Hydrodewaxing catalyst and its preparation method

A hydrogen decondensation and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Catalyst Preparation

[0031] 22.4g dry basis content 67wt% small hole alumina (specific surface area is 290m 2 g -1 , pore volume 0.48mL·g -1 ) and 1.5mol / L, 65mL nitric acid aqueous solution were stirred to prepare peptized binder. 45g dry basis content 67wt% macroporous alumina (specific surface 320m2 g -1 , pore volume 1.10mL·g -1 ) and hydrogen nano ZSM-5 molecular sieve 41.2g (grain size is 50nm, specific surface area is 380m 2 g -1 , Manufacturer: Tianjin Shenneng Technology Co., Ltd., SiO 2 / Al 2 o 3 Mole ratio = 25, 97% by weight on a dry basis) was mixed with the above-mentioned peptized binder. Add 1% of the extruding aid squash powder based on the weight of the dry basis of the catalyst to the above mixture, knead and extrude, then dry at 100°C for 4 hours, and roast at 580°C for 6 hours to obtain the carrier. The carrier is impregnated with an equal volume of 70mL impregnation solution containing 12.0g ammonium metatungstate (tungsten oxide 83w...

Embodiment 2

[0036] 1. Catalyst preparation

[0037] 15g dry basis content 67wt% small hole alumina (specific surface area is 290m 2 g -1 , pore volume 0.48mL·g -1 ) and 1.5mol / L, 65mL nitric acid aqueous solution were stirred to prepare peptized binder. 44.7g dry basis content 67wt% macroporous alumina (specific surface area is 350m 2 g -1 , pore volume 0.87mL·g -1 ) and hydrogen nano ZSM-5 molecular sieve 46.4g (grain size is 70nm, specific surface area is 360m 2 g -1 , Manufacturer: Tianjin Shenneng Technology Co., Ltd., SiO 2 / Al 2 o 3 Mole ratio = 50, 97% by weight on a dry basis) was mixed with the above-mentioned peptized binder. Add 1% extrusion aid carbon black to the above mixture, knead and extrude, then dry at 100°C for 4 hours and calcined at 580°C for 6 hours to obtain the carrier. The above carrier is impregnated with an equal volume of 65mL impregnating solution containing 12.0g ammonium metatungstate (tungsten oxide content 83wt%) and 20.8g nickel nitrate (nicke...

Embodiment 3

[0041] 1. Catalyst preparation

[0042] The specific preparation process is the same as in Example 1, except that the catalyst proportioning ratio is different. Small pore alumina 15.0g; macroporous alumina 44.7g, hydrogen nano ZSM-5 molecular sieve 51.5g (grain size is 80nm, specific surface area is 360m 2 g -1 , Manufacturer: Tianjin Shenneng Technology Co., Ltd., SiO 2 / Al 2 o 3 Molar ratio=80, dry basis 97wt%), ammonium metatungstate (tungsten oxide 83wt%) 8.4g, nickel nitrate (nickel oxide 24wt%) 12.5g, obtain catalyst C, its properties are shown in Table 1.

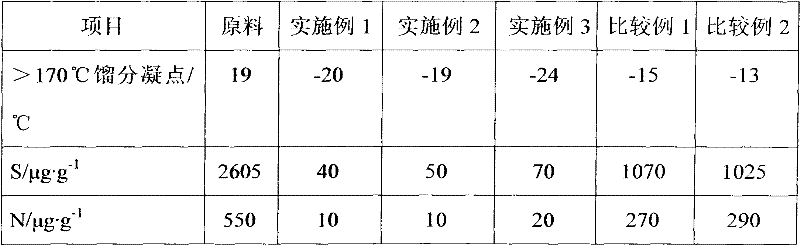

[0043] 2. Process evaluation

[0044] Process conditions are the same as in Example 1, and the reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com