Technique for processing silicon fluoride ball in G3 grade

A processing technology, technology of silicon nitride balls, applied in the direction of metal processing equipment, manufacturing tools, spherical grinders, etc., can solve the problems of easy magnetization, self-heavy weight, high lubrication requirements, etc., and achieve the effect of simple process and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

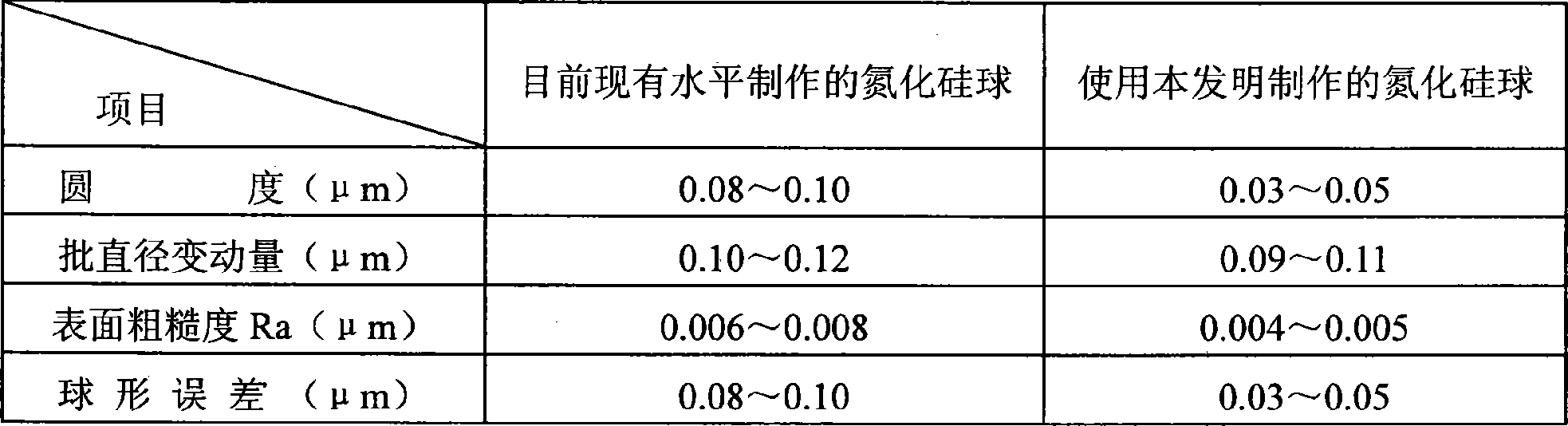

Image

Examples

Embodiment 1

[0027] Embodiment 1: In order to deepen the understanding of the present invention, the following describes the present invention in detail by taking silicon nitride balls with a processing specification of φ5.0 mm as an example. The size of the blank is φ5.40mm, and there is a total grinding amount of 0.40mm. Grinding equipment: 3M4780B vertical circulation grinding ball machine produced by Henan Xinji. The grinding liquid uses diesel oil as the oil agent. Add a milling agent every 60 minutes, and the milling agent is made by milling boron carbide abrasives of different sizes in different processes and 200 type stearic acid on a milling machine by weight ratio 1 / 2 for 48 hours.

[0028] 1. Eliminate internal stress

[0029] Use a drying box or a heating furnace to heat the ceramic ball to 140°C, keep it warm for 6 hours, and then cool it to room temperature.

[0030] 2. Coarse grinding process

[0031] Processing specifications: φ5.0mm Blank size: φ5.40mm

[0032] Theore...

Embodiment 2

[0063] Embodiment 2: The present invention will be described in detail by taking a silicon nitride ball with a processing specification of φ12.7 mm as an example. The size of the blank is φ13.1mm, and the total grinding amount is 0.40mm. Grinding equipment: 3M4780B vertical circulation grinding ball machine produced by Henan Xinji. The grinding liquid uses diesel oil as the oil agent. Every 50 minutes, add a mixed grinding liquid, which is made by mixing boron carbide abrasives of different particle sizes and 200 type stearic acid in a weight ratio 3 / 4 on a mixing mill for 48 hours in different processes.

[0064] 1. Eliminate internal stress

[0065] Use a drying box or heating furnace to heat the ceramic ball to 150°C, keep it warm for 7 hours, and then cool it to room temperature.

[0066] 2. Coarse grinding process

[0067] Processing specifications: φ12.7mm Blank size: φ13.1mm

[0068] Theoretical grinding amount: 0.21mm Use abrasive: 320 mesh

[0069] Unloading siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com