Preparation method of permanent ferrite material

A technology of permanent magnet ferrite and ferrite, which is applied in the direction of magnetism of inorganic materials, can solve the problems of high price, poor combination and compactness, and the inability to further reduce the cost, and achieve the effect of excellent performance, compact material, and cost saving of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

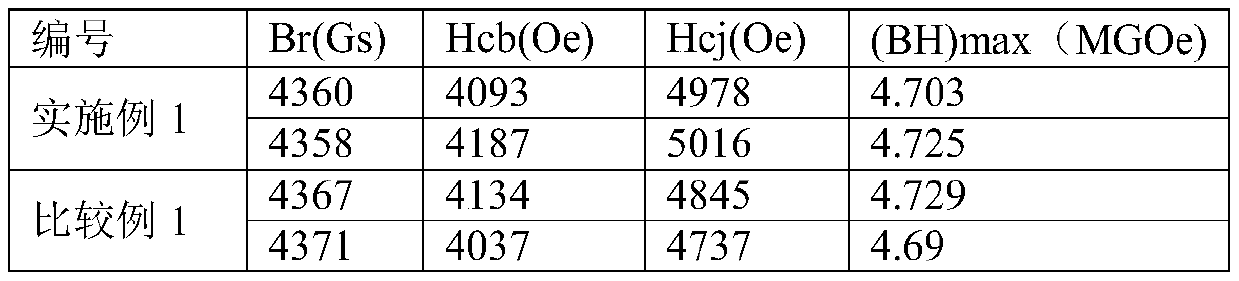

Embodiment 1

[0032] A kind of permanent magnet ferrite material, described permanent magnet ferrite material has Sr 0.43 Ca 0.15 La 0.42 Fe 10.95 co 0.25 o 19 Main phase ferrite material, its preparation method is as follows:

[0033] (1) Calcined material preparation: according to the molar ratio of Sr: Ca: La: Fe: Co is 0.43: 0.15: 0.42: 10.95: 0.25 and then weigh Fe 2 o 3 (purity≥99.3wt%, Cl - ≤0.1wt%, the original average particle size of the particles ≤1.5um), CaCO 3 (purity≥98.5wt%, the original average particle size of particles≤1.0um), La 2 o 3 (Purity≥99.3wt%, original average particle size of particles≤5um), cobalt carbonate (original average particle size≤3um), SrCO 3 (purity≥97wt%, the original average particle size of the particles≤1.5um) and other raw materials are subjected to wet primary ball milling, the ball milling time is 5 hours, the average particle size of the mixed particles is 0.8um, and then the slurry is dried in an oven, After 10MPa pressure pre-compr...

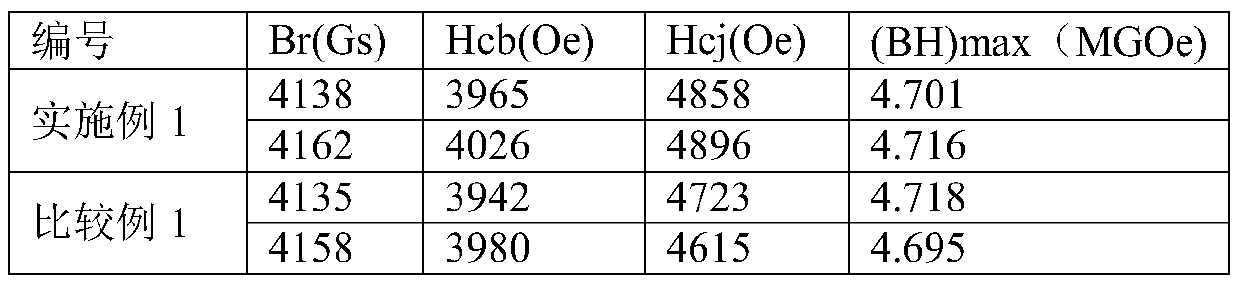

Embodiment 2

[0047] A kind of permanent magnet ferrite material, described permanent magnet ferrite material has Sr 0.5 Ca 0.18 La 0.32 Fe 10.75 co 0.25 o 19 Main phase ferrite material, its preparation method is as follows:

[0048] (1) Calcined material preparation: Weigh Fe according to the molar ratio of Sr: Ca: La: Fe: Co 0.5: 0.18: 0.32: 10.75: 0.25 2 o 3 (purity≥99.3wt%, Cl - ≤0.1wt%, the original average particle size of the particles ≤1.5um), CaCO 3 (purity≥98.5wt%, the original average particle size of particles≤1.0um), La 2 o 3 (purity≥99.3wt%, the original average particle size of particles≤5um), Co 2 o 3 (the original average particle size of particles≤3um), SrCO 3 (purity≥97wt%, the original average particle size of the particles≤1.5um) and other raw materials were wet-processed for a ball mill, and the ball milling time was 3 hours. The average particle size of the mixed particles was 0.9um, and then the slurry was dried in an oven. After 8 MPa pressure pre-comp...

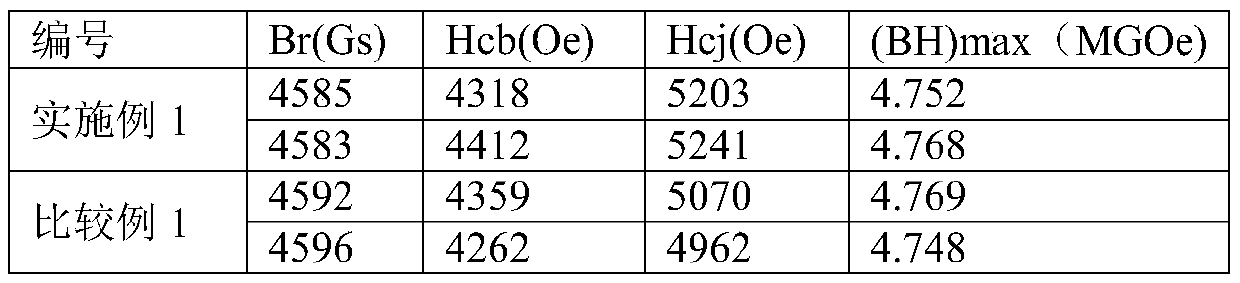

Embodiment 3

[0062] A kind of permanent magnet ferrite material, described permanent magnet ferrite material has Sr 0.35Ca 0.22 La 0.43 Fe 11.32 co 0.28 o 19 Main phase ferrite material, its preparation method is as follows:

[0063] (1) Preparation of calcined material: Weigh Fe according to the molar ratio of Sr: Ca: La: Fe: Co: 0.35: 0.22: 0.43: 11.32: 0.28 2 o 3 (purity≥99.3wt%, Cl - ≤0.1wt%, the original average particle size of the particles ≤1.5um), CaCO 3 (purity≥98.5wt%, the original average particle size of particles≤1.0um), La 2 o 3 (purity≥99.3wt%, the original average particle size of particles≤5um), Co 2 o 3 (the original average particle size of particles≤3um), SrCO 3 (purity ≥ 97wt%, original average particle size of particles ≤ 1.5um) and other raw materials were subjected to wet primary ball milling, the ball milling time was 8 hours, the average particle size of the mixed particles was 0.6um, and then the slurry was dried in an oven. After 12MPa pressure pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com