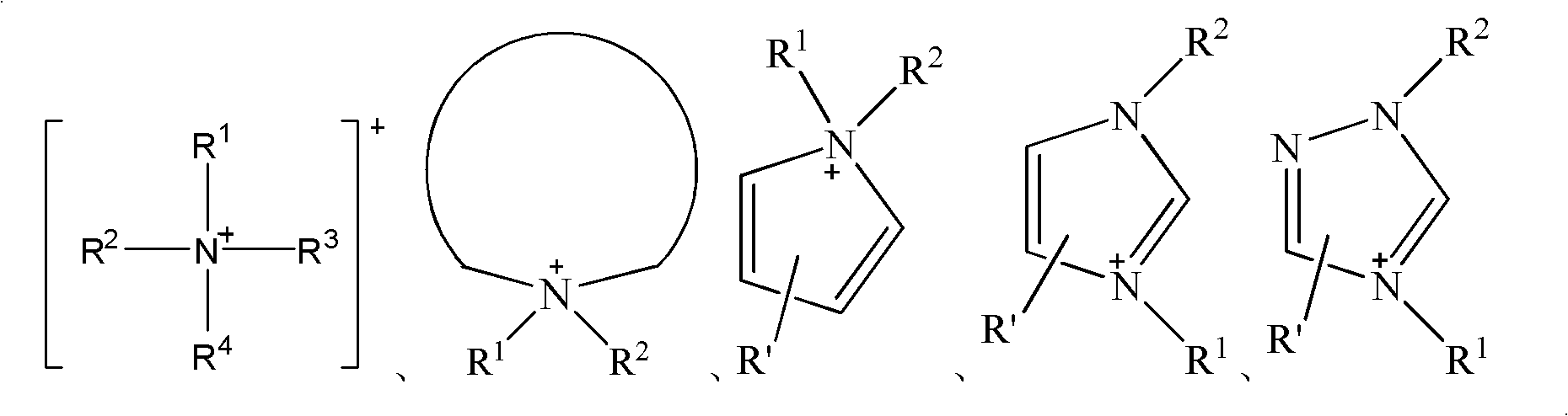

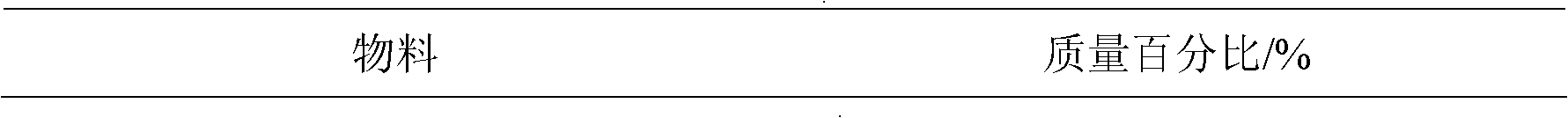

Ice-covering-proof coating containing electrolyte

ActiveCN102140288ALowering the freezing pointTo achieve the effect of anti-icingAntifouling/underwater paintsPaints with biocidesHigh pressureSolvent

The invention discloses an ice-covering-proof coating containing electrolyte, which consists of organic silicon modified polyelectrolyte, silicon fluoride modified acrylic ester, nanometer material, dissolvent, pigment, aleveling agent, a fire retardant and preservatives and bactericides. All the materials are as follows according to mass percents: 5 to 90% of organic silicon modified polyelectrolyte, 0 to 80% of silicon fluoride modified acrylic ester, 0.1 to 20% of nanometer material, 0 to 60% of dissolvent, 0 to 30% of pigment, 0 to 5% of leveling agent, 0 to 10% of fire retardant and 0 to 3% of preservatives and bactericides. The ice-covering-proof coating is obtained by uniformly grinding all the materials according to the amount. The ice-covering-proof coating is coated on the surfaces of parts such as high-voltage cables, iron towers, telecommunication lines, aircrafts and the like and can effectively prevent the parts from being covered by ice. The method is simple and practical in the engineering, is convenient to control and has lower cost and good using effect.

Owner:张家港楚人新材料科技有限公司

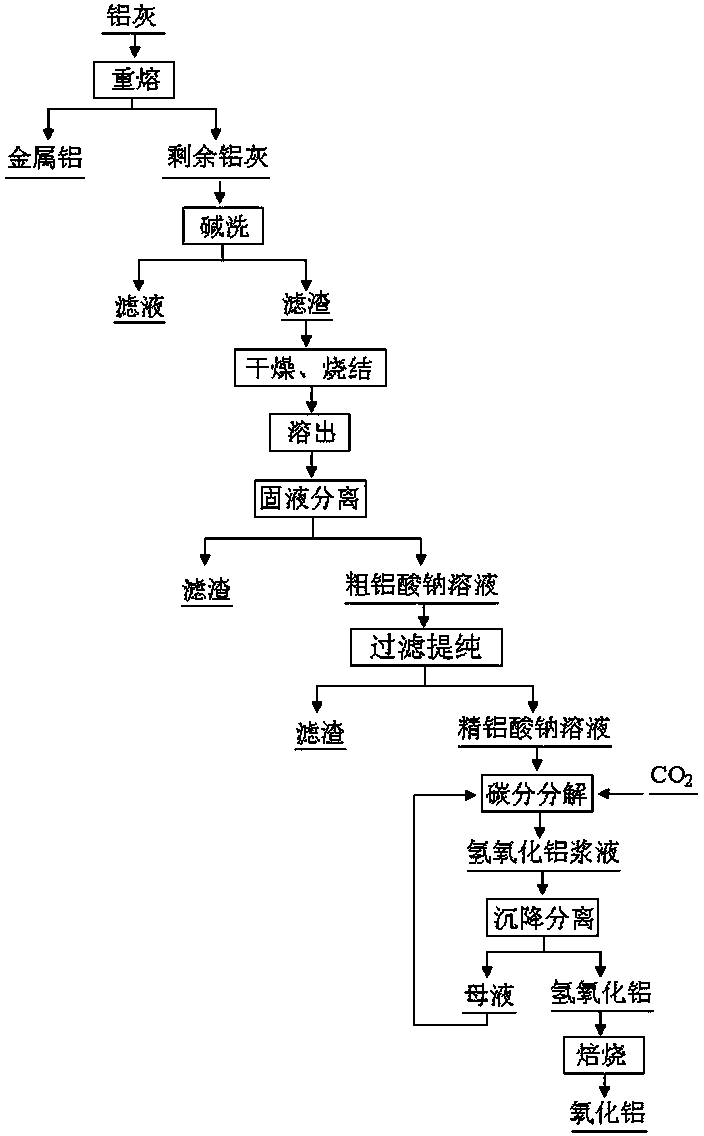

Method for harmlessly treating aluminum ash and preparing sandy alumina

ActiveCN104261445ARealize recycling of resourcesHarmlessAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium electrolysisAluminium hydroxide

The invention discloses a method for harmlessly treating aluminum ash and preparing sandy alumina. The method disclosed by the invention mainly comprises the following main steps of remelting, alkaline washing, drying and sintering, dissolving out, filtrating and purifying, carbon component decomposition, and roasting, and is specifically implemented by taking aluminum ash produced in the processes of aluminum electrolytic smelting and coarse aluminum refining as a raw material through the process post-treatment steps of recovering metallic aluminium, carrying out alkaline wash for removing impurities, sintering sodium carbonate, dissolving out sintered clinker, carrying out deep impurities removal on a sodium aluminate solution, separating and washing carbon components and aluminum hydroxide, roasting aluminum hydroxide, evaporating carbon component mother liquor, and the like, so that a sandy alumina product is obtained. Fluorine in aluminum ash, after being discharged in silicon fluoride form, is absorbed by using an aqueous solution. The method disclosed by the invention realizes the harmless treatment of aluminum ash, the method is simple in process and low in production cost, and the environmental pollution and the resource wastes caused by the aluminum ash are avoided.

Owner:KUNMING METALLURGY INST

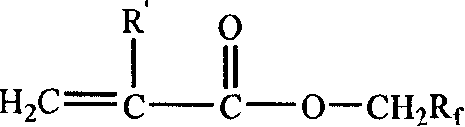

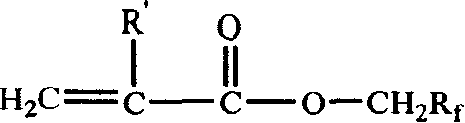

Radiation curing silicon fluoride coating and preparation method and application thereof

ActiveCN105885494AGood weather resistanceImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesWeather resistanceHeat resistance

The invention belongs to the field of coatings, relates to a radiation curing silicon fluoride coating and a preparation method and application thereof, and particularly discloses a radiation curing silicon fluoride coating. The coating is prepared from 30-70wt% of reactive acrylate prepolymer, 15-50wt% of reactive acrylate monomer, 3-8wt% of photoinitiator, 0-35wt% of pigment, 0-10wt% of filler and 0-5wt% of additive. Compared with the prior art, the radiation curing silicon fluoride coating has better color and pattern expressive force when carrying out surface treatment on decorative materials, has good antibacterial, anti-pollution, self-cleaning, waterproof and anti-mold properties and better weather resistance, heat resistance and mechanical performance, is wider is application range and can be widely applied to surface treatment, beautifying and protection of indoor and outdoor decoration materials.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

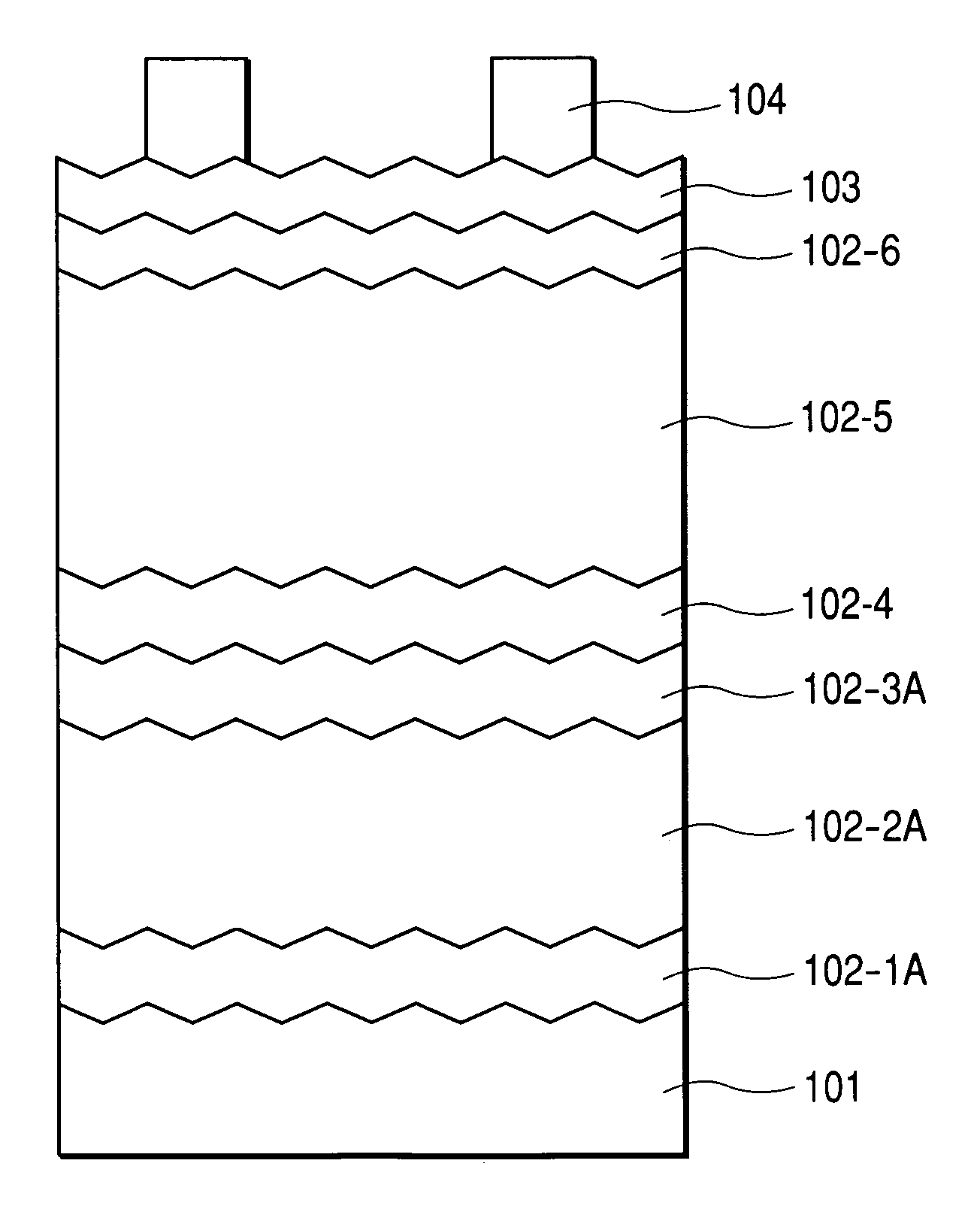

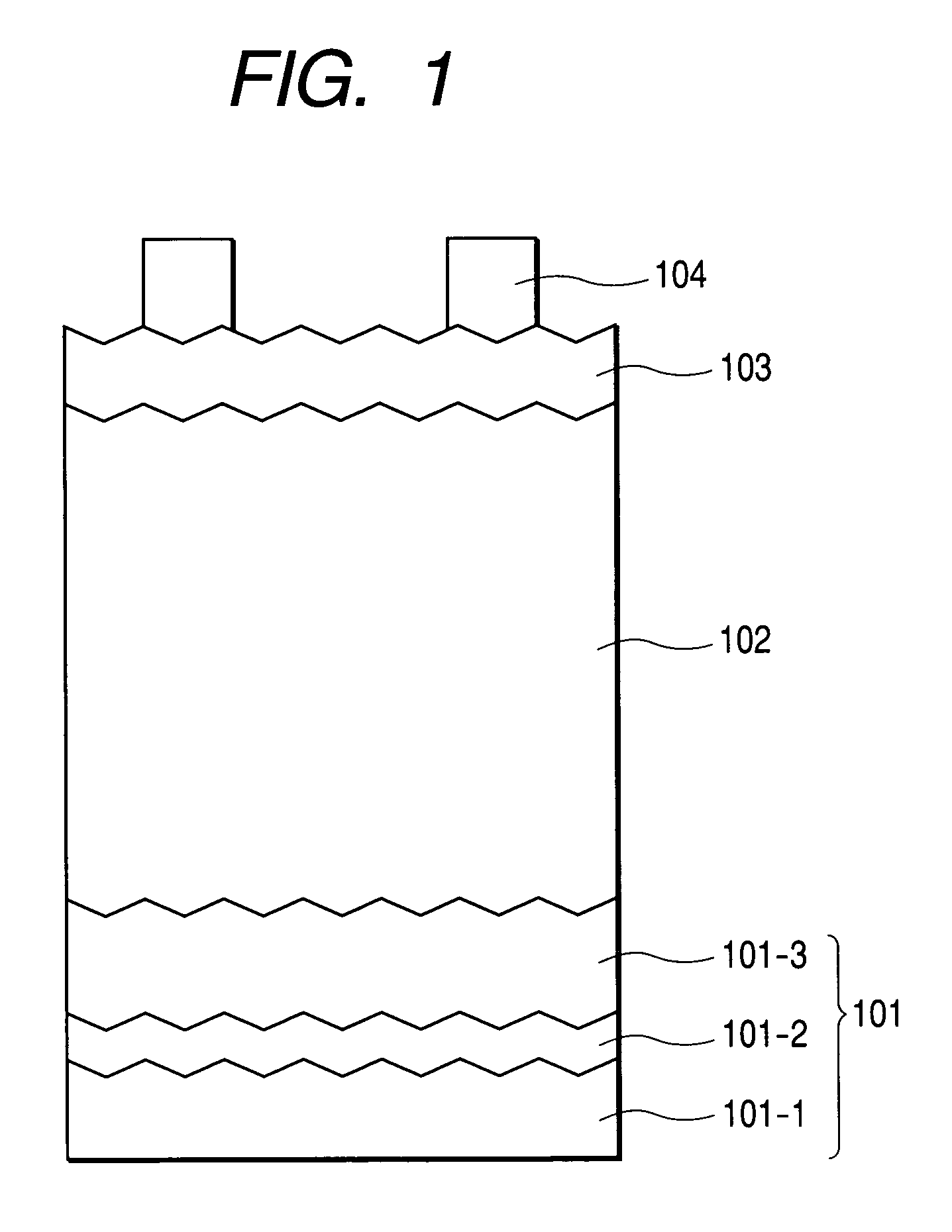

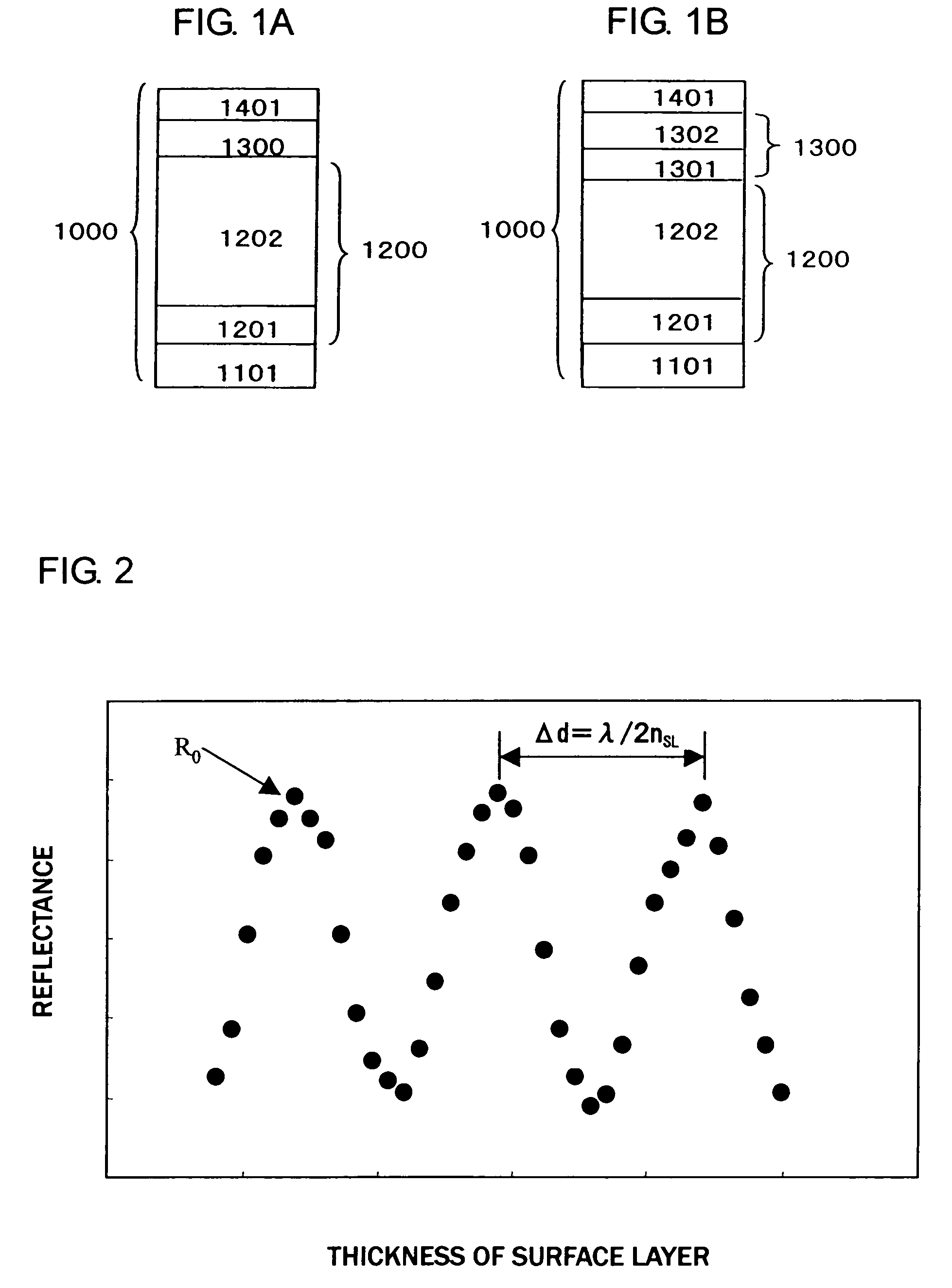

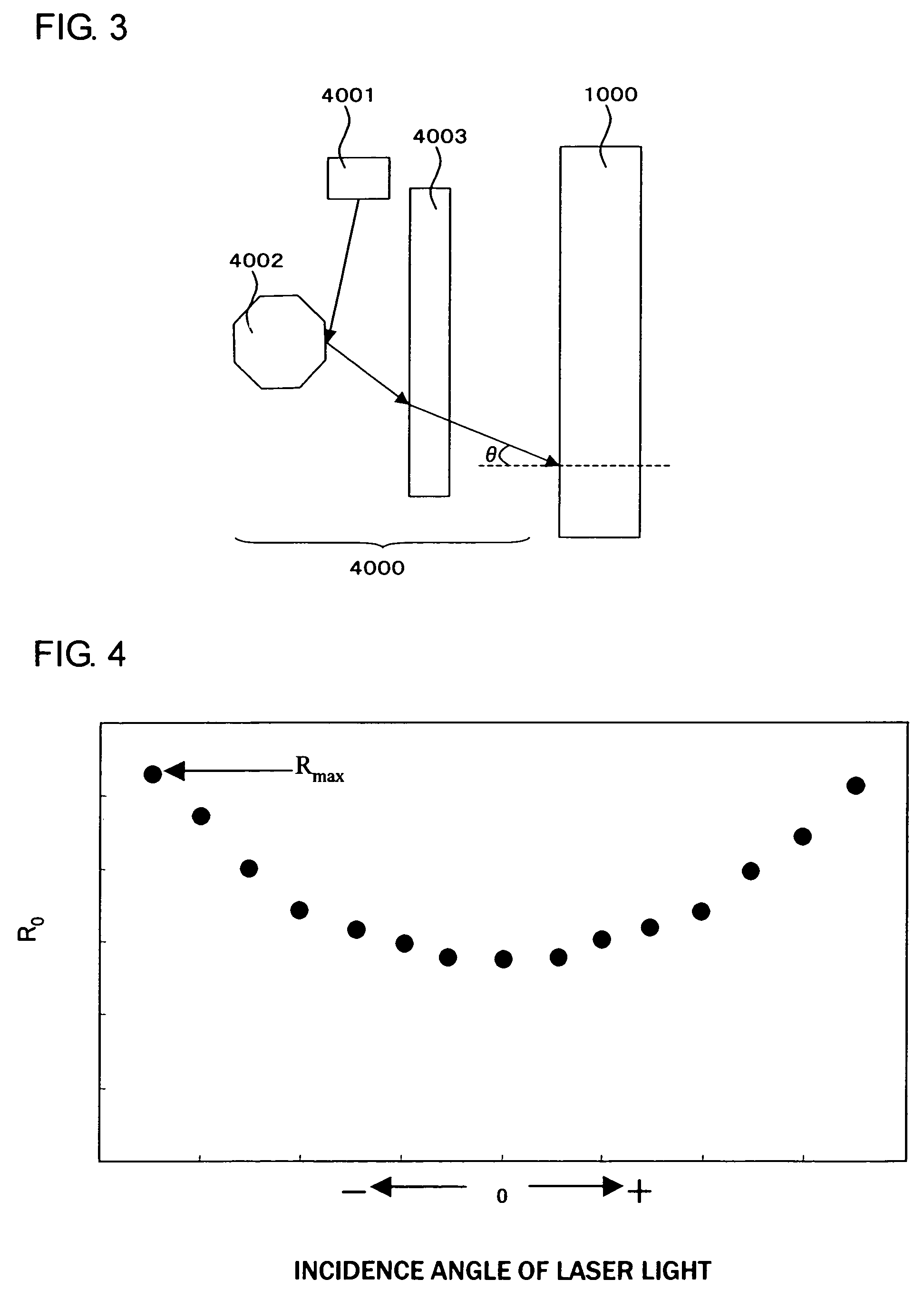

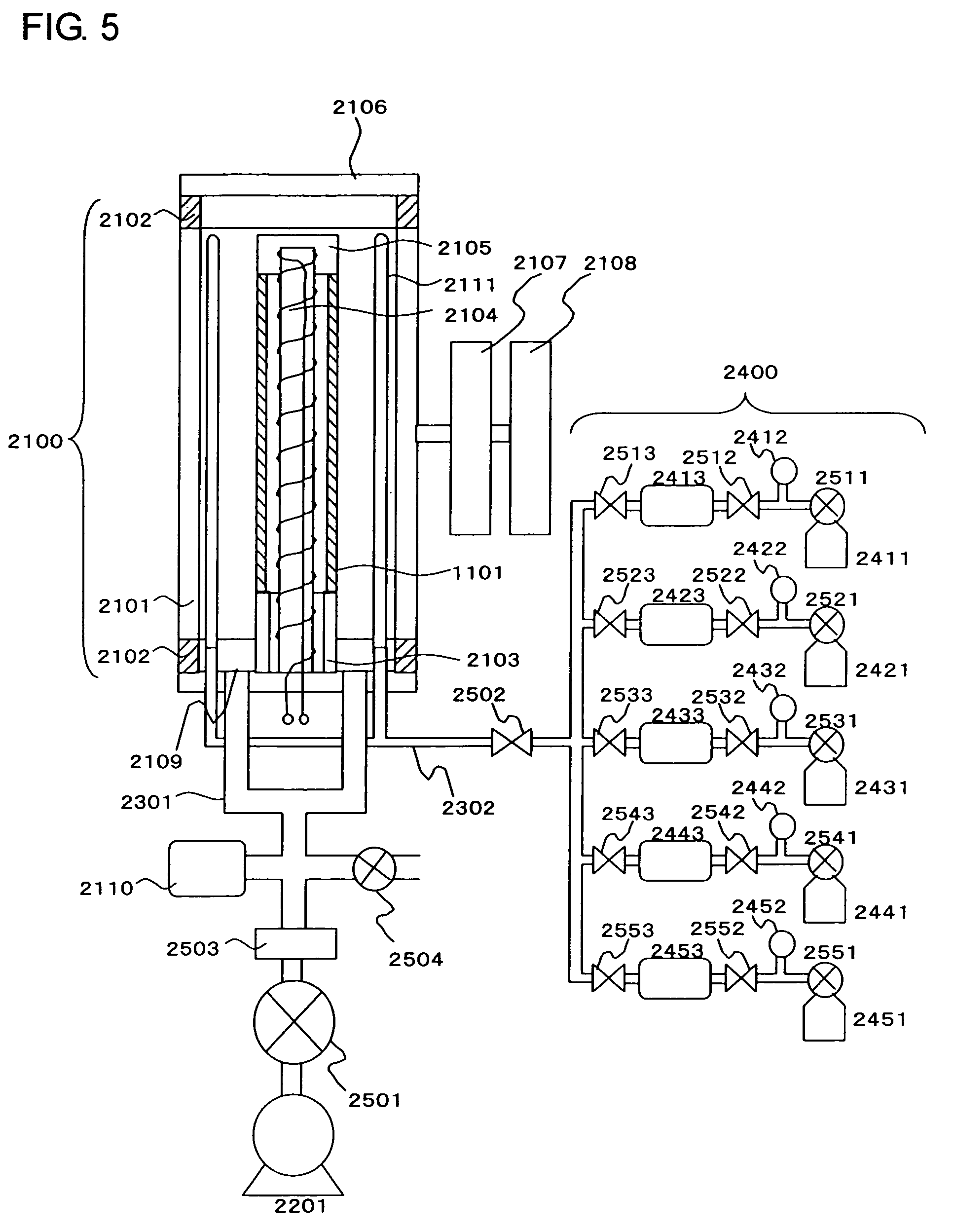

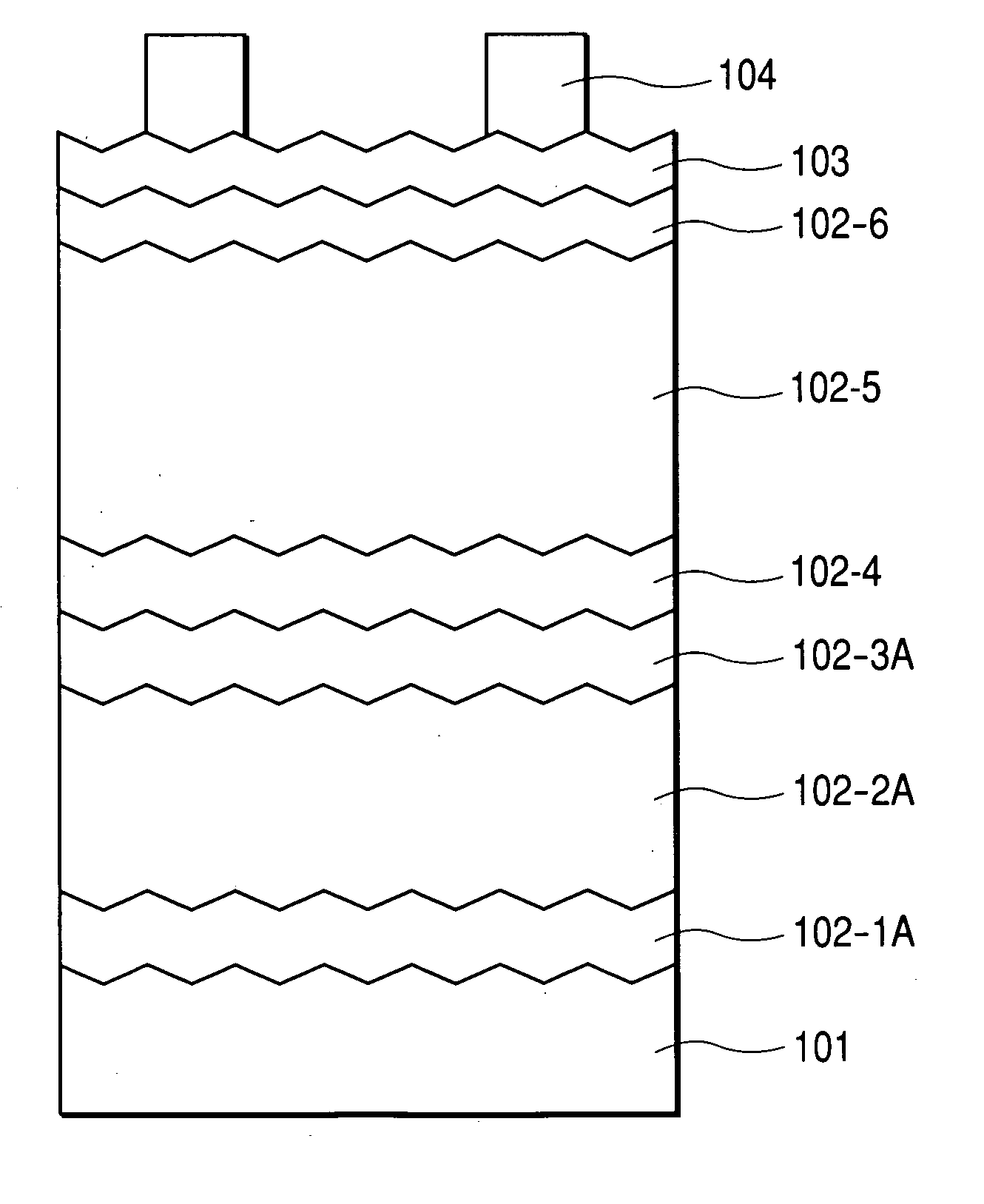

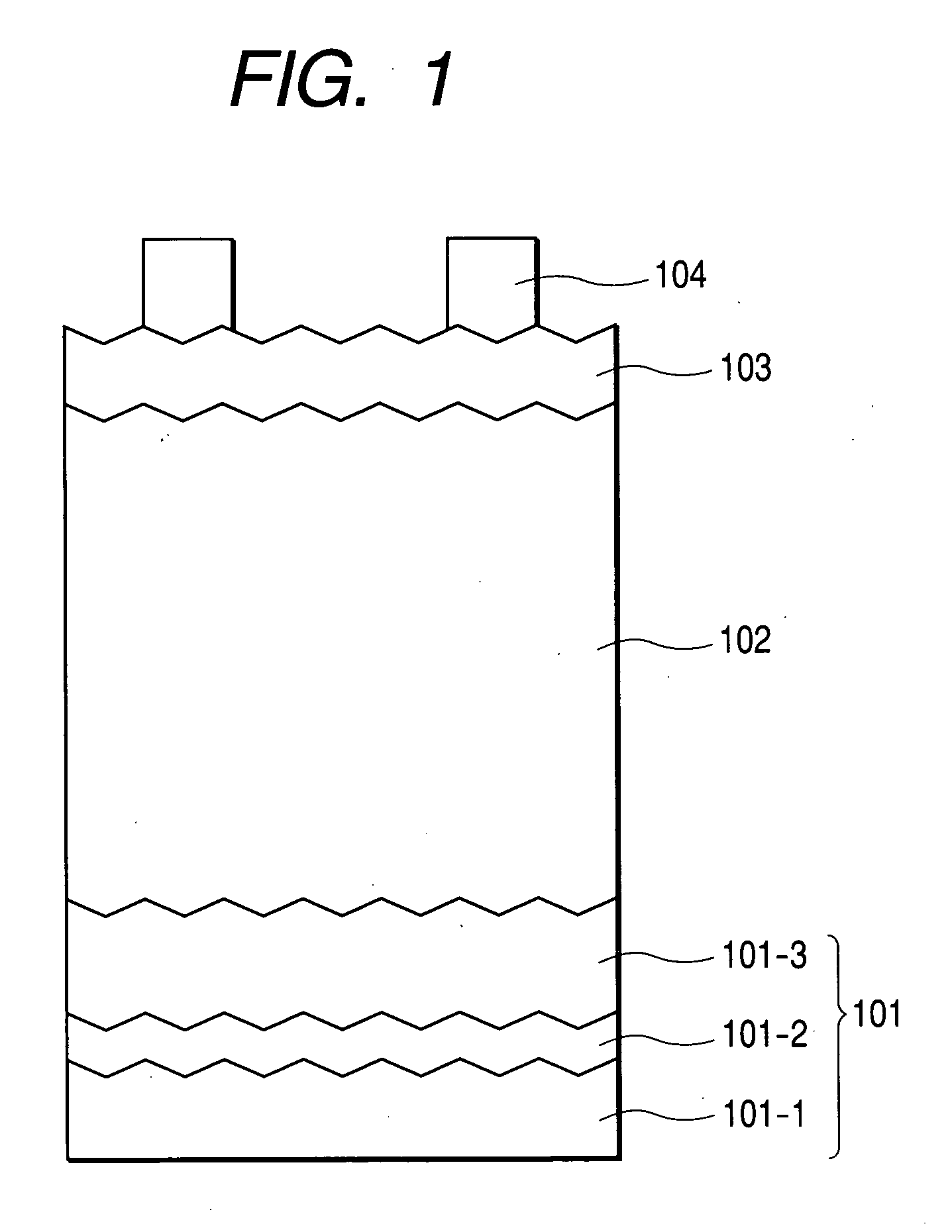

Electrophotographic photosensitive member

InactiveUS7498110B2Excellent electric potential propertySuppresses degradation of image qualityElectrographic process apparatusSurface layerInter layer

There is provided an electrophotographic photosensitive member used in an electrophotographic apparatus which meets energy saving and higher image quality. The electrophotographic photosensitive member has excellent potential properties, and can suppress the image quality degradation caused by interference. The electrophotographic photosensitive member of the present invention including on a conductive substrate at least a photoconductive layer mainly composed of amorphous silicon, a surface layer, and at least one intermediate layer interposed between the photoconductive layer and the surface layer, wherein the surface layer contains a metal fluoride (exclusive of silicon fluoride) and the intermediate layer contains a metal oxide.

Owner:CANON KK

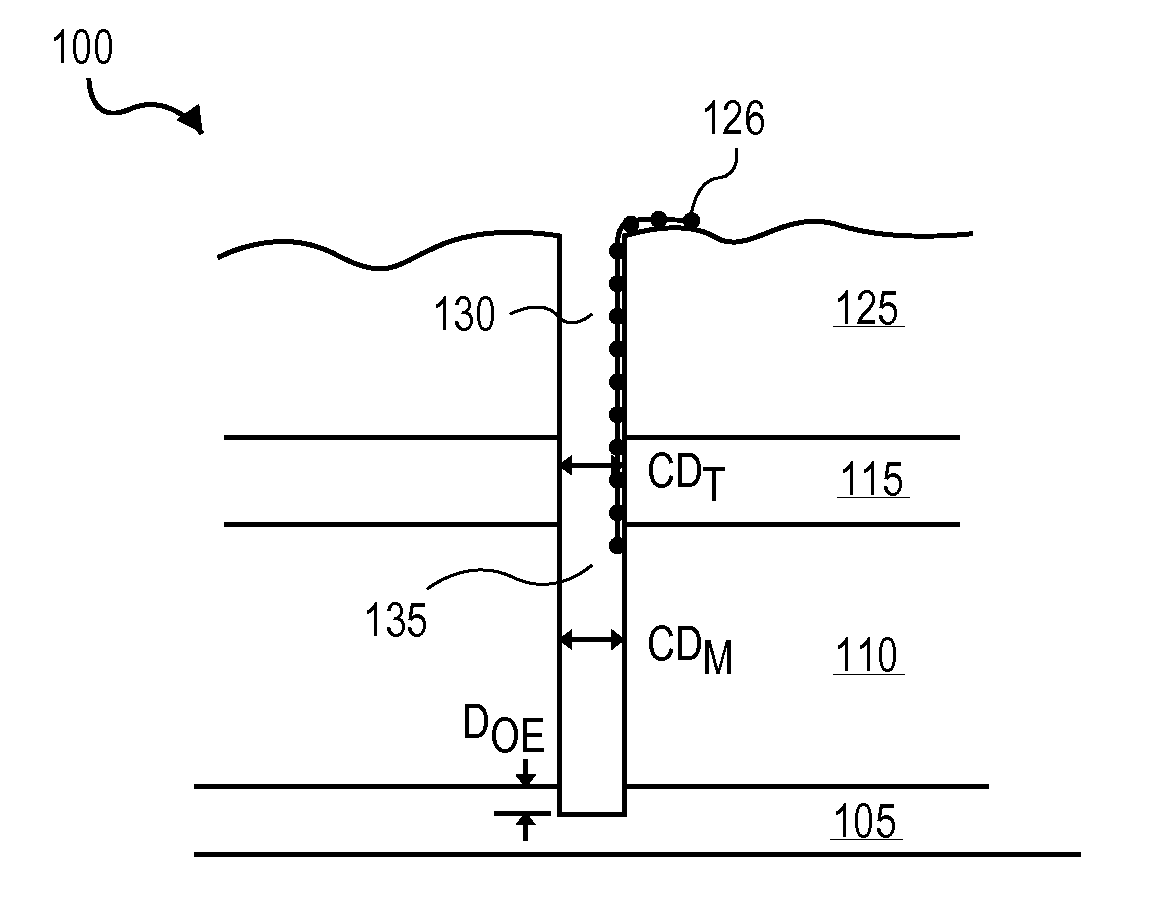

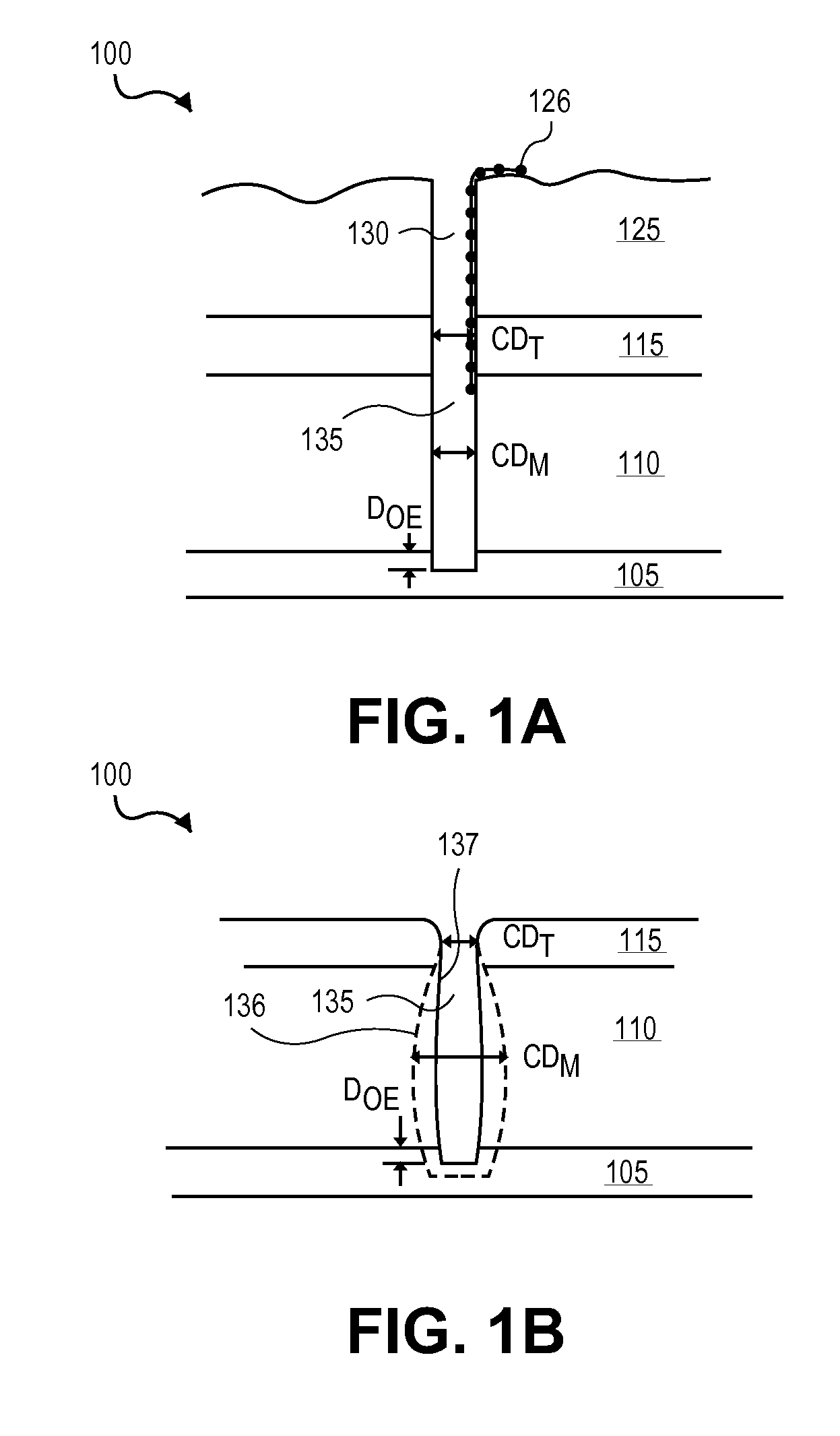

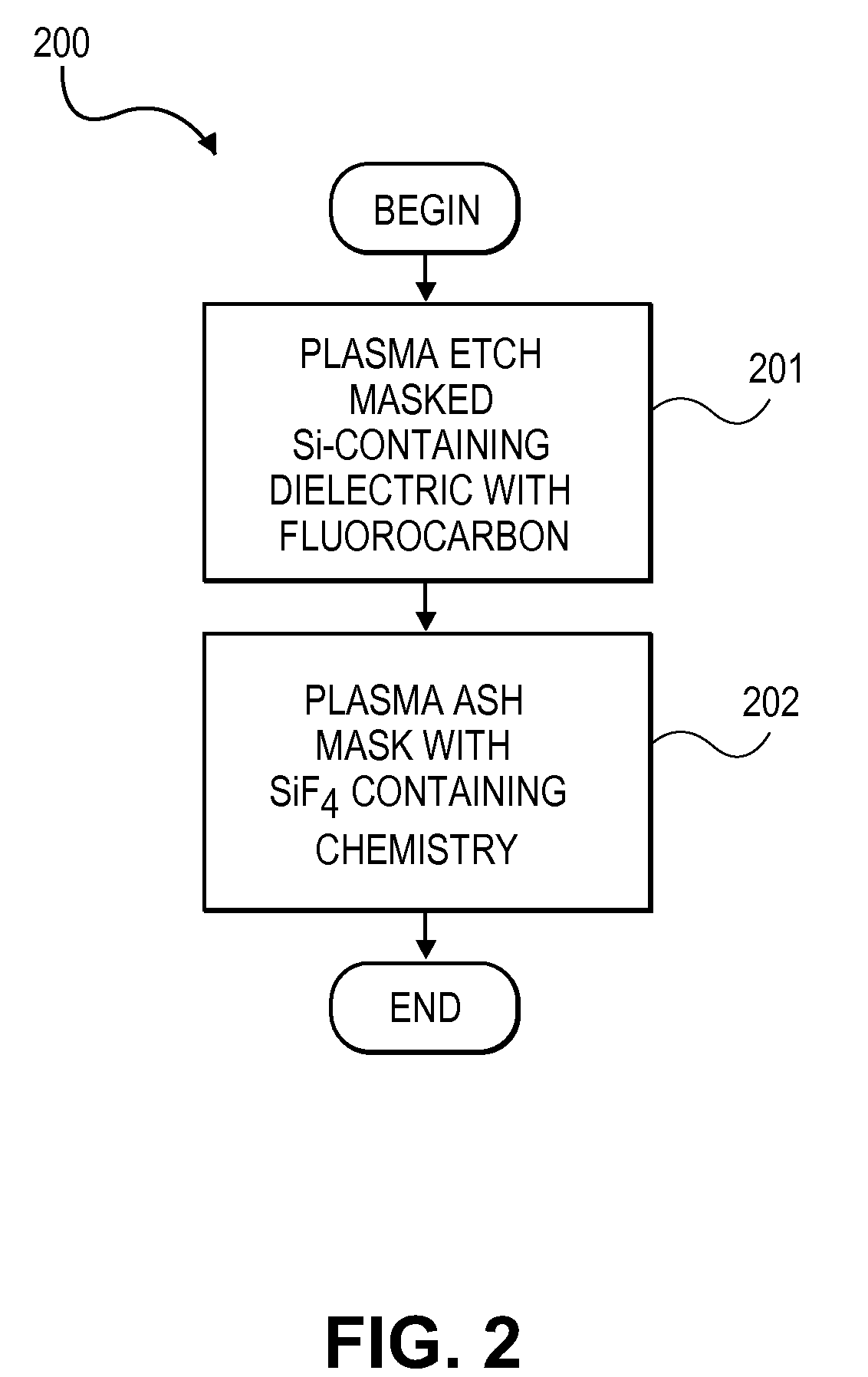

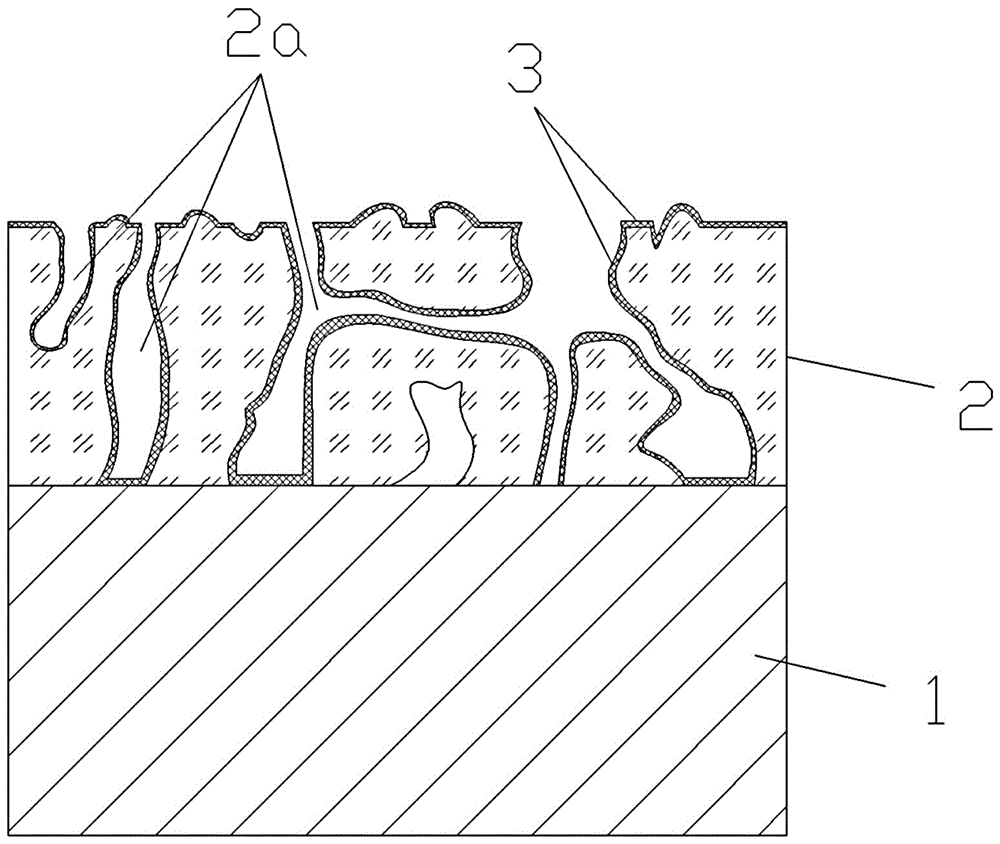

Plasma-based organic mask removal with silicon fluoride

InactiveUS20110079918A1Reduce lateral etchReduce harmSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryMolecular nitrogen

Removal of organic mask material from an etched dielectric film with an etchant gas mixture including silicon fluoride (SiF4). In certain embodiments, SiF4 is combined in an etchant gas mixture of molecular nitrogen (N2), carbon dioxide (CO2) to in-situ strip an organic mask material from a porous low-k dielectric film that has been etched to form a damascene interconnect structure with reduced etch profile bowing and reduced ashing damage to the low-k dielectric film.

Owner:APPLIED MATERIALS INC

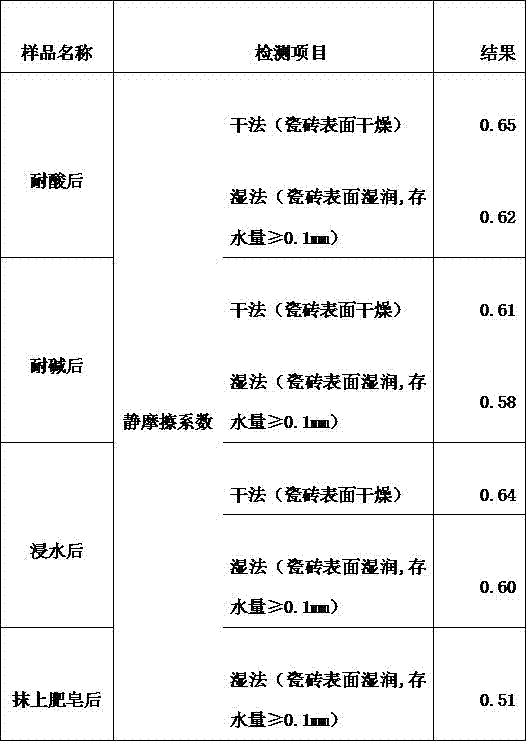

Slipproofing agent for surface of ceramic tile and preparation method of slipproofing agent

The invention provides a slipproofing agent for the surface of a ceramic tile and a preparation method of the slipproofing agent. The slipproofing agent is prepared from villiaumite, a corrosion inhibitor, a surfactant, a humectant, essence and the balance of water, wherein the villiaumite is ammonium fluoride and / or ammonium hydrogen fluoride. The preparation method of the slipproofing agent comprises the following steps:, at 25 to 30 DEG C, weighing and taking proper raw materials in sequence, and uniformly agitating the proper raw materials, so as to subsequently obtain the slipproofing agent for the surface of the ceramic tile. According to the slipproofing agent, the villiaumite is used as a main raw material; a product is a neutral aqueous solution; a fluorine ion generates a chemical reaction with a silicate component in the ceramic tile under the action of an ammonium ion in a formula, so as to produce silicon fluoride gas for escaping; the direct effect of the chemical reaction is that numerous nano-sized microporous structures are formed in the surface of the ceramic tile; thus, a slipproofing effect is achieved; nontoxic and harmless raw materials are used by the formula of the slipproofing agent; a neutral solution is convenient to transport and use; further, the slipproofing agent provided by the invention has ultrahigh seepage force.

Owner:GUANGDONG QINGZHU TECH CO LTD

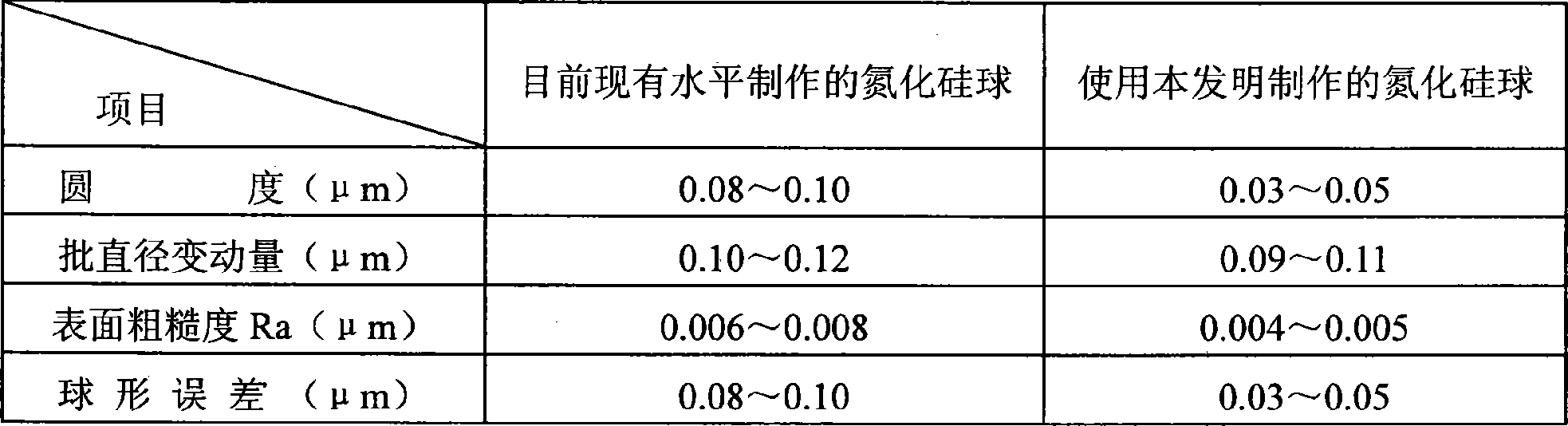

Technique for processing silicon fluoride ball in G3 grade

InactiveCN101049676ASimple processEasy to manufactureOther chemical processesSpherical surface grinding machinesInternal stressSuperfine grinding

A process for preparing the G3-class silicon nitride balls includes such steps as eliminating internal stress by heating at 130-160 deg.C for 6-8 hr and cooling in air, primary grinding, fine grinding, superfine grinding, and brightening by chromium oxide.

Owner:SHANDONG DONGE STEEL BALL GRP

Anti-reflective coating composition and coating film with excellent stain resistance

ActiveUS20050239933A1Lower surface energyLow refractive indexGroup 4/14 element organic compoundsTwo pole connectionsAnti-reflective coatingPolymer science

The present invention relates to a coating composition for forming an anti-reflective coating layer for a display device, comprising a fluorinated silane with low surface tension, a conductive polymer with antistatic properties, water, and a solvent. Thus, the coating film of the present invention prepared by coating the composition has high anti-reflection, excellent stain resistance to liquid-phase stains such as fingerprints and the solid-phase stains such as dust by controlling the refractive index, surface energy, and conductivity, and thus can be usefully applied to the outermost side of a display device, regardless of the type of substrates such as a Braun tube or a flat display film and the presence of other coating layers such as a hard coating layer and an anti-glare coating layer.

Owner:LG CHEM LTD

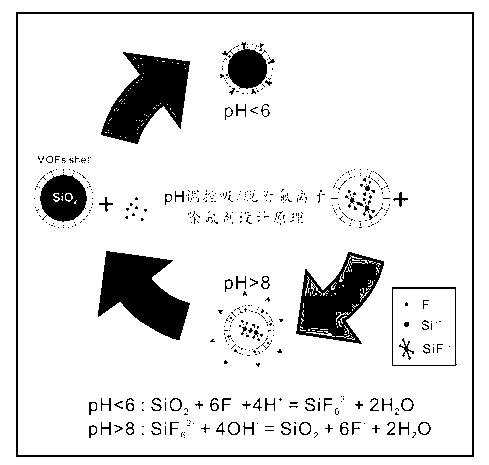

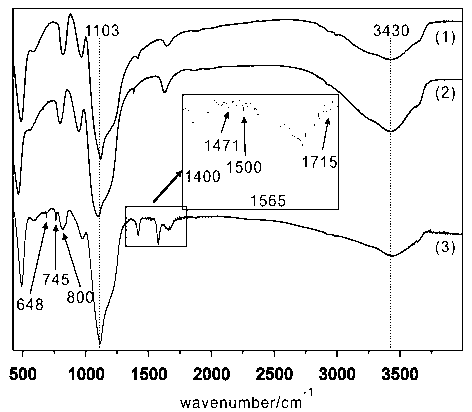

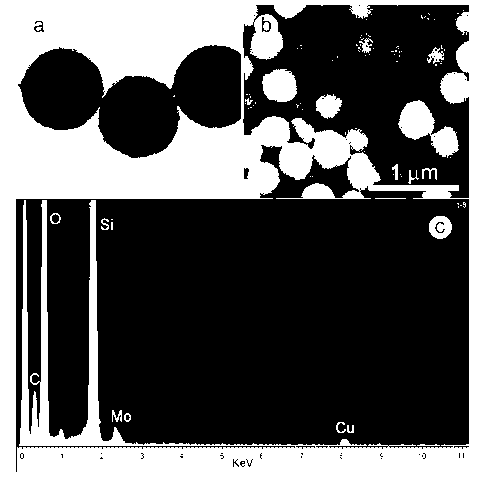

Fluorine removal agent with fluorine ion absorption/desorption function through pH value regulation and control and preparation method thereof

InactiveCN103157441APrecise thickness controlPrecise control of structure sizeOther chemical processesAlkali metal oxides/hydroxidesSilica particleHexafluoride

The invention discloses a fluorine removal agent with a fluorine ion absorption / desorption function through pH value regulation and control. The agent is of a core-shell structure. The agent mainly comprises a silica core and a metal organic framework shell layer which covers a silica surface and is provided with pore paths, wherein silica particles are spherical or irregular in shape, and the particle size is 100-5000 nanometers; and the pore size of the pore paths of the shell layer is between the diameters of a hydrated fluorine ion and a hydrated silicon hexafluoride ion. The invention further discloses a preparation method of the fluorine removal agent. The fluorine removal agent has the fluorine ion absorption / desorption function through pH value regulation and control. The fluorine removal agent can greatly absorb the fluorine ions in the water under the acid condition, and the fluorine ions which are greatly absorbed by the fluorine removal agent can be greatly desorbed under the alkaline condition. The method has the characteristics of accurately controlled thickness, pore path structure and pore size of the metal organic framework shell layer, and is low in preparation equipment investment, simple in technology and easy to operate.

Owner:CILIN & CAS ENVIRONMENTAL TECH ANHUIINC

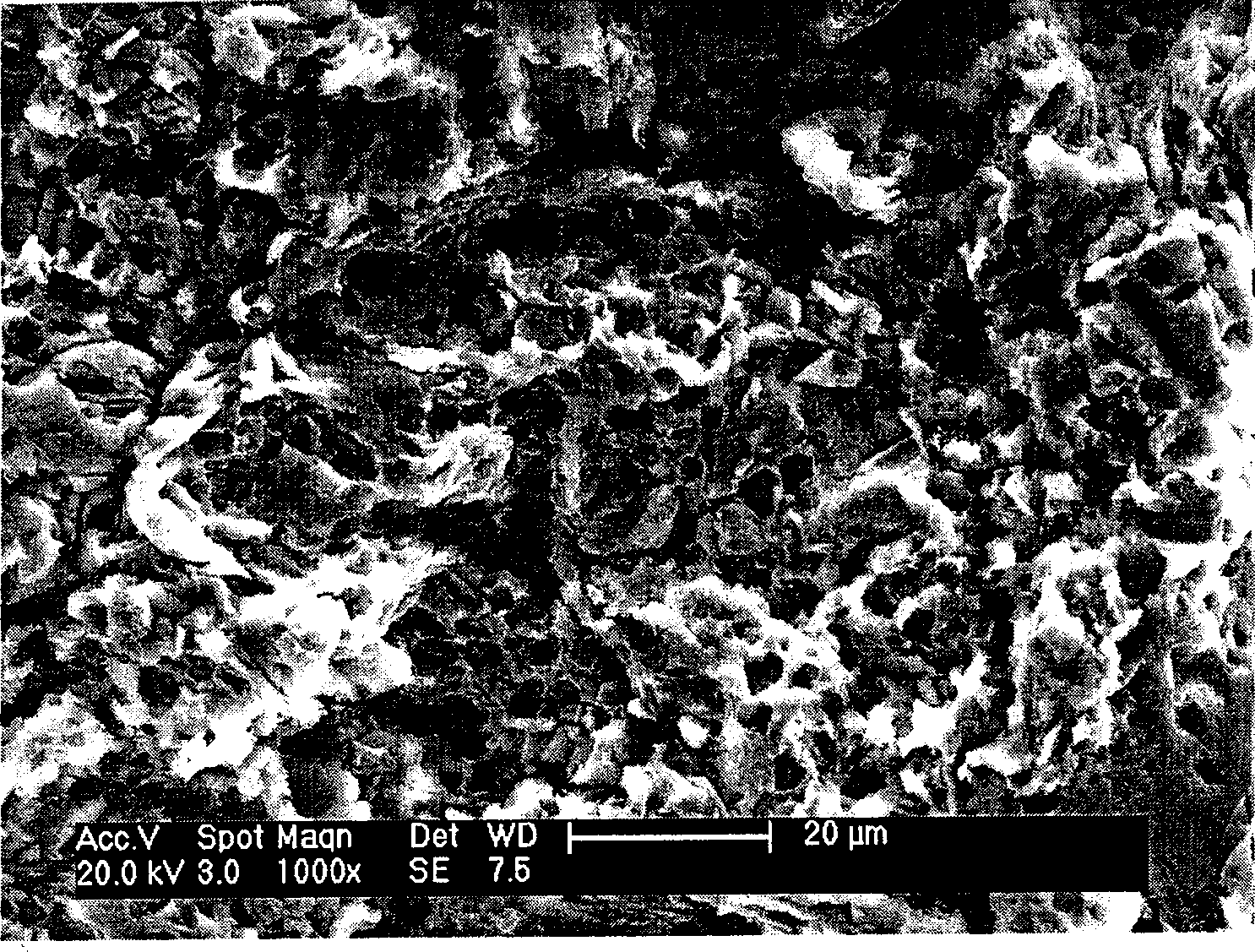

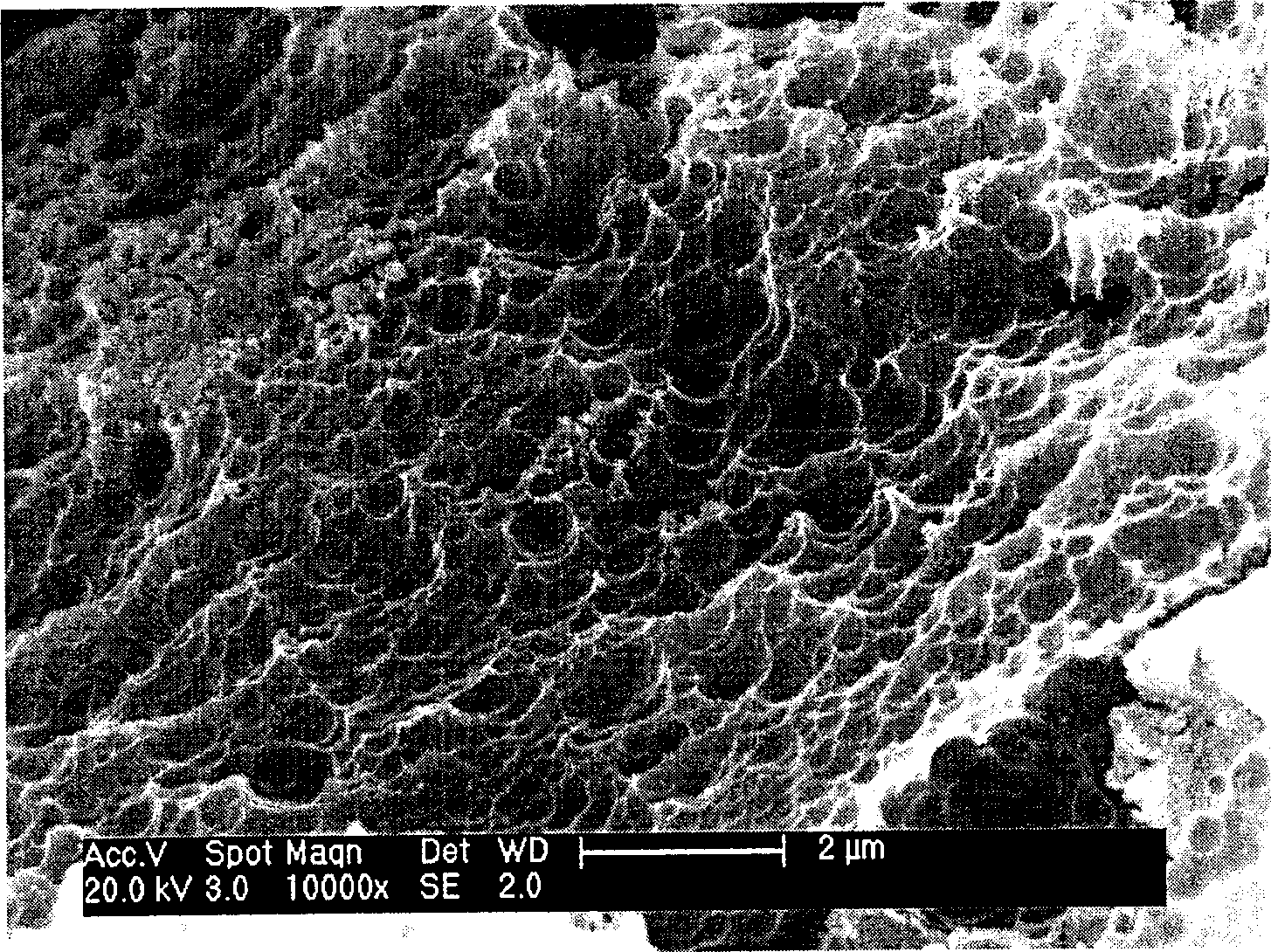

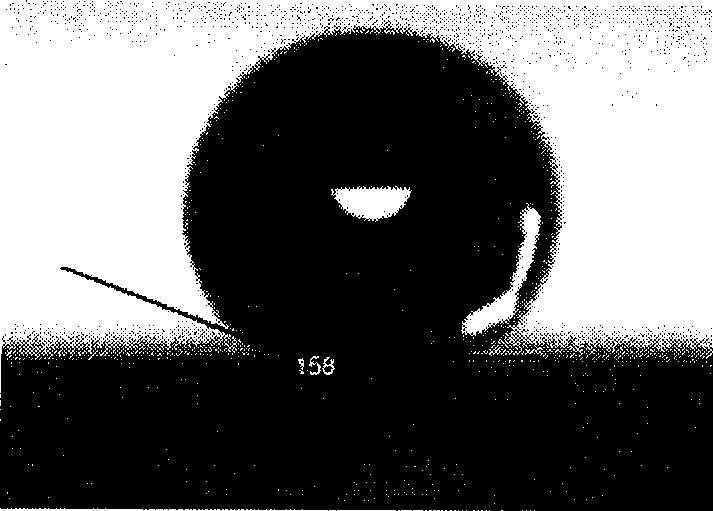

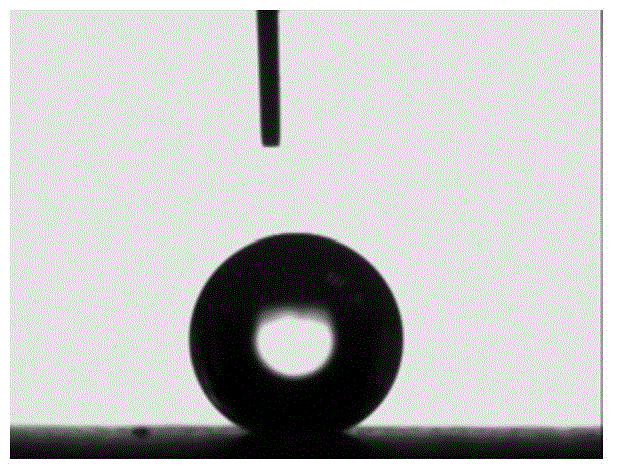

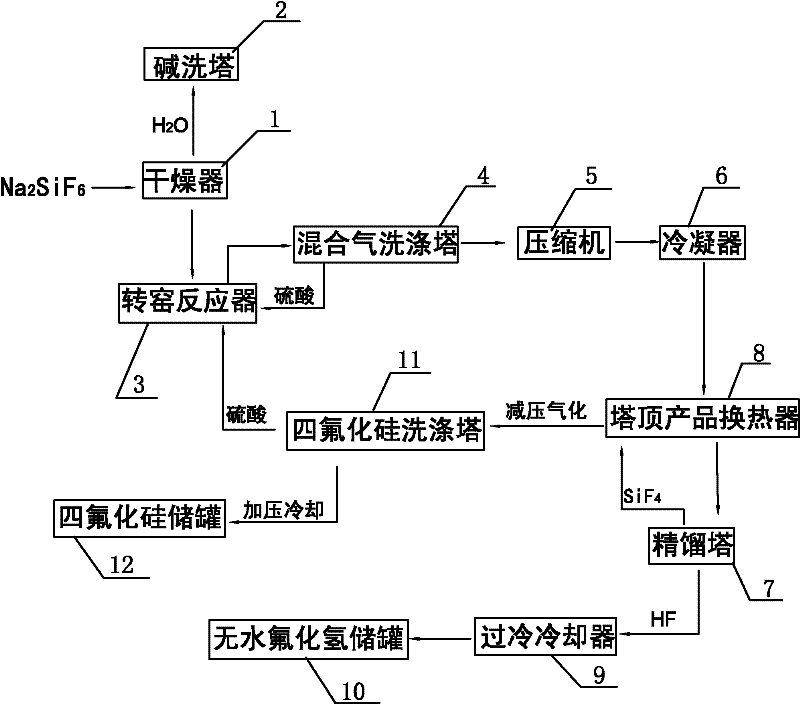

Aluminum product surface super-hydrophobic film and making method thereof

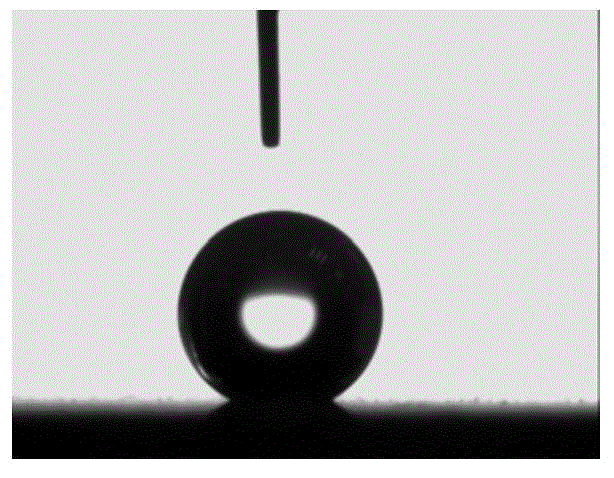

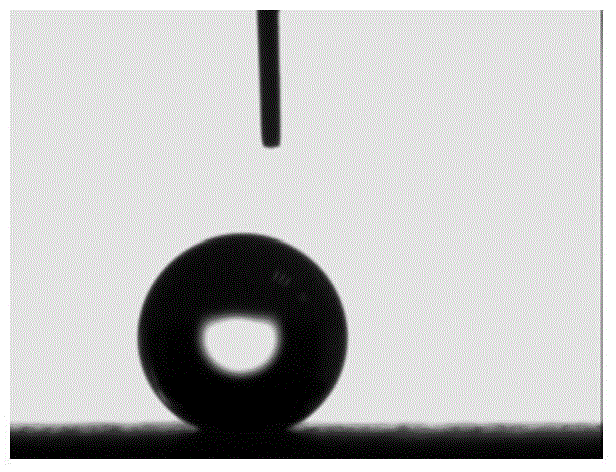

InactiveCN104131322AExcellent superhydrophobicityImprove self-cleaning functionAnodisationWear resistanceRolling angle

The invention relates to an aluminum product surface super-hydrophobic film and a making method thereof. The method comprises the following steps: 1, placing an aluminum product in an electrolyte as an anode, and anodizing under a current density of 0.1-0.5A.cm<-2> for 1-20min to obtain an anodized aluminum surface; and 2, immersing the anodized aluminum surface in an ethanol solution containing silicon fluoride for at least 1min, carrying out heat treatment on the obtained workpiece at 100-200DEG C for 5-40min, and naturally cooling to obtain the aluminum product surface super-hydrophobic film. The making method of the super-hydrophobic surface has the advantages of simplicity, low cost and easy industrialization. The super-hydrophobic surface made in the invention has a contact angle exceeding 150DEG, a roll angle of below 10DEG and stable hydrophobicity. The surface has the advantages of very good super-hydrophobic function, very good automatic cleaning function, excellent wear resistance and excellent corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH

Silicon fluoride super-amphiphobic non-stick coating material

The invention relates to a non-sticking paint containing fluorine-silicon materials, which comprises a coating material portion and a curing agent portion, wherein the amount of the curing agent is 6.5-12% of the coating material portion, the coating material portion mainly comprises fluorocarbon resin, 10-20% of organosilicon resin, 3-30% of color filler, 1-5% of silicon micronized quartz powder and 3-10% of fluorine micronized powder, the curing agent is at least one of biuret, HDI trimer and organotin, the fluorocarbon resin is prepared from perfluoroethylene monomer, alkyl vinyl ester and functional monomers through copolymerization, wherein the fluorine content is greater than 35wt%, the solid content is greater than 50%, the organosilicon resin is end monohydric organosilicon resin.

Owner:ZIBO YINGQIANG CHEM TECH

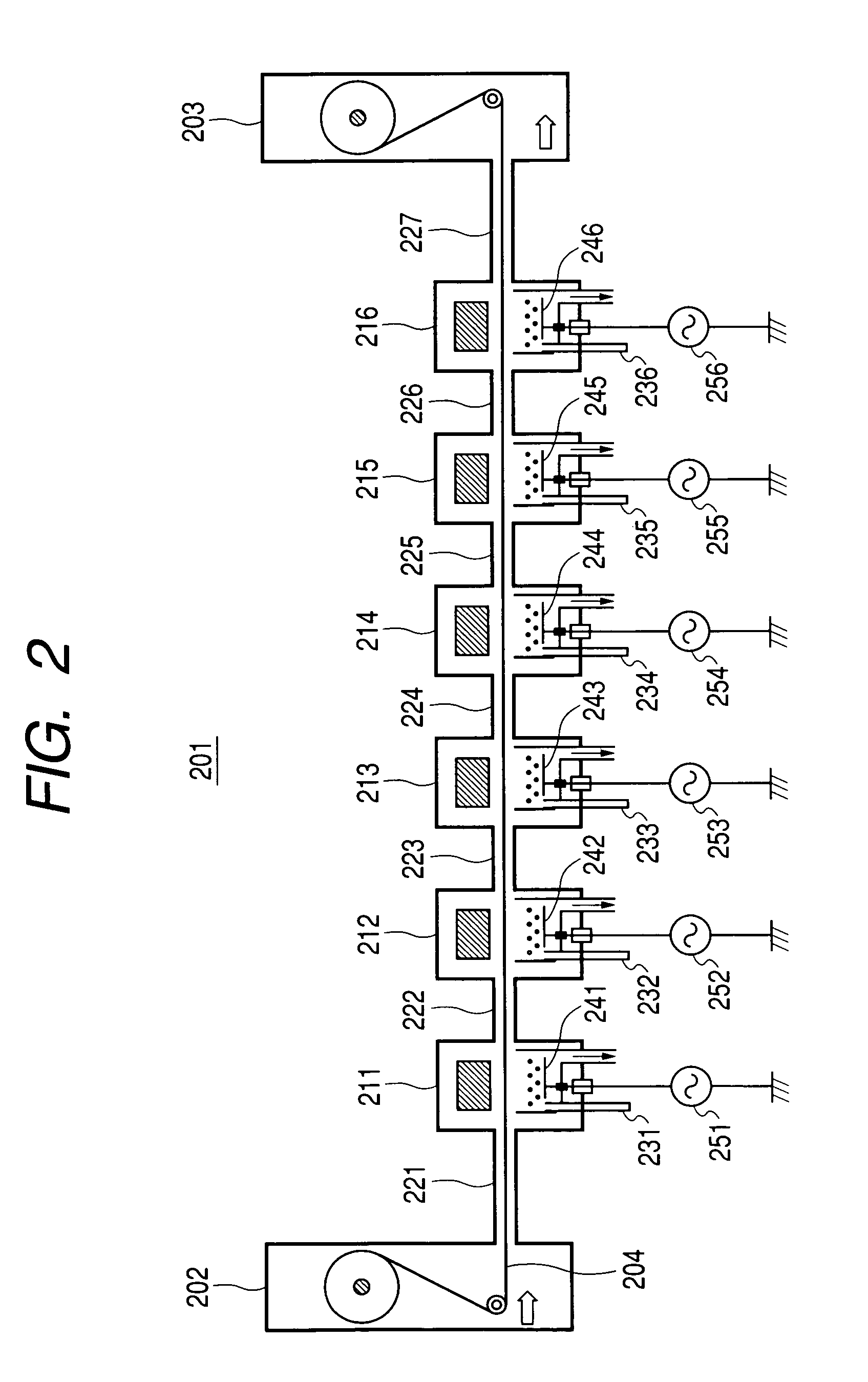

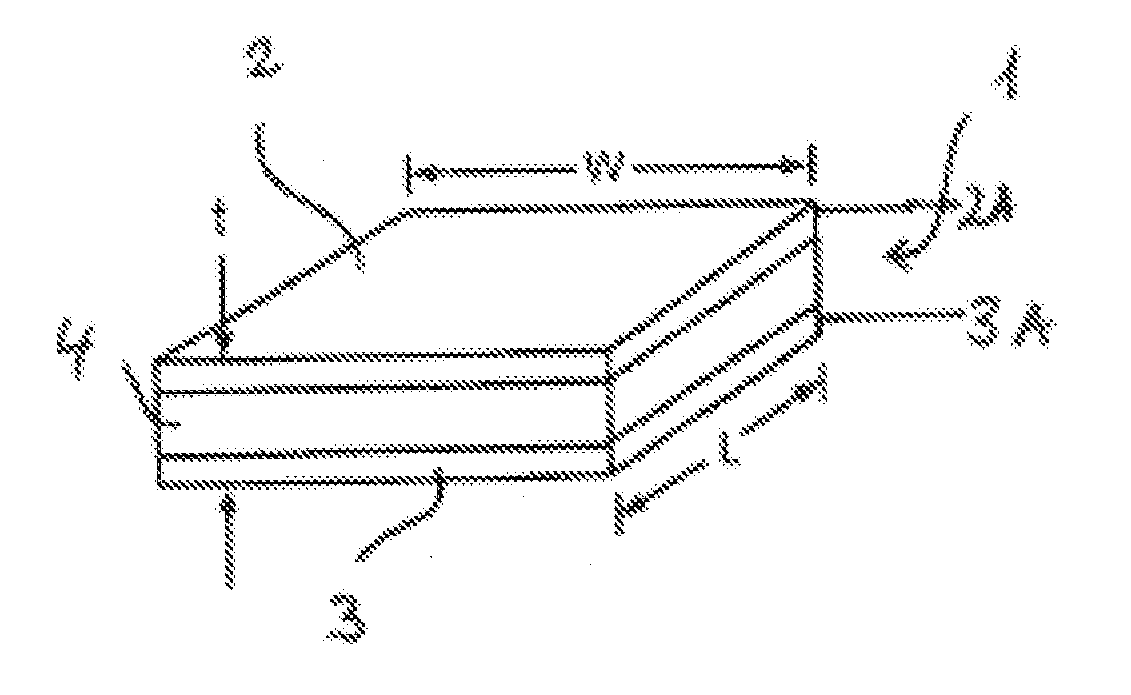

Method of forming silicon-based thin film, silicon-based thin film, and photovoltaic element

InactiveUS20050227457A1Improve featuresLow costPolycrystalline material growthFinal product manufactureLuminous intensityHydrogen

A method of forming a silicon-based thin film according to the present invention comprises introducing a source gas containing silicon fluoride and hydrogen into a vacuum vessel, and using a high frequency plasma CVD method to form a silicon-based thin film on a substrate introduced into the vacuum vessel, wherein a luminous intensity attributed to SiFα (440 nm) is not smaller than a luminous intensity attributed to Hα (656 nm), thereby providing a photovoltaic element with excellent performance at a low cost as compared with a conventional one, a method of forming a silicon-based thin film with excellent characteristics in a short process cycle time at a further increased film-forming rate, a silicon-based thin film formed by the method, and a photovoltaic element comprising the silicon-based thin film with excellent characteristics, adhesion, and resistance to the environments.

Owner:CANON KK

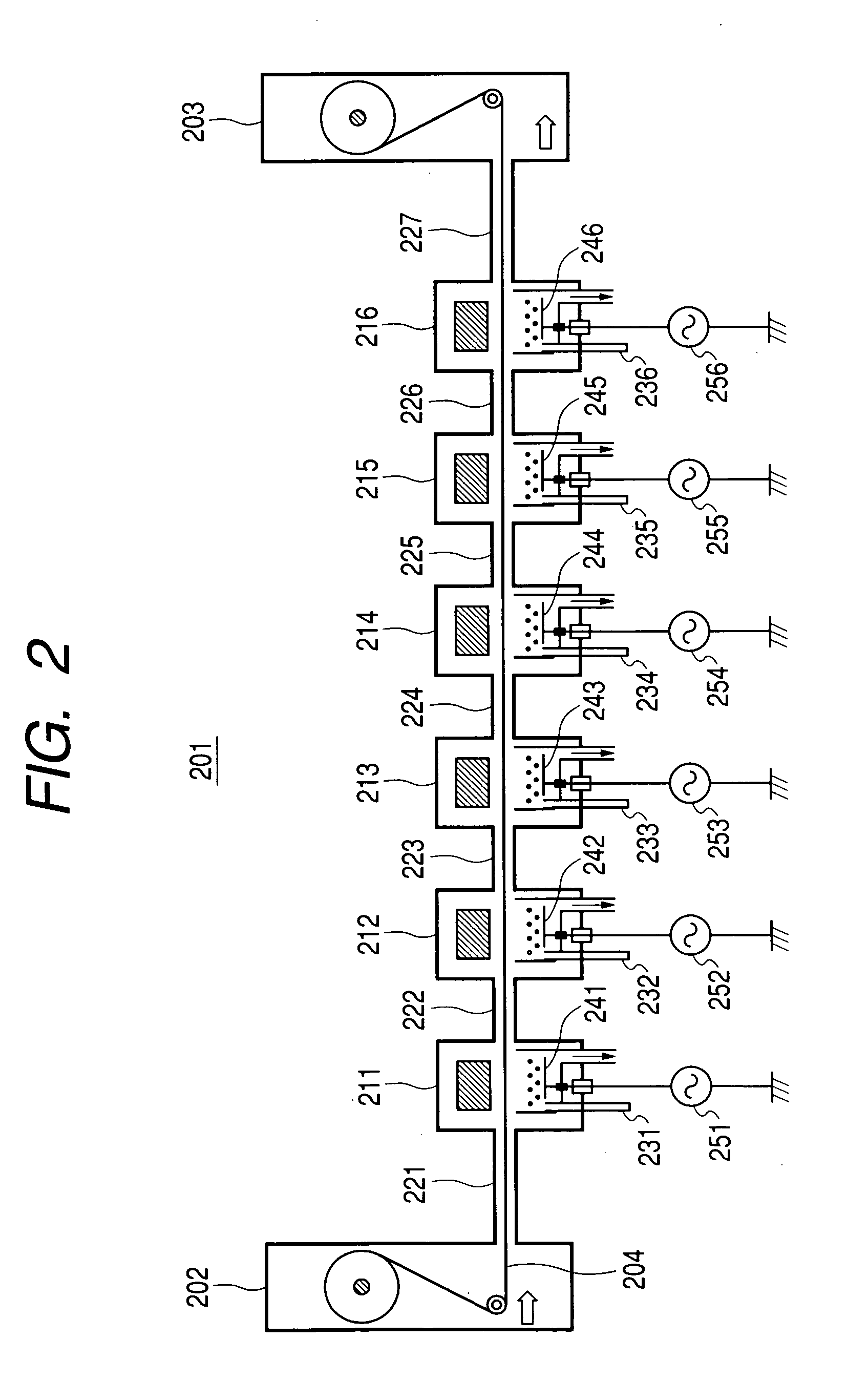

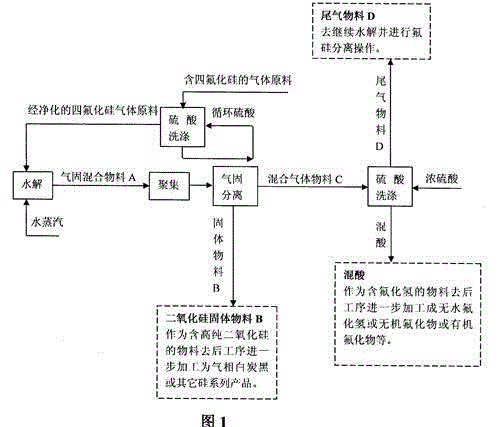

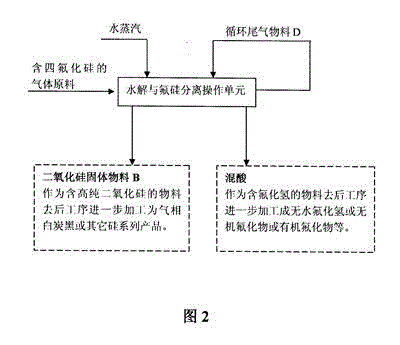

Gas phase hydrolysis and fluoride-silicon separation method of silicon tetrafluoride

InactiveCN103601195ASimple purification methodLow hydrolysis temperatureSilicaFluorine/hydrogen-fluorideChemical industrySilicon tetrafluoride

A two-step method is adopted to carry out low temperature gas phase hydrolysis and fluoride-silicon separation operations of silicon tetrafluoride. In a first step, a silicon tetrafluoride gas is hydrolyzed into a fluosilicic acid gas and silicon dioxide particles at a low temperature; in a second step, a hydrogen fluoride gas is dissolved by a washing operation of high concentrated sulfuric acid so as to promote complete decomposition of the fluosilicic acid into the hydrogen fluoride gas and a silicon tetrafluoride gas; decomposed and separated hydrogen fluoride gas is completely dissolved in high concentrated sulfuric acid; decomposed and separated silicon tetrafluoride can be continuously carried out hydrolysis and fluoride-silicon separation operations; and finally complete separation of the fluoride and silicon elements are realized. The method has the beneficial effects that a gas raw material containing relatively low silicon tetrafluoride content can be used; a method for purifying the raw material is simple; total conversion rate of silicon tetrafluoride introduced into a production apparatus system can reach over 98%; and hydrolysis temperature is relatively low, so that the method can realize industrial production relatively easily. The method is suitable for recovery and utilization of fluoride- and silicon-containing materials from industries such as phosphorus chemical industry, fluorine chemical industry, electron industry, glass processing industry and aluminium alloy processing industry.

Owner:班仁义

Method for preparing super-hydrophobic surface by nano-composite electro-brush plating

A method for preparing a super-hydrophobic surface by nano-composite electro-brush plating belongs to the method for preparing of the super-hydrophobic surface. The method comprises the following steps: step1, preparation of plating: firstly, polishing carbon steel basal body, wherein the surface roughness Ra is 0.8, and then drying after cleaning; sedimentating double-layered nano-composite plating with micro-nano double coarse structure on the carbon steel basal body according to the process order of electrocleaning-second actification-third actification-bottom layer plating-plating of nanometer C / Ni composite plating-plating of nanometer Cu / Ni composite plating, using deionized water to wash after each step is finished, and then conducting next step; placing brush plated sample into alcohol, washing for 30 min in an ultrasonic cleaner, placing in a drying box at the temperature of 60 DEG C to dry for 1 h; step2, surface chemical modification: placing dried sample in prepared silicon fluoride solution to soak for 40 min at the temperature of 60 DEG C, wherein the mass ratio of Actyflon-G607 and absolute ethyl alcohol is 1:49, and taking out to dry in the drying box at the temperature of 100 DEG C for 1 h.

Owner:CHINA UNIV OF MINING & TECH

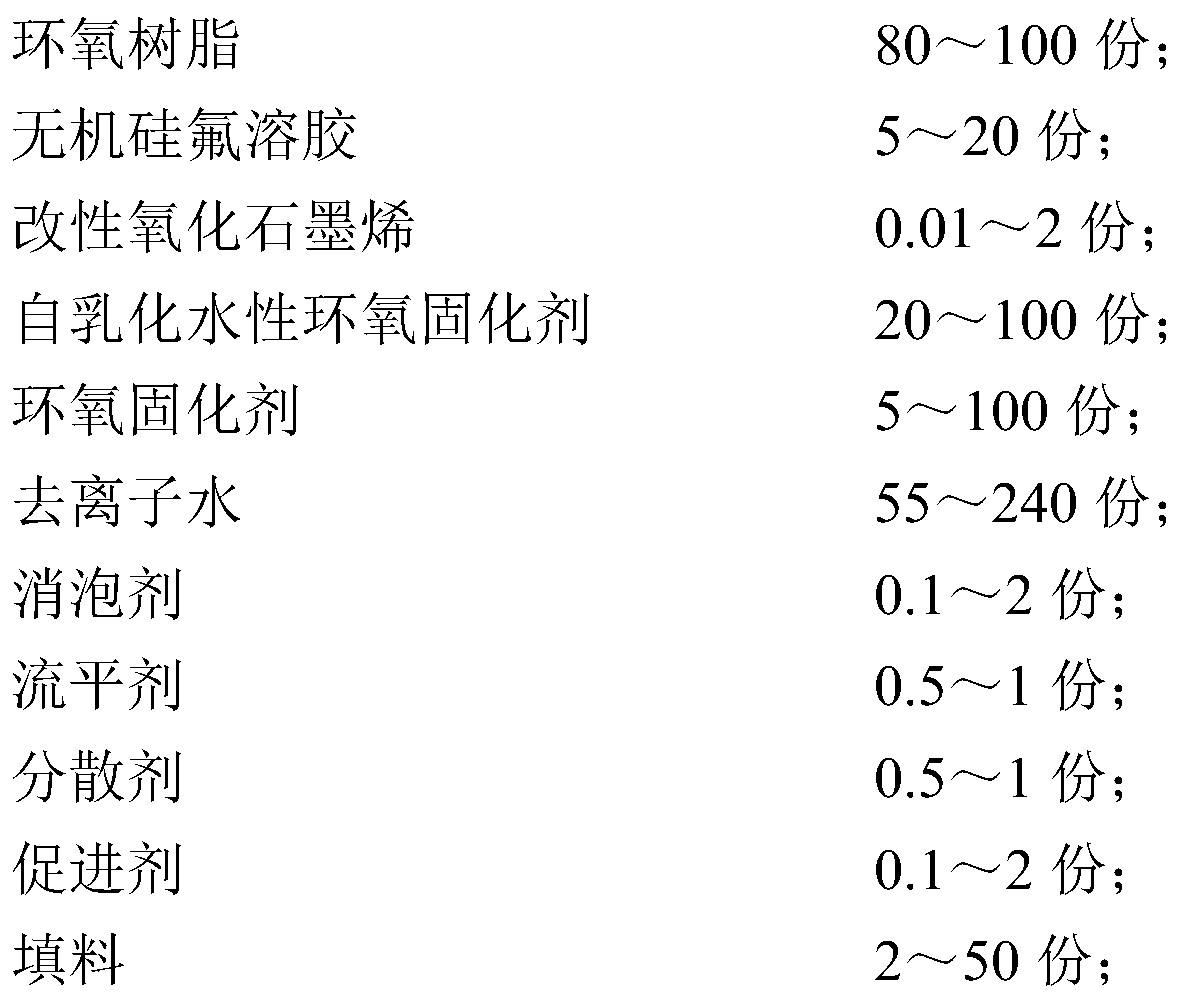

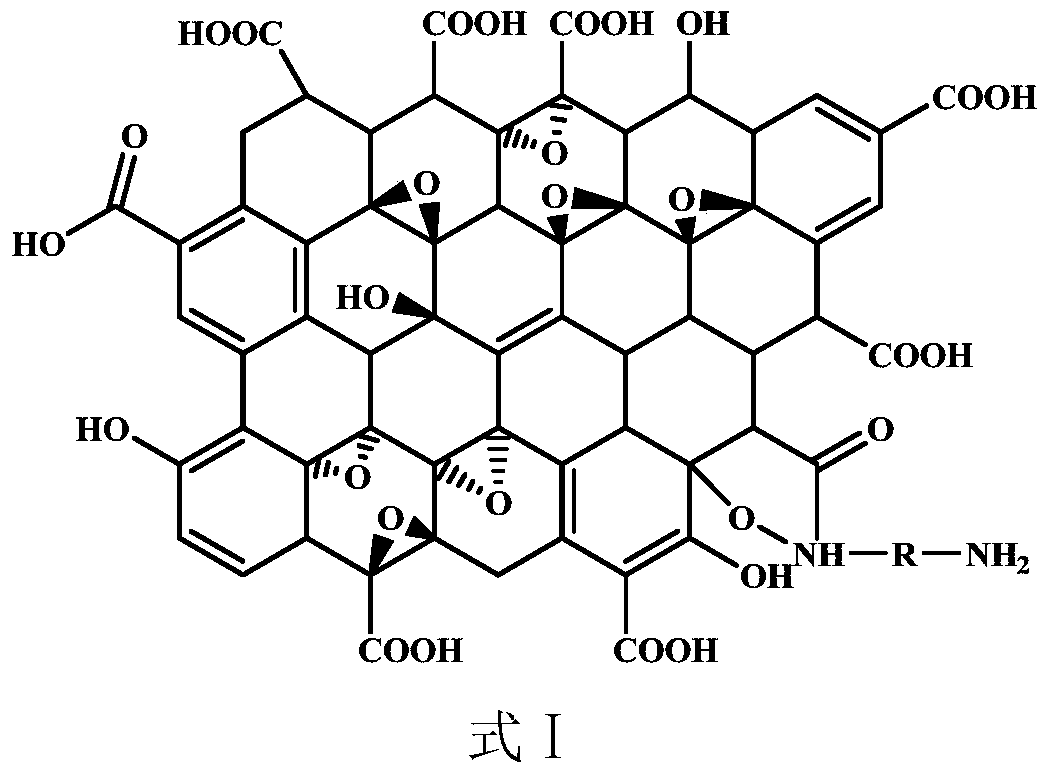

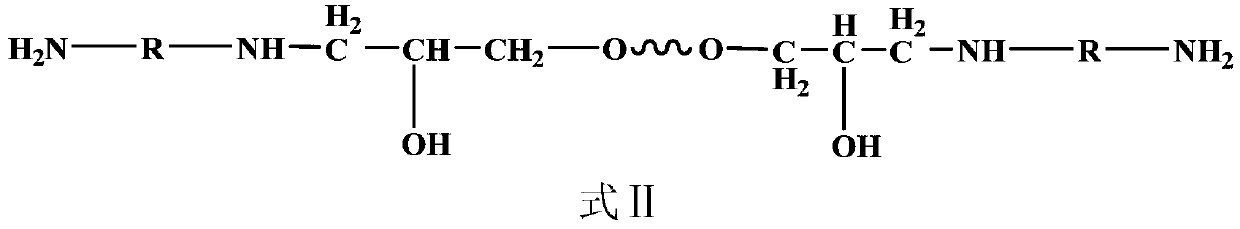

Low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof

ActiveCN110330862AWear-resistantLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceFluorographene

The invention discloses a low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof. The molecular structure of the coating contains structures such as epoxy groups, polyether, silicon fluoride and graphene; in the stage of emulsifying epoxy resin of the coating, the coating has excellent aqueous property and high emulsifying capability owing to a self-emulsifying aqueous epoxy curing agent, the coating has good compatibility with the epoxy resin, and the stability of emulsion is improved. In a curing stage of modification of a graphene oxide modified coating, it is ensured that the self-emulsifying water-based epoxy curing agent does not separate out from a coating layer to form a stable coating layer; a flexible micro-region is formed by flexiblelong-chain polyether in the coating layer, so that the mechanical property of a coating film is improved; by silicon-fluorine sol, the surface energy of the coating film is reduced; graphene is grafted into the molecular structure through chemical bonds, after the dispersion performance is improved, the graphene can cover a metal surface efficiently, and the corrosion resistance of the coating layer is improved. Therefore, the coating provided by the invention has excellent properties of adhesion, hardness, acid and alkali resistance, water resistance and the like after film formation, variouscomponents are compatible well, and the coating can be used for metal parts and the like.

Owner:中科广化(重庆)新材料研究院有限公司 +2

Method for preprocessing biomass

The present invention relates to a method for pretreating biomass instead of sodium hydroxide, fulfuric acid and vapor explosion. Said invention is characterized by that it adopts the following steps: pulverizing cellulose-live biomasses of crop straw and stalk, grass and wood, etc., removing impurity, making acid hydrolysis, separating and extracting cellulose, using cellulose to hydrolyze cellulose, using saccharomycetes to make fermentation to produce ethyl alcohol and recover silicon fluoride. The above-mentioned acid is hydrofluoric acid.

Owner:SHAANXI UNIV OF SCI & TECH

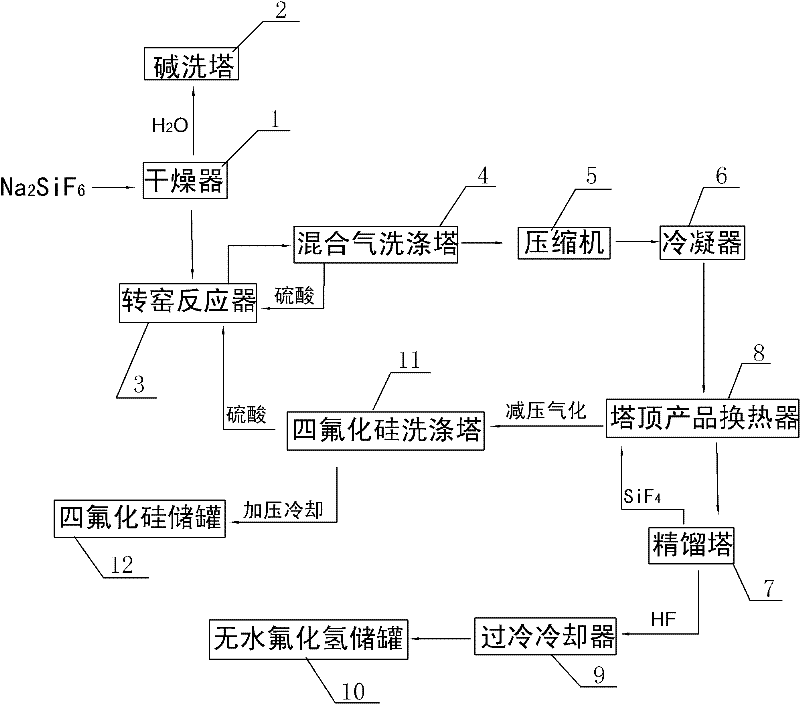

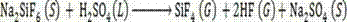

Method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride by taking sodium fluorosilicate as raw material

InactiveCN102557043AWell mixedAdequate responseFluorine/hydrogen-fluorideHalogenated silanesSilicon tetrafluorideSodium sulfate

The invention discloses a method for preparing silicon tetrafluoride and anhydrous hydrogen fluoride by taking sodium fluorosilicate as a raw material. The method is characterized by comprising the following steps of: (1) drying sodium fluorosilicate for removing water; (2) adding the dried sodium fluorosilicate and sulfuric acid into a rotary kiln reactor in the molar ratio of 1:1, and reacting at the temperature of 160-220 DEG C for 30-180 minutes to generate a sodium sulfate solid and a mixed gas of silicon tetrafluoride and hydrogen fluoride; (3) dedusting, pressurizing and precooling to between 20 DEG C below zero and 30 DEG C below zero; (4) feeding the precooled mixed gas into a rectifying tower for separating, controlling the pressure of the rectifying tower at 0.6-0.75 MPaG and the temperature of tower top condenser between 70 DEG C below zero and 80 DEG C below zero, and discharging anhydrous hydrogen fluoride from the tower bottom; and (5) discharging silicon tetrafluoride from the tower top in the form of a liquid phase, decompressing, gasifying, dedusting and feeding into a silicon tetrafluoride washing tower to obtain silicon tetrafluoride gas. The method has the advantages that: corrosion to equipment can be reduced greatly, the obtained silicon tetrafluoride and hydrogen fluoride products have high purity, and the production process has low energy consumption and is environmentally-friendly.

Owner:SEDIN NINGBO ENG

Super-hydrophobic glass coating and preparation method thereof

The invention discloses a super-hydrophobic glass coating and a preparation method thereof. The super-hydrophobic glass coating comprises a nanoporous glass film and a low-surface-energy hydrophobic film which are attached to the glass surface sequentially from inside to outside, wherein the thickness of the nanoporous glass film is 150-1000 nm, the pore size thereof is 1-100 nm, the low-surface-energy hydrophobic film refers to siloxane or fluorinated siloxane with the thickness being 1-20 nm, and the surface energy of the low-surface-energy hydrophobic film is less than 40 mN / m. The preparation method includes sputtering a glass film on a glass substrate, performing heat treatment to enable the glass film to achieve phase separation and subjecting the glass film to acid washing so as to obtain the nanoporous glass film; performing dip-coating of the low-surface-energy hydrophobic film so as to obtain the super-hydrophobic glass coating. The super-hydrophobic glass coating and the preparation method thereof have the advantages that a water contact angle is above 150 degrees, so that a super-hydrophobic surface can be obtained, and anti-fingerprint, anti-oil and hydrophobic effects are improved; the low-surface-energy material can be attached to the outer surface of the nanoporous glass film and the inner walls of nanoporous glass film layer pores, and accordingly the super-hydrophobic glass coating with the surface worn has the same super-hydrophobic performance.

Owner:安徽凯盛基础材料科技有限公司 +1

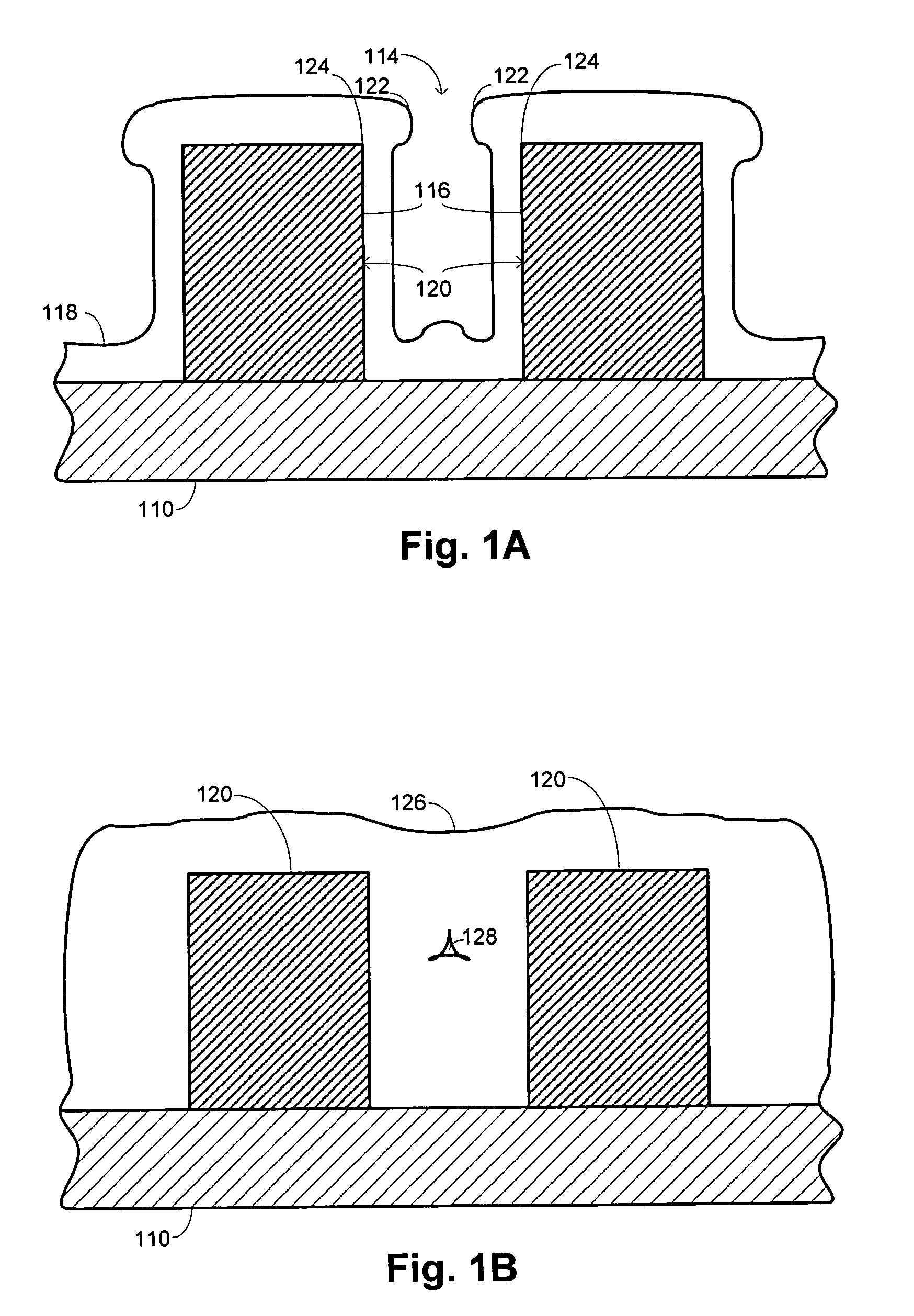

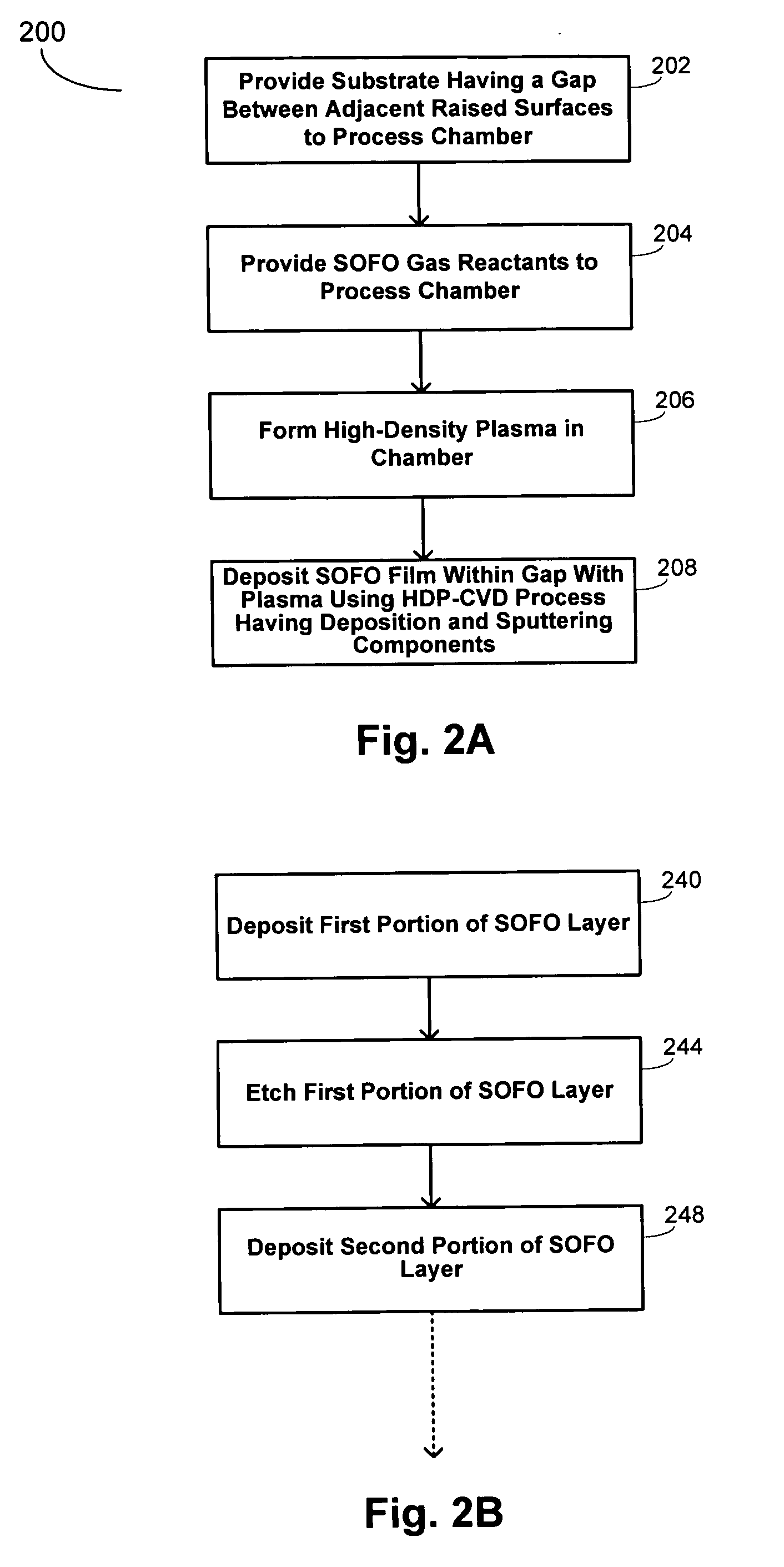

Methods for improving low k FSG film gap-fill characteristics

InactiveUS20070111543A1Improve gap fill characteristicLow dielectric constantElectric discharge tubesSemiconductor/solid-state device manufacturingChemistryLow-k dielectric

The present invention relates to fluorinated silicate glass (FSG) with low dielectric constant and improved gap-fill characteristics. In the present method, a fluorinated silicon source, an optional fluorine source, an optional carbon source, a hydrogen source, and an oxygenator are used as the reactant gases. Inert or carrier gas(es) may also be used. In accordance with the present invention, the reactant gas mixture does not comprise a silane compound having the general formula SixHy, wherein x has a range of 1 to 2, y has a range of 4 to 6. The material deposited is thus referred to herein alternatively as “SixFy-only FSG” or “SixFy-only fluorinated oxide” (“SOFO”).

Owner:APPLIED MATERIALS INC

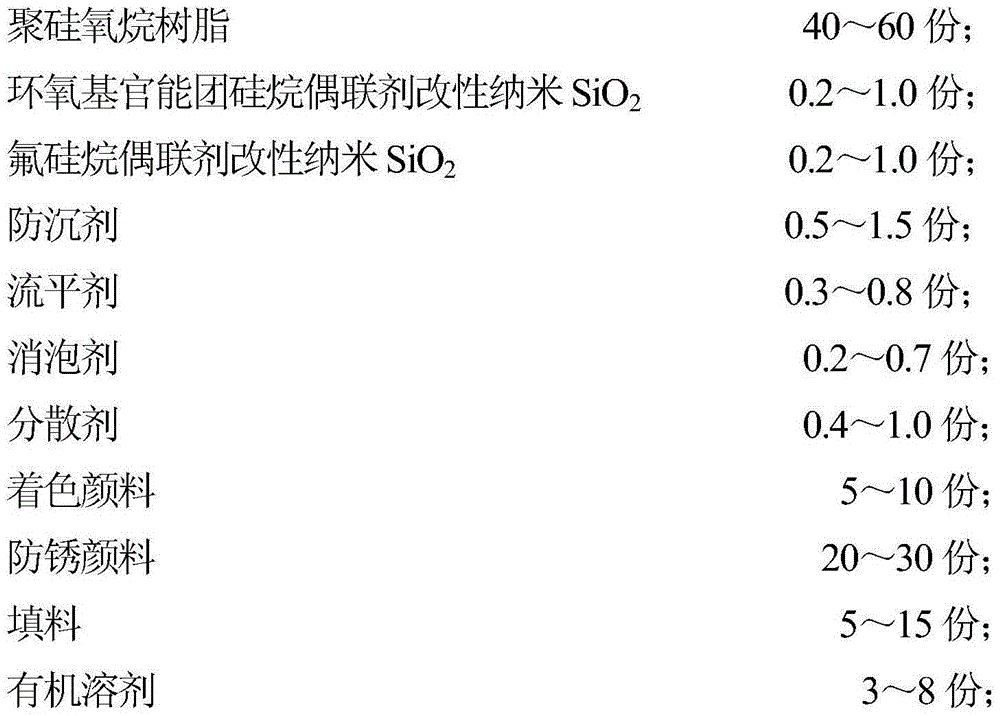

Botton-surface combined type antifouling and antiseptic nanometer polysiloxanes coating and preparation method thereof

ActiveCN106479354AImprove anti-corrosion performanceFunction increaseAnti-corrosive paintsPigment treatment with organosilicon compoundsEpoxyDefoaming Agents

The invention relates to a nano particle modification technique and a coating technique, in particular to a bottom-surface combined type antifouling and antiseptic nanometer polysiloxane coating and a preparation method thereof. Firstly, epoxy functional groups of nanometer particles are modified by a silane coupling agent and a silicon fluoride coupling agent. Then, by mass part, 40-60 parts of polysiloxane resin, 0.2-1 part of epoxy functional group silane coupling agent modified nano SiO2, 0.2-1 part of silicon fluoride coupling agent modified nano SiO2, 0.5-1.5 parts of an anti-settling agent, 0.3-0.8 part of a leveling agent, 0.2-0.7 part of a defoaming agent, 0.4-1 part of a dispersant, 5-10 parts of a coloring pigment, 20-30 parts of an antirust pigment, 5-15 parts of a filler, and 3-8 parts of an organic solvent are taken, dispersed and grinded into the fineness less than 30[mu]m to prepare a component A. The component A and a component B are mixed to prepare the antifouling and antiseptic nanometer polysiloxane coating. The coating has a high solid characteristic, and excellent corrosion resisting, weather-proof, and antifouling performances, and is suitable for anticorrosion fields of a plurality of occasions.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aqueous silicon fluoro polymer and its preparation method and water dispersion of said polymer

The invention relates to a water silicon-fluoride polymer and the method to make. The feature is that: mixing the methyl containing hydrogen silicone oil 100 portions, the allyl alcohol polyoxyethylene polyoxy propylene aether 1-500 portions, acrylic fluoride alkyl ester 0.1-500 portions and containing end reaction double bond organic silicane cross link agent 0-80 portions, polyaddition reacting by the existence of catalyst. The invention also relates to the water dispersing agent of the water silicon-fluoride compound that is made up from the reaction of 100 portions water and 1-80 portions water silicon-fluoride compound. The invention has good stability, and high surface activity.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

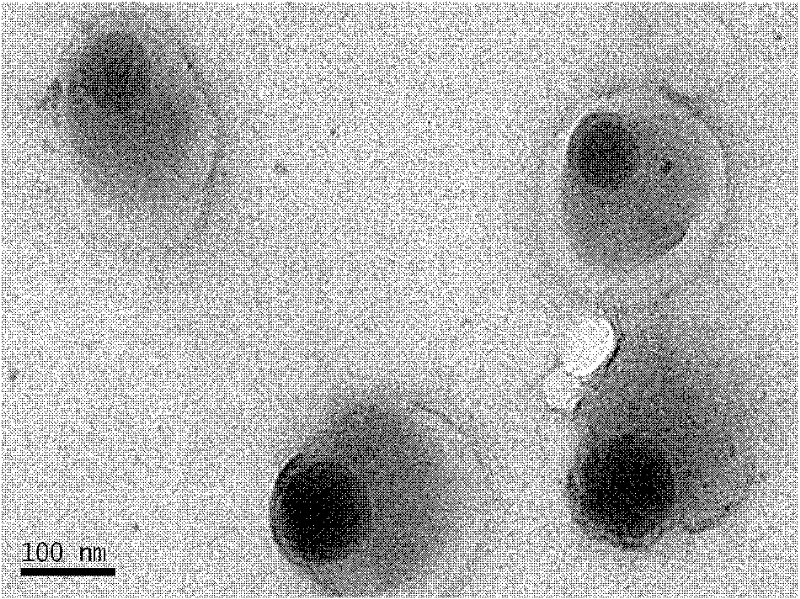

Fluorosilicate self-cleaning glass nanophase material and producing method thereof

The invention discloses a silicon fluoride self-cleaning glass nano-material, which is composed of solvent and active ingredients; the active ingredients are fluorinated modified silicone nano-particles, and the reaction raw materials comprise ortho-silicon ester and fluorine modified alkyl silane, with the ratio volume and dosage reaching 1.5-3:0.15-1.8. The invention also discloses a manufacturing method for the silicon fluoride self-cleaning glass nano-material, comprising two steps: synthesizing the surface modification of silica nano-particles, silica nano-particles; the ratio between volume and dosage for each added reactant is as follows: solvent: water: ortho-silicon ester: fluorine modified alkyl silane equals to 100: 1.5-3: 1.5-3: 0.15-1.8. The invention has simple production process, stable product performance, higher storage stability, excellent chemical properties, low surface energy and good tolerance against pollution, which is used for glass surface treatment; the contact angle between water and coating is greater than 110 degrees.

Owner:GUANGZHOU BAIYUN CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com