Surface treating method for sea water corrosion-resistant metal aluminum or aluminum alloy

A technology of aluminum alloy surface and treatment method, which is applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of insufficient hydrophobicity, hysteresis of contact angle, harsh selection, etc., and achieve the preparation process and required equipment Simple, improved seawater corrosion resistance, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Use high-pressure airflow to blast sand pellets with a particle size of 425 μm through a spray gun to sandblast the aluminum surface to construct micron-scale surface morphology, remove surface oil with 6g / L sodium hydroxide solution, and then put it into clean water for ultrasonic cleaning for 3 minutes. The electrolyte solution was prepared with the following components: sulfuric acid 100g / L, oxalic acid 10g / L, glycerin 10g / L, and the rest was distilled water. The cleaned aluminum is used as the anode, the nickel is used as the cathode, and the current intensity is 1.5A / dm 2 , the ice-water bath controlled the temperature at 2° C., and the reaction time was 30 min. Then put the sample into clean water and ultrasonically clean it for 3 minutes. Prepare fluorosilane solution: dissolve fluorosilane in ethanol solvent, the mass percentage of fluorosilane to ethanol is 1%, then adjust the pH value of distilled water to 3 with acetic acid, add acetic acid aqueous solution ...

Embodiment 2

[0032] Use high-pressure airflow to blast sand pellets with particle sizes of 325 μm, 250 μm and 180 μm through a spray gun to sandblast the surface of aluminum alloy to construct micron-scale surface morphology, remove surface oil with 6g / L sodium hydroxide solution, and then put Ultrasonic cleaning in clean water for 3 minutes. The electrolyte solution was prepared with the following components: sulfuric acid 80g / L, oxalic acid 7g / L, glycerin 10g / L, and the rest was distilled water. The cleaned metal is used as the anode, nickel is used as the cathode, and the current intensity is 2A / dm 2 , the ice-water bath controlled the temperature at 2°C, and the reaction time was 20 min. Then put the sample into clean water and ultrasonically clean it for 3 minutes. Preparation of fluorosilane solution: dissolve fluorosilane in ethanol solvent, the mass percentage of fluorosilane to ethanol is 1.5%, then adjust the pH value of distilled water to 3 with acetic acid, add acetic acid aq...

Embodiment 3

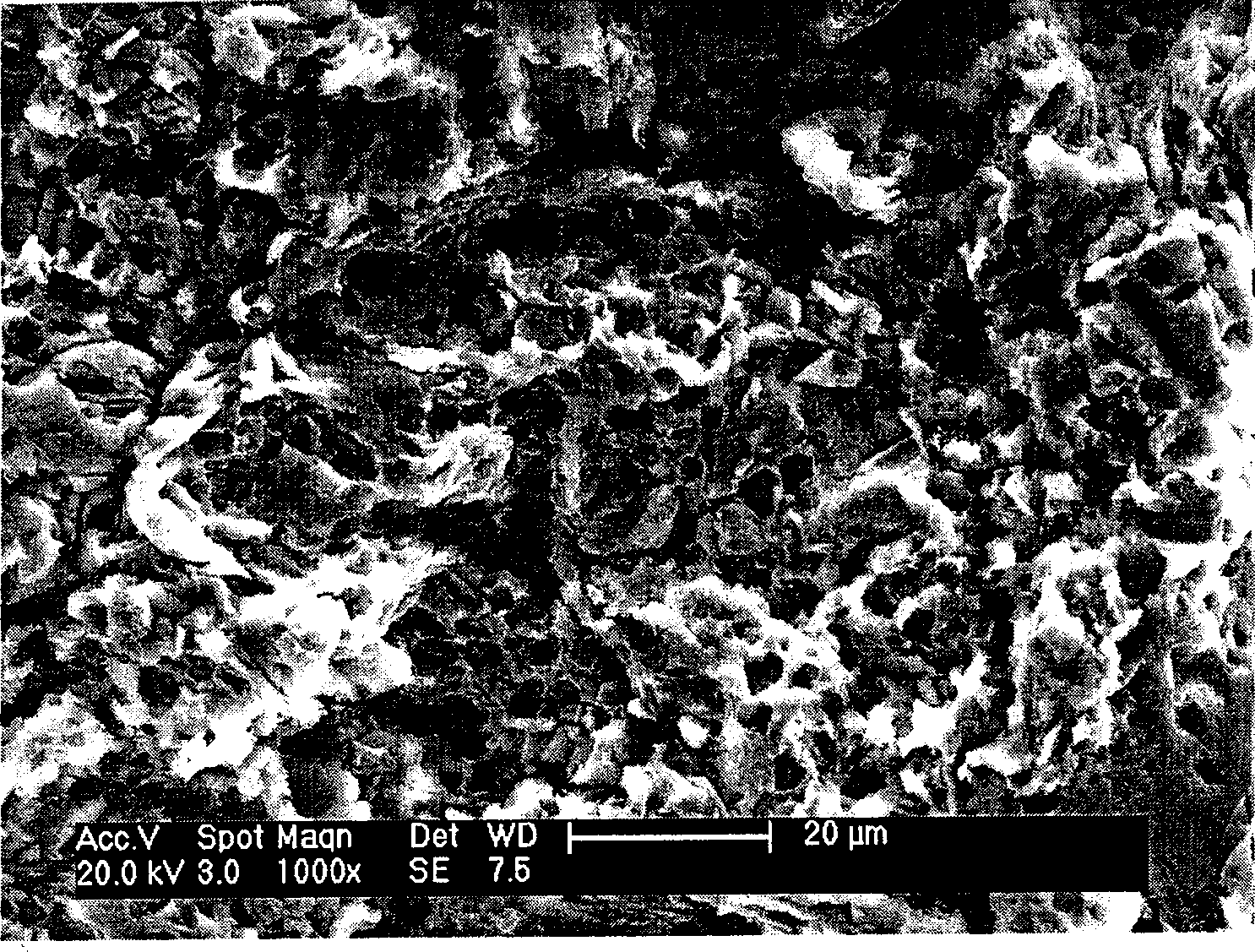

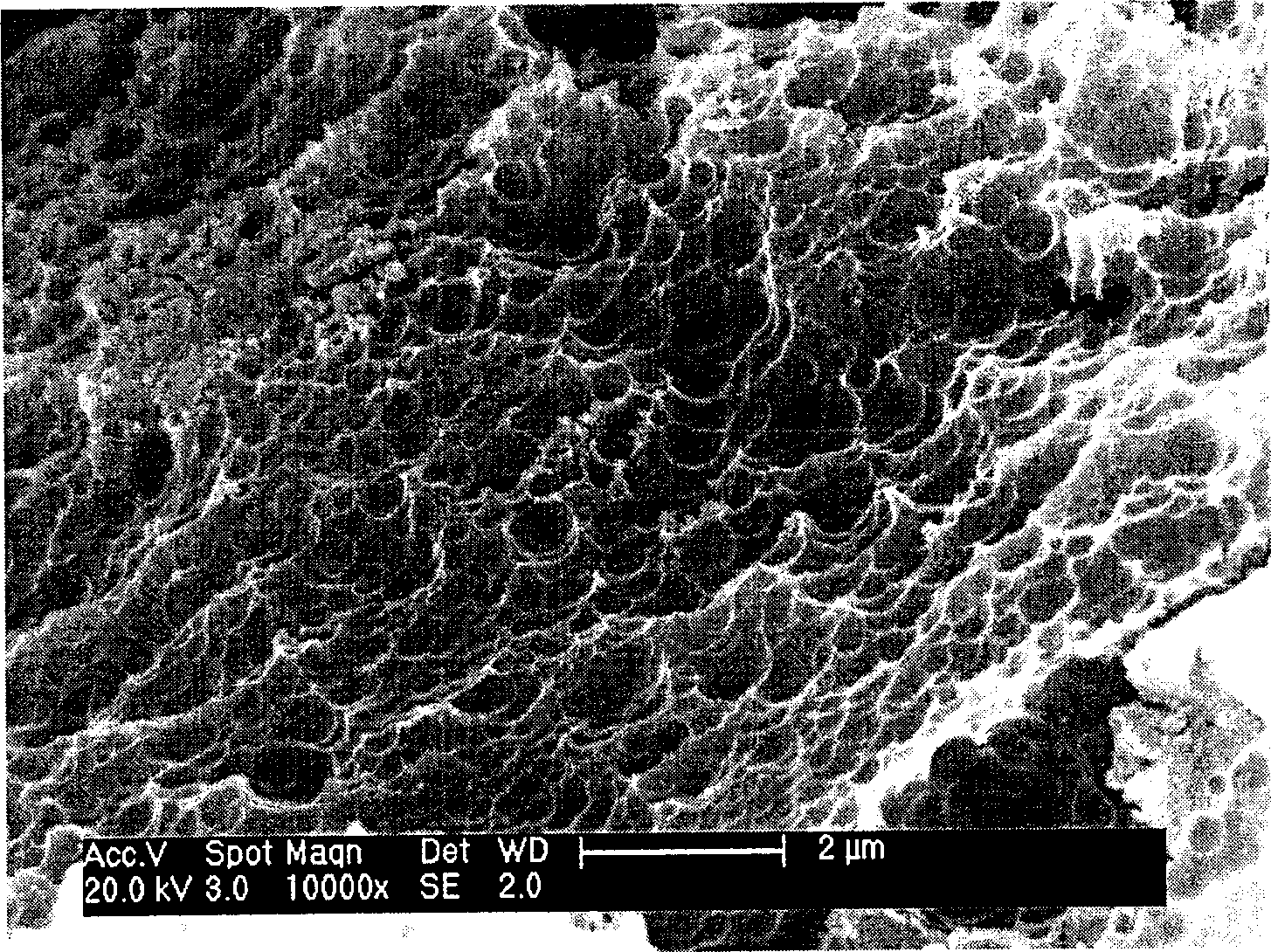

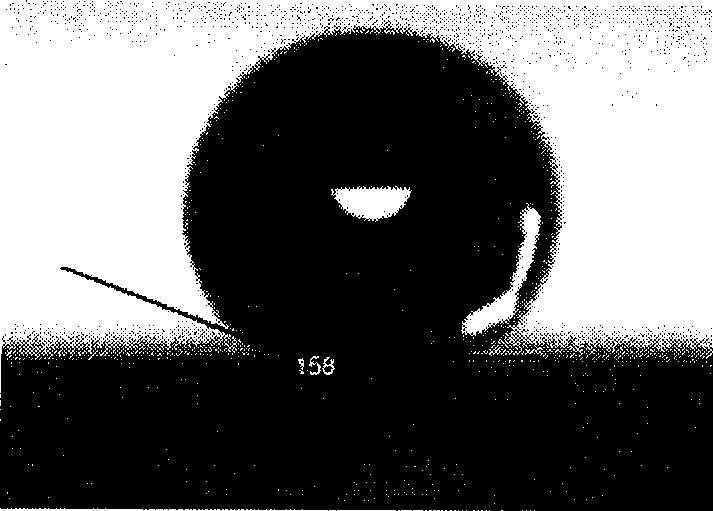

[0036] Use high-pressure airflow to blast sand pellets with a particle size of 106 μm through a spray gun to sandblast the aluminum alloy surface to construct micron-scale surface morphology, remove surface oil with 6g / L sodium hydroxide solution, and then put it into clean water for ultrasonic cleaning for 3 minutes . Observing the surface with a scanning electron microscope, it can be seen that the surface is uneven, such as figure 1shown. The electrolyte solution was prepared with the following components: sulfuric acid 120g / L, oxalic acid 7g / L, glycerin 10g / L, and the rest was distilled water. The cleaned metal is used as the anode, nickel is used as the cathode, and the current intensity is 1.5A / dm 2 , the ice-water bath controlled the temperature at 2°C, and the reaction time was 20 min. Then put the sample into clean water and ultrasonically clean it for 3 minutes. Observing the surface with a scanning electron microscope, it can be seen that there are a large numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com