Aqueous silicon fluoro polymer and its preparation method and water dispersion of said polymer

A technology of fluoropolymer and water-based silicon, which is applied in the preparation of the polymer and the field of the aqueous dispersion of the polymer, which can solve problems such as environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

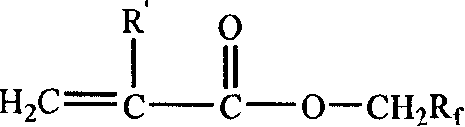

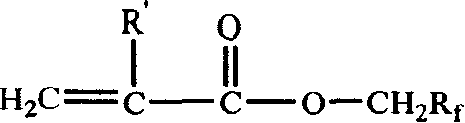

[0029] 100g of methyl hydrogen-containing silicone oil (hydrogen content is 0.1%), 1.0g of allyl alcohol polyoxyethylene polyoxypropylene ether, 0.1g of trifluoroethyl acrylate (see formula (1) for the structure, wherein R'=H , R f =-CF 3 ) and 2.0g vinyltrimethoxysilane (CH 2 =CHSi(OCH 3 ) 3 ) into a four-necked flask with a high-speed stirrer, a thermometer, a condenser tube and a dropping funnel, and the temperature is controlled at 80° C., and 2.06 g of chloroplatinic acid / isopropanol solution is added dropwise under stirring (the mass fraction of chloroplatinic acid 0.5%), the dropwise addition was completed in 40 minutes, and after 3 hours of reaction, a water-based silicon fluoropolymer whose appearance was a colorless transparent viscous liquid was obtained.

[0030] Add 100 g of the water-based silicon fluoropolymer obtained by the above reaction and 400 g of distilled water (the mass fraction of the polymer is 20%) in a high-speed shear emulsifier, and high-speed...

Embodiment 2

[0032] 100g of methyl hydrogen-containing silicone oil (hydrogen content is 0.118%), 10g of allyl alcohol polyoxyethylene polyoxypropylene ether, 1.0g of α-fluorinated trifluoroethyl acrylate (see formula (1) for the structure, wherein R' = F, R f =-CF 3 ) and 2.0g vinyltriethoxysilane (CH 2 =CHSi(OC 2 h 5 ) 3 ) into a four-necked flask with a high-speed stirrer, a thermometer, a condenser tube and a dropping funnel, and the temperature is controlled at 85° C., and 2.26 g of chloroplatinic acid / isopropanol solution is added dropwise under stirring (the mass fraction of chloroplatinic acid 0.5%), the dropwise addition was completed in 40 minutes, and after 3 hours of reaction, the water-based silicon fluoropolymer whose appearance was a colorless transparent viscous liquid was obtained;

[0033] Add 100 g of the water-based silicon fluoropolymer obtained by the above reaction and 400 g of distilled water (the mass fraction of the polymer is 20%) in a high-speed shear emuls...

Embodiment 3

[0035] 100g of methyl hydrogen-containing silicone oil (hydrogen content is 0.175%, 50g allyl alcohol polyoxyethylene polyoxypropylene ether, 5.0g α-hexafluorobutyl methacrylate (see formula (1) for structure, wherein R'= -CH 3 , R f =-CH(CF 3 ) 2 ) and 5.0g α-methylvinyltrimethoxysilane (CH 2 =C(CH 3 )Si(OCH 3 ) 3 ) was added into a four-necked flask with a high-speed stirrer, a thermometer, a condenser tube and a dropping funnel, and the temperature was controlled at 88° C., and 3.20 g of chloroplatinic acid / isopropanol solution was added dropwise under stirring (the mass fraction of chloroplatinic acid 0.5%), the dropwise addition was completed in 40 minutes, and after 3 hours of reaction, the water-based silicon fluoropolymer whose appearance was a colorless viscous liquid was obtained;

[0036]Add 100 g of the water-based silicon fluoropolymer obtained by the above reaction and 400 g of distilled water (the mass fraction of the polymer is 20%) in a high-speed shear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com