Patents

Literature

1260results about How to "Lowering the freezing point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodewaxing catalyst and its preparation method

ActiveCN102451748AImprove the effect of impurity removalInhibit carbon depositionMolecular sieve catalystsRefining to eliminate hetero atomsImpurityChemistry

The invention discloses a hydrodewaxing catalyst and its preparation method. With the weight of the catalyst as the reference, the catalyst contains the following components of: by weight, 5-10% of tungsten oxide, 1-5% of nickel oxide, 40-50% of nanometer ZSM-5 molecular sieve, 10-40% of macroporous alumina and the balance being a binder. The catalyst is prepared by the following steps of: firstly kneading the nanometer ZSM-5 molecular sieve, macroporous alumina and the binder to prepare a carrier, dipping loaded active metal, and finally carrying out hydrothermal treatment. The hydrodewaxing catalyst provided by the invention has a good shape-selective catalysis function and simultaneously has a good hydrofinishing function, and is especially suitable for the hydrofinishing and pour point reduction processes of a waxy hydrocarbon oil material containing high content of impurities such as sulfur, nitrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

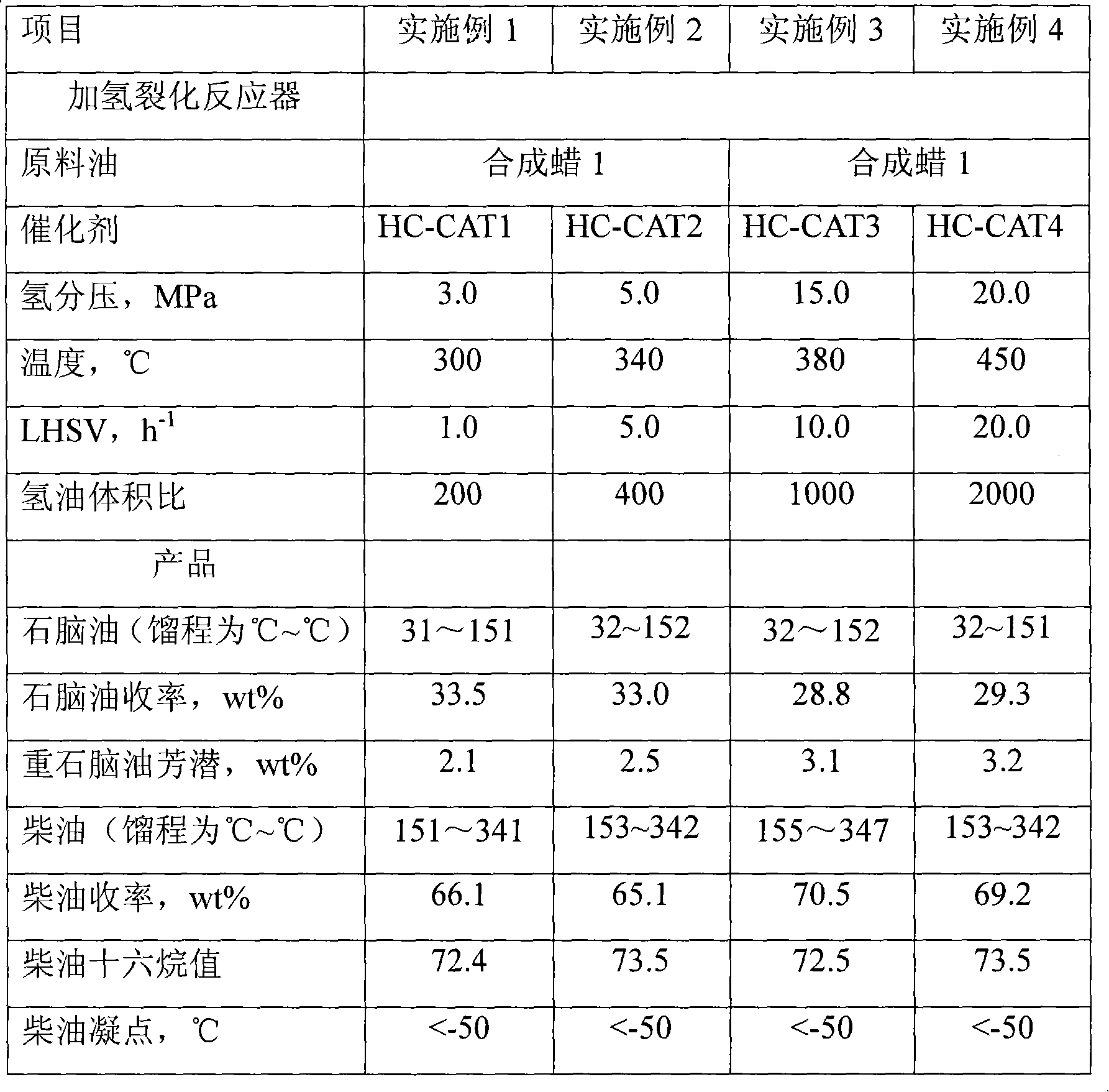

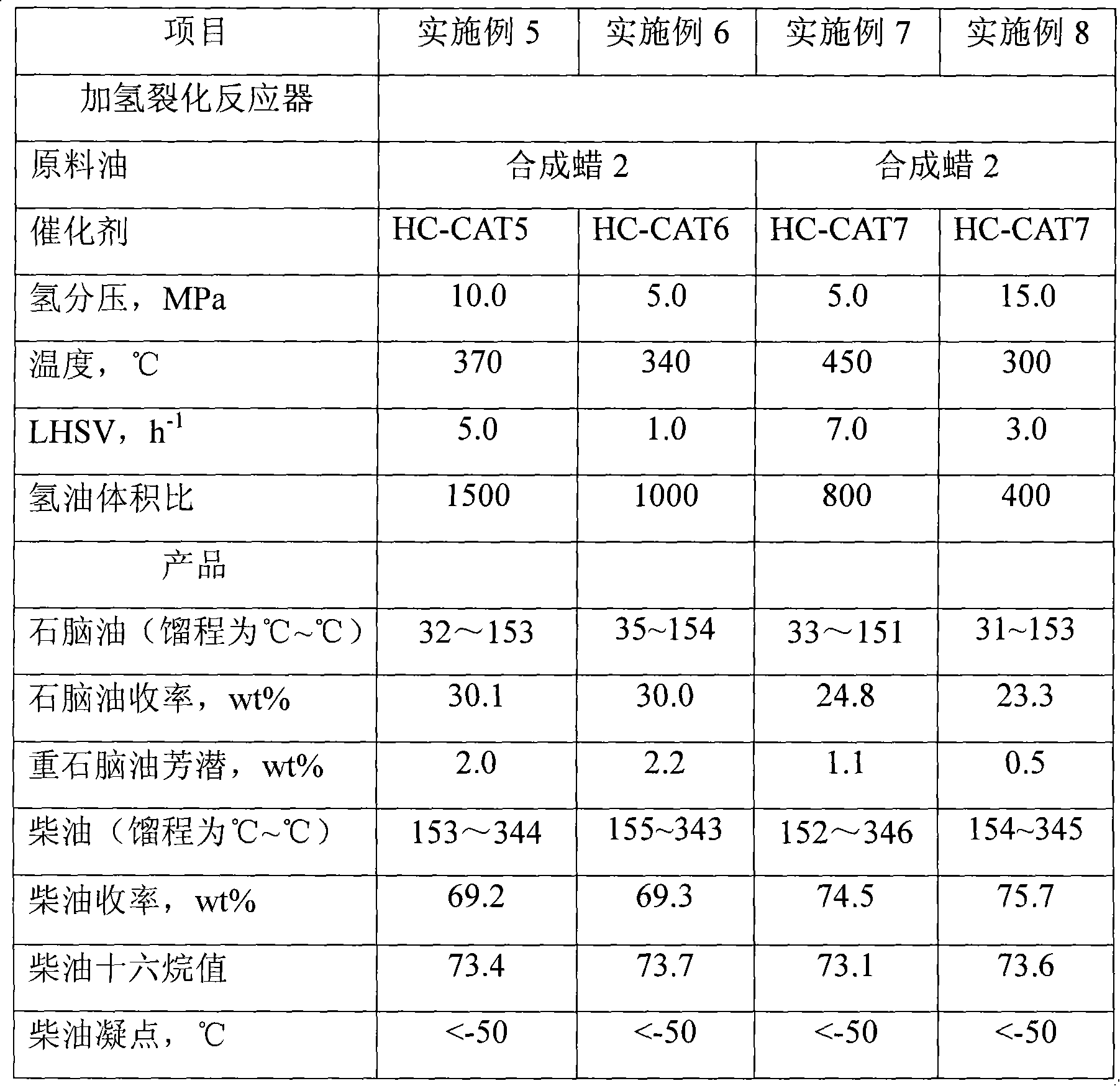

Combined hydrogenation method of producing diesel oil with high cetane number and low solidifying point

InactiveCN1417298AIncrease cetane numberLowering the freezing pointNaphtha reformingChemistryProduct gas

The combined hydrogenation method of producing diesel oil with high cetane number and low solidifying point includes contacting the raw material oil and hydrogen with hydrogenating upgrading catalystor hydrogenating cracking catalyst first, contacting the unseparated reaction effluent with pour point reducing hydrocatalyst feeding the cooled reaction product into high pressure separator to separate liquid product further flowing to the fractionating system and returning the hydrogen-rich gas to reactor. The said method can raise the cetane number of diesel oil and lower the solidifying pointsimultaneously in the same equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Squeezable Assembly for Pasty Products

InactiveUS20070275131A1Good flexibilityMinimize thermal denaturationReady-for-oven doughsFrozen sweetsEngineeringMechanical engineering

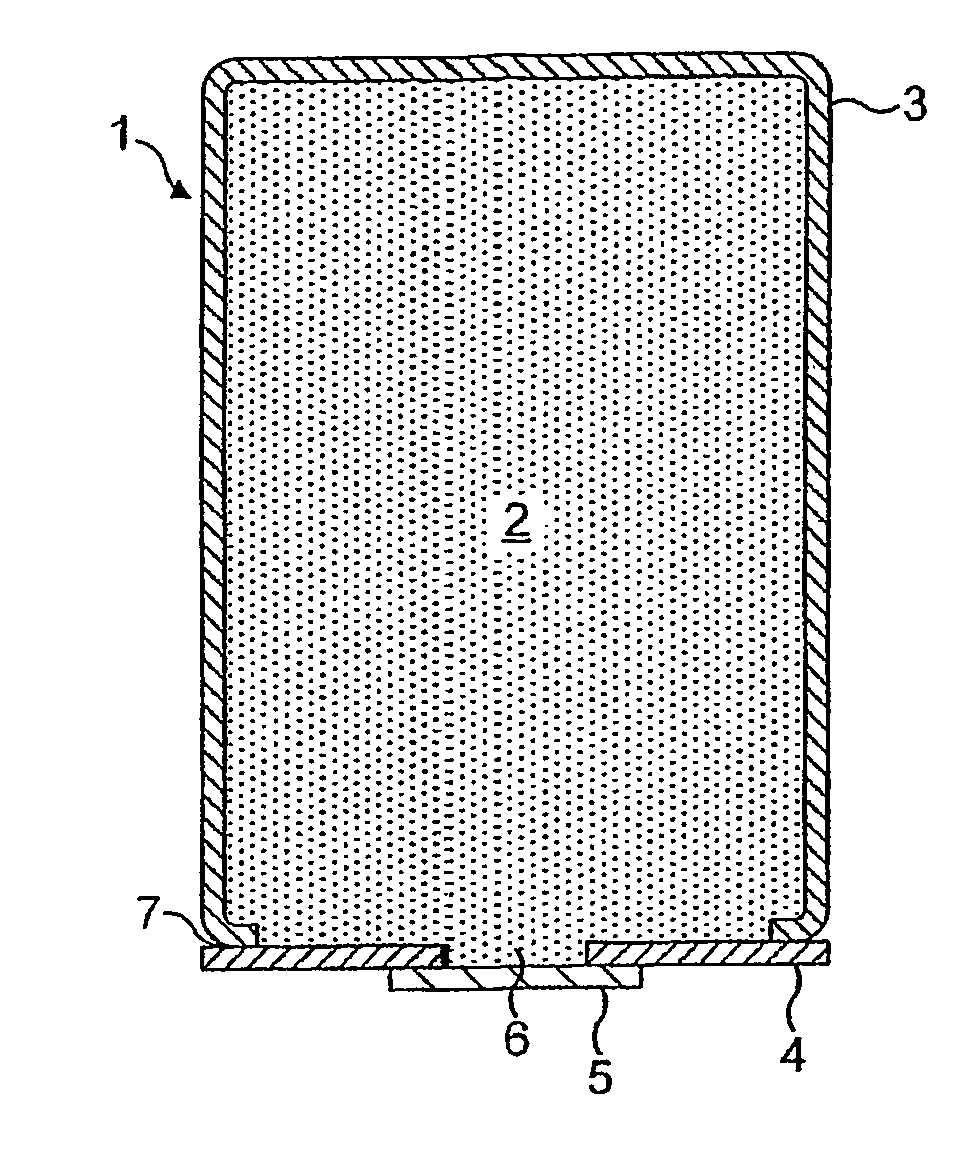

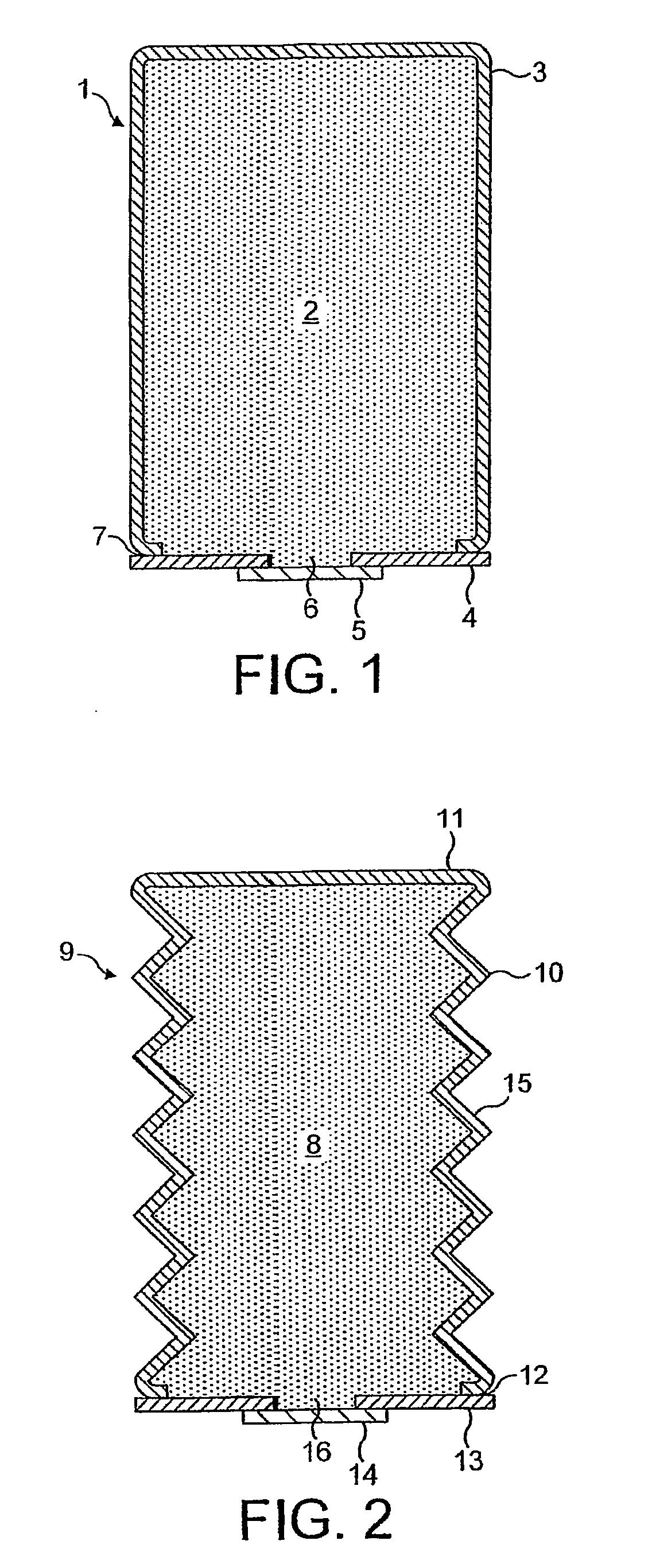

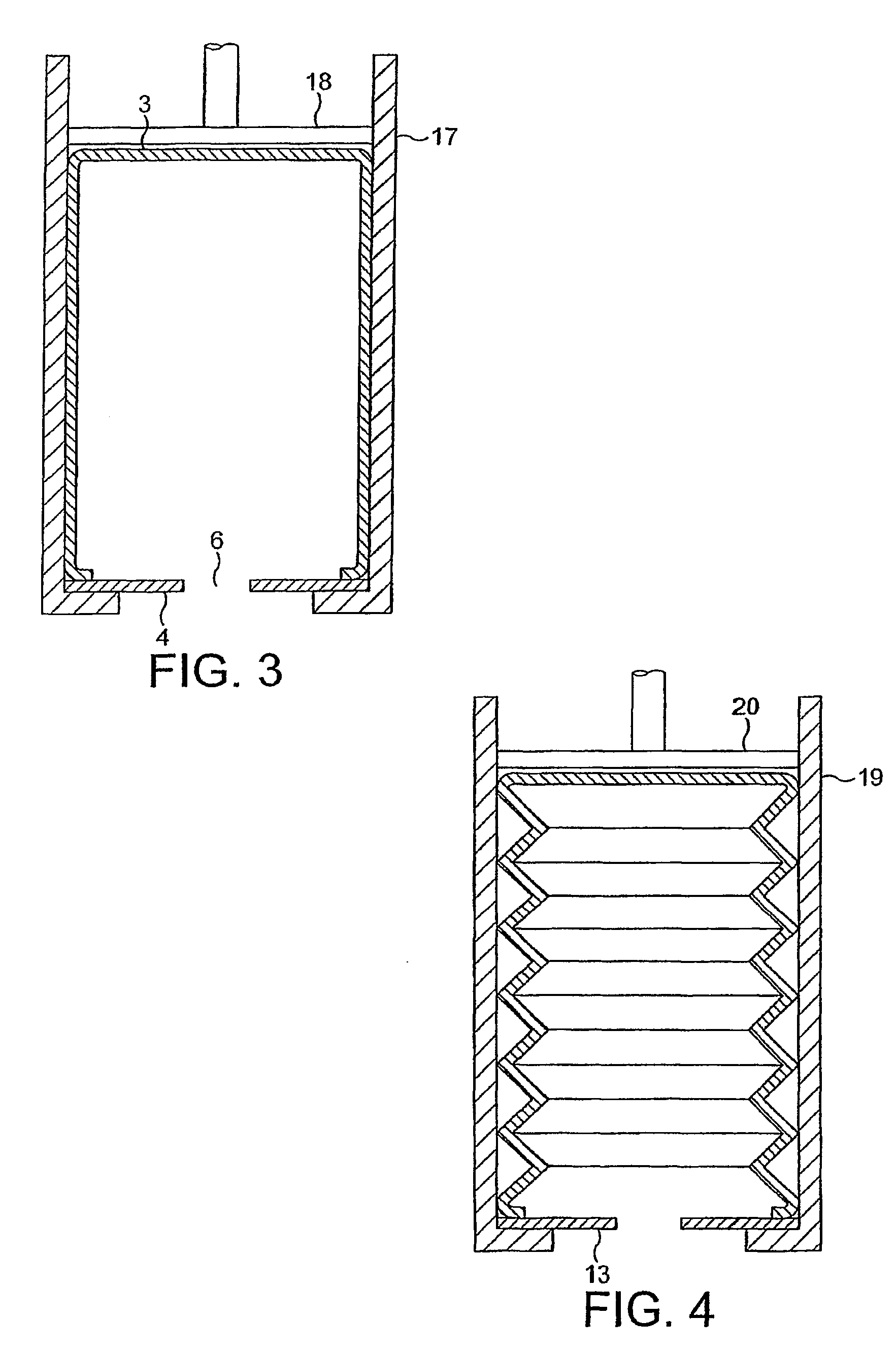

A squeezable assembly (9) for shelf-stable, chilled or frozen pasty products comprising—a body formed by a tube or a container presenting a bottom (11), lateral walls (15) and a rim (12) in the accordion form,—a rigid plastic cap (13) attached to the end of the tube or the rim (12) of the container comprising an aperture (16),—a cover seal (14) to close the aperture (16) and—a product (2) contained in the assembly (19).

Owner:NESTEC SA

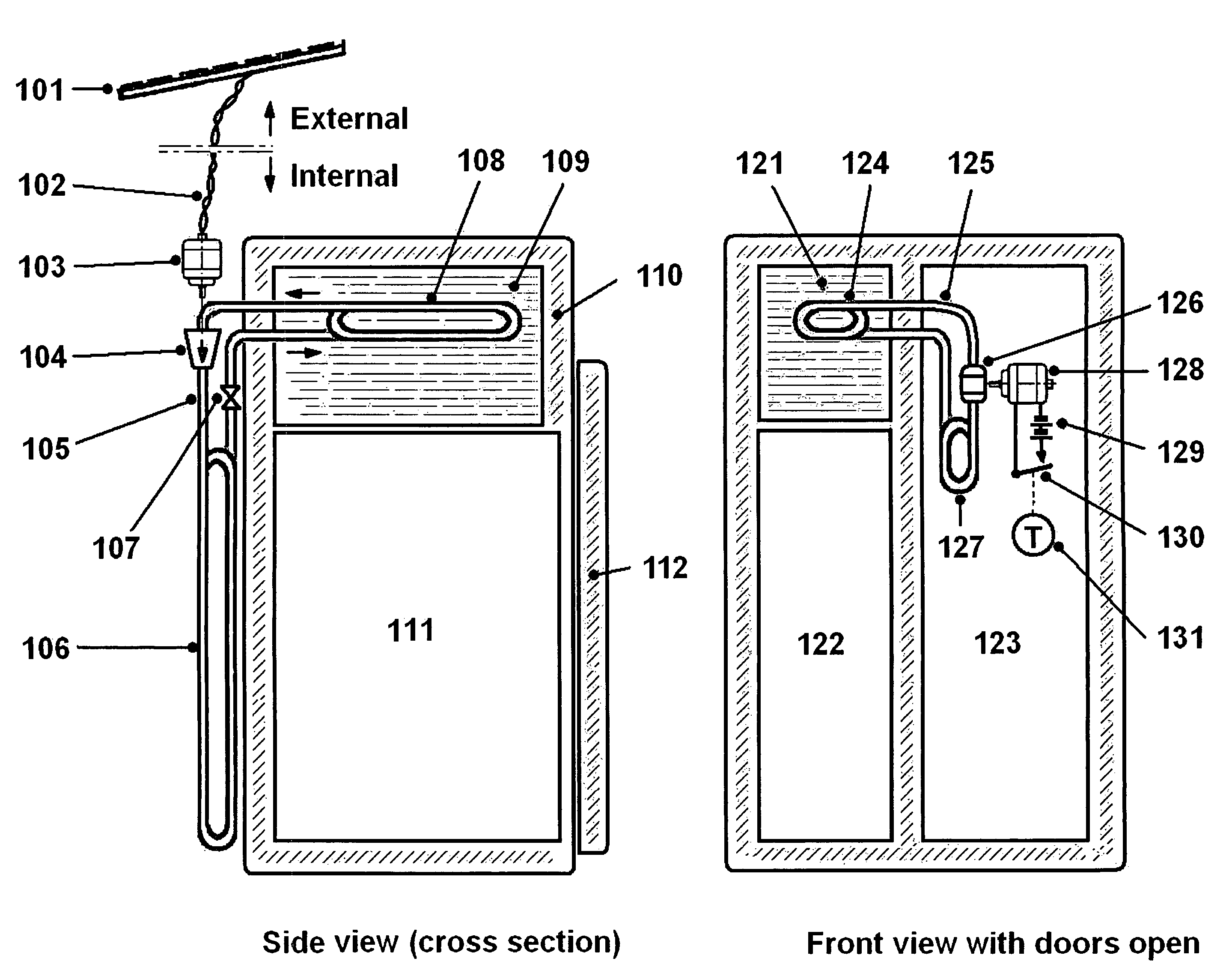

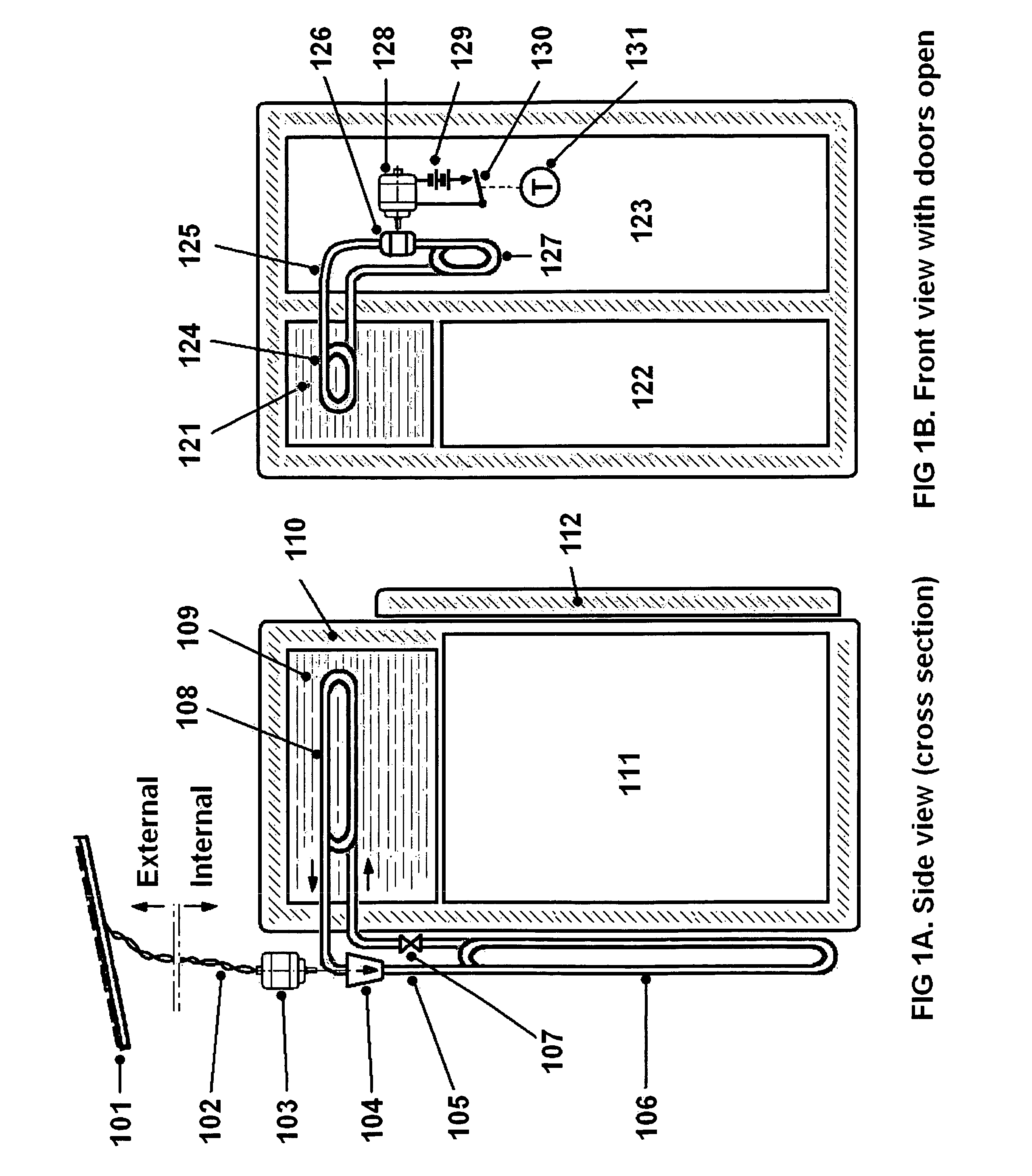

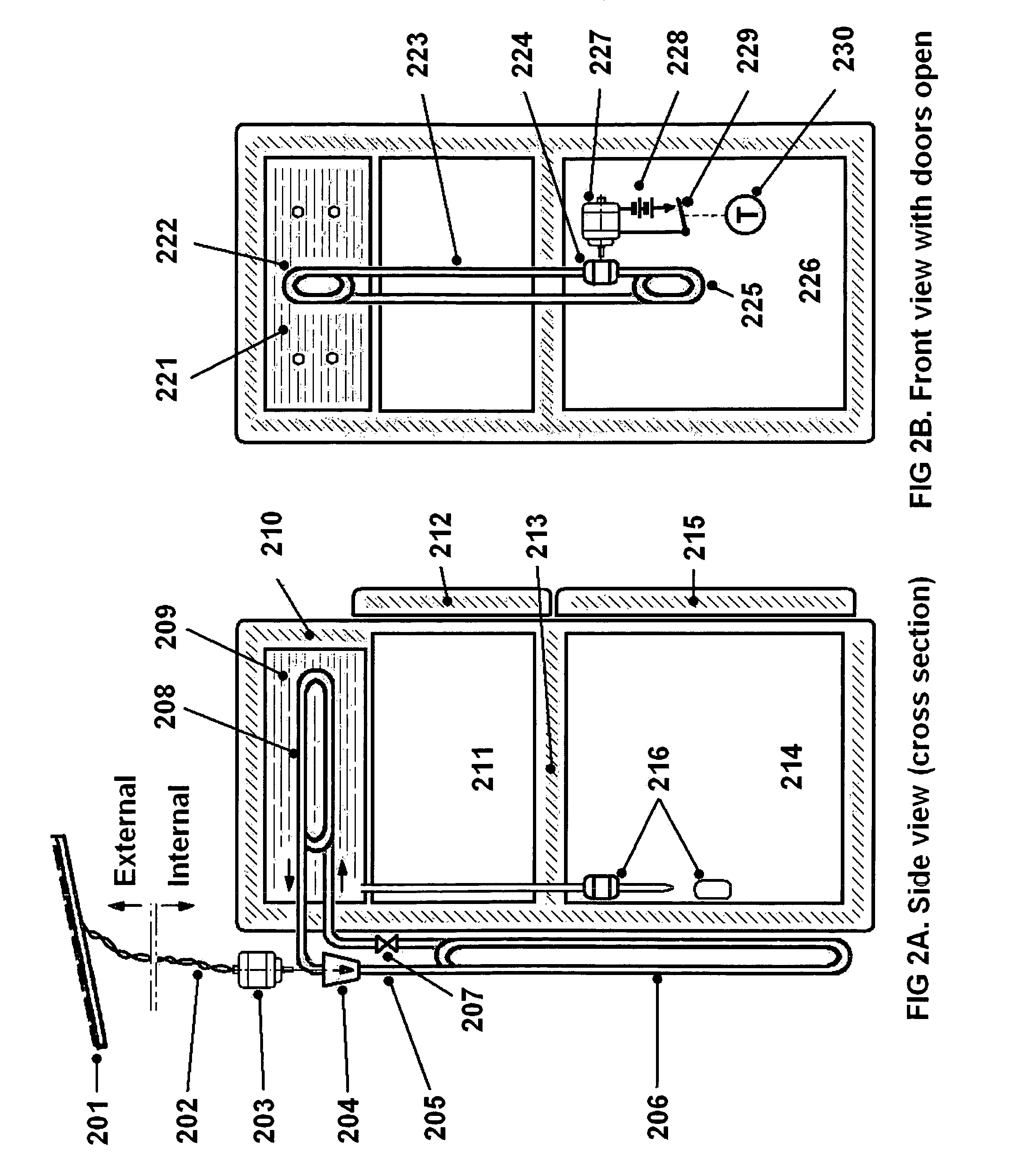

Solar-powered refrigerator using a mixture of glycerin, alcohol and water to store energy

InactiveUS7543455B1Freezing pointLowering the freezing pointDomestic refrigeratorsMachines using solar energySolar energy conversionRefrigerated temperature

A solar-powered refrigerator is disclosed. It uses a solar photovoltaic panel to convert solar energy to electricity to power a DC motor. The DC motor drives the compressor of a vapor-compression refrigeration system to freeze an energy-storage vessel, located in the freezer. The energy-storage vessel is filled with a mixture of glycerin, alcohol and water, with a freezing point of 10° F. to −10° F. In the absence of sunlight, the temperature of the frozen mixture can maintain near its freezing point for more than one day. The temperature of the refrigerator is maintained to a desirable value, for example 37° F., by a pair of heat-exchange coils and a thermostat, with or without sunlight.

Owner:CHEN CHENGJUN JULIAN

Diesel oil hydro-upgrading catalyst and preparation method thereof

ActiveCN103100416AHigh catalytic activity and diesel yieldLarge freezing point depressionMolecular sieve catalystsHydrocarbon oils treatmentCycloalkaneMolecular sieve

The invention discloses a diesel oil hydro-upgrading catalyst and a preparation method thereof. The catalyst comprises: a carrier composed of a modified beta molecular sieve and alumina, and hydrogenation active metal components. Specifically, the modified beta molecular sieve is prepared by: subjecting a crystallized beta molecular sieve slurry directly to ammonium exchange and a template agent removal treatment, then conducting a hydrothermal treatment first, and performing an aluminum salt solution treatment, under the condition of maintaining a high beta molecular sieve crystallinity, removing part of non-framework aluminum uniformly, thus obtaining the beta molecular sieve with the characteristics of high Si / Al ratio, large specific surface area, appropriate acidity and acid distribution, and reasonable pore structure, etc. The modified beta molecular sieve especially has a suitable cracking effect and a very good isomerization effect on long-chain alkane and the long side chain alkyl of aromatic hydrocarbon and cyclane, so that the catalyst can greatly reduce the condensation point of diesel oil fraction while keeping a high diesel oil yield, improve the cetane number of modified diesel oil, as well as effectively reduce the density and sulfur content of a diesel oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

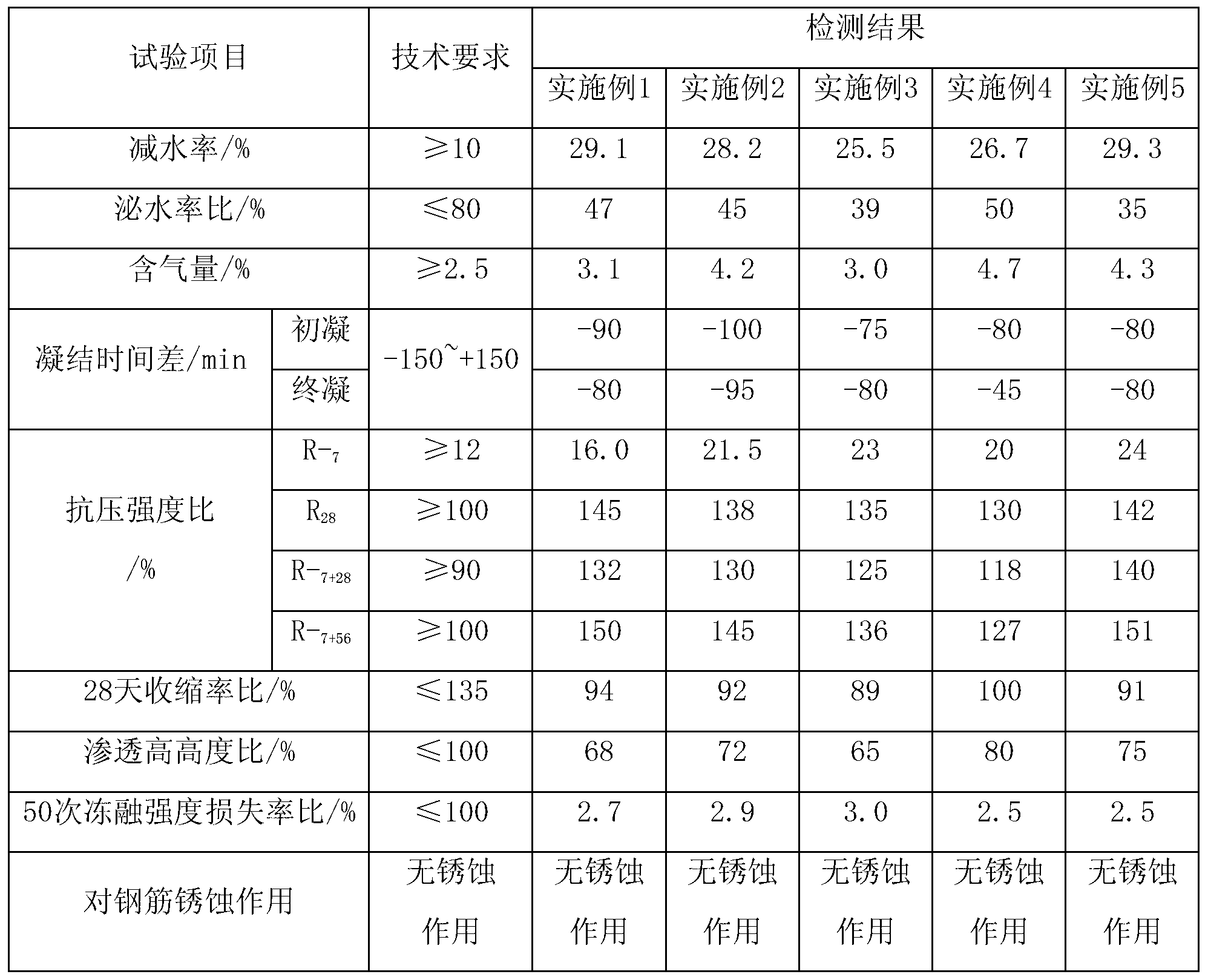

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Method of hydro up grading isomerizing pour point depression to produce diesel oil

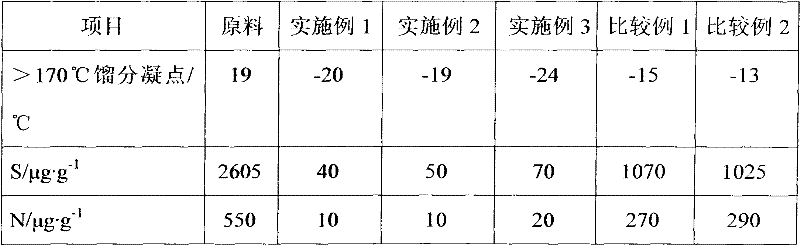

ActiveCN1718683ALittle impact on yieldExtended operating cycleHydrocarbon oils refiningNaphthaSulfur

A process for preparing the clean diesel oil by hydromodifying, isomerizing and lowering pour point features that the fractional oil raw material and H2 pass through a catalyst bed to obtain clean high-quality diesel and the naphtha product with low contents of sulfur and nitrogen and high content of arylhydrocarbon. Said catalyst bed contains hydrocatalyst bed containing beta zeolite (0.5-20 wt.%).

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

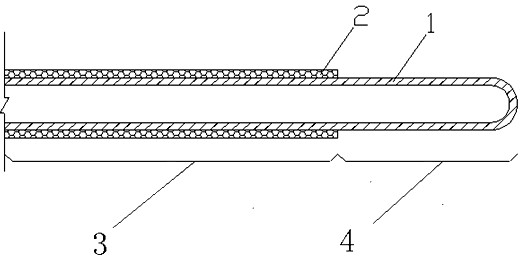

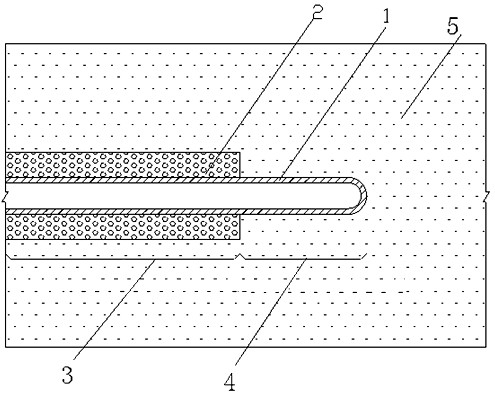

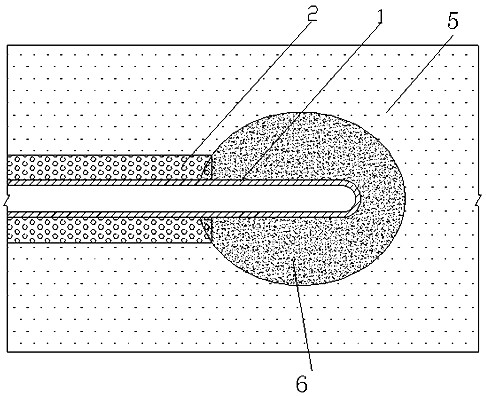

Cryoablation probe shell covered by expandable hydrogel and preparation method thereof

ActiveCN101999931ALowering the freezing pointPrevent Freezing InjuriesSurgical instruments for heatingCoatingsNormal tissueBiomedical engineering

The invention discloses a cryoablation probe shell covered by expandable hydrogel and a preparation method thereof. The cryoablation probe shell is characterized by comprising a cryoablation probe shell made of metal and a hydrogel coating covering the probe shell, wherein the cryoablation probe shell comprises integrated working section and non-working section; the hydrogel coating is uniformly coated on the non-working section of the cryoablation probe shell, and the thickness of the hydrogel coating is 50 mu m to 500 mu m. The hydrogel coating comprises degradable porous hydrophilic hydrogel and absorbs water to rapidly expand to form a hydrogel isolating membrane to isolate the cryoablation probe from normal tissue, and plays the function of protecting the normal tissue of a non-target area.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

Denitrifying agent for directly removing basic nitrogen compound from shale oil

InactiveCN101967389ASettling fastGood removal effectHydrocarbon oils refiningPhosphoric acidChemistry

The invention relates to a denitrifying agent for directly removing a basic nitrogen compound from shale oil. The denitrifying agent comprises the following components in percentage by weight: 40 to 80 percent of B, 0.5 to 10 percent of L, 0.1 to 0.5 percent of S and the balance of water, wherein B is phosphoric acid; L is Lewis acid; and S is a water-soluble demulsifier. The B in the formula can provide H+ which is complexed into salt with a lone electron pair of the basic nitrogen compound so as to remove the basic nitrogen compound from oil; L can accept the lone electron pair of the basic nitrogen compound to be complexed into salt, and the synergistic effect of B and L has high capacity of removing basic nitrogen; and S has good demulsifying effect and can improve the uniformly mixing degree of the water-soluble B and L agents with oil in the oil stirring process. Therefore, the nitrogen removal efficiency of a primary agent is improved.

Owner:DAQING OILFIELD CO LTD +1

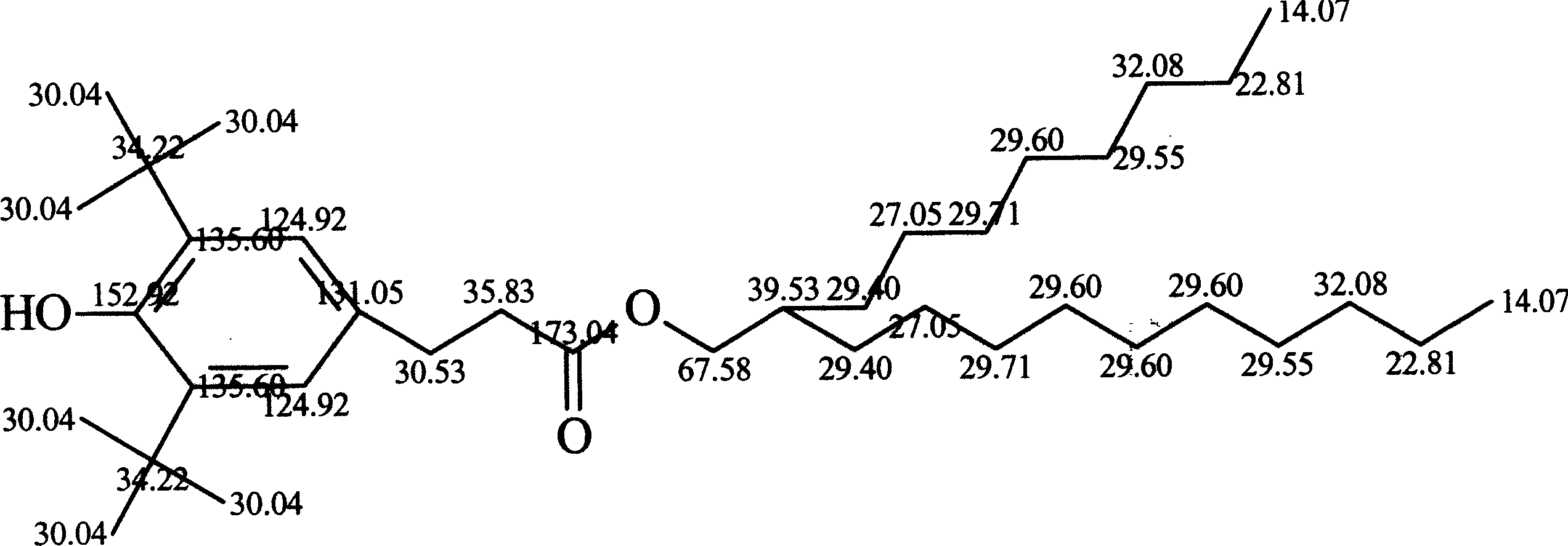

Liquid antioxidant and its preparing method

ActiveCN1611563ALowering the freezing pointReduce volatilityChemical inhibitorsCarboxylic esterHigh oxygen

Then invention relates to a kind of liquid anti-oxidant with the structure of type (1). Among (1), R1 and R2 is C1-C8 alkyl, m is 0, 1, 2 or 3, and A is C12-C32 alkyl with a branched chain; the branched chain is in beta of fundamental chain, and C number difference of branched chain and fundamental chain is 4. In the invention, make oxyphenyl carboxylic ester react with Guerber alcohol of 10-32 C number in the condition of catalyst, in 80-240deg.C, in order to get the liquid anti-oxidant. The liquid anti-oxidant is liquid in ordinary temperature, and it has low condensation point, low volatilization, and high oxygen resistance, so that it is convenient for practical application and allotment.

Owner:CHINA PETROLEUM & CHEM CORP +1

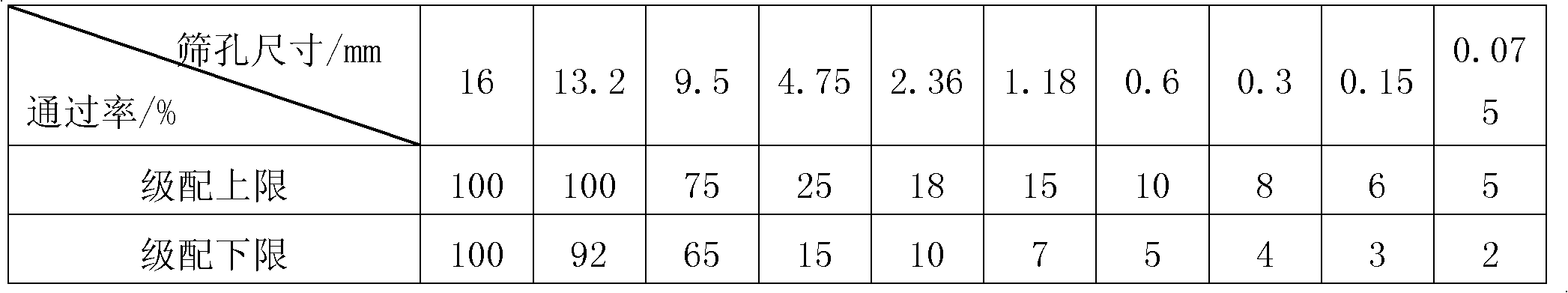

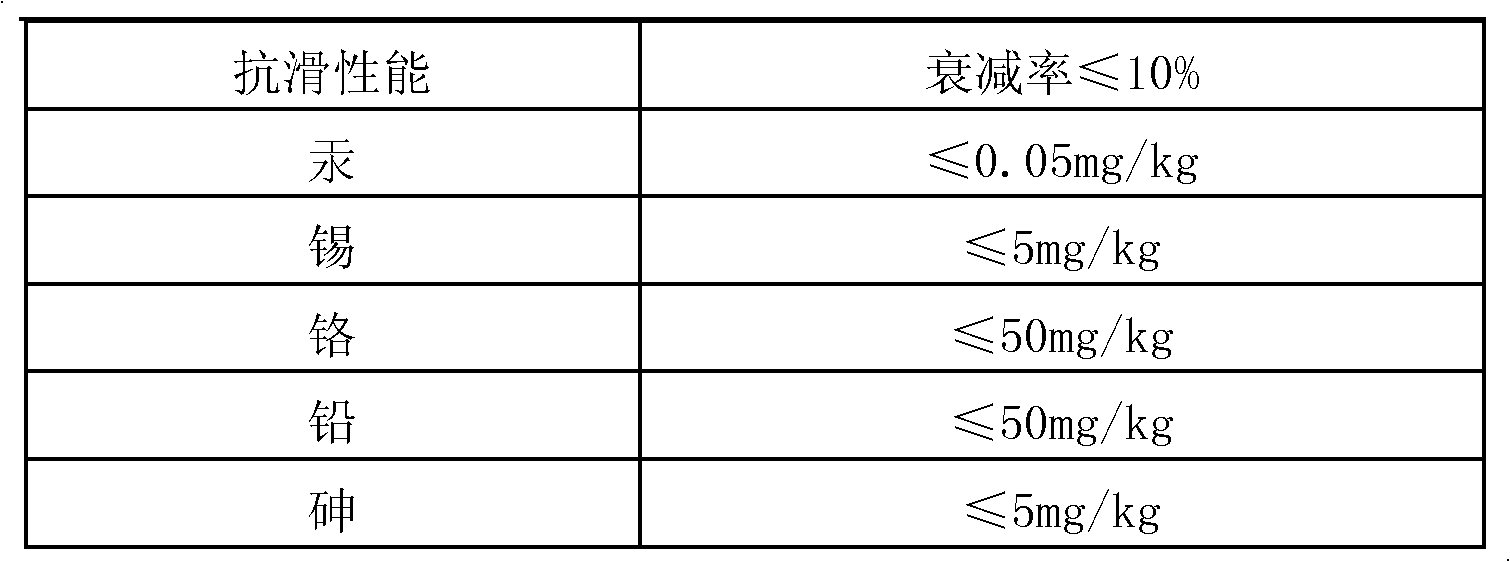

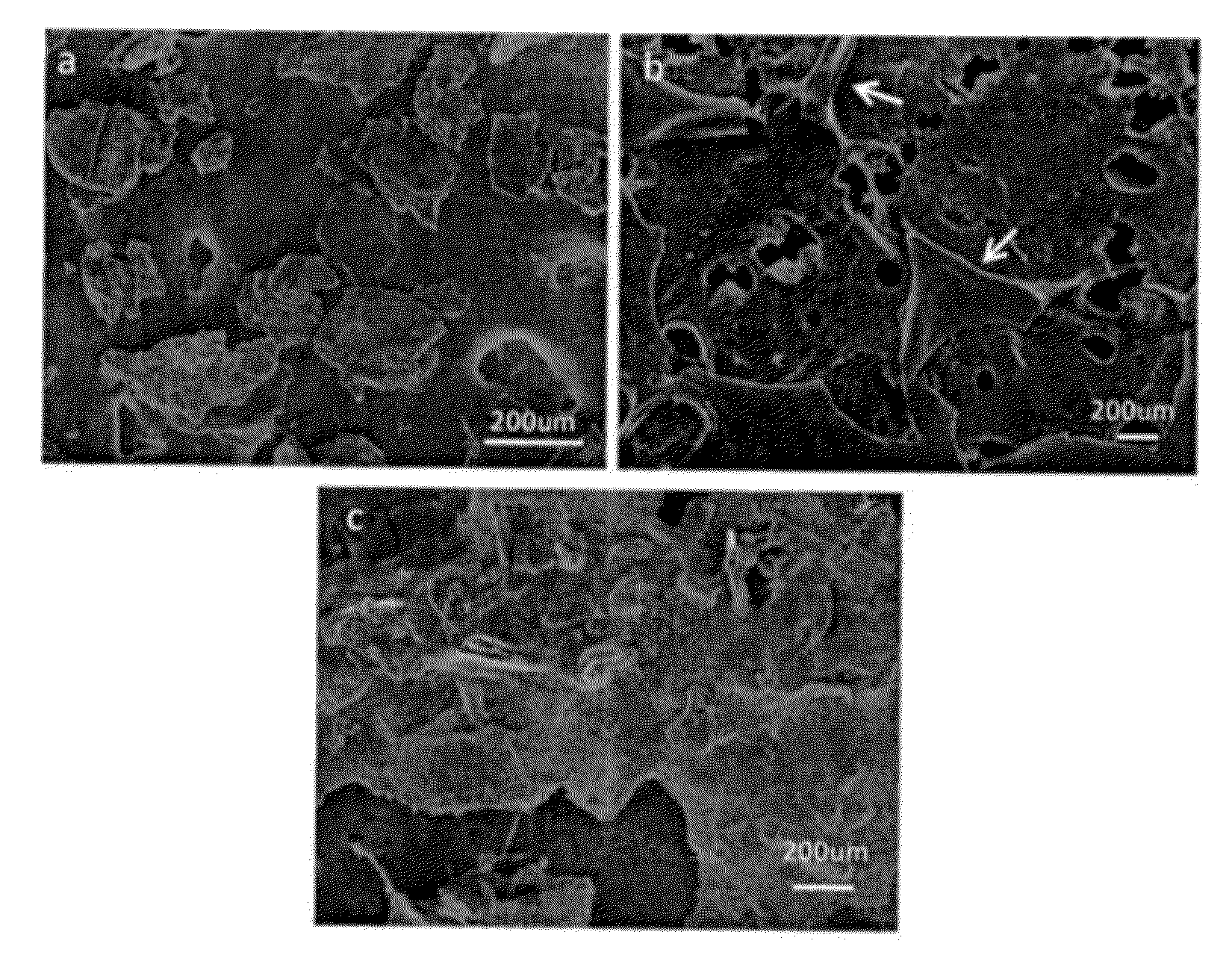

Preparation method for deicing, antiskid and denoising asphalt pavement material

The invention relates to a preparation method for a deicing, antiskid and denoising asphalt pavement material. The method is characterized by comprising the following steps: 1) preparation of rubber modified asphalt with high viscosity and high elasticity; 2) preparation of an organic / inorganic ice inhibiting material; 3) selection of mineral aggregate gradation; 4) preparation of the deicing, antiskid and denoising asphalt pavement material, which is realized by preparing mineral aggregate, the rubber modified asphalt with high viscosity and high elasticity, the organic / inorganic ice inhibiting material and fibers according to a mass ratio of 100: 4.8-5.1: 1.05-2.1: 0.225-0.533, heating the rubber modified asphalt with high viscosity and high elasticity at a temperature of 165 to 175 DEGC, and mixing and stirring the mineral aggregate, the rubber modified asphalt with high viscosity and high elasticity, the organic / inorganic ice inhibiting material and the fibers at a temperature of180 to 190 DEG C for 60 to 90 s, with paving temperature being 165 to 180 DEG C, so as to obtain the deicing, antiskid and denoising asphalt pavement material. The asphalt pavement material prepared by using the method has the characteristics of ice removal, skid resistance and noise reduction.

Owner:WUHAN UNIV OF TECH

Alumina supporter containing modified gamma zeolite and its preparation method

ActiveCN1765492ALowering the freezing pointReduce crackingMolecular sieve catalystsCatalyst activation/preparationIon exchangeMetal

The invention discloses an alumina support containing Y zeolite and relative preparing method. The carrier utilizes the Y zeolite and alumina as carriers, while the property of zeolite can be changed via changing the metallic positive ions between the VIB group and / or VIII group to adjust the acid distribution, especially the proportion of B acid and L acid. The invention can be used a carrier of hydro-treating catalyst to fraction prepare the winter cleaning diesel fuel from poor diesel fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low temperaure catalyst for producing intermediate fraction oil with heavy alkane and its preparation method

InactiveCN1389545AHigh activityHigh yieldMolecular sieve catalystsCatalyst activation/preparationChemistryNickel oxides

There is a kind of low temperature catalyst of mid distillate in producing heavy alkenes, its weight percentage composing is Y zeolite 20%-40%, phosphor-tungsten mixed multi-acid or silicon-tungsten mixed multi-acid 5%-20%, nickel oxide 5-10%, alumina 40-60%. The surface of catalyst 250-450m2 / g, hole capacity 0.45-0.70 ml / g, TPD acidity 0.8-1.9 mmol / g. The catalyst in the invention has strong low-temperature reaction active and mid-oil selectivity to heavy alkenes, it applies to process of hydrogenation cracking which creates mid-distillate.

Owner:SYNFUELS CHINA TECH CO LTD

Ice-covering-proof coating containing electrolyte

ActiveCN102140288ALowering the freezing pointTo achieve the effect of anti-icingAntifouling/underwater paintsPaints with biocidesHigh pressureSolvent

The invention discloses an ice-covering-proof coating containing electrolyte, which consists of organic silicon modified polyelectrolyte, silicon fluoride modified acrylic ester, nanometer material, dissolvent, pigment, aleveling agent, a fire retardant and preservatives and bactericides. All the materials are as follows according to mass percents: 5 to 90% of organic silicon modified polyelectrolyte, 0 to 80% of silicon fluoride modified acrylic ester, 0.1 to 20% of nanometer material, 0 to 60% of dissolvent, 0 to 30% of pigment, 0 to 5% of leveling agent, 0 to 10% of fire retardant and 0 to 3% of preservatives and bactericides. The ice-covering-proof coating is obtained by uniformly grinding all the materials according to the amount. The ice-covering-proof coating is coated on the surfaces of parts such as high-voltage cables, iron towers, telecommunication lines, aircrafts and the like and can effectively prevent the parts from being covered by ice. The method is simple and practical in the engineering, is convenient to control and has lower cost and good using effect.

Owner:张家港楚人新材料科技有限公司

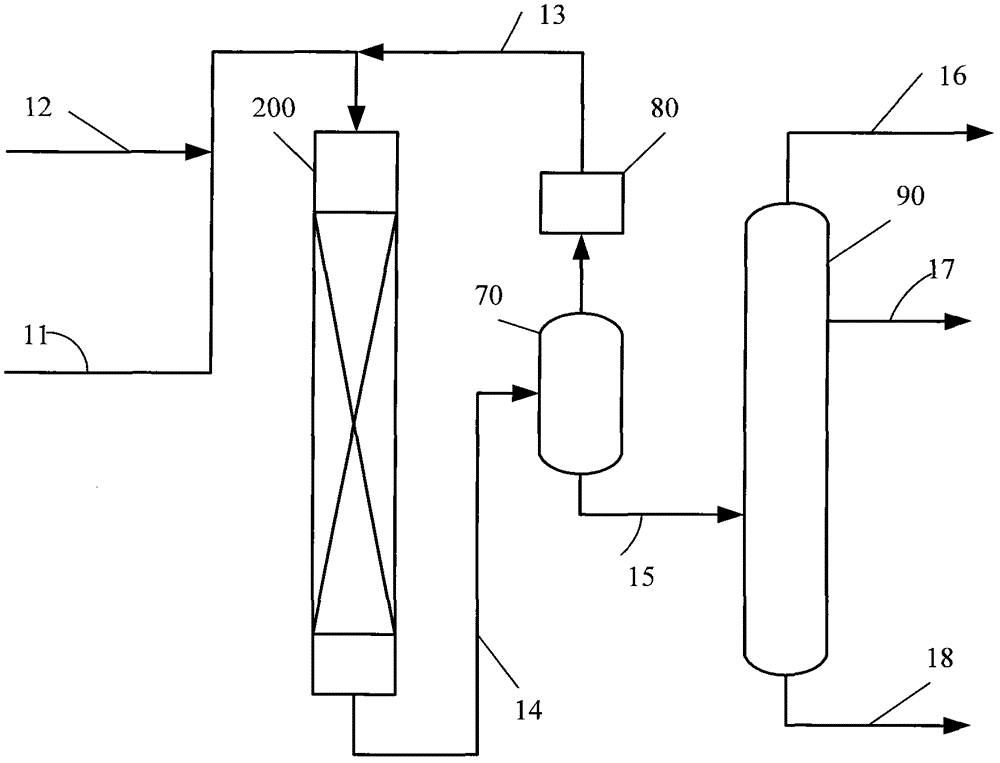

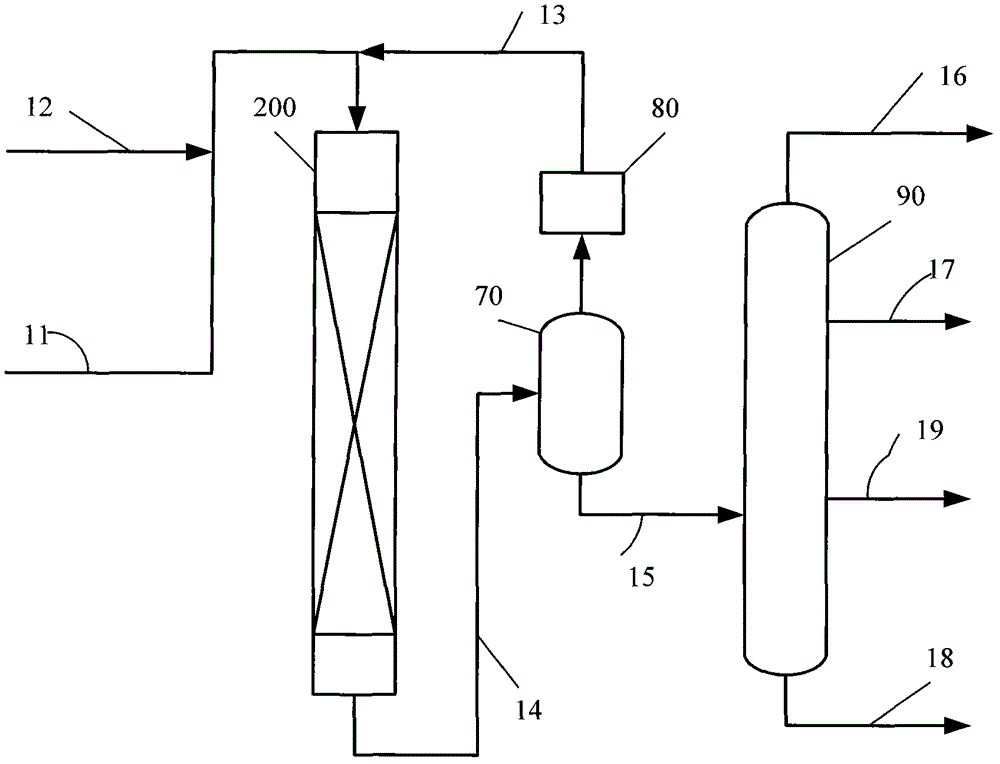

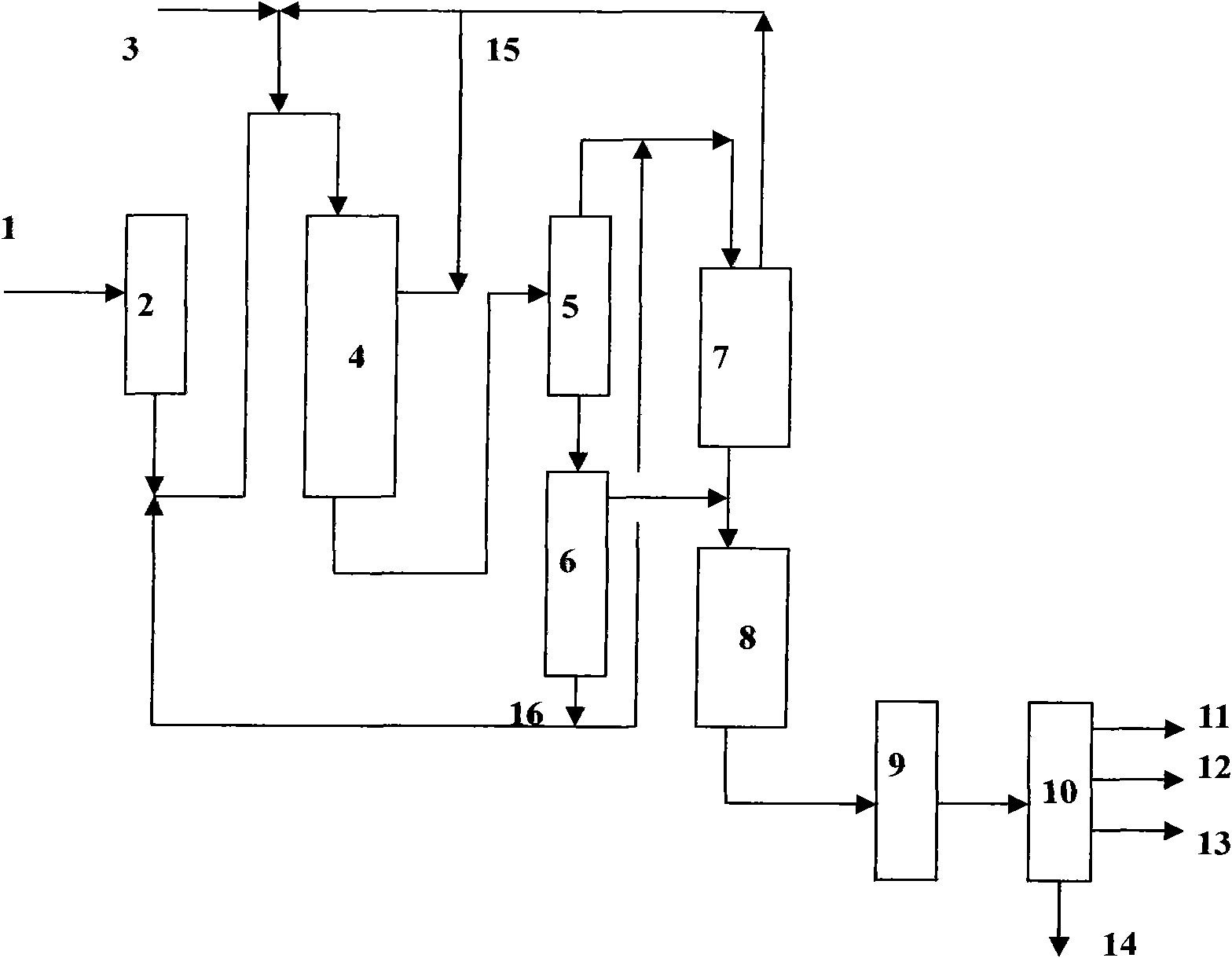

Method for preparing diesel oil component or jet fuel component by using animal and plant oil

ActiveCN103059901AHigh yieldHigh calorific valueLiquid hydrocarbon mixture productionBio-feedstockOil and greaseAlkane

The invention provides a method for preparing a diesel oil component or jet fuel component by using animal and plant oil. The method comprises the following steps of: (1) dividing the animal and plant oil into at least two parts, introducing the at least two parts of animal and plant oil to a plurality of catalyst beds of a first hydrogenation reactor, and enabling the at least two parts of animal and plant oil and a hydrodeoxygenation catalyst to contact and react to obtain n-alkanes with the carbon number of 8-24; (2) filling an isomerization catalyst in a second hydrogenation reactor, introducing a reaction product obtained in the step (1) to the second hydrogenation reactor, and reducing a condensation point after isomerization reaction to obtain a diesel oil component; or, (3) filling a selective cracking catalyst in the second hydrogenation reactor, introducing the reaction product obtained in the step (1) to the second hydrogenation reactor, and then, carrying out selective hydrocracking and isomerization to obtain a jet fuel blending component. The method provided by the invention is high in jet fuel yield; and the prepared jet fuel blending component is good in quality and can be mixed with the traditional petroleum-based jet fuel according to any proportion so as to be an excellent blending component.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude oil pour point depressant and preparation method thereof

ActiveCN101845299ADosage is smallLarge range of pour point reductionDrilling compositionMaleic anhydrideWax

The invention discloses a crude oil pour point depressant, which is compounded by the following components in percentage by weight: 99.0 to 99.8 percent of quadripolymer, 0.1 to 0.5 percent of fumed silica, and 0.1 to 0.5 percent of nonionic fluorocarbon surfactant, wherein the quadripolymer is formed by polymerizing monomer higher alcohol acrylate, methylacrylic acid, maleic anhydride, and styrene. The crude oil pour point depressant has the advantages of small dosage, great pour point depression, excellent wax resistance effect, and the like. The experimental results prove that: the pour point depressant obviously lowers the condensation point of the crude oil, widens the Newton fluid temperature range of the crude oil, and reduces the viscosity at non-Newton fluid temperature. In the application of Jianghan oilfield, the freezing point of the crude oil can be reduced to 7 DEG C below zero from 25 DEG C by adding 0.025 mass percent of the pour point depressant, the reduction range is 32 DEG C, and the on-site using effect is good.

Owner:HUBEI UNIV +1

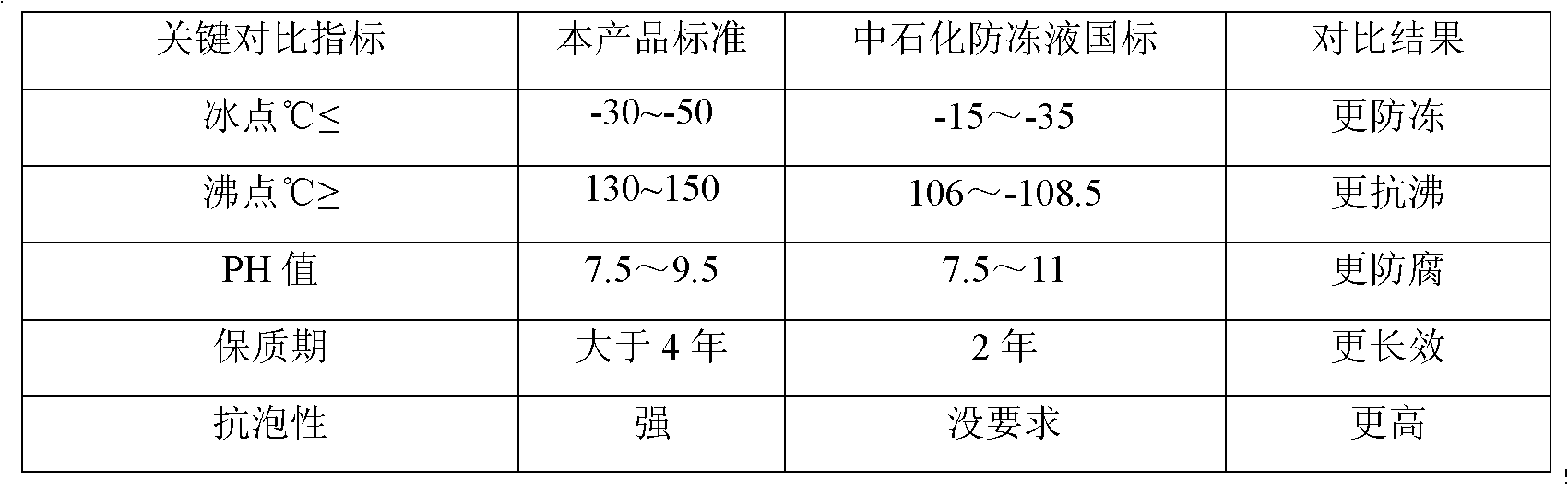

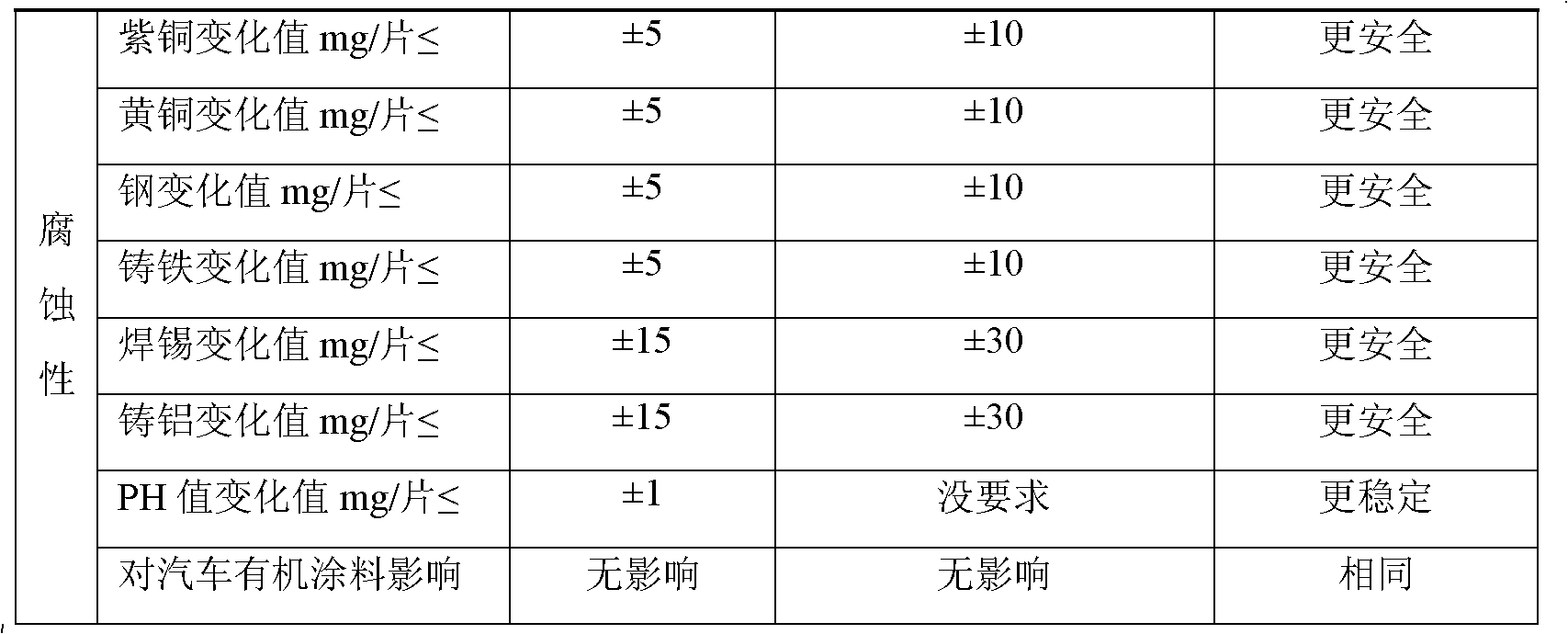

Non-aqueous coolant for engine

ActiveCN102002347AStable pHImprove antifreeze effectHeat-exchange elementsOctanoic AcidsPhosphoric acid

The invention relates to a non-aqueous coolant for an engine, which is characterized by comprising the following components in percent by weight: 10-80 percent of ethylene glycol, 10-80 percent of propylene glycol, 5-20 percent of polyol, 0.1-0.8 percent of phosphate-molybdate, 0.2-0.9 percent of silicate ester, 0.1-1 percent of 4-methyl 1H-benzotriazole, 0.2-0.8 percent of citric acid, 0.2-1 percent of sebacic acid, 0.1-1 percent of octanoic acid, 0.4-1.2 percent of citrate and 0.01-0.2 percent of cosolvent. The non-aqueous coolant has freezing point of -30--50 DEG C and boiling point of 130-150 DEG C, and ensures that the cold start of the engine is realized in cold weather; meanwhile, the working temperature of the engine is improved to 95-150 DEG C from the original 85-95 DEG C. The non-aqueous coolant belongs to a non-aqueous system, avoids electrochemical corrosion, and is a buffer system with pH of 7.5-9.5; and the added relevant auxiliaries have active corrosion resistance on aluminum and aluminum alloy and copper.

Owner:HEFEI UNIV OF TECH

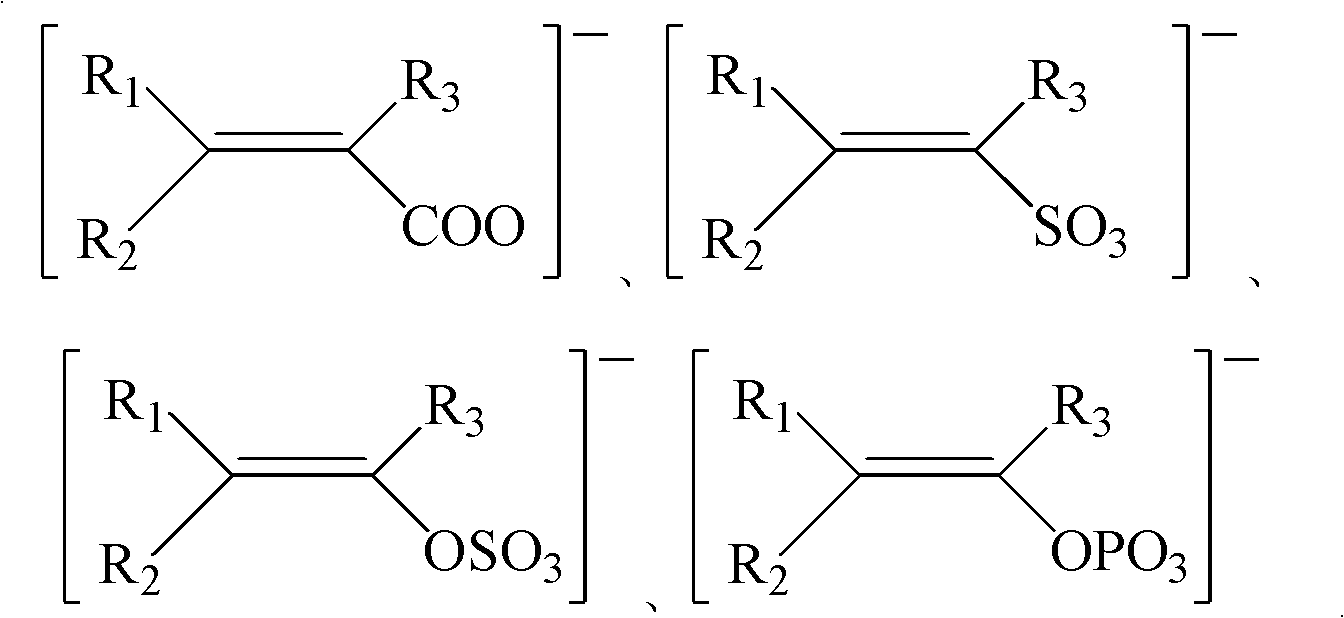

Coal flotation agent and preparation method thereof

The invention discloses a coal flotation agent. The coal flotation agent is prepared from the following materials in parts by weight: 100 parts of oil-containing sludge, 100-400 parts of water, 0.25-1.5 parts of emulsifying agent, 0.1-5 parts of viscosity reducer and 0-5 parts of foaming agent. Besides, the invention further discloses a preparation method of the coal flotation agent. The coal flotation agent disclosed by the invention adopts the oil-containing sludge as the materials, and is added with the emulsifying agent, the viscosity reducer, the foaming agent and water. The produced coal flotation agent is an emulsion type coal flotation agent, so that the flotation agent is easy to disperse in a water phase during a coal flotation process, and therefore, the collection efficiency is improved. The condensation point of the oil-containing sludge is higher, and the added pour point reducer can be used for lowering the condensation point of the oil-containing sludge, so that the oil-containing sludge is improved in mobility and convenient to disperse; besides a foaming effect and a foam stabilizing effect, the added foaming agent can be used for achieving the effect of a cosurfactant during a process of preparing the emulsion type coal flotation agent, and can be cooperated with the emulsifying agent to stabilize the emulsion; and the added water can be used for improving the proportion of a continuous phase, and therefore, the coal flotation agent is beneficial to preparing oil-in-water emulsion.

Owner:陕西延长石油矿业有限责任公司 +1

Method for producing high grade of diesel oil from charking full distillate oil

ActiveCN101003750ALowering the freezing pointLittle impact on yieldTreatment with hydrotreatment processesGasoline stabilisationNaphthaEnergy consumption

This invention discloses a method for producing high-quality diesel oil from whole fraction oil of coking. The method comprises: separating whole fraction of coking into light fraction oil of coking (containing part of light diesel oil fraction) and heavy fraction oil of coking (containing heavy diesel oil fraction), hydrogenation-modifying heavy fraction oil of coking in the presence of beta-zeolite-containing hydrogenation catalyst, mixing the modification product with light fraction oil of coking, and hydrogenation-refining. The method can obtain high-quality clean diesel oil and high-quality naphtha, and has such advantages as simple process and low energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

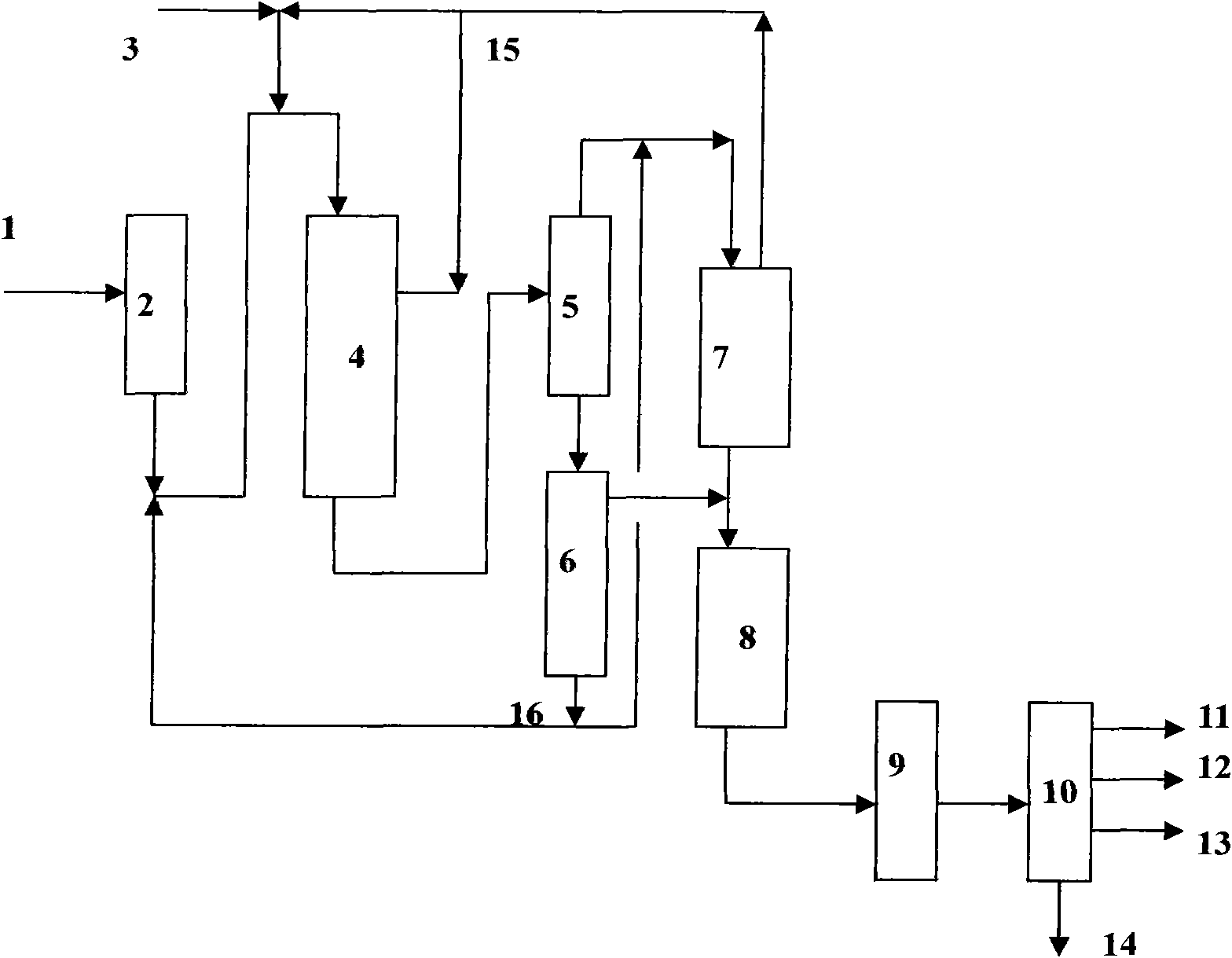

Hydrocracking method for blending ethylene tar

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

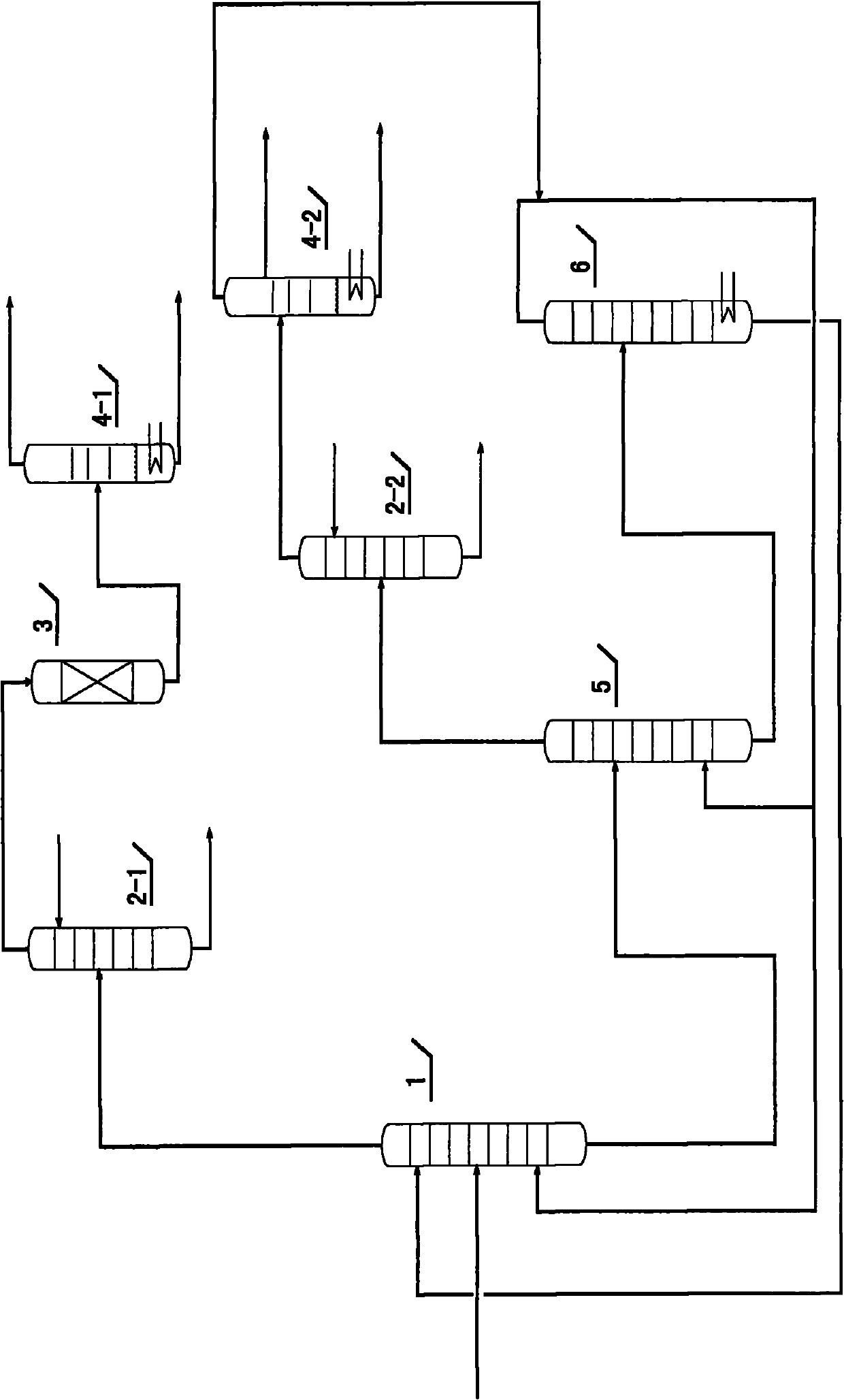

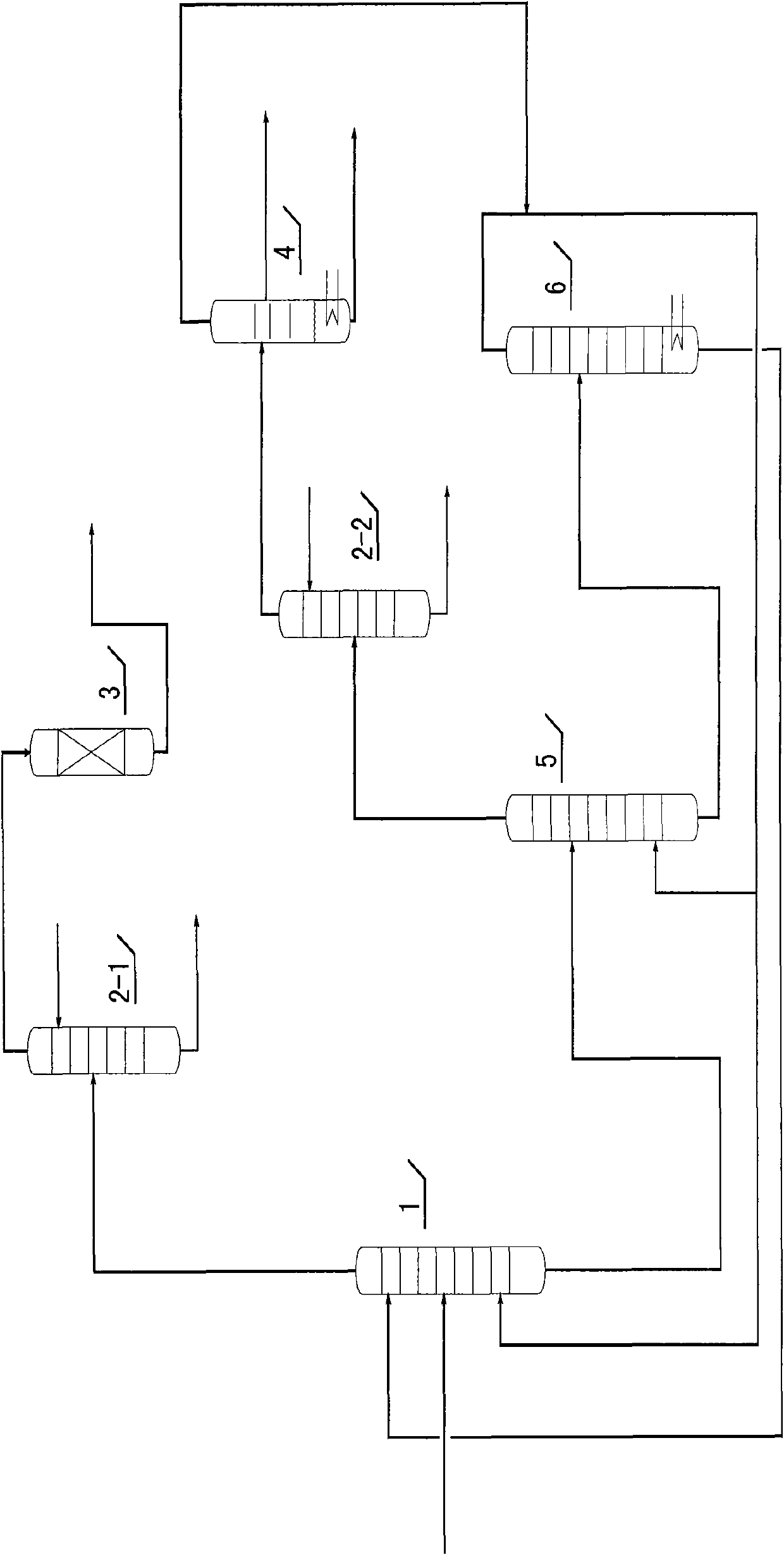

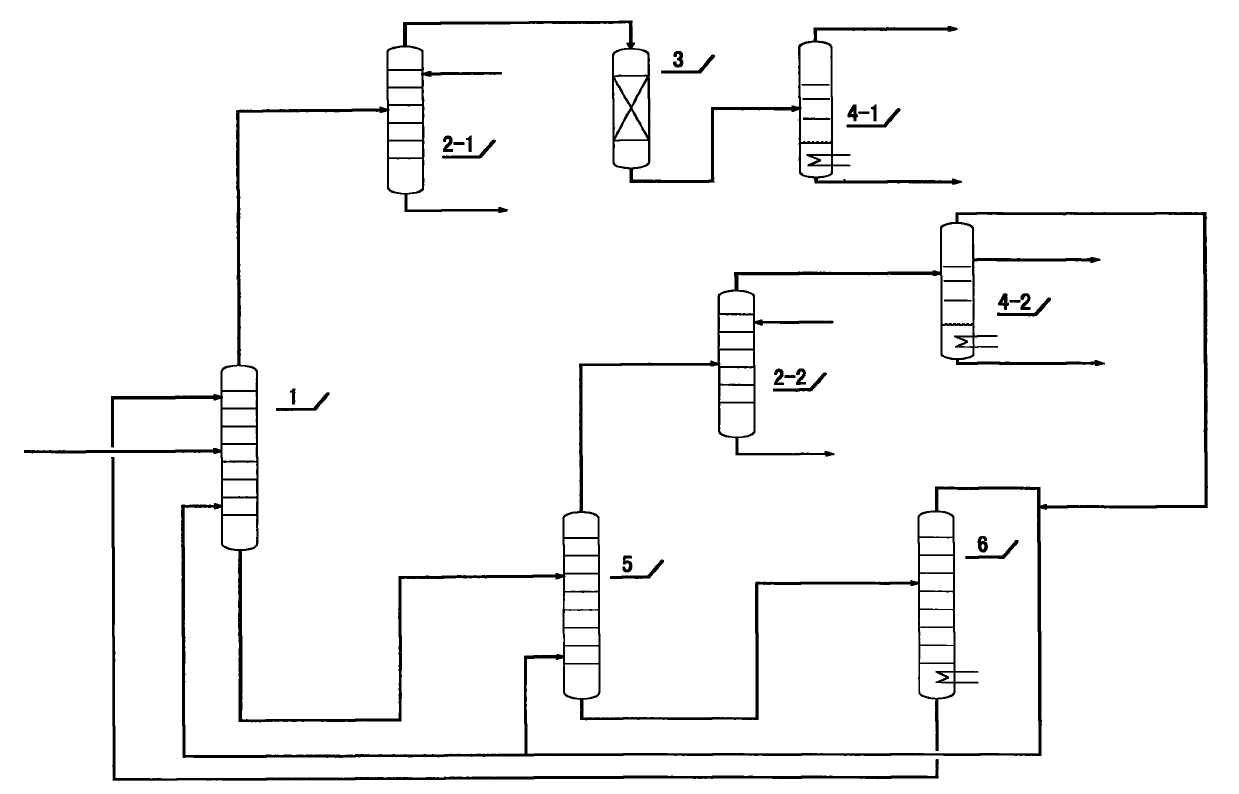

System for producing diesel of high quality and method thereof

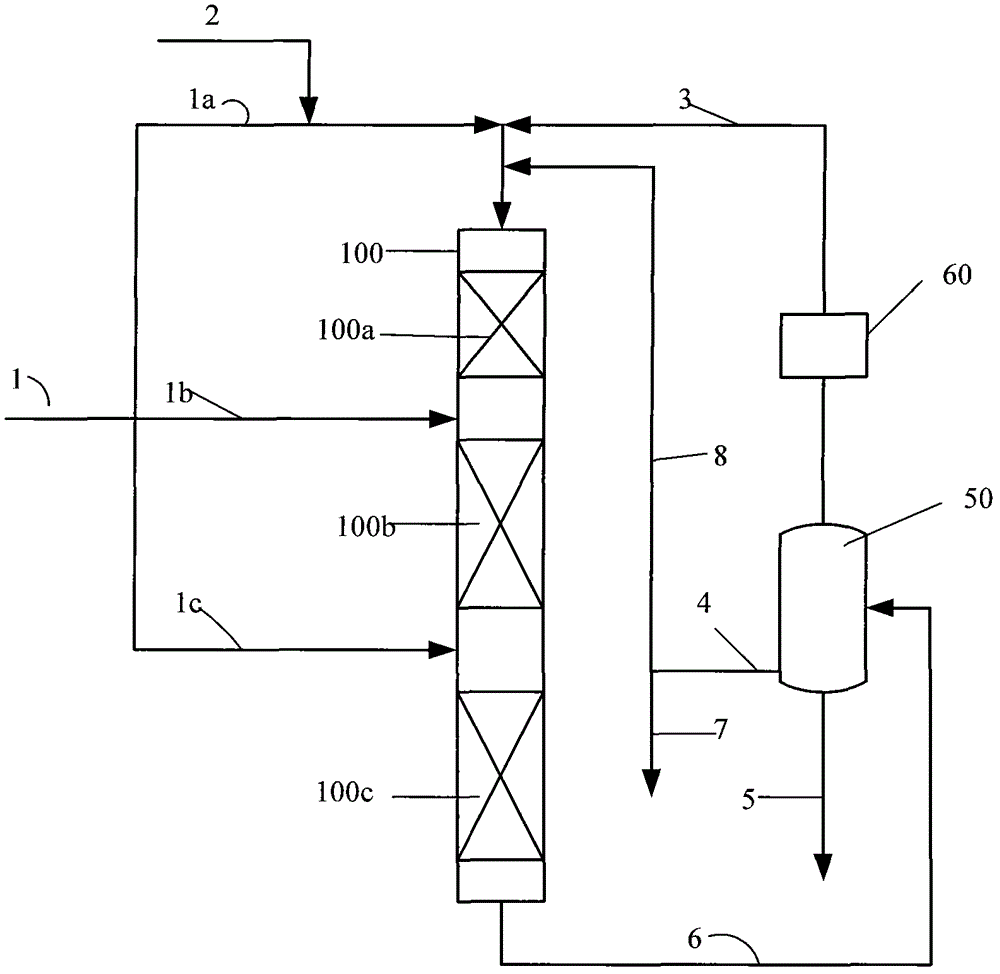

ActiveCN102021024AIncrease cetane numberLowering the freezing pointTreatment with hydrotreatment processesHydrogenation reactionPulp and paper industry

The present invention relates to a system for producing diesel of high quality and method thereof. The system comprises an extraction unit. The system is characterized in that the top of the extraction unit is connected with a raffinate-oil washing tower via pipes, the top of the raffinate-oil washing tower is connected with a hydrogenation reaction system via pipes, products are extracted from the bottom of the hydrogenation reaction system via pipes, the bottom of the extraction unit is connected with a return washing tower via pipes, the top of the return washing tower is connected with an extract-oil washing tower via pipes, the bottom of the return washing tower is connected with a recovery tower, the top of the extract-oil washing tower is connected with a extract-oil cutting tower via pipes, the top of the extract-oil cutting tower is connected respectively with the bottom of the extraction unit and connected with the bottom of the return tower via pipes, light aromatic hydrocarbon products are directly extracted out from the side lines of the extract-oil cutting tower via pipes, heavy aromatic hydrocarbon products are directly extracted out from the bottom of the extract-oil cutting tower via pipes, the top of the recovery tower is connected respectively with the bottom of the extraction unit and the bottom of the return tower, and the bottom of the recovery tower is connected with the top of the extraction unit via pipes. The hydrogenation unit is only applied to raffinate oil and extract oil with special requirements, so that the scale is small and the cost is low. Moreover, the diversification of raw materials processed by the system is obvious. Not only can straight-run diesel oil can be processed, but also the catalyzed diesel oil and the coking diesel oil can be processed. In addition, the invention separates aromatic hydrocarbon from diesel oil, therefore the cetane number of the diesel oil is improved greatly.

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

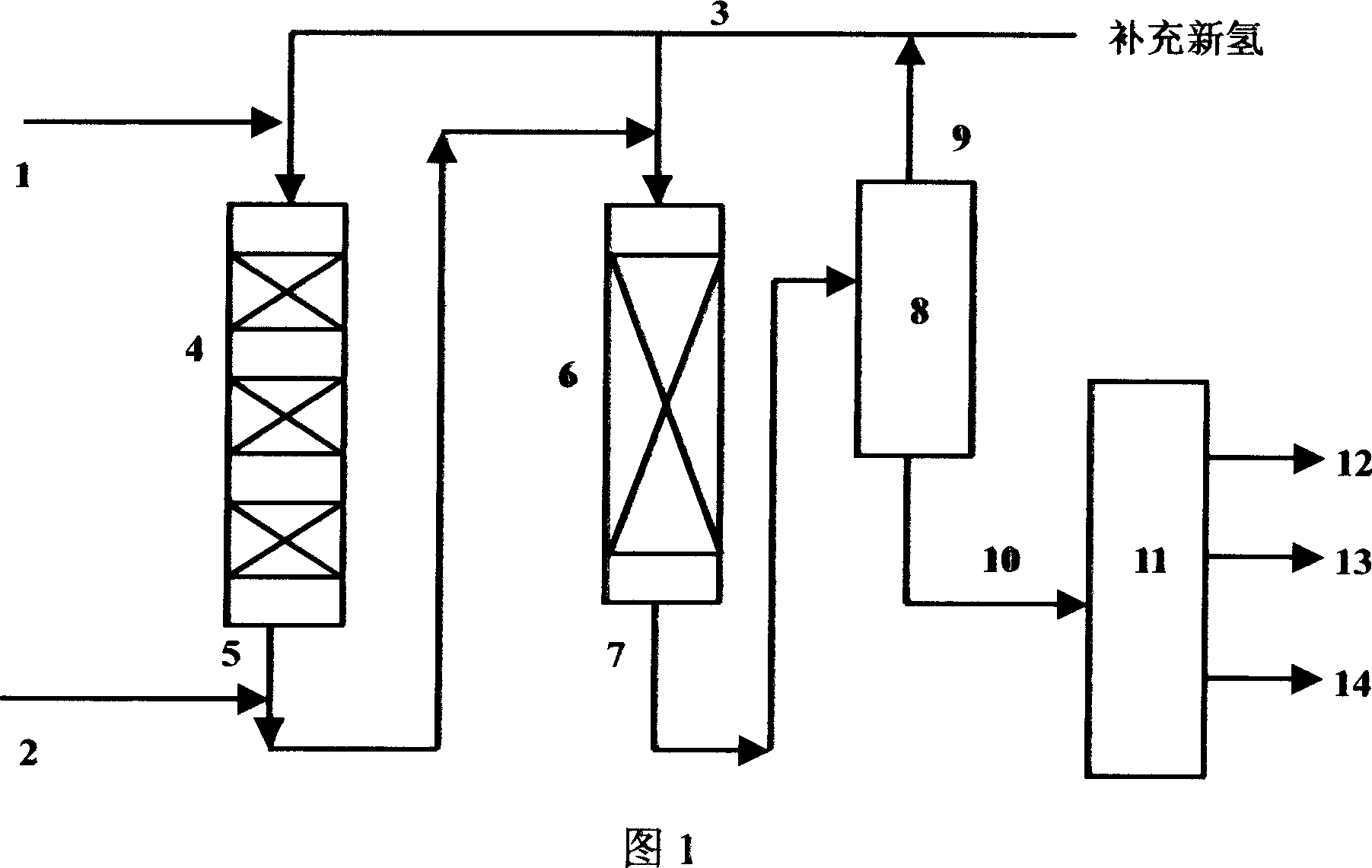

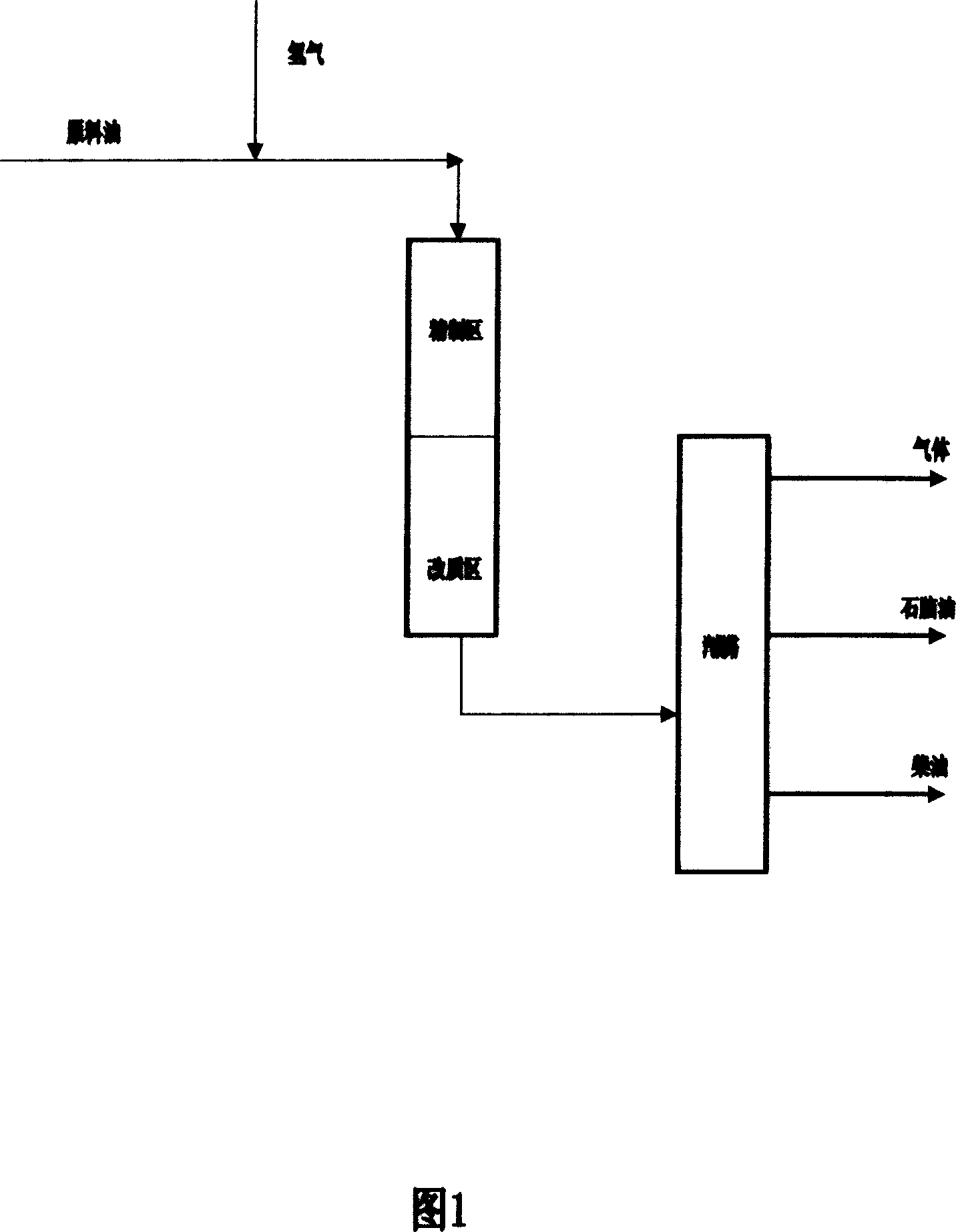

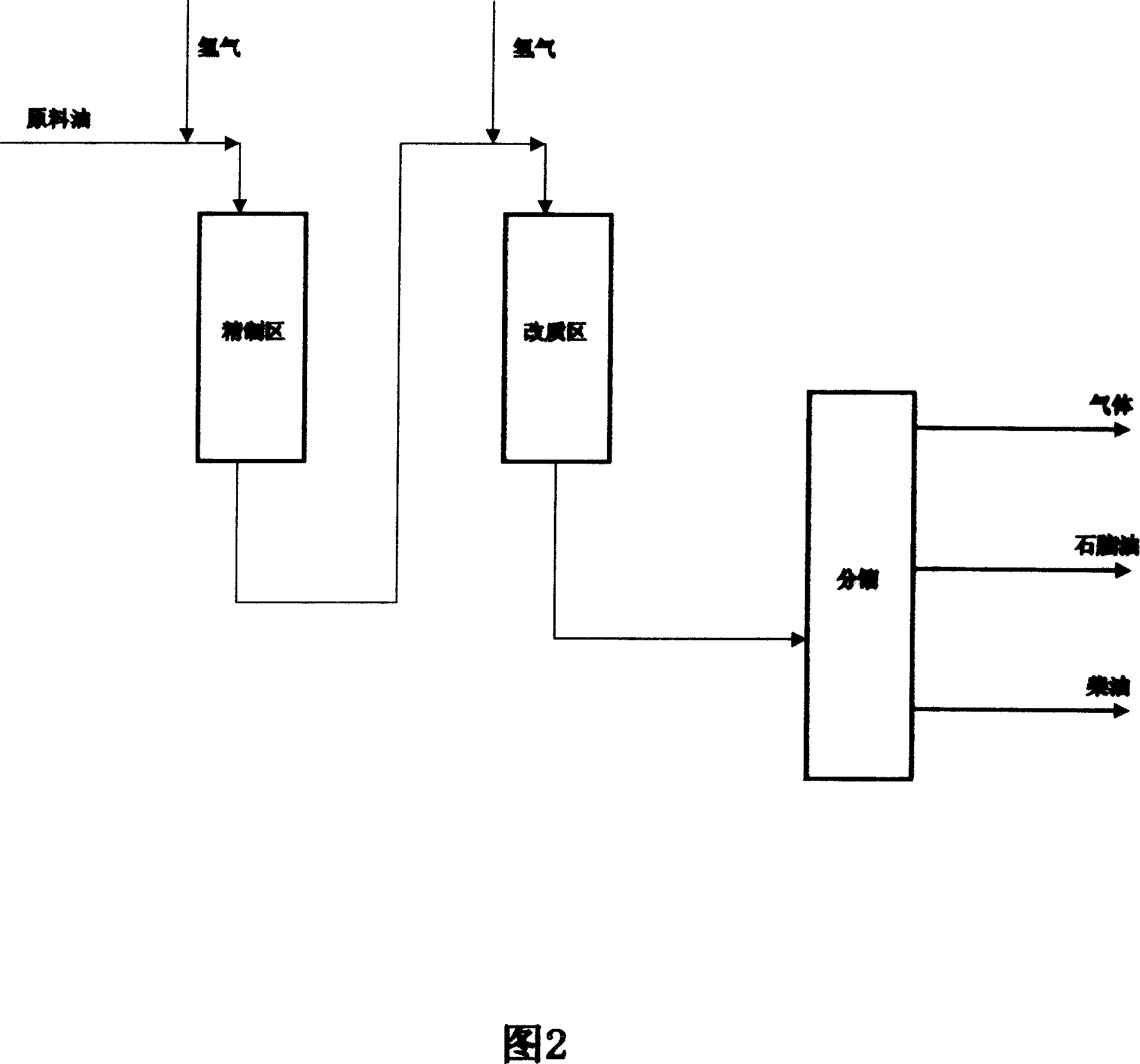

Hydrogenation for producing high-bioctyl-value and low-freezing-point diesel oil

ActiveCN1896187AIncrease cetane numberLowering the freezing pointRefining to eliminate hetero atomsLiquid productHydrogen

Hydrogenation of low-set point and high-cetyl value diesel oil is carried out by contacting raw material oil with hydrogen and hydrogenation refined catalyst in the first reactive area, entering reactant into the second reactive area to contact with hydrogenation modified catalyst, cooling, separating, returning the hydrogen-enriched gas separated into reactor to reuse, and entering the liquid product into fractional system. It has higher recovery rate, more cetyl of diesel oil and lower set point.

Owner:CHINA PETROLEUM & CHEM CORP

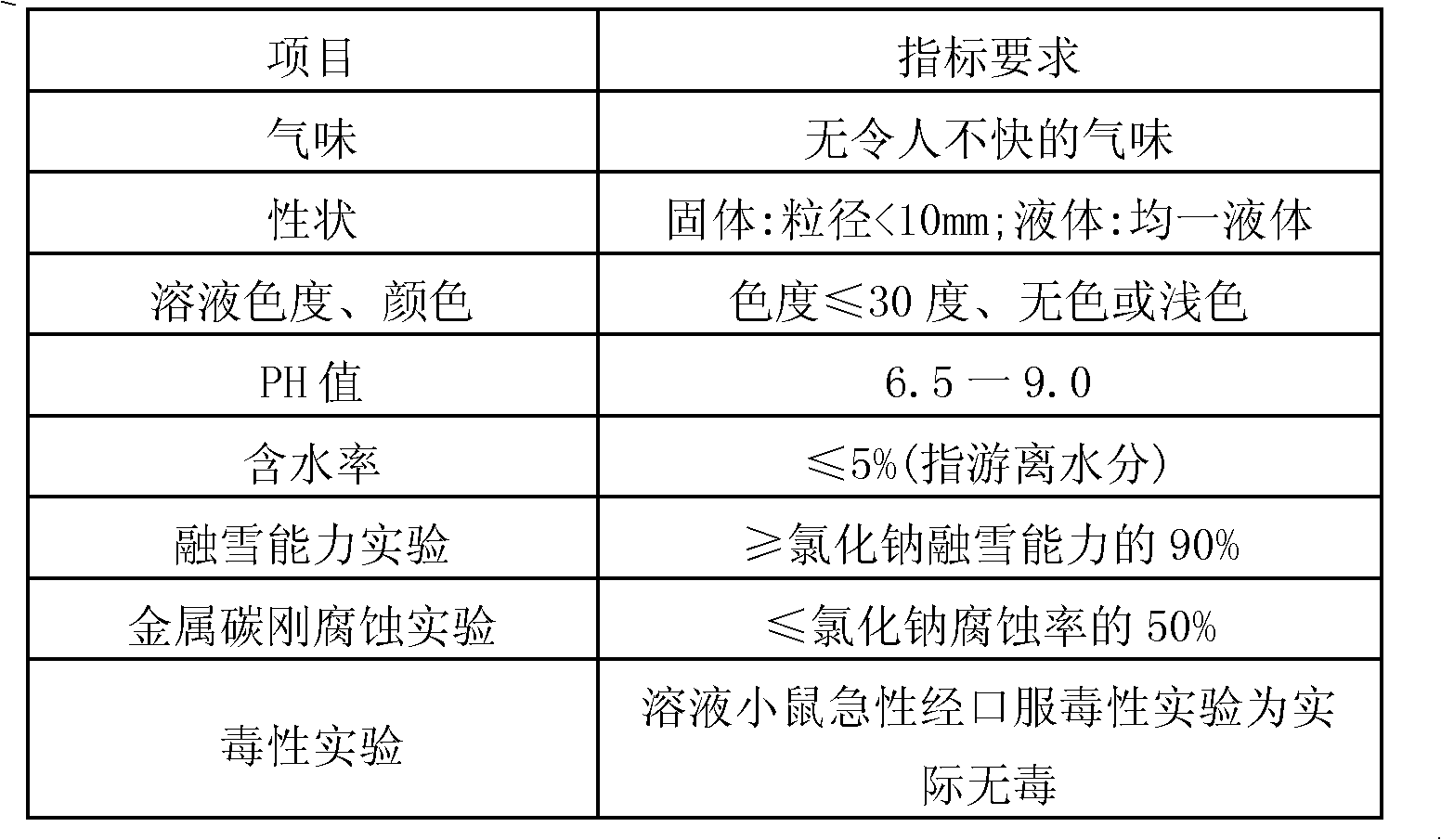

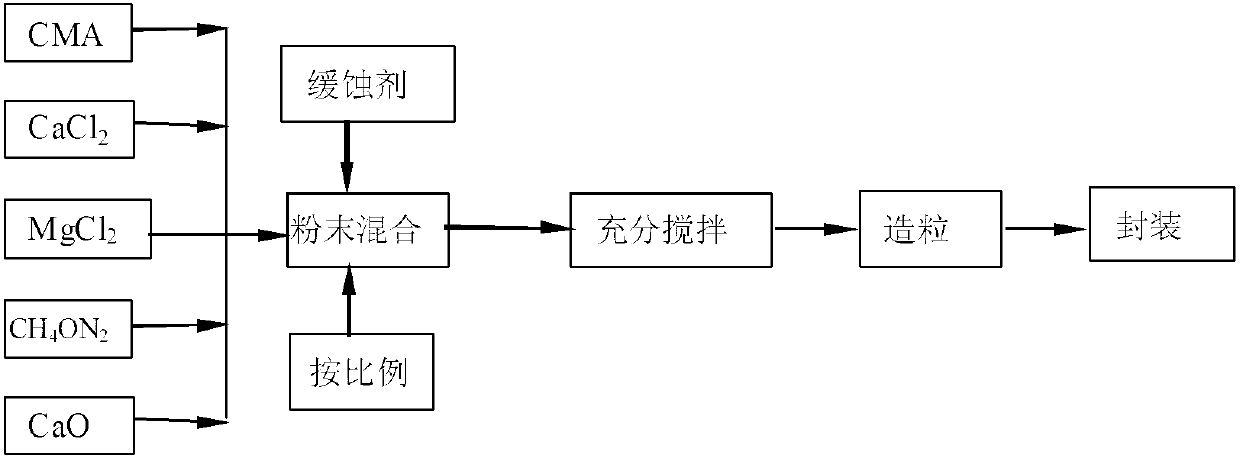

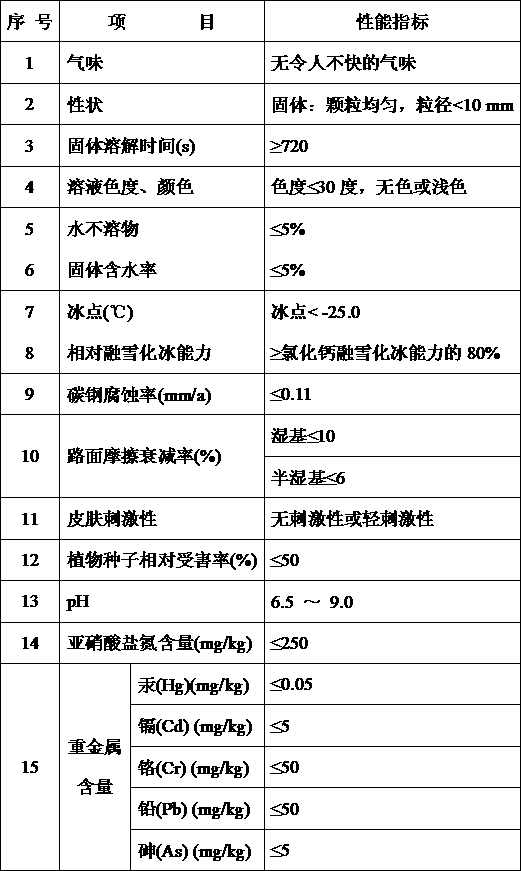

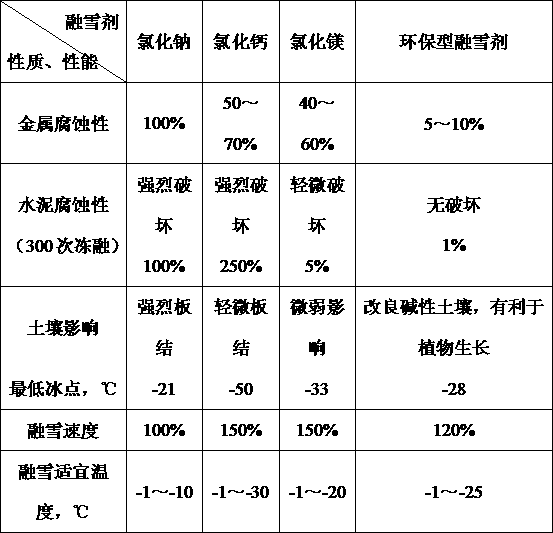

Environment-friendly snow melting agent and preparation method thereof

ActiveCN103342988AReduce manufacturing costSimple production processOther chemical processesSnow meltingEthylic acid

The invention relates to an environment-friendly snow melting agent and a preparation method of the snow melting agent, and belongs to the field of the snow melting agents. The snow melting agent is prepared from acetates and chlorine salts with low corrosivity as the main raw materials by mixing acetates including potassium acetate, magnesium acetate and calcium acetate with calcium chloride and magnesium chloride in a certain proportion, as well as a small quantity of corrosion inhibitor. The common fault that a common inorganic snow melting agent is high in corrosivity is effectively overcome, the cost is reduced, and therefore the snow melting agent is suitable for promotion and application.

Owner:SHENYANG POLYTECHNIC UNIV

Hydrogenation catalyst carrier and production thereof

A carrier of hydrocatalyst for the hydrocracking of heavy oil, hydromodifying of poor diesel oil, etc is prepared from amorphour silicon aluminium, modified beta-molecular sieve and aluminium oxide. Its preparing process is also disclosed. Said catalyst has high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diesel oil fraction upgrading and pour point reducing process

ActiveCN101089135AReduce usageReduce contentRefining to eliminate hetero atomsHydrogenOxidation stability

The diesel oil fraction upgrading and pour point reducing process has the mixture of diesel oil material and hydrogen passing through the hydroupgrading reaction region to result in diesel oil with low solidification point through reaction under certain condition. The catalyst in the hydroupgrading reaction region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst, and at least one kind of upgrading catalyst containing beta-zeolite. The present invention can lower the solidification point, 95 vol% point temperature and sulfur content of diesel oil, and raise cetane number and oxidation stability under mild condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing diesel oil and chemical materials by f-t synthetic wax

InactiveCN101177619ALowering the freezing pointHigh activityHydrocarbon oil crackingGasoline stabilisationWaxNaphtha

The invention discloses a method for producing chemical raw material and diesel oil by Fischer-Tropsch synthetic wax and the method is that the Fischer-Tropsch synthetic wax and hydrogen gas contact with hydrogen cracking catalyst under hydrogen cracking condition and then the reaction products are treated by fractionation; diesel distillate obtained is the clean diesel with a low freezing point, while the naphtha cut obtained is high-quality raw material used for cracking of steam to ethane, and distillation range is higher than the hydrogen cracking of tail oil circulation of the diesel oil, wherein, the hydrogen cracking catalyst is the hydrogen cracking catalyst containing Beta zeolite and the weight content of the Beta zeolite in the catalyst is 0.5 percent to 60 percent; the Beta zeolite has properties that SiO2 / Al2O3 molar ratio is 20 to 150 and Na2O less than or equal to 0.2w percent. The method of the invention can prepare the Fischer-Tropsch synthetic wax into the clean diesel oil with a low freezing point and high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

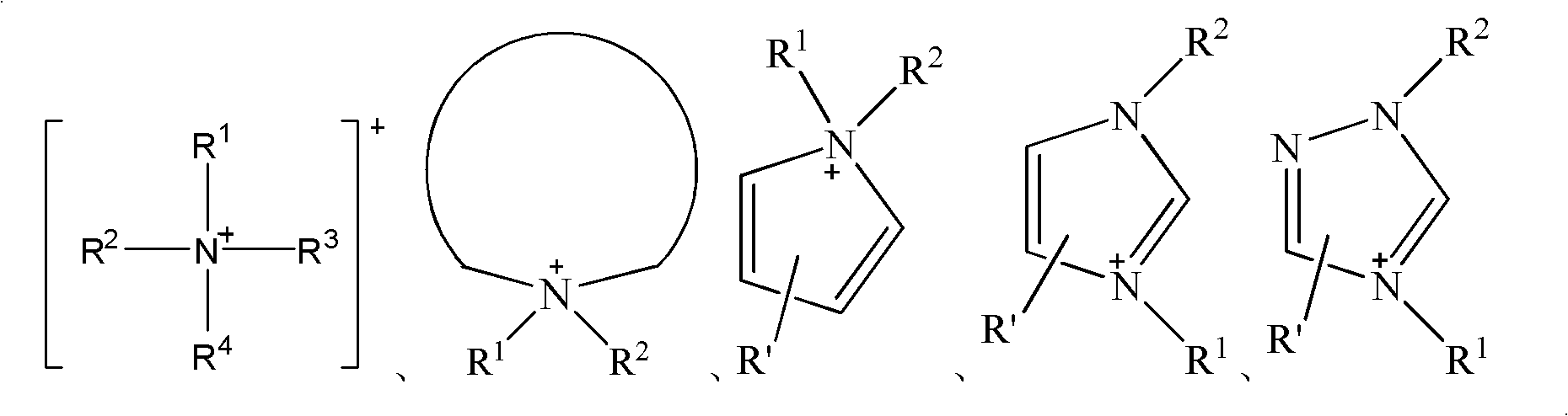

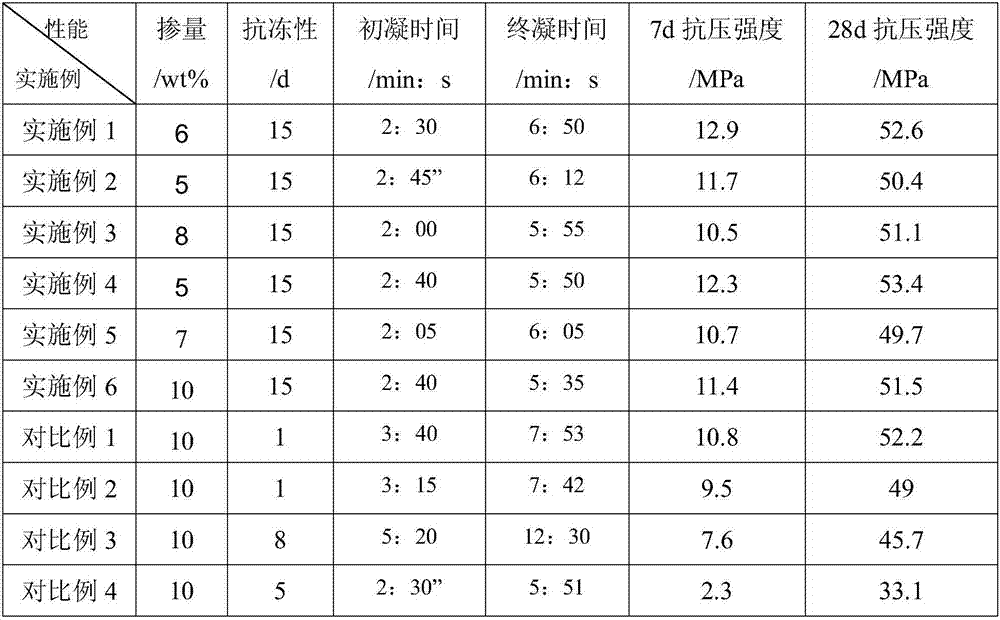

Freezing resistant type alkali-free accelerator, and preparation method and application thereof

The invention discloses a freezing resistant type alkali-free accelerator, and a preparation method and application thereof. The freezing resistant type alkali-free accelerator is prepared by the following steps: aluminum sulfate, an alcohol amine, a fluoride, a stabilizer and water are firstly mixed uniformly to prepare an alkali-free accelerator, and the product is mixed with a freezing resistant liquid containing glycine and soluble starch for reaction, thus the freezing resistant type alkali-free accelerator is obtained. The freezing resistant type alkali-free accelerator has good freezing resistant ability, so that the accelerator can be normally stored and transported in winter, and the freezing resistant type accelerator contains ingredients such as the soluble starch, so that the setting time of the accelerator can be reduced in a synergistic manner, the concrete strength is not influenced, and the practical application of the accelerator is facilitated.

Owner:四川苏博特新材料有限公司 +1

Sealant Composition and Method of Making It

InactiveUS20120118199A1Easy to cleanImprove abilitiesTyre partsOther chemical processesAnti freezingPreservative

Valve-through tire puncture sealant compositions including dissolved and undissolved natural bio-materials, anti-freezing agents and other rigid particles are invented. In the preparation, an aqueous solution with 0.1-10 wt % dissolved bio-materials and 0.1%-10 wt % tackifier is mixed with anti-freezing agent, in which 0.01-5 wt % rigid particles of bio-materials and other particles are suspended. Weight percentage of water and anti-freezing agent are 20-40 wt % and 20-70 wt % respectively. Trace amounts of additives such as colouring and preservative are possibly added to the sealant. The invention includes the method for preparing the sealant composition containing bio-materials. The proposed sealant compositions have several advantages: Environmentally friendly, insignificant settling, long shelf-life, etc. The sealant is capable of sealing puncture formed by less than or equal to 6.35 mm spike for long duration, i.e. more than 30 hours.

Owner:TOP ALLIANCE TECH

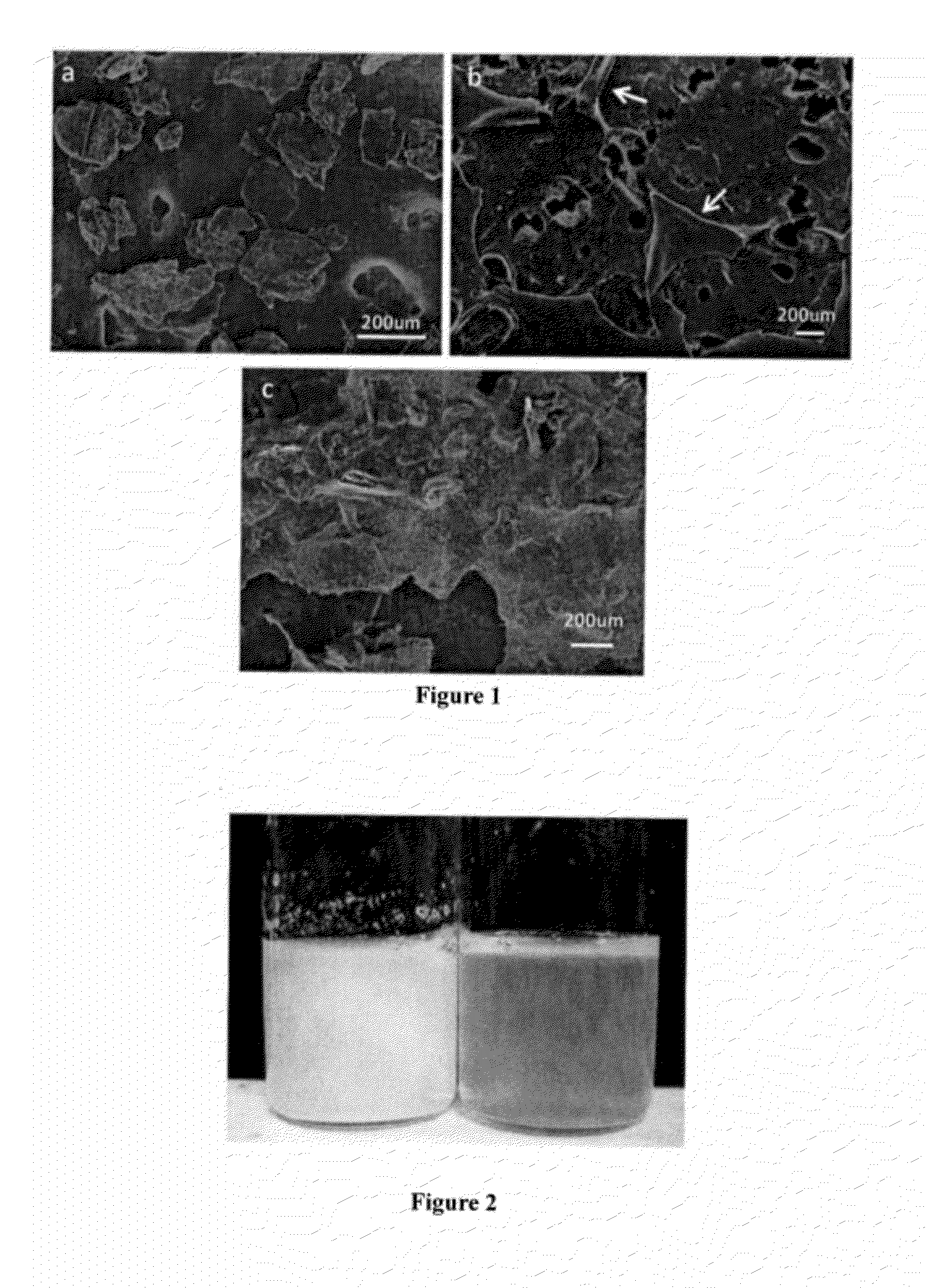

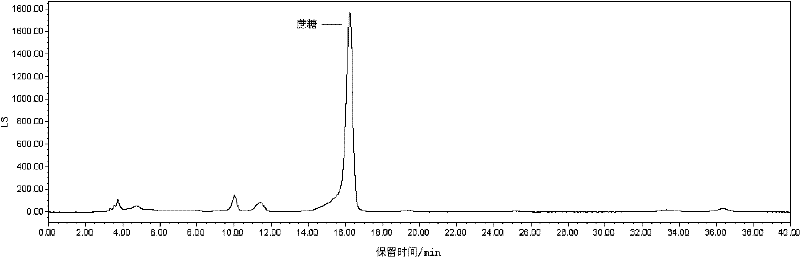

Early evaluating method for tea tree winter resistance

InactiveCN102650622AIncrease osmotic pressureIncrease concentrationComponent separationFloristicsAgroforestry

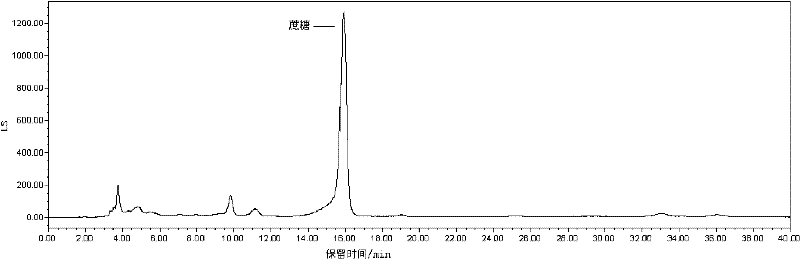

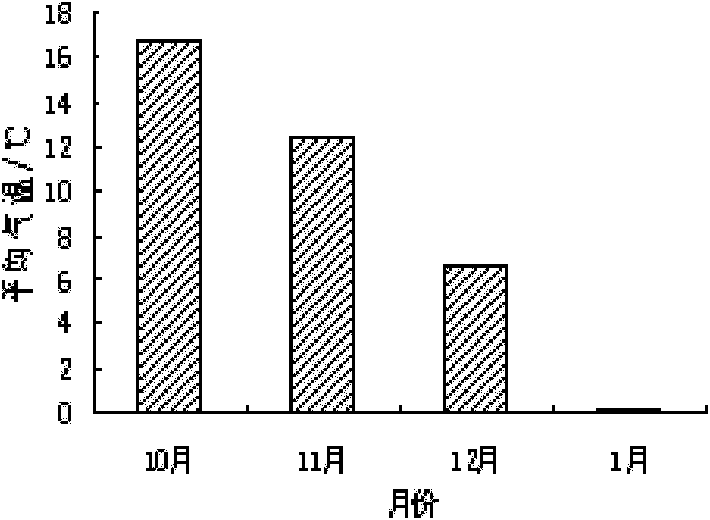

The invention belongs to the field of botany, and particularly relates to an early evaluating method for tea tree winter resistance. The soluble sugar (mainly cane sugar) content is one important physiological basis for the strength of the tea tree winter resistance and one important presentation of the low temperature adaptability of the tea tree variety; and as the temperature is gradually lowered with the approaching of the winter, the cane sugar content of the tea tree leaves is gradually increased, however the tea tree variety with high winter resistance has higher-increased cane sugar content than the tea tree variety with low winter resistance. The early evaluating method for the tea tree winter resistance evaluates the winter resistance of the tea tree by measuring the cane sugar content in the tee tree leaves, so as to evaluate and select the tee tree variety with high winter resistance and provide basis for variety introduction for the tea tree.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com