Patents

Literature

134 results about "Osteolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Osteolysis is an active resorption of bone matrix by osteoclasts and can be interpreted as the reverse of ossification. Although osteoclasts are active during the natural formation of healthy bone the term "osteolysis" specifically refers to a pathological process. Osteolysis often occurs in the proximity of a prosthesis that causes either an immunological response or changes in the bone's structural load. Osteolysis may also be caused by pathologies like bone tumors, cysts, or chronic inflammation.

Treatment of bone disorders

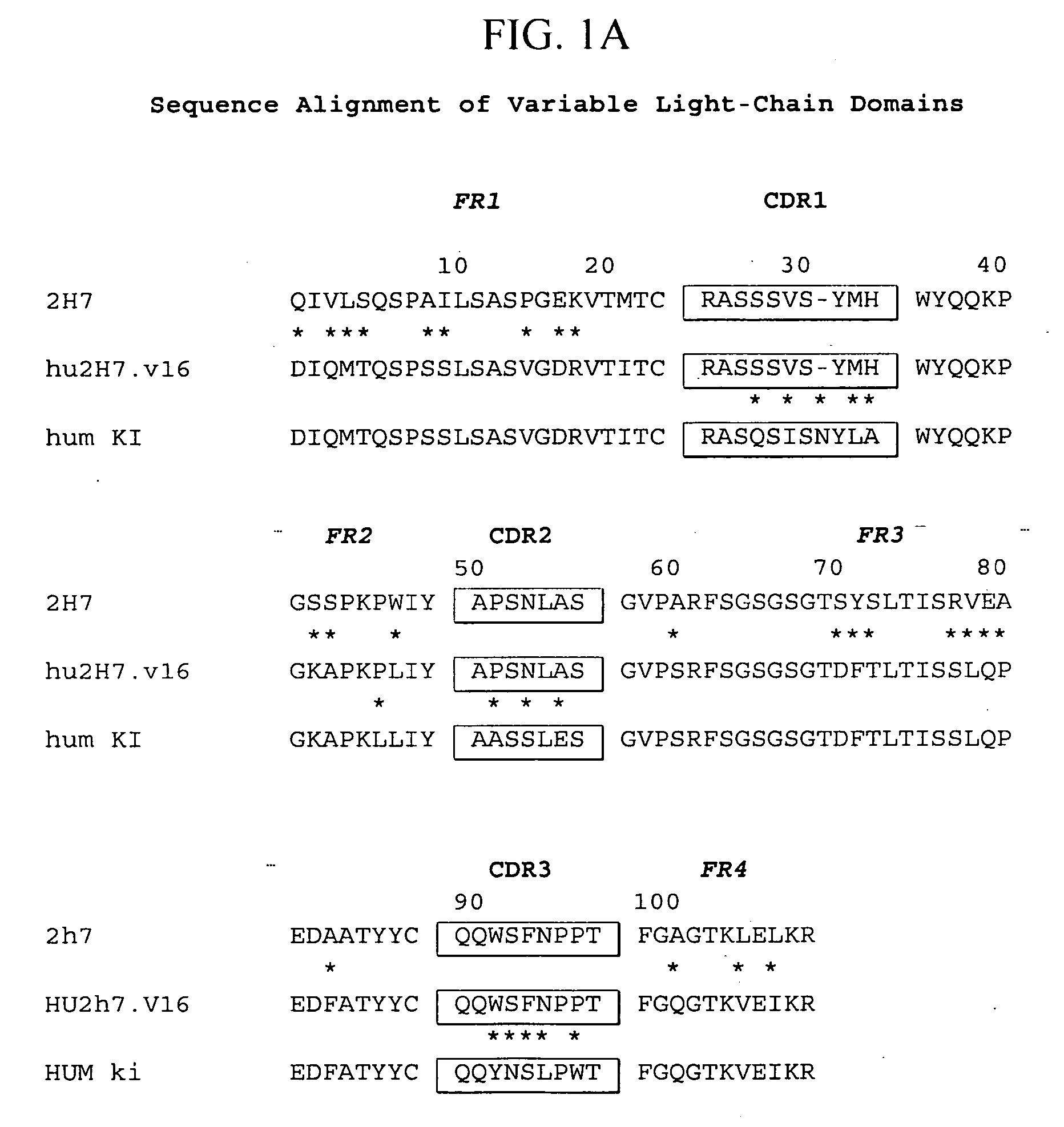

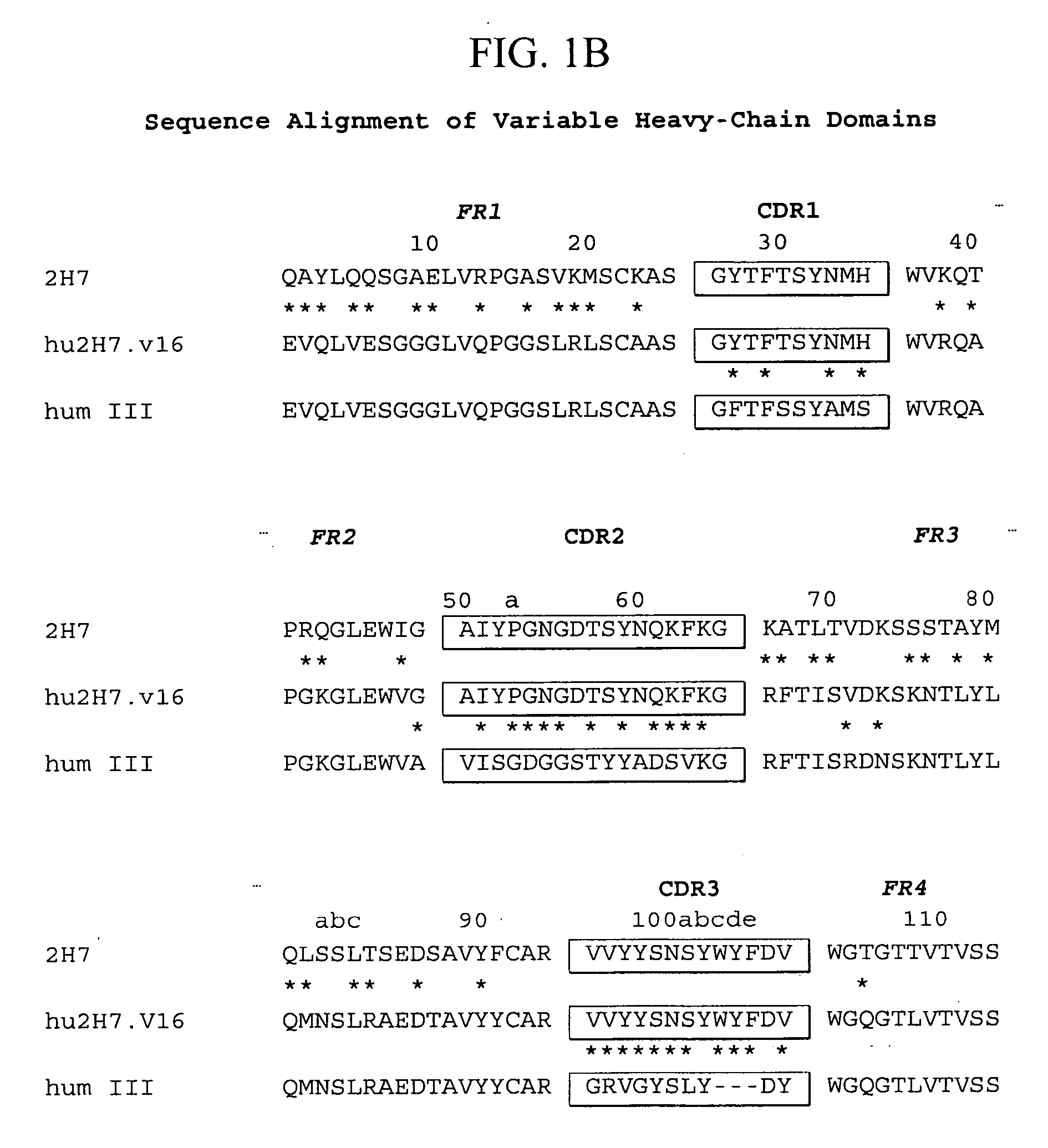

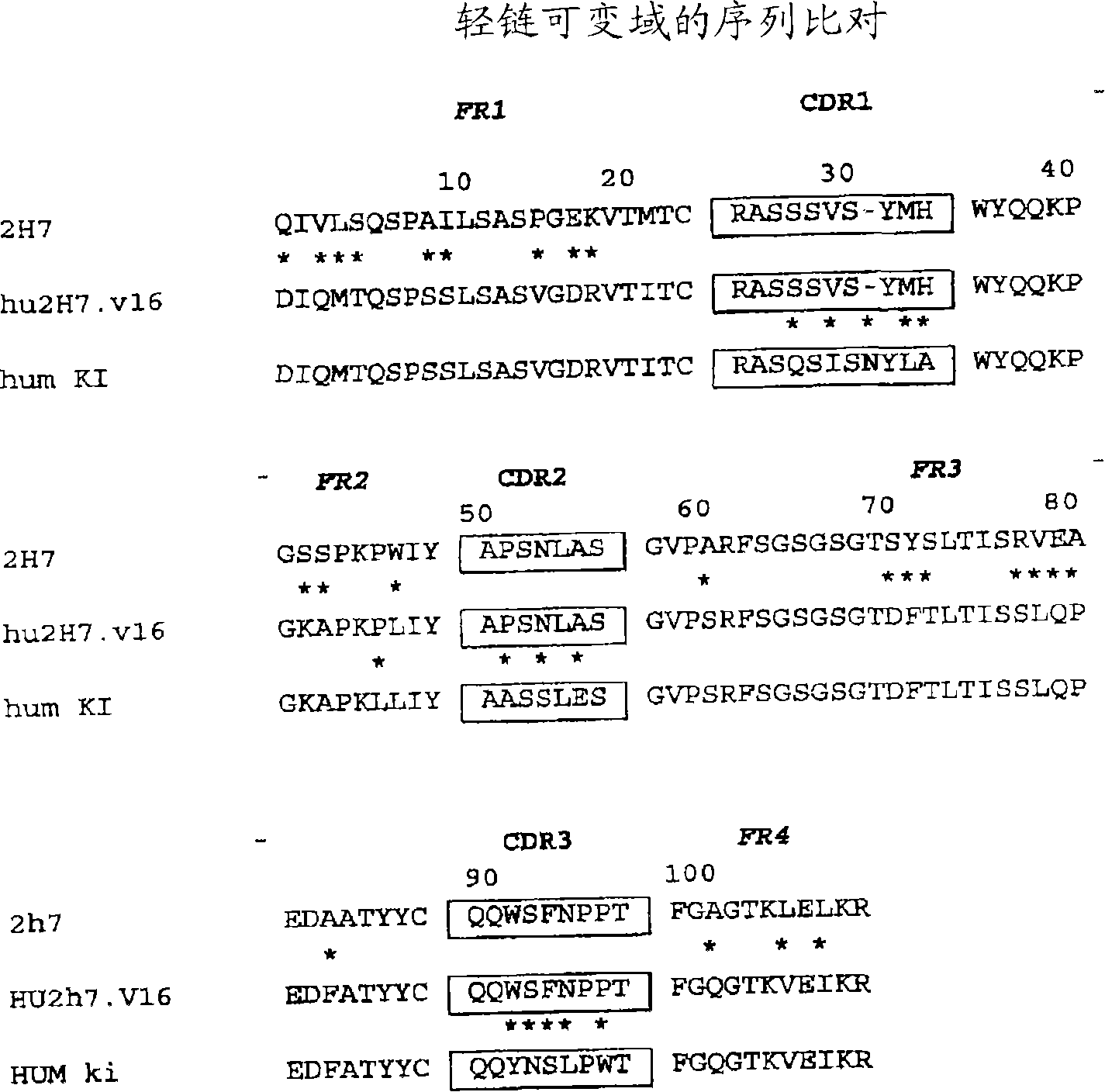

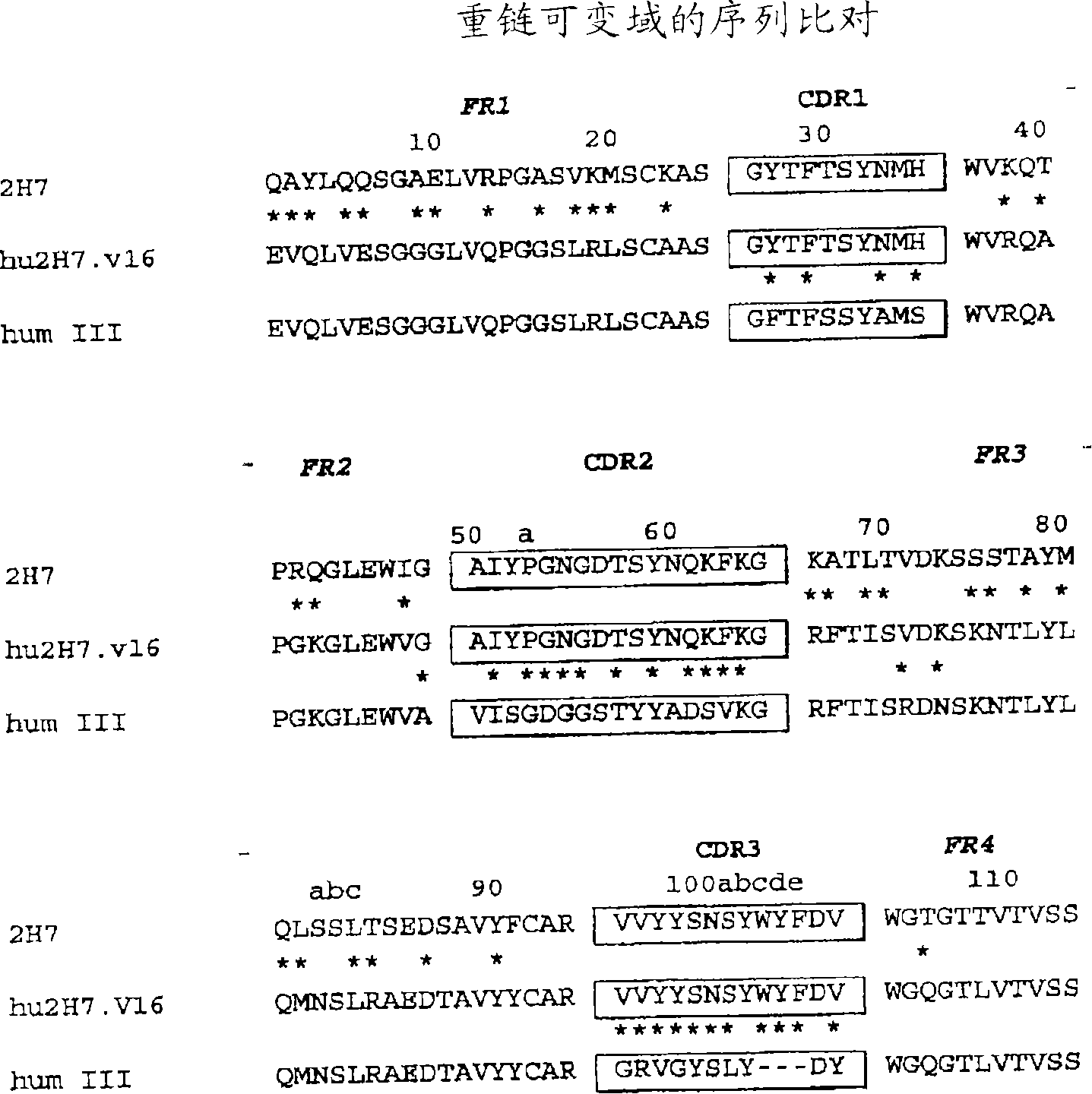

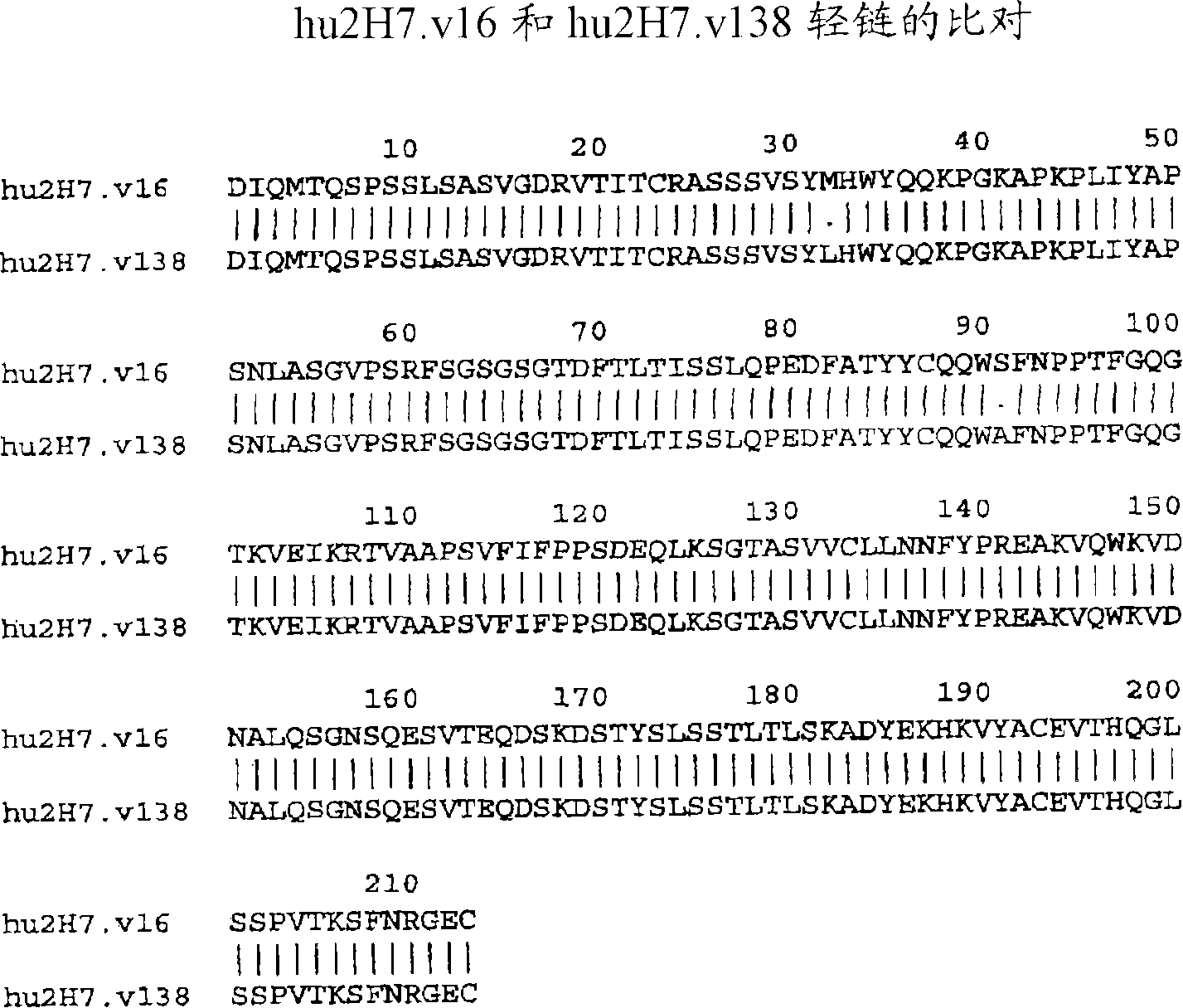

InactiveUS20060263355A1Enhance osteoblast formationImprove bone formationBiocidePeptide/protein ingredientsDiseaseCD20

Methods of treatment of various bone indications, such as osteoporosis, in a mammal are provided wherein an effective amount of an antagonist that binds to a B-cell surface marker, such as a CD20 antibody, is administered, optionally also with another medicament such as an agent that treats such disorders in an effective amount. Articles of manufacture are also provided. Further, a method of inhibiting osteolysis in a mammal is provided comprising introducing into said mammal an isolated odontoprogenitor or osteoprogenitor cell comprising a nucleic acid encoding an antibody that binds to a B-cell surface marker.

Owner:GENENTECH INC

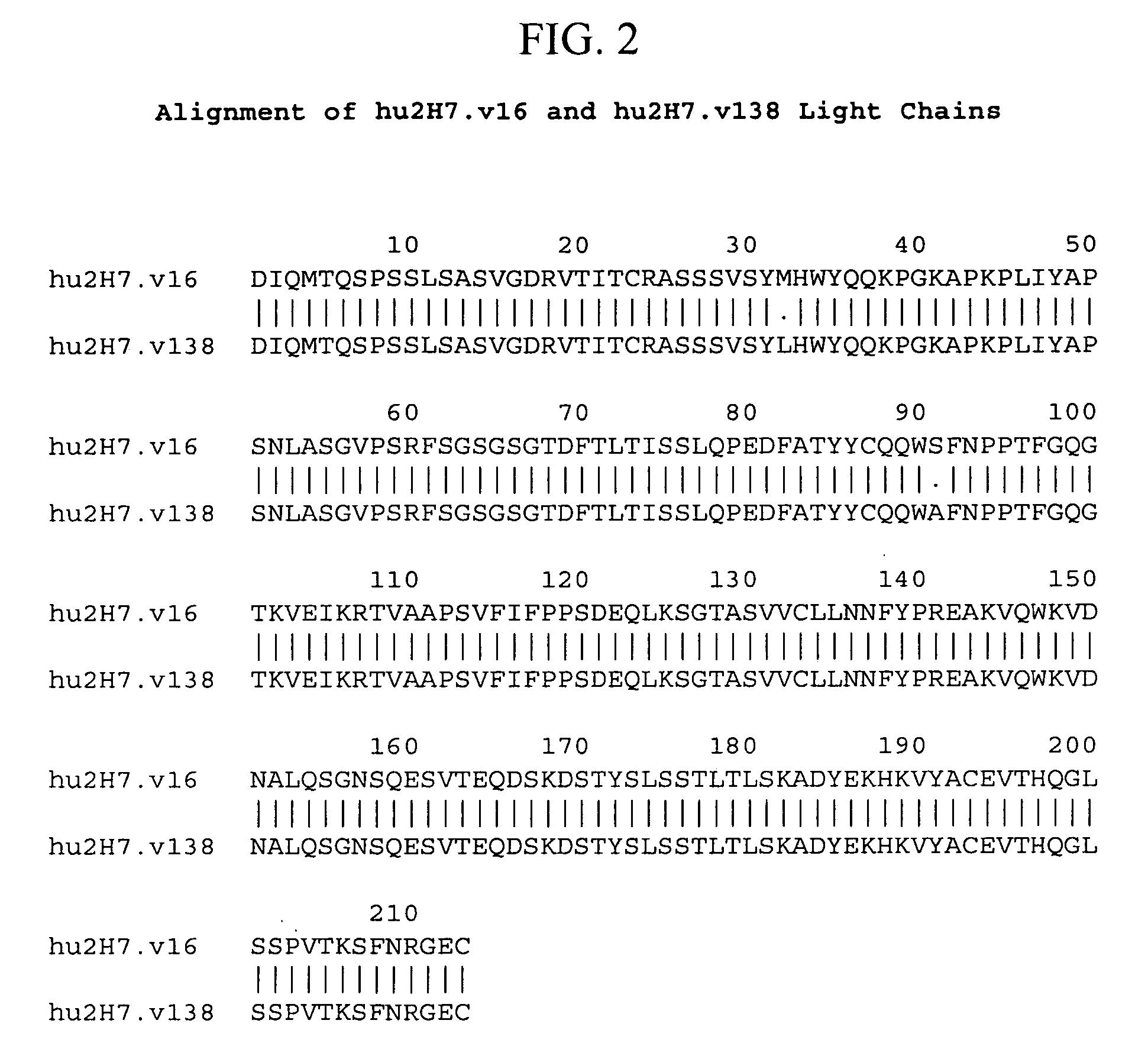

Locally administrated low doses of corticosteroids

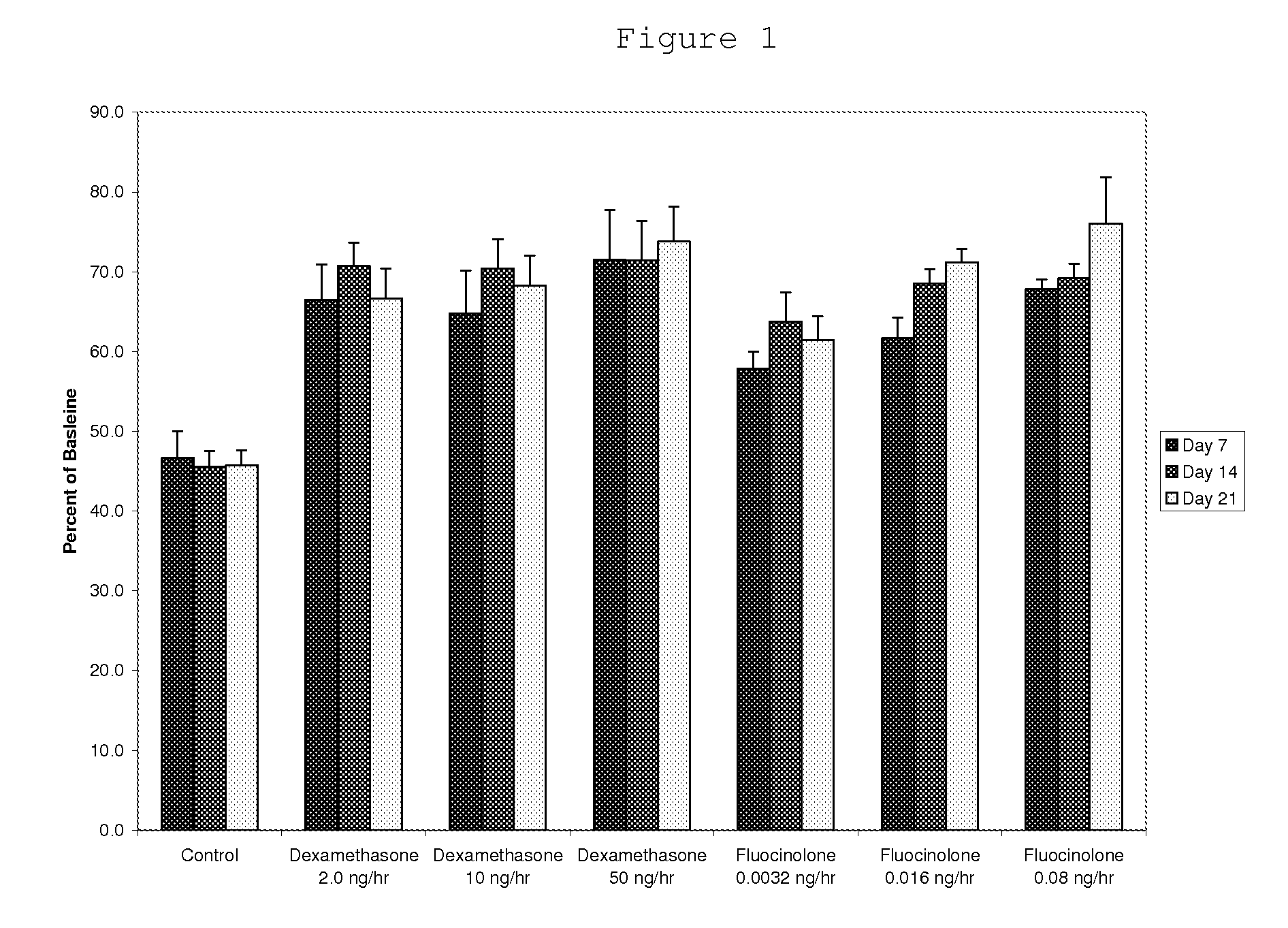

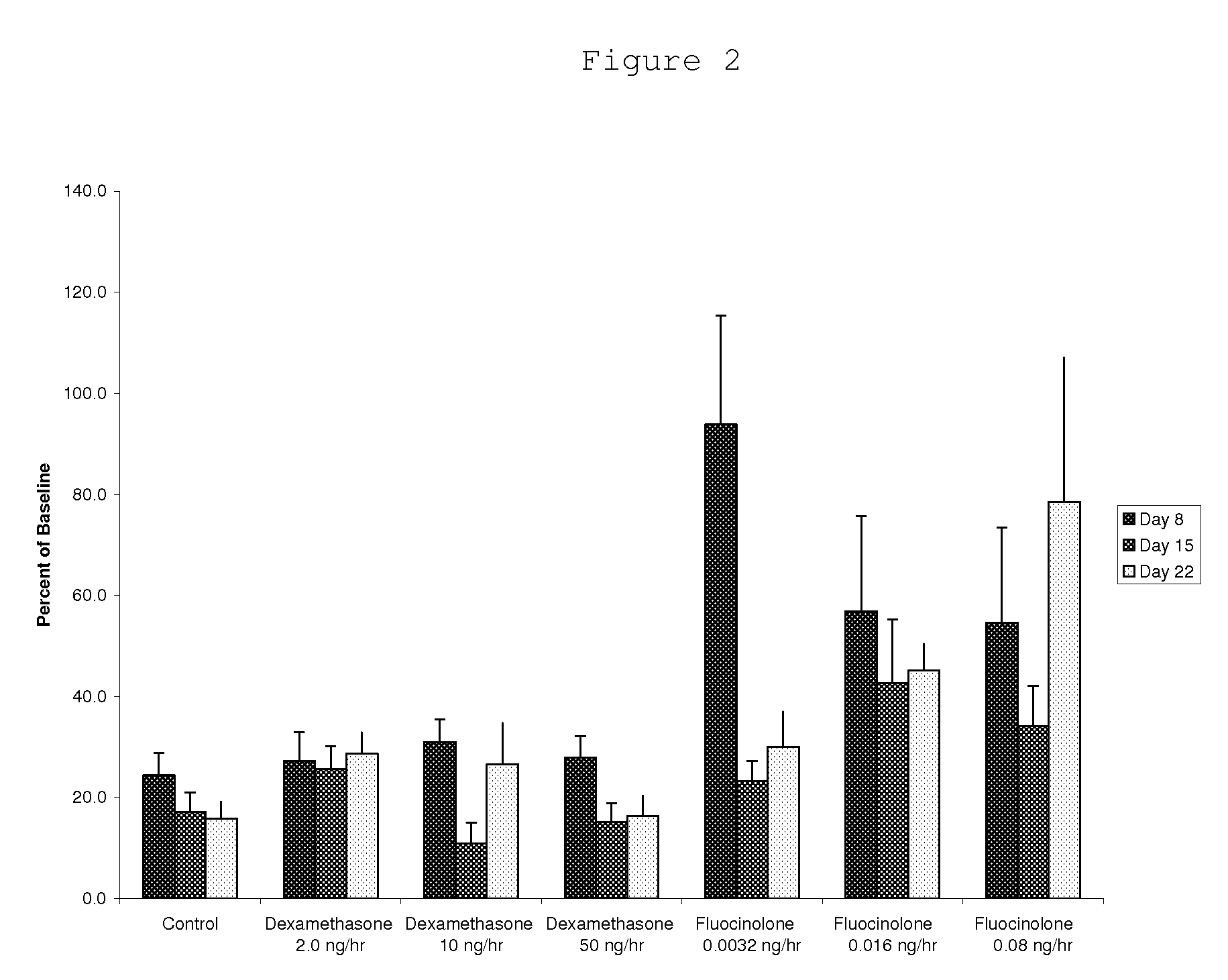

This invention provides for using a locally delivered low dose of a corticosteroid to treat pain caused by any inflammatory disease including sciatica, herniated disc, stenosis, mylopathy, low back pain, facet pain, osteoarthritis, rheumatoid arthritis, osteolysis, tendonitis, carpal tunnel syndrome, or tarsal tunnel syndrome. More specifically, a locally delivered low dose of a corticosteroid can be released into the epidural space, perineural space, or the foramenal space at or near the site of a patient's pain by a drug pump or a biodegradable drug depot.

Owner:MEDTRONIC INC +1

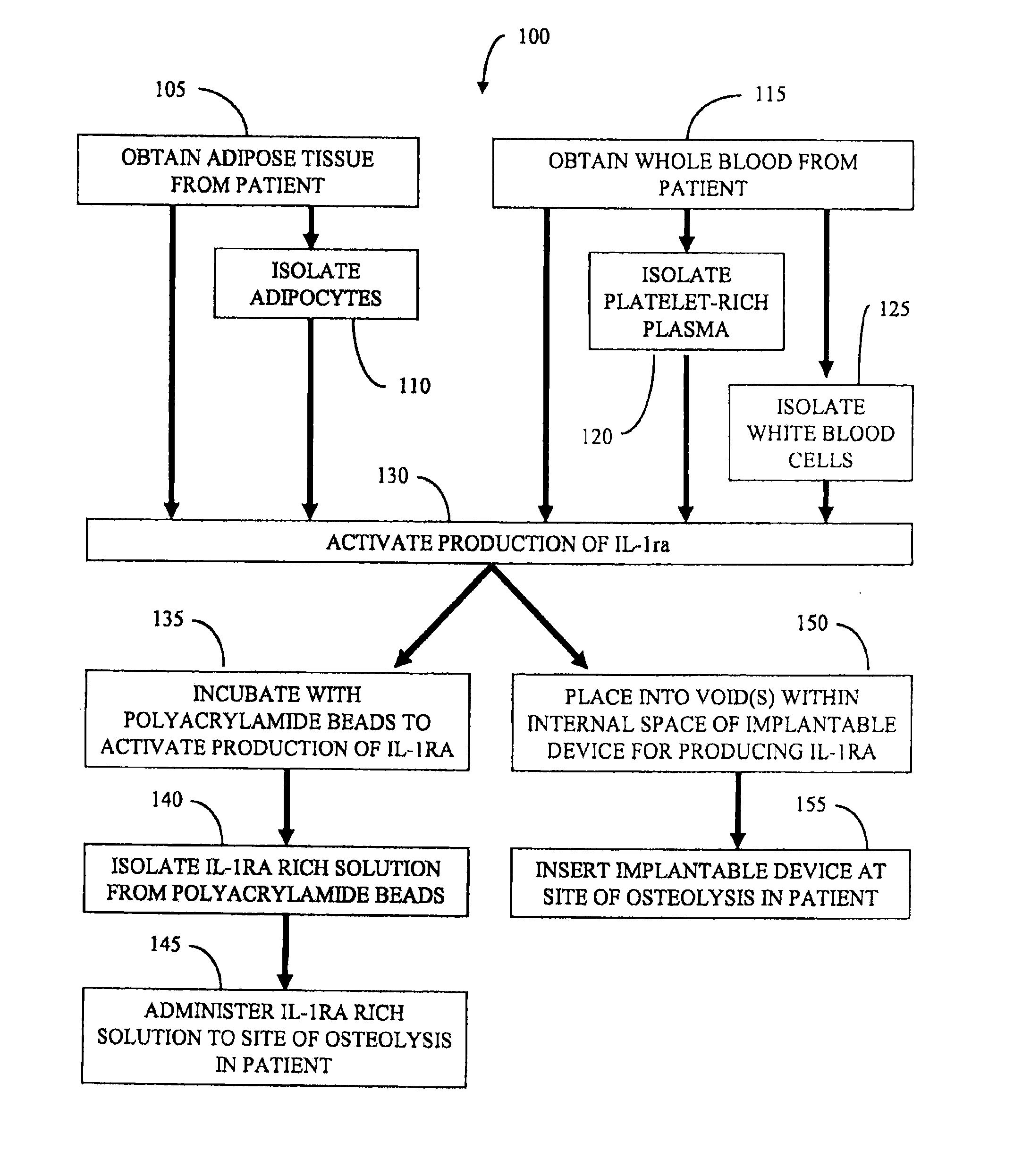

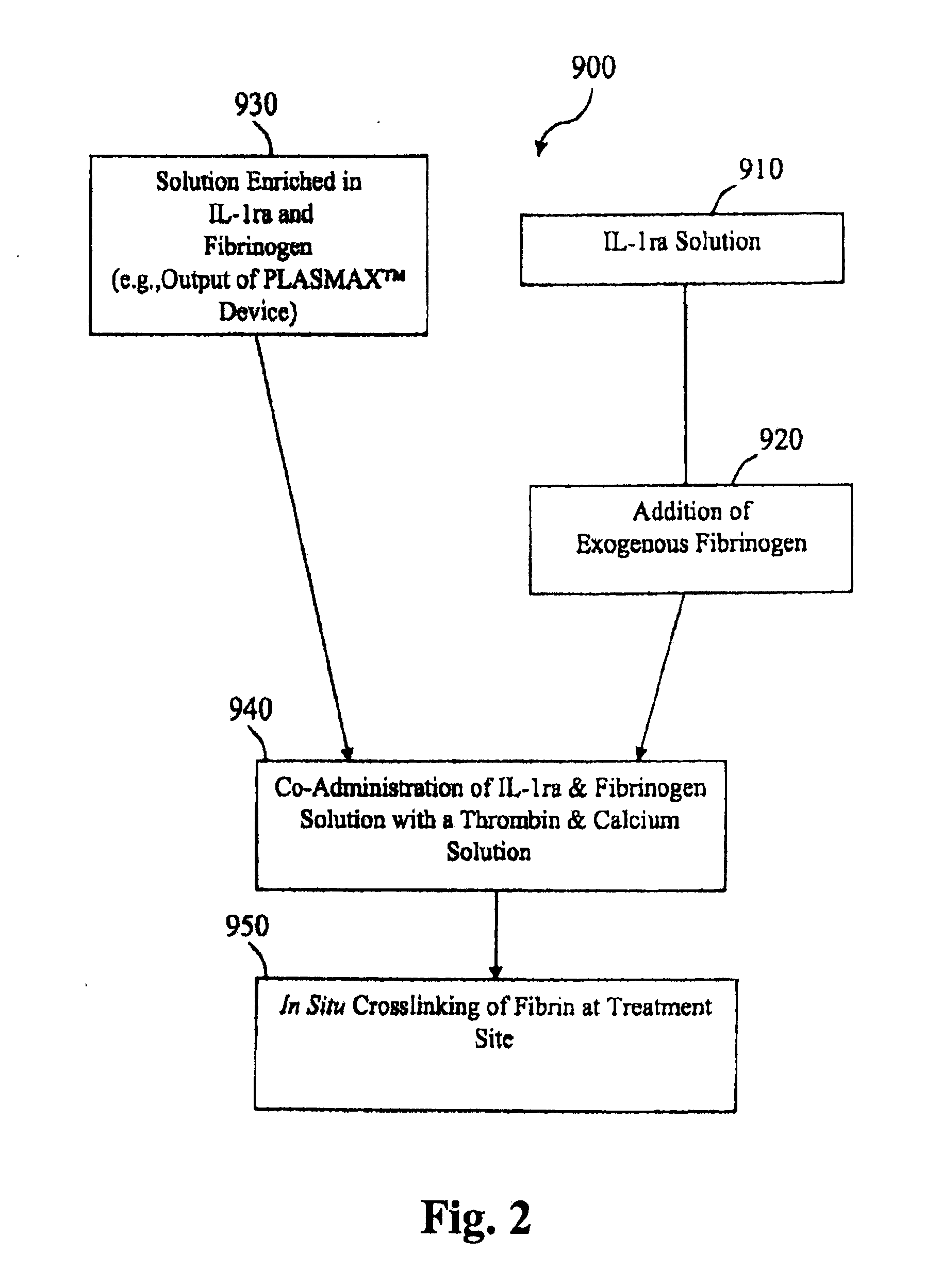

Osteolysis treatment

InactiveUS20110052561A1Reduce inflammationShorten the progressPeptide/protein ingredientsSkeletal disorderWhite blood cellImplanted device

Methods and treatments for osteolysis employing interleukin-1 receptor antagonist (IL-1ra). Activating production of interleukin-1 receptor antagonist includes incubating adipose tissue, adipocytes, whole blood, platelet rich plasma, and / or isolated white blood cells with polyacrylamide beads to produce a solution rich in interleukin-1 receptor antagonist. Activating the production of interleukin-1 receptor antagonist includes using an implantable device loaded with adipose tissue, adipocytes, whole blood, platelet rich plasma, and / or isolated white blood cells. Methods for treating osteolysis at the site of an artificial joint in a patient include administering and / or inserting the solution rich in interleukin-1 receptor antagonist and / or the implantable device, respectively.

Owner:BIOMET MFG CORP

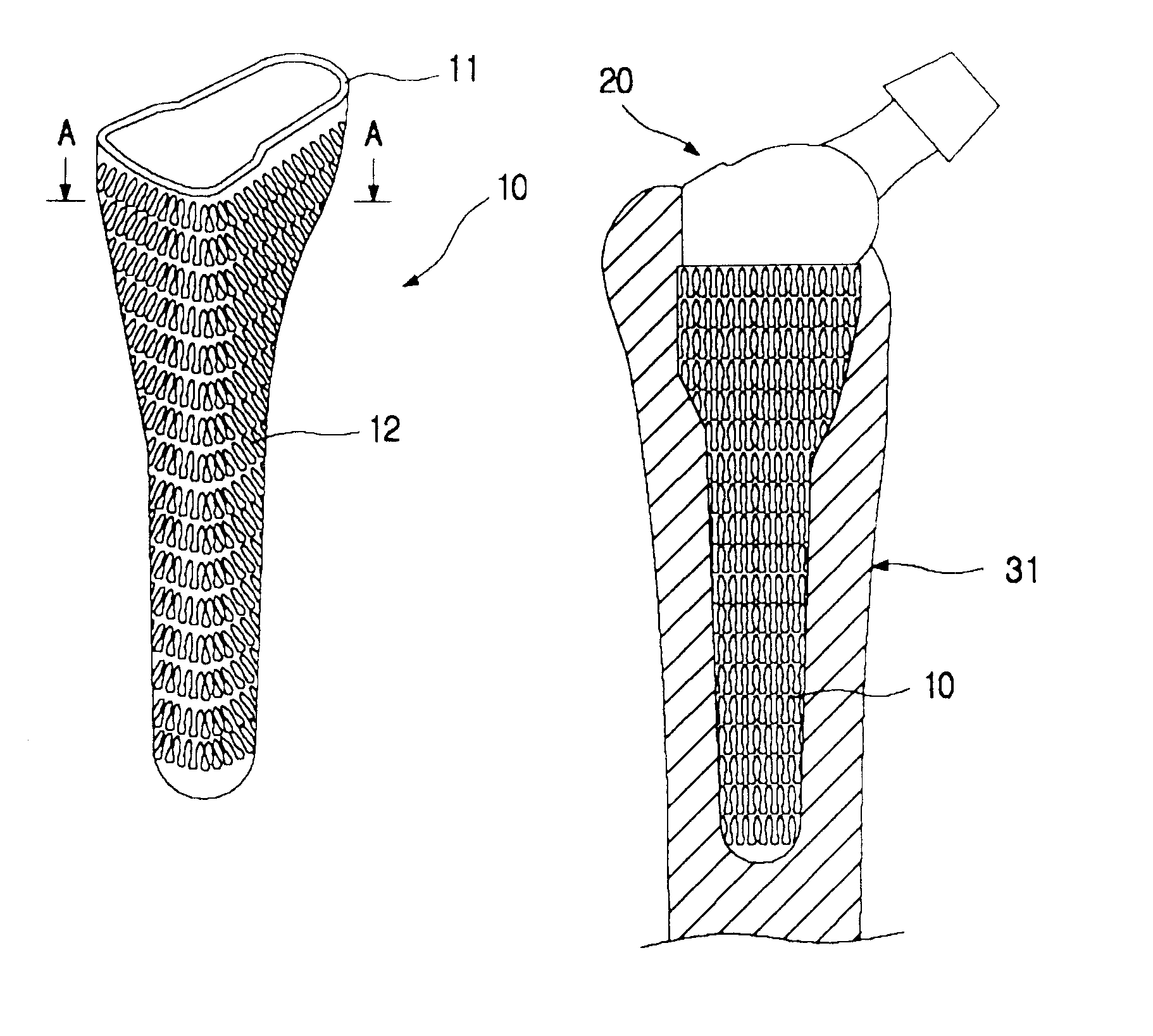

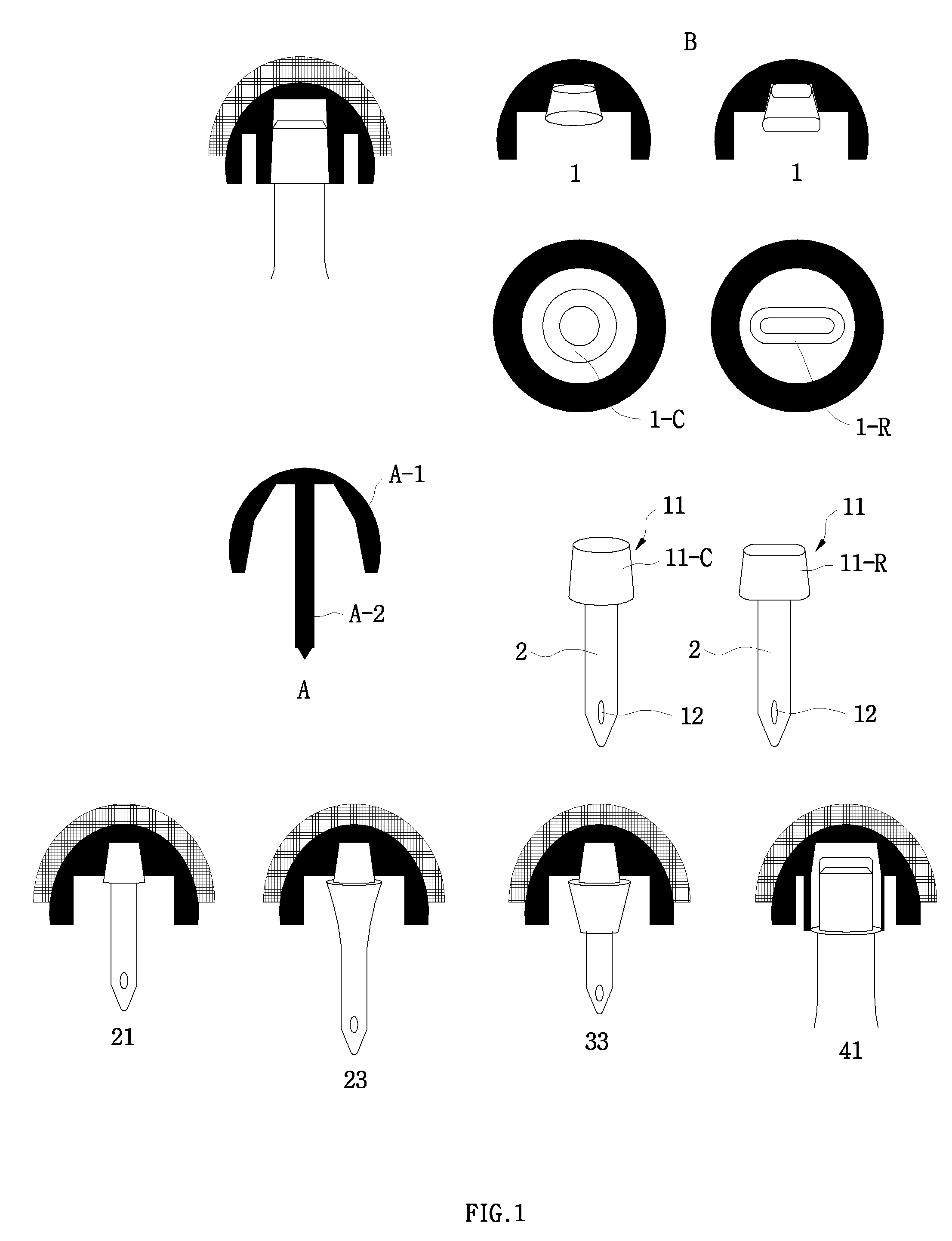

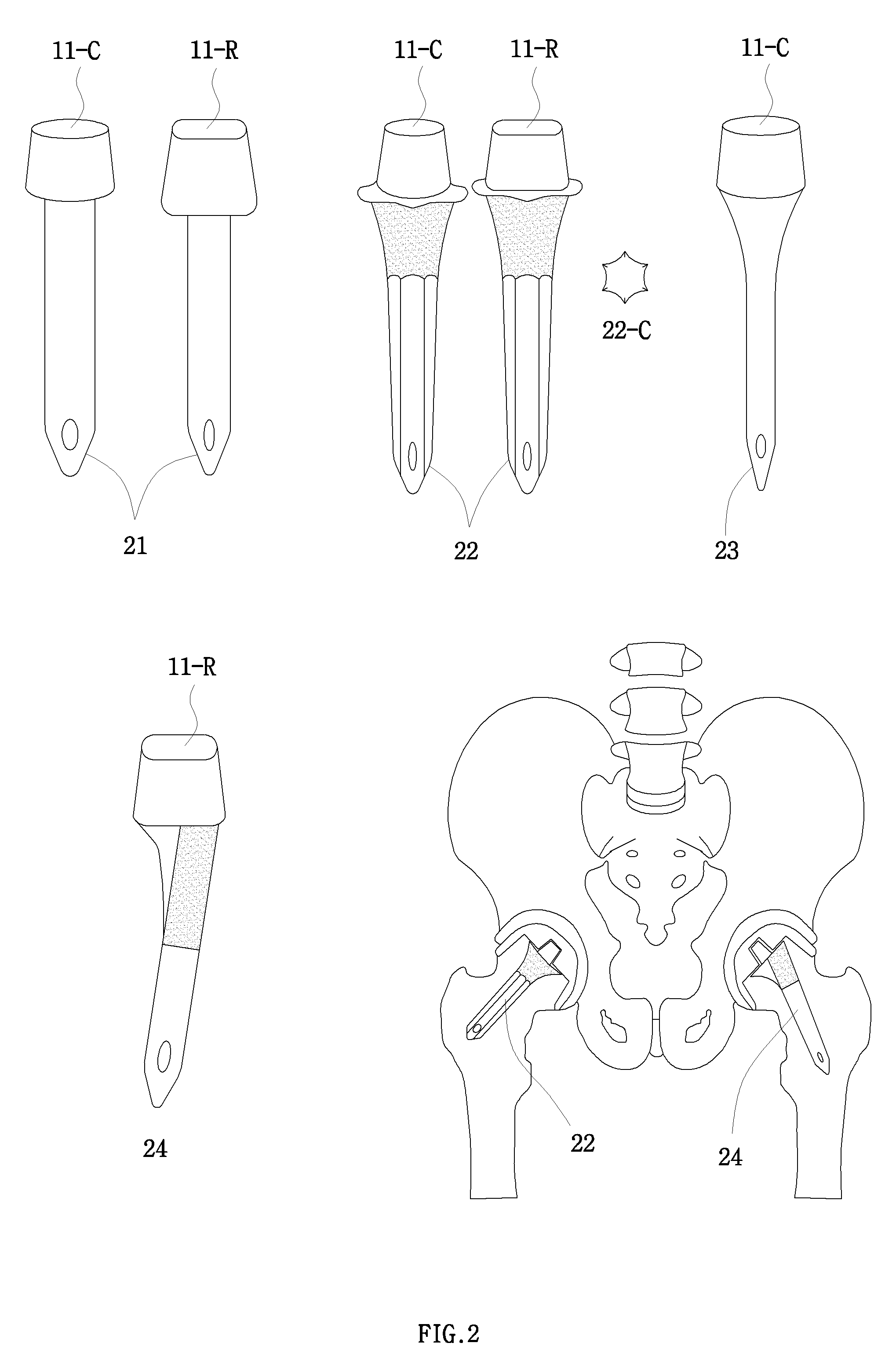

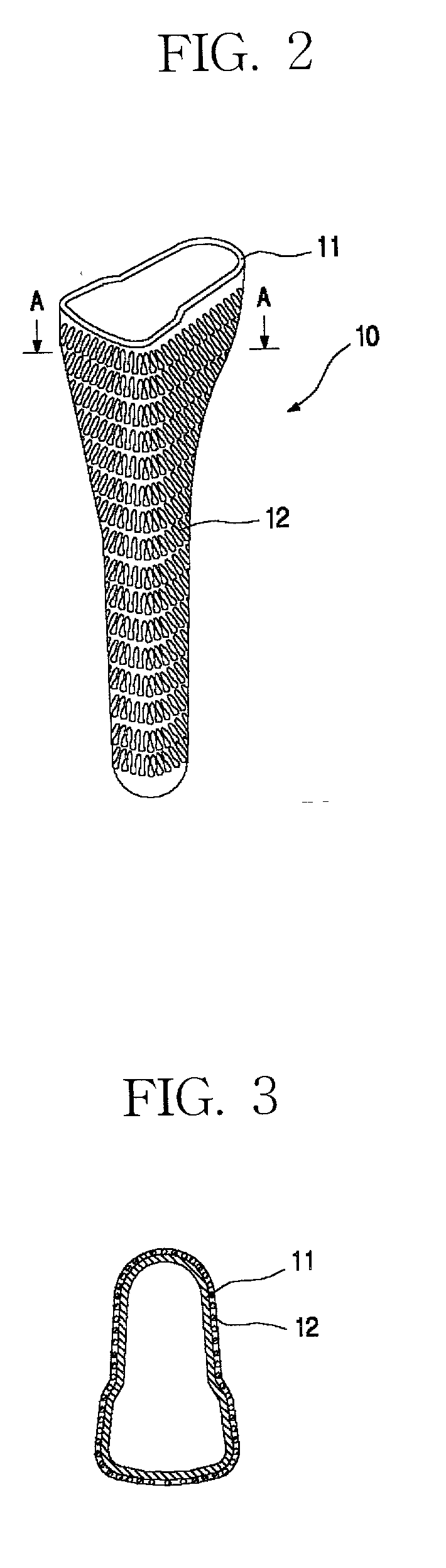

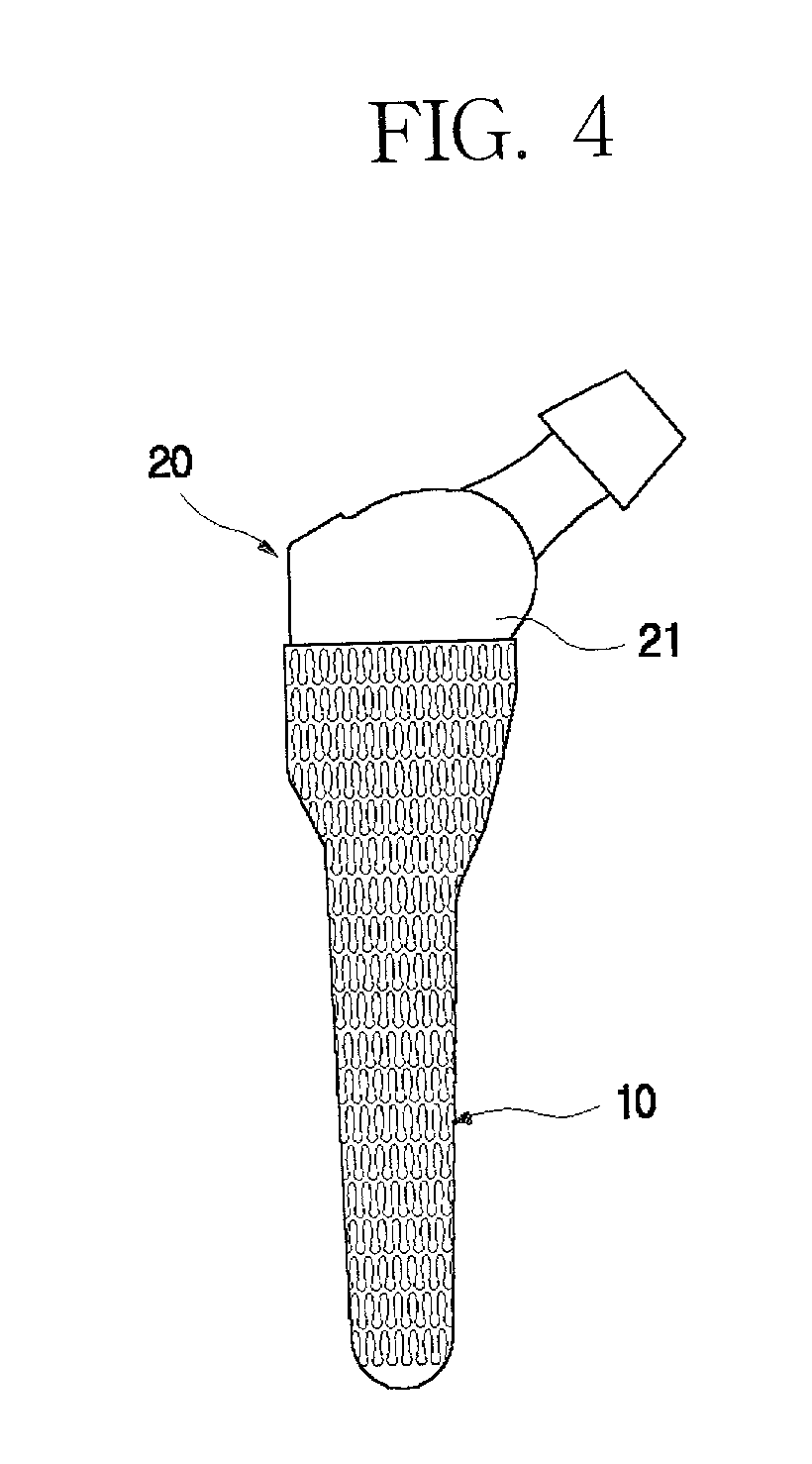

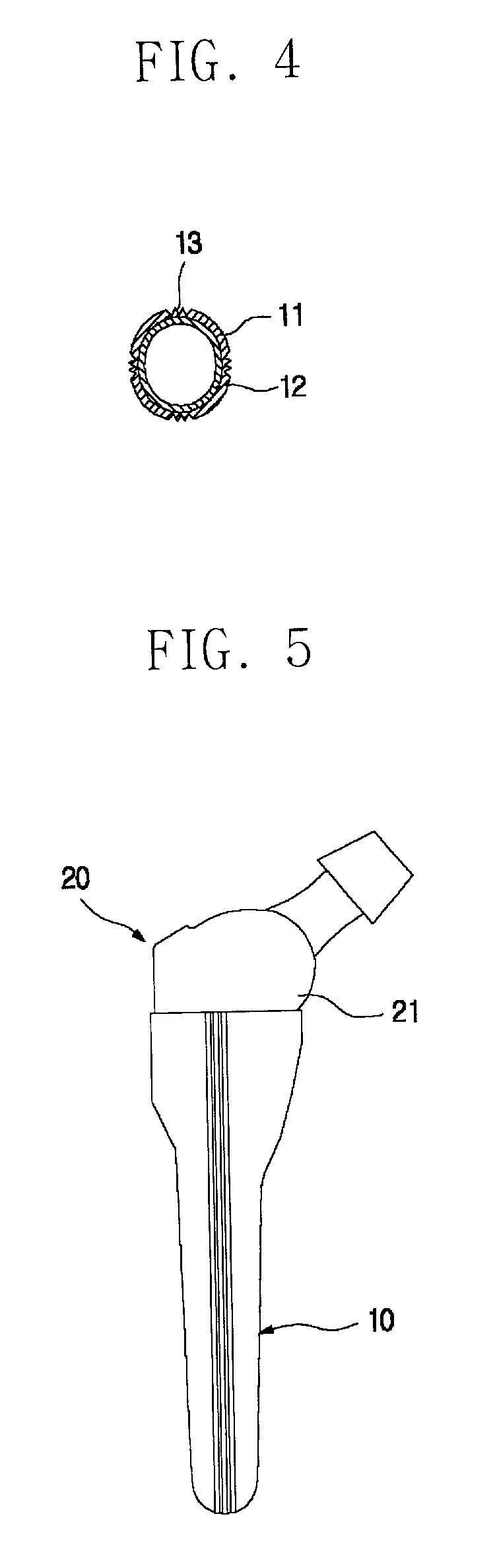

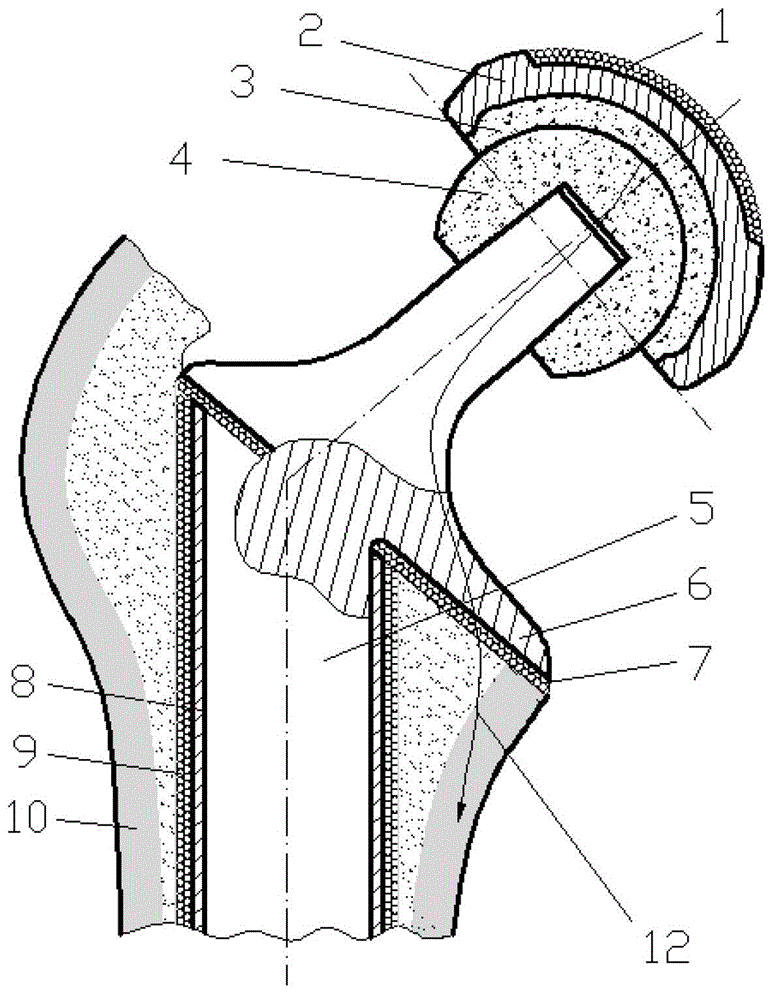

Metal jacket for a cementless artificial joint stem and artificial joint having the jacket

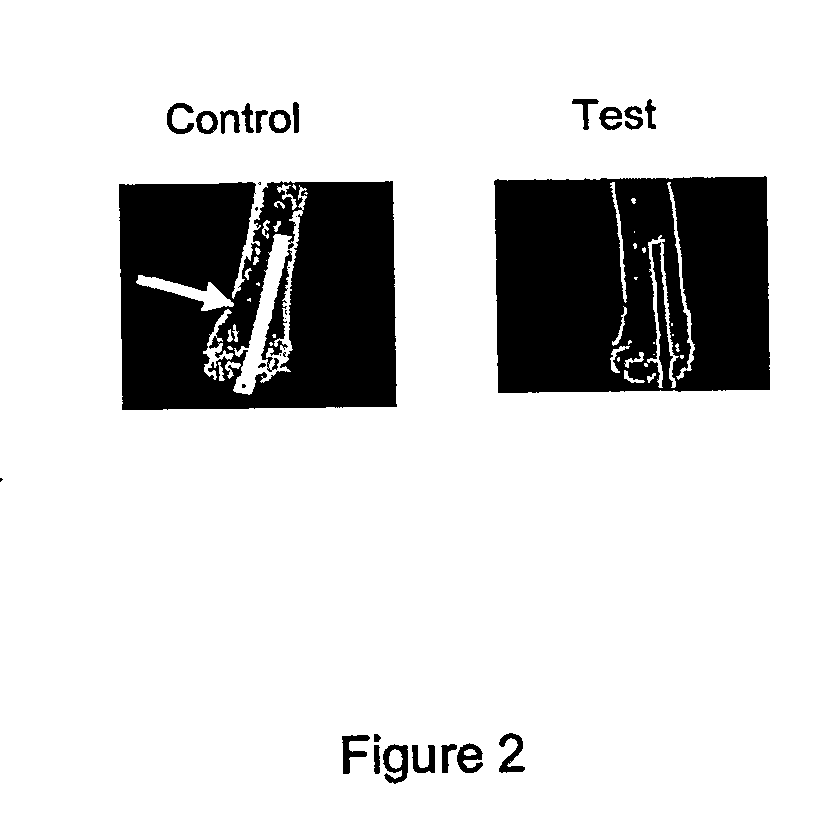

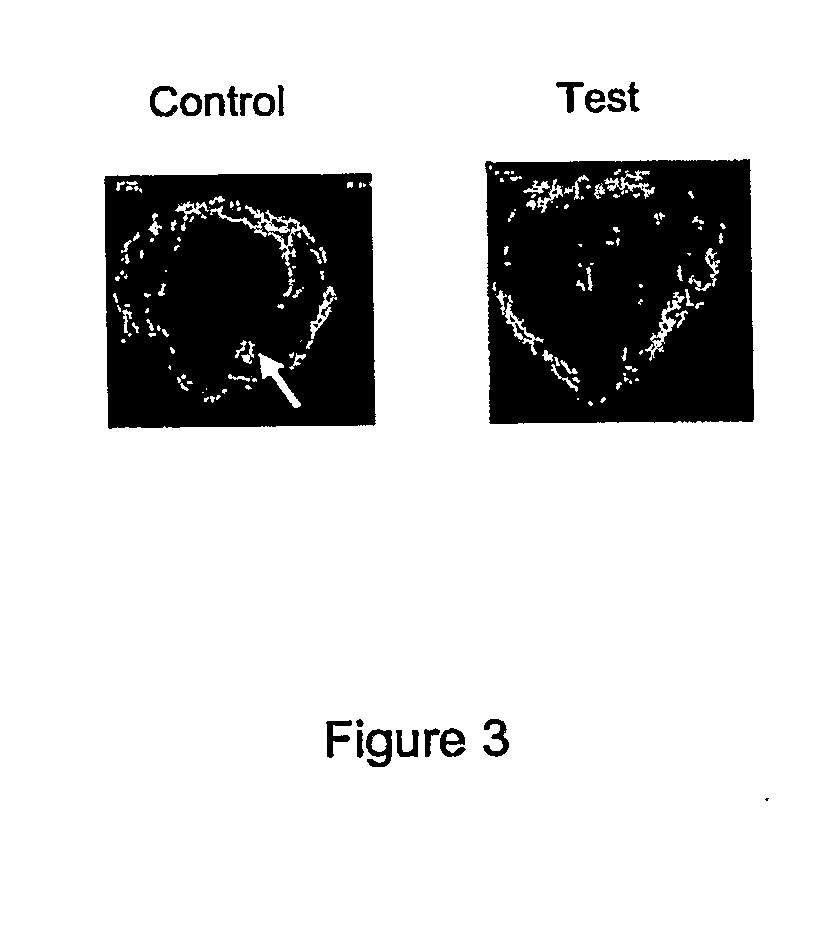

InactiveUS6497728B2Suppress formationMinimize osteolysisBone implantJoint implantsHuman bodyArtificial joints

The present invention is intended to provide a metal jacket for a cementless artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced and stress shielding phenomena can also be markedly relieved, due to the construction of the metal jacket which can be fixed to the bone and can enclose the surface of the stem so as to allow for the stem of artificial joint to slide vertically relative to the bone, and wherein osteolysis of a bone due to the infiltration of wear particles can be minimized by curbing the gap formation between the bone and the stem.To that end, there is provided according to the invention, a metal jacket for a cementless artificial joint stem, which jacket is so formed as to enclose at least a part of the cementless artificial joint stem 21, said stem with jacket being inserted longitudinally in the opening formed in the bone canal of a human body, and on the surface of which jacket surface-processed metal layer or metal wires 12 is formed so that the bone can make interlocking with the metal jacket as the bone gets on-growth onto the metal jacket.

Owner:KOREA ADVANCED INST OF SCI & TECH

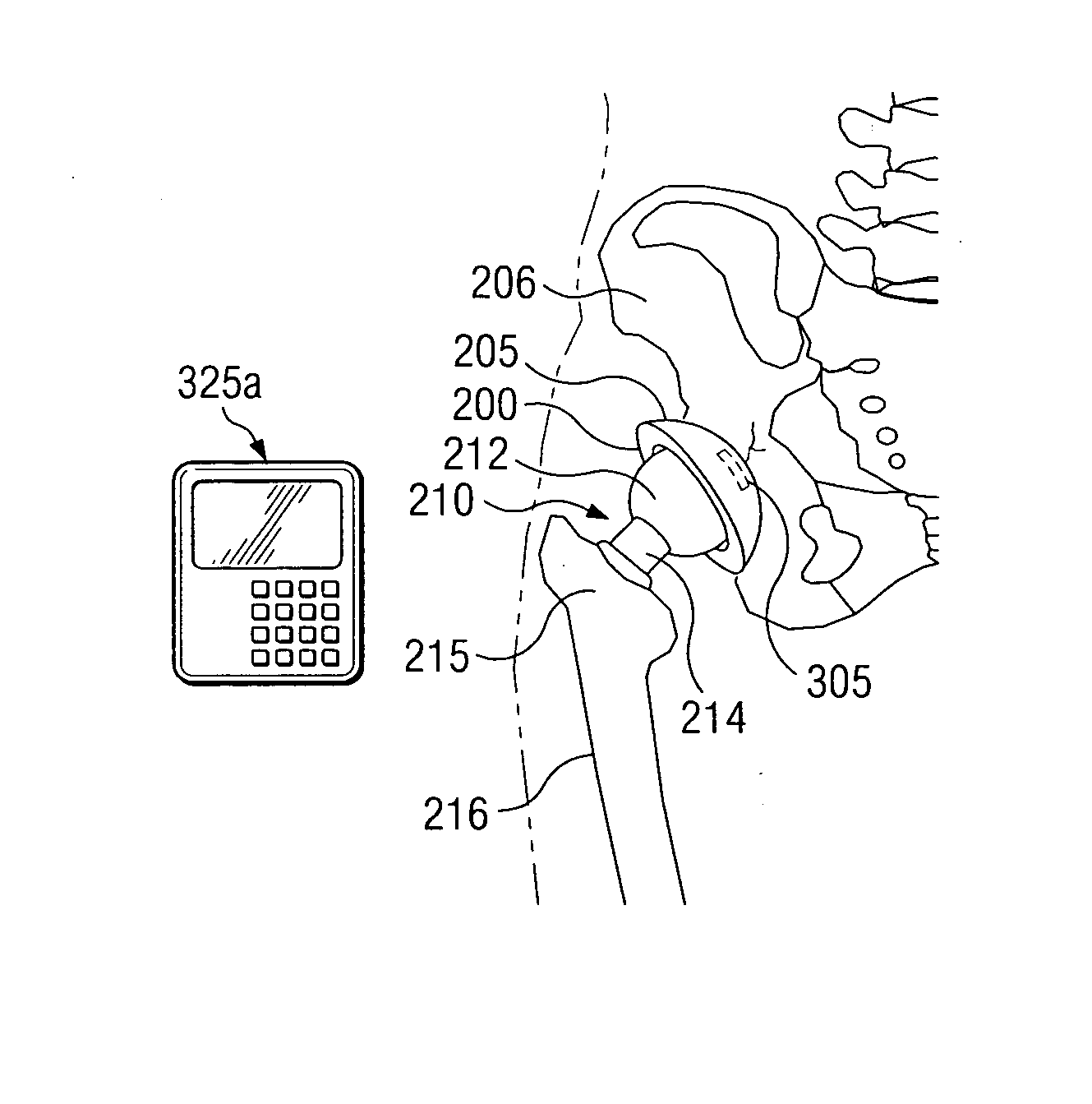

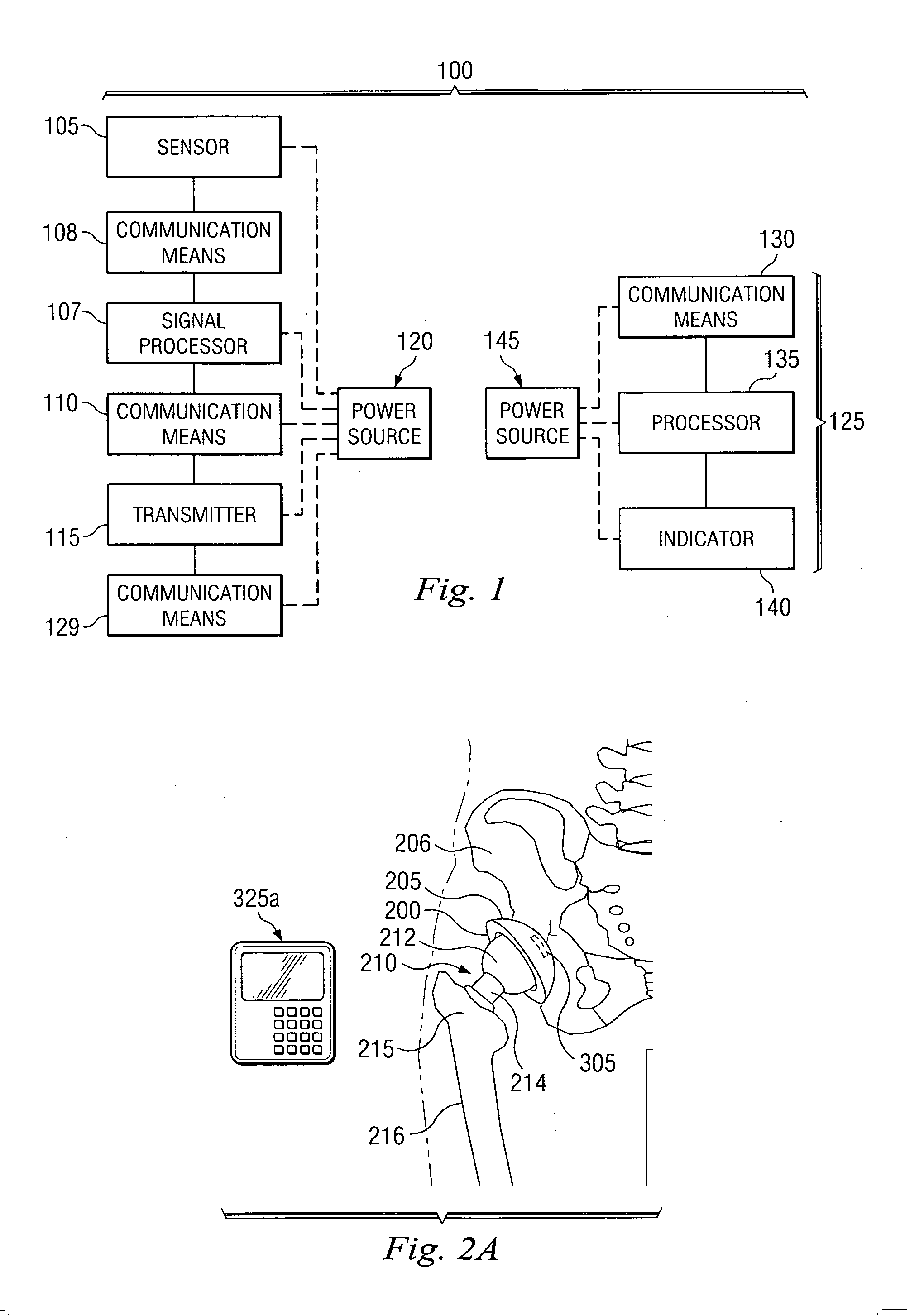

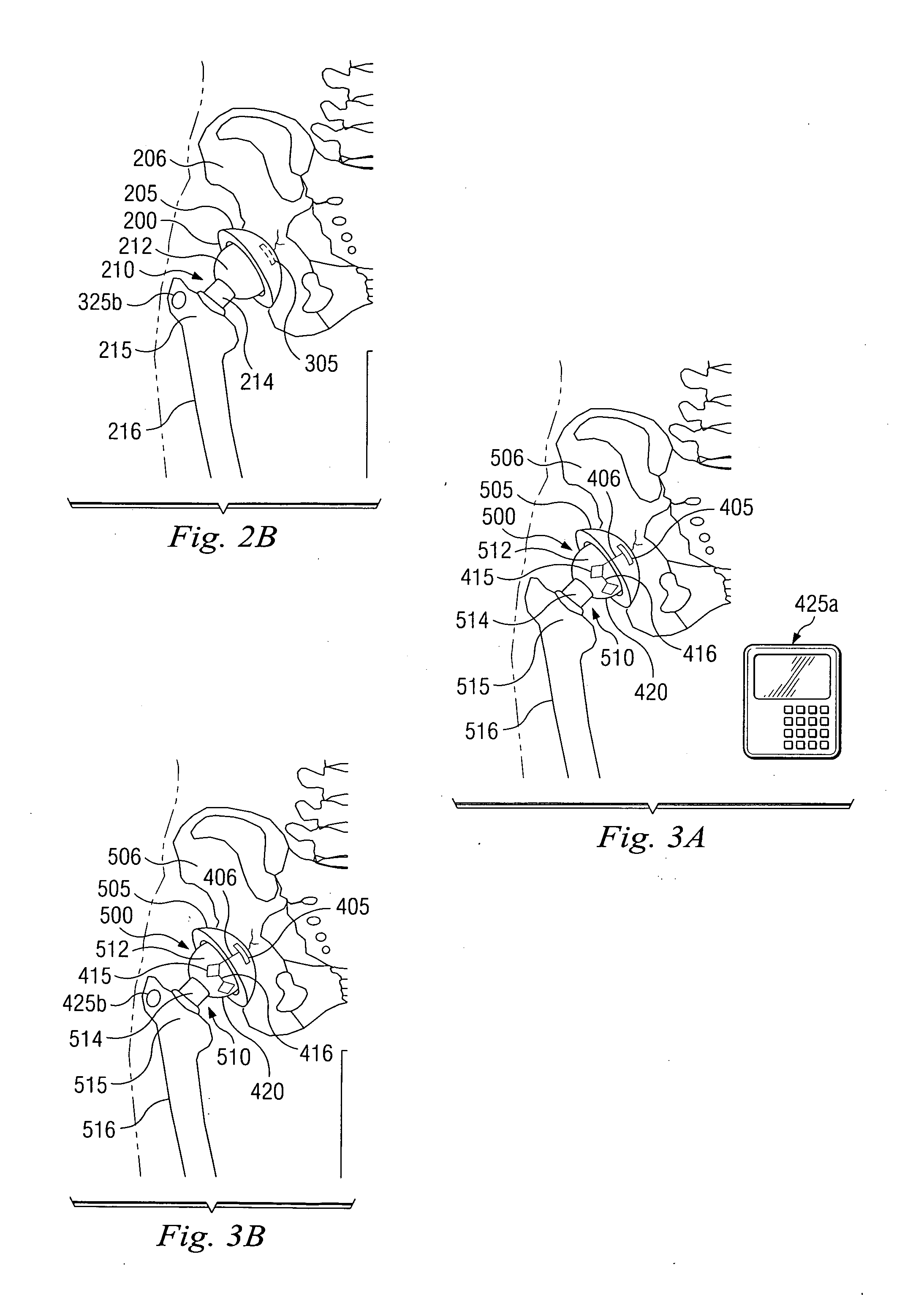

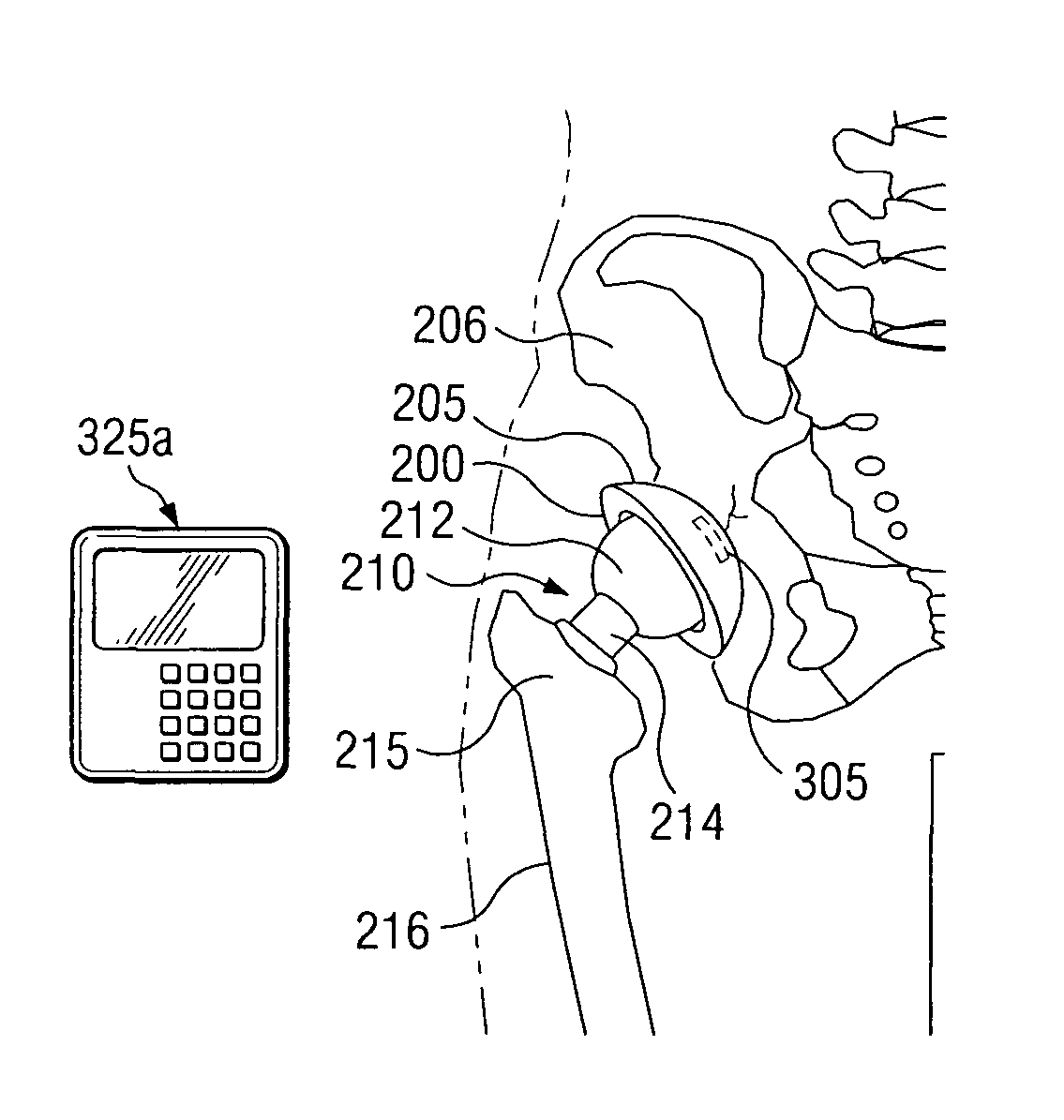

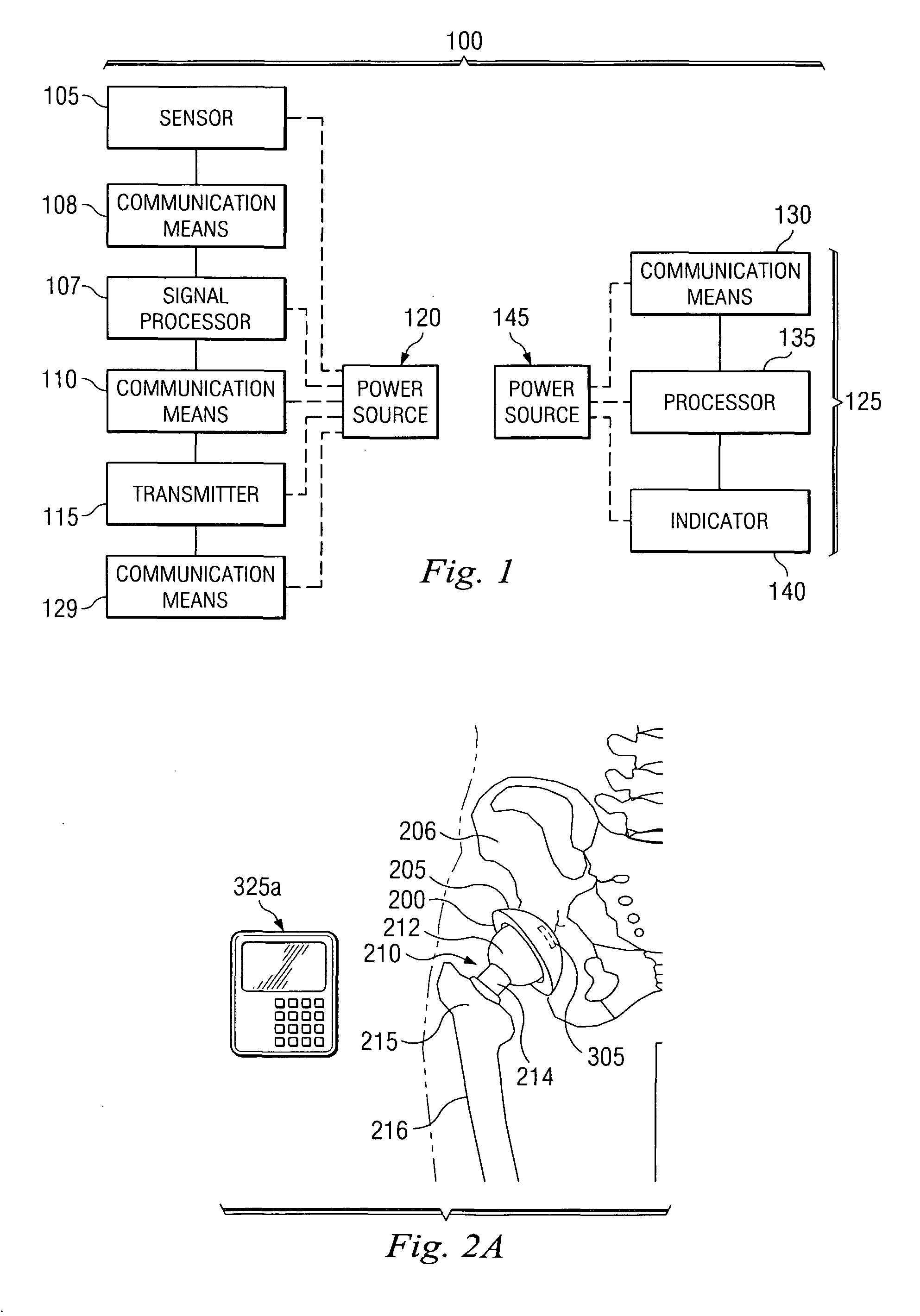

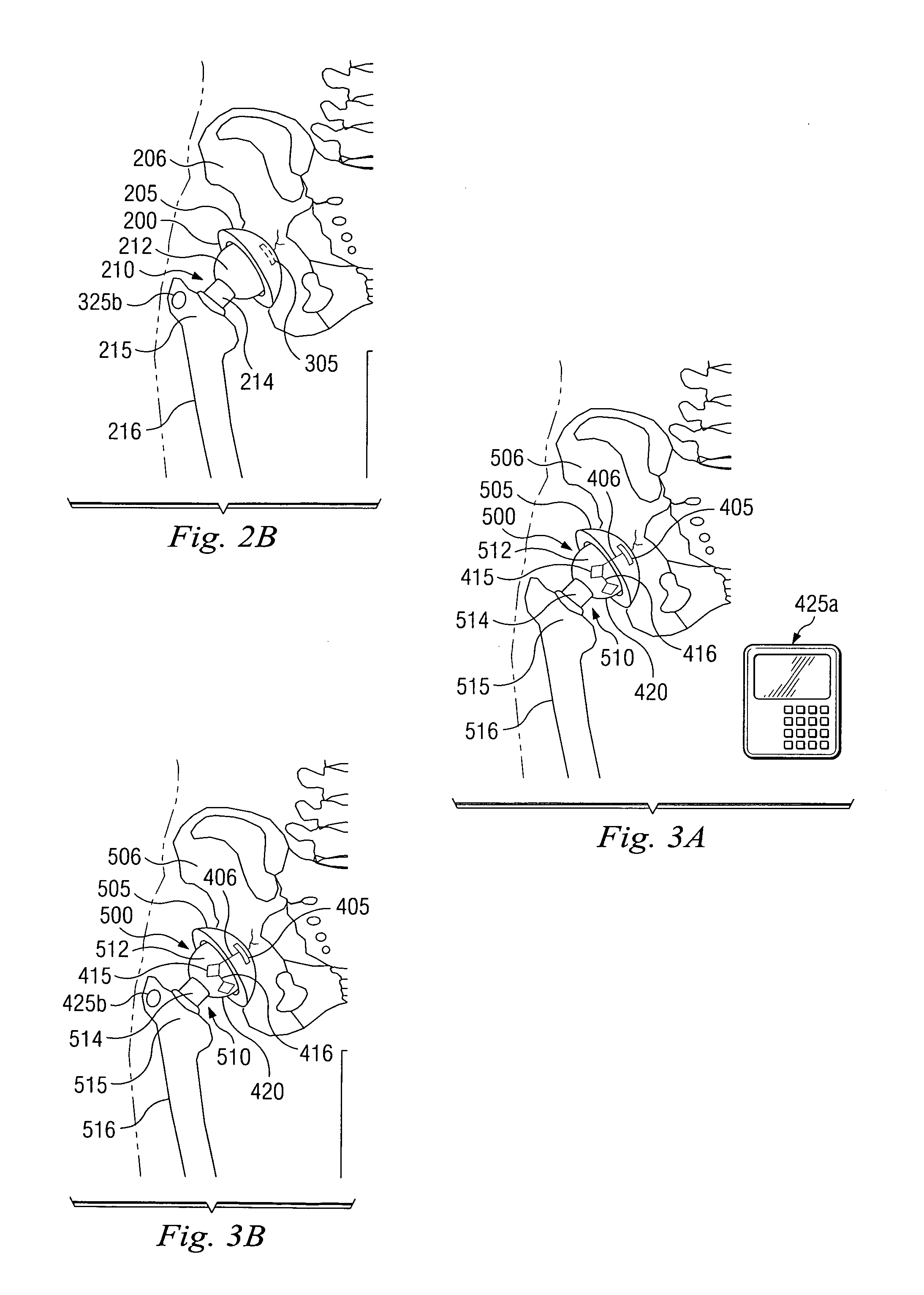

Methods for detecting osteolytic conditions in the body

Methods and systems for detecting a biological response indicative of osteolysis or osteolytic pre-conditions in bone.

Owner:WARSAW ORTHOPEDIC INC

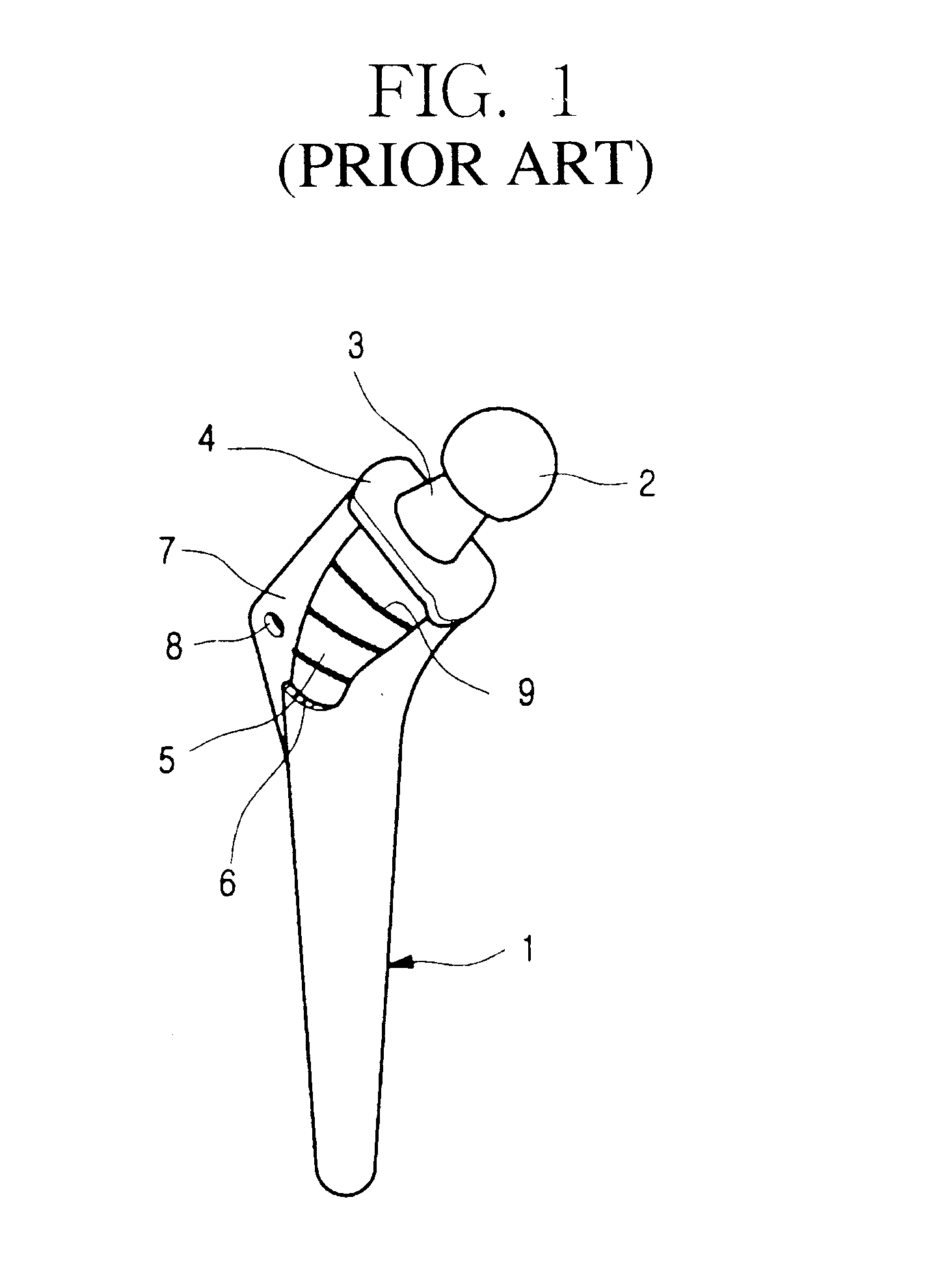

Modular Femoral Head Surface Replacement, Modular Femoral Neck Stem, and Related Sleeve, Adapter, and Osteoconducting Rod

InactiveUS20090043397A1Relief the painRestore stabilityInternal osteosythesisBone implantEtiologyBody of femur

Disclosed therein is a big femoral head and femoral head surface replacement, which are used for hip osteoarthritis and vascular necrosis of femoral head. As a person get older and aged, the weight bearing hip joint is indispensably changed to osteoarthritis and sometimes showed avascular necrosis of the femoral head with unknown etiology. The deformed femoral head and hip joint should be replaced with the THA. Till now, the total hip replacement is performed in such a way that the necrosed femoral head and a healthy femoral neck are all removed and a femoral stem is inserted into the marrow cavity, and in this case, a small femoral head causes a reduction of a range of motion and dislocation of the hip joint occasionally, and osteolysis due to abrasion of plastic acetabular liner. In case of a conventional femoral head surface replacement (hereinafter, called “conventional FHSR”), a complication of femoral neck fracture and could not combined use with conventional THA. Recently, hard bearing system such as metal on metal THA or ceramic on ceramic THA without using plastic has been introduced to solve the problem of osteolysis due to abraded plastic particles generated when the THA is worn out as time goes. But there also have many problems as a limited range of motion, resected normal femoral neck and difficulties of rereplacement of the femoral stem. Because of the big femoral head or the FHSR can increase the range of motion and lower dislocation rate these devices are gradually widespread in young active person and Asian peoples. This invented design of the modularity gives the convenience to the surgeon and economically lower burden to patients to use of the FHSR and big femoral head system. The related accessory showed initial stability of the FHSR during operation and prevent from femoral neck fracture in follow-up periods.

Owner:PARK HYUNG BAE

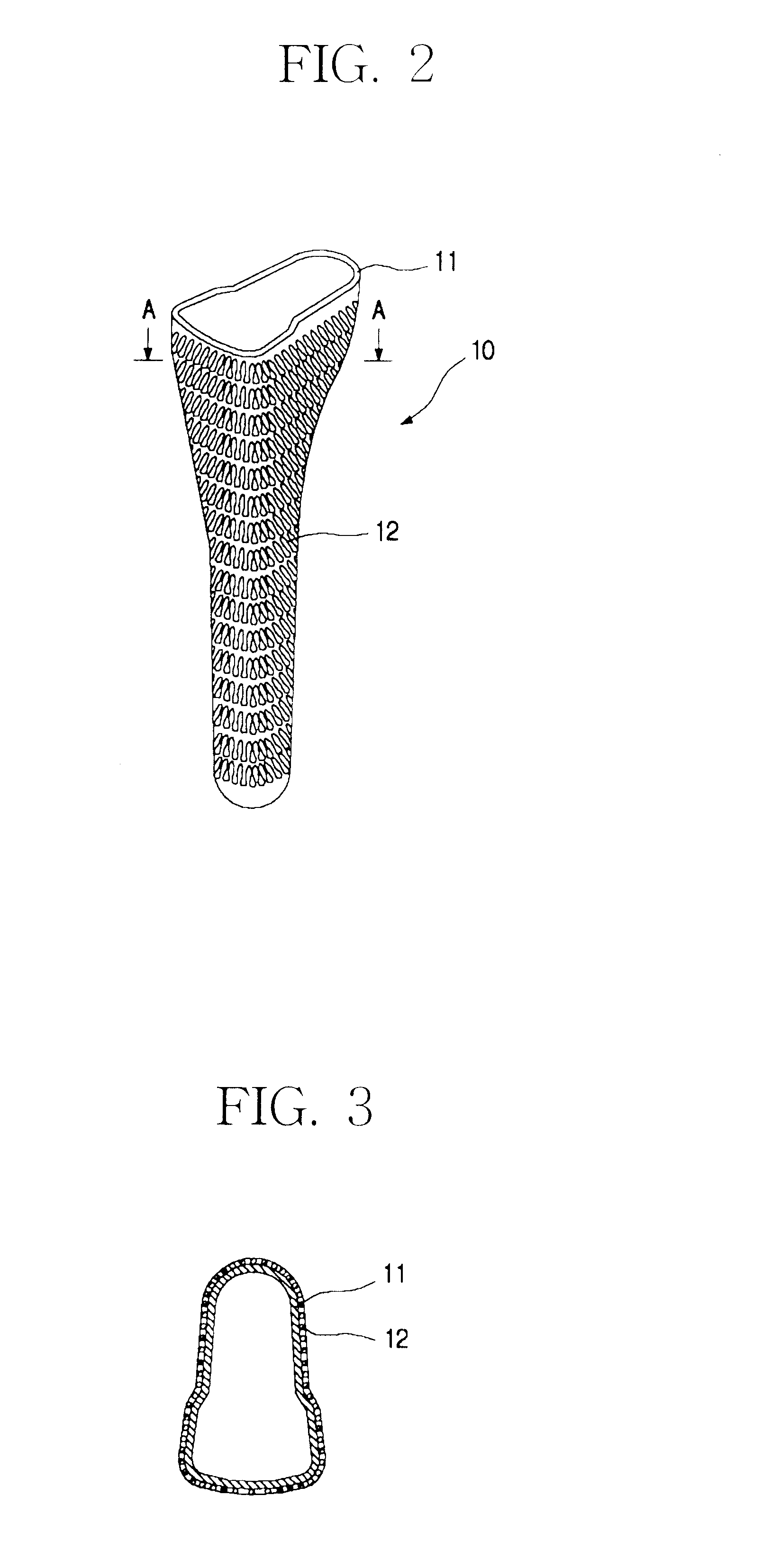

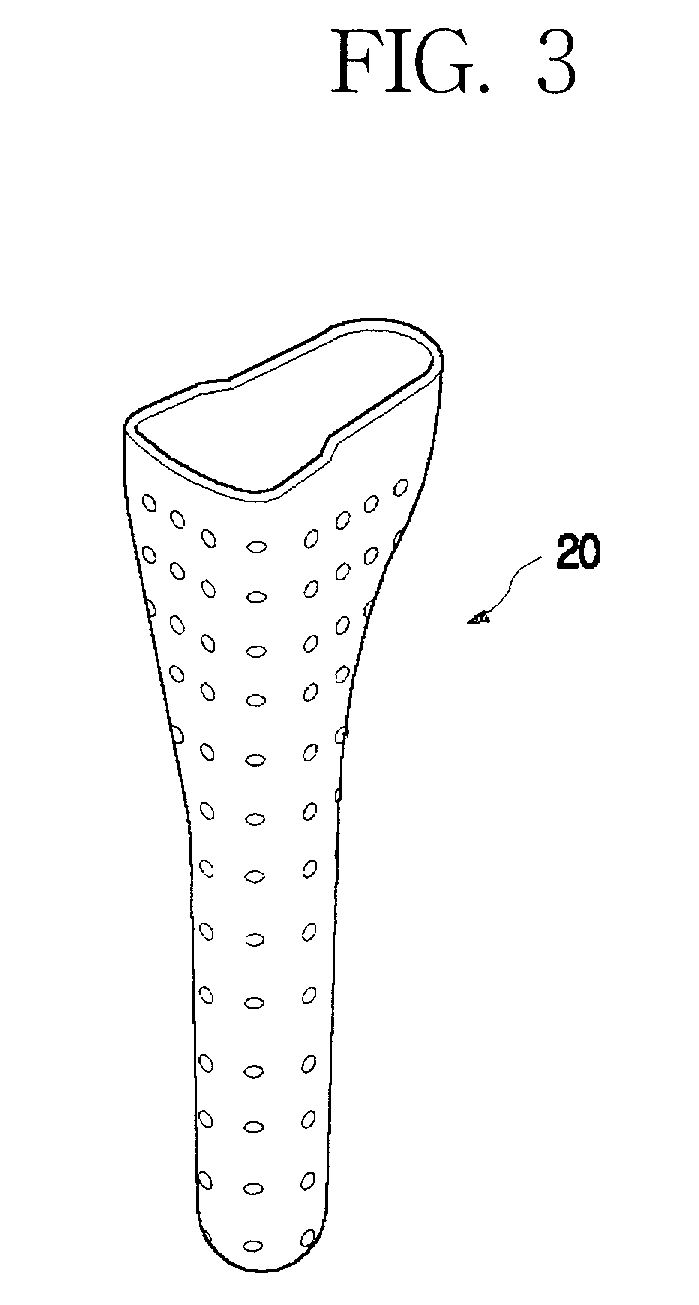

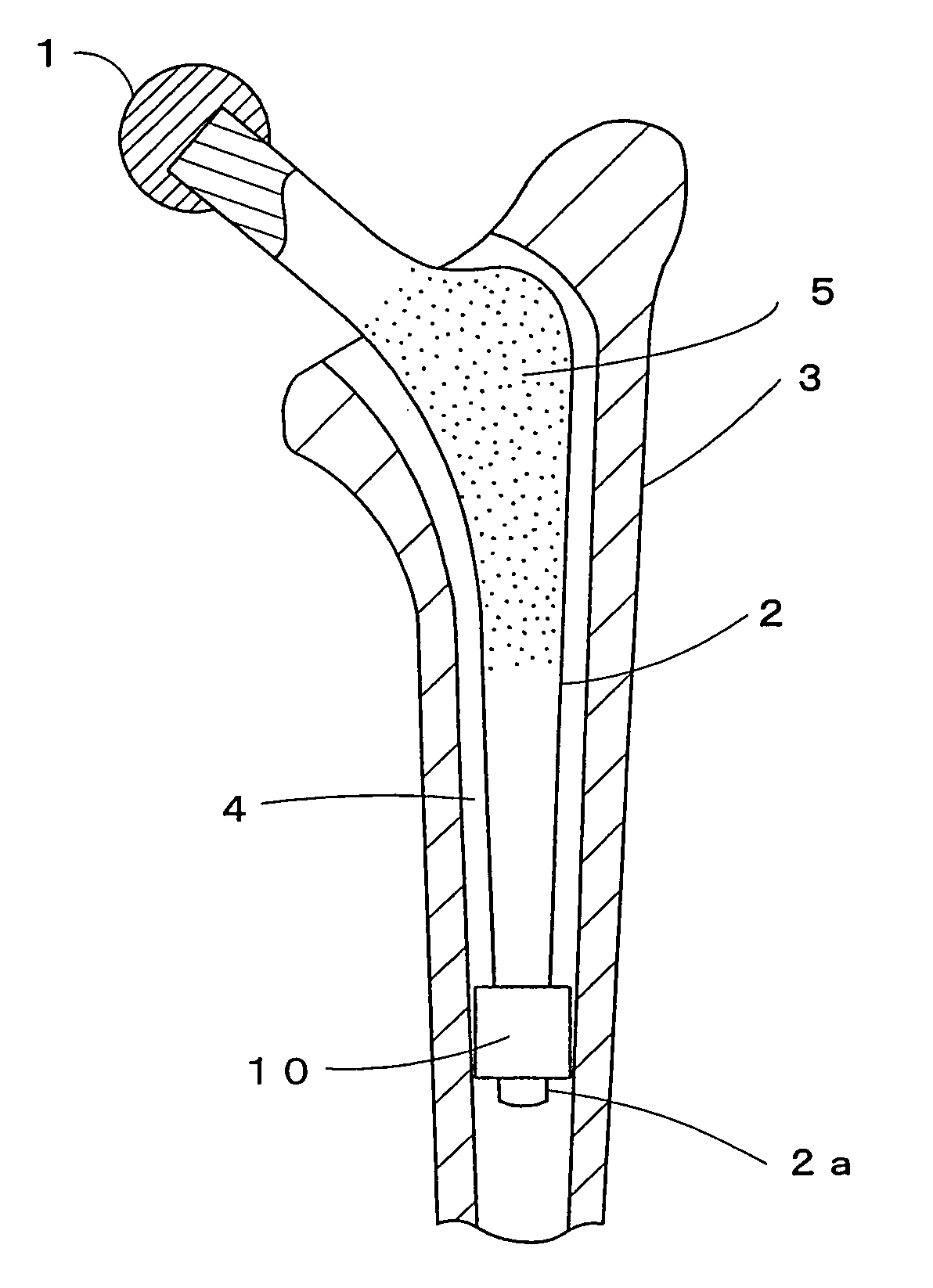

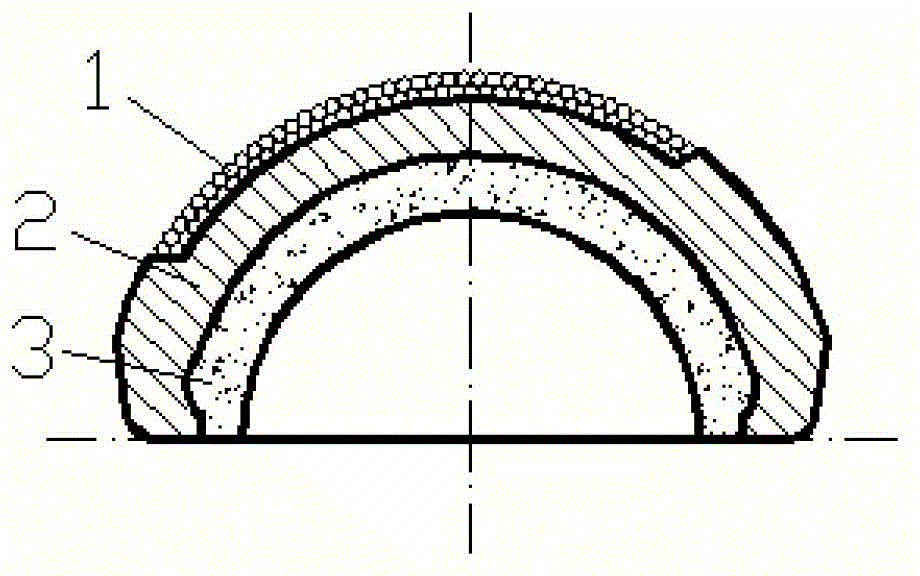

Plastic jacket for a cementless artificial joint stem and artificial joint having the jacket

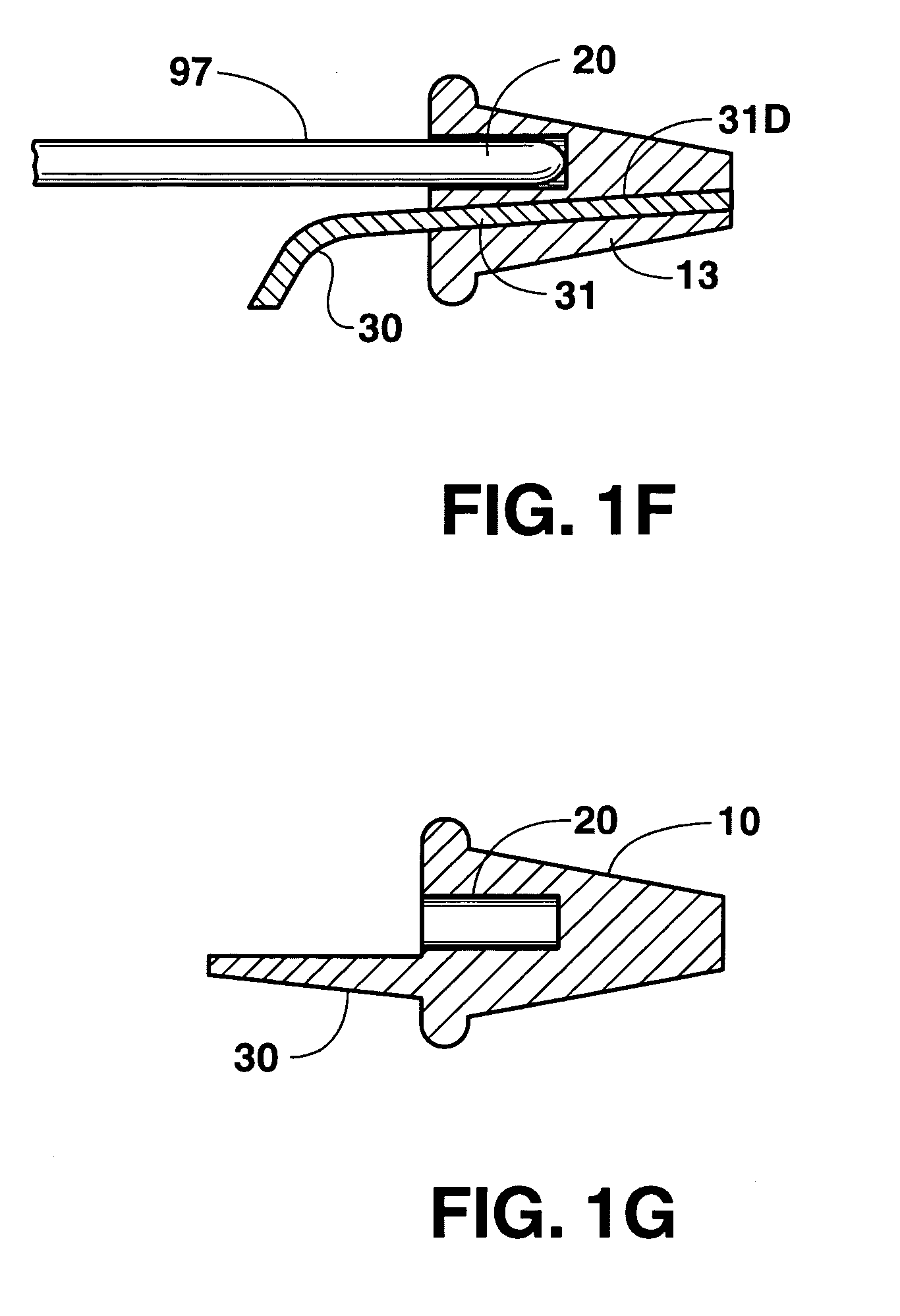

The present invention is intended to provide a plastic jacket for a cementless artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced and stress shielding phenomena can also be markedly relieved, due to the construction of the plastic jacket which can be fixed to the bone canal and can enclose the surface of the stem so as to allow for the stem of artificial joint to slide vertically relative to the bone, and wherein osteolysis of a bone due to the infiltration of wear particles can be minimized by curbing the gap formation between the bone and the stem. To that end, there is provided according to the invention, a plastic jacket 20 for a cementless artificial joint stem 31, which is made of plastics and is so formed as to enclose at least a part of the stem 31 of a cementless artificial joint 30, said stem with jacket being inserted longitudinally in the opening formed in the bone canal of a human body, and which has a porous or roughened surface so that a femur can make interlocking with the plastic jacket as the bone gets in-growth onto the porous plastic jacket surface.

Owner:KOREA ADVANCED INST OF SCI & TECH

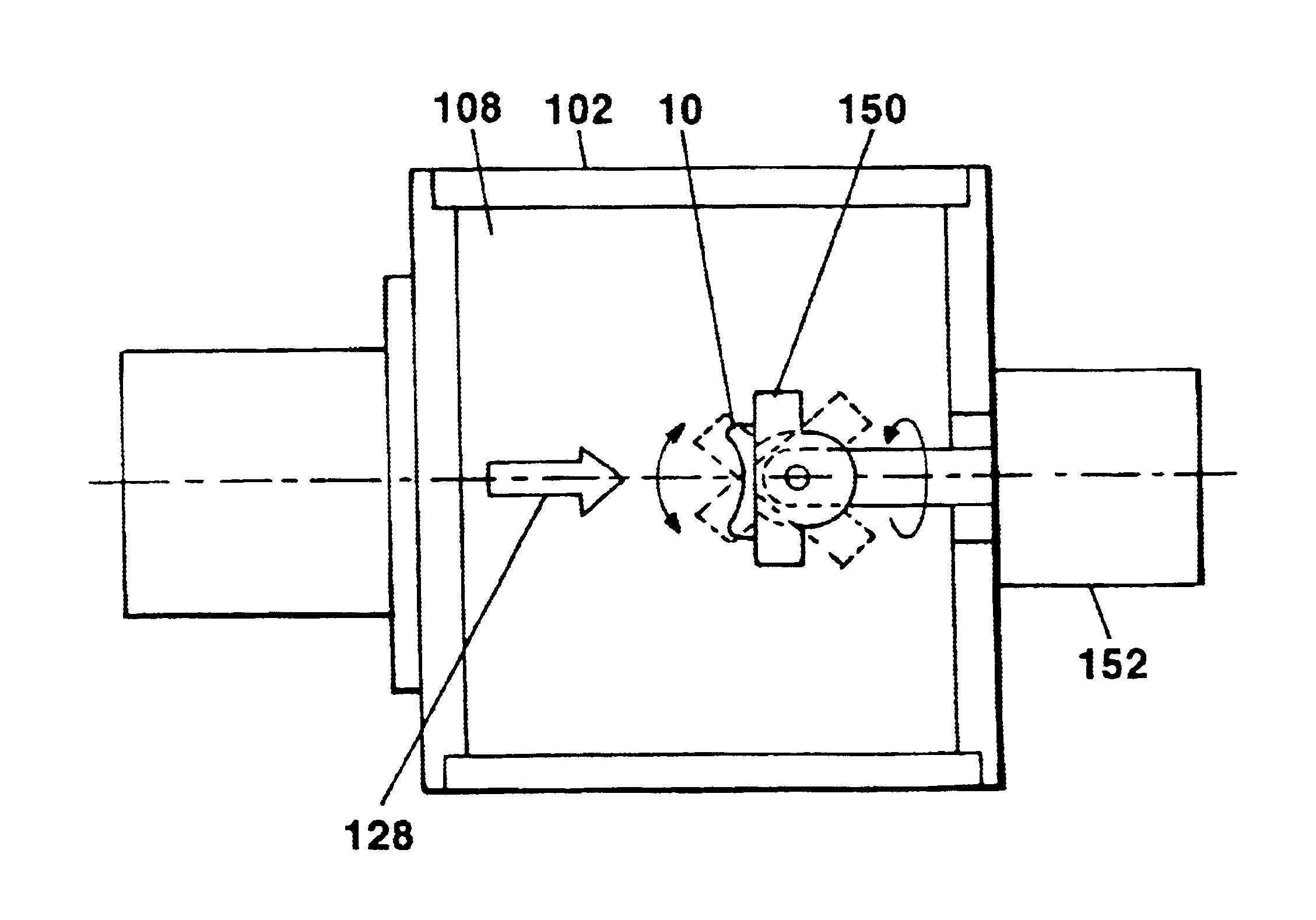

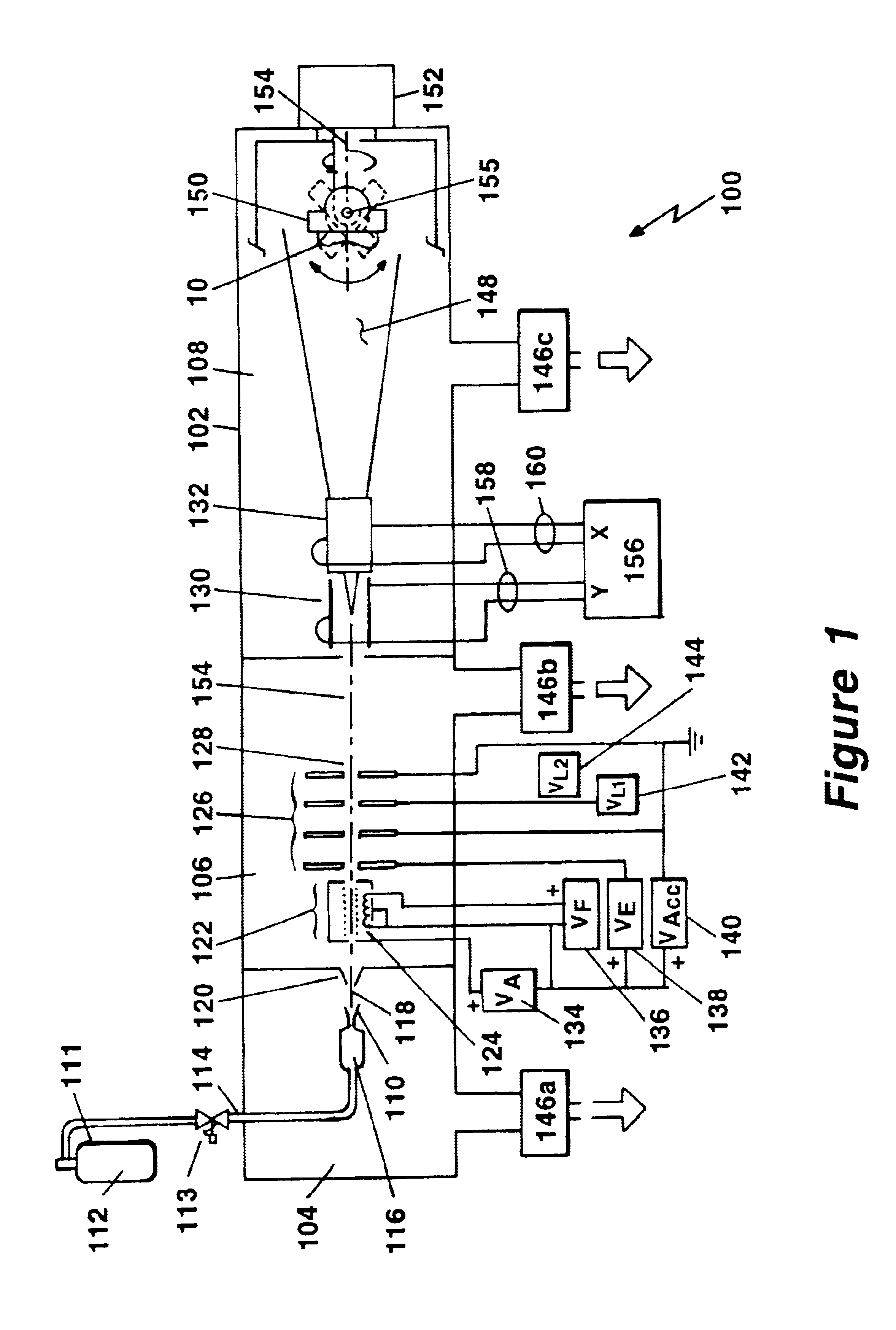

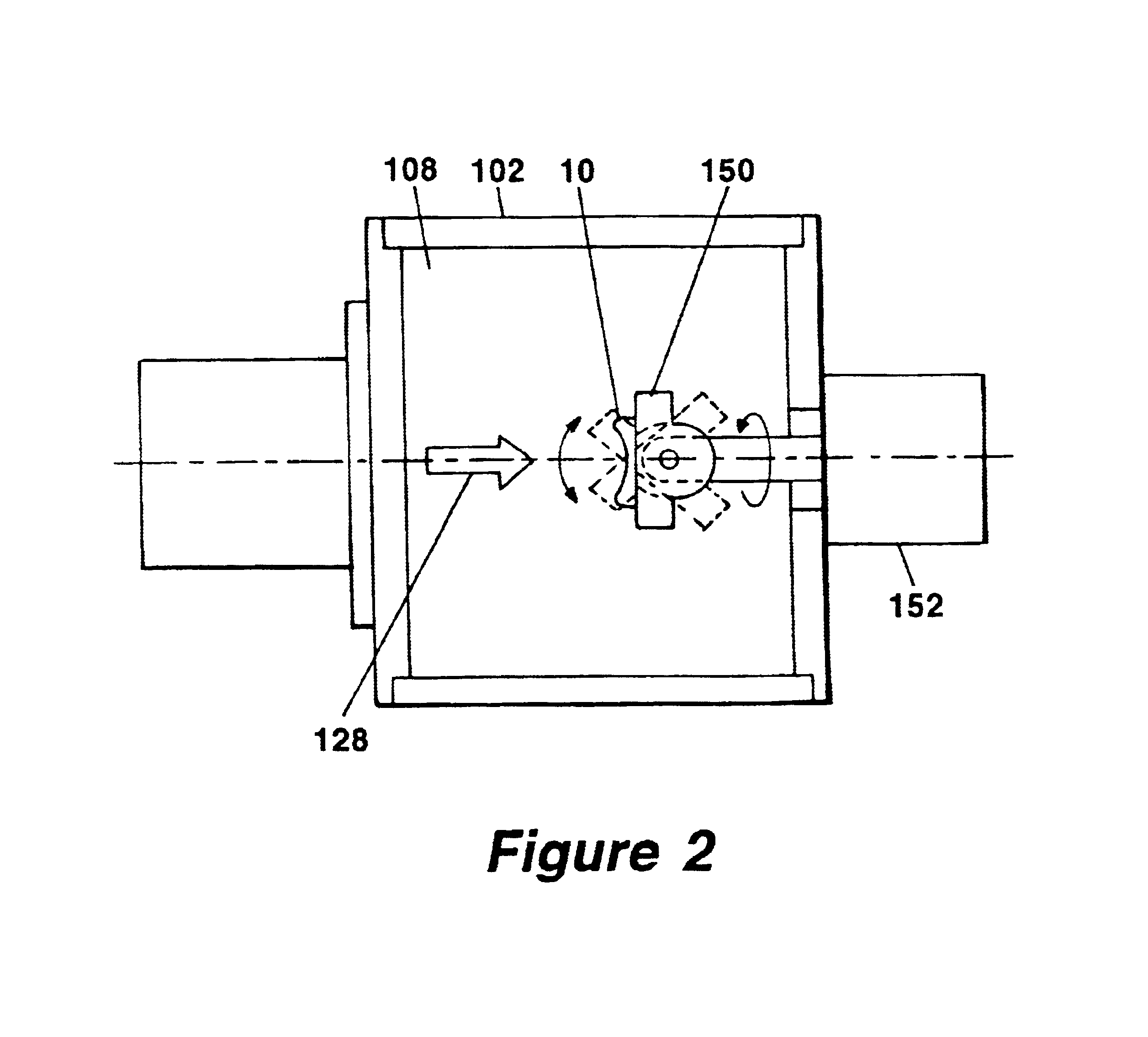

Method and system for improving the effectiveness of artificial joints by the application of gas cluster ion beam technology

InactiveUS6863786B2Minimize impactMinimize wear debrisCellsElectric discharge tubesSurface patternGas cluster ion beam

Regardless of the materials used in an artificial joint component design, the present invention applies gas cluster ion beam (GCIB) technology in order to modify the component's surface(s) so as to increase lubrication between contact surfaces, thereby substantially reducing wear debris, osteolysis complications, and accelerated wear failure. The approach of the surface modification comprises an atomic level surface patterning utilizing GCIB to apply a predetermined pattern to the surface(s) of the joint implant to reduce frictional wear at the interface of the surfaces. A reduction in wear debris by GCIB patterning on any surface(s) of a joint prosthesis reduces accelerated failure due to wear and osteolysis and results in a substantial cost savings to the healthcare system, and reduces patient pain and suffering.

Owner:EXOGENESIS CORP +1

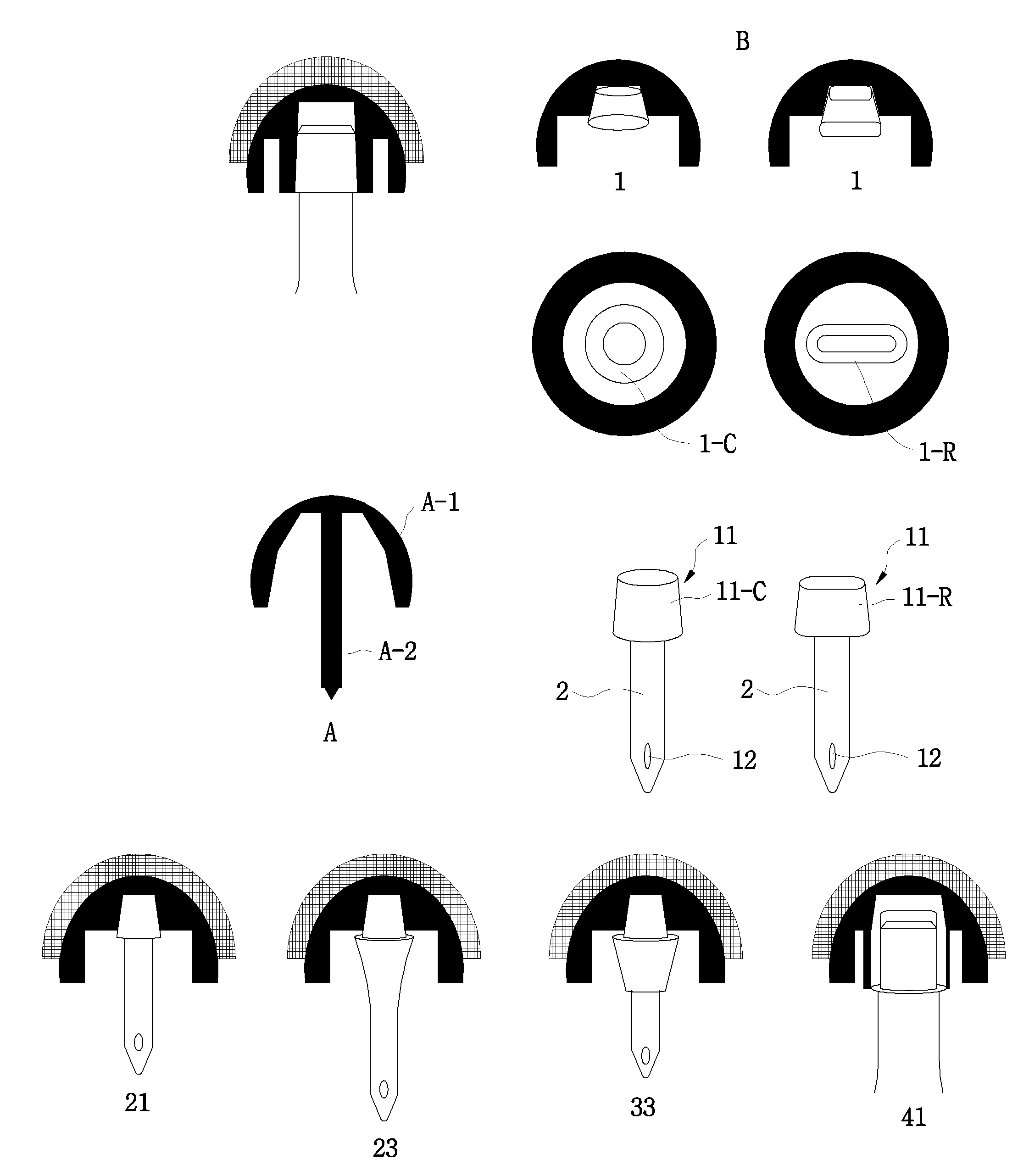

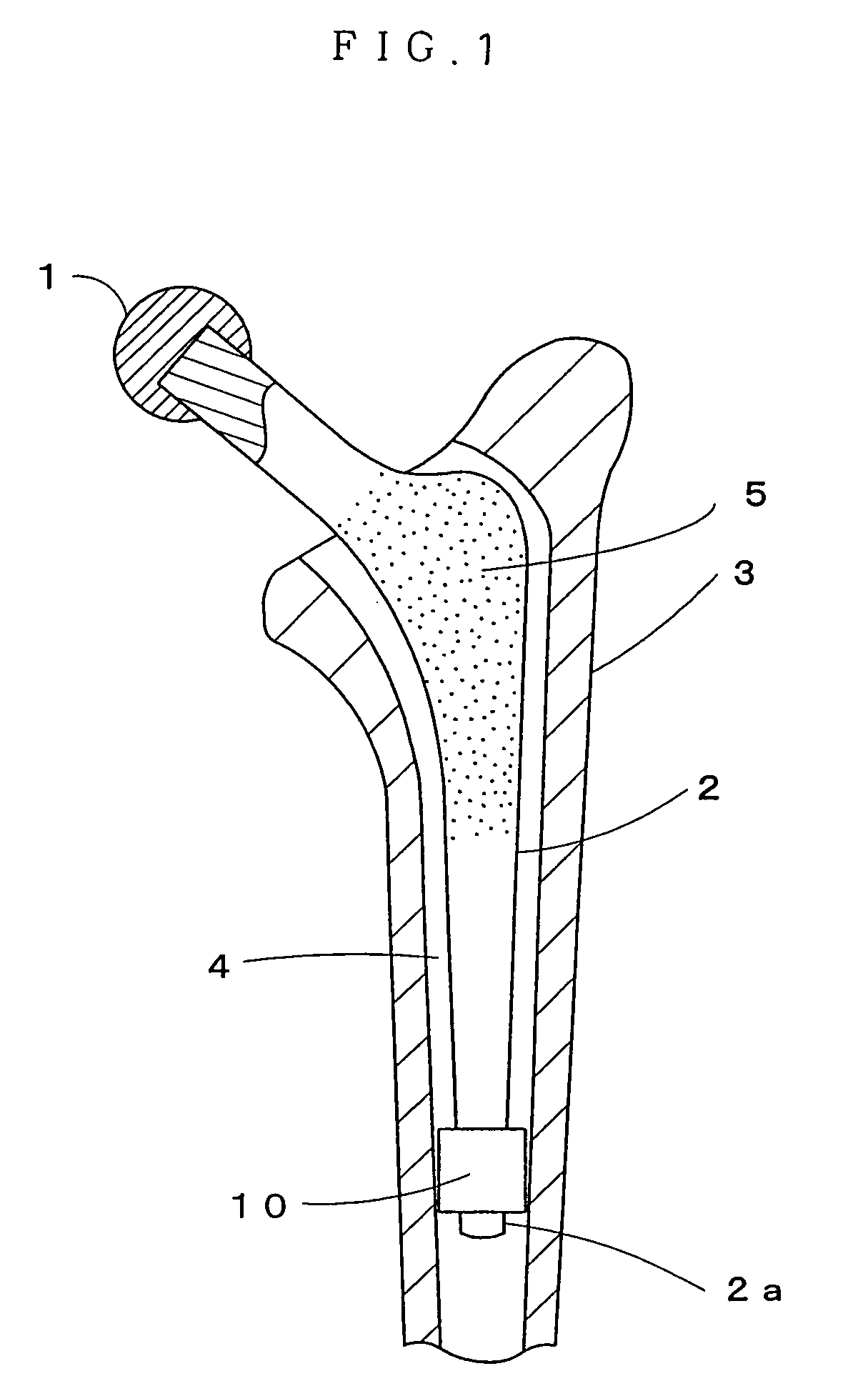

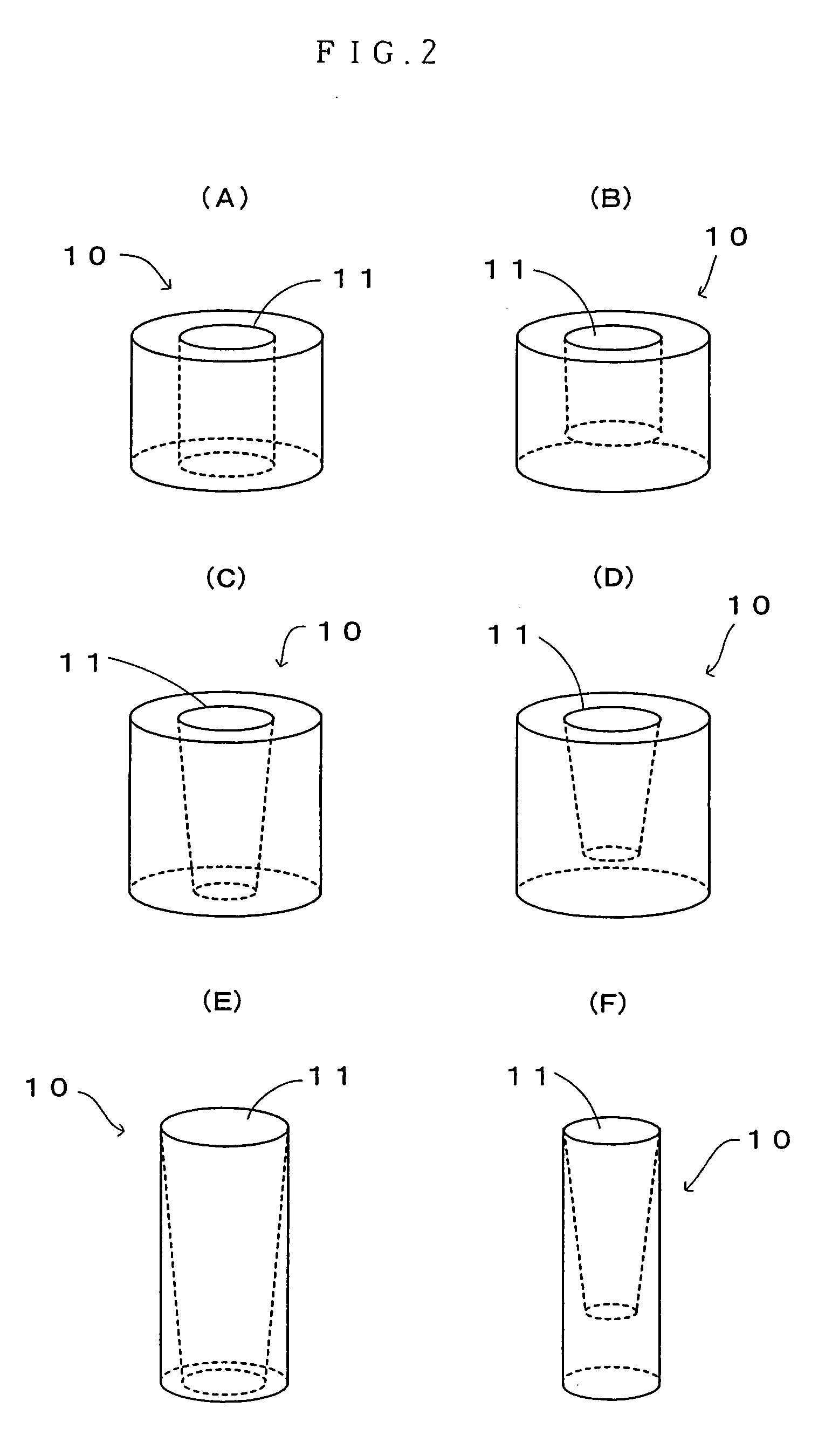

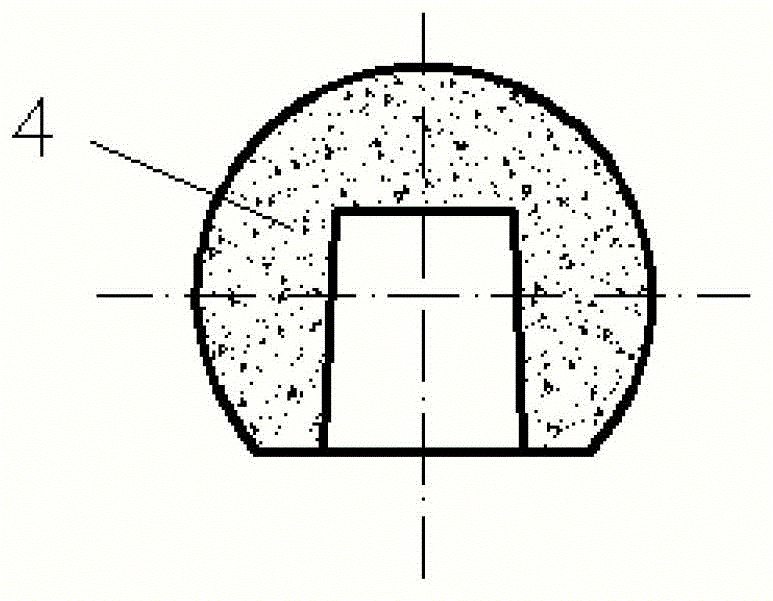

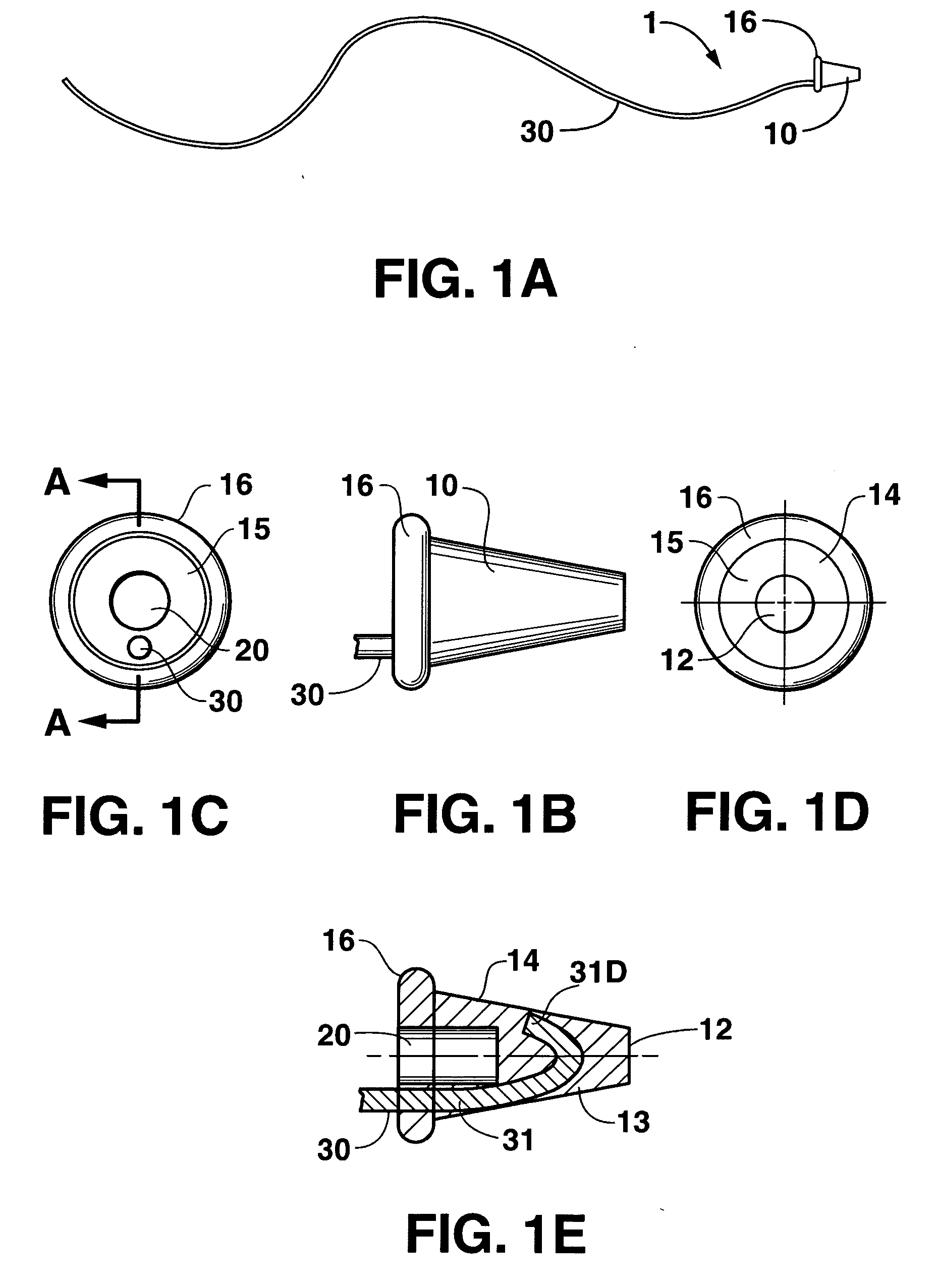

Distal tip for the positioning of artificial joint stem

The present invention provides a distal tip for the positioning of artificial joint stem that is capable of reliably guiding the insertion of the stem of the cementless artificial joint into a bone canal and positioning the distal end portion of the stem that is inserted into the bone canal at a planned position, thereby to maintain the entire stem in a favorable posture in the bone canal, and prevent osteolysis and loosening of the artificial join even when the distal tip is used. The distal tip 10 for the positioning of artificial joint stem is mounted near the distal end portion 2a of the stem of the cementless artificial joint thereby to guide the distal end portion 2a of the stem so as not to make direct contact with the inner surface of the bone canal 4 of the bone 3 when the stem 2 of the artificial joint is inserted into the bone canal 4, and make stable positioning of the stem distal end portion 2a when the insertion of the stem 2 is completed, wherein the distal tip 10 is made of a biodegradable and absorbable material.

Owner:SENKO MED INSTR MFG CO LTD

Metal jacket for a cementless artificial joint stem and artificial joint having the jacket

InactiveUS20010016780A1Suppress formationMinimize osteolysisBone implantJoint implantsHuman bodyStress shielding

The present invention is intended to provide a metal jacket for a cementless artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced and stress shielding phenomena can also be markedly relieved, due to the construction of the metal jacket which can be fixed to the bone and can enclose the surface of the stem so as to allow for the stem of artificial joint to slide vertically relative to the bone, and wherein osteolysis of a bone due to the infiltration of wear particles can be minimized by curbing the gap formation between the bone and the stem. To that end, there is provided according to the invention, a metal jacket for a cementless artificial joint stem, which jacket is so formed as to enclose at least a part of the cementless artificial joint stem 21, said stem with jacket being inserted longitudinally in the opening formed in the bone canal of a human body, and on the surface of which jacket surface-processed metal layer or metal wires 12 is formed so that the bone can make interlocking with the metal jacket as the bone gets on-growth onto the metal jacket.

Owner:KOREA ADVANCED INST OF SCI & TECH

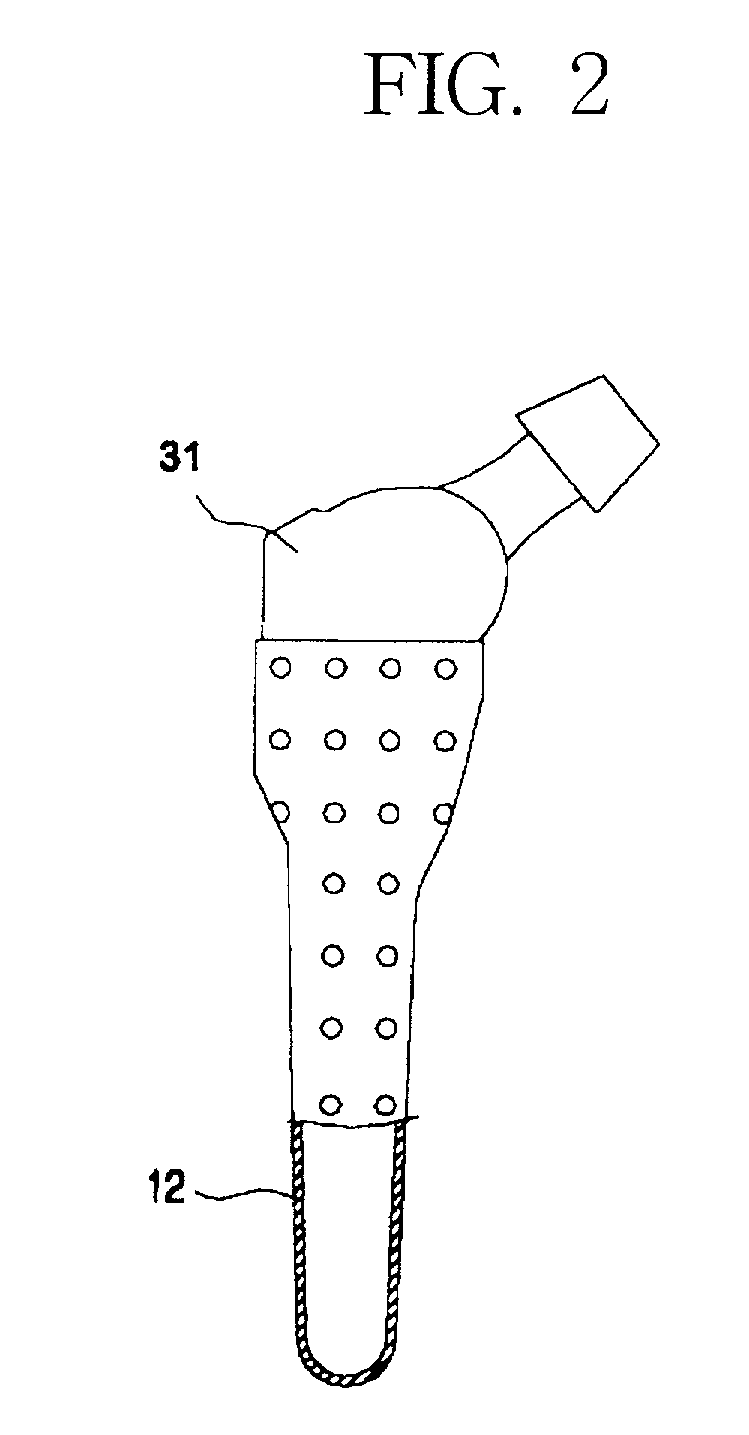

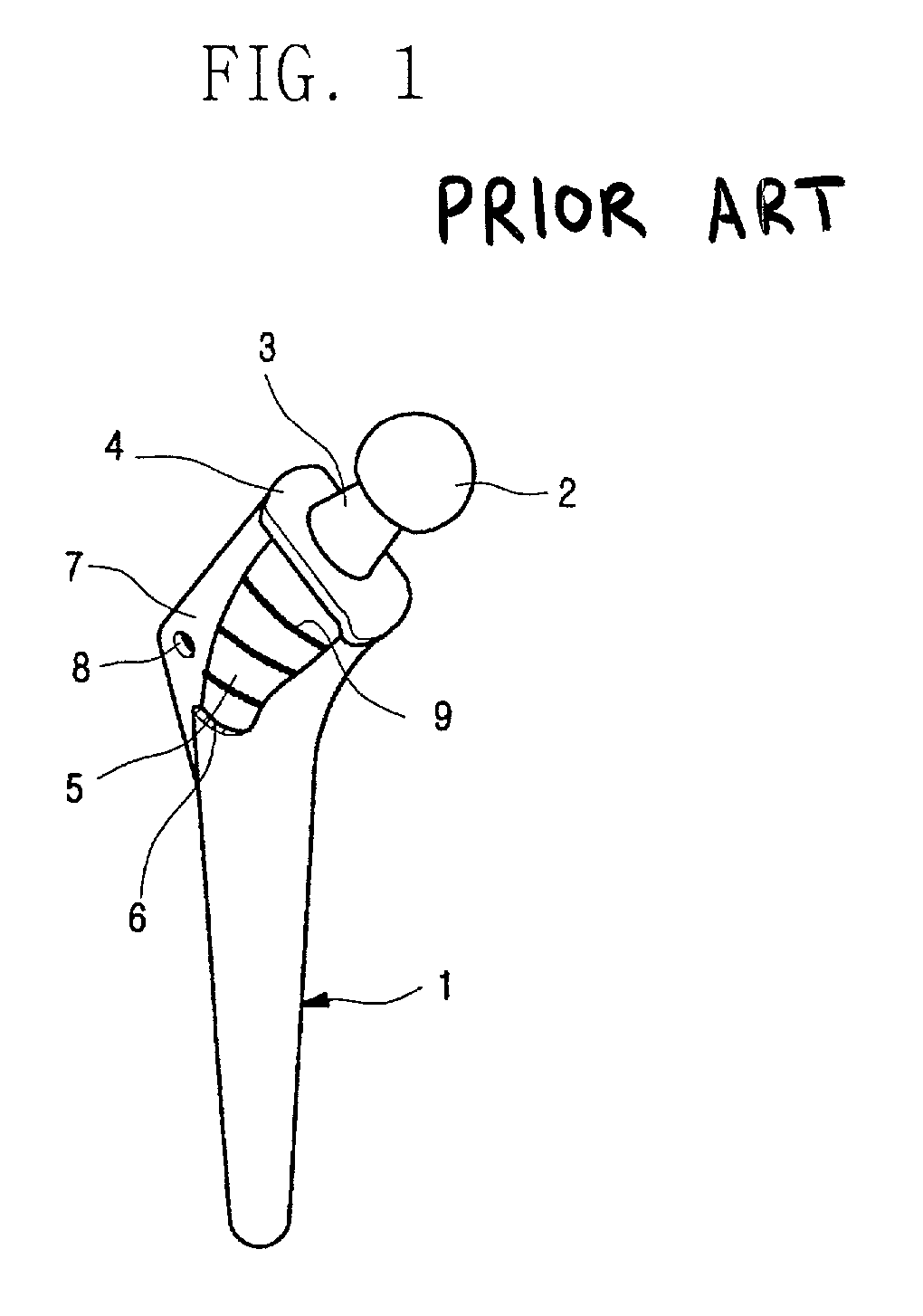

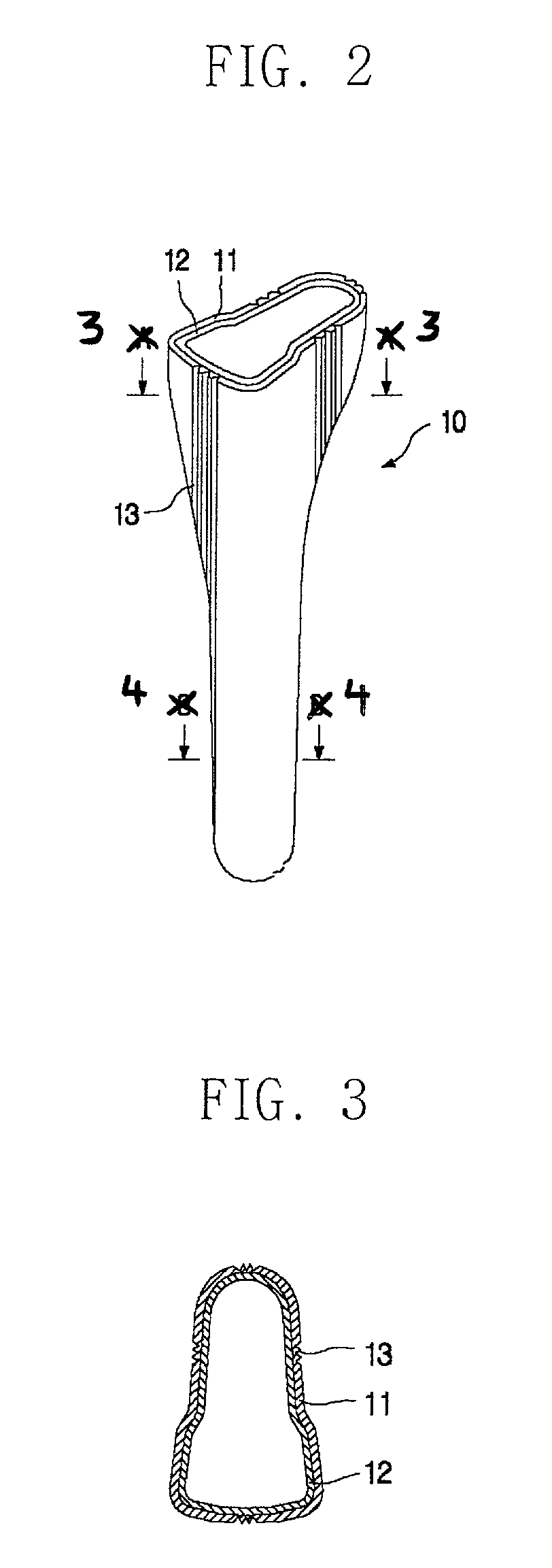

Cement jacket for a cemented artificial joint stem and artificial joint having the cement jacket

InactiveUS20010014828A1Increase anchorageEasy dischargeBone implantJoint implantsHigh resistanceFiber

The present invention relates to a cement jacket for a cemented artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced while the compressive force beneficial for the strengthening of the bone is significantly increased and stress shielding phenomena which makes the bone resorbed can also be markedly relieved, due to the construction of the cement jacket which can be fixed within the bone canal and can enclose the surface of the stem so as to allow for the artificial joint stem to slide vertically relative to the bone, and wherein the osteolysis of a femur due to the infiltration of wear particle can be minimized by curbing the gap formation between the femur and the stem. According to the invention, there is provided a cement jacket 10 for an artificial joint stem 21 for enclosing at least a part of the cemented artificial joint which is inserted longitudinally in the opening formed in the bone canal of a human body. The cement jacket 10 may be made of all cement, or the inner surface of said jacket of cement is coated with a plastic film 12 having a high resistance to abrasion. The cement jacket itself could be reinforced by imbedded wire or fiber. And preferably the outer surface of said cement jacket 10 is formed with discharging paths 13 in the longitudinal direction, so that excessive cement paste poured into the bone canal previously for the surgical purpose can be easily discharged upward at the time of inserting the jacket. (FIG. 2).

Owner:KOREA ADVANCED INST OF SCI & TECH

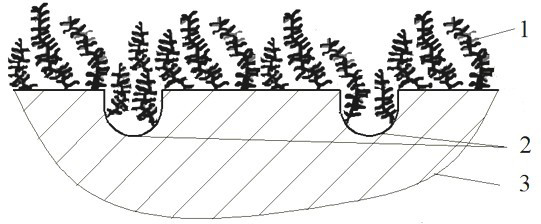

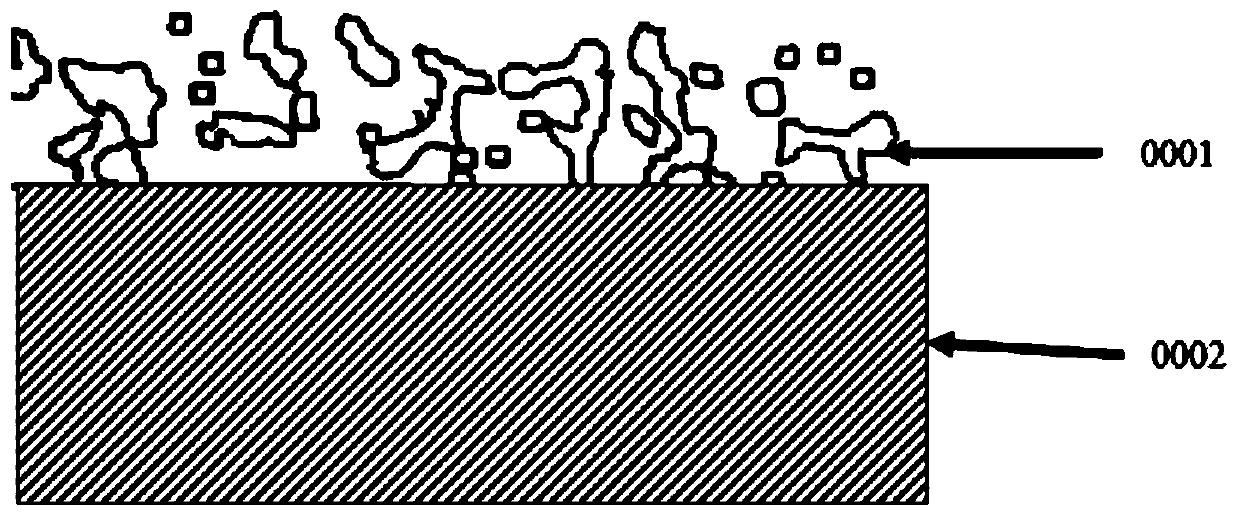

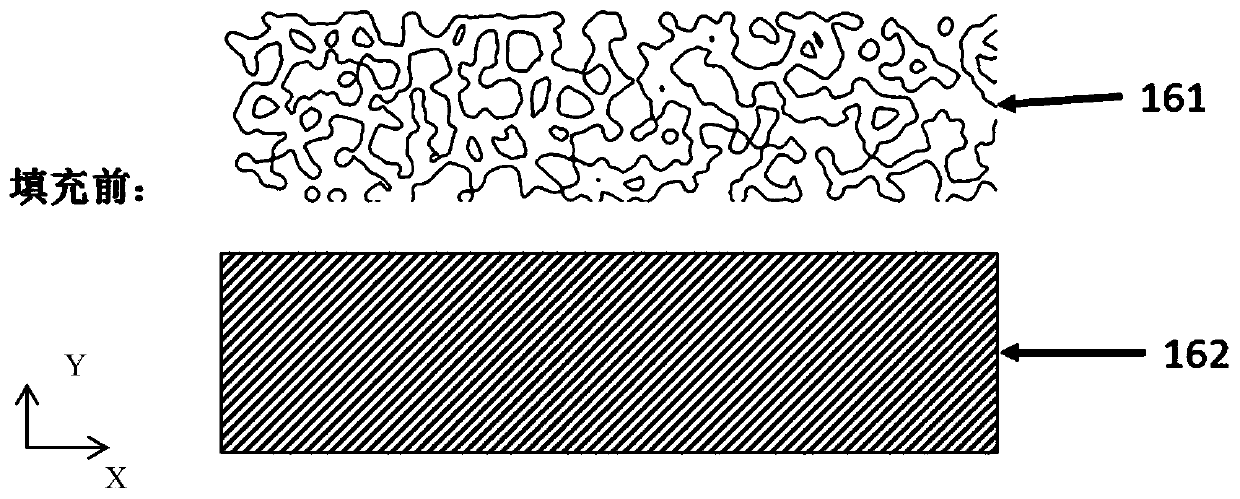

Bionic multi-scale structural surface with excellent tribological performance and preparation method

InactiveCN102492950AReduce wearGuaranteed long-term lubricationAnodisationMetallic material coating processesSurface layerArtificial joints

The invention discloses a bionic multi-scale structural surface with excellent tribological performance and a preparation method. The preparation method includes steps of simulating multiple holes and brush structure on a shallow surface layer of the natural joint cartilage and a lubricating function, building a micrometer-scale porous structure on the friction surface of an artificial joint physically or chemically, grafting polymer molecule brushes which are high in hydrophile and fine biocompatibility so as to form a multi-scale structural surface from micrometers, nanometers to molecules. The tribological performance of an implantation body is evidently improved, tissue reactivity of abrasive dust, osteolysis and loosening can be effectively alleviated, and the service life of the artificial joint can be prolonged evidently.

Owner:NANJING UNIV OF SCI & TECH

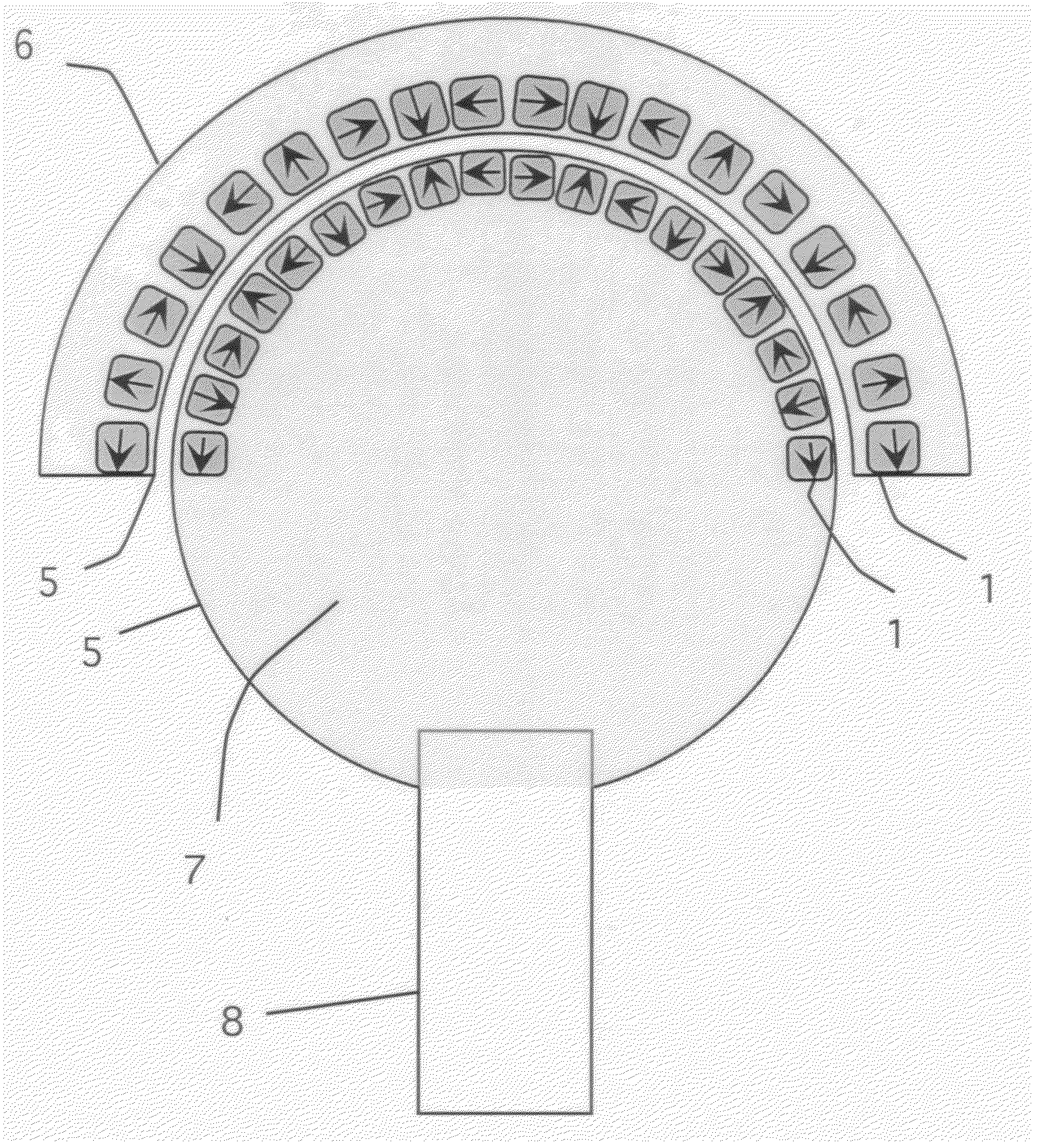

Prosthetic Joints

InactiveUS20150005886A1Mitigate wear and failure processLongevityJoint implantsHip jointsJoint dislocationOperative Surgical Procedures

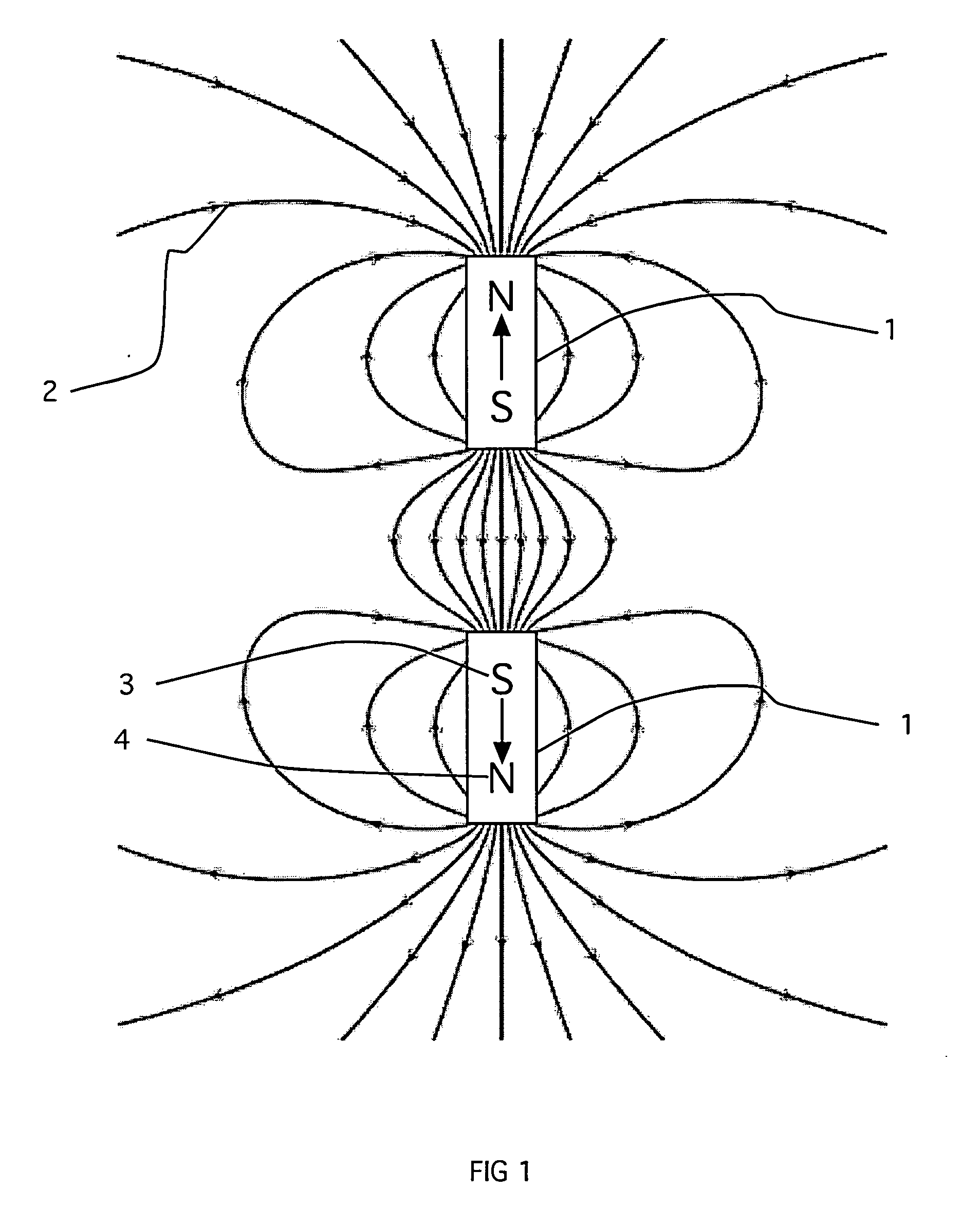

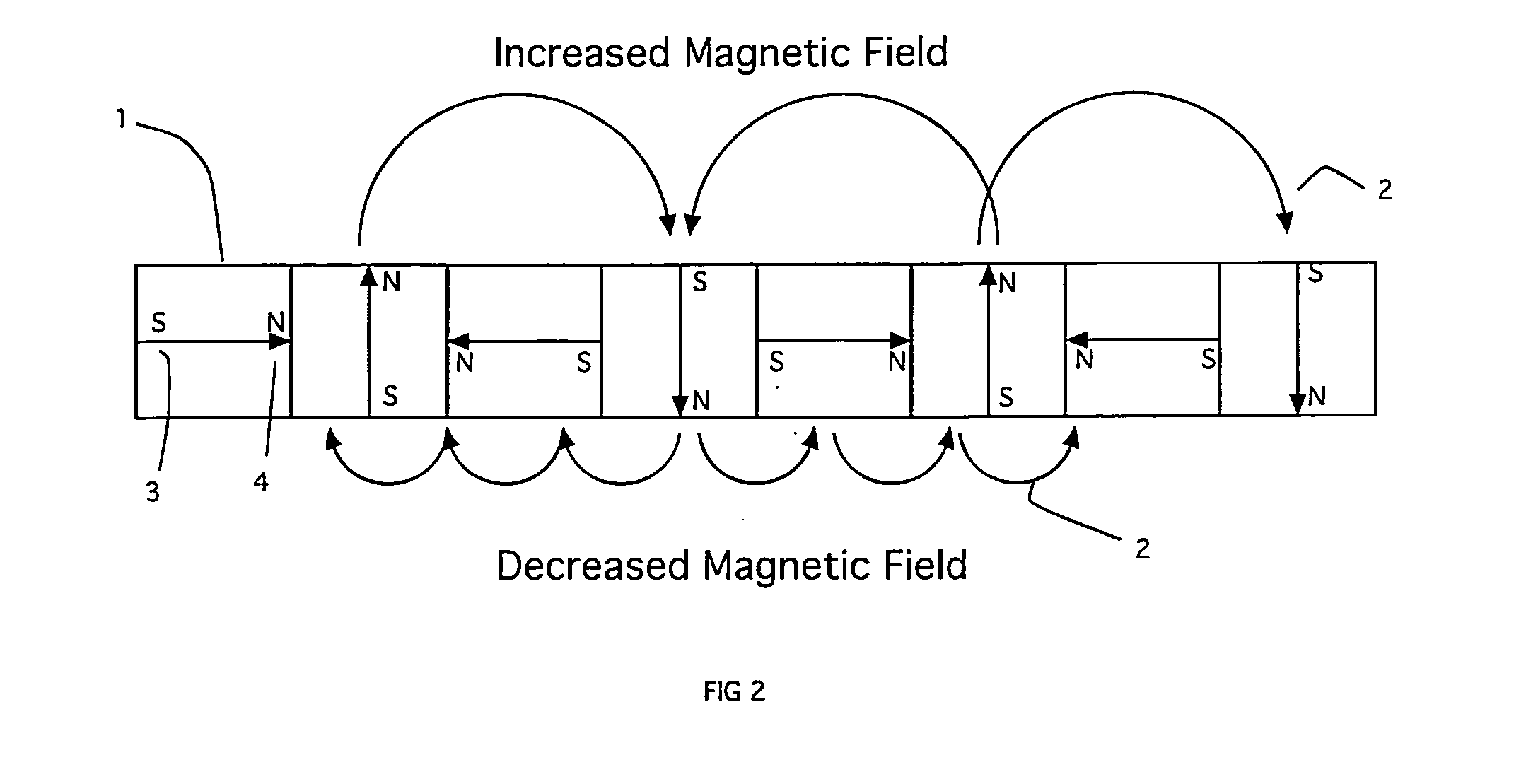

Methods are described for improving the performance of implanted prosthetic joints through the use of magnetic technology. Arrays of magnets are employed to modify static and / or dynamic loads developed on prosthetic joints during their use. Resulting advantages include, but are not limited to: longer functional prosthetic life; reduced frequency of surgical procedures for repair or replacement of prosthetics; reduced rate of prosthetic-associated complications such as osteolysis and / or joint dislocation; and enhanced economic benefits proceeding from these advantages.

Owner:PINNEO JOHN MICHAEL

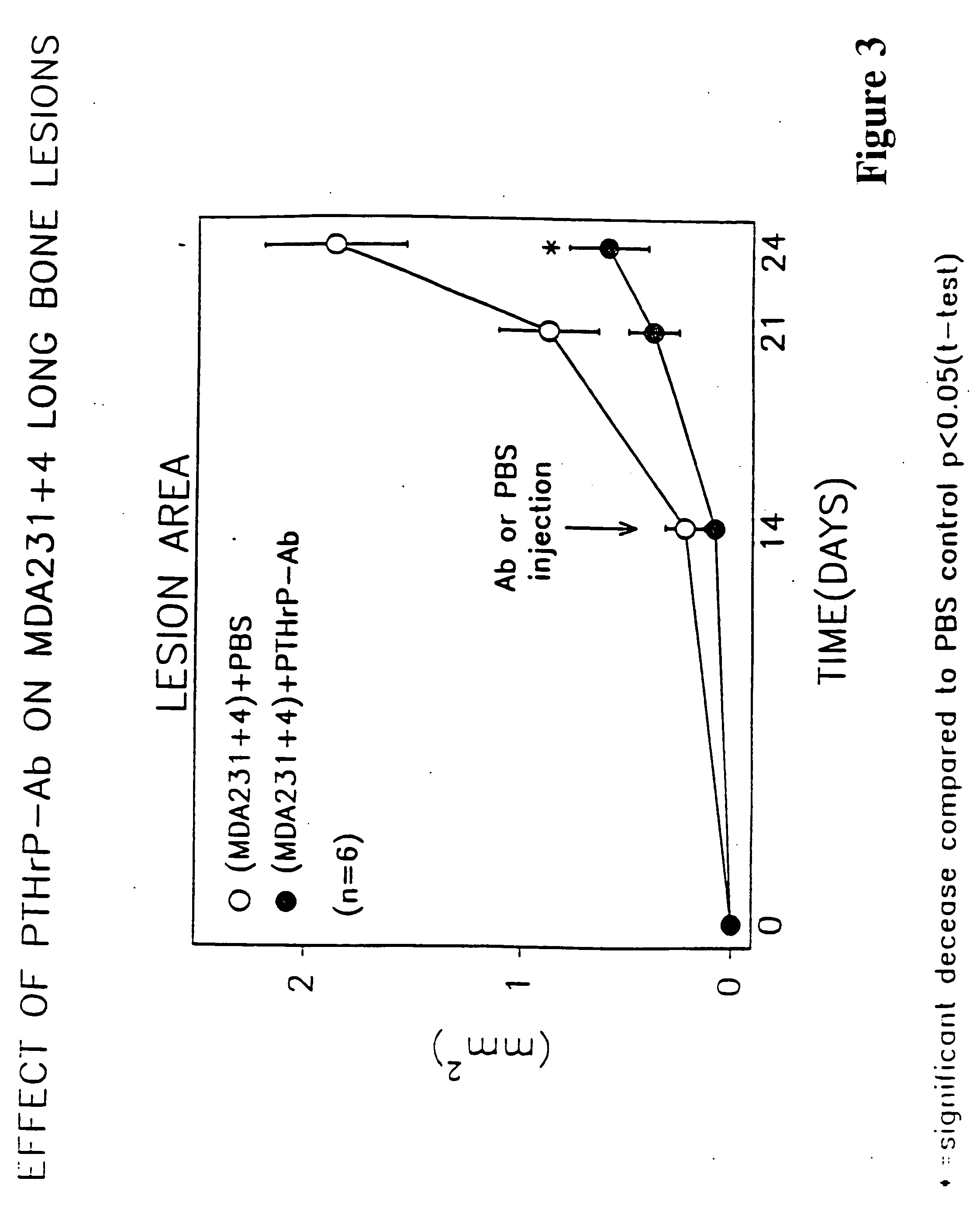

Method to ameliorate osteolysis and metastasis

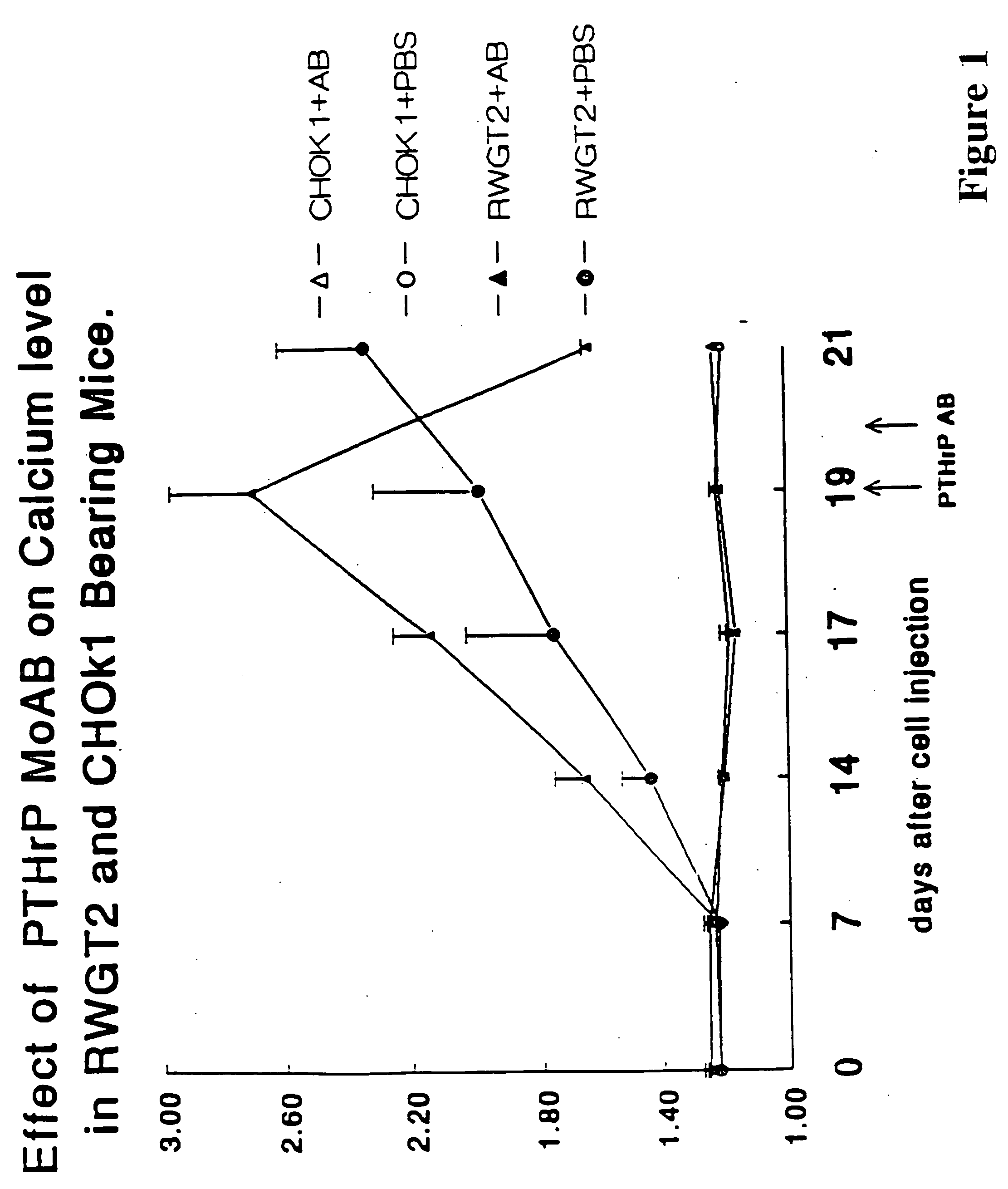

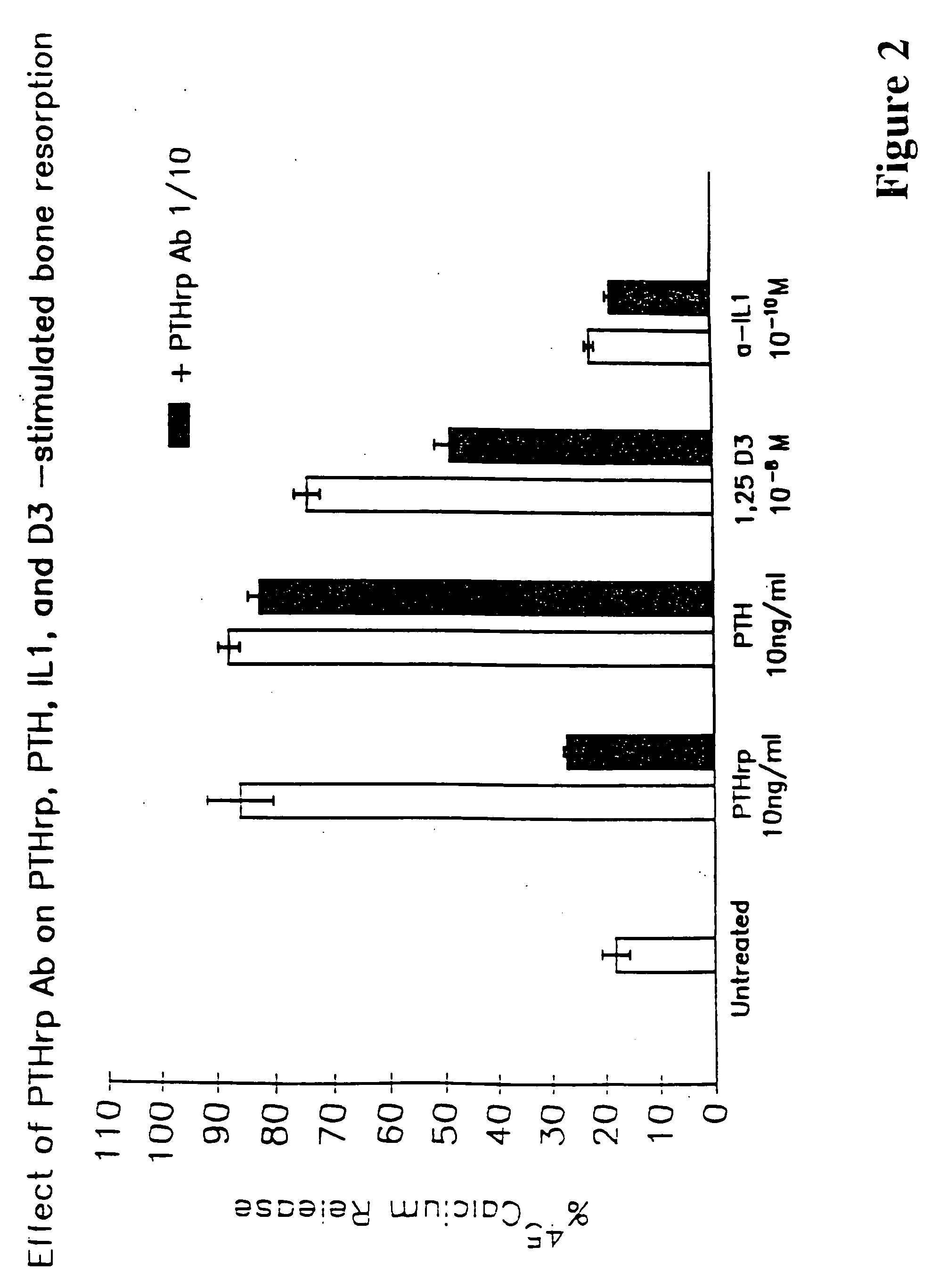

A therapeutically effective amount of an antibody for a compound selected from the group consisting of PTHrp, TGFα, IL-1α, IL-1β, IL-6, Lymphotoxin, TNF, PGE; 1,25 dihydroxy vitamin D3 and an antigenic fragment thereof used in the treatment of cancer metastasis to bone and cancer cell growth in bone as well as osteolysis and symptomatic sequelae thereof. An antibody immunoreactive with parathyroid hormone-related protein (PTHrp) is particularly preferred. Antibodies with human characteristics are included in the invention for application of the invention method to human subjects. Also, the antibody can be administered in an injectable is formulation in combination with a therapeutically effective amount of a bisphosphonate or pyrophosphate having the general structure formula wherein X is a linking moiety allowing for the interconnection of the phosphonate groups, and pharmaceutically acceptable salts, hydrates and partial hydrates thereof. The antibody and bisphosphonate act synergistically in the treatment of cancer metastases to bone and symptomatic sequelae thereof and particularly as regards bone resorption.

Owner:XENOTECH CALIFORNIA

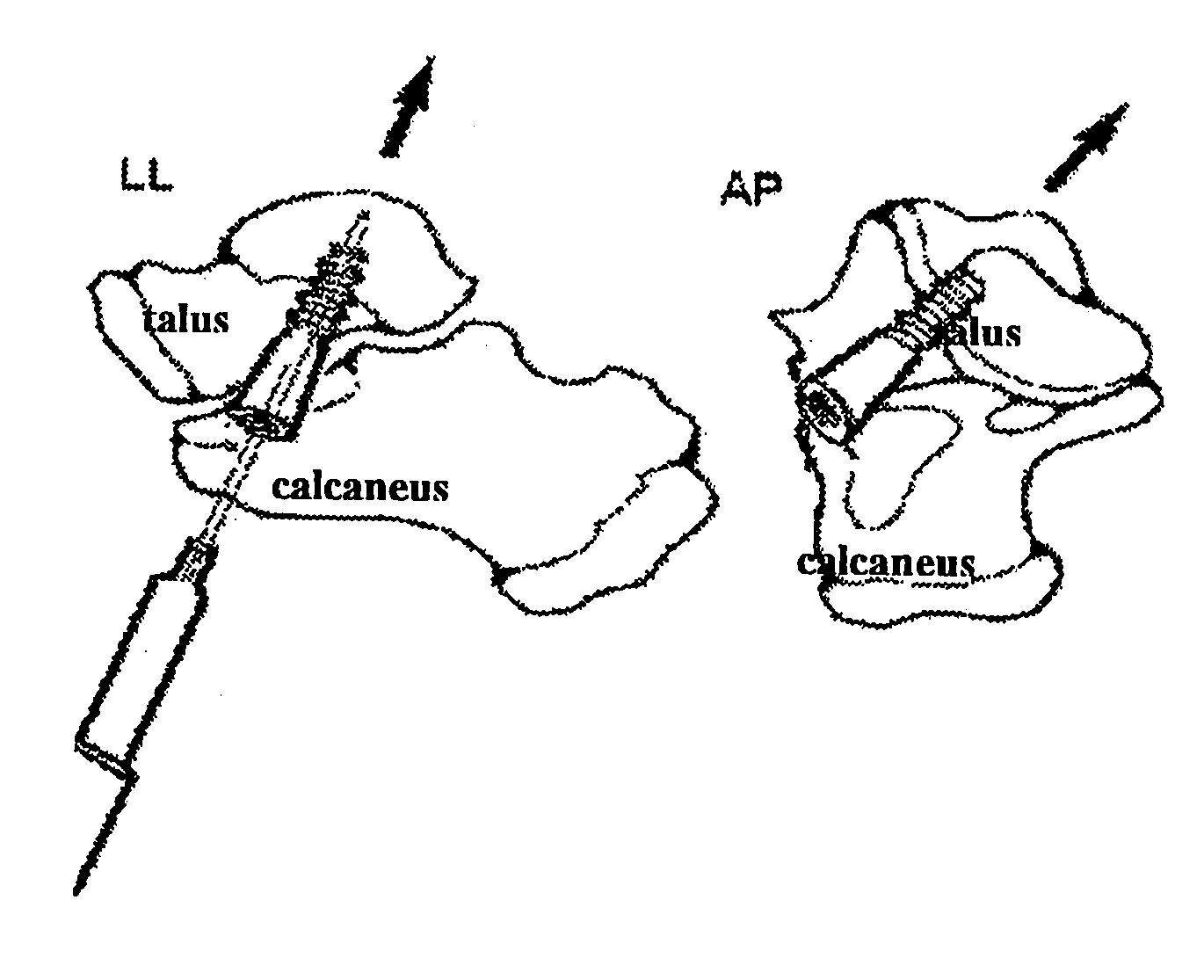

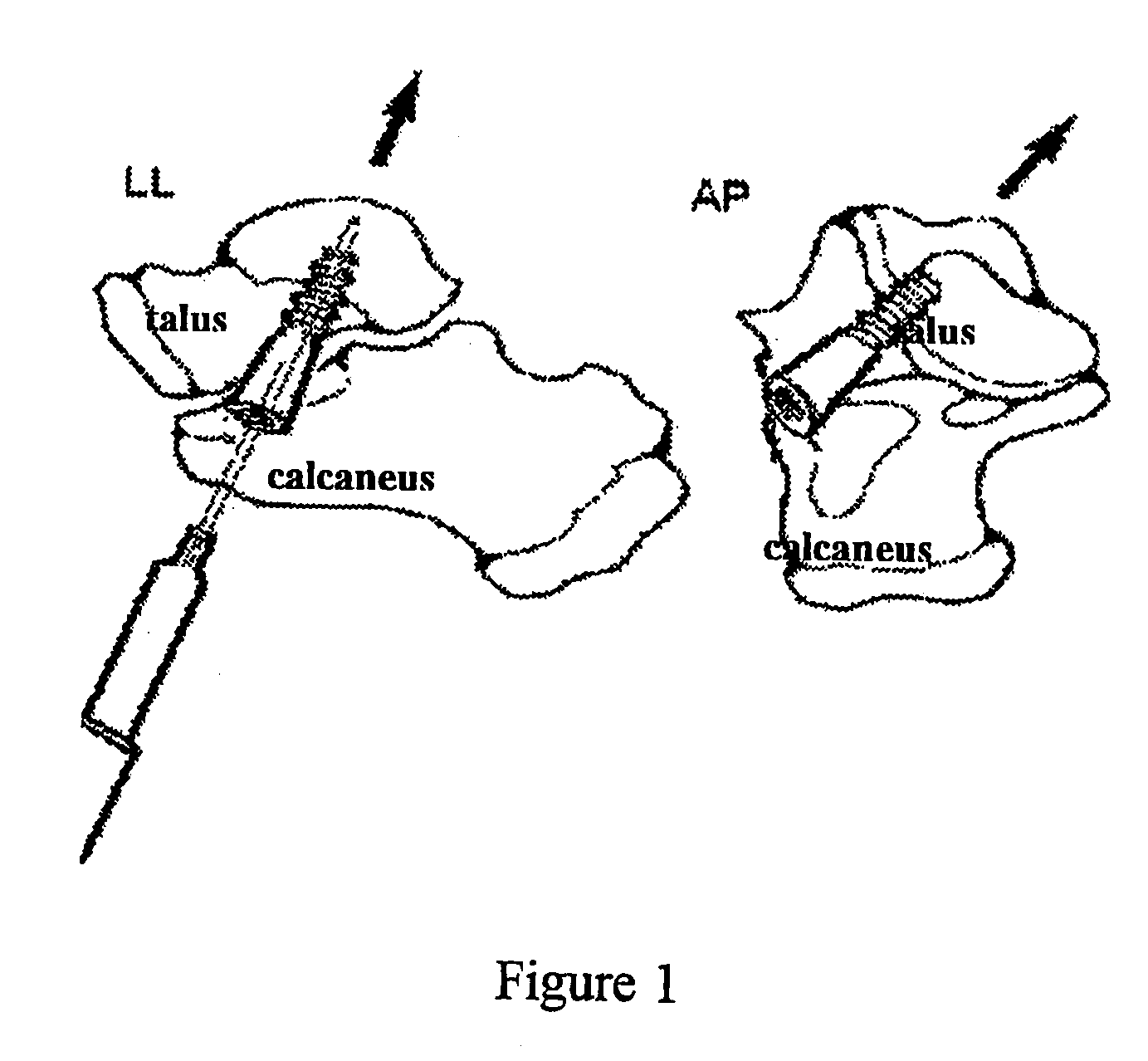

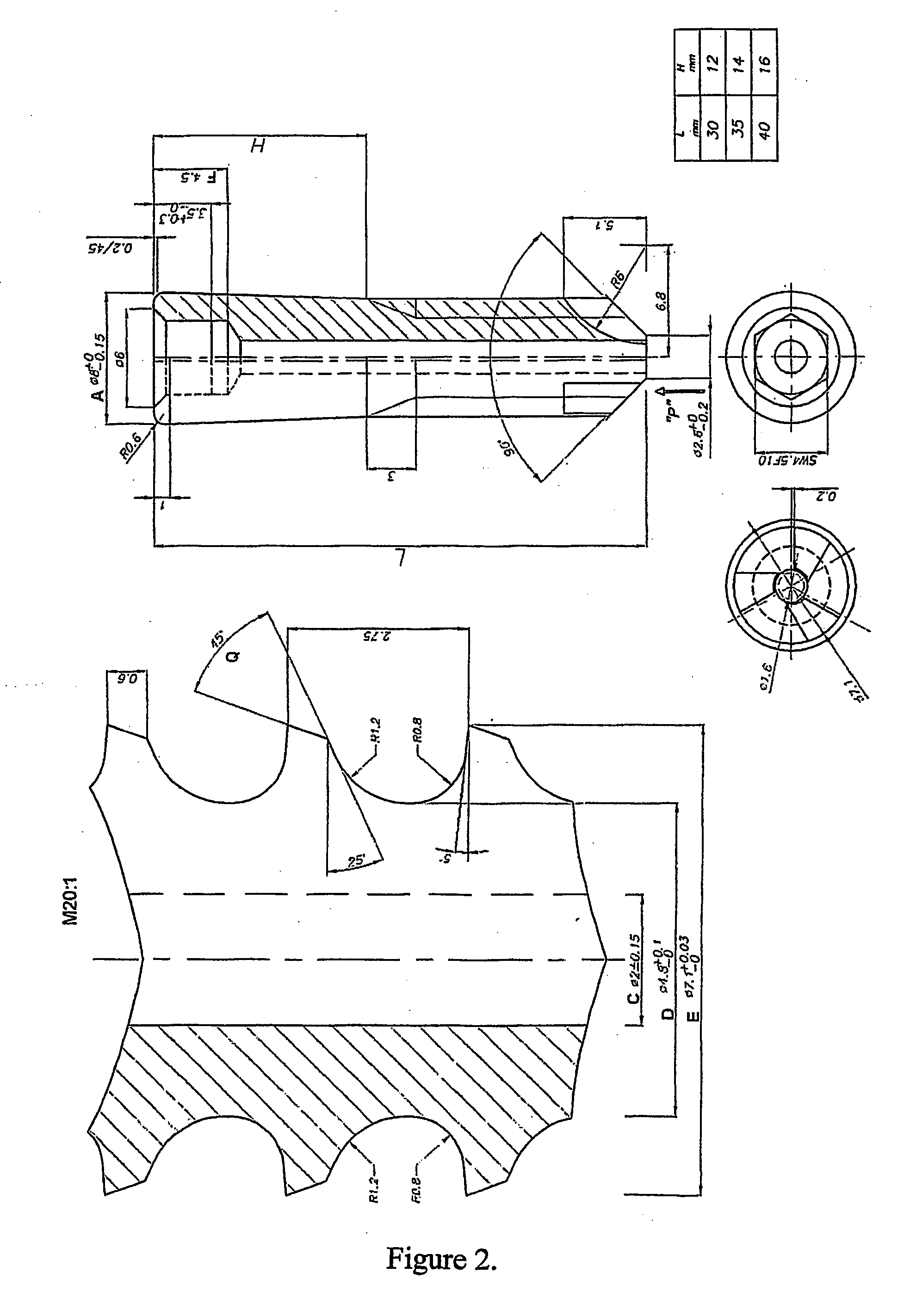

Canulated titanium implant for correcting flat feet in children

InactiveUS20090082818A1Easier correctly placedReduce harmSuture equipmentsAnkle jointsCalcaneusEngineering

It is possible to satisfy all the requirements of minimal invasiveness with maximal permanent result by placing the invented implants (screw). The shape of the screw solves all mentioned technical problems that occurred thus far, i.e. it can be directed through a small gap in the skin by Kirschner's guide-wire (because the screw is hollow-canulated). The screw is larger in body, so a much greater force is needed for it to break. If it does break, it can be removed easier with less lesions to the surrounding bone tissue. At the point of the screw are trisect cuts (on the apex thread) which also make the lesion of the bone lesser as is as it is inserted in its position. Since the head of the screw is bigger and conical, without a narrow part leading to the screw-thread, the screw self-tightens into the bone, which makes the loosening rarer. The loosening is also rarer because of the shape of the screw-thread. The screw has the equal effect throughout the whole time it is implanted in the body. The osteolysis of the heel bone in which the screw stems against is also reduced. The conical shape of the head of the screw, without a narrow part (neck) between the head and the screw-thread, it does not allow ingrowing of the bone tissue, so it can be easily removed when the necessary time of correction is finished. The time necessary for the surgical procedure is significantly shorter, taking up 15 minutes, thus reducing the possibility of a infection, which is also helped by a small operative area. After the placement of the screw, the patient can walk two days after the surgery and he / she does not need any plaster immobilization or physical therapy. The screw is made out of titanium alloy, which gives it a certain toughness; the patient can undergo magnetic examinations, if there is need for such, while the screw is implanted.

Owner:ROTH SANDOR UMLAUT OVER

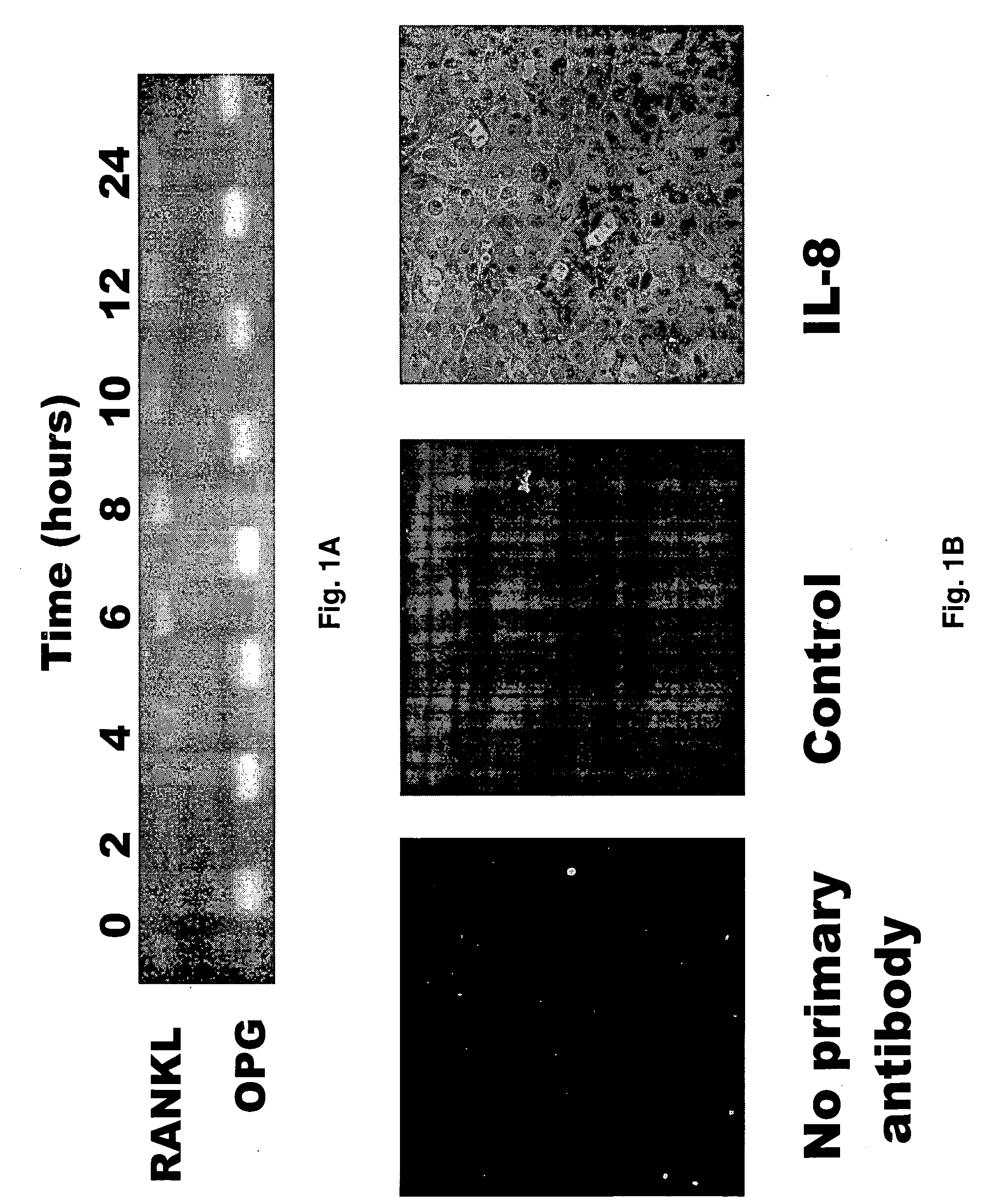

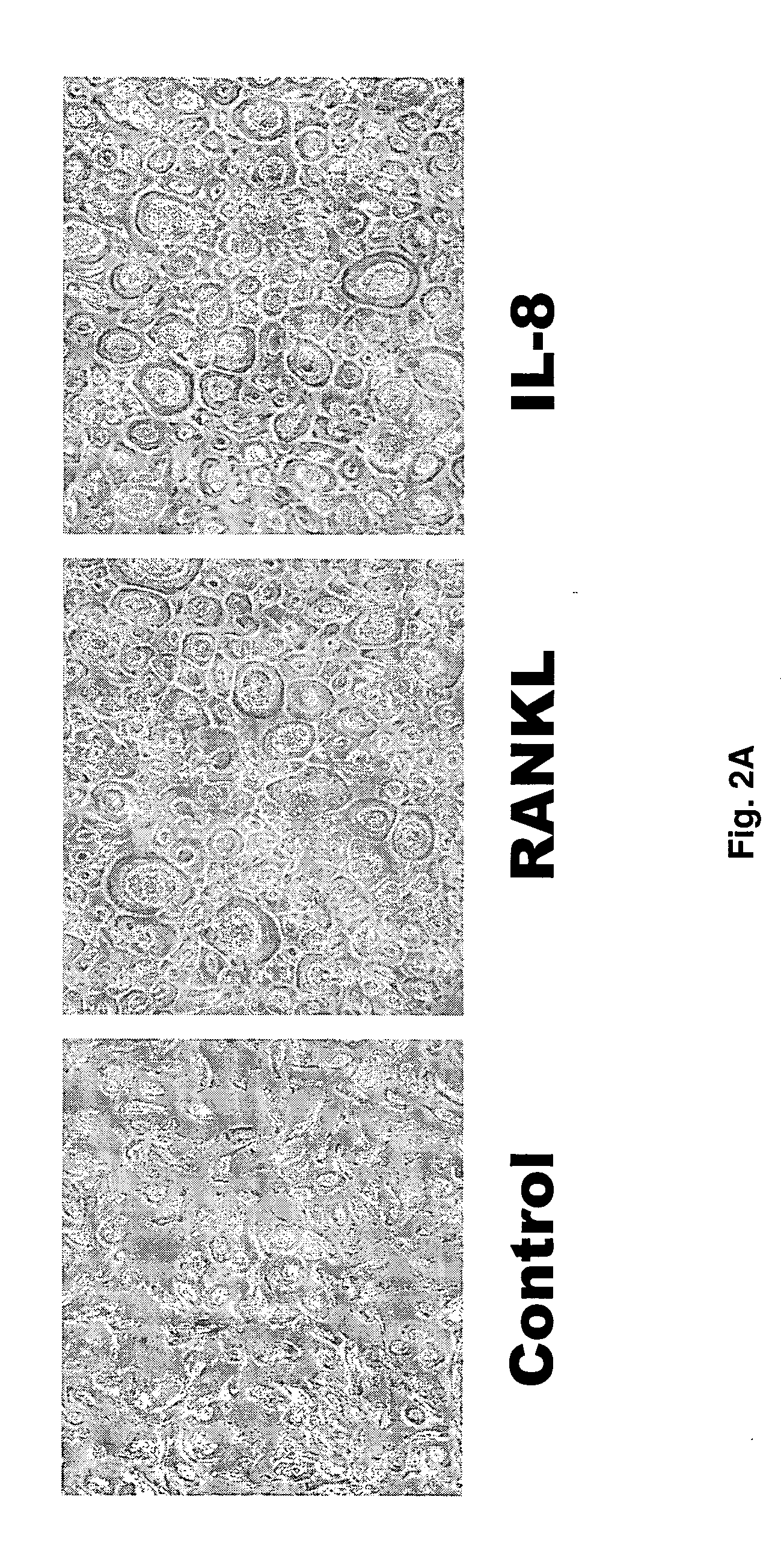

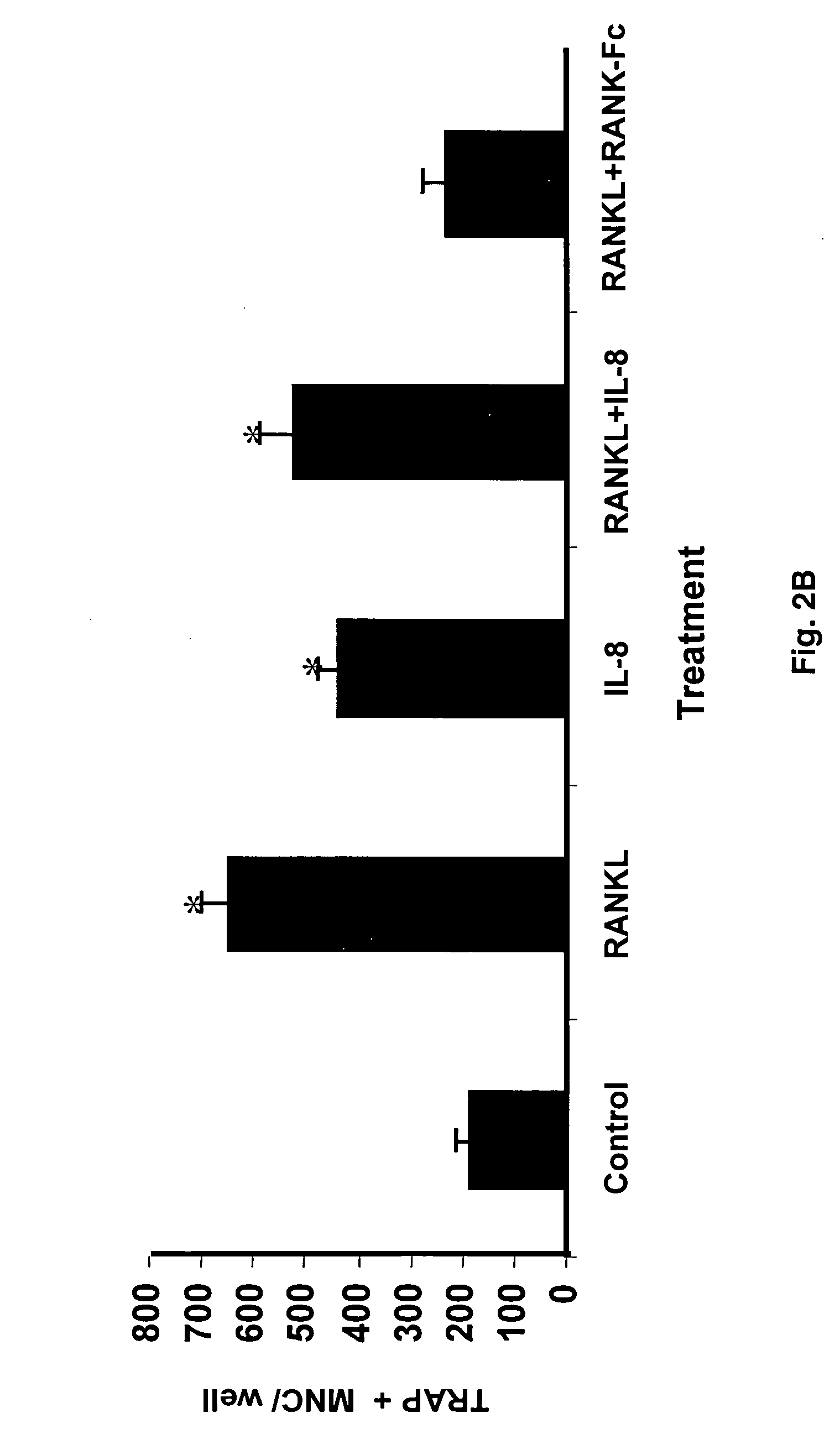

Anti-interleukin 8 therapy for tumor osteolysis

InactiveUS20050142136A1Stimulate osteoclastic bone resorptionRegulate expressionPeptide/protein ingredientsImmunoglobulins against cytokines/lymphokines/interferonsAbnormal tissue growthCancer cell

The present invention reports stimulatory effects of interleukin 8 (IL-8) on human osteoclast formation and bone resorption, indicating IL-8 as a potent activator of bone destruction common in metastatic bone diseases. Tumor growth and osteolysis were inhibited by anti-IL-8 antibody or antisense IL-8. Additionally, IL-8 was able to confer an osteolytic phenotype on non-osteolytic cancer cells. These results identify tumor-induced osteolysis and bone resorption as potential targets of anti-IL-8 therapy.

Owner:ARKANSAS FOR MEDICAL SCI UNIV OF THE

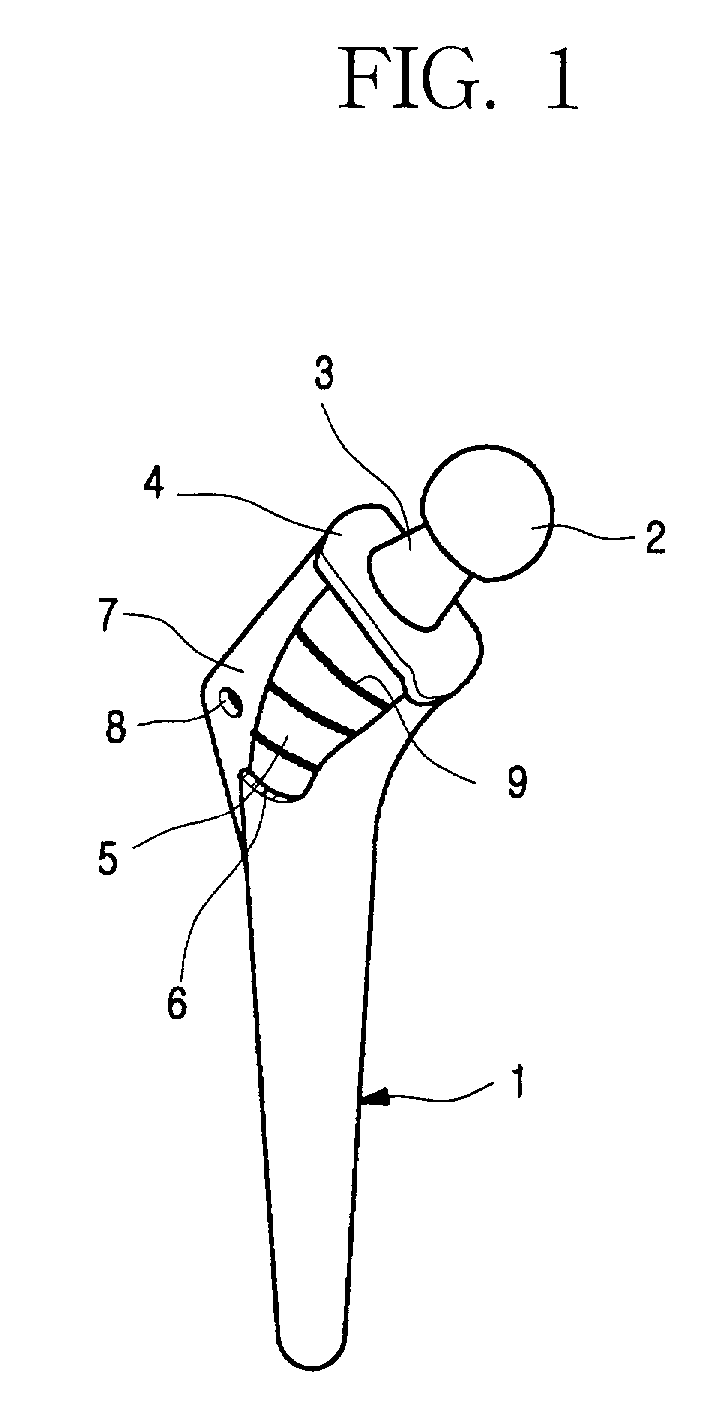

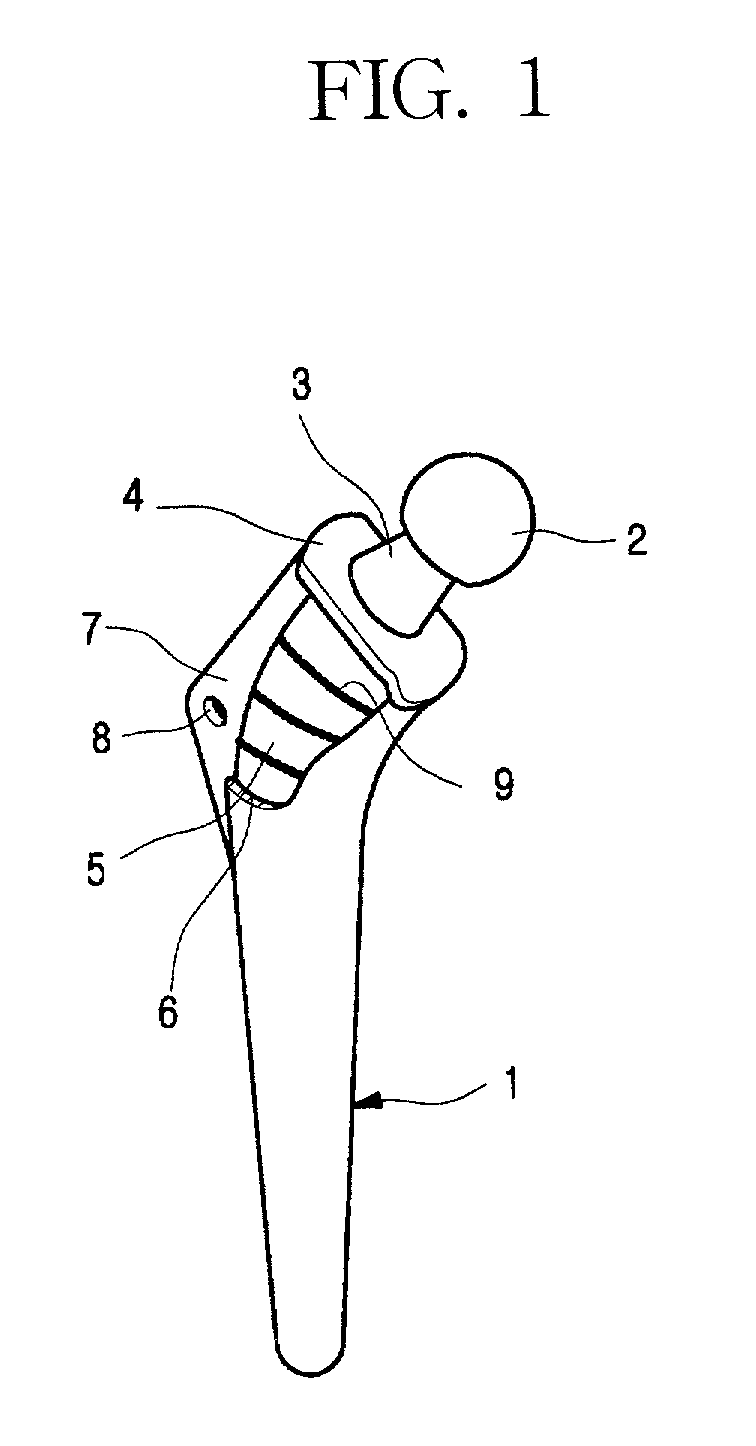

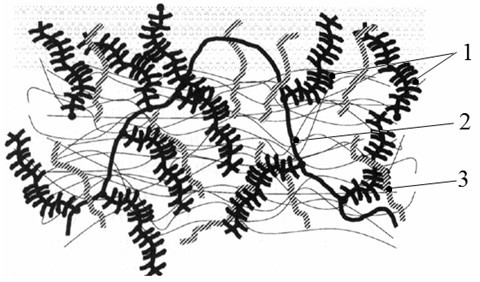

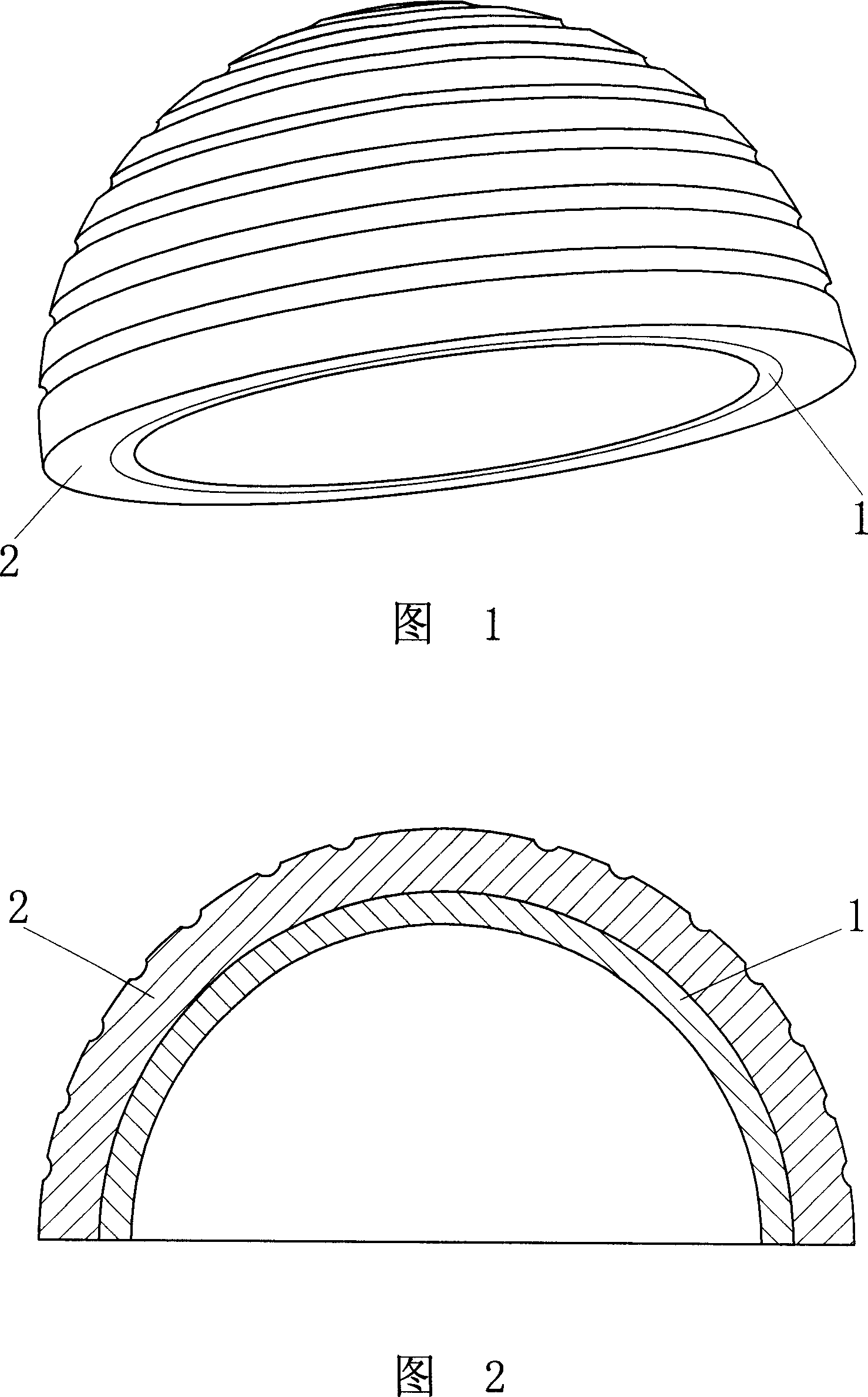

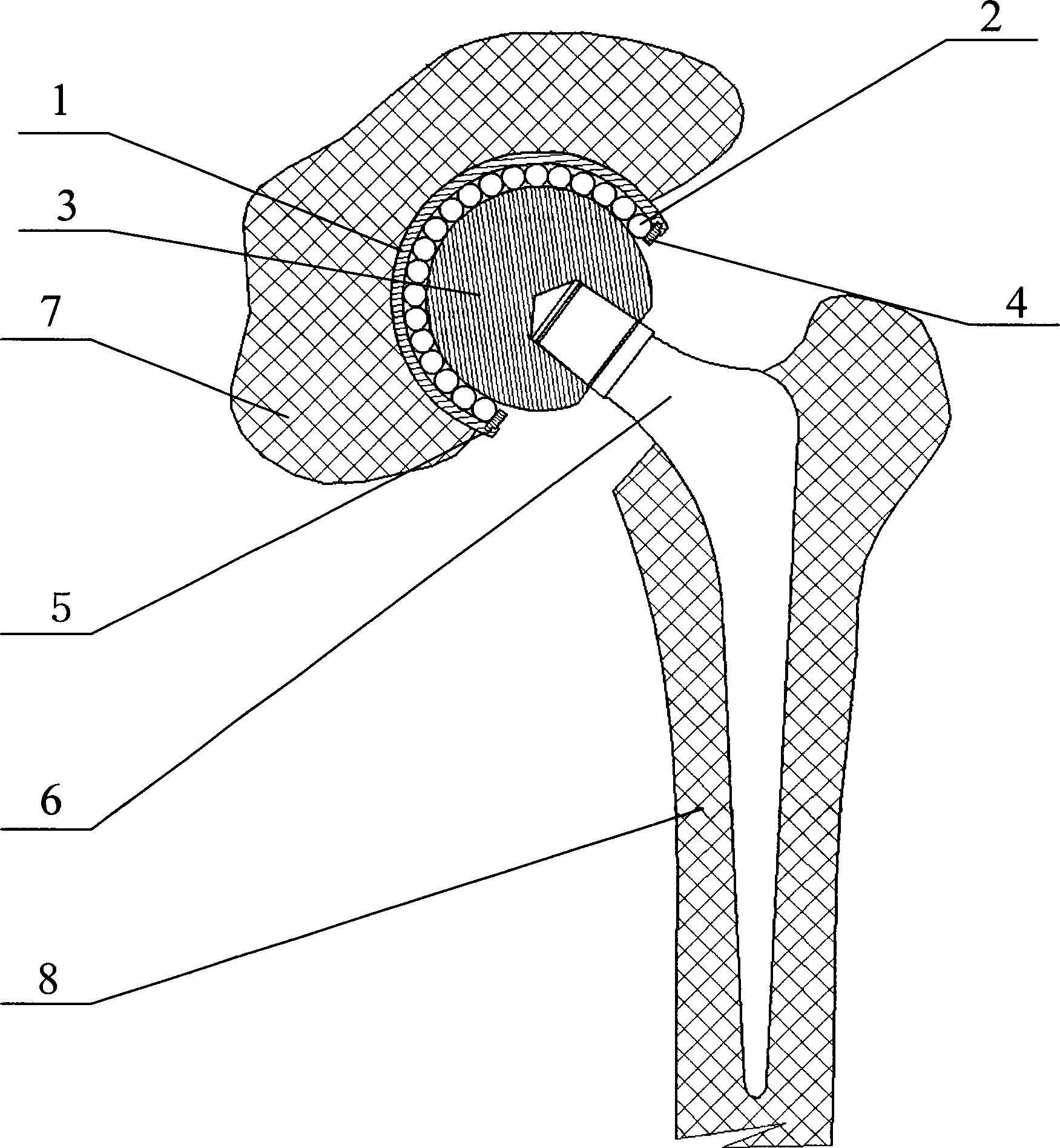

Novel artificial hip joint and manufacturing method thereof

ActiveCN102973335AReduce loosenessStress reliefJoint implantsHip jointsRight femoral headFemoral stem

The invention discloses a novel artificial hip joint and a manufacturing method thereof. The novel artificial hip joint comprises an advanced porous layer PCA (porous coated anatomic) spherical crown (1), an alloy acetabular cup (2), a metal ceramic acetabular lining (3), a metal ceramic femoral head (4), a metal handle (5), a collar (6), an advanced porous layer PCA plane ring (7), a metal handle guide pipe (8) and an advanced porous layer PCA net ring (9). According to the invention, the stress shielding of the artificial hip joint is removed and the proximal femoral osteopenia is prevented through femoral stem separation; the stress shielding on acetabular fossae is removed by increasing the pressure intensity; the osteolysis, the stem looseness and the femoral brittleness caused by wear debris are greatly reduced by using the metal ceramic acetabular lining and the femoral head with flexibility enhancement; and by improving the raw material selection and diffusion welding processes of the PCA structure part, the binding force of the PCA structure part and the bone tissues of a human body is increased, the postoperative problems of a patient are reduced, the comprehensive quality of the artificial hip joint is essentially improved, and the service life of the artificial hip joint is essentially prolonged to be longer than thirty or forty years at least.

Owner:刘昌星 +1

Ultra-high-molecular-weight-polyethylene and drug complexes artificial joint material and its preparation method, and artificial joint prepared therefrom

InactiveCN101007184AInhibition of differentiationInhibitory activityJoint implantsAcetabular cupsHuman bodyArtificial hip joints

Owner:SOUTHWEST JIAOTONG UNIV

Rolling type bipolar head

InactiveCN103892941ASimple structureEasy to manufactureJoint implantsHip jointsHuman bodyArtificial hip joints

The invention discloses a rolling type bipolar head. The rolling type bipolar head comprises a metal acetabulum cup, balls, a bulb and a cup edge clamping ring, wherein the outer spherical surface of the bulb is matched with the inner spherical surface of the metal acetabulum cup through the balls, the cup edge clamping ring is installed at the edge of the metal acetabulum cup to prevent the balls from falling out, and the bulb is connected with the thighbone stem awl in a matched mode. The components can be applied to an artificial hip joint prosthesis replacement operation after being combined into a whole. Compared with a common artificial hip joint prosthesis, the rolling type bipolar head is most characterized by adopting a rolling type artificial hip joint spherical surface to replace a common sliding friction type artificial hip joint spherical surface. After the rolling type bipolar head is implanted into the human body, little abrasion is generated, friction chips generated by the common sliding friction type artificial hip joint spherical surface are avoided, and osteolysis caused by the friction chips is also avoided. The rolling type bipolar head guarantees that the joint spherical surface moves flexibly and is longer in service life to the maximum extent, and a patient can better recover the normal hip joint motion function of the human body by means of the rolling type bipolar head.

Owner:BEIJING AKEC MEDICAL

Methods for detecting osteolytic conditions in the body

Methods and systems for detecting a biological response indicative of osteolysis or osteolytic pre-conditions in bone.

Owner:WARSAW ORTHOPEDIC INC

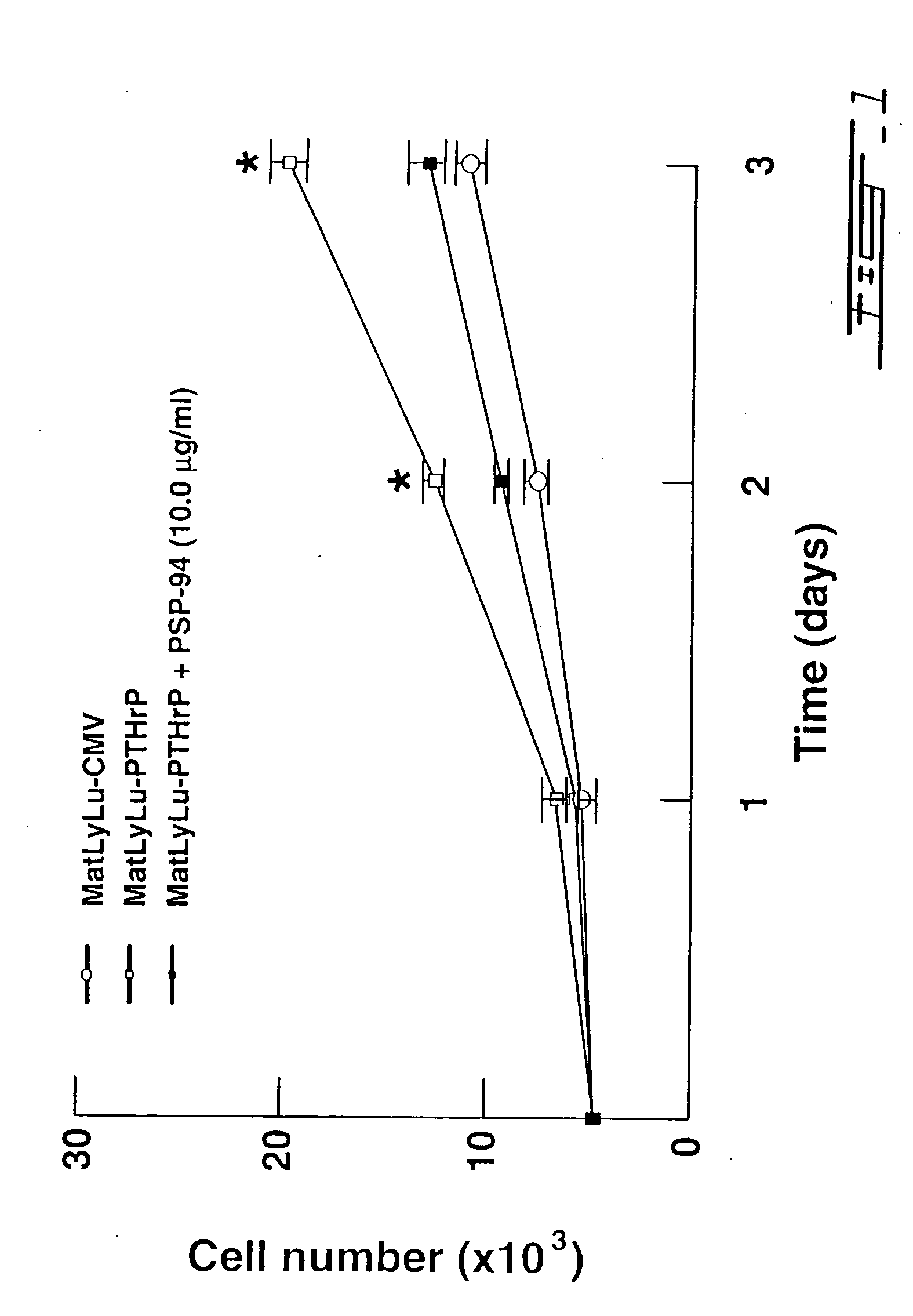

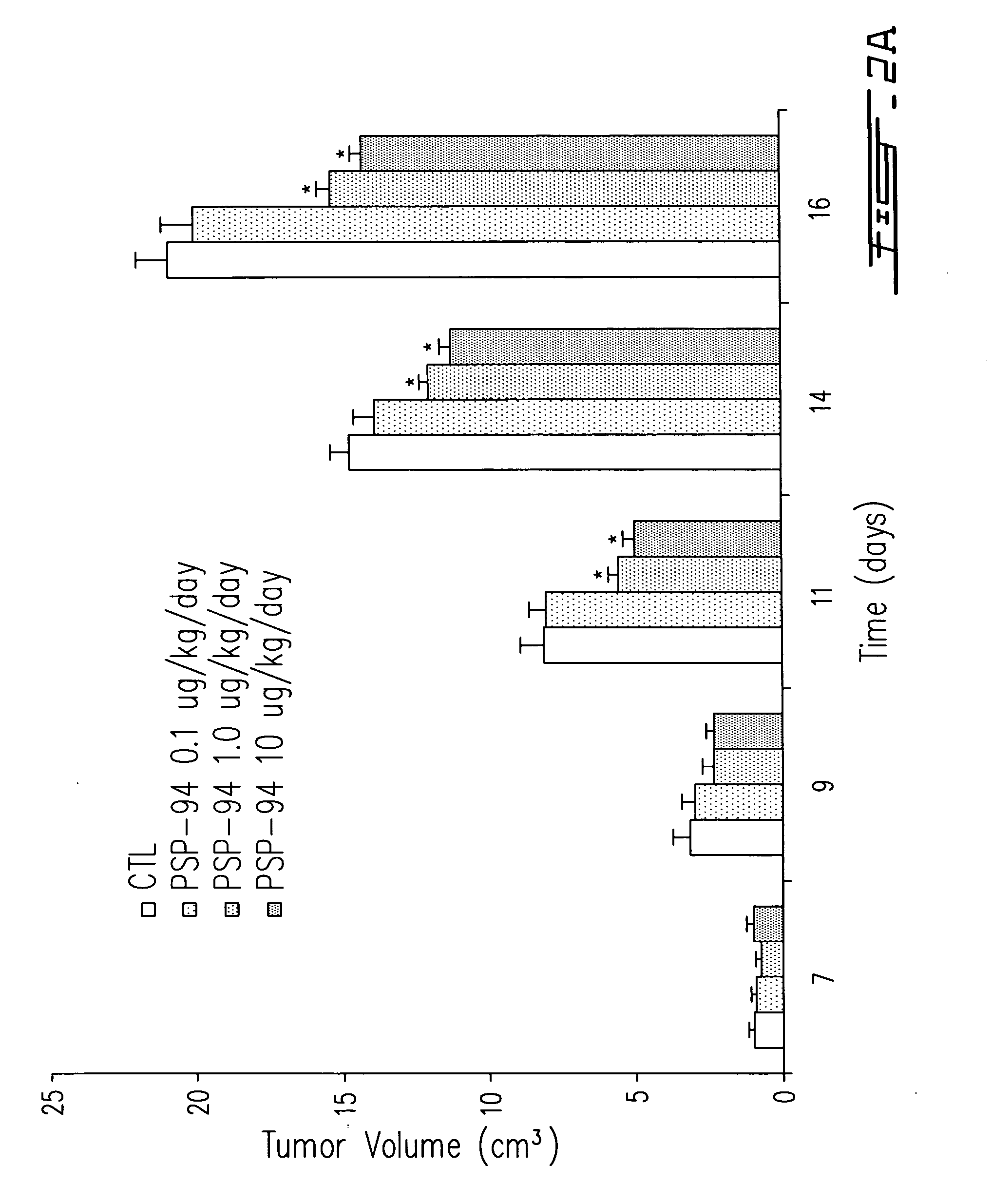

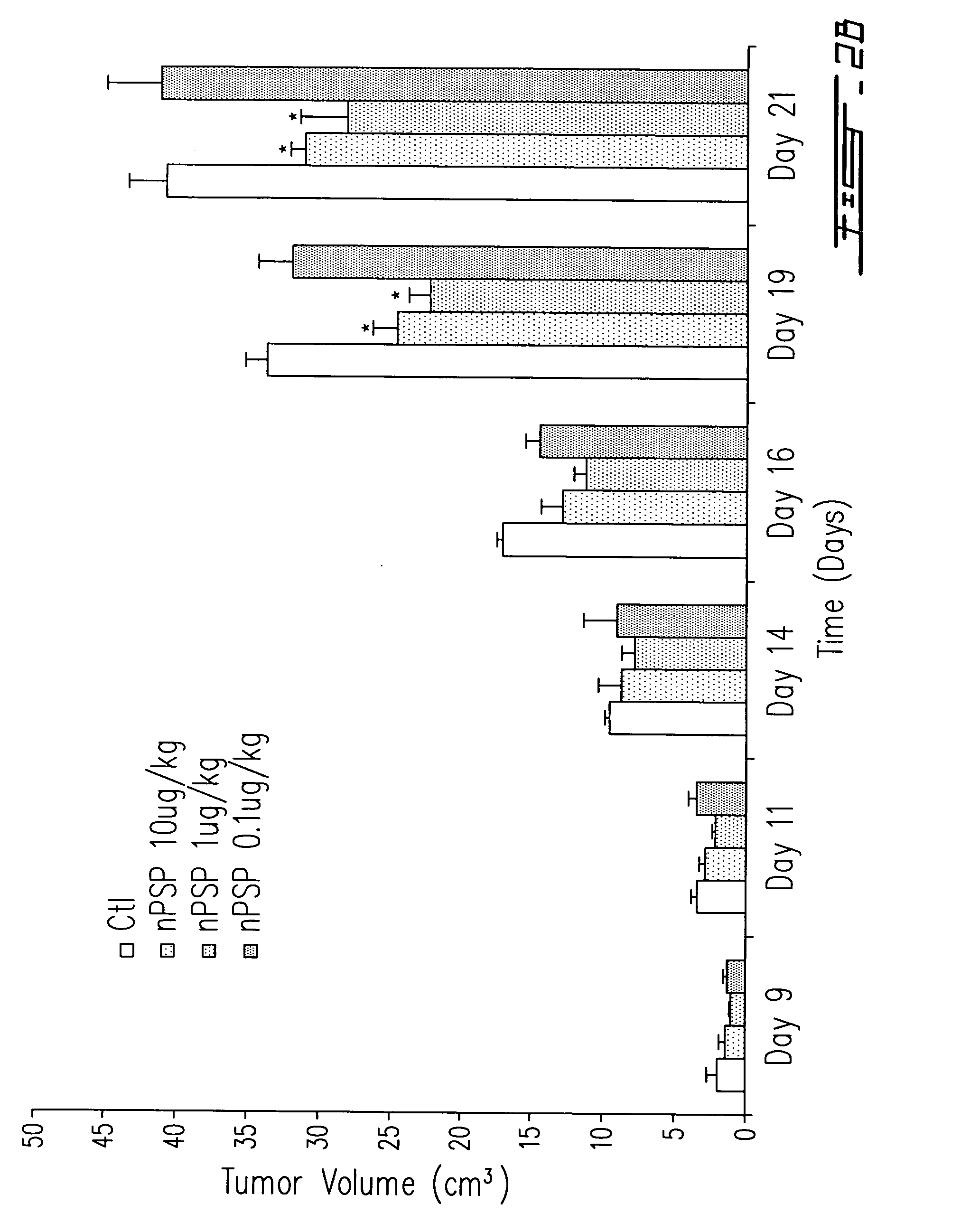

PSP-94: use for treatment of hypercalcemia and bone metastasis

InactiveUS20050026833A1Reduce capacityDecreased cell growthCompound screeningApoptosis detectionLymphatic SpreadBiochemical markers

The present invention discloses the use of PSP-94, PCK3145 and other derivatives and biologically active analogues for treating a patient having a condition such as metastasis, metastatic cancer, a condition associated with elevated levels of parathyroid hormone-related protein (PTHrP), PTHrP-induced osteolysis and / or hypercalcemia of malignancy. These compounds were found to be effective treatment modalities for bone metastasis caused by prostate cancer. Furthermore, decrease in cellular and plasma PTHrP levels as well as plasma calcium levels observed by treatment with such compound can serve as useful biochemical markers for monitoring the efficacy of these anti-metastatic compounds.

Owner:AMBRILIA BIOPHARMA INC

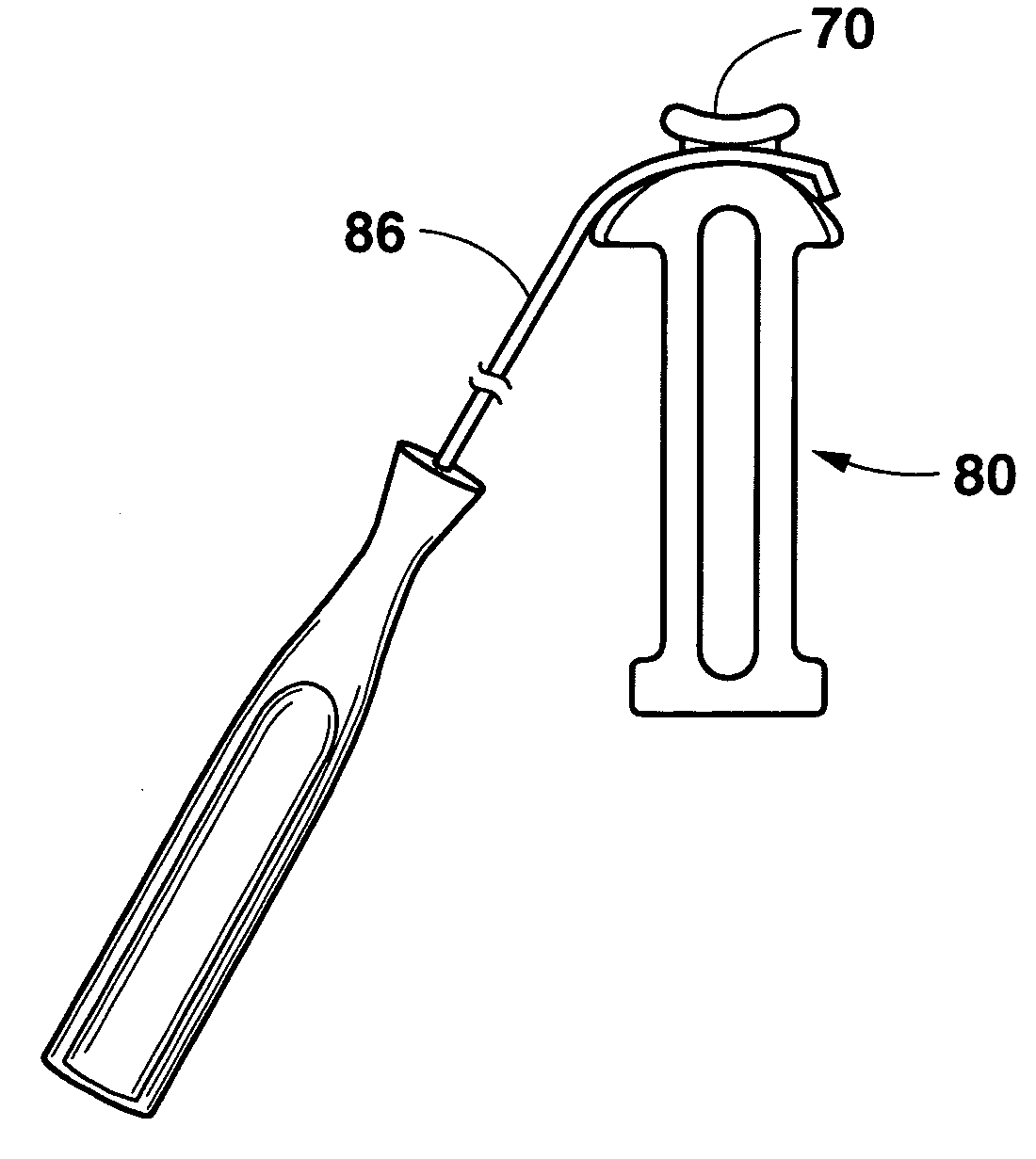

Instruments for osteolysis repair

ActiveUS20060190000A1Prevent materialImproved debridementBone implantJoint implantsEngineeringBiomedical engineering

A plug for plugging a hole of a bone or implant body during injection of an osteoregenerative material comprising, generally, a plug body, the plug body configured to plug a hole of the body to prevent osteoregenerative material from leaking through the hole, and a tail, the tail attached to the plug body for use in removing the plug body from the hole. In one embodiment, the plug body has an insertion cavity on a trailing end thereof for use in inserting the plug into a hole of the body. The plug body preferably has a frustoconical configuration. The plug body is preferably made of a resilient material, such as silicon.

Owner:WRIGHT MEDICAL TECH

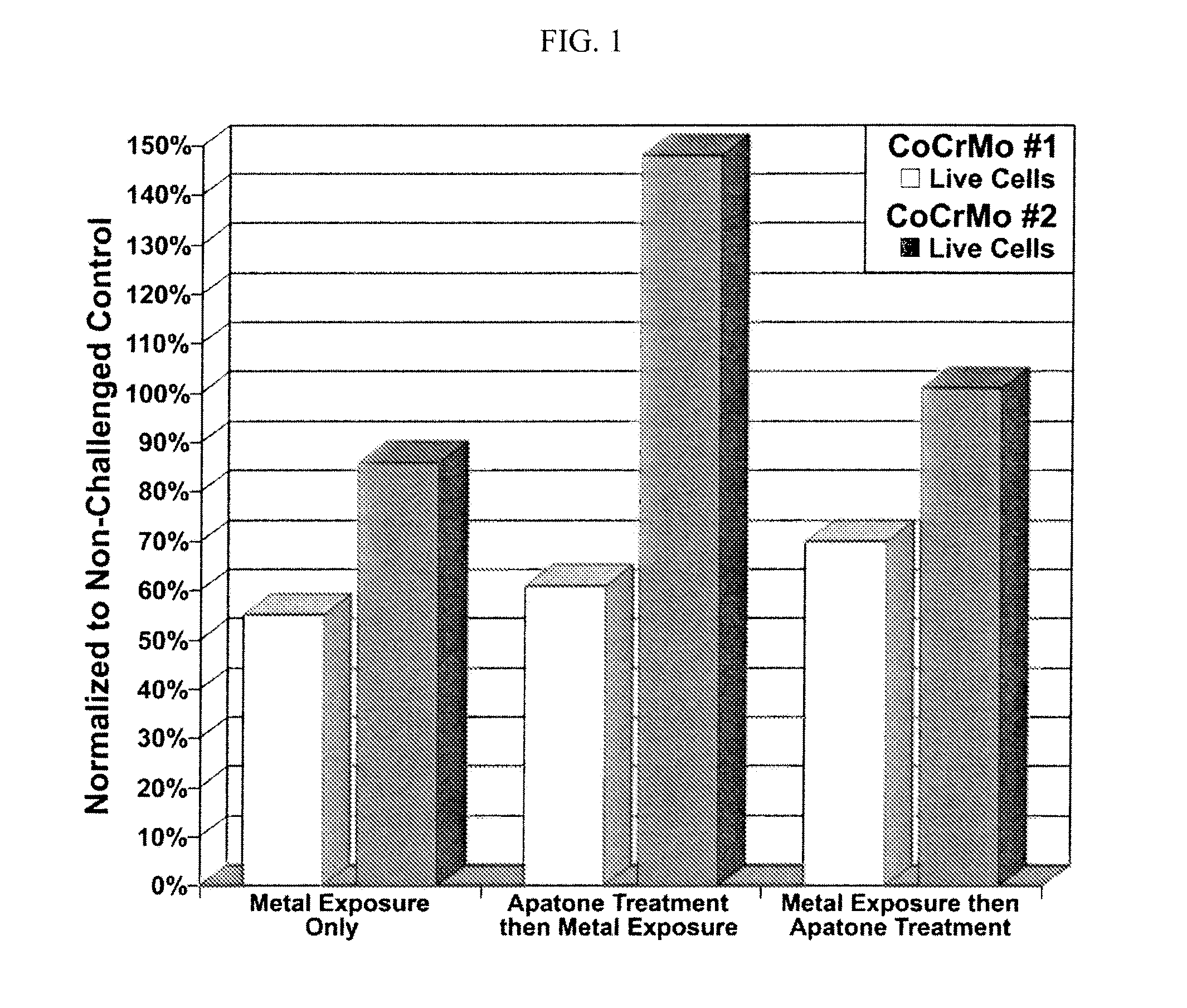

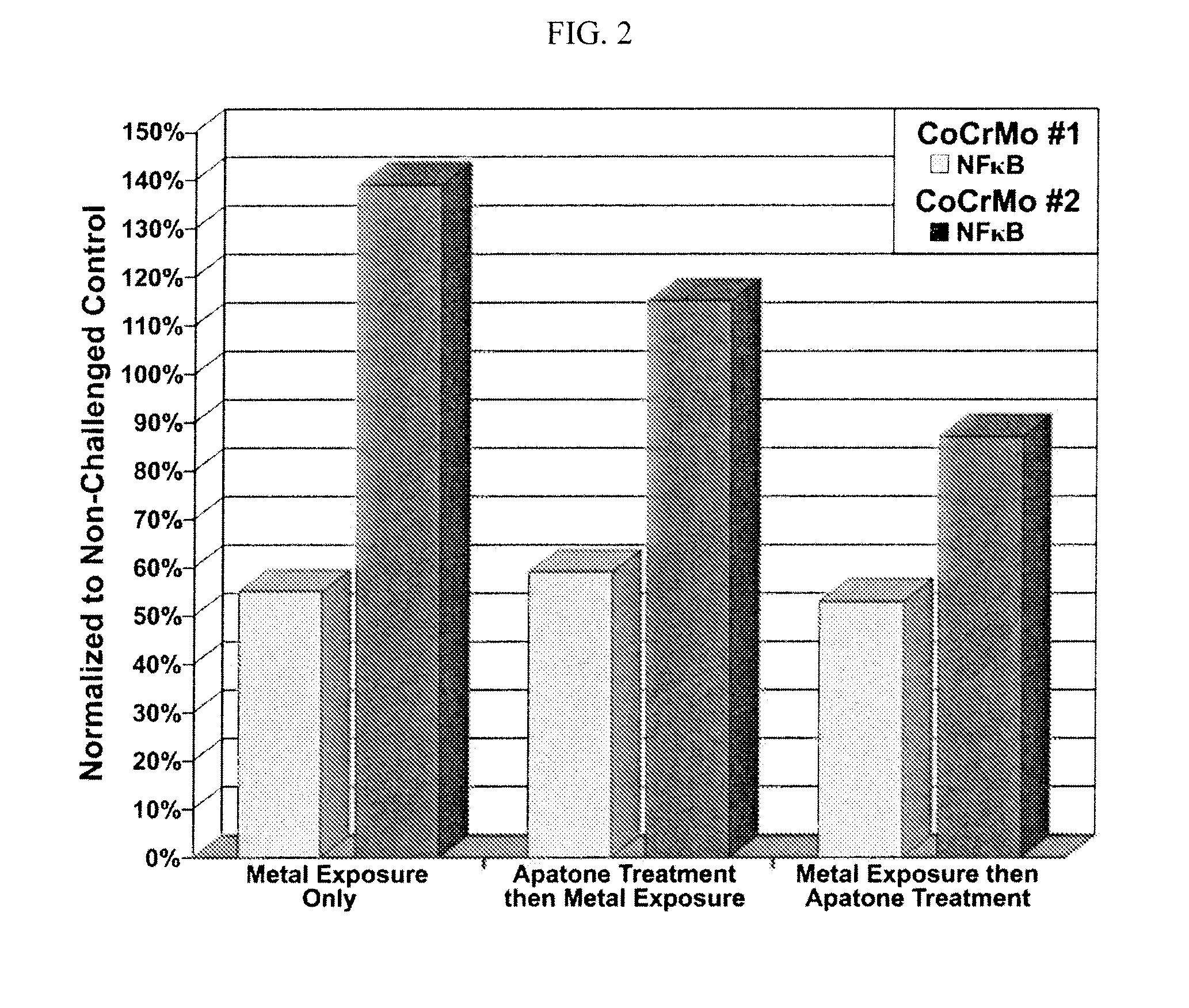

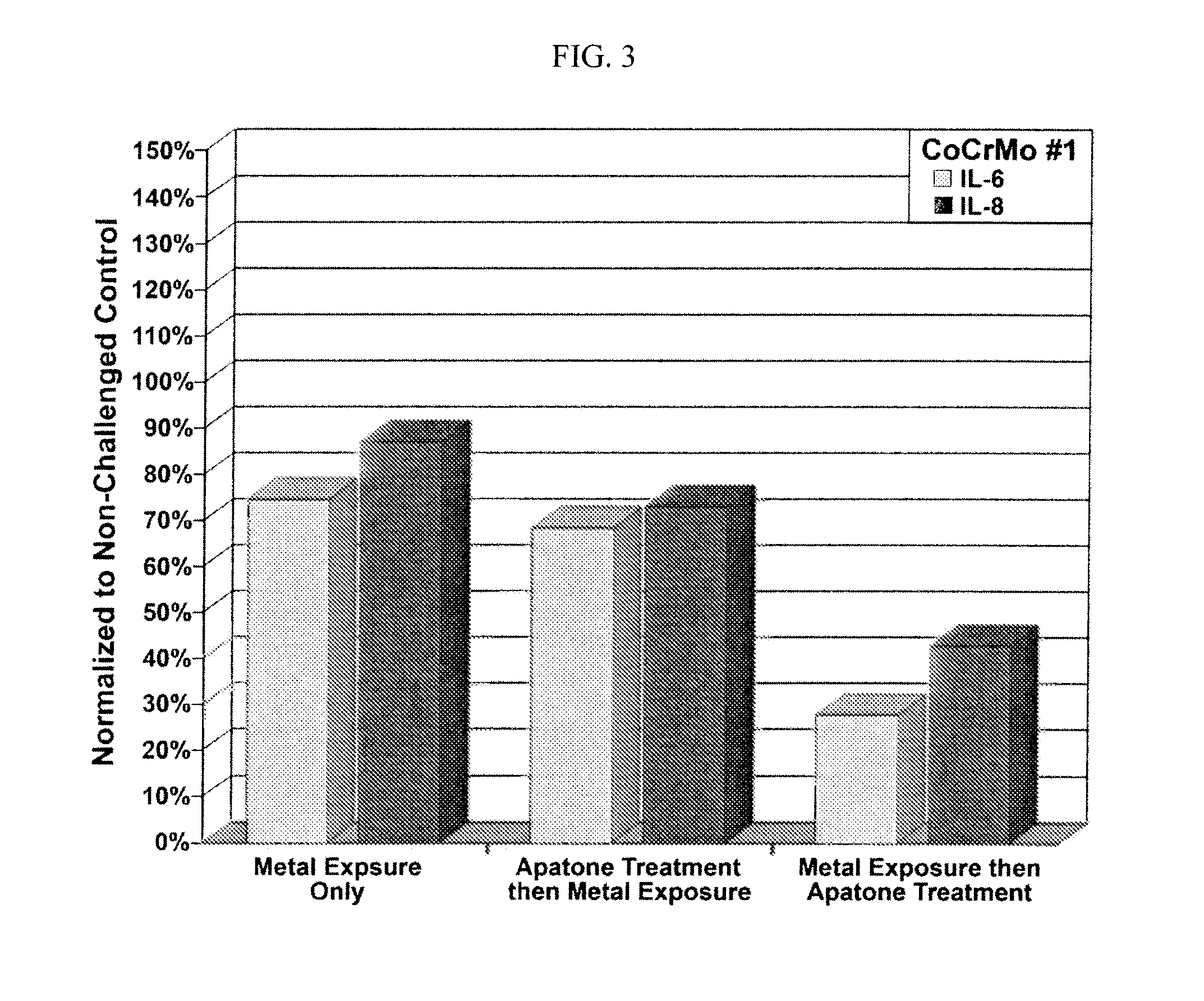

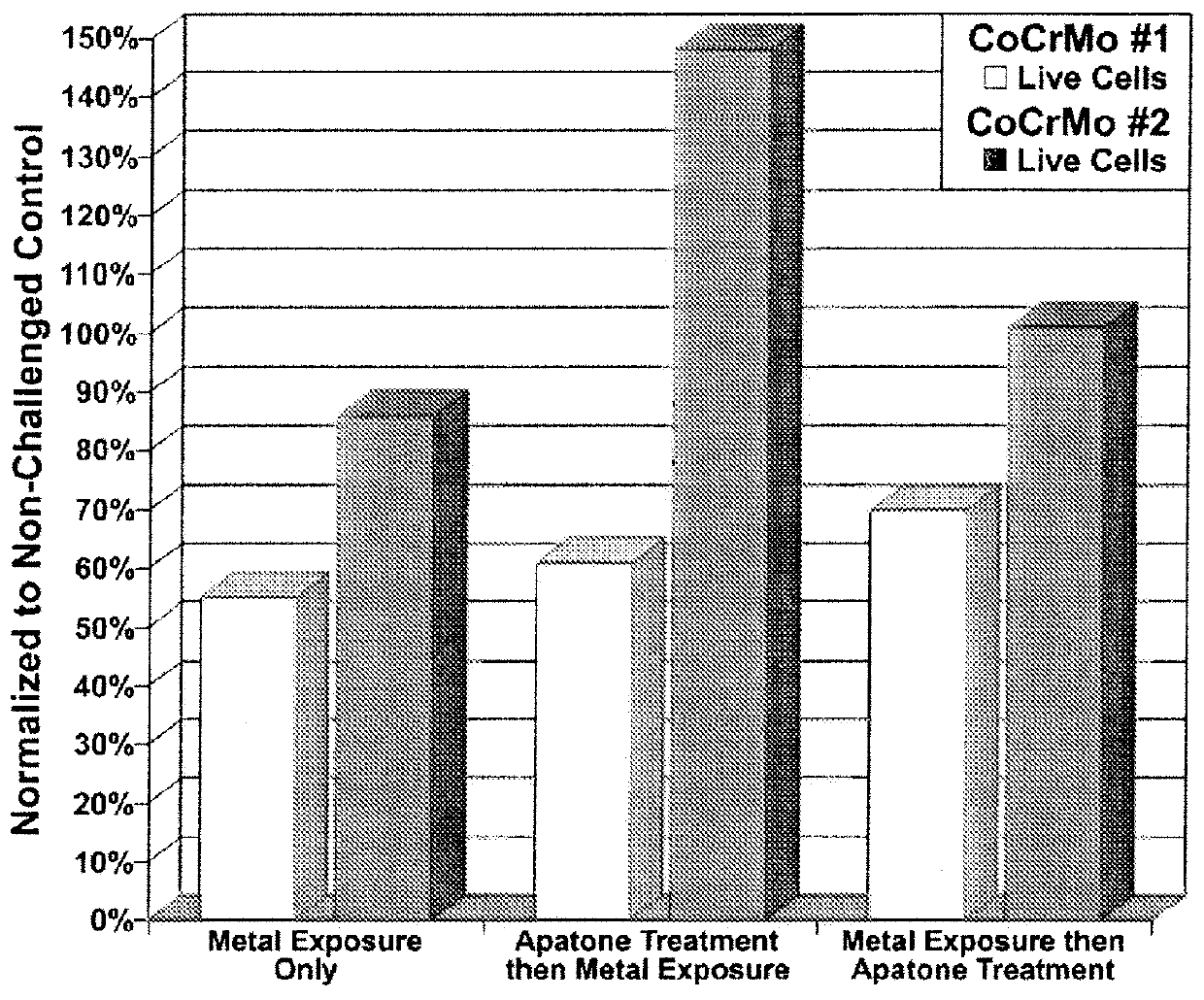

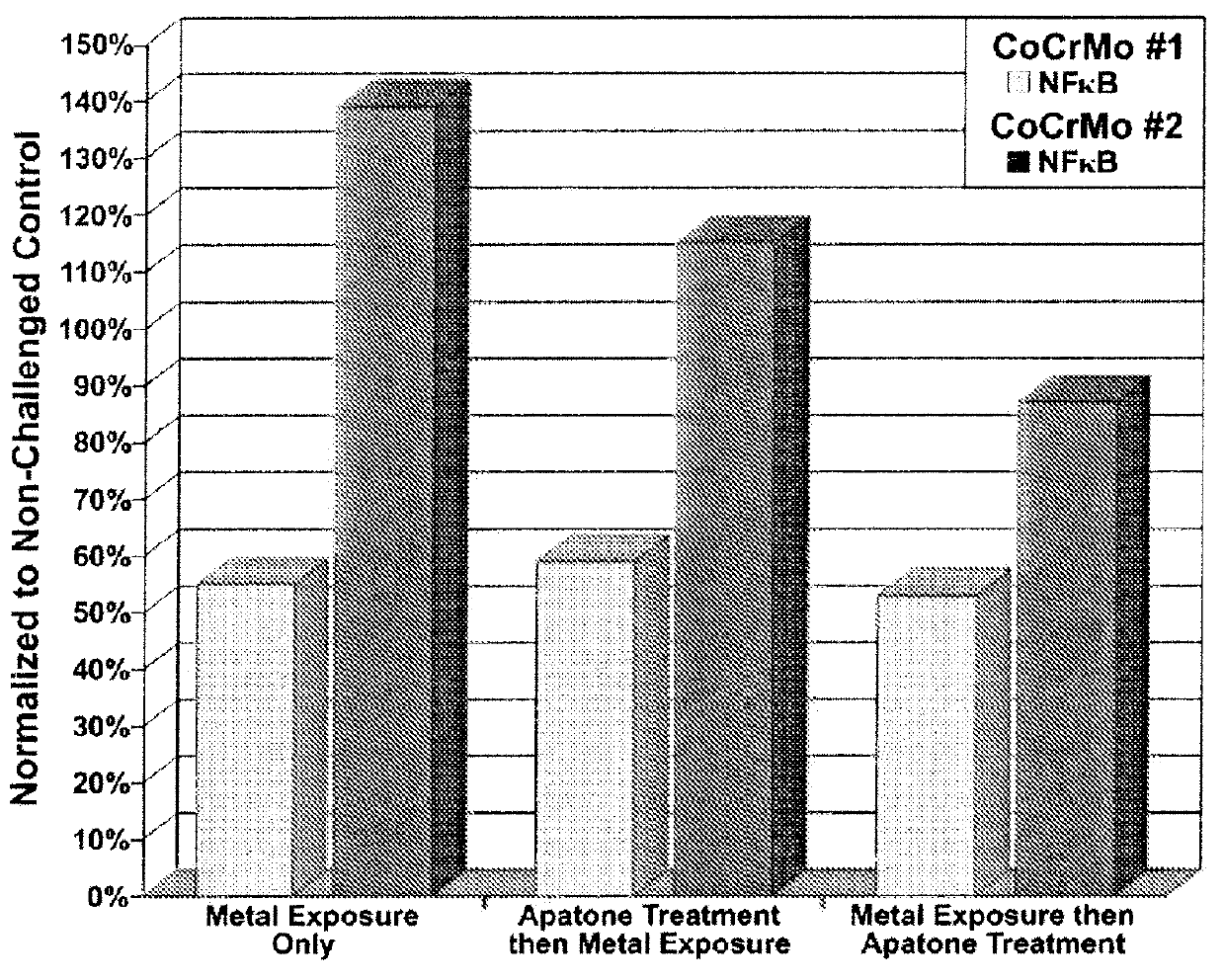

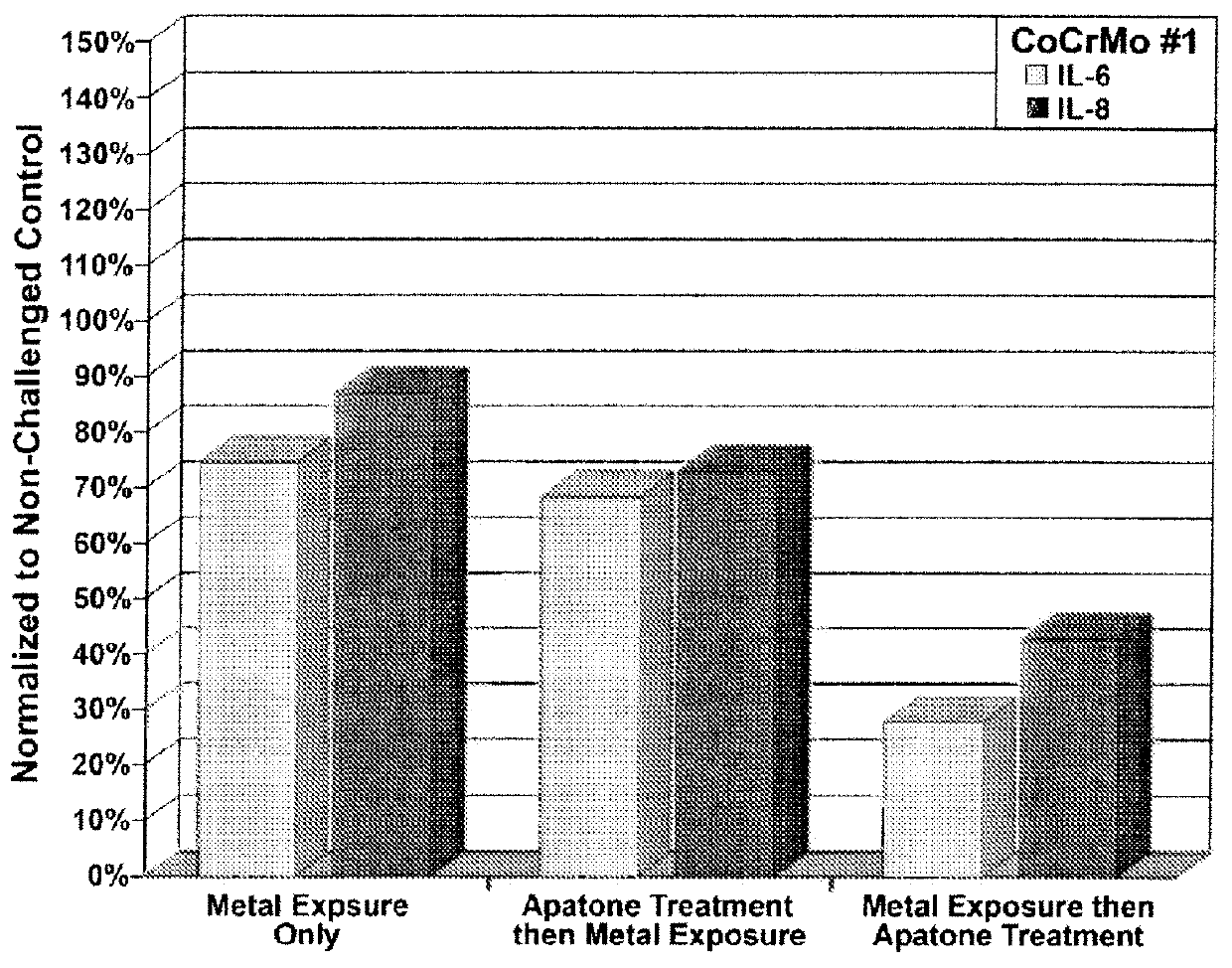

Vitamin C and vitamin K, and compositions thereof for treatment of osteolysis or prolongation of prosthetic implant

ActiveUS9050265B2Extended functional lifeReduce productionBiocideDigestive systemVitamin CEnantiomer

Provided herein is a method of treating, preventing, or managing osteolysis in a subject, comprising administering to the subject a therapeutically effective amount of vitamin C, or a pharmaceutically acceptable salt, solvate, or hydrate thereof, in combination with vitamin K, or a single enantiomer, a mixture of enantiomers, or a mixture of diastereomers thereof, or a pharmaceutically acceptable salt, solvate, or hydrate thereof.

Owner:IC MEDTECH CORP

Treatment of bone disorders

InactiveCN101166764APromote formationPeptide/protein ingredientsDigestive systemCD20Antiendomysial antibodies

Methods of treatment of various bone indications, such as osteoporosis, in a mammal are provided wherein an effective amount of an antagonist that binds to a B-cell surface marker, such as a CD20 antibody, is administered, optionally also with another medicament such as an agent that treats such disorders in an effective amount. Articles of manufacture are also provided. Further, a method of inhibiting osteolysis in a mammal is provided comprising introducing into said mammal an isolated odontoprogenitor or osteoprogenitor cell comprising a nucleic acid encoding an antibody that binds to a B-cell surface marker.

Owner:GENENTECH INC

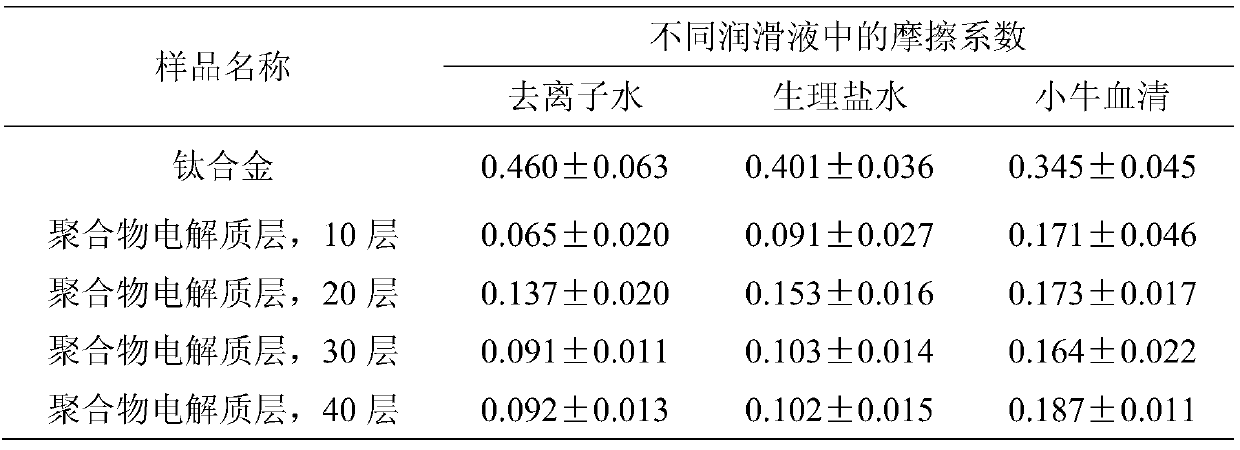

Titanium alloy artificial joint with bio-lubrication surface layer and preparation method thereof

ActiveCN109529108AEasy to operateShort preparation cycleTissue regenerationCoatingsAlloy substrateLayer by layer self assembly

The invention discloses a titanium alloy artificial joint with a bio-lubrication surface layer, wherein the titanium alloy artificial joint is composed of a titanium alloy substrate and the bio-lubrication surface layer, and the bio-lubrication surface layer is a polymer electrolyte layer prepared by a layer-by-layer self-assembly technology. A preparation method of the joint comprises the following steps: (1) preparing a polycationic electrolyte solution and a polyanionic electrolyte solution; (2) carrying out hydroxylation treatment of the titanium alloy substrate to form a hydroxylated substrate; and (3) carrying out layer-by-layer self-assembly of the polyelectrolyte layer to form the bio-lubrication surface layer; and completing preparation of the titanium alloy artificial joint. Theartificial joint has good lubrication effect, can effectively reduce abrasive debris, improve tribological properties, achieve the effects of osteolysis inhibition and aseptic loosening, and prolong the service life of the artificial joint.

Owner:NANJING FORESTRY UNIV

Compositions and Methods for Detecting and Treating Implant Loosening and Osteolysis

InactiveUS20120189543A1Increased riskPrevent looseningAntipyreticAnalgesicsTherapeutic implantBiomedical engineering

Methods and compositions for detecting, diagnosing, and treating osteolysis and implant loosening are disclosed.

Owner:HOSPITAL FOR SPECIAL SURGERY

Methods and Compositions for Improving the Incorporation of Orthopaedic and Orthodontic Implants

InactiveUS20090319044A1Increase incorporationReduce osteolysisBone implantSkeletal disorderDevice implantMetallic materials

The present invention provides methods of improving the incorporation of an implantable device into a bone of a host in need thereof. More particularly, the methods of the present invention include implanting the device into the bone of a host, wherein the device is at least partially made of a non-metallic material. Disposed on at least one surface of the device is an amount of hydroxyapatite and bisphosphonate, which in combination, are effective to reduce osteolysis and improve incorporation of the implant into the host bone compared to an implant without the hydroxyapatite and / or bisphosphonate. The present invention also provides methods for making such implants, as well as, the implants themselves.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

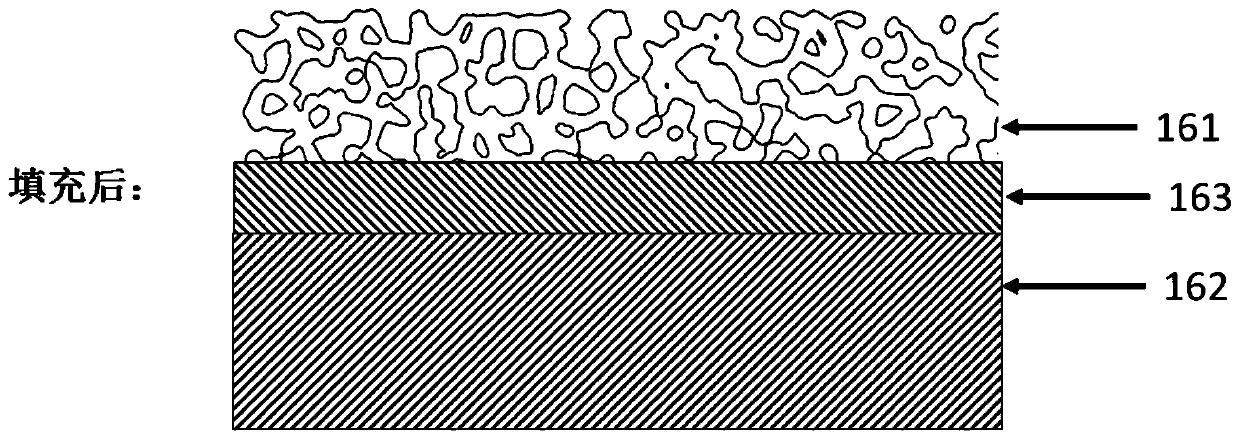

Connection structure of porous surface structure and substrate, preparation method and prosthesis

ActiveCN111449806AReduce thicknessGuaranteed basic strengthDental implantsAnkle jointsProsthesisRelative motion

The invention discloses a connection structure of a porous surface structure and a substrate, a preparation method and a prosthesis. A high polymer material layer is arranged in a gap between the porous surface structure and the substrate, so that the porous surface structure is tightly connected with the substrate, the basic strength of the connecting structure is ensured, the stress shielding phenomenon is improved, and the problem of postoperative osteolysis is solved; wherein a pre-connected complex is arranged on the substrate, the pre-connected complex comprises another porous structureand an intermediate which are connected in advance, the pre-connected complex and the substrate are combined in advance through various methods, and then the substrate with the pre-connected complex is tightly connected with the porous surface structure through a high polymer material layer. Relative movement and even falling between a structure body formed by the high polymer material layer and the porous structure on the surface of the high polymer material layer and the substrate with a smooth surface can be prevented; on the basis of the surface of the porous structure, it can be guaranteed that the surface of the artificial implant prosthesis has excellent bone ingrowth performance, the strength of the substrate is not substantially affected, and the rigidity of the overall compositestructure is optimized to reduce the stress shielding risk.

Owner:YBNX MEDICAL TECH SUZHOU CO LTD

Bioactive surface coating of biomedical degradable magnesium alloy and preparation method thereof

InactiveCN103120805AControl degradation rateGenerally low biological activityCoatingsMicro arc oxidationPlasma electrolytic oxidation

The invention provides a bioactive surface coating of a biomedical degradable magnesium alloy and a preparation method thereof. The bioactive surface coating is characterized in that strontium (Sr) is introduced as an active element of the coating. The preparation method of the coating containing strontium provided by the invention relates to the methods of chemical deposition, electrochemical deposition and micro-arc oxidation. The bioactive surface coating not only can control the degradation rate of magnesium alloy, but also can be used for improving the surface bioactivity of a magnesium alloy implantation device, by the release of strontium, the coating has a certain bone induction effect and inhibition on osteolysis, thus promoting the repair of bone tissues around the implantation device, and improving the implantation success rate of a magnesium alloy device. The bioactive surface coating provided by the invention aims at further improving the bioactivity of a biodegradable magnesium alloy surface coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Vitamin c and vitamin k, and compositions thereof for treatment of osteolysis or prolongation of prosthetic implant

ActiveUS20120184609A1Reduce productionIncreasing cell proliferationBiocideDigestive systemVitamin CEnantiomer

Provided herein is a method of treating, preventing, or managing osteolysis in a subject, comprising administering to the subject a therapeutically effective amount of vitamin C, or a pharmaceutically acceptable salt, solvate, or hydrate thereof, in combination with vitamin K, or a single enantiomer, a mixture of enantiomers, or a mixture of diastereomers thereof, or a pharmaceutically acceptable salt, solvate, or hydrate thereof.

Owner:IC MEDTECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com