Bionic multi-scale structural surface with excellent tribological performance and preparation method

A technology of structural surface and tribology, used in medical science, prosthesis, metal material coating technology, etc., can solve problems such as adverse biological reactions, affecting the quality and service life of artificial joints, and easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

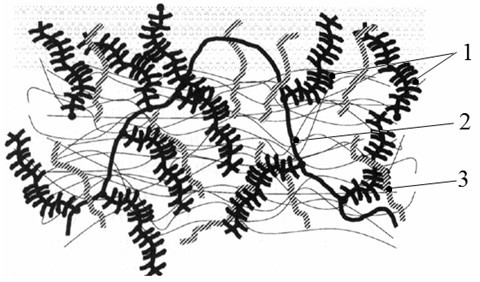

[0028] A method for preparing a bionic multi-scale structure of an artificial joint friction surface, comprising the following steps:

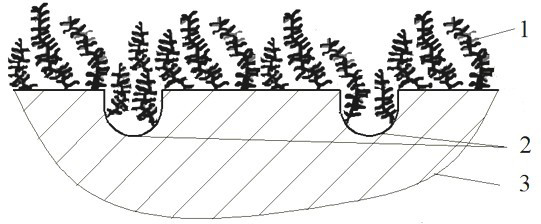

[0029] (1)) Prepare micropore groups on the surface of titanium alloy, cobalt-based alloy, and stainless steel alloy by laser etching or anodic oxidation; the diameter of micropores prepared by laser etching is 100-500 μm, and the depth is 10-80 μm. Micropore area density is 1-20%;

[0030] (2) in H 2 O plasma, O 2 Pretreatment in plasma or ultraviolet light for 5-30min to obtain hydroxylated surface;

[0031] (3) Put it in a silane coupling agent with a mass fraction of 1-20% and let it stand for 2-24h, dry and solidify in a vacuum oven to obtain a silanized surface;

[0032] (4) In the presence of a photosensitizer, ultraviolet light triggers the grafting of biocompatible monomers on the surface of the porous substrate, preferably the photosensitizer is pre-coated on the ultra-high molecular weight surface. Immerse in an acetone solution...

Embodiment 1

[0036] A pulsed laser is used to prepare a regular microporous structure on the surface of titanium alloy (TC4). The pore diameter is 500 μm, the depth is 80 μm, and the area density of the micropore group is 1%. A plasma etching machine with a 500w high-frequency output H 2 O steam plasma, treat the surface of the porous titanium alloy for 5 minutes; immerse in an ethanol solution with a mass fraction of 20% methacryloxypropyltrioxymethylsilane, let stand at room temperature for 2 hours, wash with ethanol, and cure in a vacuum oven. Immerse the silanized sample in 0.01mol / L benzophenone in acetone solution for 180s to attach photosensitizer, dry in dark room to remove acetone; prepare 0.05mol / L MPC monomer solution, and pass nitrogen gas to remove oxygen, sample Immerse in the monomer solution and put it under the ultraviolet lamp to irradiate the grafting for 60min.

Embodiment 2

[0038] Such as Figure 4 As shown, a regular microporous structure was prepared on the surface of titanium alloy (TC4) with a pulsed laser, and the pore diameter was 350 μm, the depth was 52 μm, and the area density of the micropore group was 2.6%. frequency output H 2 O plasma, treat the surface of the porous titanium alloy for 10 minutes; immerse in an ethanol solution with a mass fraction of 10% methacryloxypropyltrioxymethylsilane, let stand at room temperature for 6 hours, wash with ethanol, and cure in a vacuum oven. Immerse the silanized sample in the acetone solution of 0.1mol / L benzophenone for 60s to attach the photosensitizer, and dry it in a dark room to remove the acetone; prepare a 1mol / L NVP monomer solution, pass through nitrogen to remove oxygen, and immerse the sample in The monomer solution was irradiated and grafted under ultraviolet light for 45min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com