Novel artificial hip joint and manufacturing method thereof

A hip joint and artificial technology, applied in the direction of hip joints, joint implants, joint implants, etc., to achieve the effects of increasing service life, eliminating stress shielding, and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

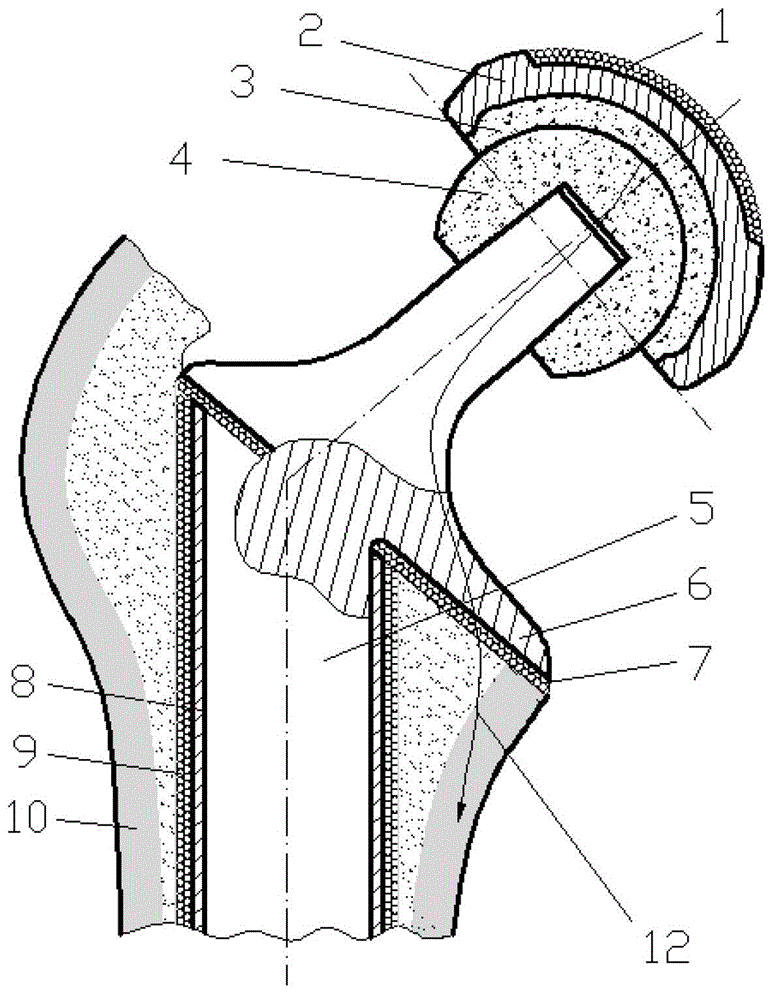

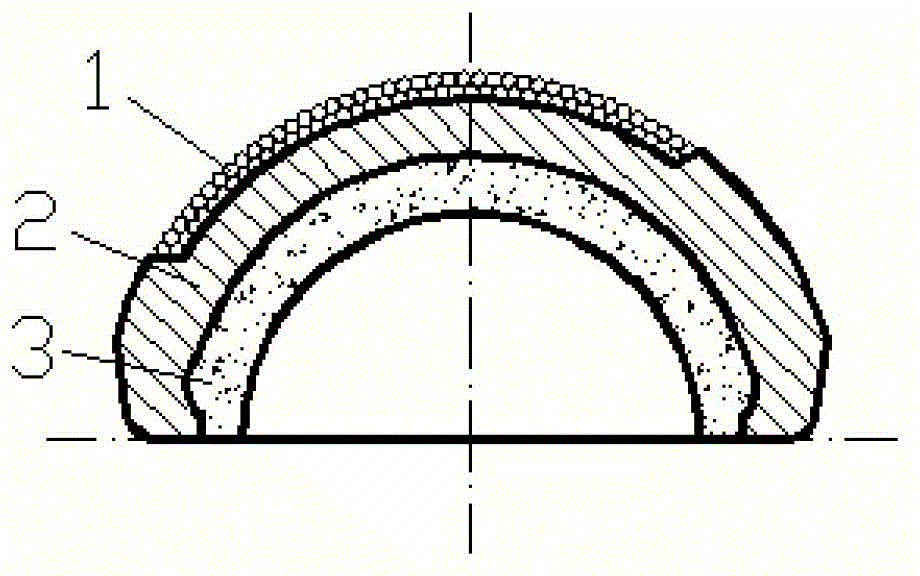

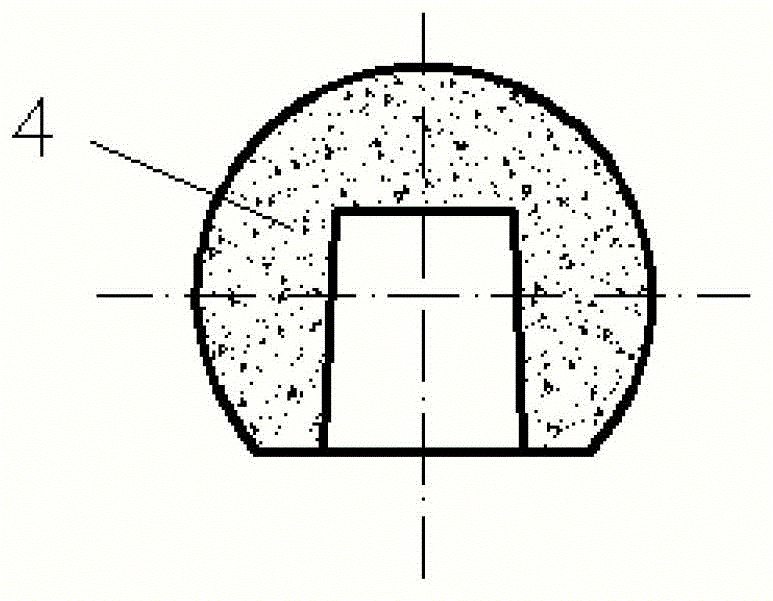

[0039] Such as figure 1 , Figure 4-Figure 7 As shown, a new type of artificial hip joint, including advanced porous layer PCA spherical crown 1, alloy acetabular cup 2, metal ceramic acetabular liner 3, metal ceramic femoral head 4, metal handle 5, collar 6, advanced porous layer PCA plane Circle 7, metal handle catheter 8, advanced porous layer PCA mesh circle 9, it is characterized in that,

[0040] The metal handle 5 is inserted into the metal handle conduit 8, and the two are slidingly fitted with a certain precision. The gap is 0.03-0.06mm. The metal handle 5 can slide up and down slightly in the metal handle conduit 8 without rotating, swinging or conducting stress. ;

[0041] Weld the advanced porous layer PCA plane ring 7 on the collar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com