Marine wear-resistant ultrahigh-molecular-weight polyethylene composite material

A technology of ultra-high molecular weight and composite materials, which is applied in the field of wear-resistant ultra-high molecular weight polyethylene composite materials for marine applications. It can solve the problems of low corrosion resistance and low mechanical properties in seawater, and achieve excellent compatibility and stability. And the effect of oil extraction resistance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with specific embodiment, the present invention is described in further detail, but the present invention is not limited to following examples of implementation:

[0008] In this embodiment, co-rotating twin-screw extruders, mills, and injection molding machines are used; ultra-high molecular weight polyethylene is produced in Beijing Auxiliary No. For domestic production.

[0009] The preparation process of a wear-resistant ultra-high molecular weight polyethylene composite material for marine use according to the present invention is as follows:

[0010] Firstly, the UHMWPE and the anti-salt corrosion material were mixed in an open mill at a temperature of 210°C for 30 minutes according to the ratio in the example in Table 1, and the mixed composition was pulverized into a diameter less than 3mm by a pulverizer.

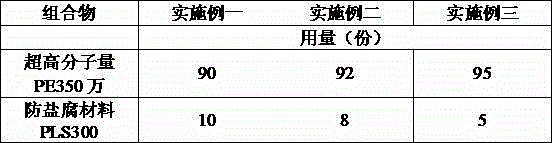

[0011] The formula corresponding to table 1 embodiment

[0012]

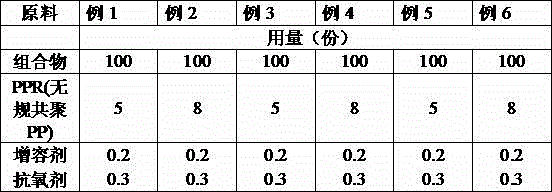

[0013] According to the ratio of the example in Table 2, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com