Non-stick ceramic paint and coating method thereof

A technology for ceramic coatings and pigments, used in coatings, devices for coating liquids on surfaces, and surface pretreatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

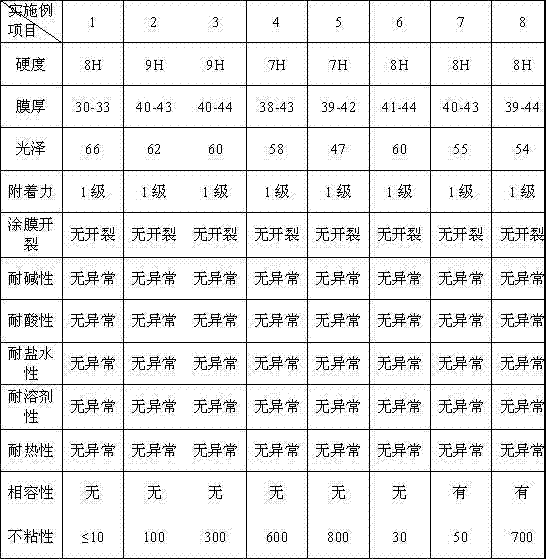

Examples

Embodiment 1-8

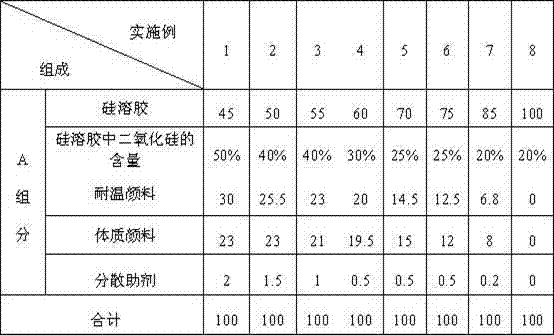

[0044] A non-stick ceramic coating, which is formed by mixing two components A and B at a mass ratio of 2:0.5~2, wherein:

[0045] Component A: According to the components and contents in Table 1, mix and grind silica sol, pigments, fillers and dispersing aids for more than 2 hours;

[0046] The particle size of the silica sol is 5-100nm, and the content of silicon dioxide in the silica sol is 20-55% by weight.

[0047] The pigment is selected from one or more of rutile, Taibai, titanium yellow, iron oxide black, iron oxide red, cobalt black, cobalt blue, cobalt green, carbon black, pearlescent or aluminum silver powder according to production requirements; the filler is a particle size smaller than 100μm powder filler, one or more selected from quartz powder, whisker silicon, alumina, diatomaceous earth, silicon carbide or diamond; pigments and fillers have no effect on product quality.

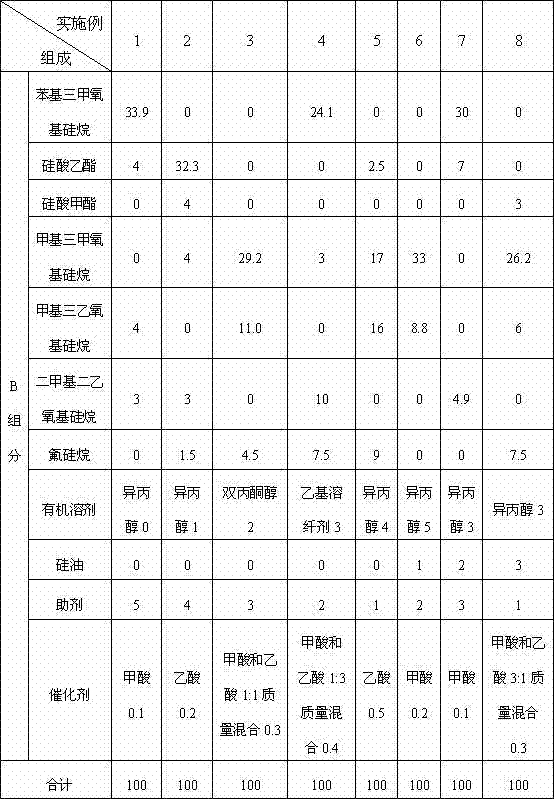

[0048] Component B: According to the components and contents in Table 2, mix the cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com