Apparatus for fitting a shoulder prosthesis

a shoulder prosthesis and applicator technology, applied in the field of inverted or anatomical shoulder prosthesis, can solve the problems of prosthesis dislocation and pain of patients, and achieve the effects of reducing interference risk, promoting relative rotation, and increasing tension in the rotator muscles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

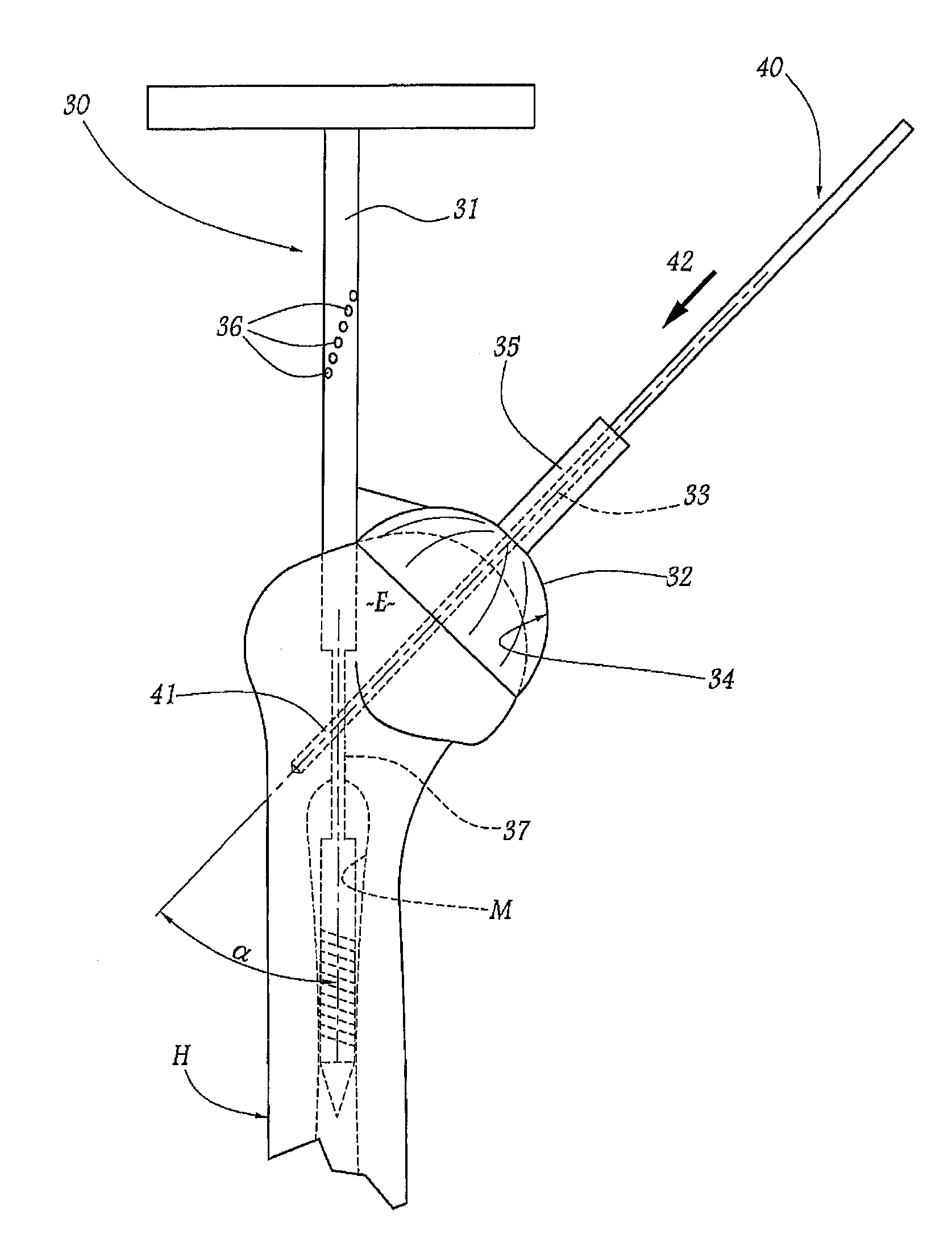

[0047]FIG. 1 shows a shoulder prosthesis 1 comprising a glenoid component 10 and a humeral component 20, respectively implanted in the scapula S and the humerus H of a patient's shoulder. The glenoid components shown herein are illustrated schematically. The method and apparatus of the various embodiments disclosed herein may be used with a variety of other glenoid components, such as for example those disclosed in U.S. Pat. Nos. 7,033,396; 6,953,478; 6,761,740; 6,626,946; 5,702,447 and U.S. Publication Nos. 2004 / 0220673; 2005 / 0278030; 2005 / 0278031; 2005 / 0278032; 2006 / 0020344, which are hereby incorporated by reference.

[0048]The glenoid component 10 comprises a head 11, also described as a head structure, which has, on the side opposing the glenoid surface G of the scapula S, a convex articular surface 11A, also described as a face, of generally hemispherical shape and, on the side turned toward the glenoid surface, an opposing face 11B. In the example considered in the figures, thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength-to-weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com