Novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy

A titanium alloy, low-cost technology, applied in the new low-cost, seawater corrosion-resistant titanium alloy, high plasticity field, can solve the problems of high material processing loss, high cost, long processing cycle, etc., to reduce the cost of raw materials and improve the deformation capacity. , the effect of improving the plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

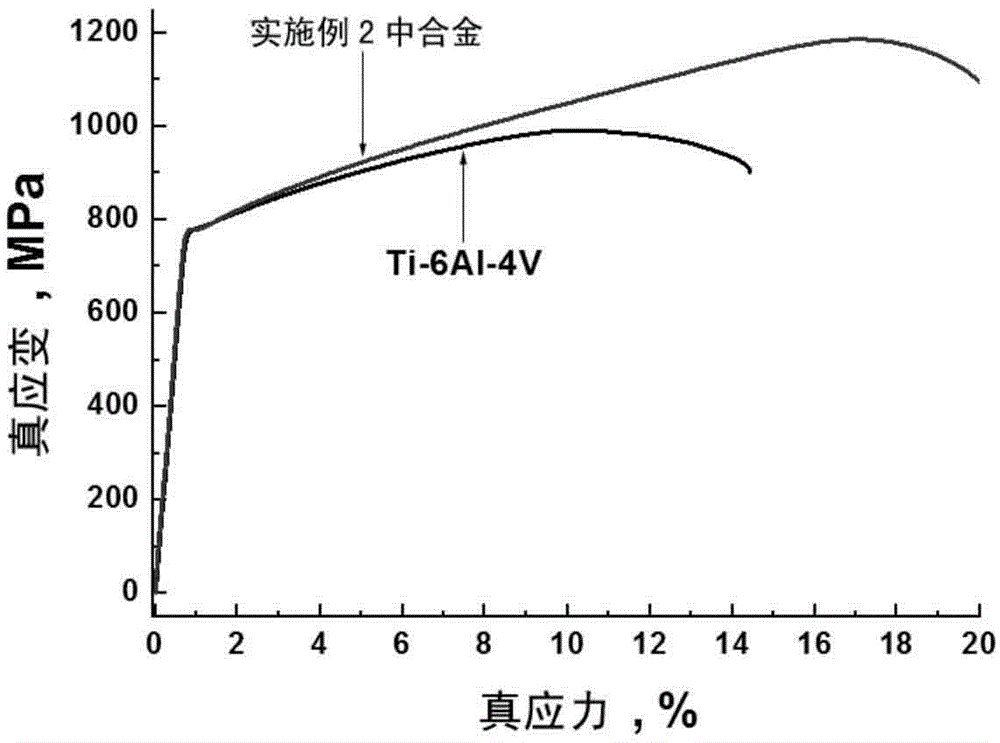

[0048] In Table 2, when the tensile strength of 1#, 2#, and 3# alloys is basically equivalent to that of Ti-6Al-4V, the plasticity and toughness are significantly improved. This is mainly due to the fact that an appropriate amount of Fe and Cu elements can reduce the activation energy of plastic deformation, produce the beneficial effects of "phase transformation plasticization" and "phase transformation toughening", and the interaction of the two elements, which comprehensively improves the plasticity and toughness of titanium alloys. . In addition, 1#, 2#, and 3# low-cost titanium alloys included in the present invention are compared with Ti-6Al-4V alloys in chemical composition, by reducing the amount of vanadium elements with higher prices, increasing the lower iron and copper elements Dosage, and further optimize the matching of the content of each element, so that the raw material cost of the new titanium alloy is significantly lower than that of the Ti-6Al-4V alloy.

...

Embodiment 4

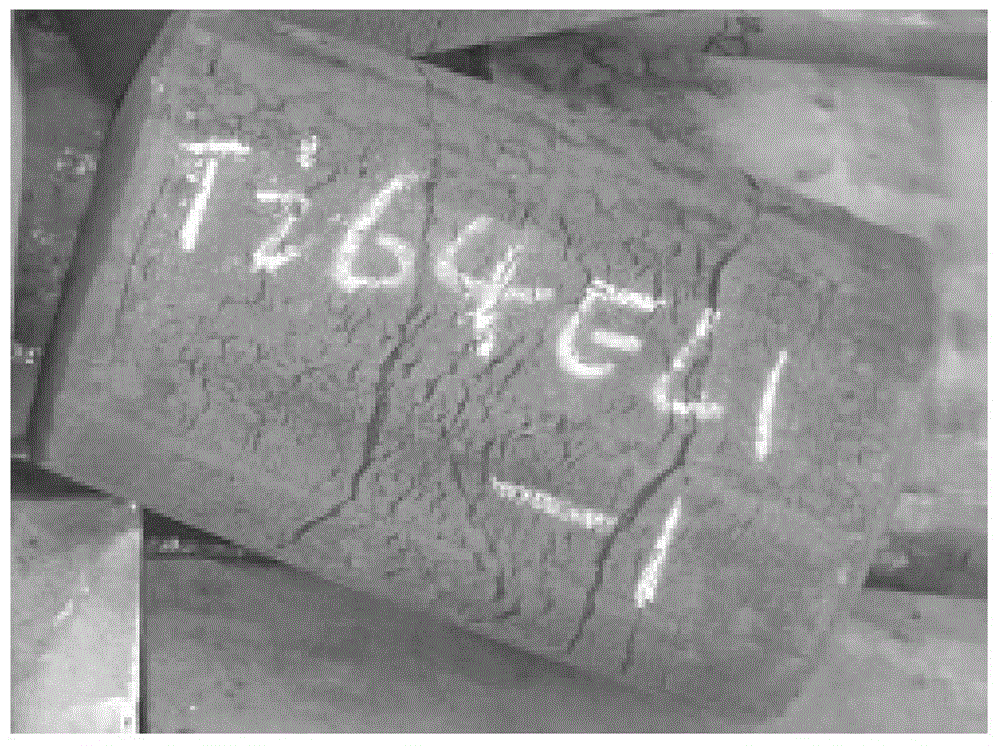

[0056] According to the composition of the chemical composition, ingredients were prepared and smelting electrodes were prepared, and a titanium alloy with low cost, high plasticity and seawater corrosion resistance was smelted by three vacuum self-consumption methods. The composition is 1#, 2#, 3# alloys in Table 1. The ingot is forged at 1150°C, and the grains are broken by upsetting at 1050°C, and then forged at 880°C in the α+β two-phase region to form a bar with a diameter of 120mm, and finally forged at 880°C through a precision forging process to form a bar with a diameter of 60mm. bar. The 60mm diameter bar was subjected to 8 different heat treatments, and the heat treatment specifications are shown in Table 3. Sampling and analysis of the rod section after heat treatment is carried out to detect the tensile strength and plasticity of the material.

[0057] 8 kinds of heat treatment systems involved in the present invention in table 3

[0058] Numbering ...

Embodiment 5

[0061] Taking the 2# composition alloy in Table 1 as the object, the corrosion behavior of the alloy in three different concentrations of NaCl solutions was studied. The concentrations of NaCl solutions were 3.5%, 7%, and 14% (weight percent). The surface morphology after soaking in the above NaCl solution for 7 weeks is as follows: Figure 13 , Image 6 , Figure 14 shown. It can be seen that after soaking in the above three NaCl solutions for 7 weeks, no obvious corrosion behavior occurred, indicating that the alloy has good seawater corrosion resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com