Patents

Literature

464results about How to "Reduced compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

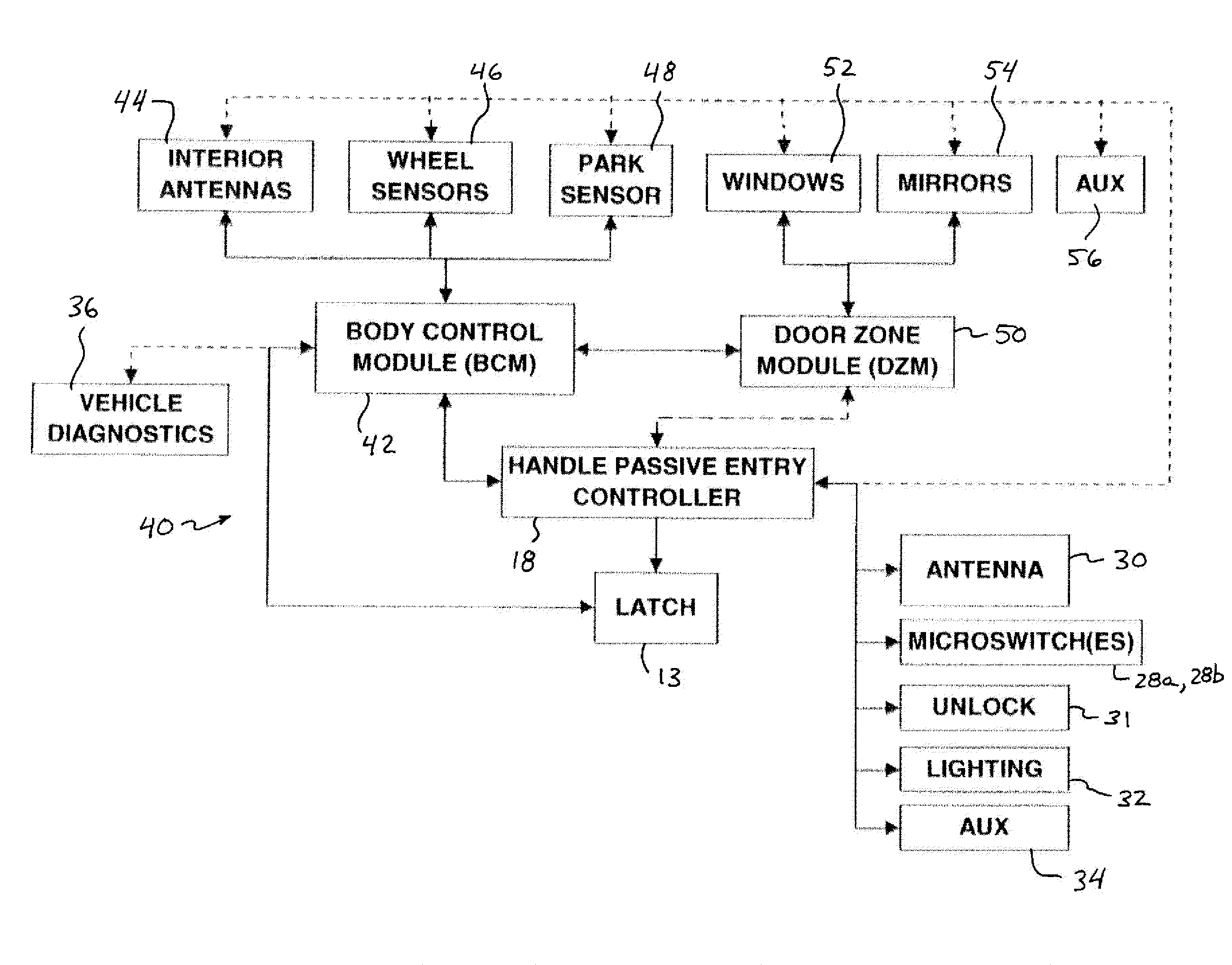

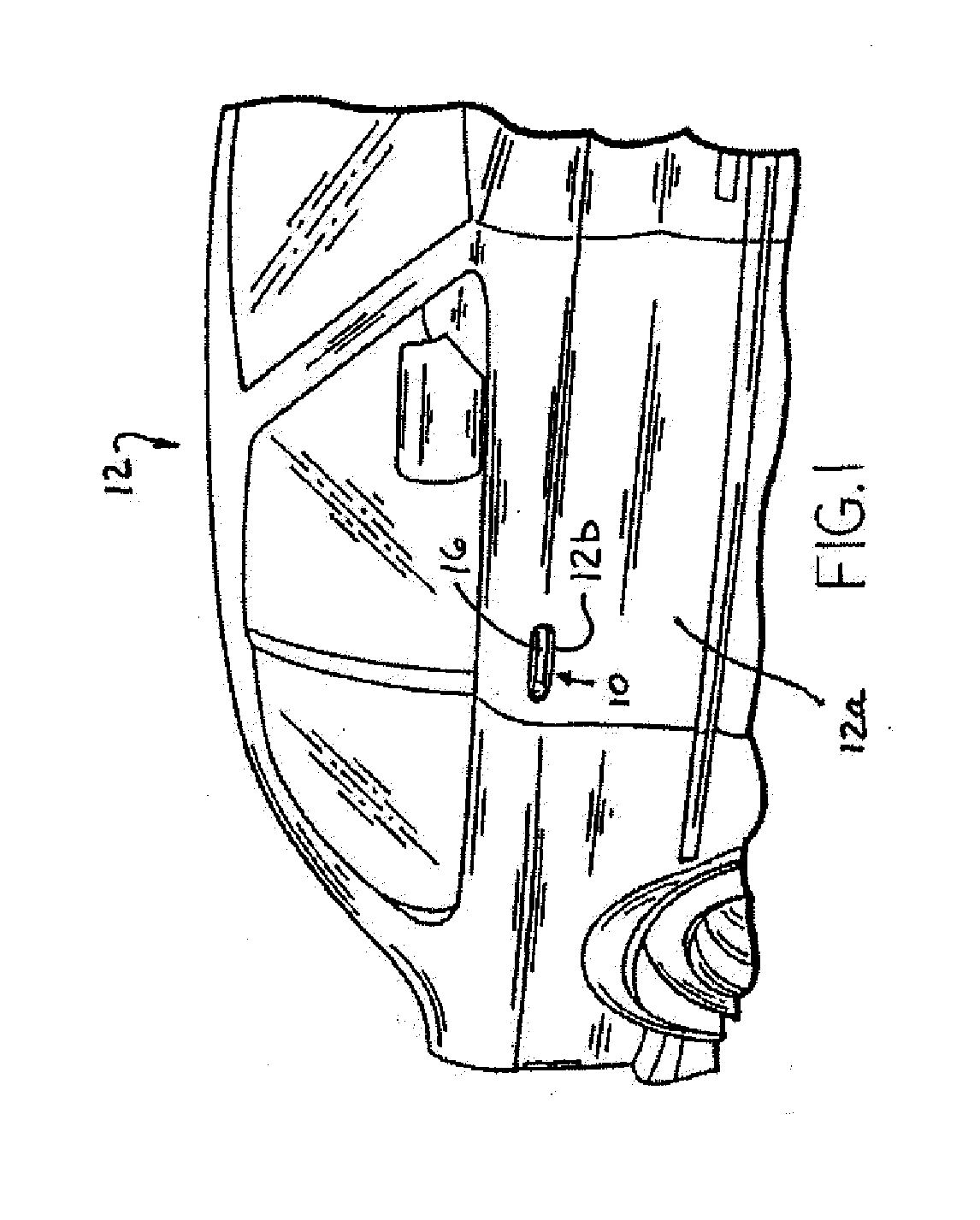

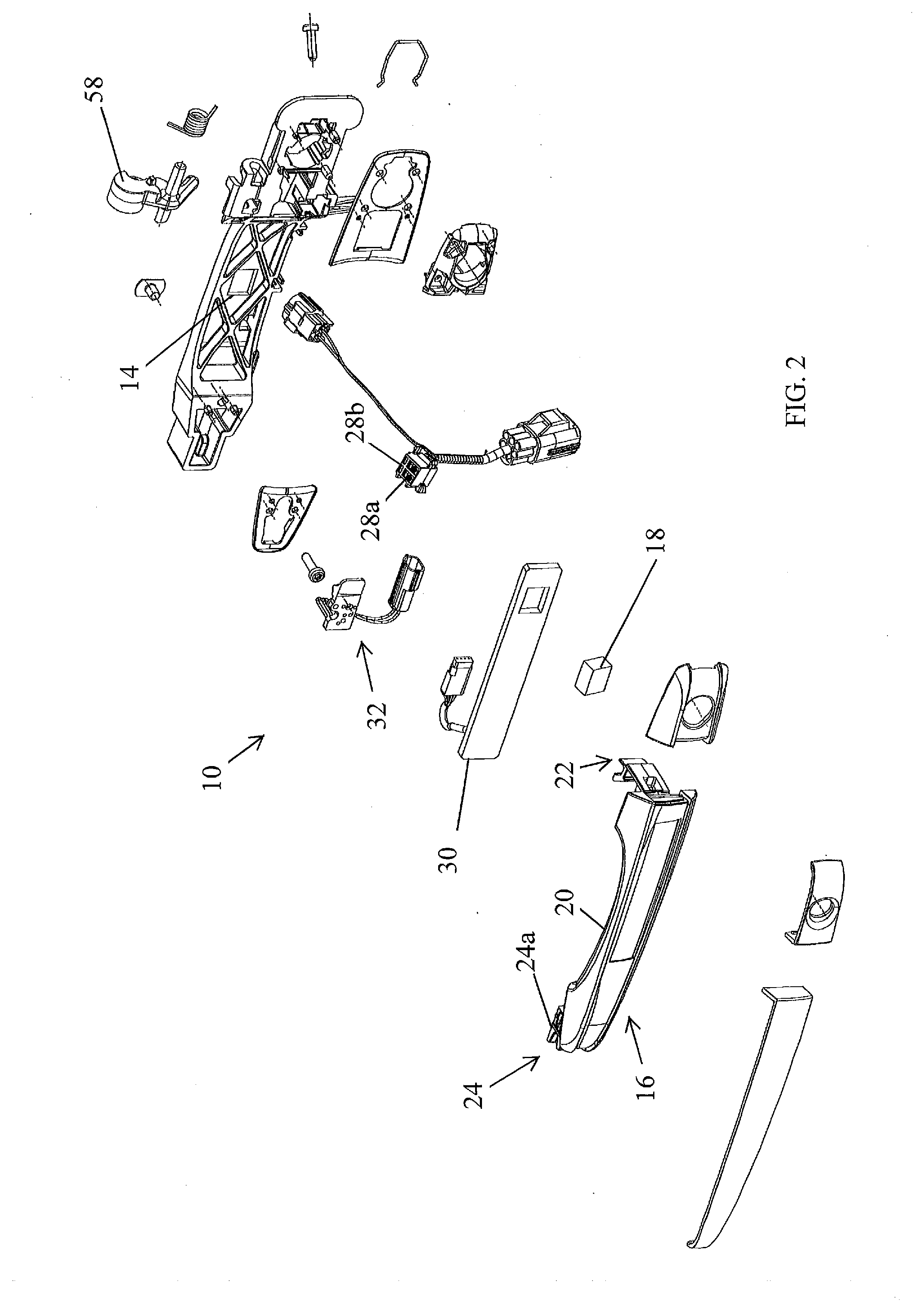

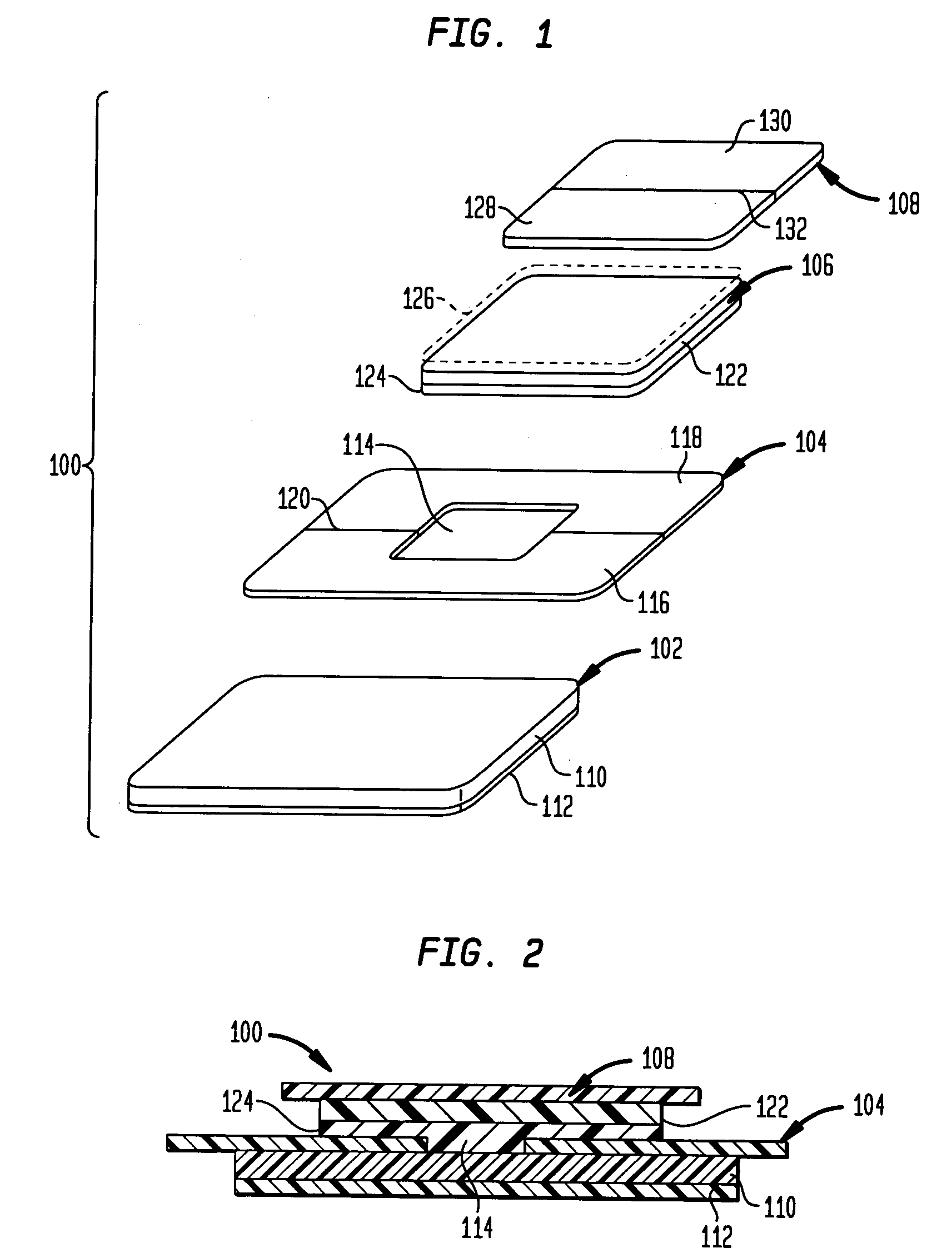

Vehicle handle with control circuitry

InactiveUS20100007463A1Improve performanceReduce communicationElectric signal transmission systemsWing handlesControl circuitEmbedded system

A handle / liftgate assembly for a door of a vehicle is mounted to a handle region of a vehicle door and includes a handle control and a handle sensor. The handle control is responsive to the handle sensor to detect the presence of or proximity of a user or operator at the vehicle door. The handle control actuates a door latch of the vehicle door to open the vehicle door independent of a door zone module or passive entry system of the vehicle door.

Owner:MAGNA MIRRORS OF AMERICA INC

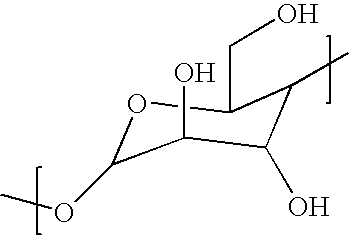

Herbicide compatibility improvement

ActiveUS20060270556A1Improved tank-mix compatibilityReduced surfactant compatibilityBiocideDead animal preservationPotassium CationAqueous solution

A herbicidal composition comprises an aqueous solution of one to a plurality of salts of glyphosate at a total glyphosate a.e. concentration not less than about 360 g / l, wherein (a) said glyphosate is in anionic form accompanied by low molecular weight non-amphiphilic cations in a total molar amount of about 110% to about 120% of the molar amount of said glyphosate; and (b) a major amount to substantially all of the low molecular weight non-amphiphilic cations are potassium cations. The composition exhibits improved tank-mix compatibility with a phenoxy-type herbicide salt formulation by comparison with an otherwise similar composition having a lower molar amount of said low molecular weight non-amphiphilic cations.

Owner:MONSANTO TECH LLC

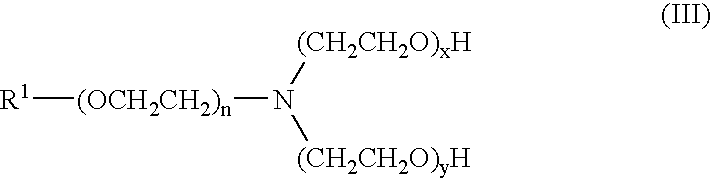

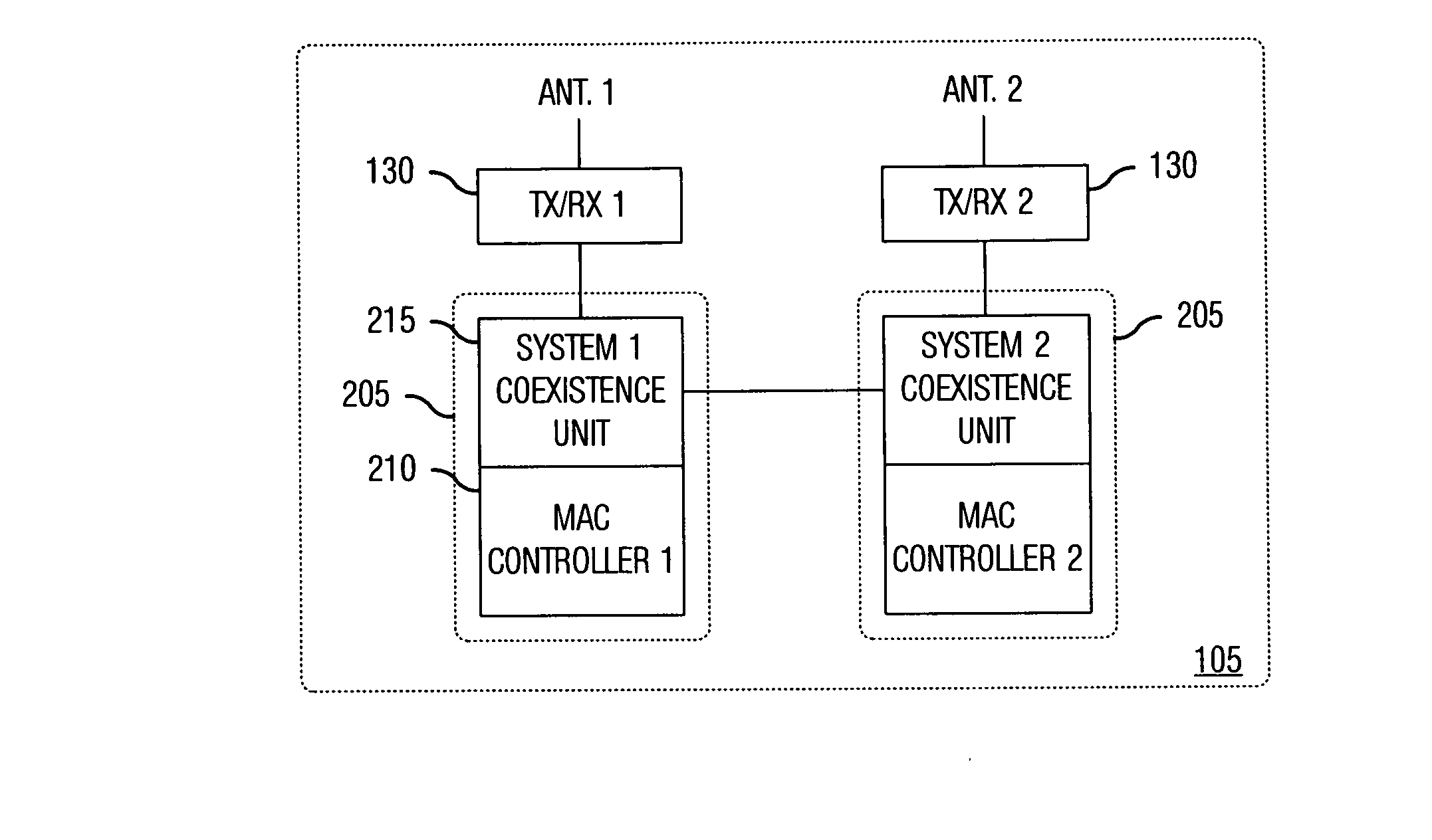

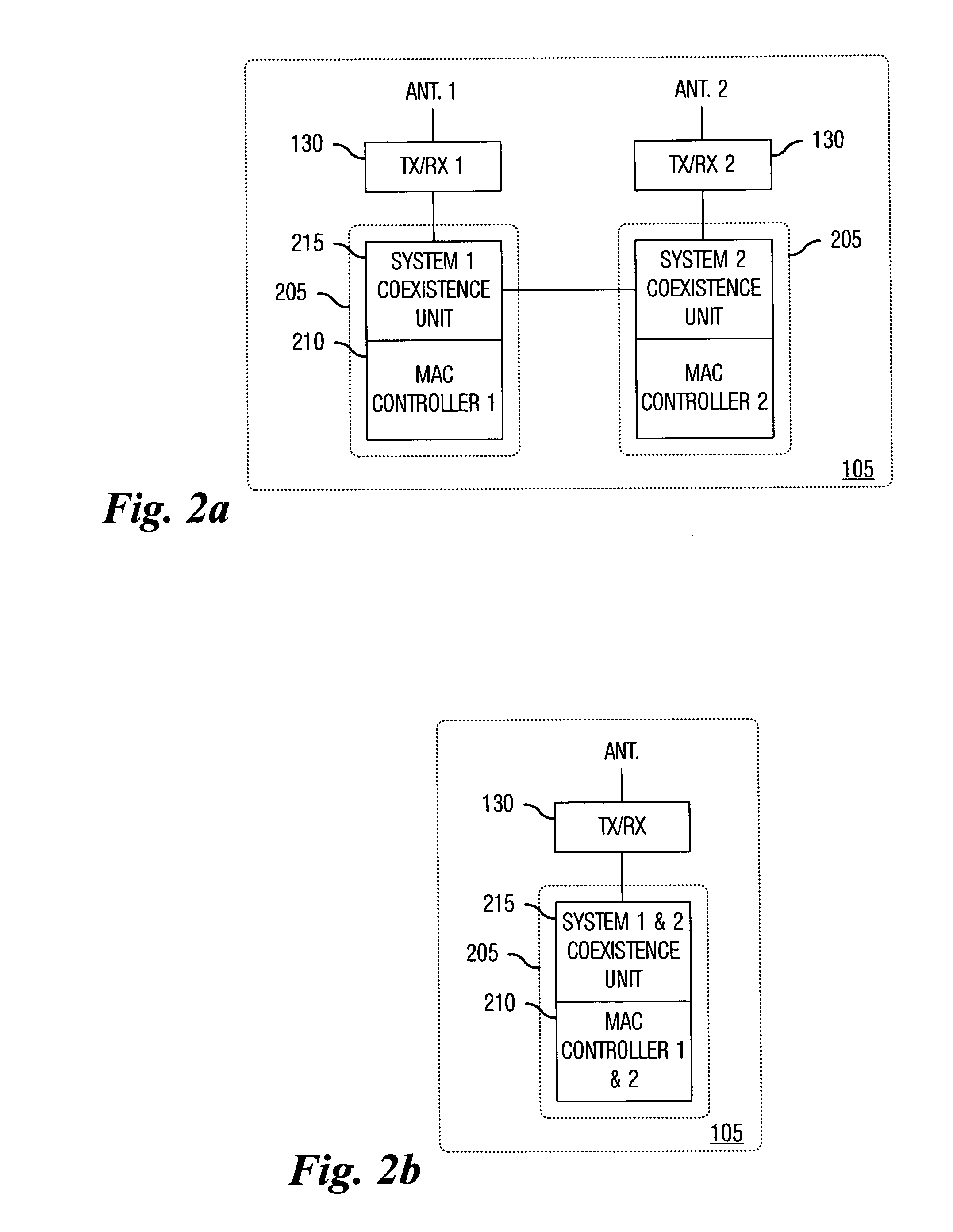

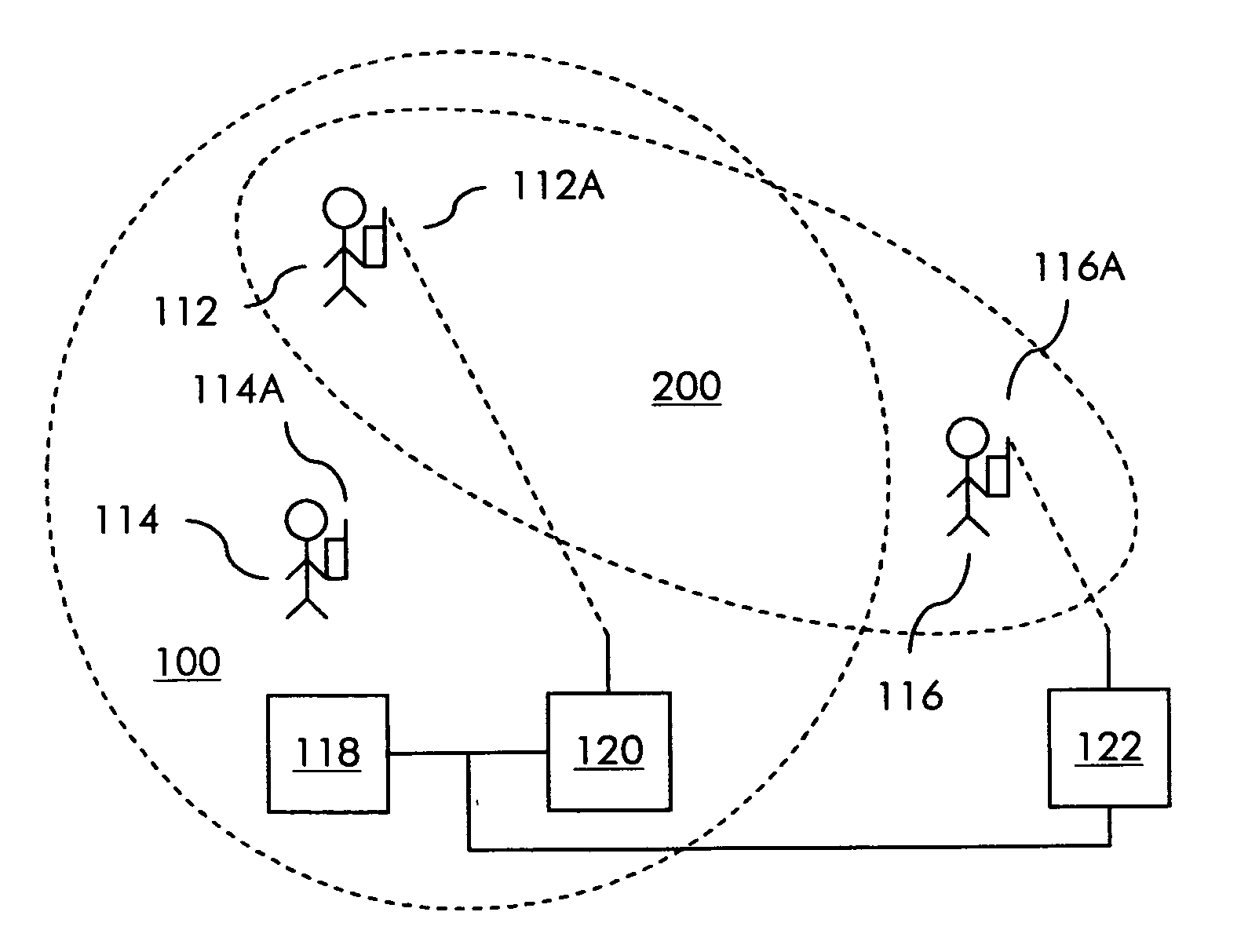

System and method for wireless communication systems coexistence

InactiveUS20070066314A1Reduced compatibilityIncrease likelihoodRadio/inductive link selection arrangementsWireless communicationData transmissionWireless communication systems

Owner:TEXAS INSTR INC

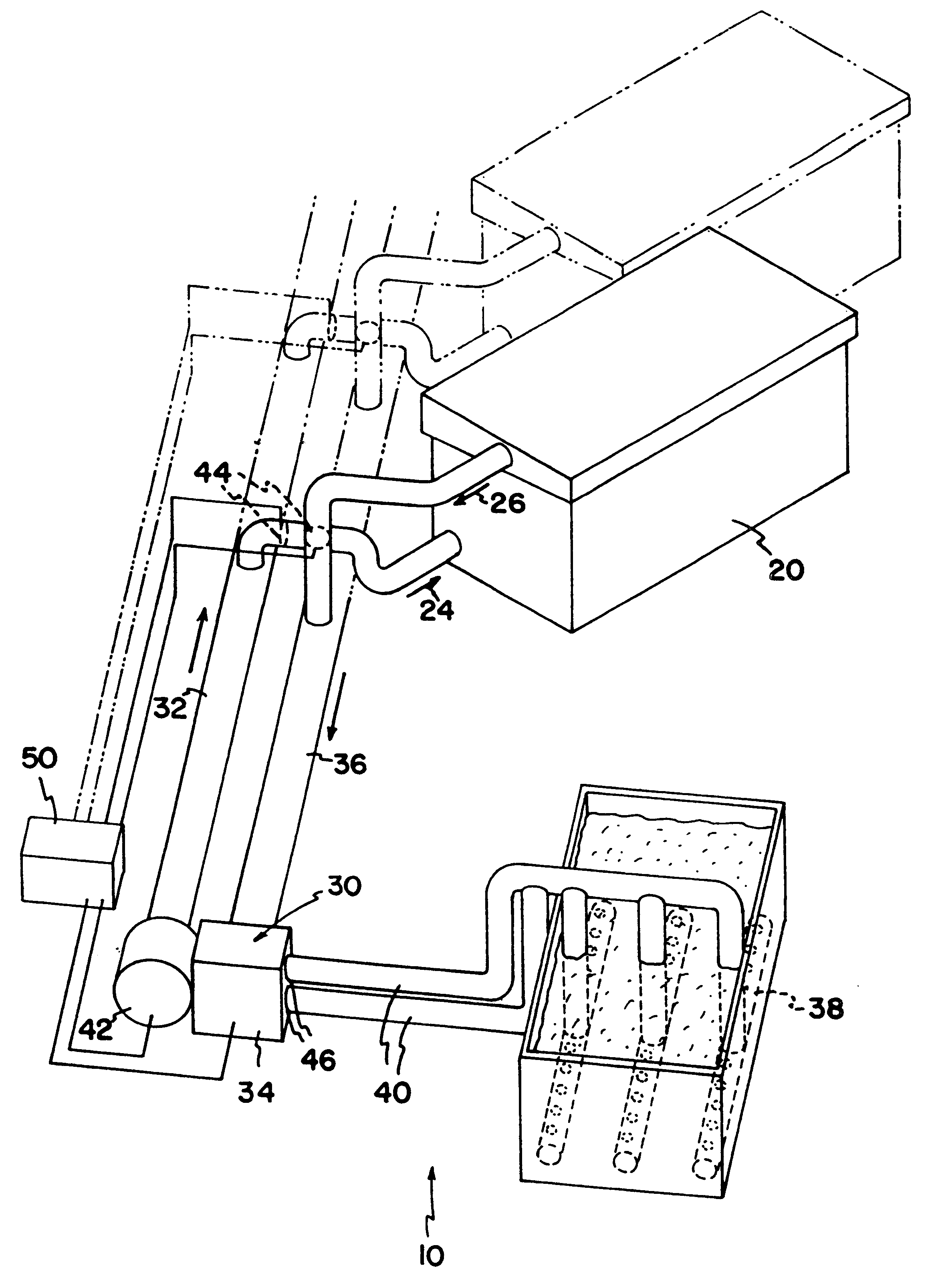

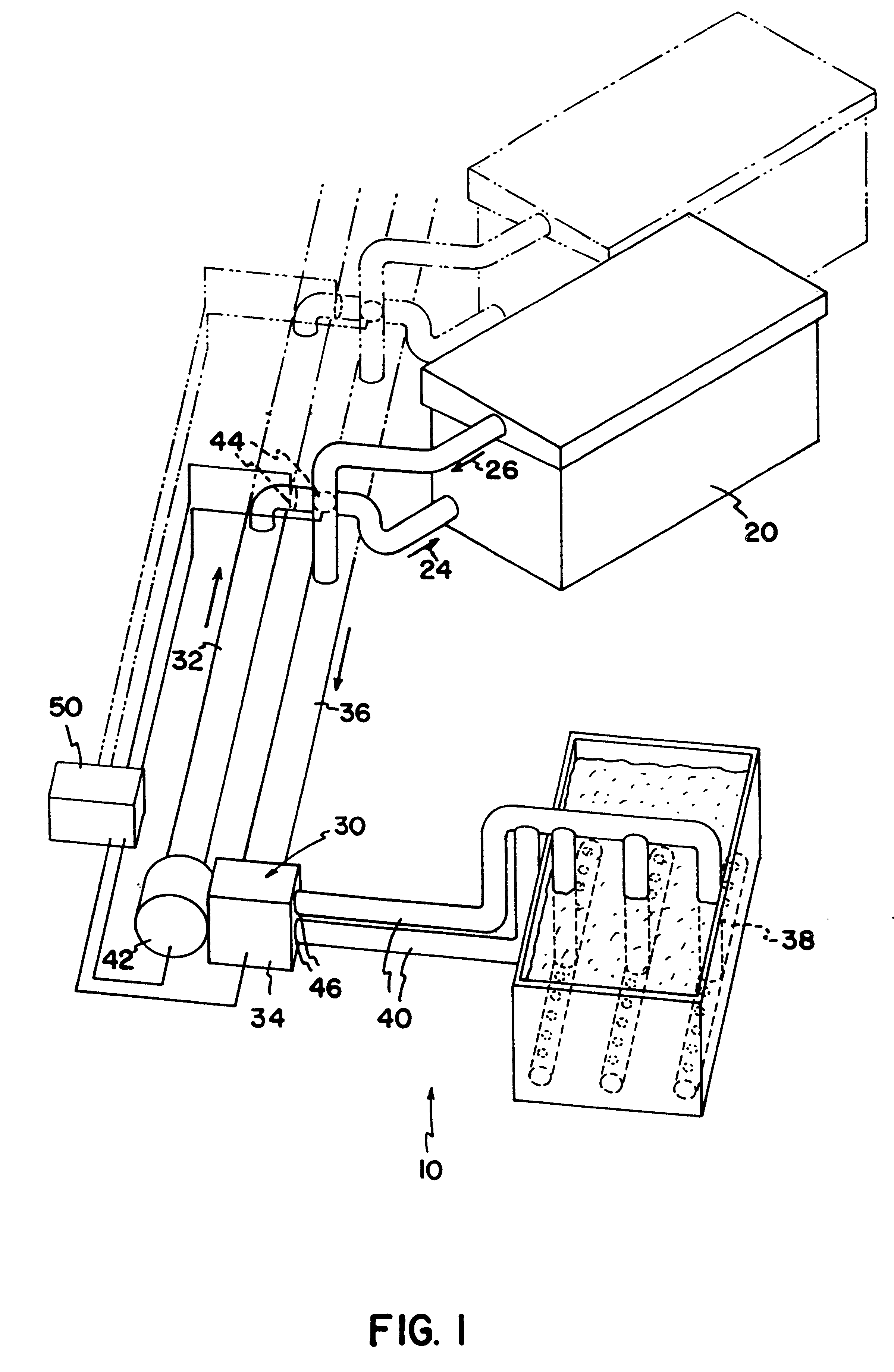

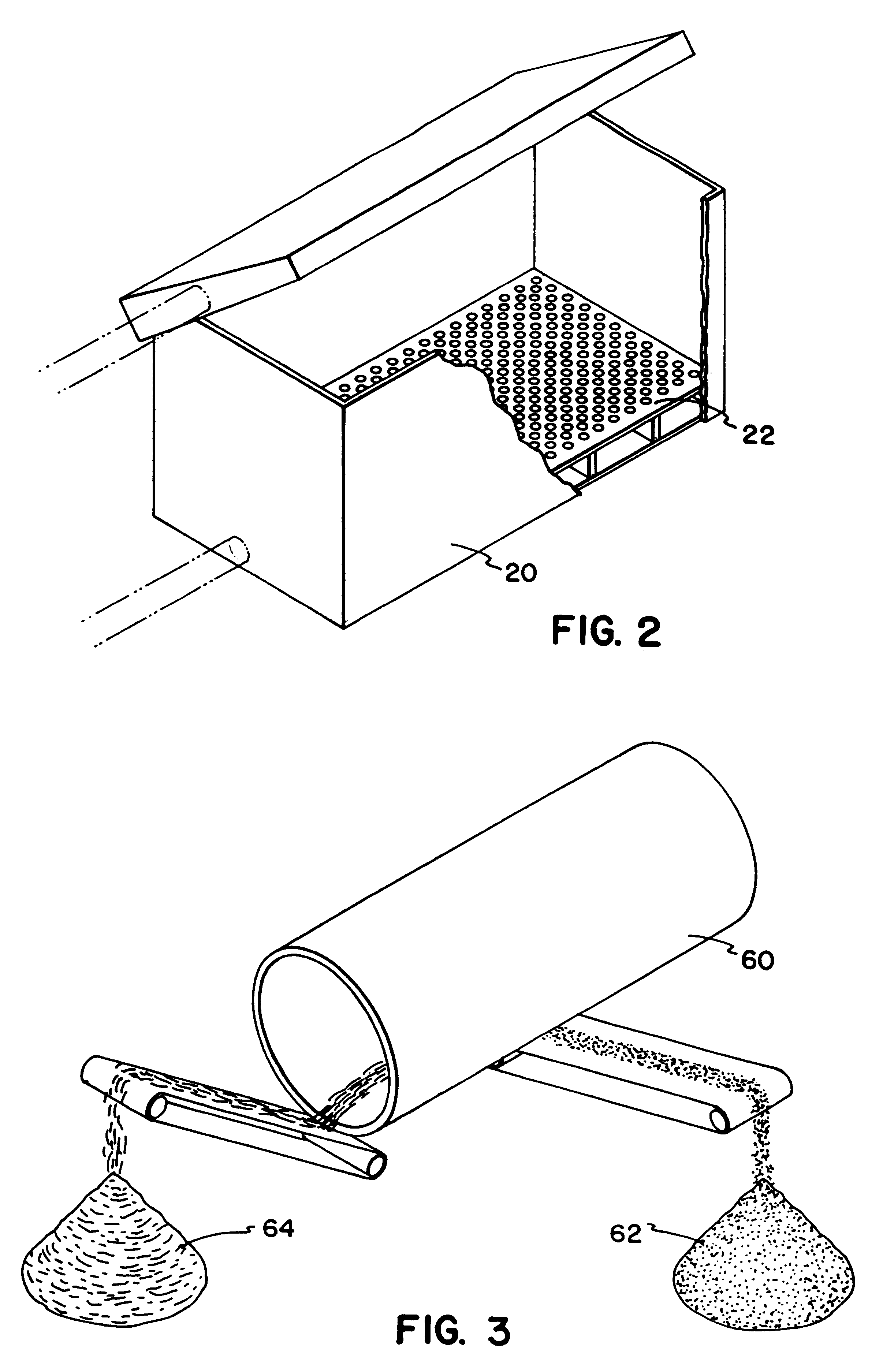

Process for controlled composting of organic material and for bioremediating soils

InactiveUS6281001B1Prevent escapeSlow and hinder microbial degradationBioreactor/fermenter combinationsBio-organic fraction processingBioremediationOrganic chemistry

Owner:MCNELLY JAMES J

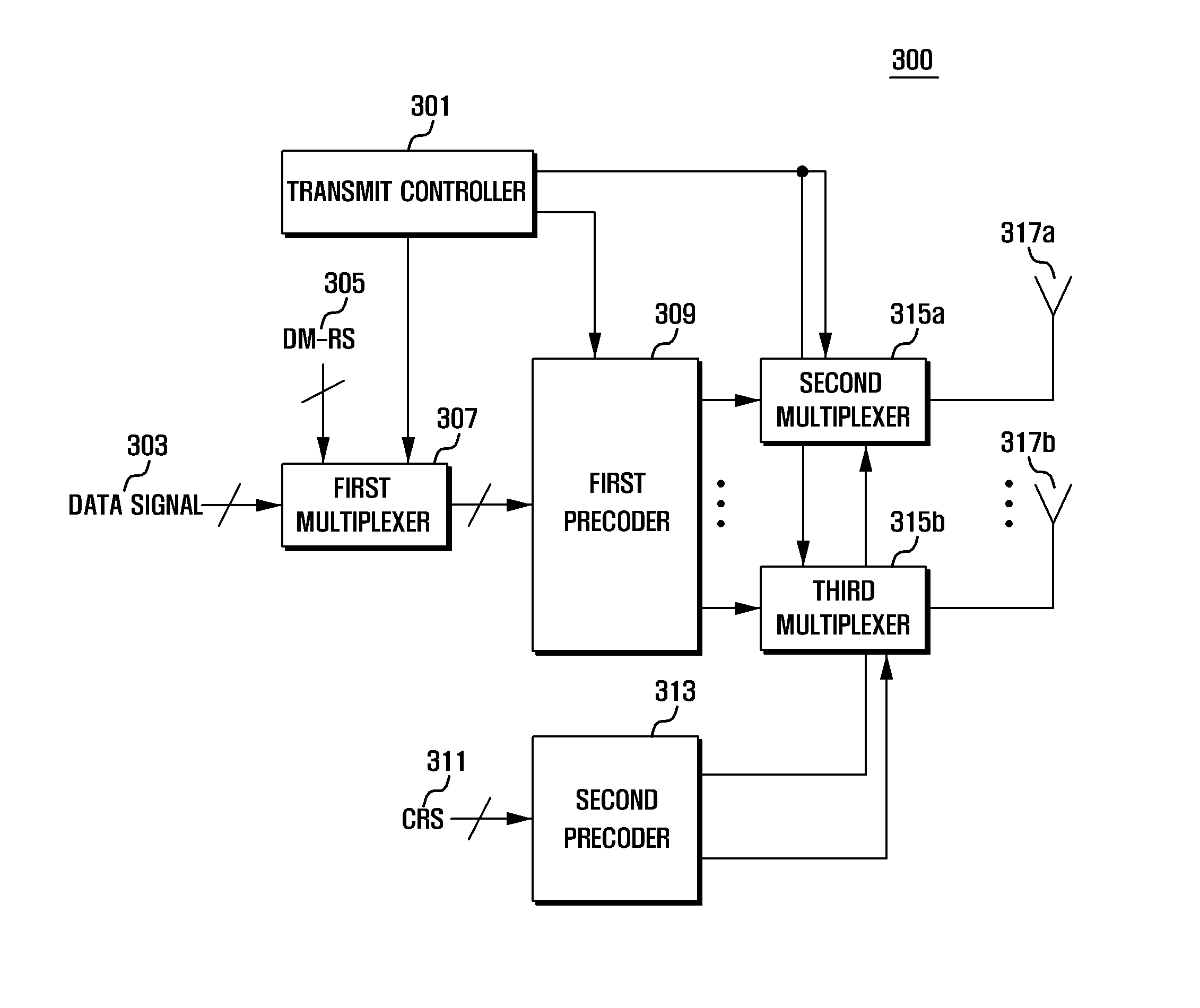

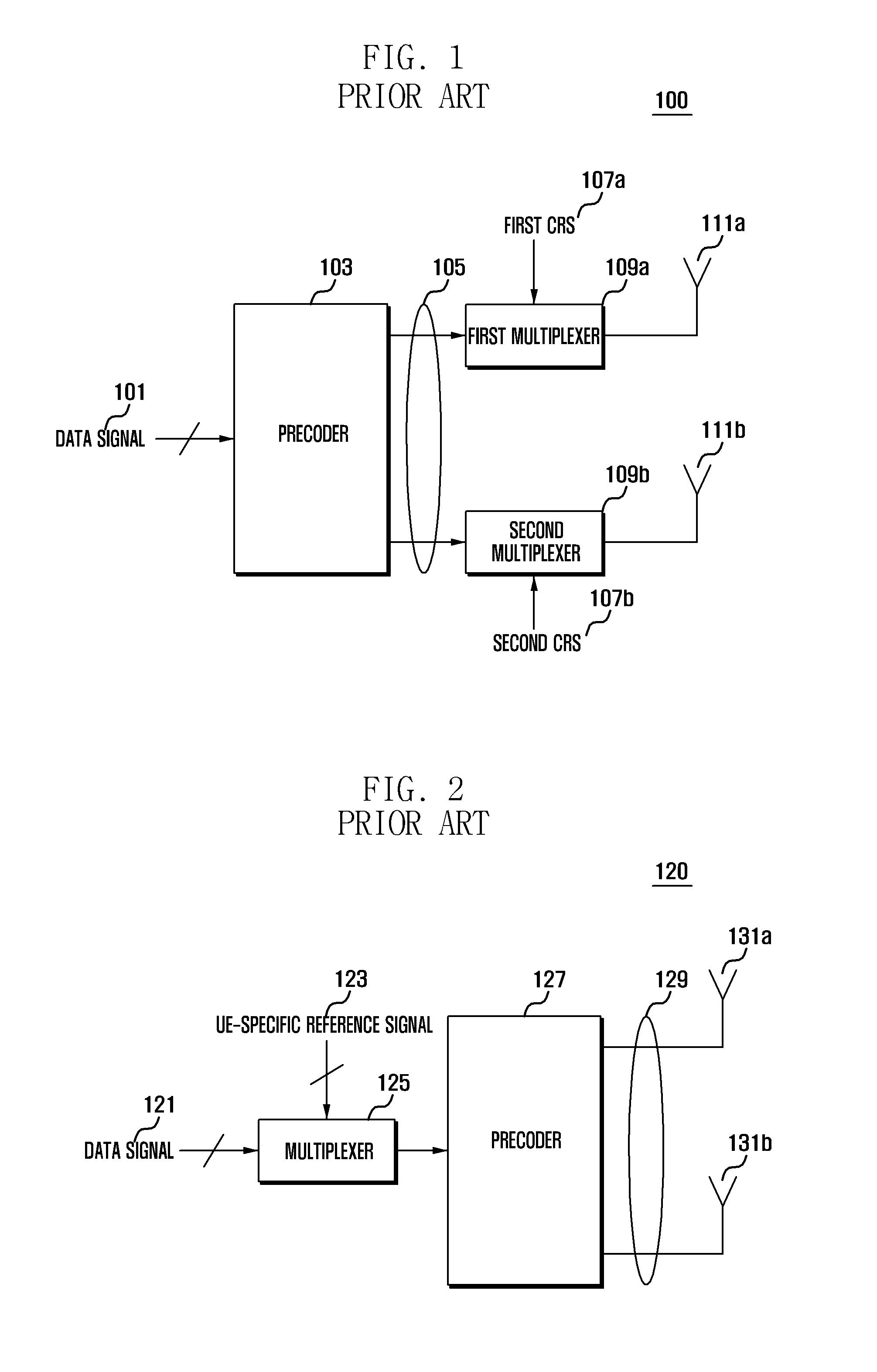

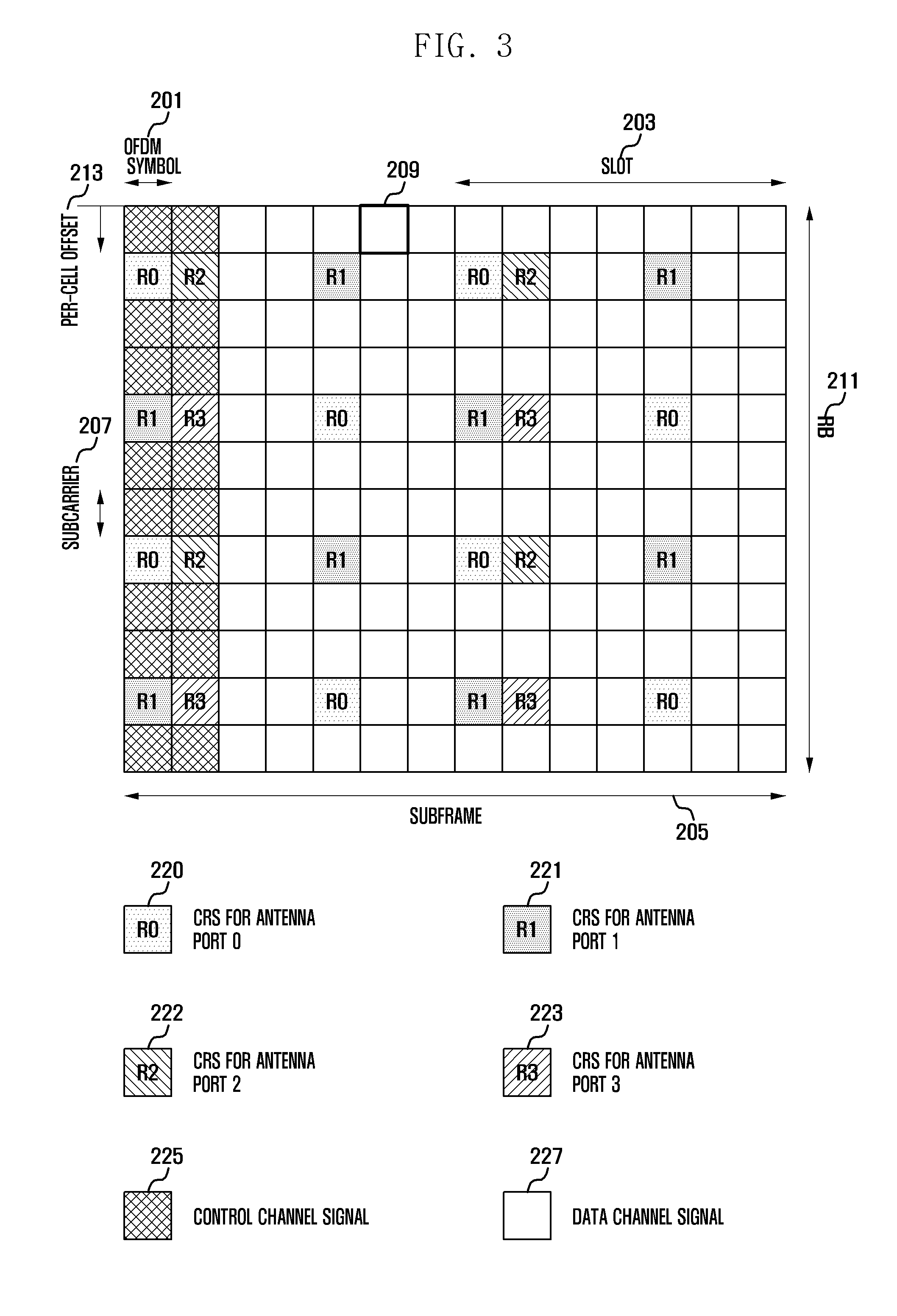

Method and apparatus for transmitting/receiving a reference signal in a wireless communication system

ActiveUS20110044250A1Reduced compatibilityLower performance requirementsSite diversityPilot signal allocationCommunications systemLTE Advanced

A method and apparatus for transmitting / receiving reference signals in Long Term Evolution (LTE) and LTE-Advanced (LTE-A) systems includes determining whether a dedicated reference signal is detected in a current subframe; estimating, if a dedicated reference signal is detected in the current subframe, a data channel using the dedicated reference signal to receive data; and estimating, if no dedicated reference signal is detected in the current subframe, a data channel using a common reference signal detected in the current subframe to receive data. The transmission scheme uses a DeModulation Reference Signal (DM-RS) for channel response estimation. To secure backward compatibility of the LTE-A system, a Common Reference Signal is transmitted in normal subframes.

Owner:SAMSUNG ELECTRONICS CO LTD

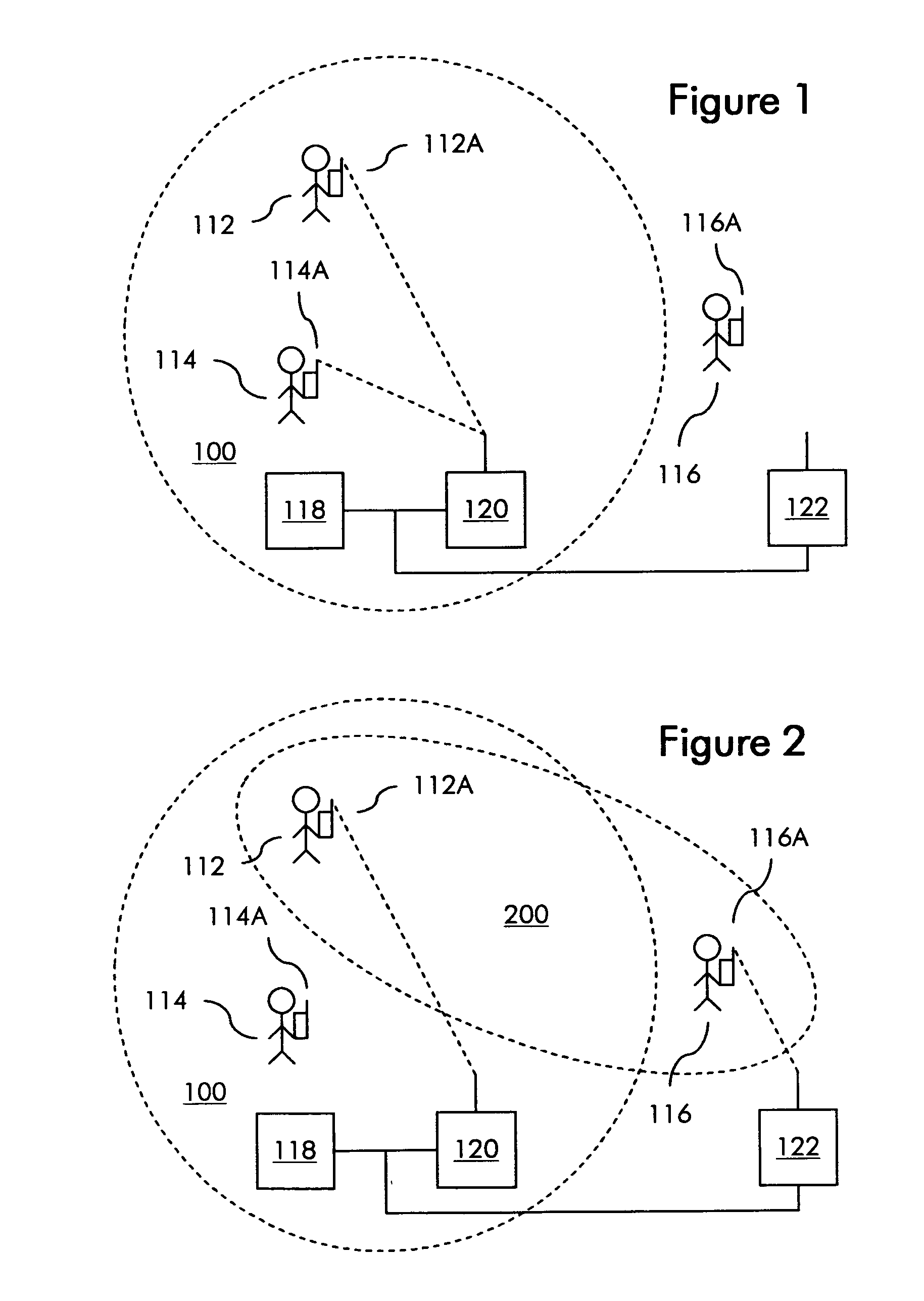

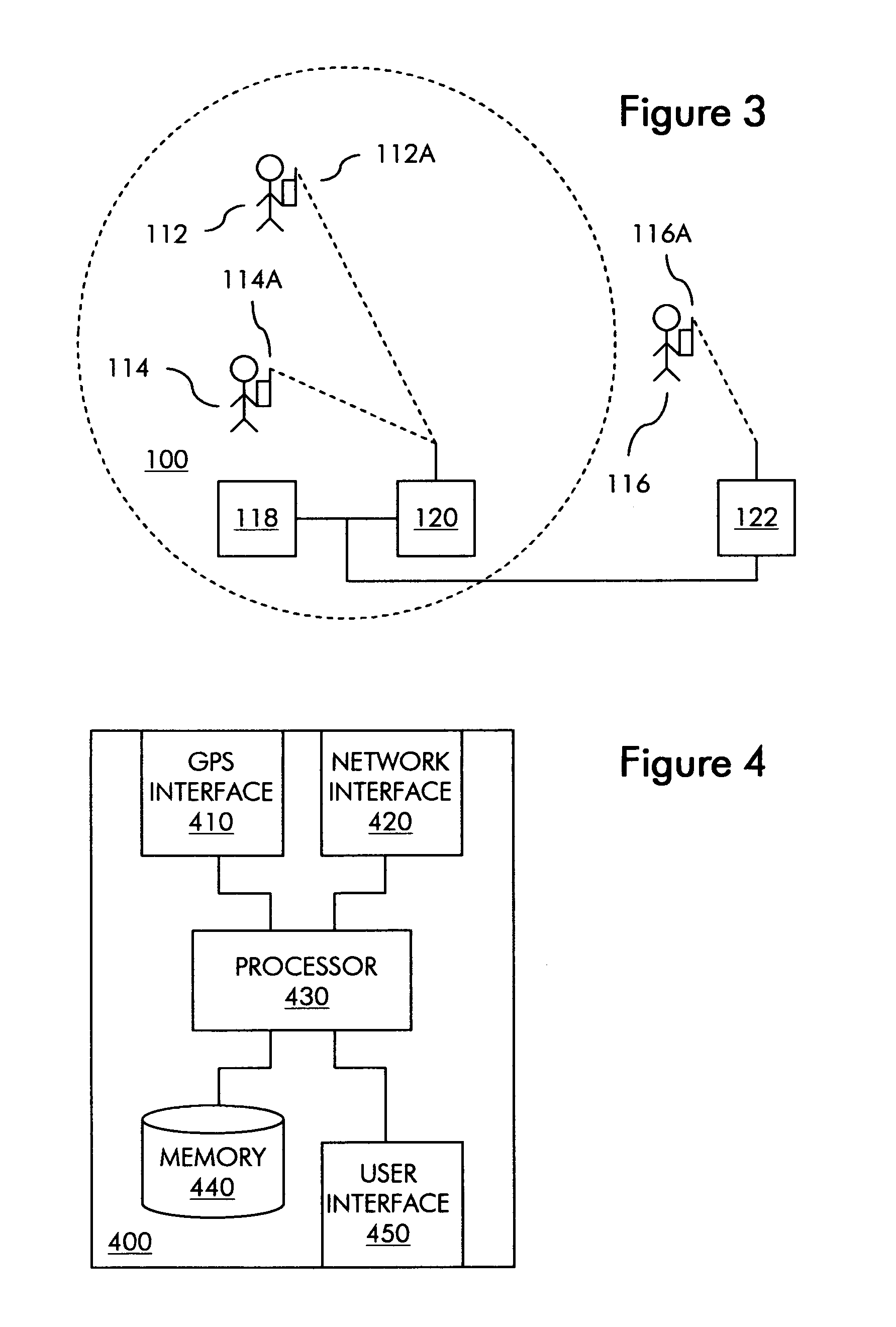

Wireless event notification system and methods for use therein

InactiveUS20090258636A1Superfluous notificationImprove privacySpecial service for subscribersServices signallingSeverity levelComputer compatibility

A wireless event notification system that selectively notifies members of events based on their location and / or interests, and devices and method for use therein. The wireless event notification system provides single or multifactor filtering based on one or more of proximity to an event, membership in a subgroup to which an event pertains and / or desire to receive events at the severity level of an event. Superfluous notifications are thereby reduced. Location-based filtering may be done by a notification server device to which member locations are reported or, to enhance member privacy, by wireless client devices using unreported member locations. Additionally, in some embodiments, wireless client devices are distributed by a system administrator to members after the system administrator has registered the members with the system to remove device acquisition, device compatibility and member registration hurdles that can present obstacles to universal participation in the system.

Owner:SHARP KK

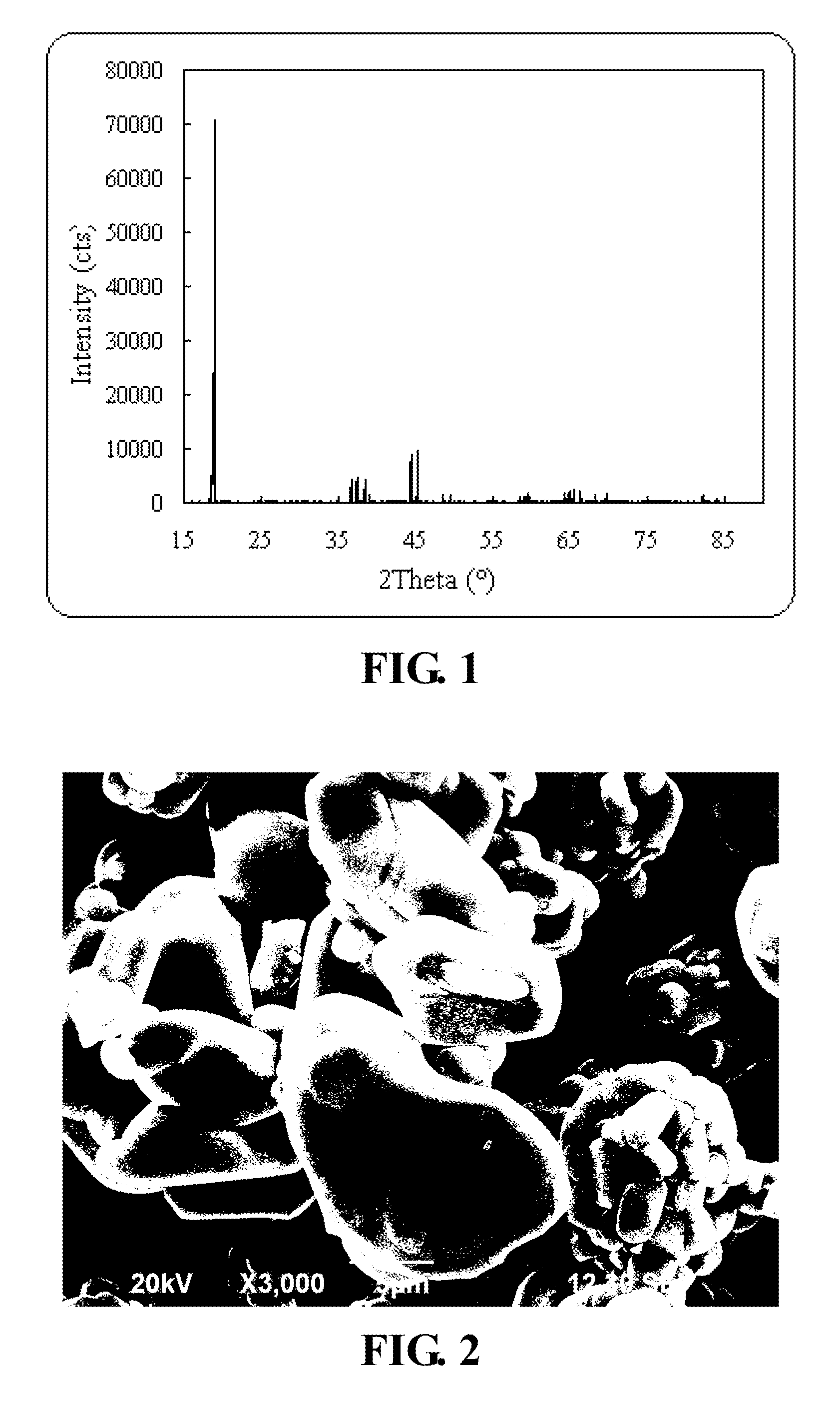

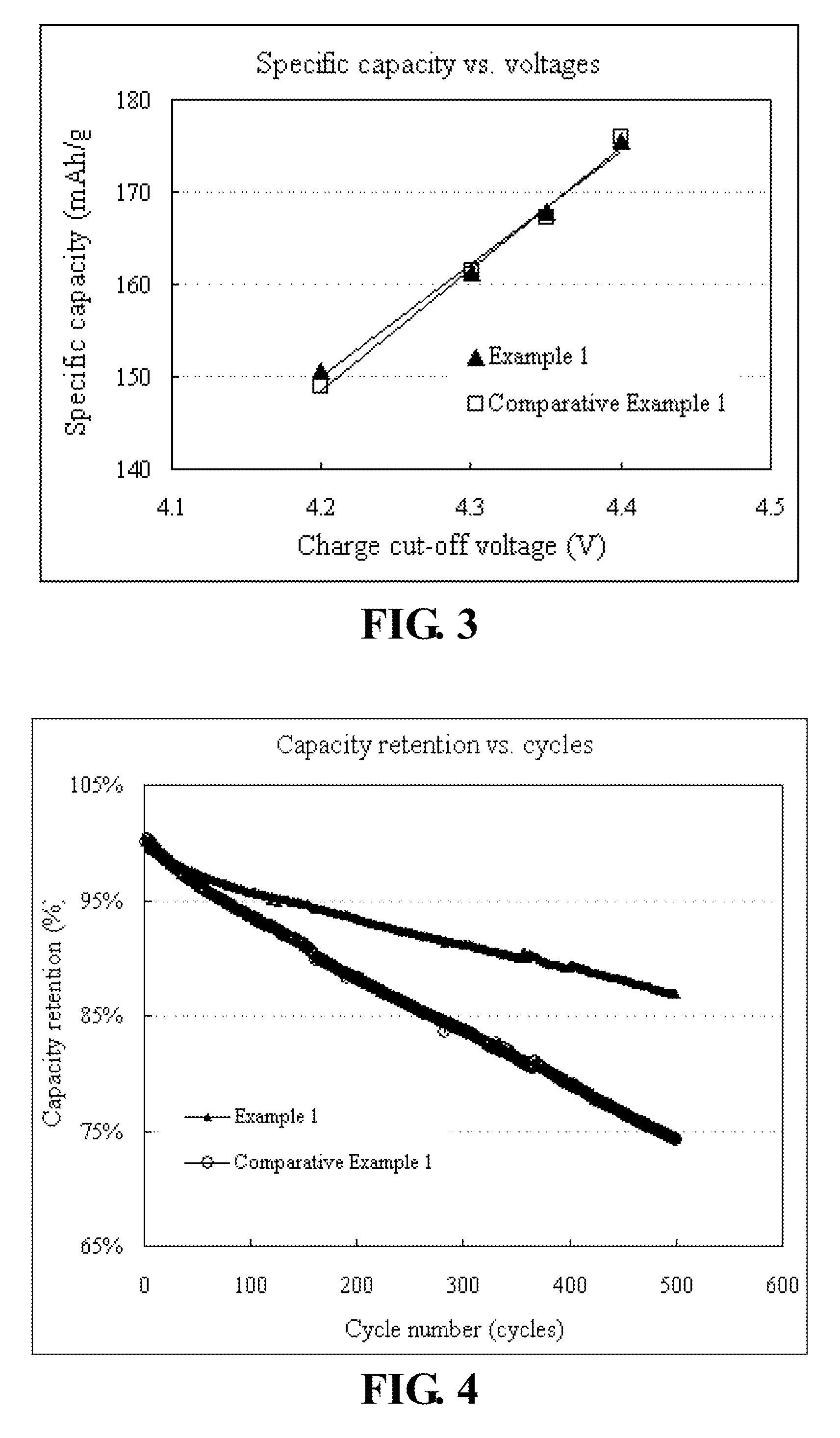

Lithium-ion batteries and cathode materials thereof

InactiveUS20130260231A1Increase energy densityImprove cycle performanceElectrode carriers/collectorsSecondary cellsPhosphateOptoelectronics

The invention provides a type of lithium-ion battery cathode materials applicable to a high charge cut-off voltage. The cathode materials comprises two active substances of LiCoO2 and Li (NixCoyMn1-x-y)O2, where 0.3≦x≦0.8, 0.1≦y≦0.4, and 0.6≦x+y≦0.9. Both LiCoO2 and Li(NixCoyMn1-x-y)O2 are doped with element M and then treated by surface coating with the oxide, sulfide, fluoride of element M′ or phosphate. The element M is at least one of the Mg, Ti, Al, Zr, B, La, Ce, Y, P, S, N or F while the element M′ is at least one of the Al, Ti, Mg, Zr, B, Si, Fe, La, Ce or Y. The cathode materials provided herein, having the advantages of excellent cycling performance and low cell swelling against high temperature, can help to remarkably increase the energy density of lithium-ion batteries. The invention also discloses a lithium-ion battery containing such cathode materials.

Owner:NINGDE AMPEREX TECH

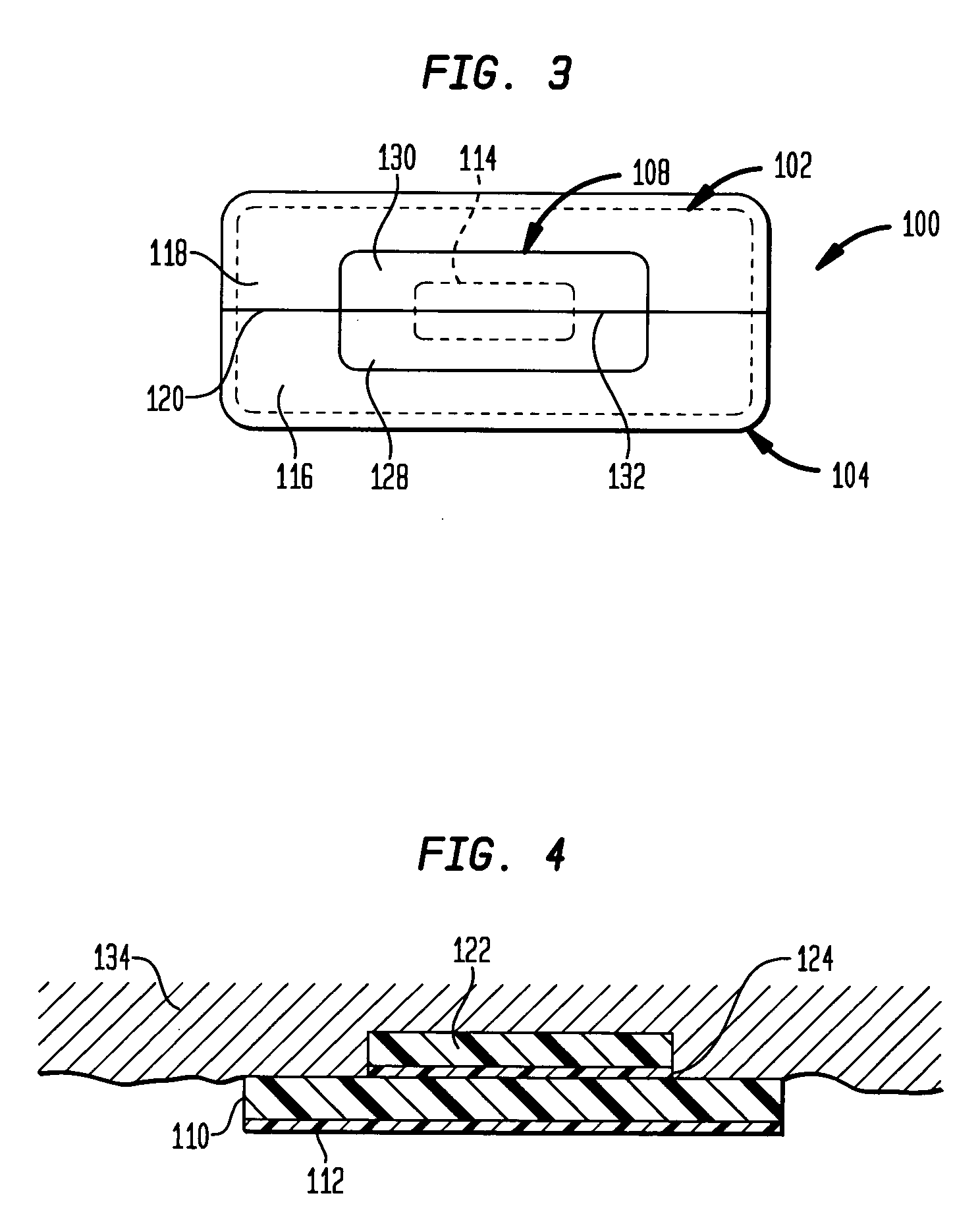

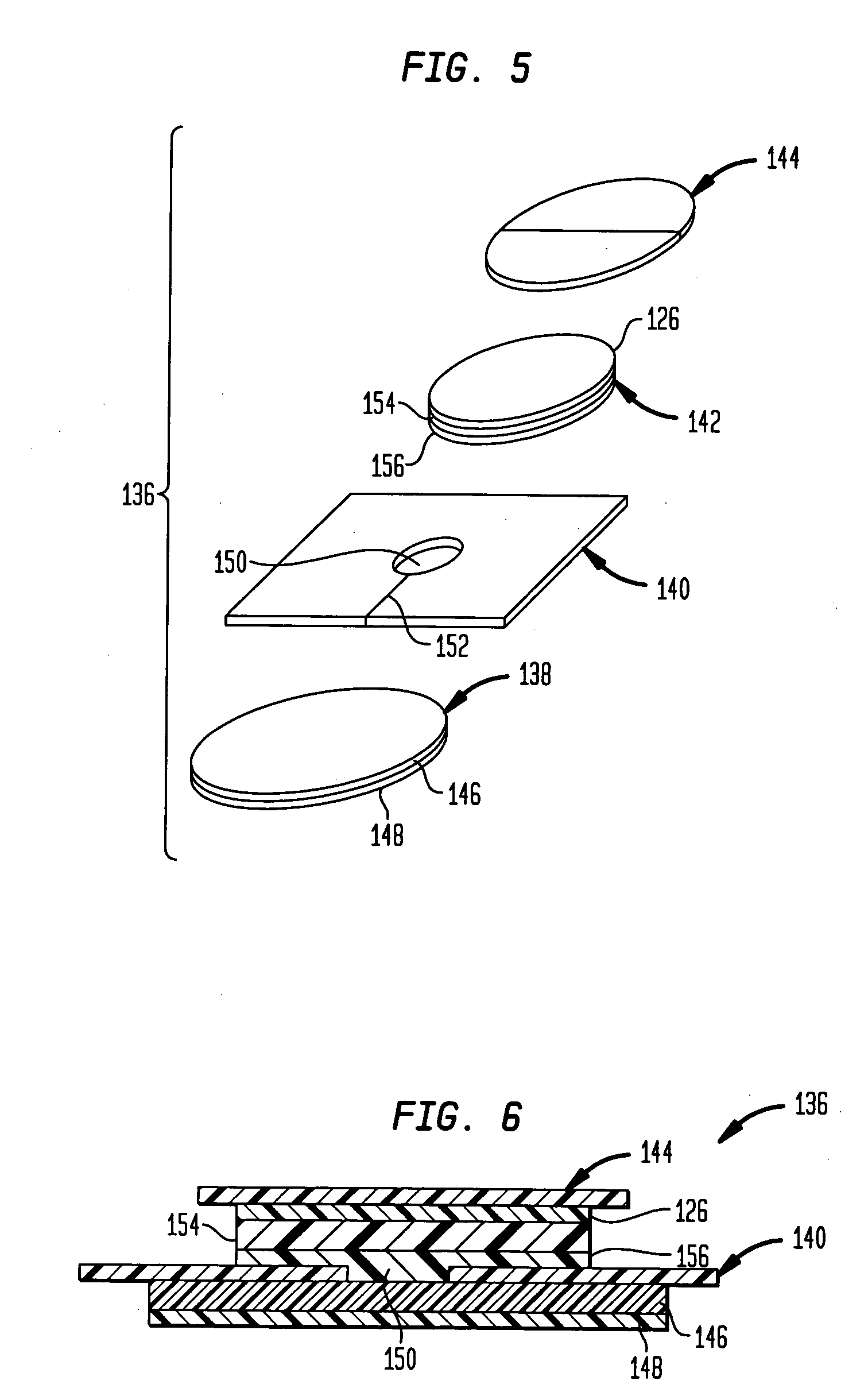

Transdermal patch incorporating active agent migration barrier layer

ActiveUS20050037059A1Inhibit migrationReduced compatibilityAdhesive dressingsMedical applicatorsActive agentInternal layer

Devices for administration of one or more active agents to the skin or mucosa of a host are formed in the nature of a double-disk patch. One outer layer functions as the primary adhesive layer for adhering the patch to the host. The other inner layer contains at least one active agent to be administered to the host. The inner layer is bonded to the outer layer through an opening provided in an interposed active agent impermeable release layer. The release layer separates a circumferential portion of the active agent containing inner layer from the outer adhesive layer to inhibit migration of the active agent therebetween.

Owner:MYLAN TECH INC

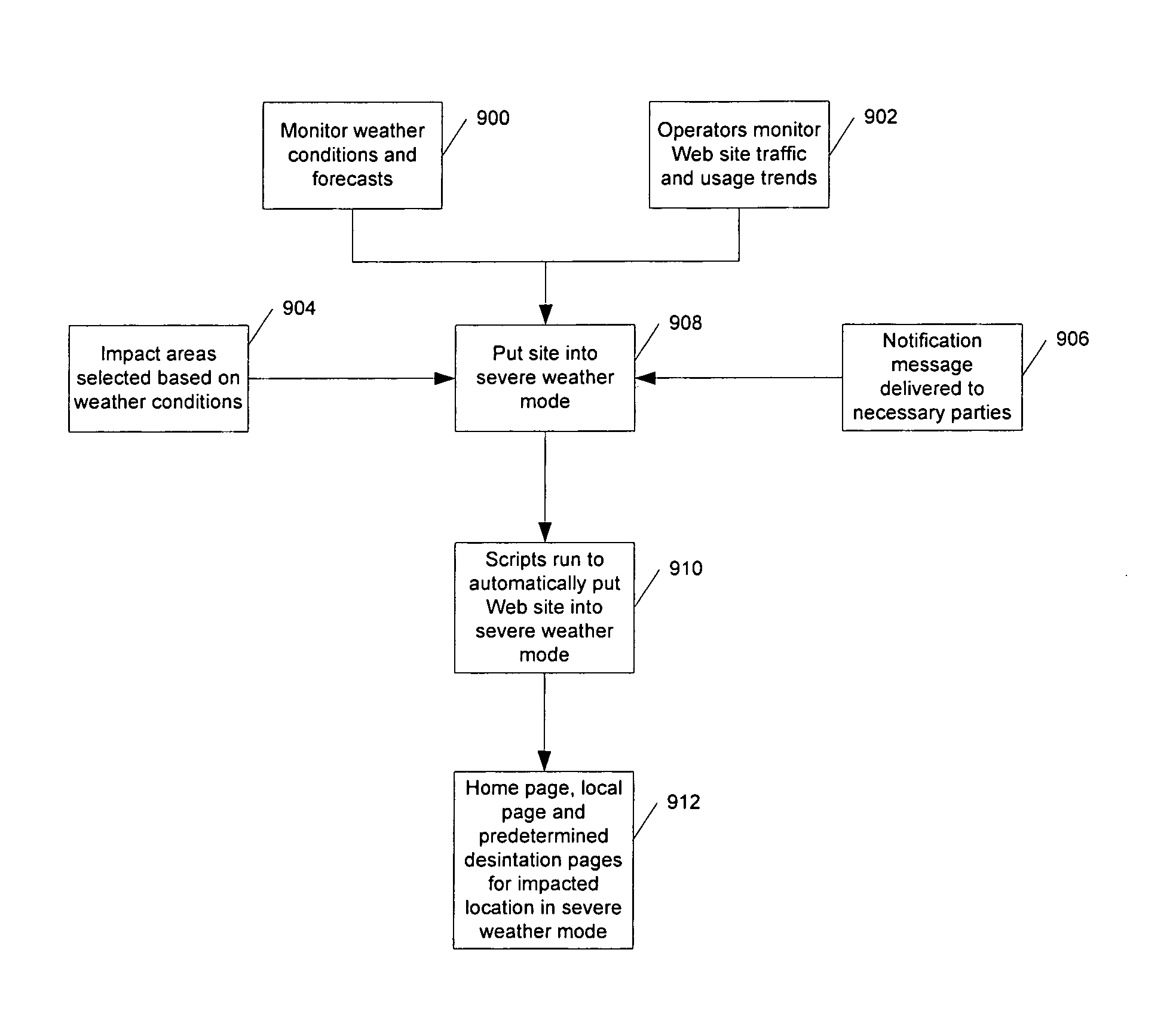

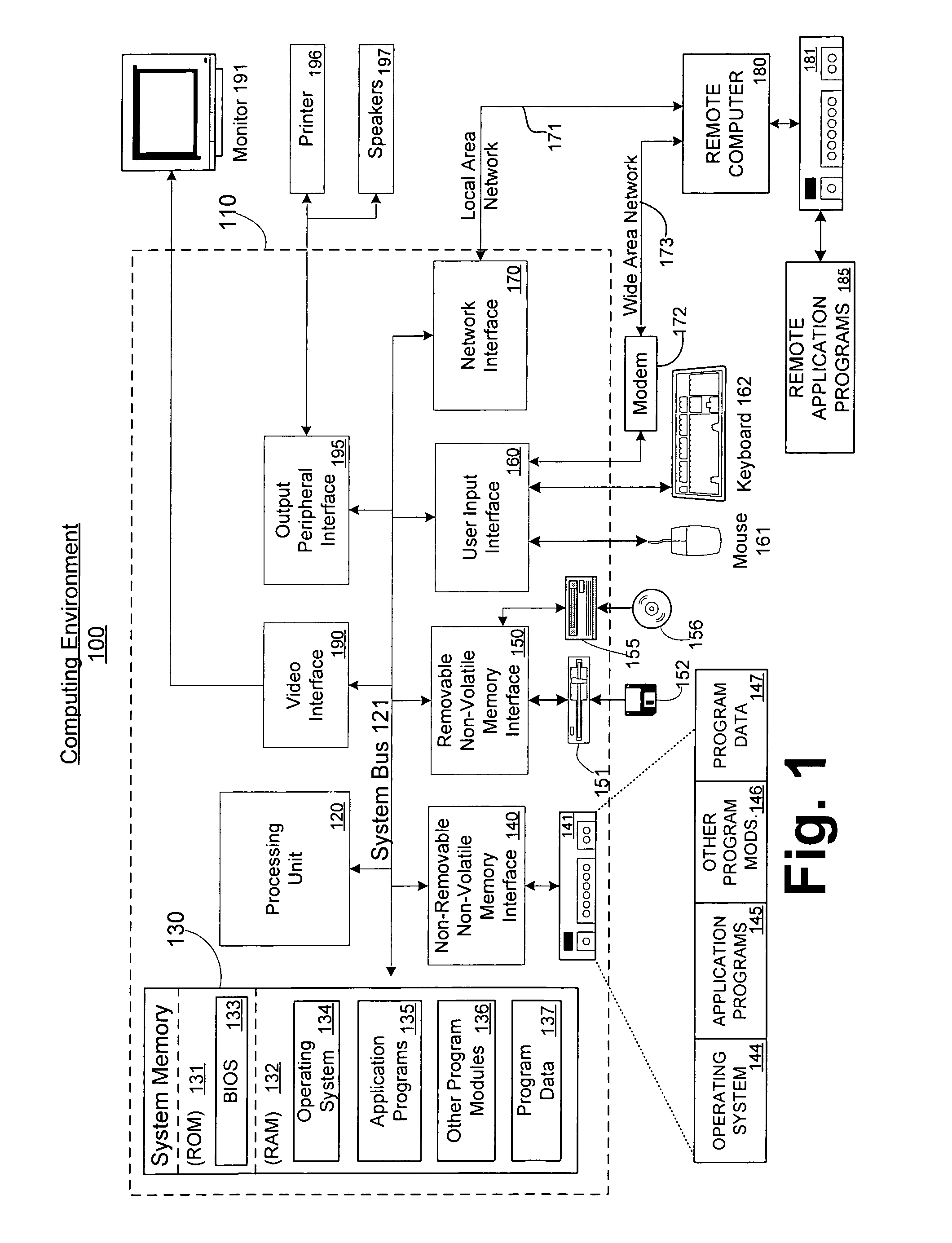

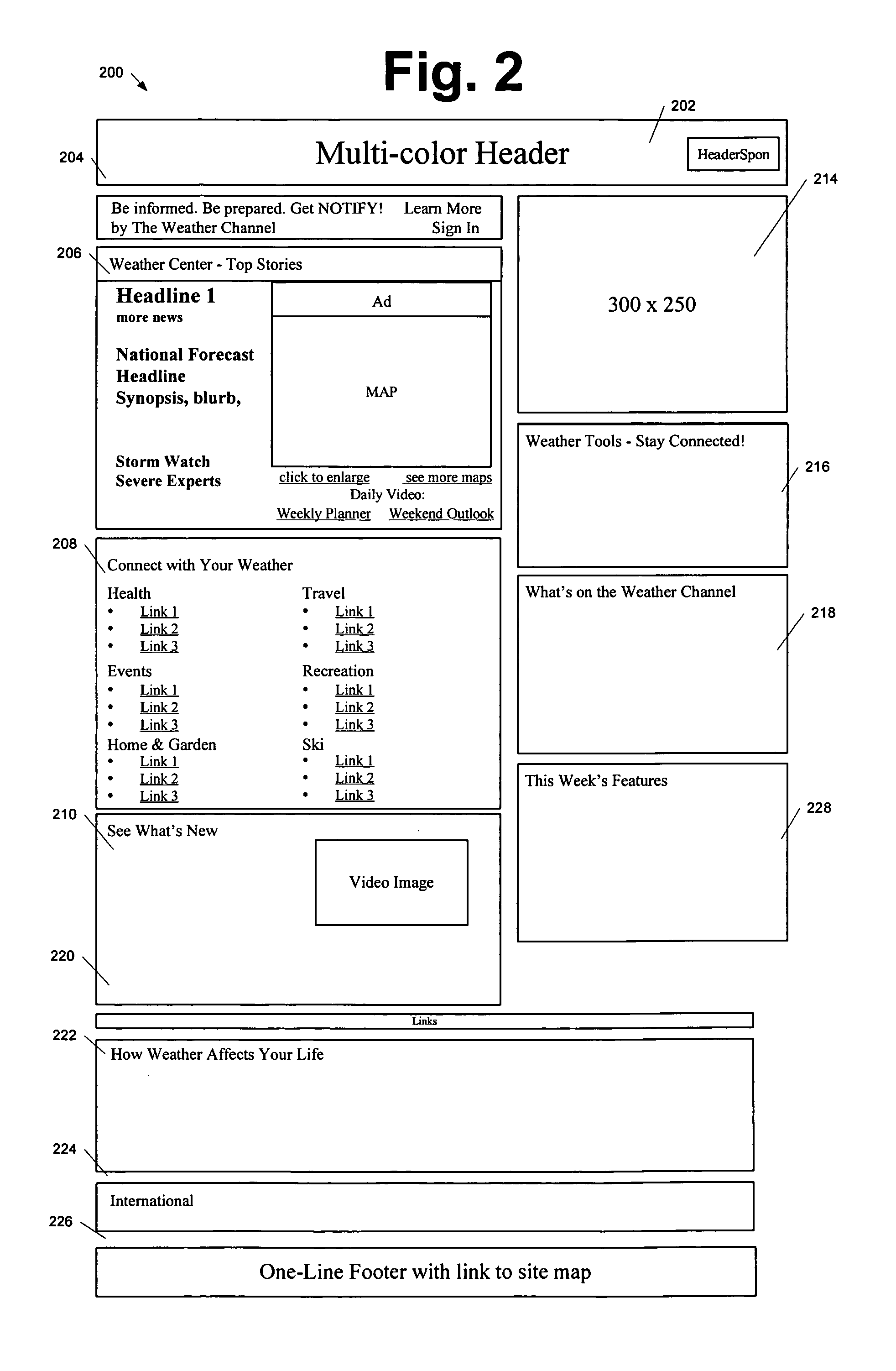

Website changes to scalability, capacity, server impact, bandwidth and end-user presentation based on a triggered event

ActiveUS7529835B1Reduce the amount requiredReduced database callDigital data information retrievalMultiple digital computer combinationsServer loadWeb site

Methods for altering content on a Web site in accordance with triggering events. Normal and alternate versions of Web site content are created, where the alternate version is a less complex and computationally expense and utilizes a reduced amount of bandwidth to be transmitted to users. When an event occurs, all or portions of the Web site are switched from the normal version to their respective alternate versions to reduce server load and bandwidth requirements so a high number of users can be served the pages. The switch from normal to alternate versions may be for all visitors of selected classes of visitors, such as those from certain geographic regions.

Owner:DTN LLC

Ceramic wall flow filter manufacture

InactiveUS20060272306A1Good chemical stabilityImprove physical stabilityDispersed particle filtrationLoose filtering material filtersHoneycombPorous ceramics

Porous ceramic wall flow filter bodies of unitary or segmented construction wherein the honeycomb channels are alternately plugged with plugging cements incorporating low expansion refractory fillers and permanent inorganic bonding agents, the latter imparting improved plug integrity and plug bonding to the porous ceramic honeycomb channel walls.

Owner:CORNING INC

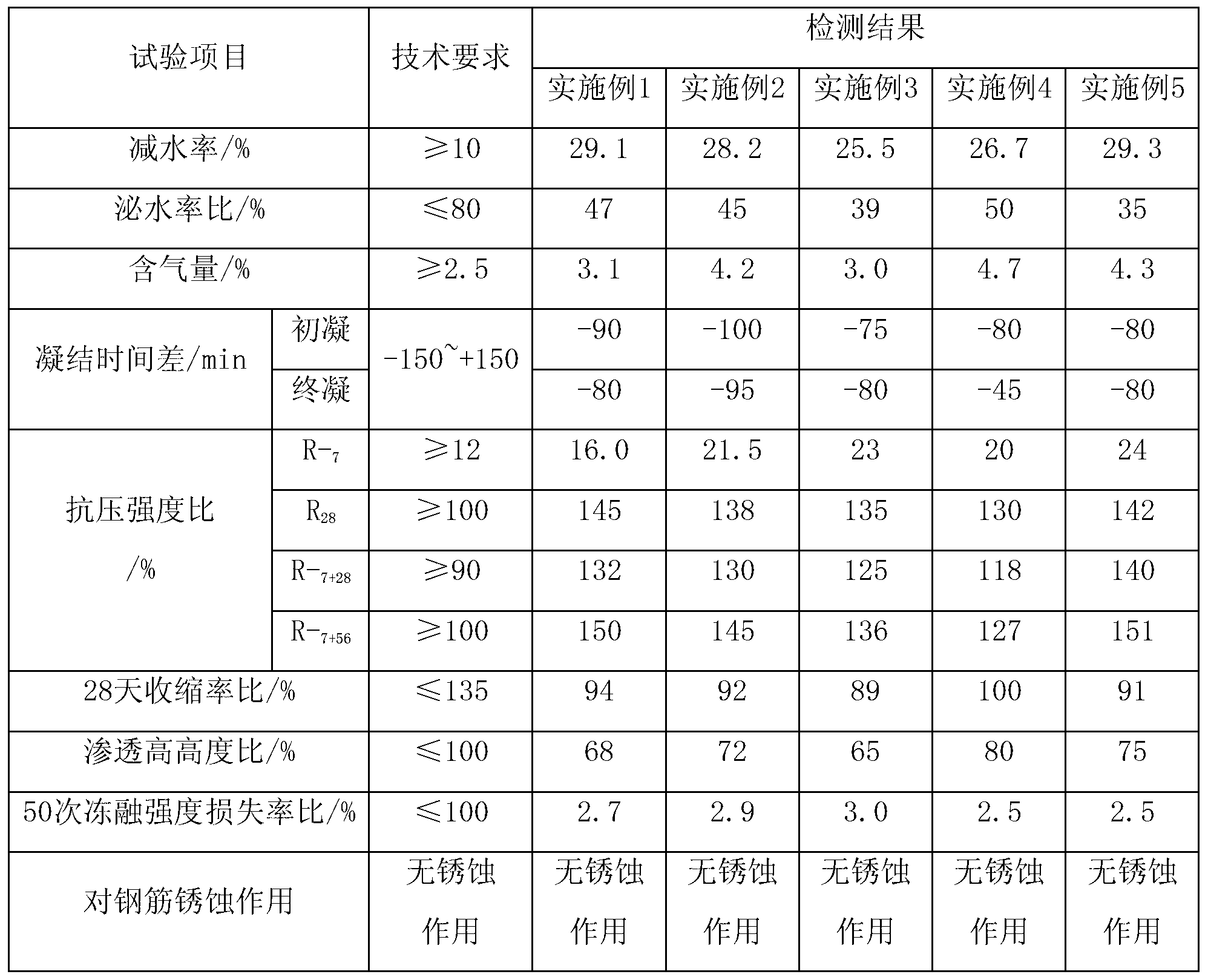

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

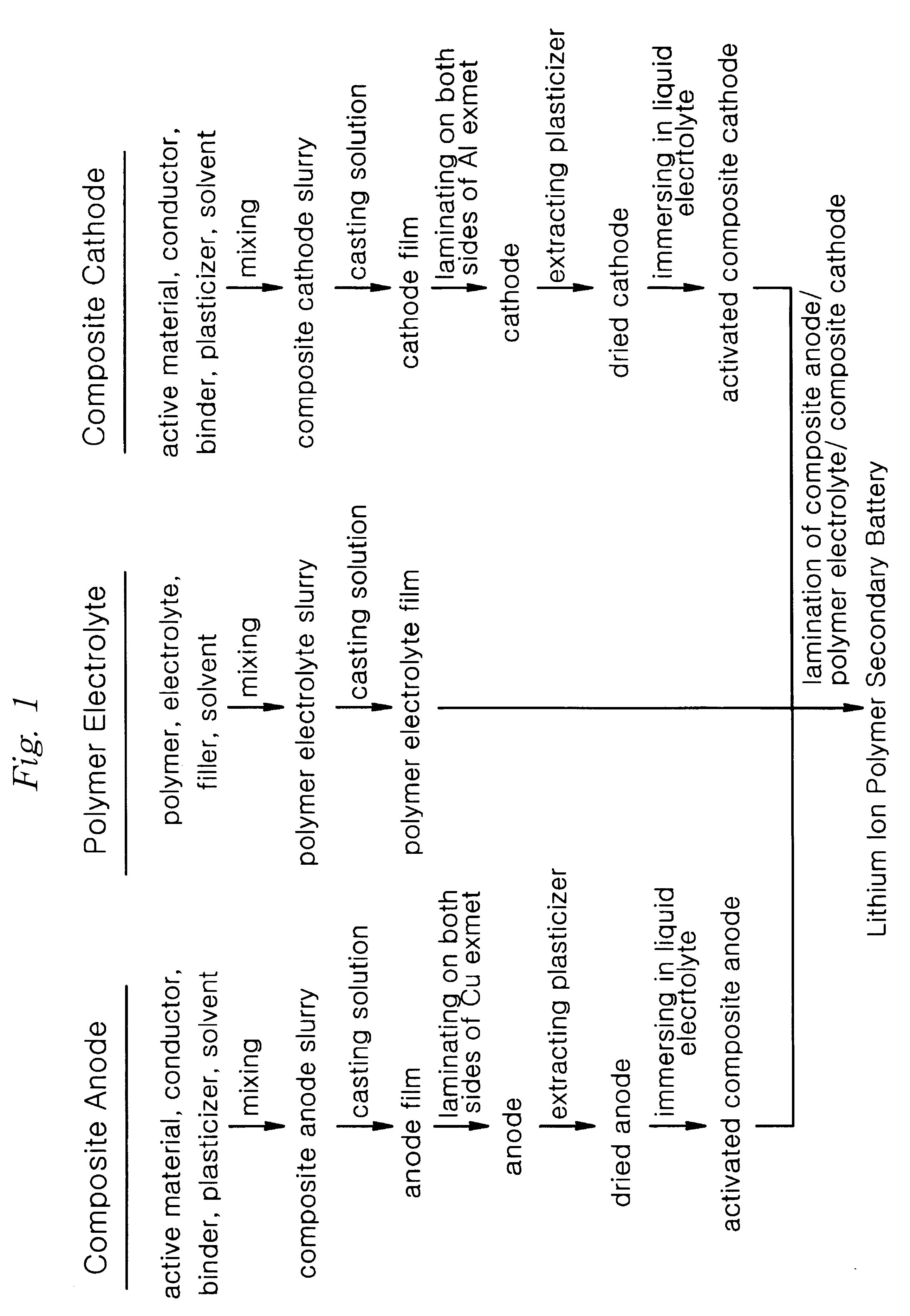

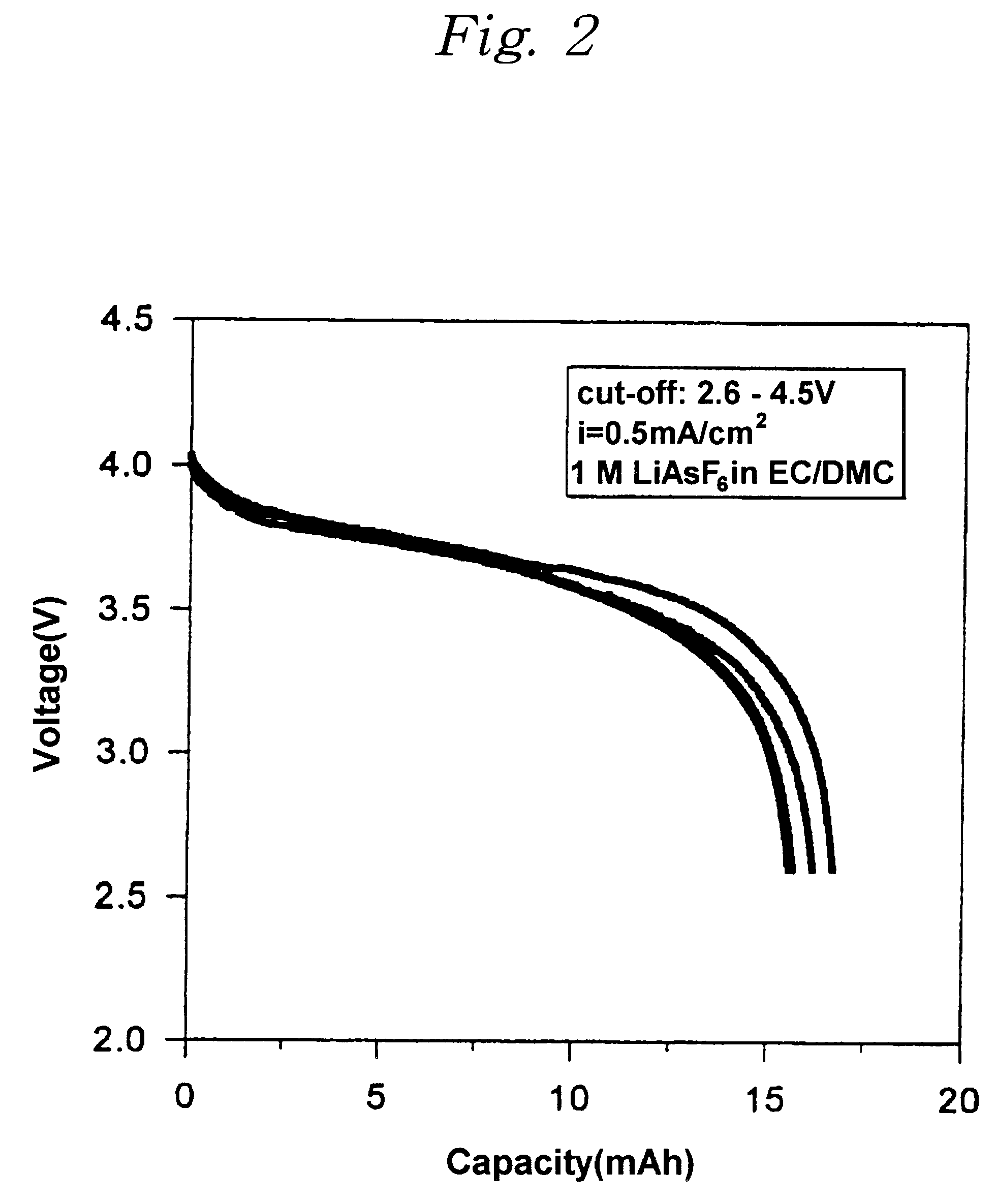

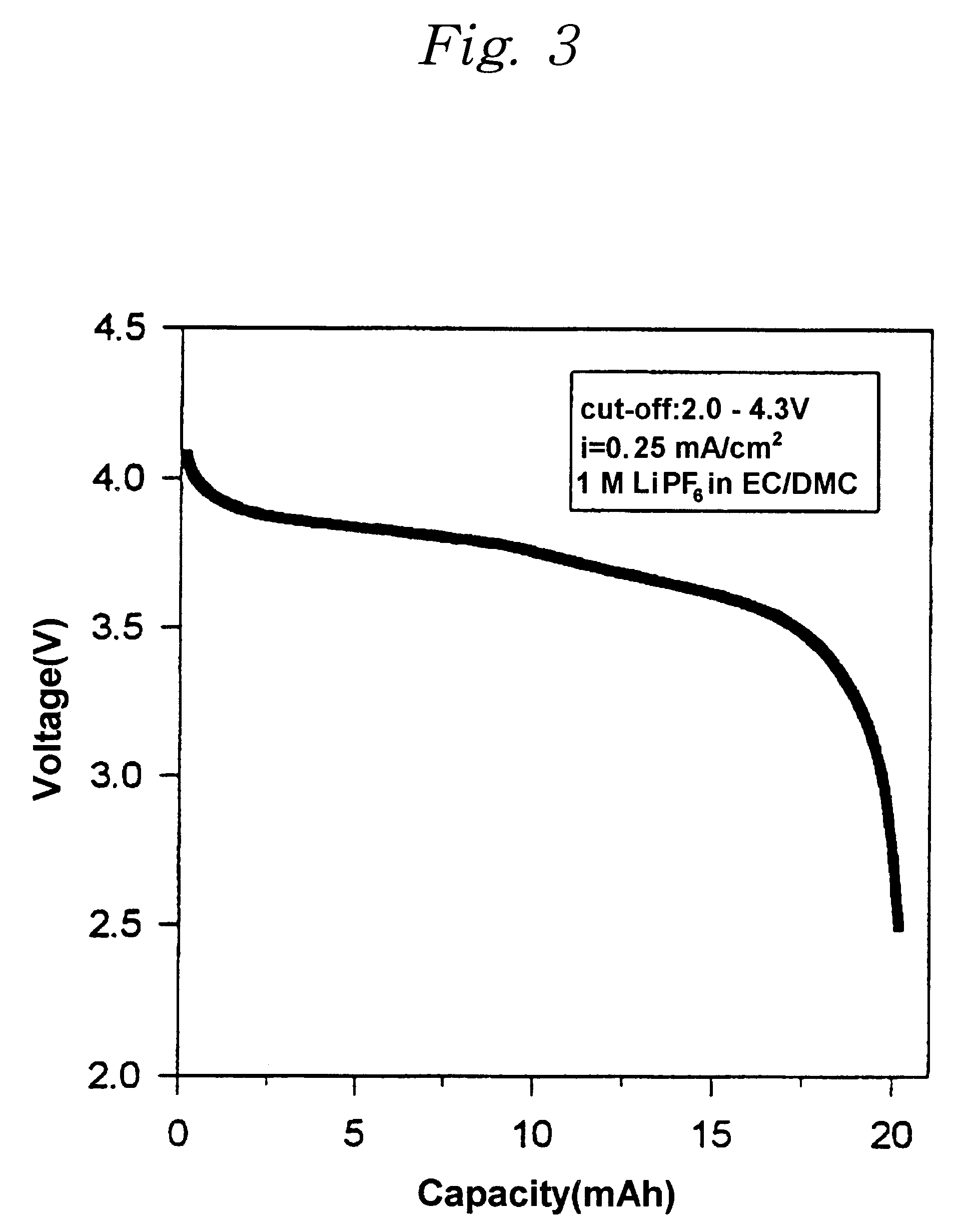

Method of preparing lithium ion polymer battery

InactiveUS6268087B1Prevent exudationInhibition of exudationElectrode rolling/calenderingFinal product manufactureComposite cathodePolymer chemistry

The present invention relates to a method of preparing a lithium ion polymer battery which has a high capacity and a good cyclability as well as no exudation of liquid electrolyte. The lithium ion polymer battery according to the present invention is prepared by the steps of forming electrode films, laminating the electrode films on both surfaces of a grid or extended metal so as to improve the interfacial adhesion between the electrode films, forming a polymer electrolyte film composed of a polymer, an electrolyte solution, and a filler, and laminating the composite anode, the polymer electrolyte and the composite cathode. The activated composite anode / polymer electrolyte film / activated composite cathode is laminated to obtain a lithium ion polymer battery structure. The lithium ion polymer battery is vacuum-packaged using a vacuum packaging apparatus.

Owner:SAMSUNG DISPLAY DEVICES CO LTD

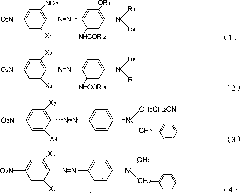

Black and blue disperse dye composition

ActiveCN101798472AWide range of applicationsGood compatibilityOrganic dyesDyeing processSunlightPhotochemistry

The invention discloses a black and blue disperse dye composition which comprises the components by weight percent: at least one 30-70% of dye monomer A shown in formula (1), at least one 15-40% of dye monomer B shown in formula (2), at least one 5-50% of dye monomer C shown in formula (3) and at least one 5-50% of dye monomer D shown in formula (4). The disperse dye composition has wide application scope of pH value, good compatibility, strong dye depth property, high color yield, good uniformity, and good sublimation fastness, washing fastness and fastness to sunlight; more importantly, the black and blue disperse dye composition has low price and convenient use, and makes up the defects of compatibility, dye depth property and tiger color of black and blue disperse dye spliced by disperse orange 288 model.

Owner:ZHEJIANG RUNTU

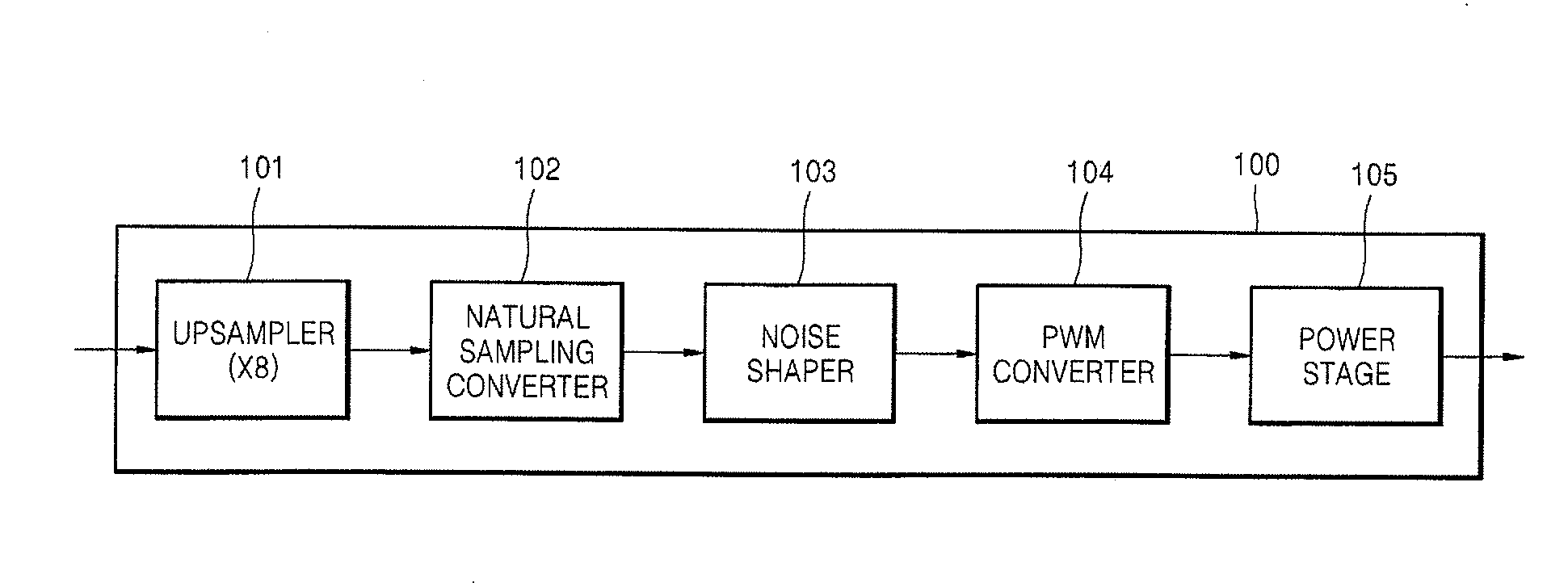

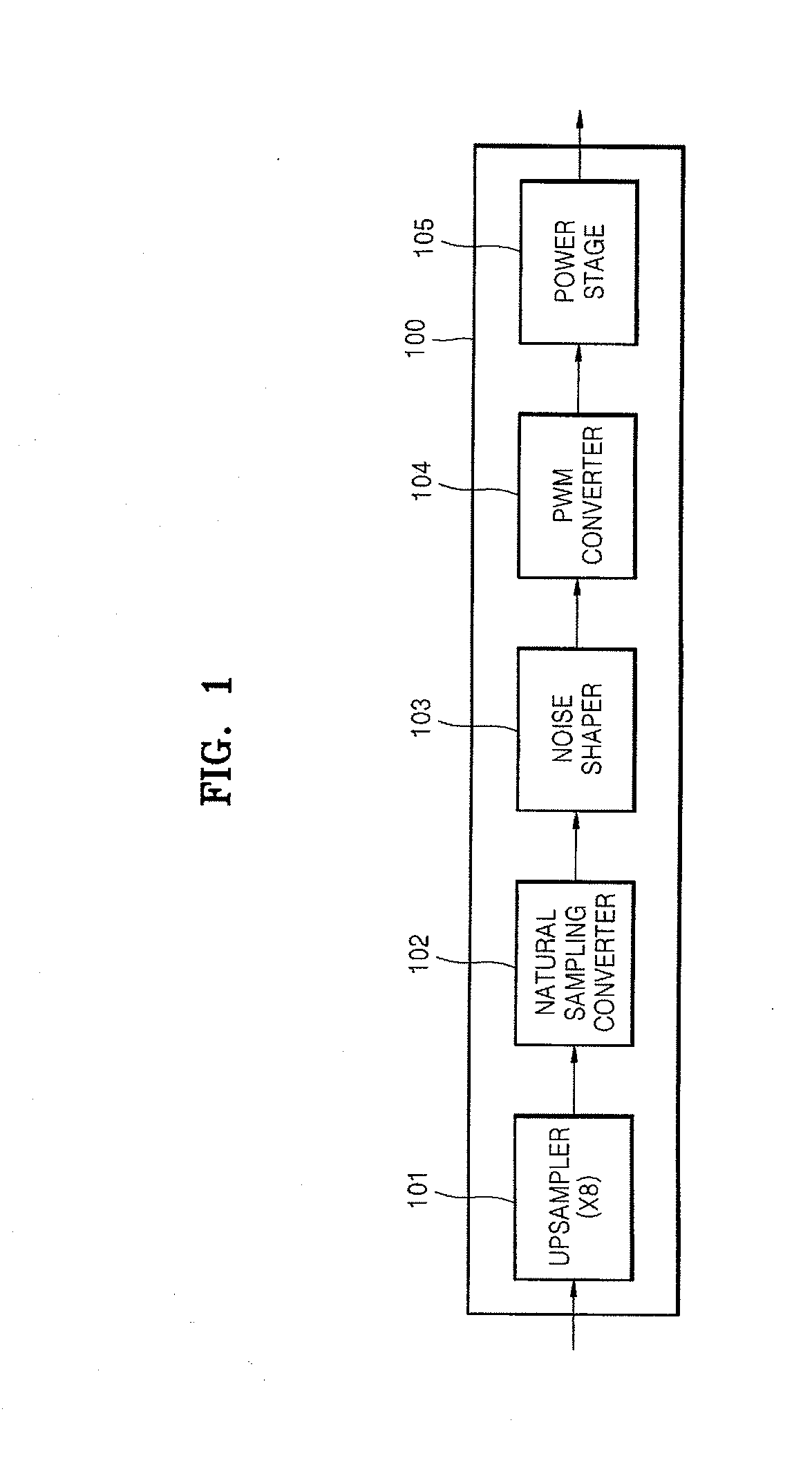

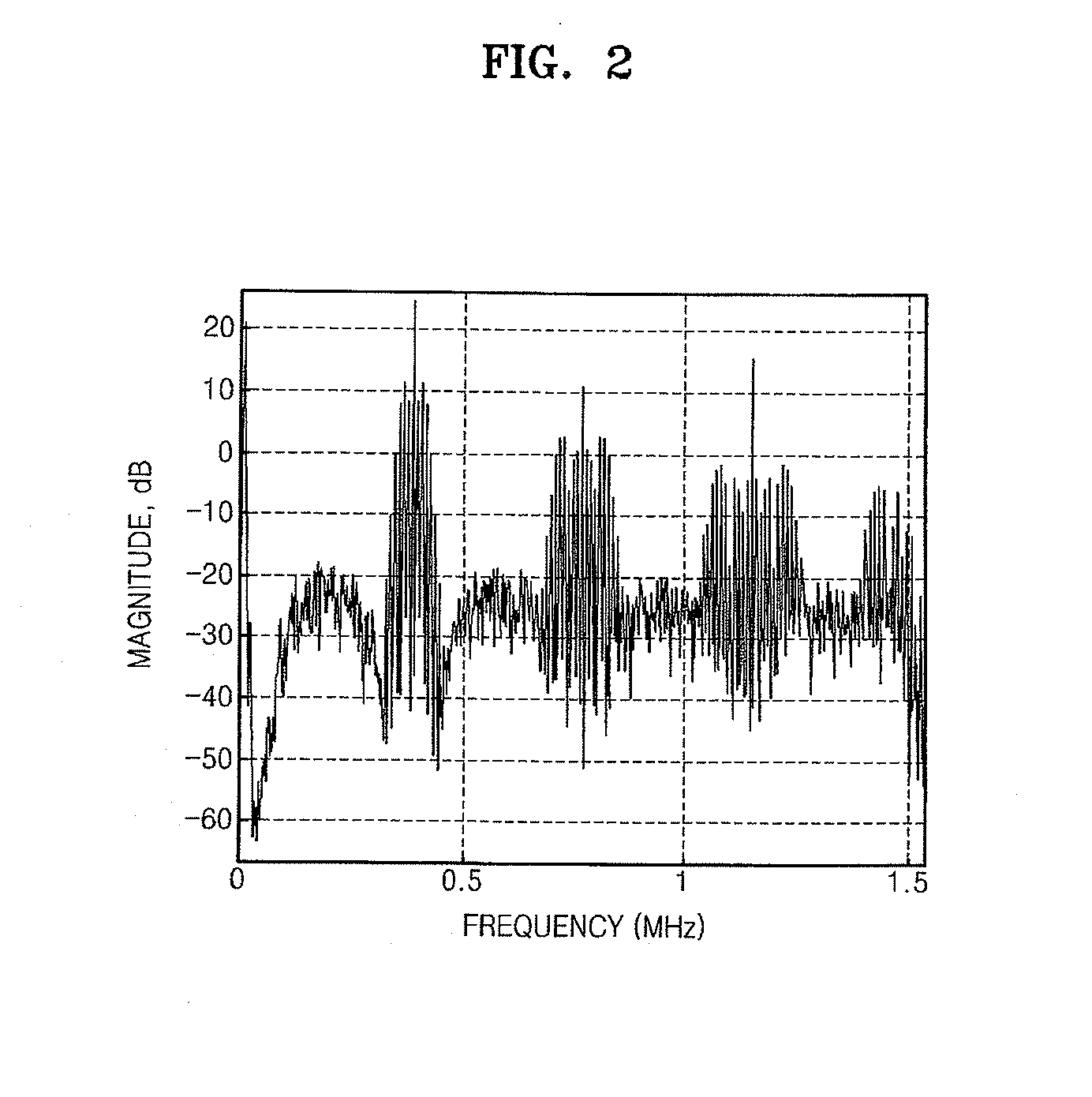

Method of and apparatus to generate pulse width modulated signal from sampled digital signal by chaotic modulation

InactiveUS20070291833A1Reduce high-frequency harmonicDecreasing electromagnetic compatibility issueAnalogue conversionAmplifier with semiconductor-devices/discharge-tubesAudio power amplifierElectromagnetic interference

A method and apparatus to generate a pulse width modulated signal from a sampled digital signal by chaotic modulation. The method includes generating predetermined chaotic intervals having random interval values using a chaotic interval generator, and generating the pulse width modulated signal from a reference signal and the sampled digital signal during each of the chaotic intervals. Thus, electromagnetic interference (EMI) that affects an audio amplifier can be remarkably reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

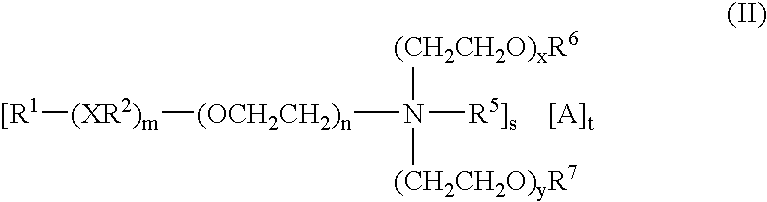

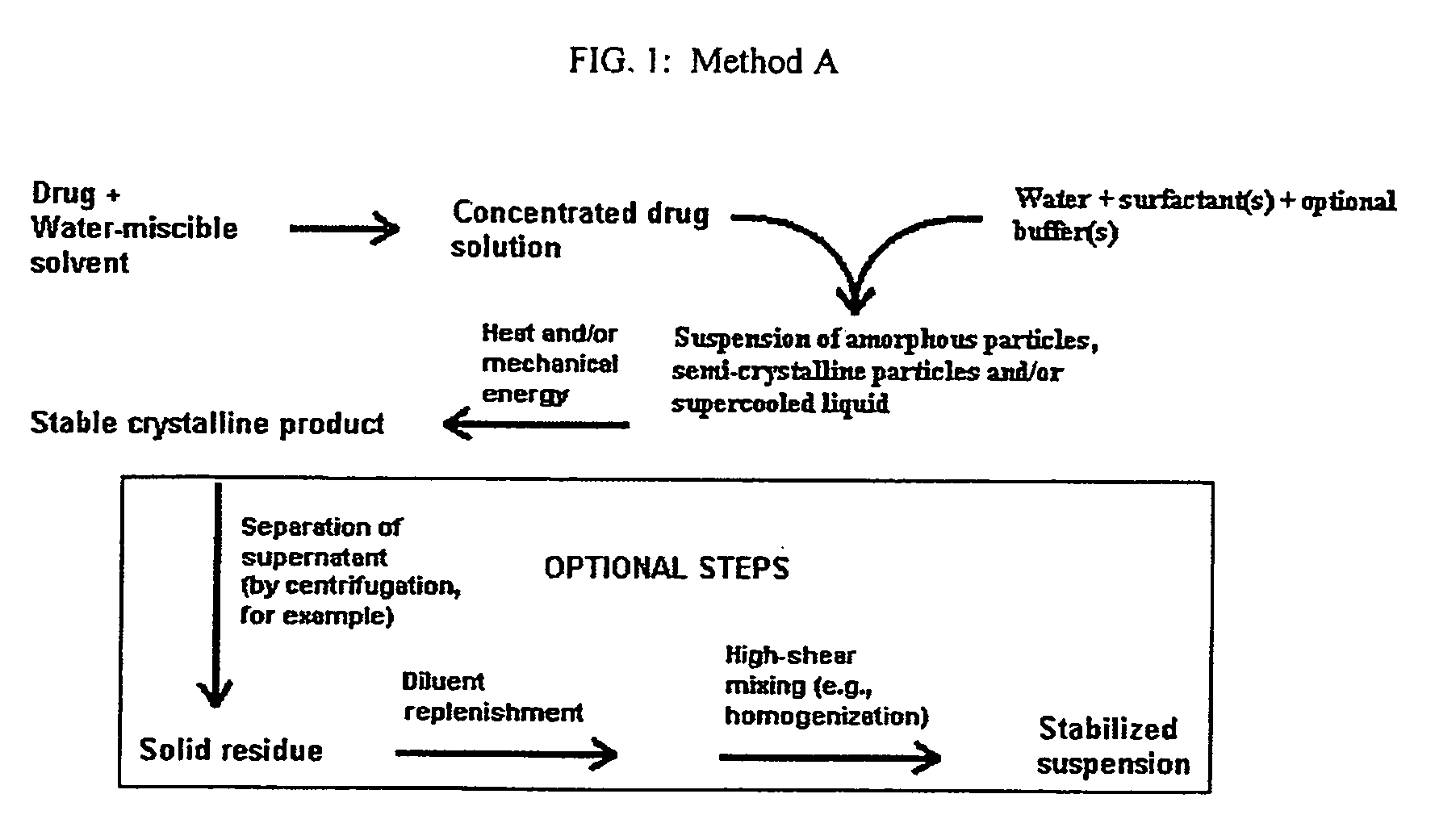

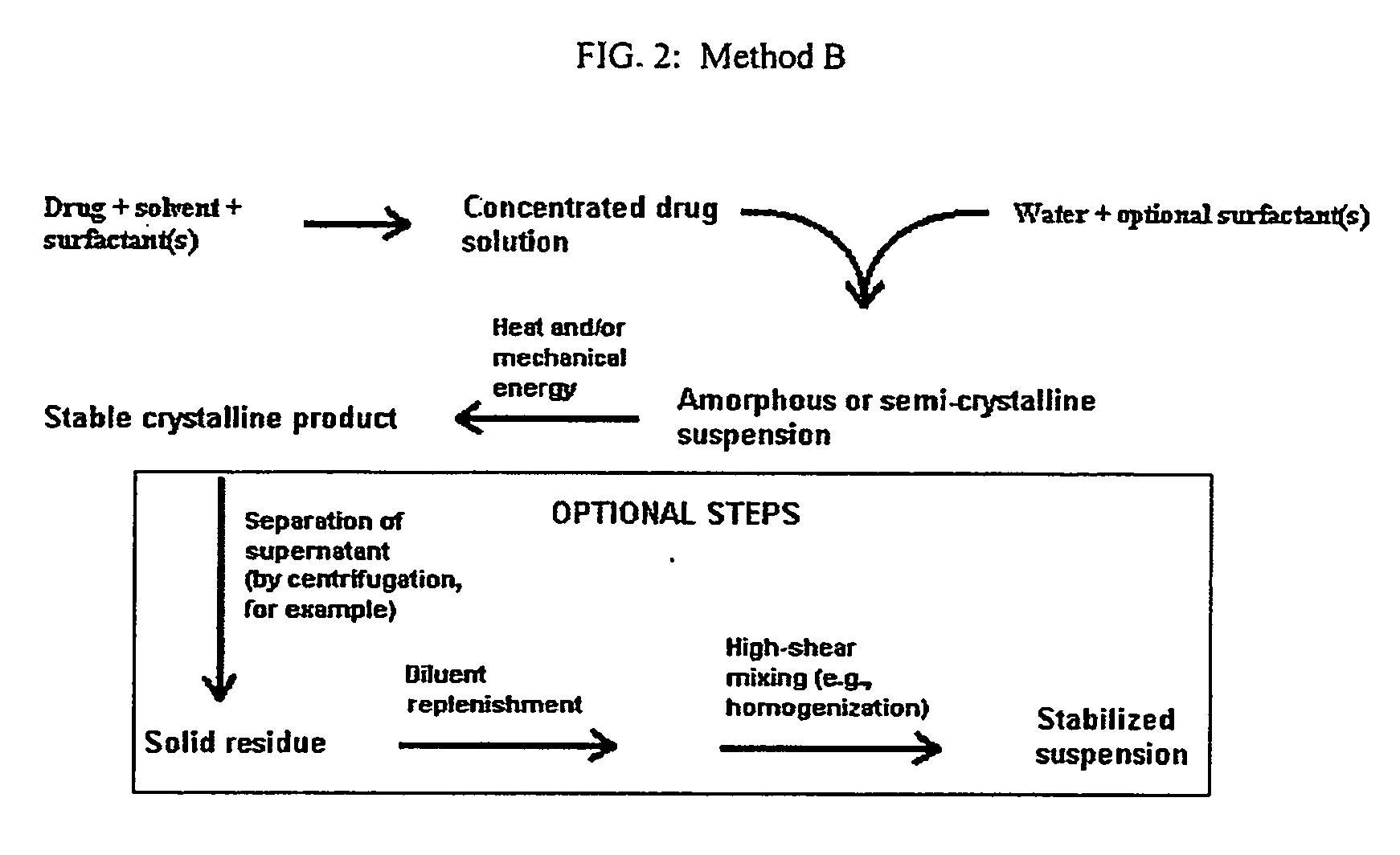

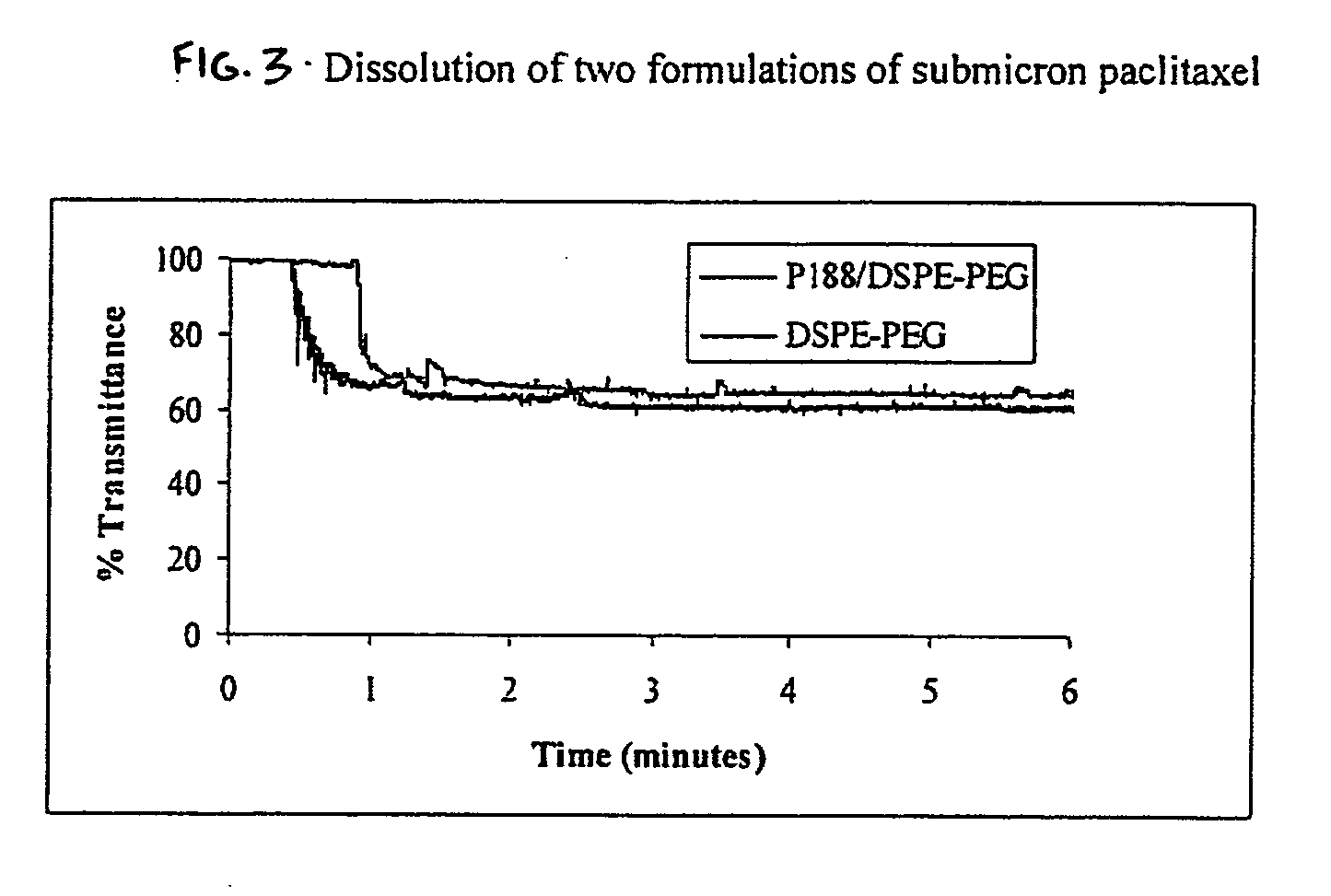

Surfactant systems for delivery of organic compounds

ActiveUS20060073199A1Poor physiological compatibilityLong-term stabilityPowder deliveryOrganic active ingredientsSimple Organic CompoundsDiagnostic agent

Submicron particles of an organic compound, such as therapeutic and diagnostic agent are disclosed. The organic compound particles are associated with at least two surfactants including a block copolymer and phospholipids conjugated with a hydrophilic polymer.

Owner:BAXTER INT INC +1

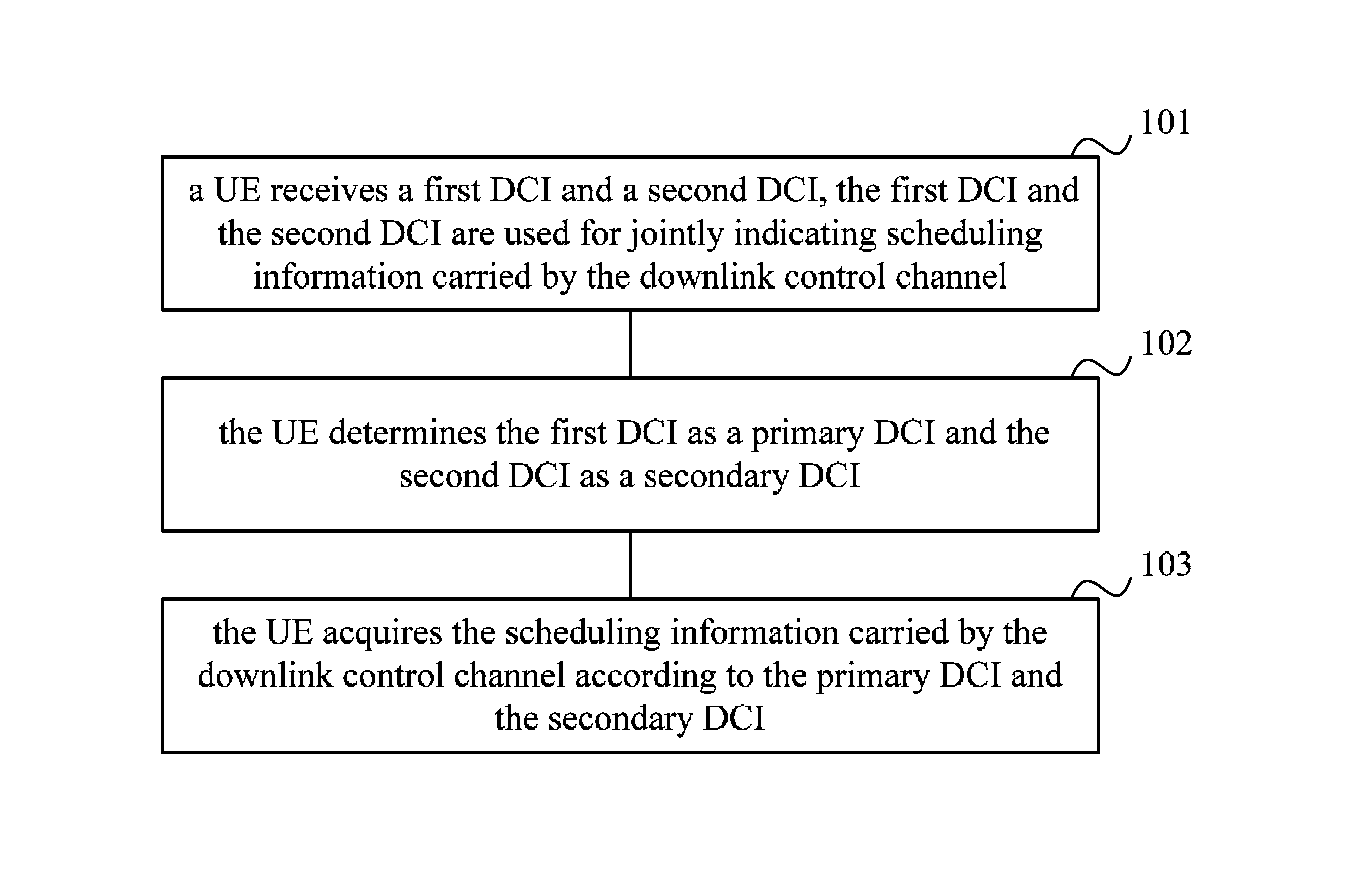

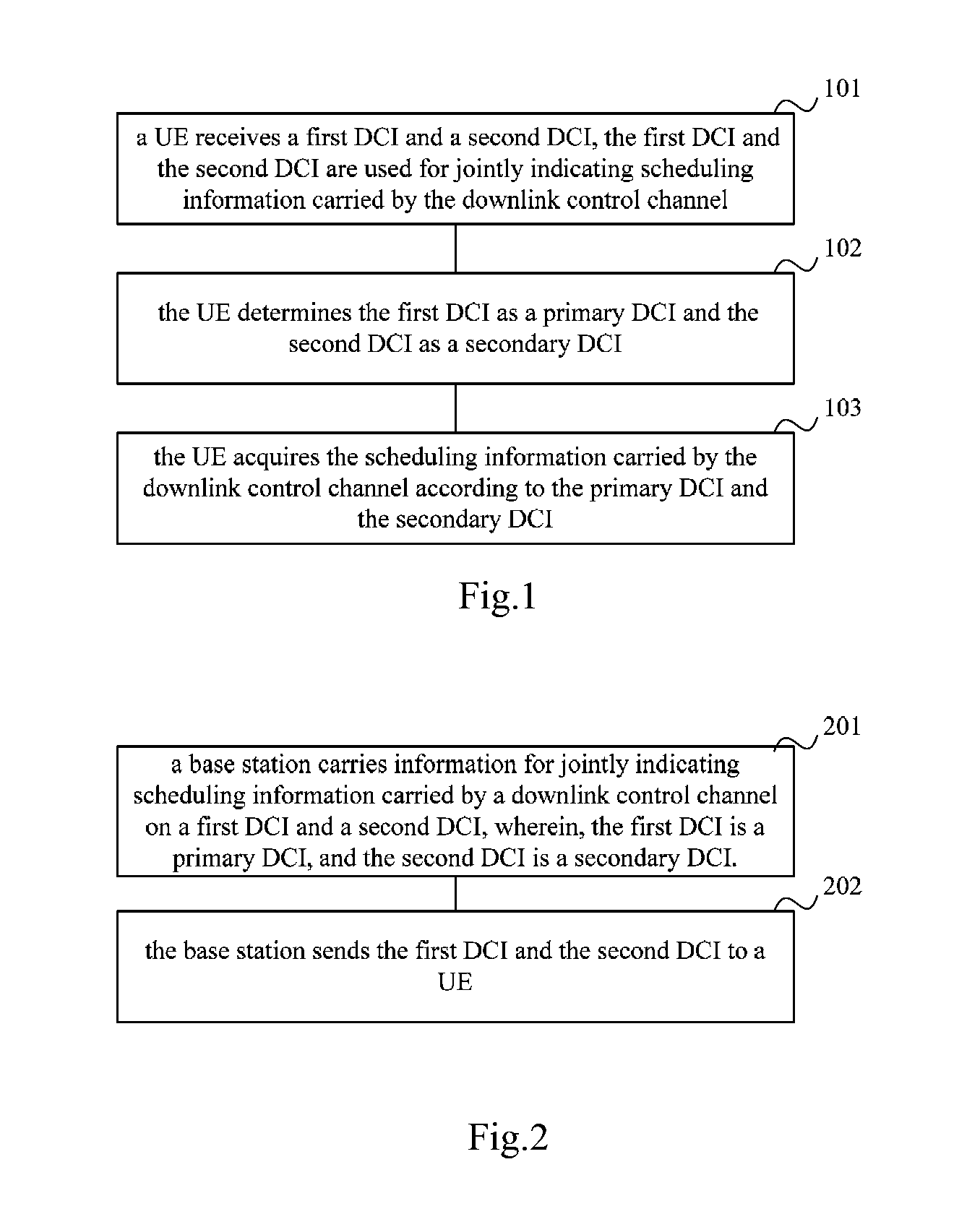

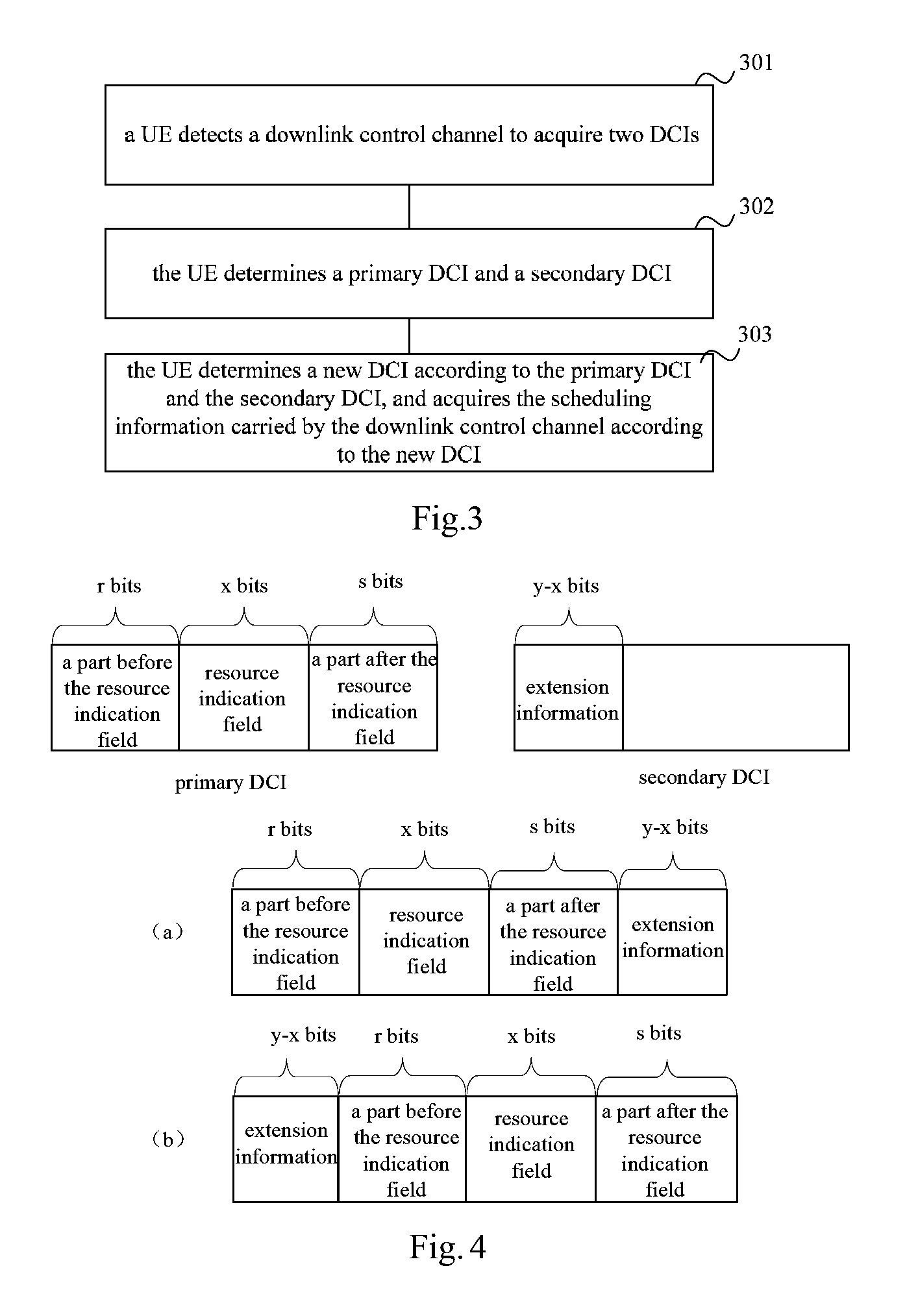

Method, device and system for transmitting downlink control channel

ActiveUS20140169312A1Ensure backward compatibilityReduced compatibilityAssess restrictionWireless commuication servicesTelecommunicationsControl channel

The present invention discloses a downlink control channel transmission method, characterized by comprising: user equipment (UE) receives a first downlink control information (DCI) and a second DCI, wherein, the first DCI and the second DCI are used for jointly indicating scheduling information carried by a downlink control channel; the UE determines the first DCI as a primary DCI and the second DCI as a secondary DCI; and the UE acquires the scheduling information carried by the downlink control channel according to the primary DCI and the secondary DCI. Also disclosed in the present invention are a communication device and a system. According to the solution provided by the present invention, the transmission of the downlink control channel corresponding to an extended resource is indicated, and the backward compatibility of the control channel is ensured.

Owner:HUAWEI TECH CO LTD

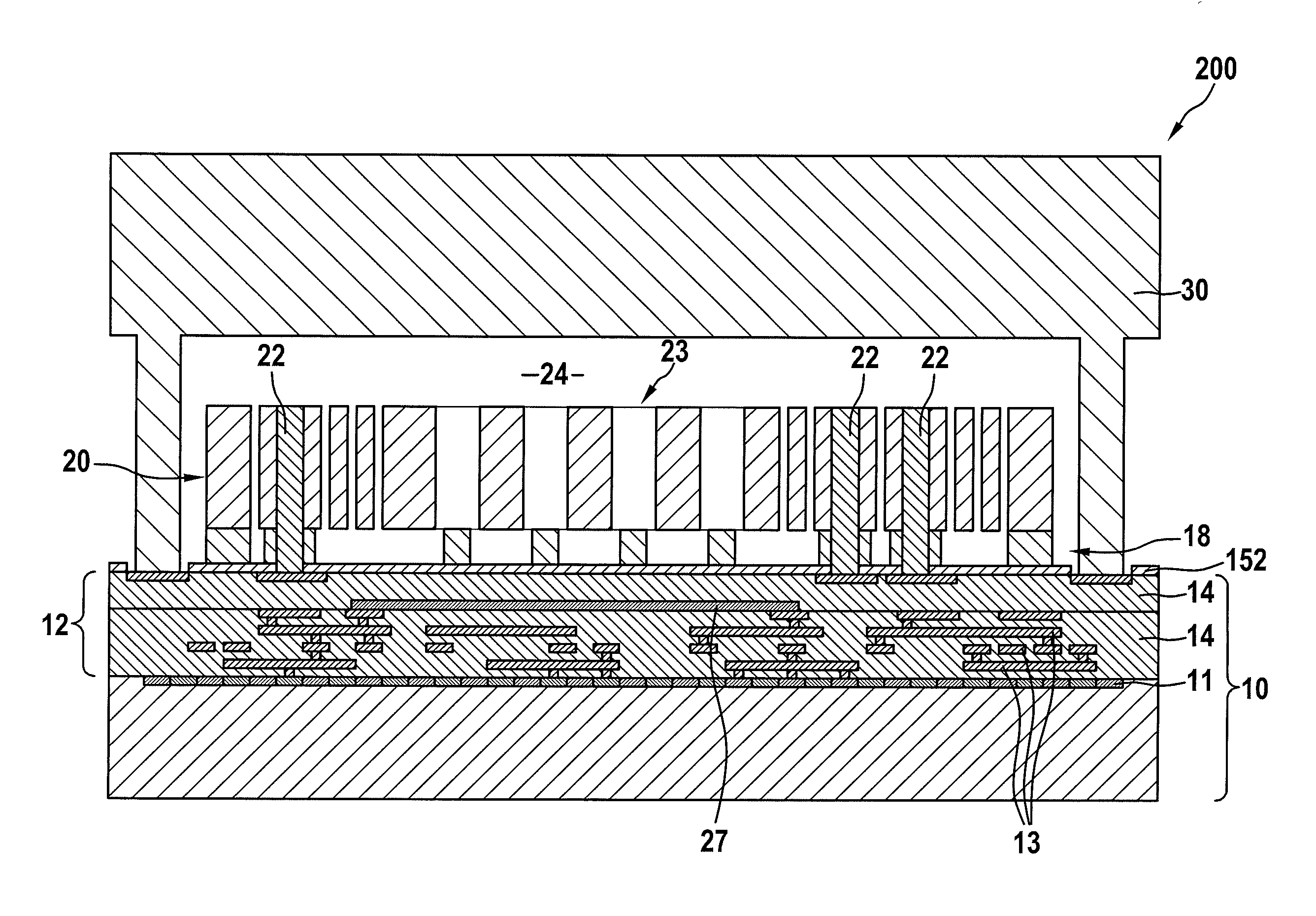

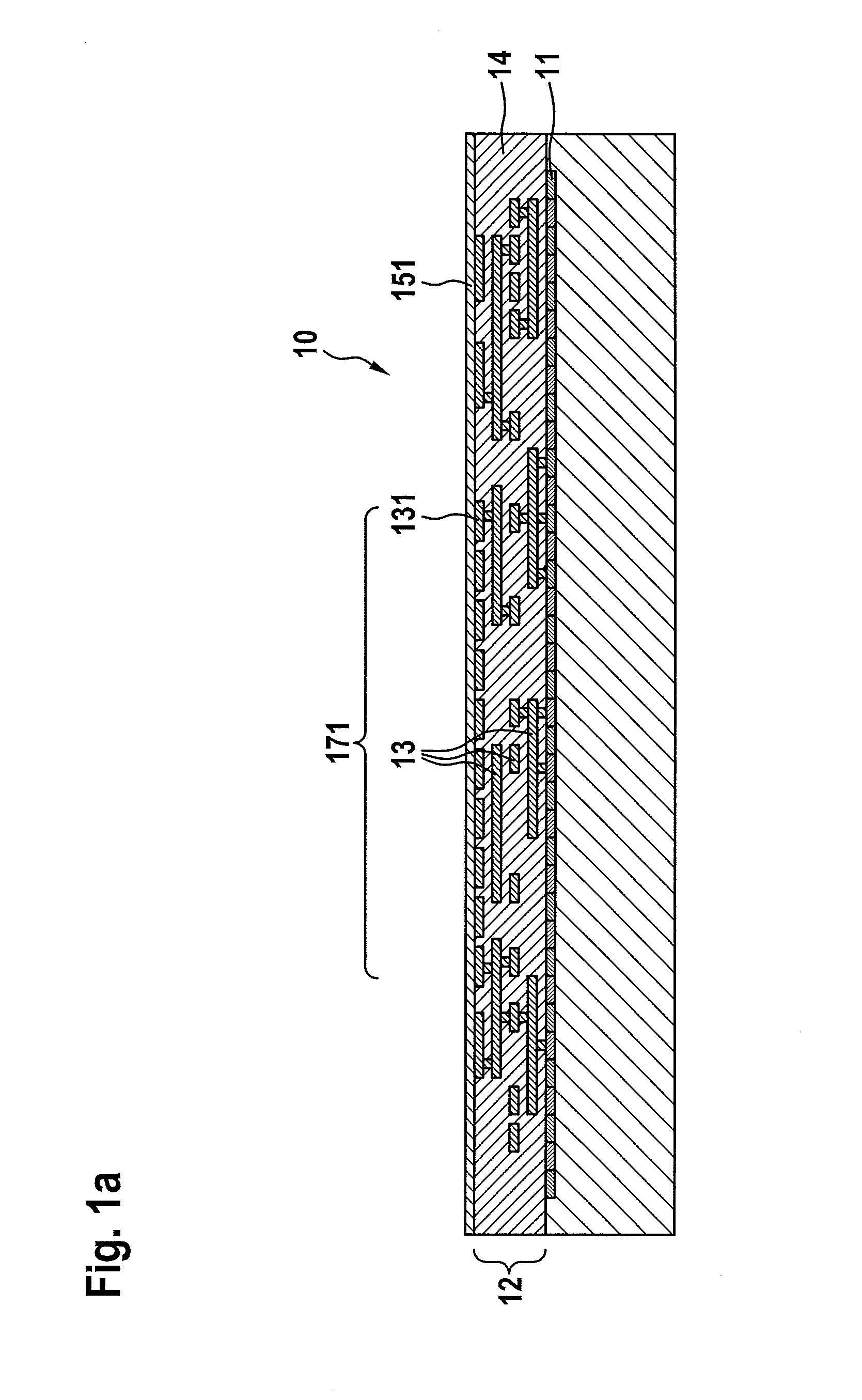

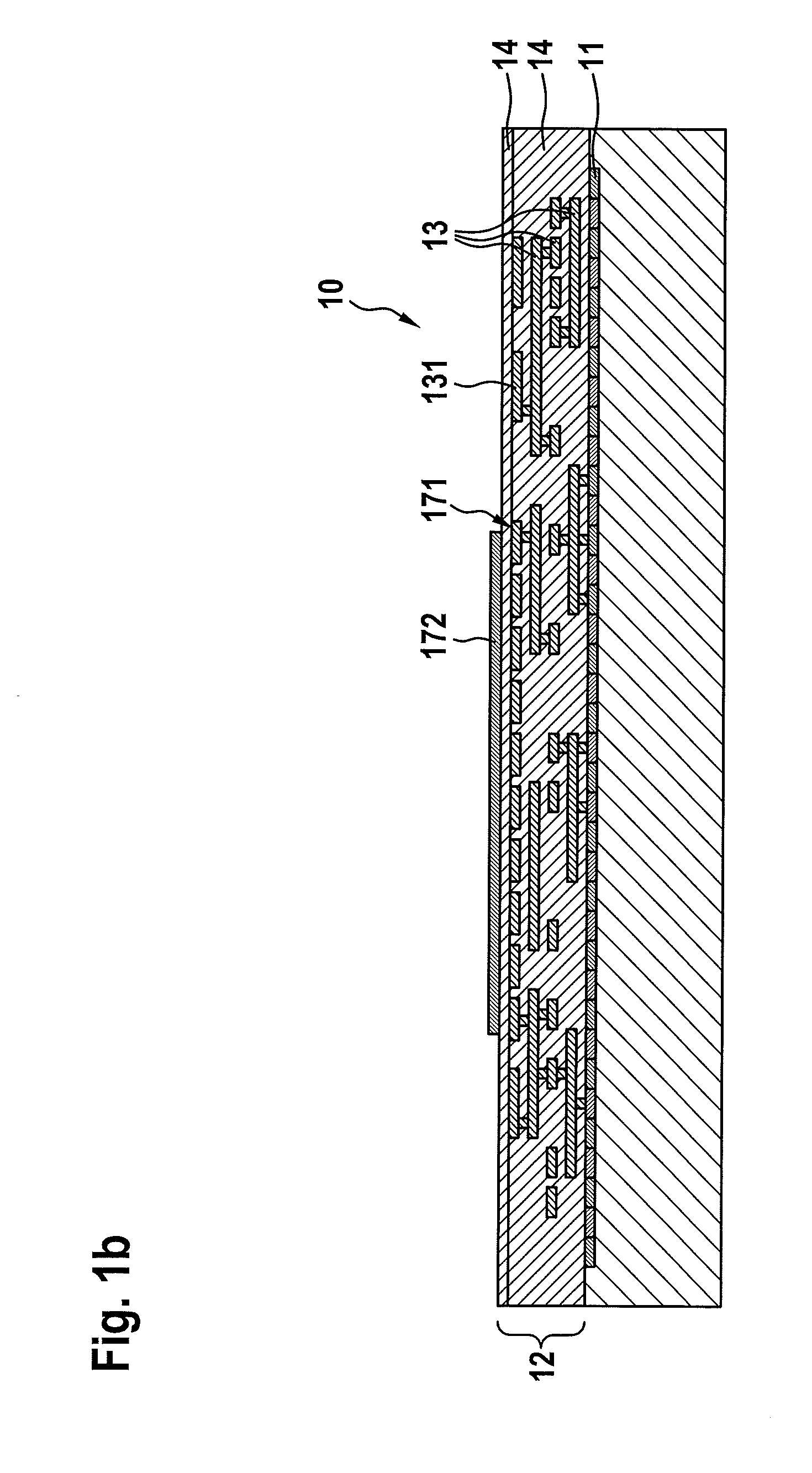

Hybrid integrated component and method for the manufacture thereof

ActiveUS20130334621A1Limited compatibilityEasy to integrateDecorative surface effectsSemiconductor/solid-state device manufacturingCMOSSensor system

An expansion of the functional scope of a hybrid integrated component including an MEMS element, a cap for the micromechanical structure of the MEMS element, and an ASIC element having circuit components is provided. In this component, the circuit components of the ASIC element interact with the micromechanical structure of the MEMS element. The MEMS element is mounted on the ASIC element in such a way that the micromechanical structure of the MEMS element is situated in a cavity between the cap and the ASIC element. The ASIC element is additionally equipped with the circuit components of a magnetic sensor system. These circuit components are produced in or on the CMOS back-end stack of the ASIC element. The magnetic sensor system may thus be implemented without enlarging the chip area.

Owner:ROBERT BOSCH GMBH

Heat insulating mortar powder and its prepn process

The heat insulating mortar powder contains cementing material, foamed modified polystyrene grain, modified expanded pearlite, cementing material modifier and fiber. The foamed modified polystyrene grain contains foamed polystyrene grain, foamed polystyrene modifier and flyash; the modified expanded pearlite contains expanded pearlite, expanded pearlite modifier and sodium hydroxide; and the cementing material modifier contains polymer adhesive, air entraining and water reducing agent and flyash activator. The preparation process includes preparing foamed modified polystyrene grain, preparing modified expanded pearlite, preparing cementing material modifier, and mixing all the materials in certain proportion. The present invention has the advantages of small heat conducting coefficient, high compression strength, good construction performance, high adhering strength, etc.

Owner:爱福家居(江苏)有限公司

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Method for preparing high-efficiency water-reducing agent of poly-carboxylic acid

The invention discloses a preparation method for a polycarboxylate high-performance water reducer, comprising the following steps: based on weight proportion, mixing 5-50% of unsaturated carboxylic acid, a derivative a of the unsaturated carboxylic acid, 45-95% of polyoxyethylene vinyl propionate ester, a derivative b of the polyoxyethylene vinyl propionate ester, as well as 0-30% of propyl sulfonate c to prepare a mixed monomer solution; then adding the initiator which takes up 0.5-15% of the total weight of the mixed monomer solution, and the chain transfer agent which takes up 0-15% of thetotal weight of the mixed monomer solution into the mixed monomer solution so as to prepare the polycarboxylate high-performance water reducer through binary or ternary copolymerization. The polycarboxylate high-performance water reducer disclosed in the invention can be widely applied to grout, mortar, concrete, gypsum and coal-water slurry, so that the mixed material can have higher mobility tosignificantly reduce the actual water consumption in the mixing process and effectively improve the concrete strength and durability, thereby showing the advantages of low mixing amount, high dispersion and high slump retaining performance.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

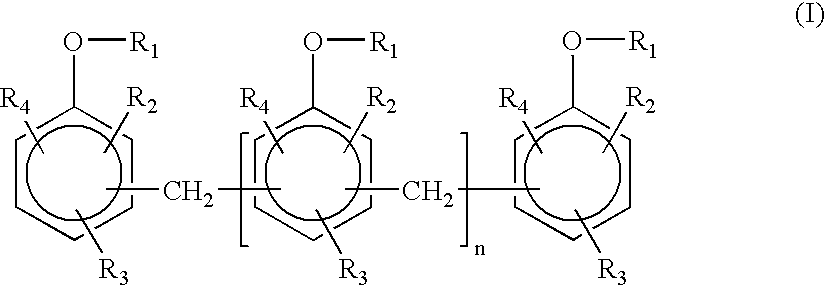

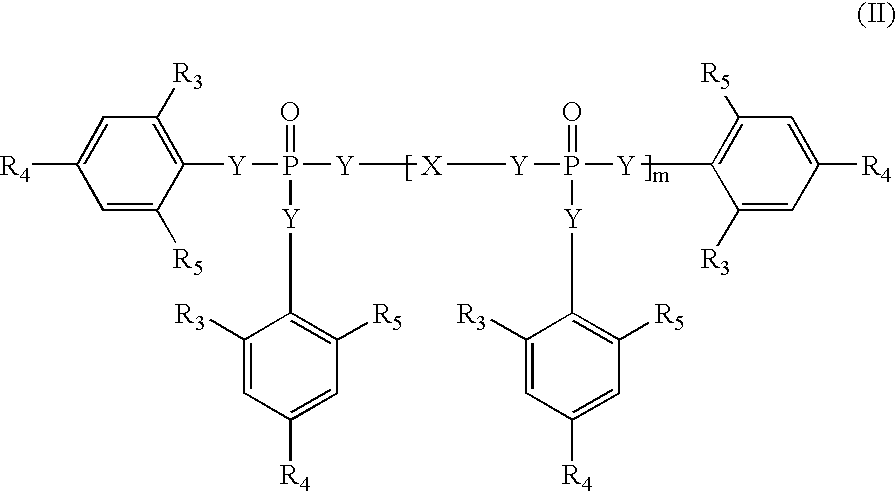

Flame retardant thermoplastic resin composition

InactiveUS20040192814A1Improve flame retardant performanceGood weather resistancePlastic/resin/waxes insulatorsDyeing processPolymer sciencePerylene derivatives

The present invention relates to a flame retardant thermoplastic resin composition that contains a phenol resin derivative having good char formability, regardless of the base resin. A flame retardant thermoplastic resin composition according to the present invention comprises (A) 100 parts by weight of a thermoplastic resin as a base resin, (B) about 0.1~100 parts by weight of a phenol resin derivative, and (C) about 0.1~50 parts by weight of a phosphorous compound or a mixture of phosphorous compounds.

Owner:LOTTE ADVANCED MATERIALS CO LTD

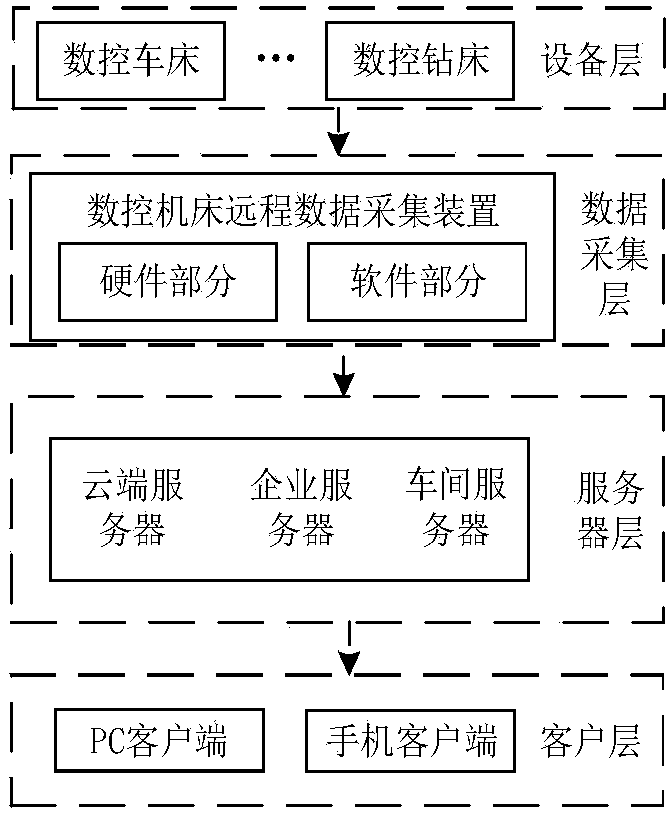

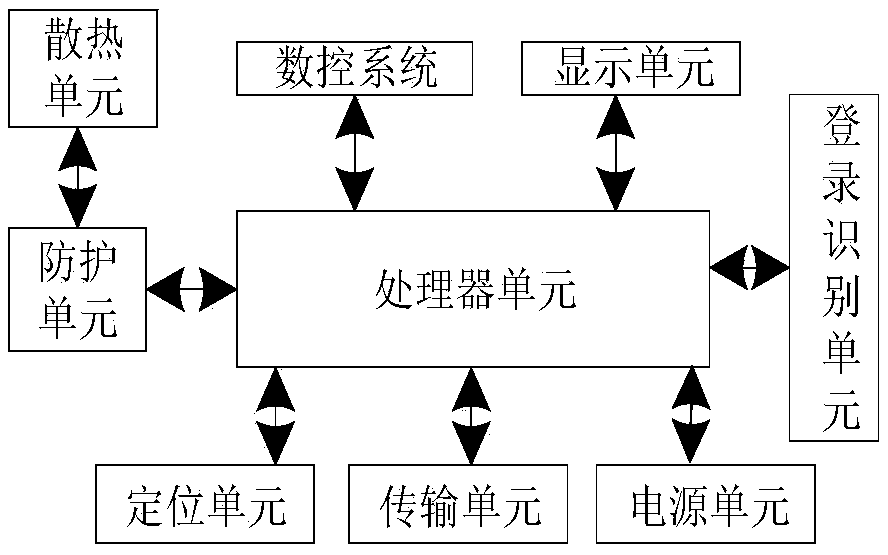

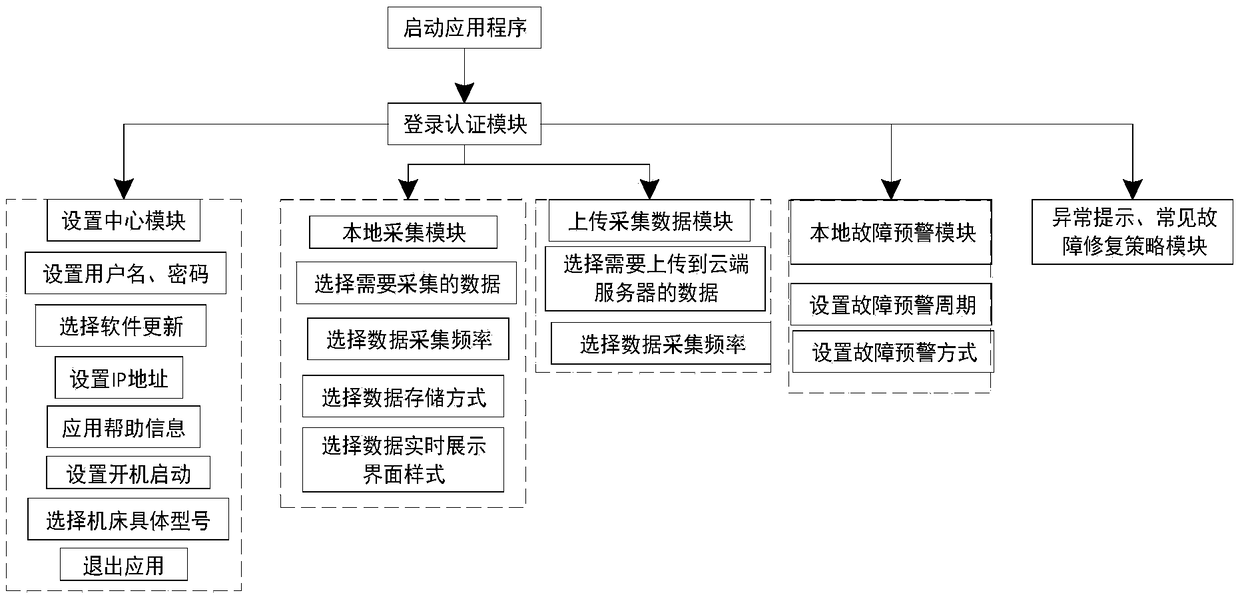

Remote data acquisition and analysis system for numerically-controlled machine tool

PendingCN108762193ARealize remote monitoringRealize remote operation and maintenanceProgramme controlComputer controlNumerical controlData acquisition

The invention discloses a remote data acquisition and analysis system for a numerically-controlled machine tool. The remote data acquisition and analysis system comprises an equipment layer, a data acquisition layer, a server layer and a client layer, wherein the equipment layer comprises the numerically-controlled machine tool; the data acquisition layer comprises a data acquisition device, and the data acquisition device is used for acquiring data of the numerically-controlled machine tool; the server layer is communicated with the data acquisition layer and is used for receiving and processing data transmitted by the data acquisition layer and storing the processed data in a database; the client layer interacts with the server layer to feed processing results of the server layer back toa user.

Owner:JILIN UNIV

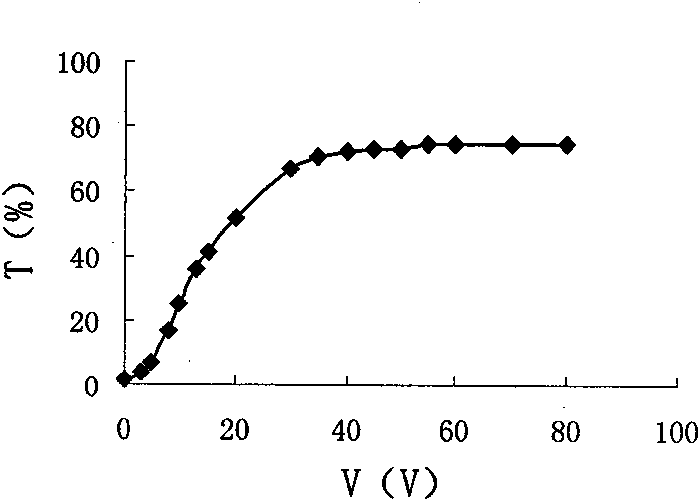

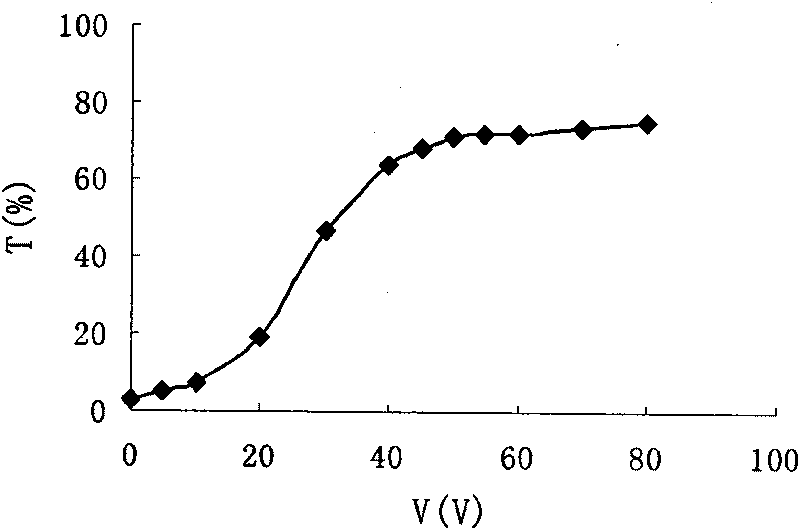

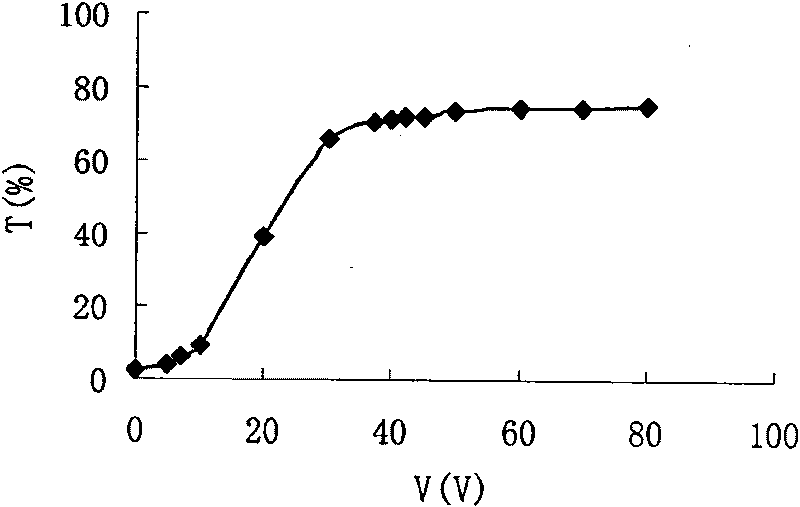

Polymer dispersed liquid crystal material and method for preparing liquid crystal films from same

ActiveCN101717647AReduce the driving voltageIncrease the driving voltageLiquid crystal compositionsNon-linear opticsPolyesterPolymer science

The invention discloses a polymer dispersed liquid crystal material and a method for preparing liquid crystal thin films from the same, which belongs to the technical field of liquid crystal application. Thin films prepared can be widely applied in liquid crystal display, intelligent glass and other related fields. A polymer dispersed liquid crystal composition comprises 20 to 80 parts by weight of polymer monomer, 1 to 10 parts by weight of photoinitiator, 20 to 70 parts by weight of oligomer and 0.1 to 10 parts by weight of polymerization inhibitor, wherein the oligomer is at least one of epoxy acrylate oligomer, urethane acrylate oligomer, polyester acrylate oligomer, polyether acrylate oligomer and unsaturated polyester oligomer, and the polymer monomer is at least one of monofunctional-group (methyl) acrylate monomer, bifunctional-group (methyl) acrylate monomer and high-functional-group acrylate monomer with three or more functional groups. A PDLC thin film prepared from the mixture provided by the invention has high contrast, low driving voltage and good stability.

Owner:青岛诚志光电科技有限公司

Film forming composition for producing soft starch material capsule and preparation method of film forming composition

ActiveCN103893771AComponent simplificationReduce interactionCosmetic preparationsToilet preparationsPolymer chemistryDirect production

The invention relates to a film forming composition for producing a soft starch material capsule and a preparation method of the film forming composition, and the soft starch material capsule prepared from the film forming composition. The composition is formed by hydroxypropyl starch and water which are in a certain proportion, wherein optionally, proper auxiliary materials such as an opacifying agent, a colorant and a flavouring agent which are used for improving the performance of the soft capsule can be added. The preparation method comprises the following steps: mixing the materials according to a certain sequence; and controllably heating the materials in a temperature rising manner so as to obtain the film forming composition. The film forming composition can be directly produced so as to obtain the soft starch material capsule by indiscriminately using a production method of the traditional soft gelatin capsule.

Owner:HUNAN ER KANG PHARMA

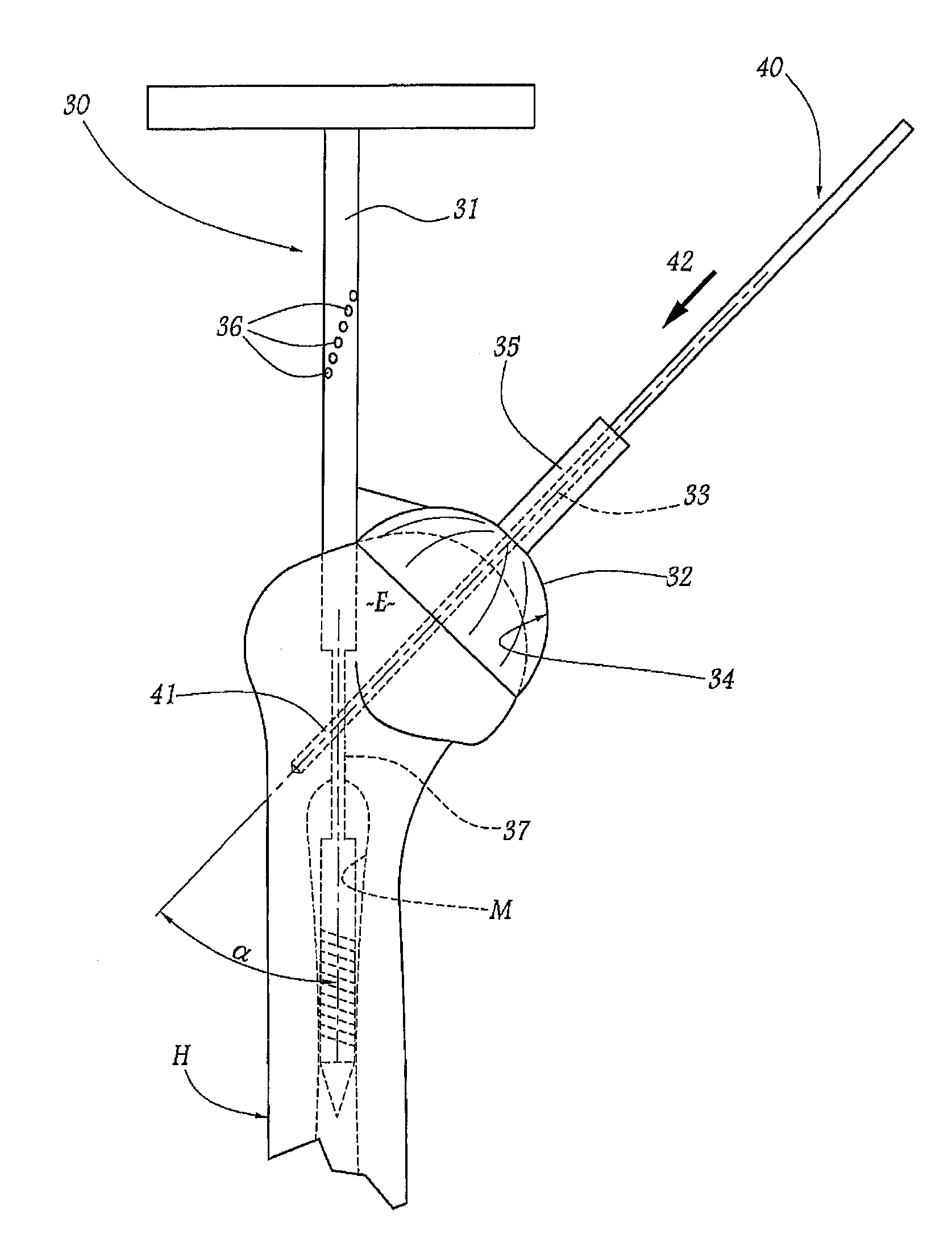

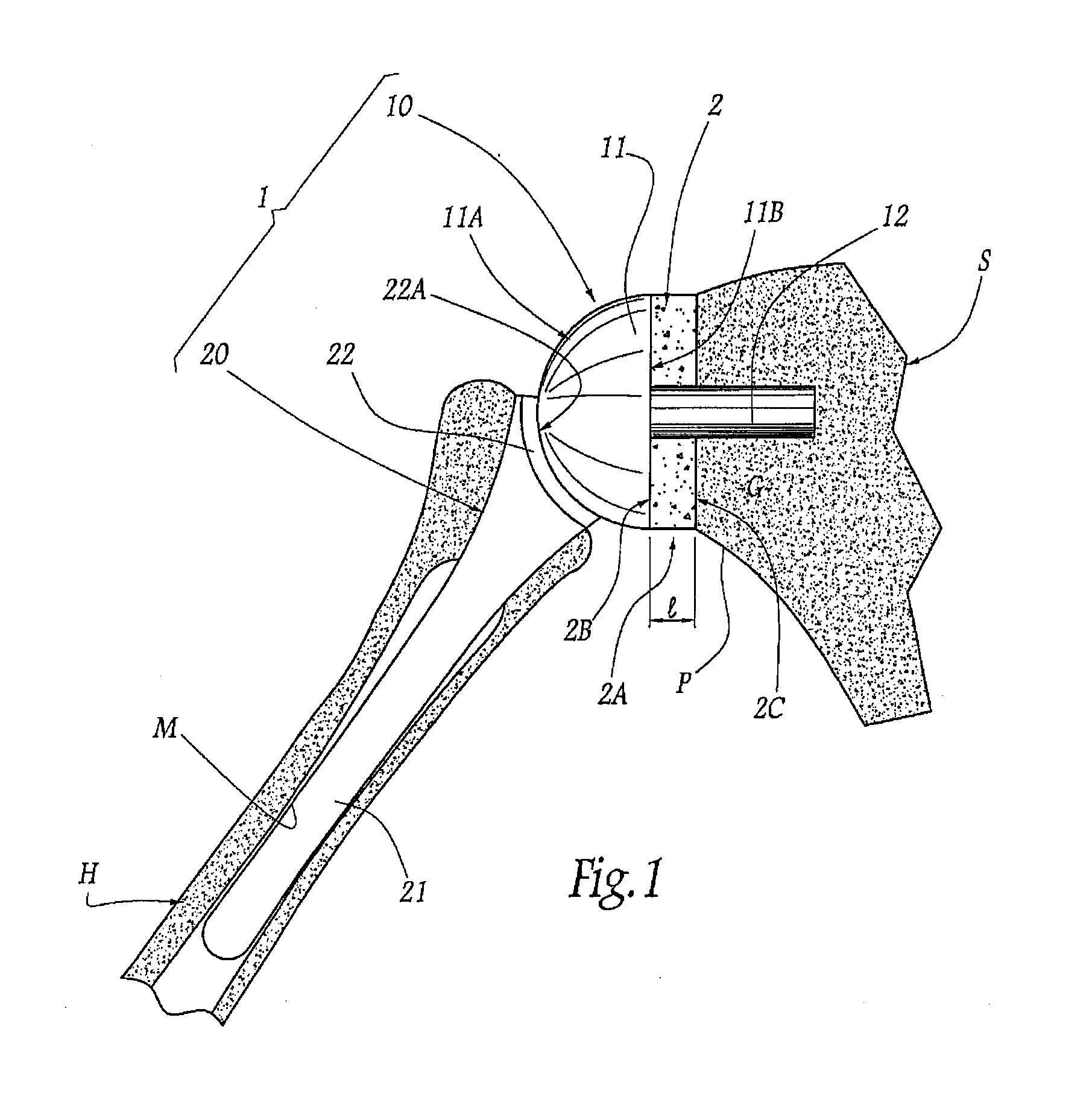

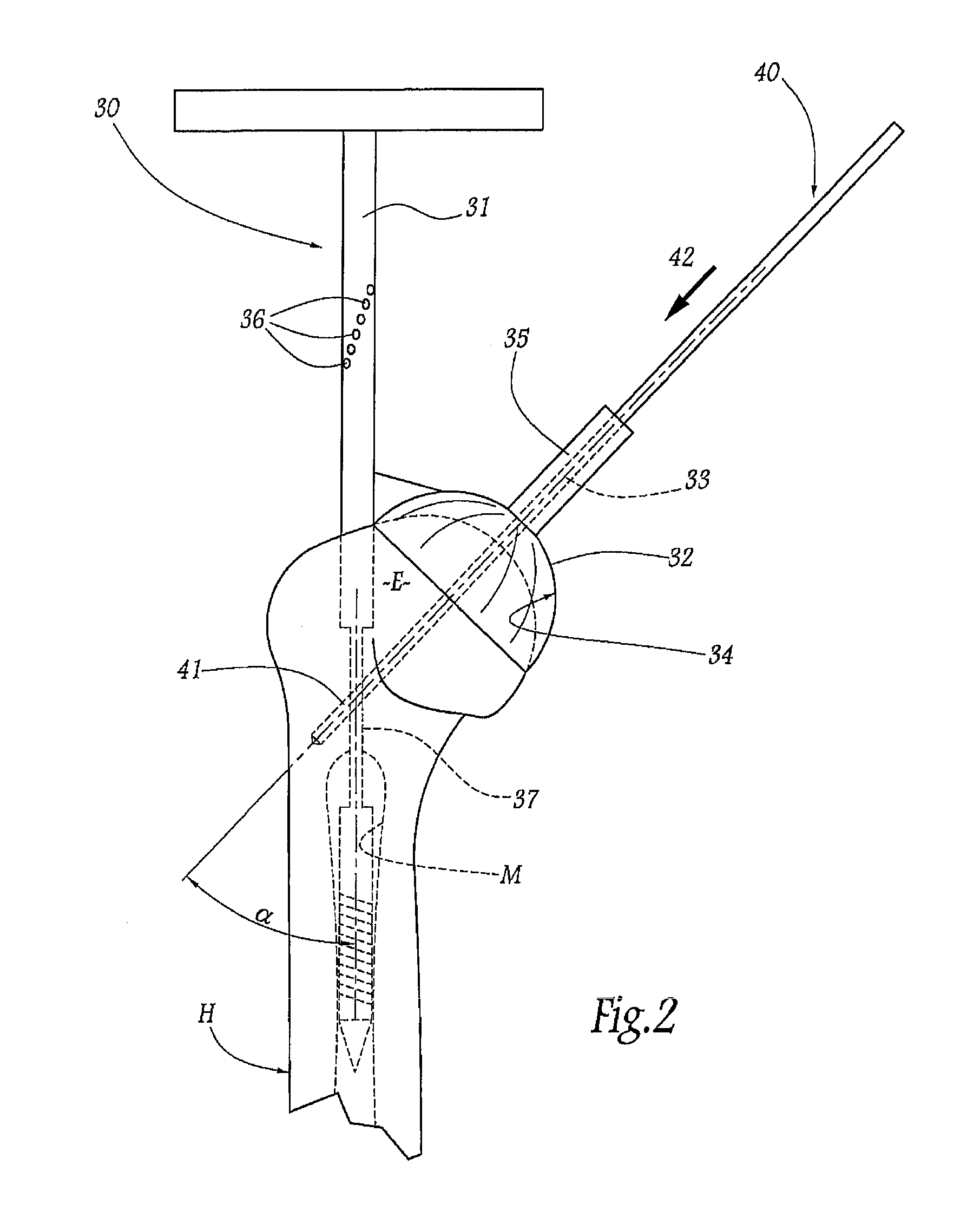

Apparatus for fitting a shoulder prosthesis

InactiveUS20110166661A1Reduce riskReduce tensionBone implantJoint implantsArticular surfacesArticular surface

Method and set of surgical instruments for fitting a shoulder prosthesis, and the shoulder prosthesis. The proposed method seeks to interpose a bone graft between the previously prepared glenoid surface of a scapula of a patient's shoulder and the face of a glenoid prosthetic component opposite the articular surface. The set of instruments permit the bone graft to be taken from the upper epiphysis of the humerus, either in situ or ex vivo.

Owner:TORNIER SA SAINT ISMIER

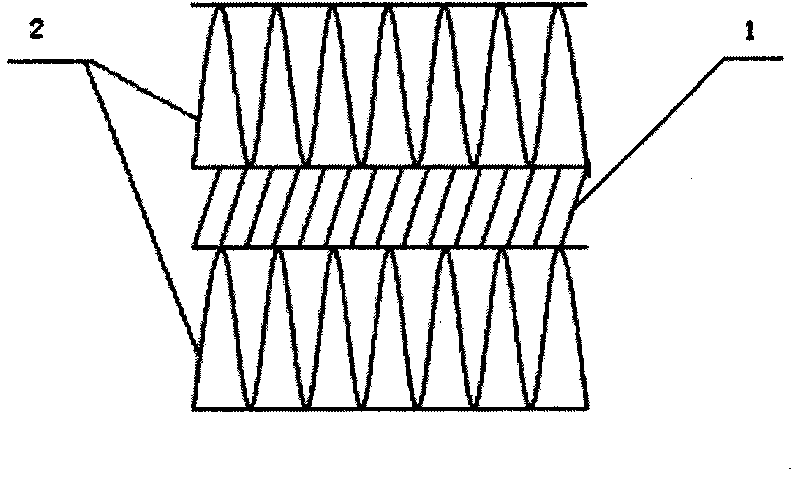

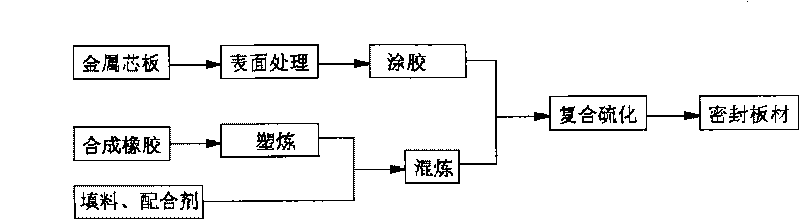

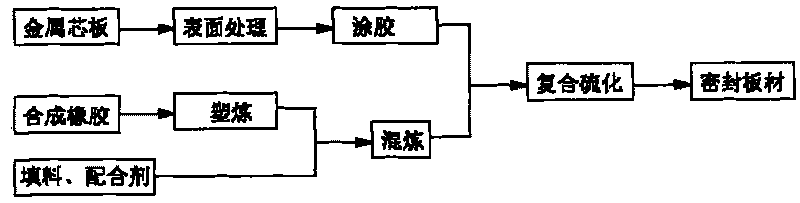

Composite sealing material and manufacturing method thereof

InactiveCN101747862AGood compression and rebound performanceGood long-term pressure resistance and sealing performanceOther chemical processesSurface finishingElastic membrane

The invention discloses a novel sealing material, which consists of a core plate and elastic membrane layers compounded on two sides of the core plate, wherein the core plate a metal or non-metal core plate after surface treatment; the elastic membrane layers are prepared from elastic foaming materials or non-foaming materials which are compounded on the surfaces of the core plate in a mechanical or chemical mode to form the membrane layers. The sealing material has the advantages of simple structure, excellent compression resilience, wonderful long-term pressurization sealability, very low creep relaxation performance, long service life and wonderful conformability with a sealing surface.

Owner:上海骏焱化工材料有限公司

Novel preparation method for polyether amine composite material

The invention discloses a novel preparation method for a polyether amine composite material, which comprises the following preparation steps: (1) preparing refined polyether polyol; and (2) preparing polyether amine. In the invention, upstream raw materials are used as starting raw materials, various monomer raw materials are used to produce a hydroxyl polyol with a multi-functional group structure, a high-activity catalyst is combined, the activity of the catalyst is improved, many tests are carried out, the tested product has high comprehensive performance, production cost is reduced, and the product is suitable to be used in more industries. In the invention, new varieties of upstream raw materials of the polyether amine product are added, the polyether products are diversified, the application adaptability of the product in the composite material is improved, product quality is improved, product cost is reduced, reaction pressure and temperature are lowered, the production safety coefficient is high, equipment manufacturing cost is lowered, energy consumption is reduced, and continuous large-scale production is promoted.

Owner:东莞市科道玛电子复合材料有限公司

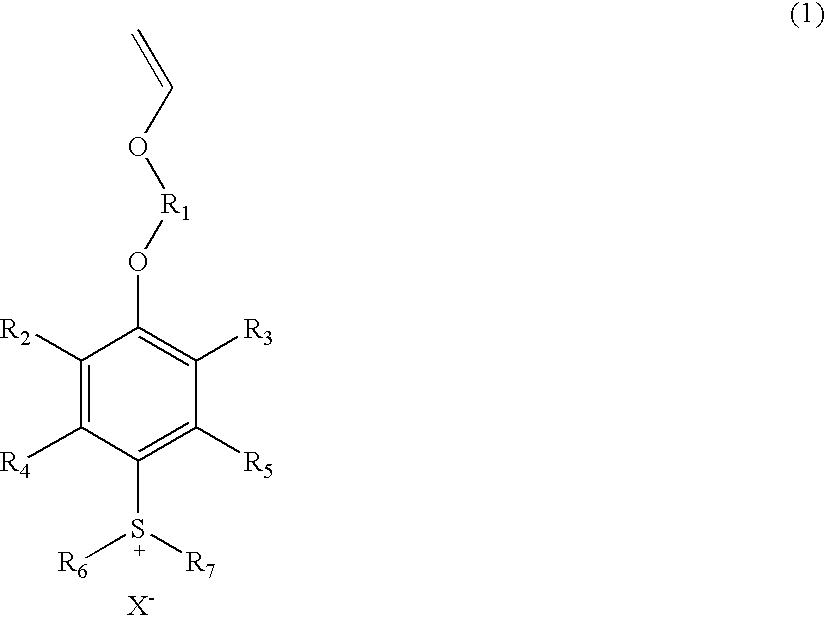

Sulfonium salts

InactiveUS20070219368A1Reduced compatibilityOrganic chemistryOrganic compound preparationHydrogen atomSulfonium

The present invention provides a sulfonium salt which can serve as a photo-acid-generator, the sulfonium salt not raising the problem of poor compatibility to a photoresist polymer having an acid-dissociable group. The sulfonium salt is represented by formula (1):wherein R1 represents a linear or branched C2 to C9 divalent hydrocarbon group; each of R2 to R5 represents a hydrogen atom or a linear or branched C1 to C3 hydrocarbon group; each of R6 and R7 represents an organic group; R6 and R7 may be linked together to form a divalent organic group; and X− represents an anion.

Owner:TOYO GOSEI IND CO

Separating method for isocyanate monomer of urethane curing agent

A method for separating isocyanic ester from polyurethane-curing agent includes; adding acid 0.01 - 0.5% as reaction inhibitor, adding distillation agent 8 -60%, carrying out three-stage separation in an internally or externally cooling membrane distiller, pumping remains separated after second or third stage to pass them into a diluting container with solvent in, heating solvent up to 80 - 140deg.C, and stirring solvent with solid remains 35 - 85% to obtain curing agent with high solid content, low isocyanic ester content, and low viscosity.

Owner:SOUTH CHINA UNIV OF TECH

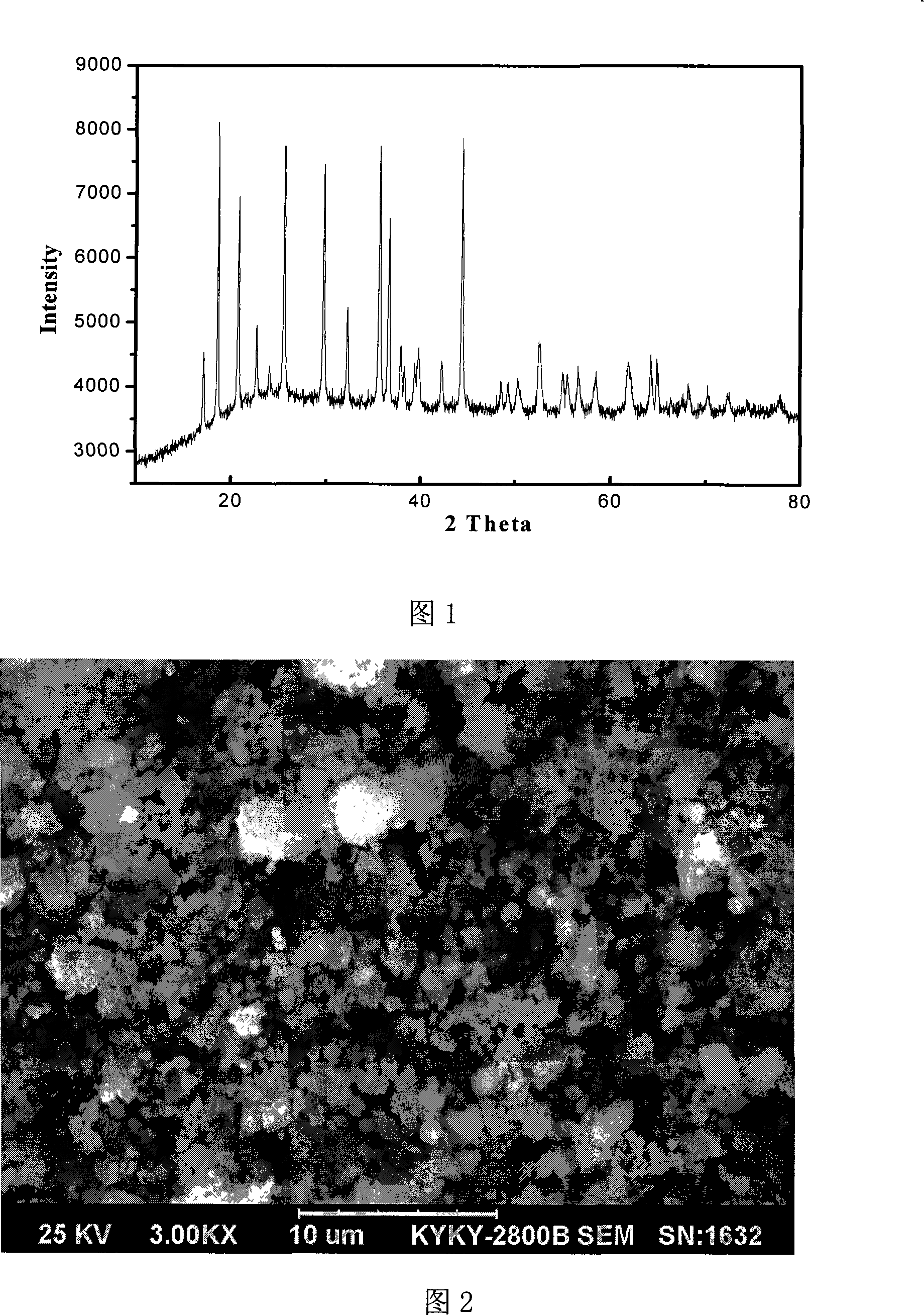

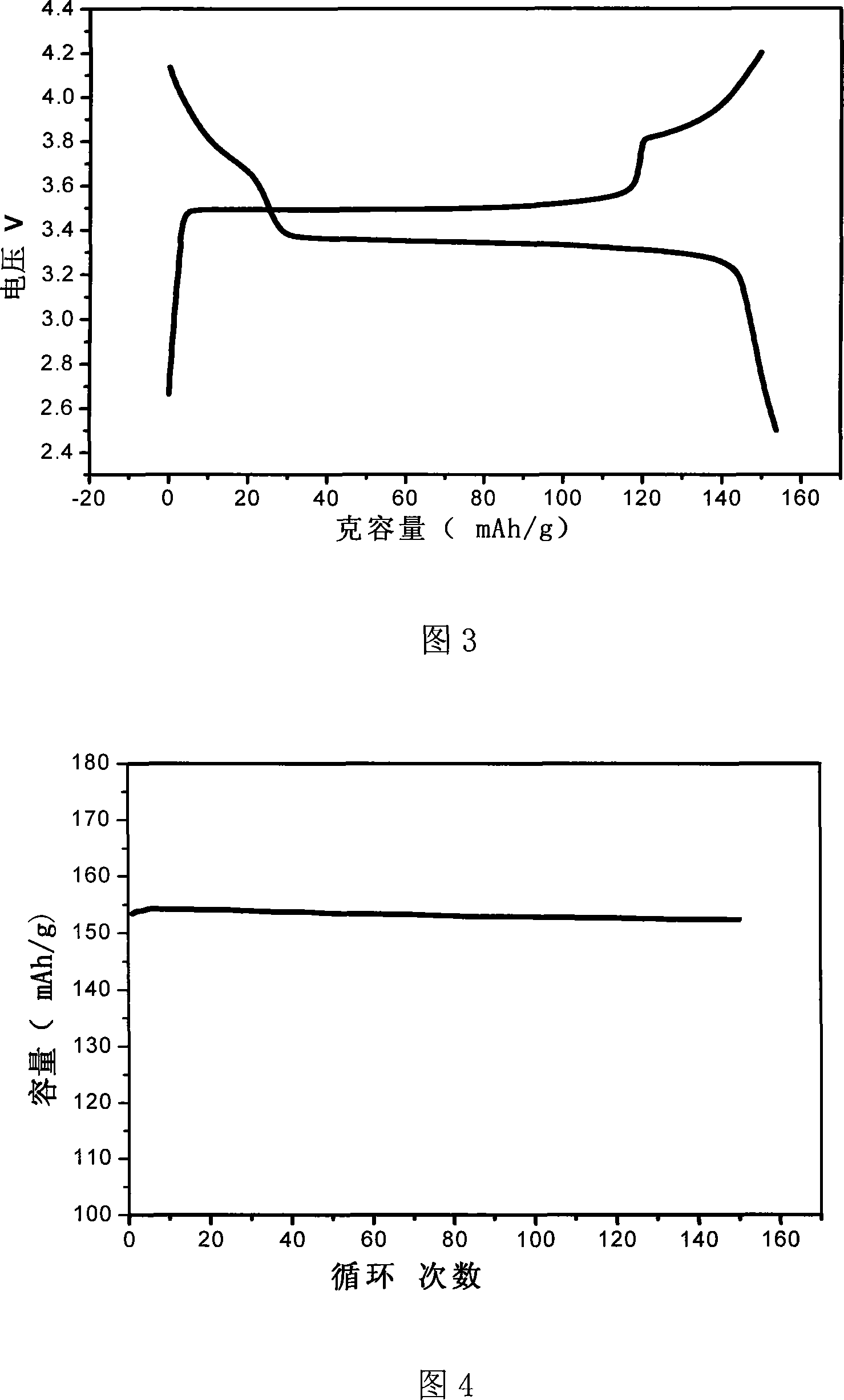

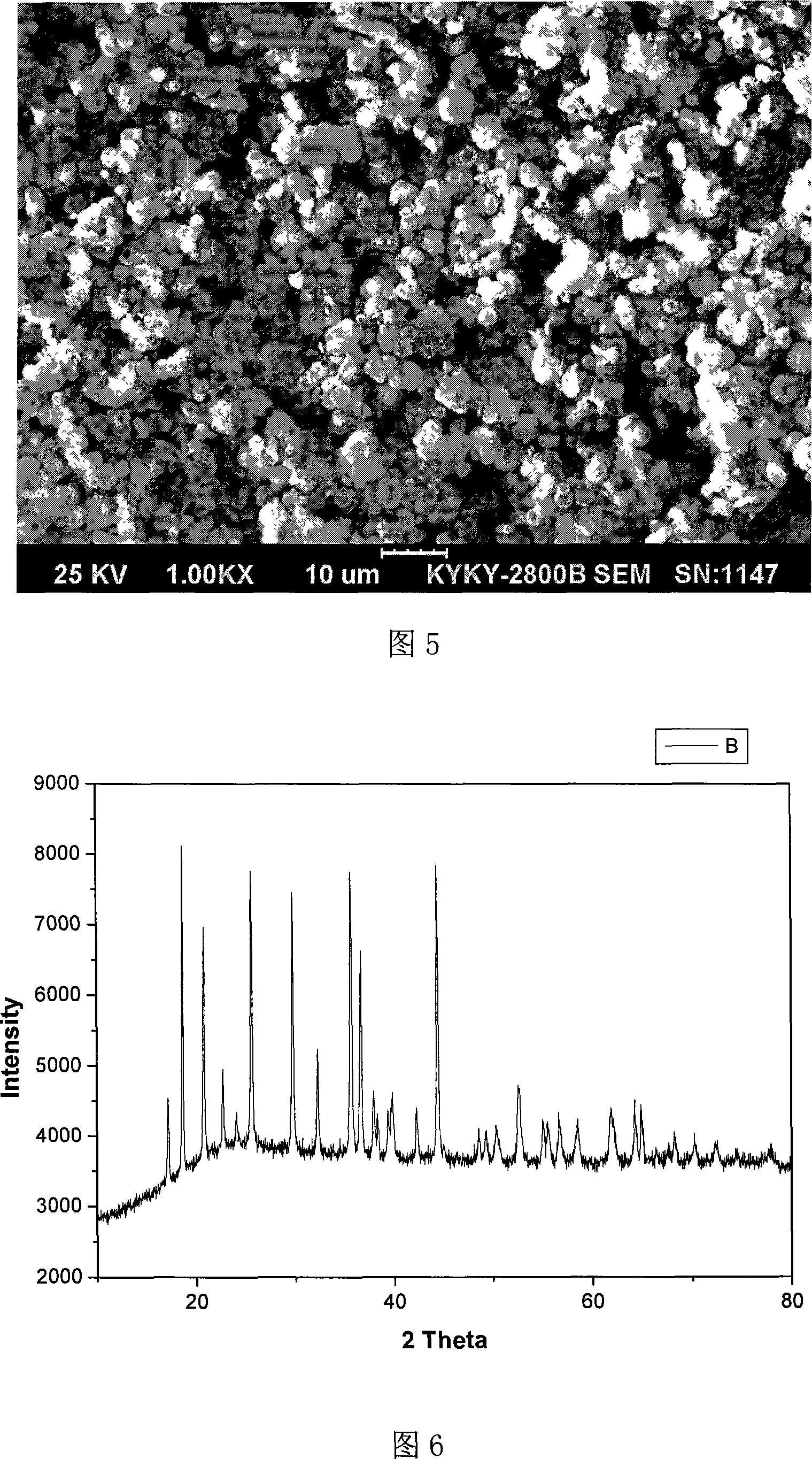

Fe base lithium sale compound anode materials and its making method

ActiveCN101188293AStable structureHigh voltage platformElectrode manufacturing processesChemical/physical/physico-chemical processesHigh rateManganese

The invention discloses a ferrous lithium salt composite anode material and thepreparation method thereof. The technical problems which are needed to be solved are to enhance the high-rate electricity discharging of the anode material, and the manufacturing and the processing performances of battery electrodes are improved. The ferrous lithium salt composite anode material has lithium iron phosphate, and forms the composite material by adulterated with or covered by nickel-cobalt-manganese-lithium or nickel-cobalt-aluminum-lithium material. The weight ratio of the lithium iron phosphate and the nickel-cobalt-manganese-lithium or the nickel-cobalt-aluminum-lithium material is 9 to 7 : 1 to 3, and the micro-morphology is in a sphericity , or is like a sphericity, with a ration between a horizontal length and a vertical length of 1.2 to 2.5. The crystal is in the structure of an olivine type, a space group is Pbnm, and a particle diameter is 1 to 20microns. The preparation method comprises mixture, fusion processing and screen separation. Compared with the prior art, the ferrous lithium salt composite anode material has the advantages of capable of lowering specific surface area, capable of enhancing the voltage platform of the anode material, favorable processing performance, high tap density, favorable conductivity, favorable rate discharge performance and safe performance, capable of improving high and low temperature cycling performance, and favorable compatibility with various cathodes and electrolytes.

Owner:常州锂源新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com