Patents

Literature

41results about How to "Reduce brittle fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

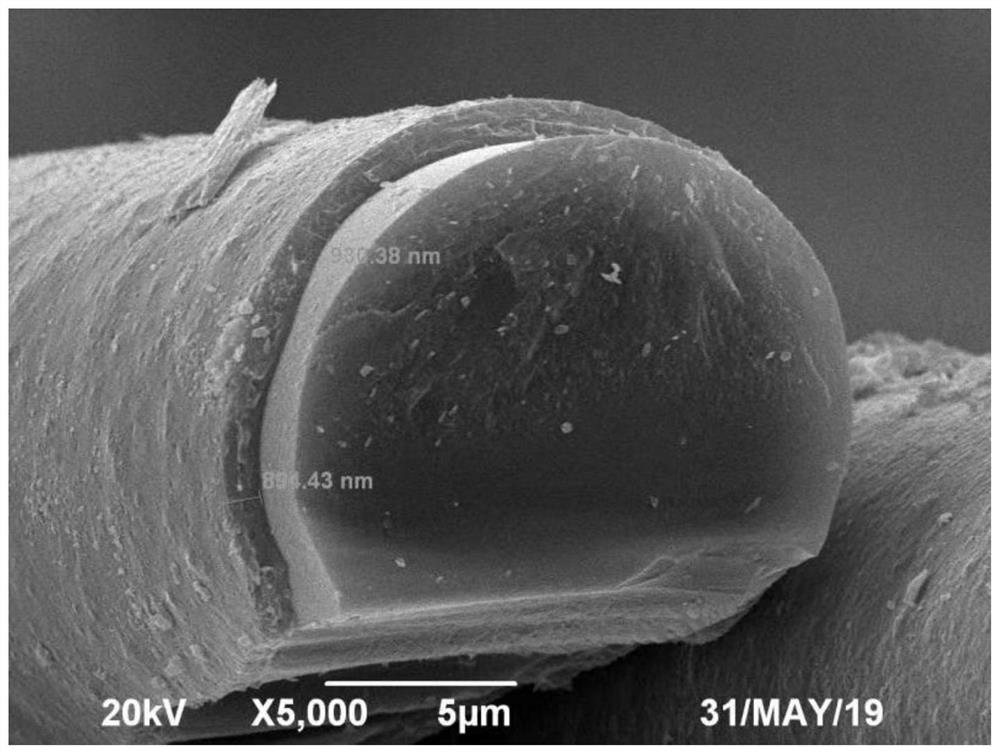

Halloysite nanotube / epoxy nanocomposite

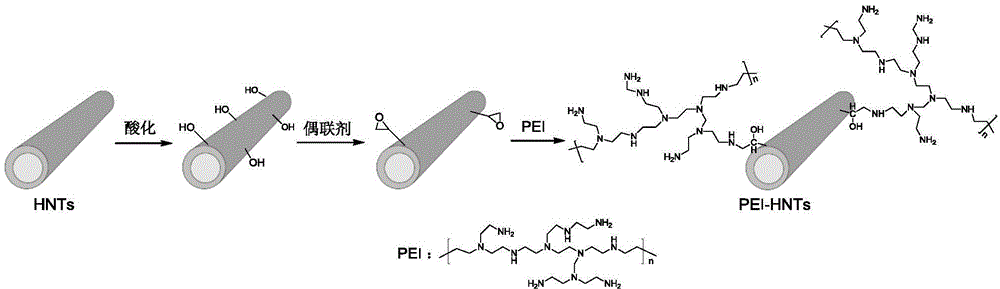

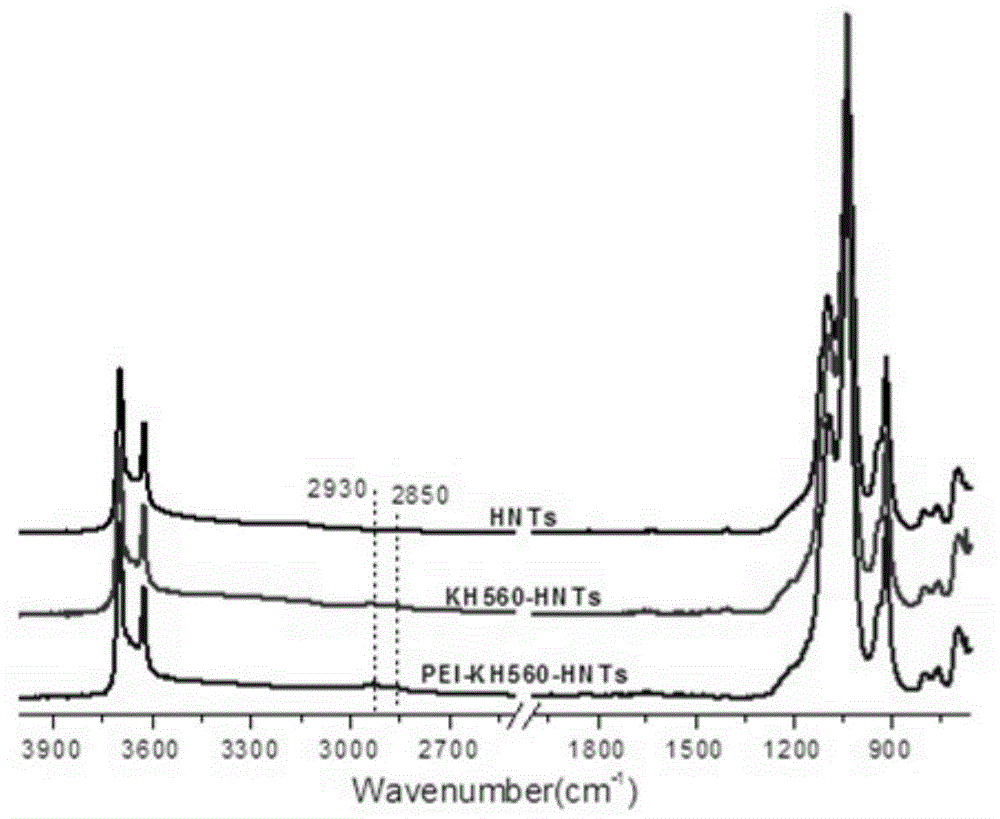

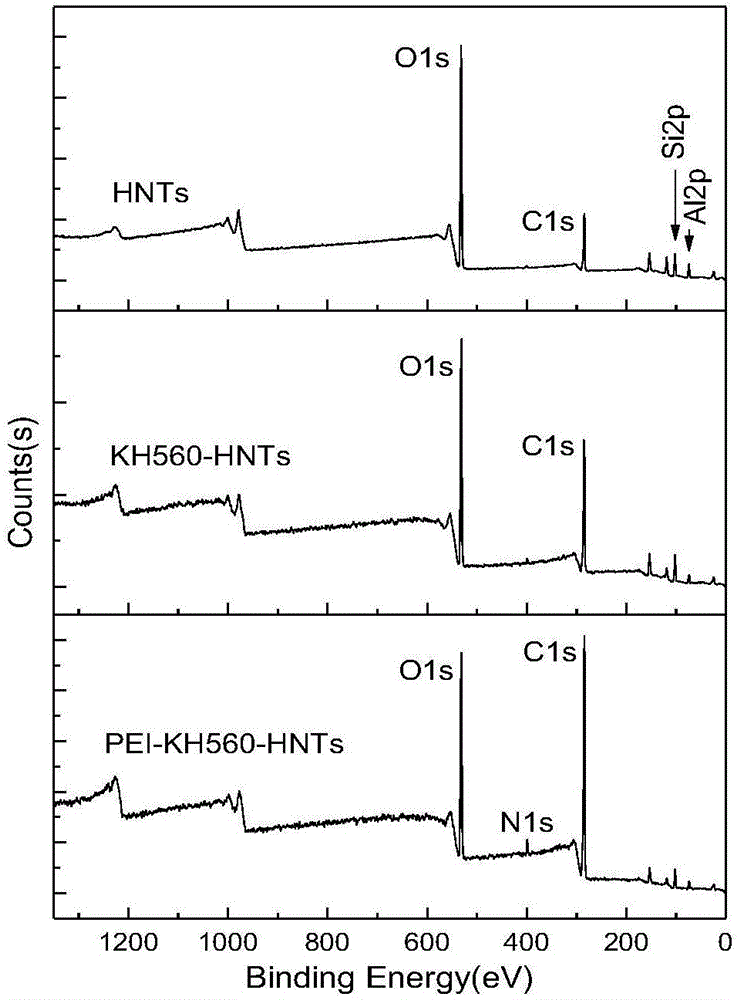

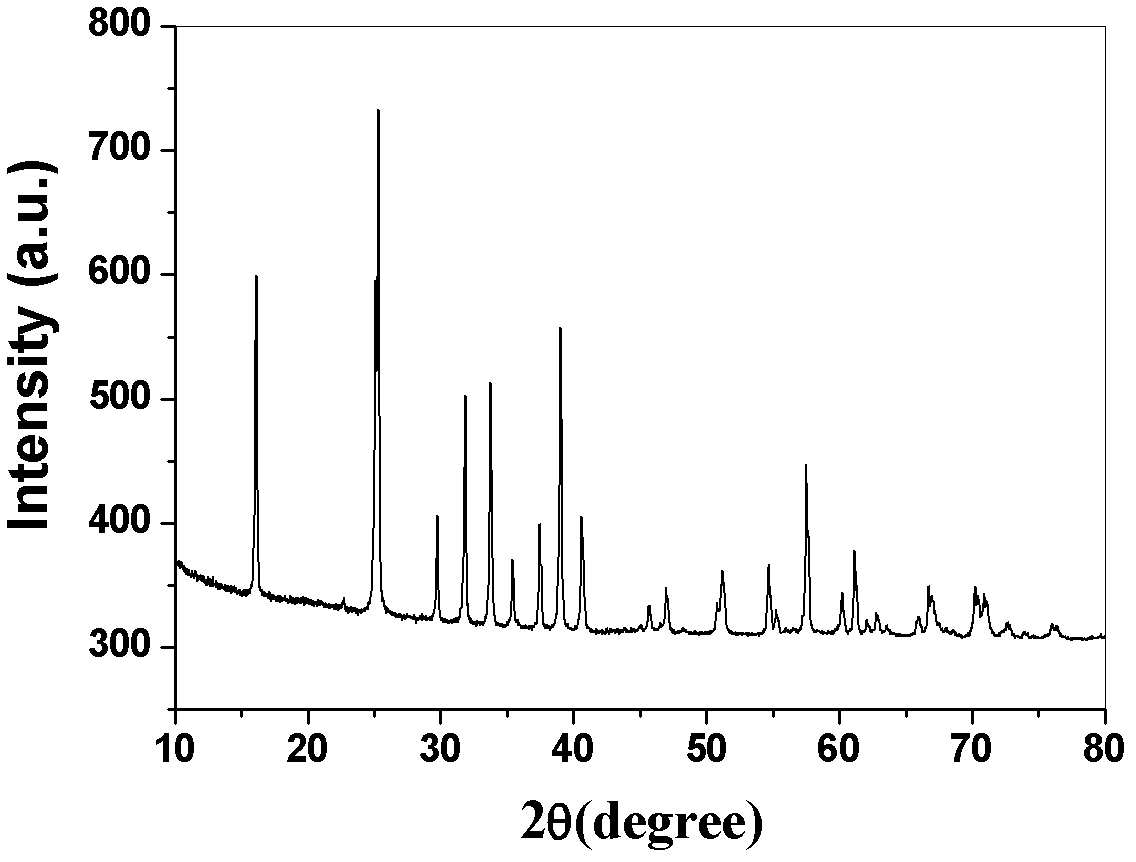

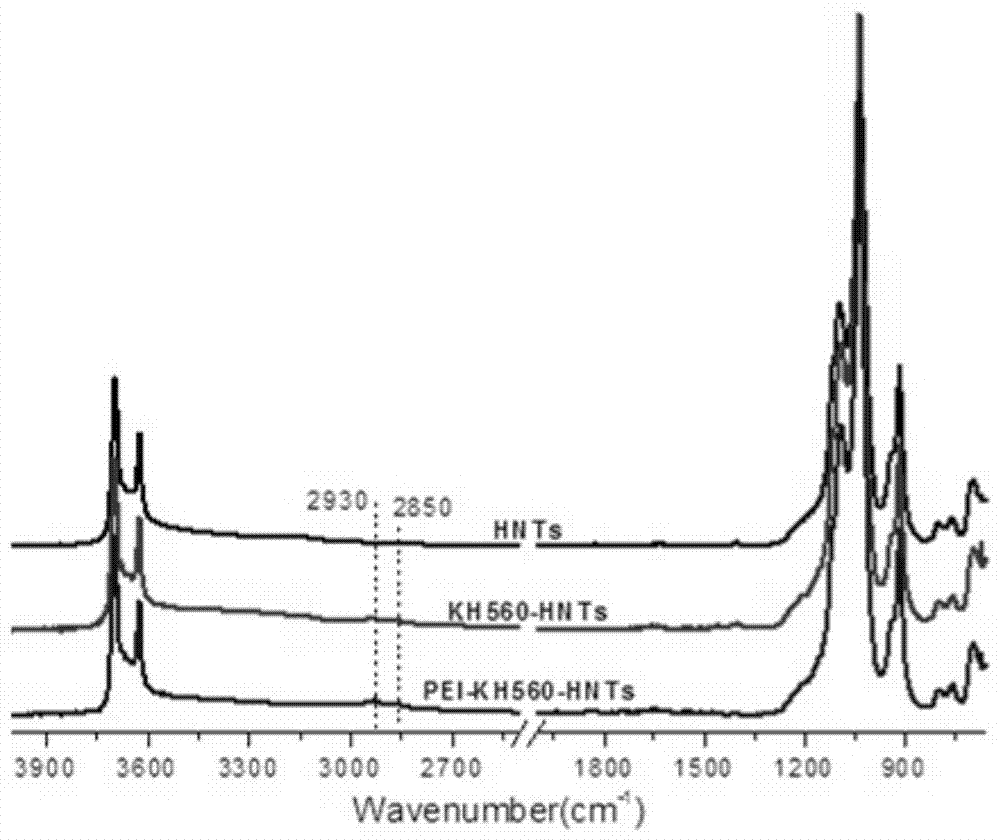

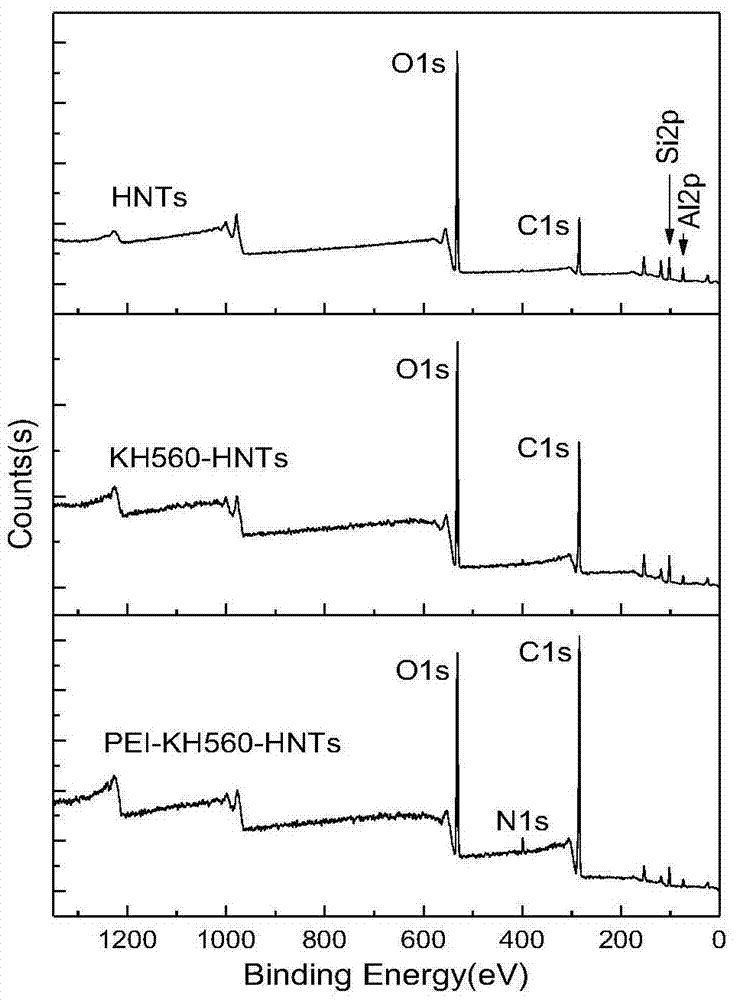

The present invention relates to the field of nano-composite materials, and specifically relates to a halloysite nanotube / epoxy nanocomposite. The halloysite nanotube is a branched polymine grafted halloysite nanotube; the branched polymine grafted weight halloysite nanotube and epoxy resin are in the weight ratio of 0.2-20:100, preferably 0.5-5:100. The hyperbranched polymine is grafted onto epoxidized HNTs, so that the branched structure has rich amino groups to generate stronger chemical bonds or hydrogen bonds between the halloysite nanotube and an epoxy matrix and to enhance the interface effect. The prepared modified halloysite nanotube can effectively improve the impact resistance of epoxy resin and reduce brittle fracture of epoxy resin, and has broad application prospects in the fields of automotive, electronics, functional materials and aerospace.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for synthesizing carboxyl butadiene-styrene latex improving concrete tensile strength

The present invention relates to a synthetic method for carboxylated styrene-butadiene latex with improved concrete bending and tensile strength through the preparation method of conjugated dienes - styrene copolymer. The preparation method involves 30 to 50 shares of butadiene or isoprene isoprene, 40 to 55 shares of styrene, 1 to 3 shares of acrylonitrile, 1 to 4 shares of N-hydroxymethylin acrylamide, 0.1 to 5 shares of methyl acrylate, 1 to 5 shares of itaconic acid, 4 to 12 shares of acrylic n-butyl, 1.0 to 2.0 shares of emulsifier, 0.4 to 1.0 shares of potassium persulphate, 0.1 to 0.8 shares of molecular weight regulator, 0.01 to 0.5 shares of pH buffer agent, 0.01 to 5 shares of potassium phosphate, 0.01 to 5 shares of chelator and 100 to 150 shares of soft water; In the polymerization reaction, monomer and a variety of agents are added with intermission. And reaction temperature control adopts the two-step laddered control. When the conversion rate reaches 99.0 percent, the mixture experiences the vacuum degassing treatment. The present invention has the advantages of low cost, strong bonding, easy mixing with the cement, convenient construction and fast film forming at room temperature. The present invention prolongs the service life of the road and reduces the brittle fracture surface of the road. Small amount of improved styrene-butadiene latex added to the road concrete can reduce the water content of the road surface, and strengthen and toughen the road.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for controlling impurities in high-carbon steel

The invention discloses a method for controlling impurities in high-carbon steel. The method comprises converter smelting, steel tapping control, top slag control, white slag manufacturing by refining, and continuous casting, wherein the method specifically comprises the following steps: step one, converter smelting: adding dust pressure blocks which are from steel enterprises and have iron content being not less than 50% at the early stage of smelting; quickly removing phosphor and controlling the smelting so that the phosphor content is not more than 0.008%; step two, slag tapping control; step three, top slag control; step four, white slag manufacturing by refining: controlling the content of (Al2O3) in the refined white slag and feeding steel ladles to a calcium-containing alloy core-spun yarn, so that the impurities are formed into plastic impurities with a low melting point; and a step five, continuous casting: producing the high-carbon steel continuous casting billet by a continuous casting process. The pure (Al2O3) in the crisp impurities of the high-carbon steel produced by the method are remarkably reduced; and the impurities in the steel mainly are 7Al2O3.12CaO plastic impurities which are silicate and sulphide impurities. The impurities in the steel are plastic composite impurities, and so the method has a remarkable effect of reducing brittle failure of the high-carbon steel in a cold-rolling process.

Owner:ANYANG IRON & STEEL

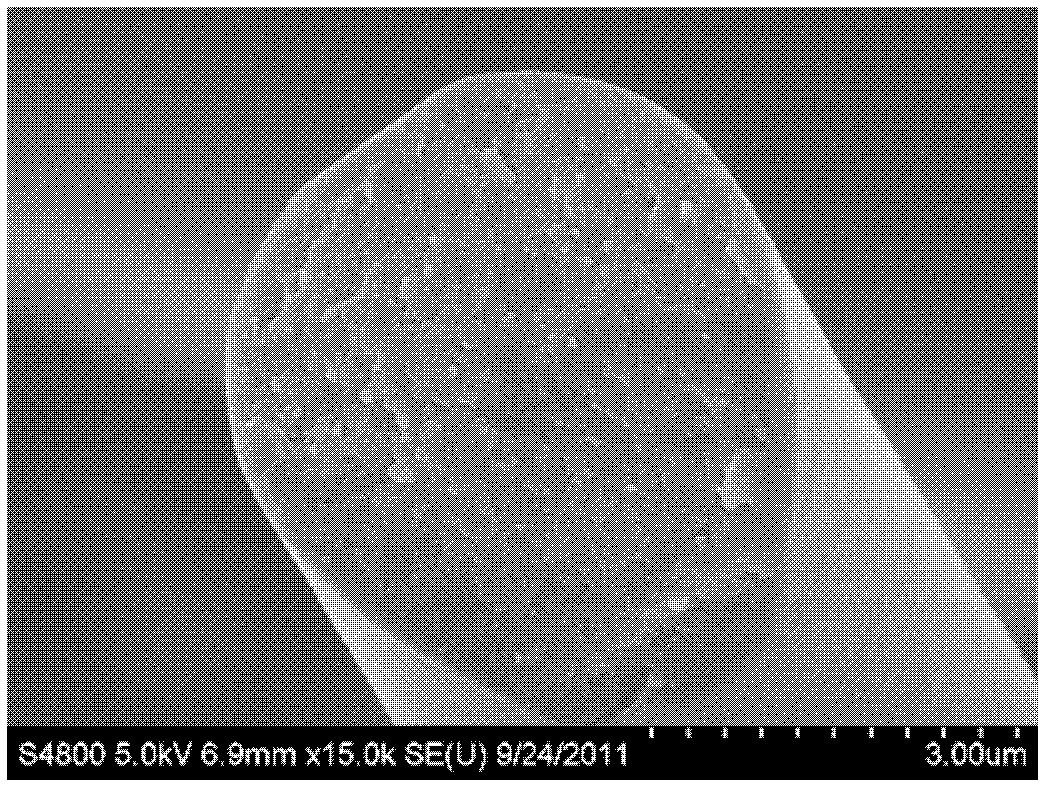

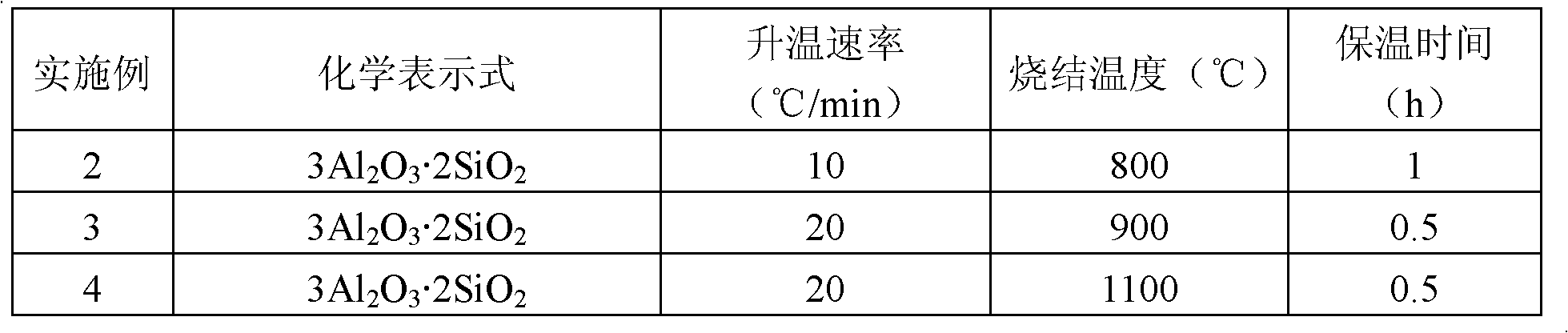

Mullite fiber preparation method

The invention discloses a mullite fiber preparation method which is efficient, rapid, environment-friendly and low in cost. The method includes: taking raw materials according to stoichiometric ratio of elements in the mullite fiber chemical formula, preparing colloid, performing fiber forming and drying for colloid discharging to obtain mullite non-crystal fiber, adding the fiber into a sagger made of wave permeable materials, placing the sagger in a special microwave oven, controlling heating rate by adjusting the microwave power under the air or oxygen atmosphere, heating to a heat treatment temperature, and cooling to the room temperature to obtain the mullite fiber. The mullite fiber prepared by the method is high in impurity and low in porosity, the grain size is about 30nm, and the fiber diameter ranges from 6 micrometers to 10 micrometers. Further, the mullite fiber is excellent in uniformity, brittle fracture and chalking of the fiber are greatly reduced, yield is increased, heat treatment temperature is lowered, heat insulation time is shortened, and production efficiency is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-temperature-resistant ceramic-based composite member and connecting method thereof

The invention relates to a high-temperature-resistant ceramic-based composite member and a connecting method thereof. The method comprises the following steps: (1) uniformly mixing silicon powder, chopped carbon fibers, an organic dispersing agent and a phenolic resin to obtain mixed slurry; (2) coating a joint face of a first to-be-connected prefabricated member and / or a second to-be-connected prefabricated member with the mixed slurry, and laminating and connecting the joint face of the first to-be-connected prefabricated member and the second to-be-connected prefabricated member so as to obtain a pre-connecting piece, wherein the first to-be-connected prefabricated member and / or the second to-be-connected prefabricated member are / is made from fiber preforms; (3) at least impregnating the joint of the pre-connecting piece with the mixed slurry, and sequentially curing and splitting the impregnated pre-connecting piece so as to obtain a pre-connected member; and (4) carrying out a silicon-zirconium alloy infiltration reaction on the pre-connected member, thereby obtaining the high-temperature-resistant ceramic-based composite member. The method disclosed by the invention has the advantages of being simple in process, capable of obviously enhancing the member connection strength and enabling the overall member to be high-temperature-resistant, and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

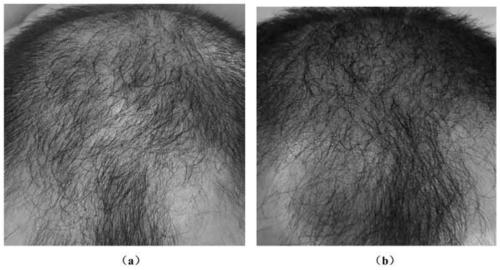

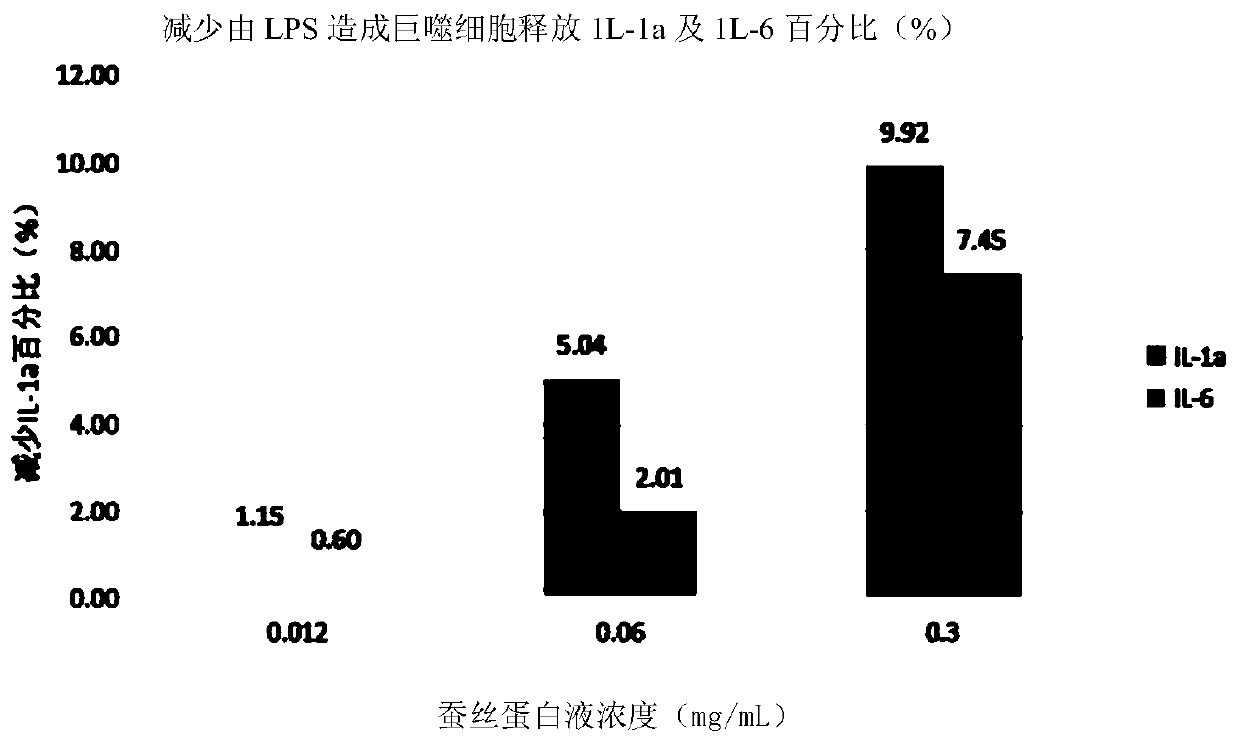

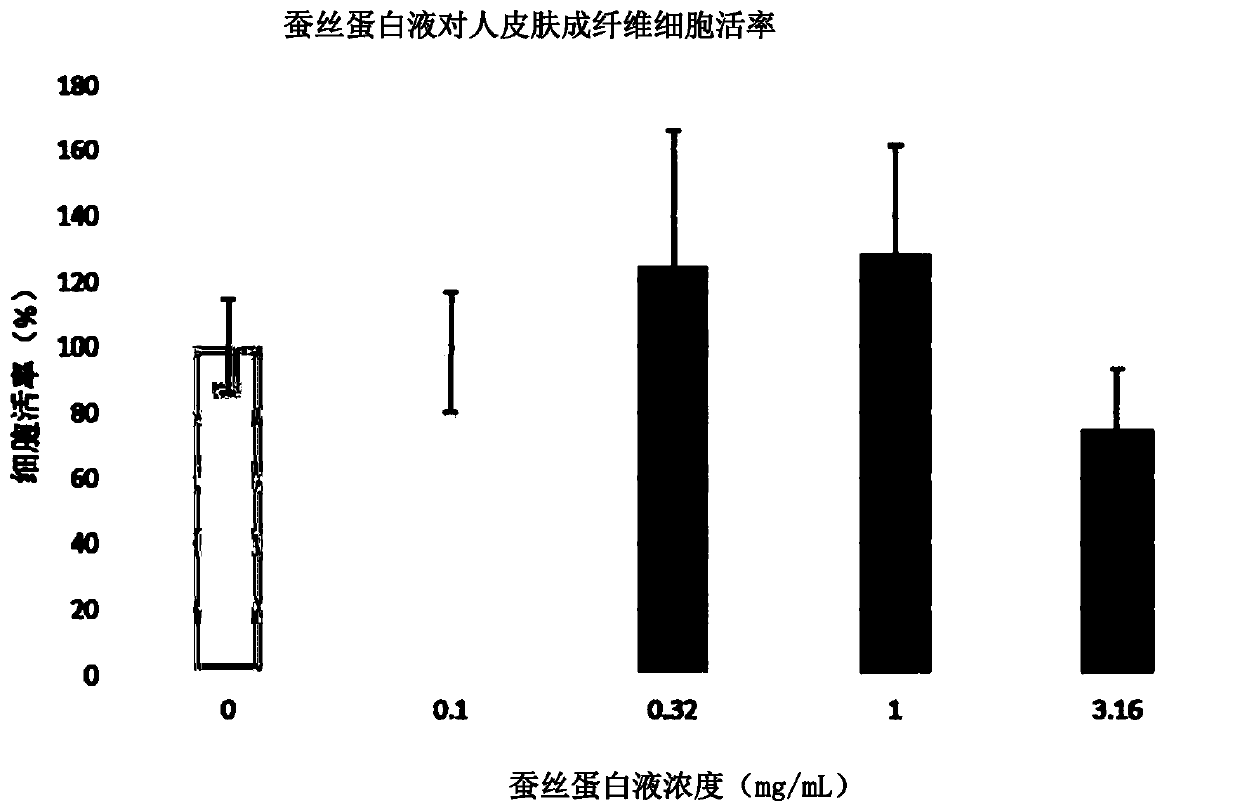

Fibroin-containing anti-hair loss and hair-solidifying shampoo composition and preparation method thereof

PendingCN111374902AReduce sheddingReduce brittle fractureCosmetic preparationsHair cosmeticsDimethyl siloxaneScalp skin

The invention discloses fibroin-containing anti-hair loss and hair-solidifying shampoo composition and a preparation method thereof. The shampoo composition is prepared from the following raw materialcomponents: 54.0-67.0 percent of deionized water, 14.0-18.0 percent of sodium laureth sulfate, 1.0-2.0 percent of glycol distearate, 1.0-3.0 percent of cocamide Methyl MEA, 0.1-0.5 percent of soapberry extract, 5.0-10.0 percent of water, 0.1-0.3 percent of guar hydroxypropyltrimonium chloride, 0.01-0.5 percent of EDTA-2Na, 0.01-0.1 percent of allantoin, 0.3-2.0 percent of polyquaternium-47, 1.0-3.0 percent of polydimethylsiloxane / laureth-23 / sodium laureth sulfate, 1.0-3.0 percent of dimethiconol / TEA dodecylbenzenesulfonate, 2.0-5.0 percent of cocamidopropyl betaine, 3.0-5.0 percent of fibroinliquid, 0.1-1.0 percent of raw ginger extract, 0-10 percent of traditional Chinese medicinal extract, 0.1-1.0 percent of tea tree oil, 0.03-1.0 percent of citric acid and a proper amount of preservative. According to the fibroin-containing anti-hair loss and hair-solidifying shampoo composition, scalp and scalp microecology are reconstructed and protected through fibroin liquid, raw ginger extract, soapberry extract and the like so as to achieve the aims of restoring and solidifying hair and reinforcing hair toughness.

Owner:GUANGZHOU QIYUAN BIO TECH CO LTD

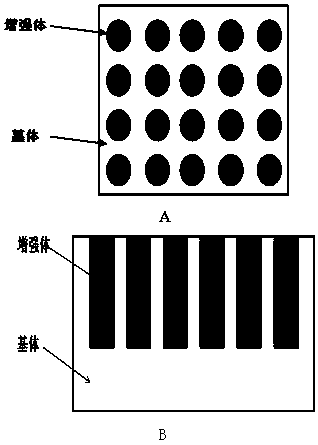

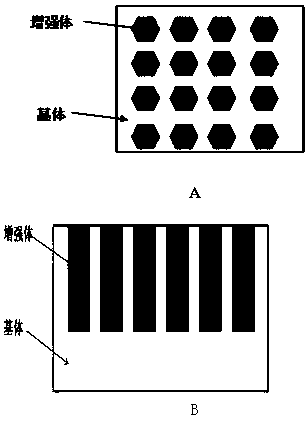

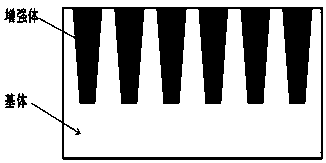

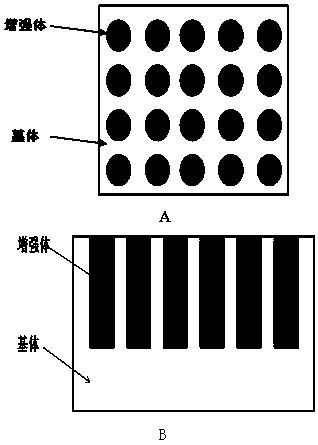

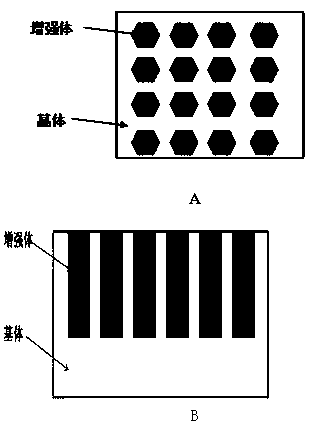

Reinforced steel-based surface-layer spatial-configuration composite containing rear earth and modified particles and preparation method thereof

The invention discloses a reinforced steel-based surface-layer spatial-configuration composite containing rear earth and modified particles and a preparation method thereof, and belongs to the technical field of powder metallurgy and composite preparation. The composite is composed of a reinforced body and a base body; the reinforced body is mixed powder of rear earth powder, the reinforced particles and 45 steel metal powder, and the base body is mixed powder of rear earth powder and 45 steel metal powder, wherein the rear earth powder is yttrium powder or neodymium powder; the preparation method comprises the steps that ball-milling is conducted on the reinforced body powder and the base body powder; the base body powder is put into a lower die, and corresponding holes are formed by means of upper dies in different shapes and filled with the reinforced body powder; vibration and pre-bulking are conducted, then forming is conducted by means of SPS, and finally, the reinforced steel-based surface-layer spatial-configuration composite containing the rear earth and the modified particles is obtained through heating treatment. According to the composite and the preparation method thereof, the technology is simple, the cost is low, the evenness of distribution of the reinforced particles with the spatial configuration in the base body is good, the bonding strength is high, and thecomposite has good durability and capability of impact resistance, corrosion resistance and oxidation resistance.

Owner:KUNMING UNIV OF SCI & TECH

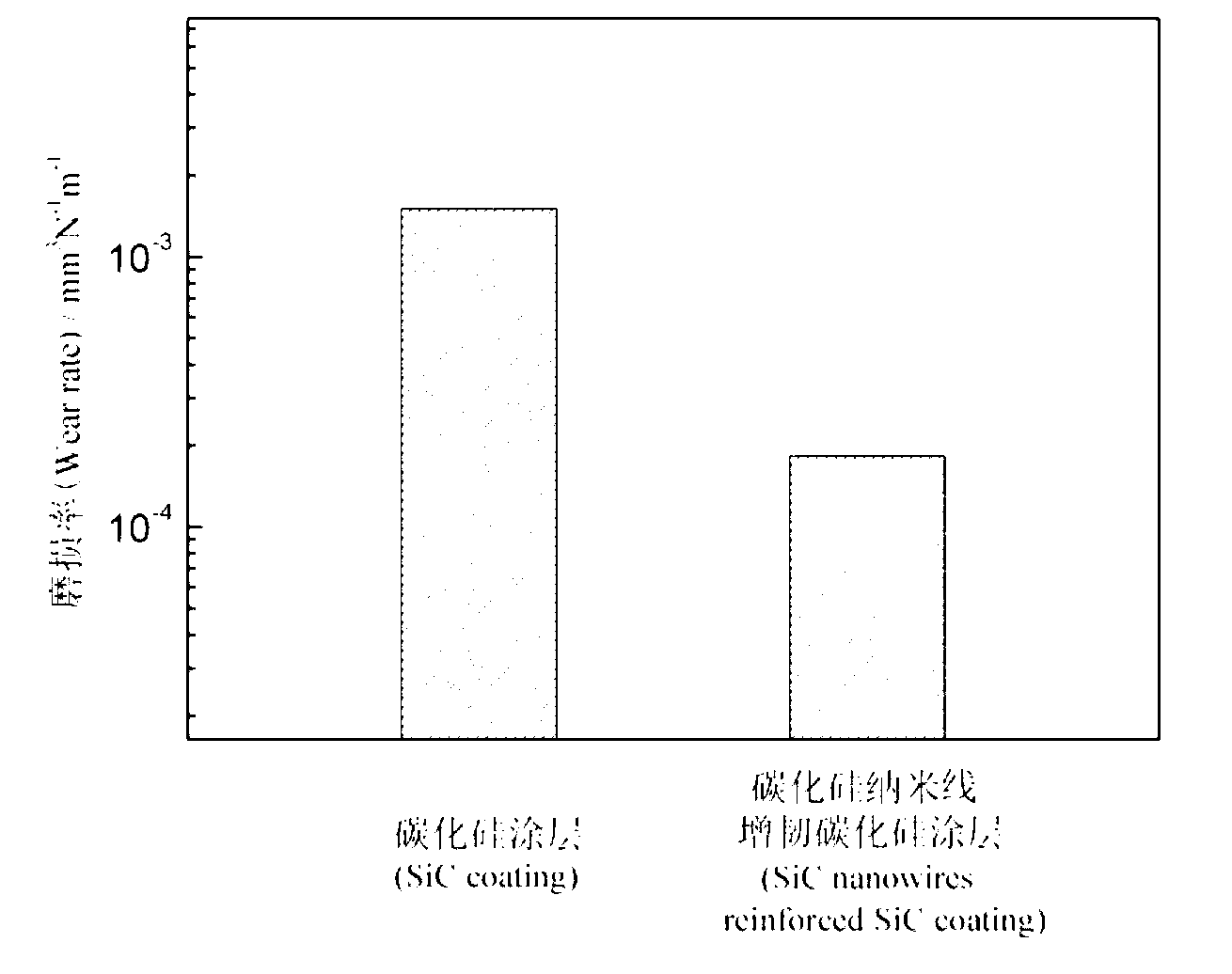

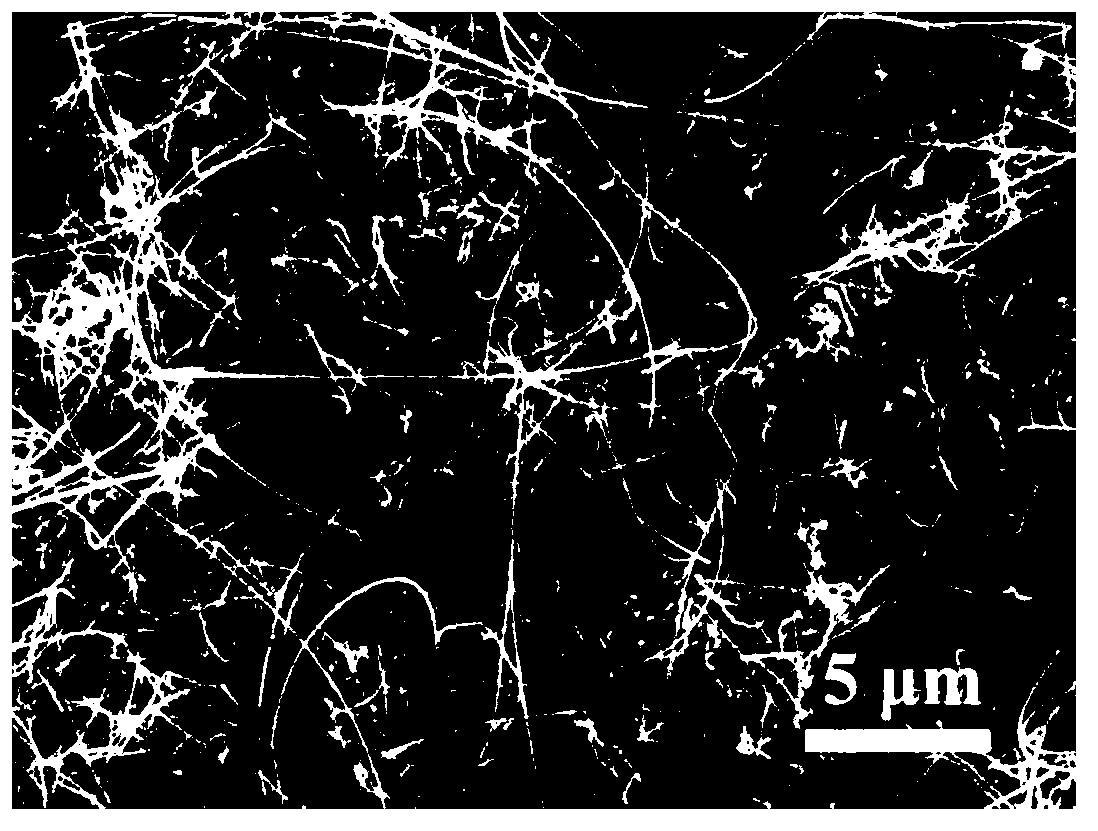

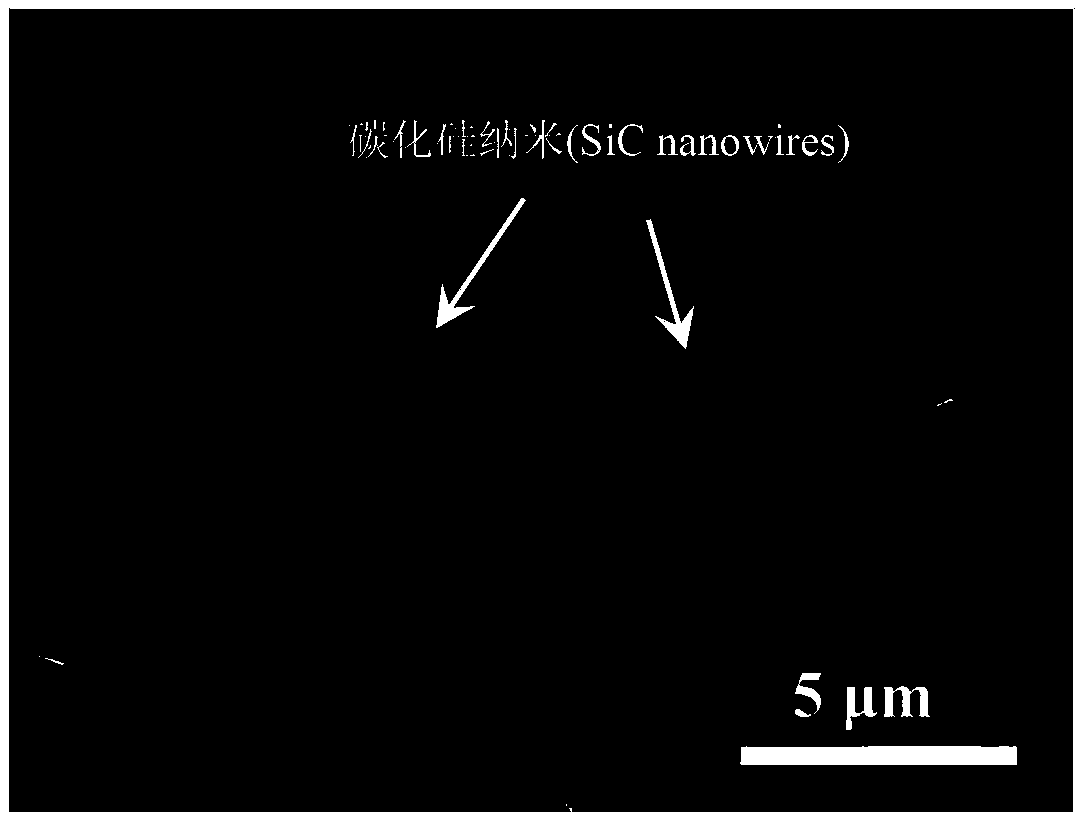

Preparation method of nano-wire reinforced SiC wear-resistant coating

The invention relates to a preparation method of a nano-wire reinforced SiC wear-resistant coating. A porous SiC nano-wire layer is prepared on the surface of a C / C (Carbon / Carbon) composite material, and the fracture toughness of the SiC coating is effectively improved by utilizing the super-high strength and elasticity modulus of the SiC nanometer and the good bonding force of the SiC nanometer with a SiC coating matrix, so that the high-temperature wear rate of the SiC coating is reduced, and the wear-resistance of the coating is enhanced. After the SiC nano-wire is added, the wear rate of the SiC coating at 800 DEG C is reduced to 1.83*10<-4>mm<3>.N<-1>.m<-1> from 1.51*10<-3>mm<3>.N<-1>.m<-1>, that is, the wear rate is reduced by one order of magnitudes.

Owner:无锡博智复合材料有限公司

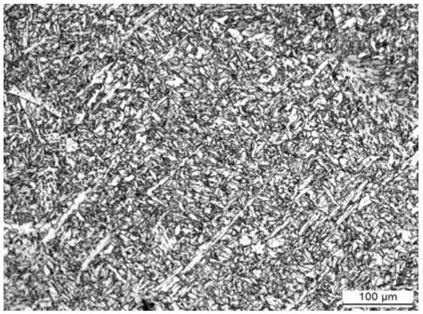

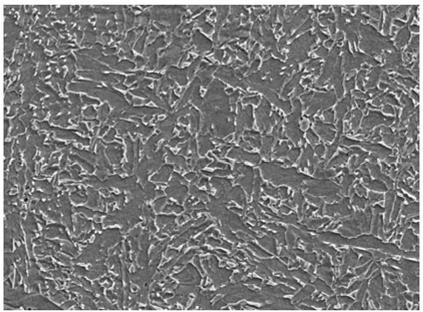

Yield strength 690 MPa class steel plate capable of bearing high heat input welding and manufacturing method

The invention belongs to the technical field of low-alloy high-strength steel and particularly relates to a yield strength 690 MPa class steel plate capable of bearing high heat input welding and a manufacturing method of the yield strength 690 MPa class steel plate. The steel plate comprises chemical components including 0.01%-0.04% of C, 0.1%-0.3% of Si, 1.7%-2.2% of Mn, 0.01%-0.05% of Nb, 0.01%-0.05% of V, 0.005%-0.025% of Ti, 0.001%-0.008% of P, 0.001%-0.005% of S, 0.05%-0.5% of Cu, 0.05%-0.5% of Ni, 0.05%-0.5% of Cr, 0.05%-0.5% of Mo, 0.0005%-0.0025% of B, 0.001%-0.005% of N, 0.00002%-0.0002% of H, 0.001%-0.005% of O 0.001%-0.015% of Al, one of Mg and Ca and the balance Fe. Ti-Mg-O or Ti-Ca-O compound occluded foreign substances accounts for 10% or higher in occluded foreign substances with the size being 0.2 micron to 3 microns, and in addition, an average of 1%-50% of Ti is contained; and the number of the occluded foreign substances with the size being 3 microns or higher in the steel plate is smaller than or equal to 120 pieces / mm<3>. An LD-RH-LF-RH smelting process is adopted, and when oxygen in molten steel is fixed to be 150 ppm to 300 ppm, Ti and Mg or Ca are added; and two-stage controlled rolling and controlled cooling are adopted. The steel plate has good toughness performance and can bear 100 kJ / cm to 200 kJ / cm high heat input welding.

Owner:NORTHEASTERN UNIV

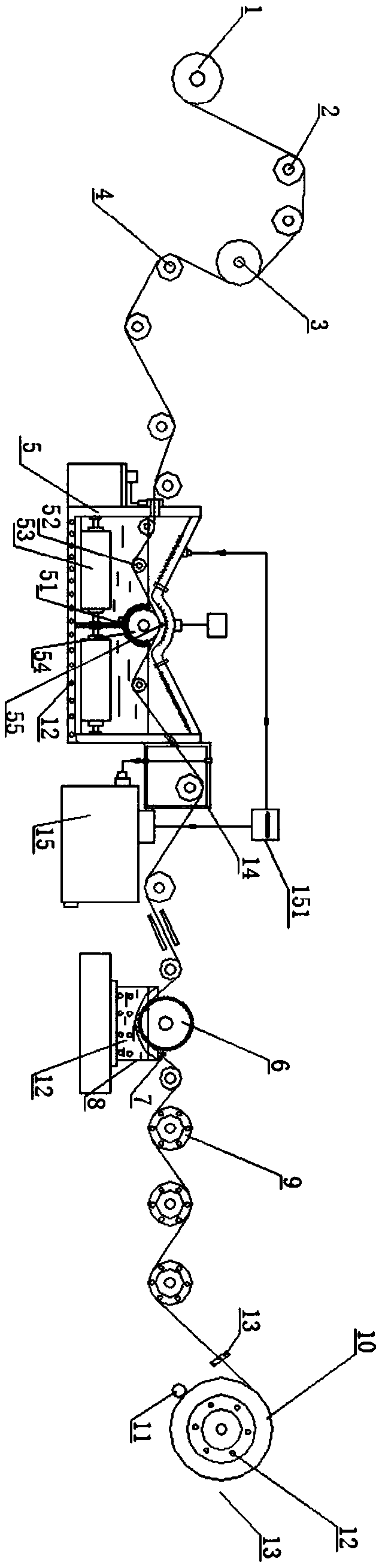

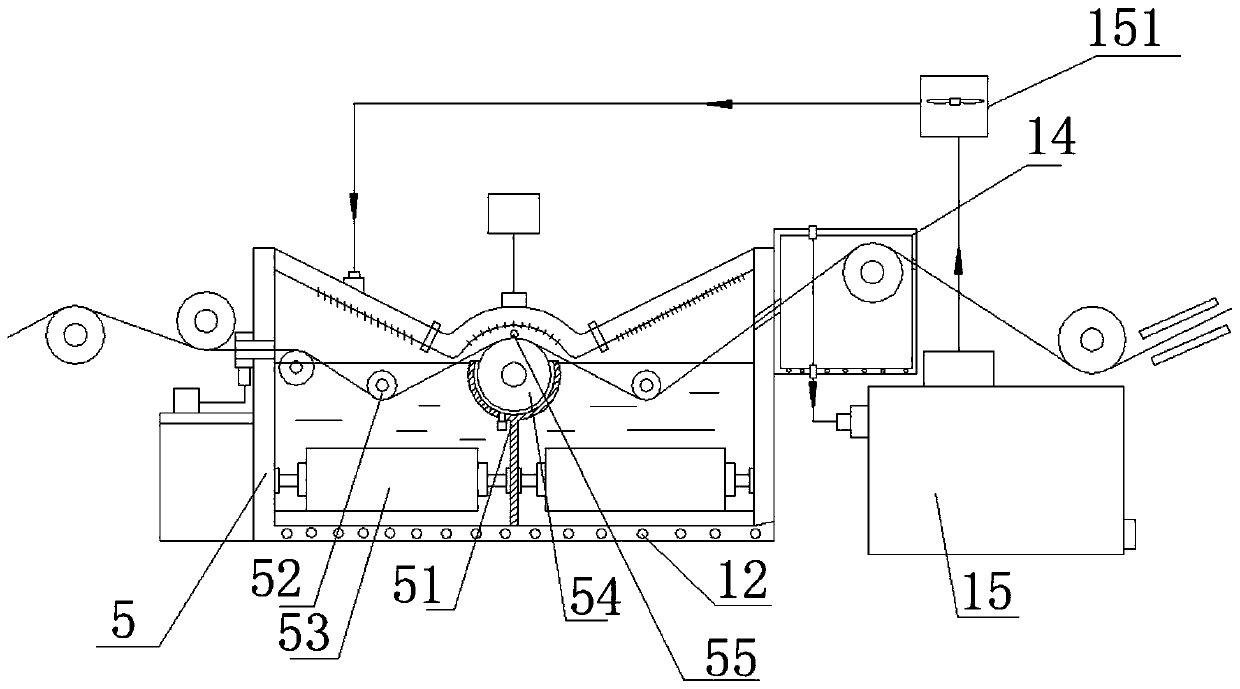

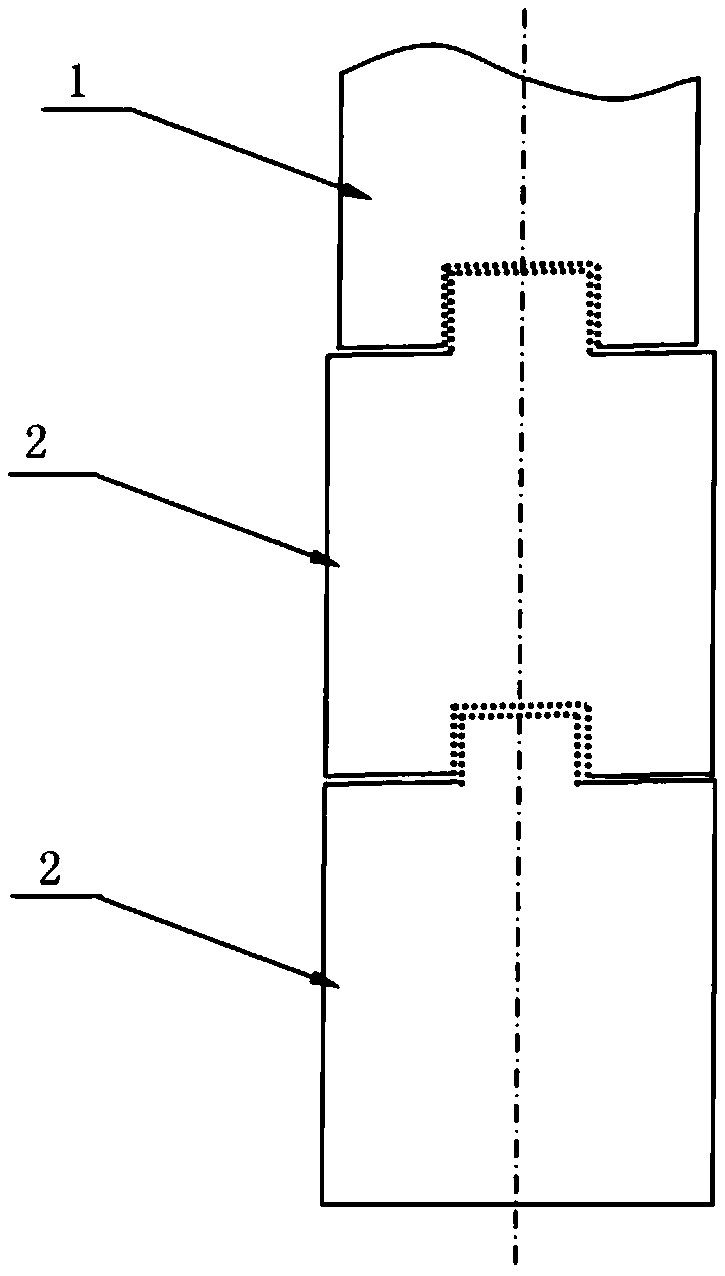

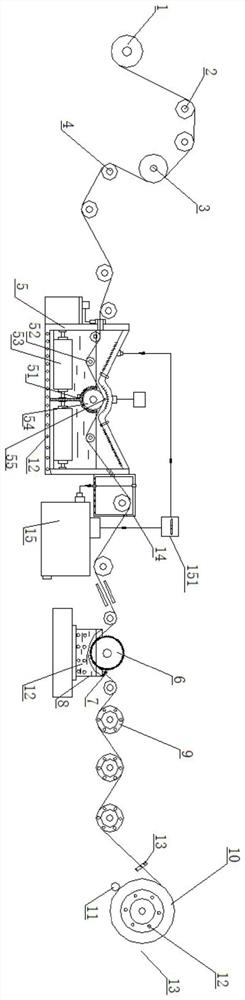

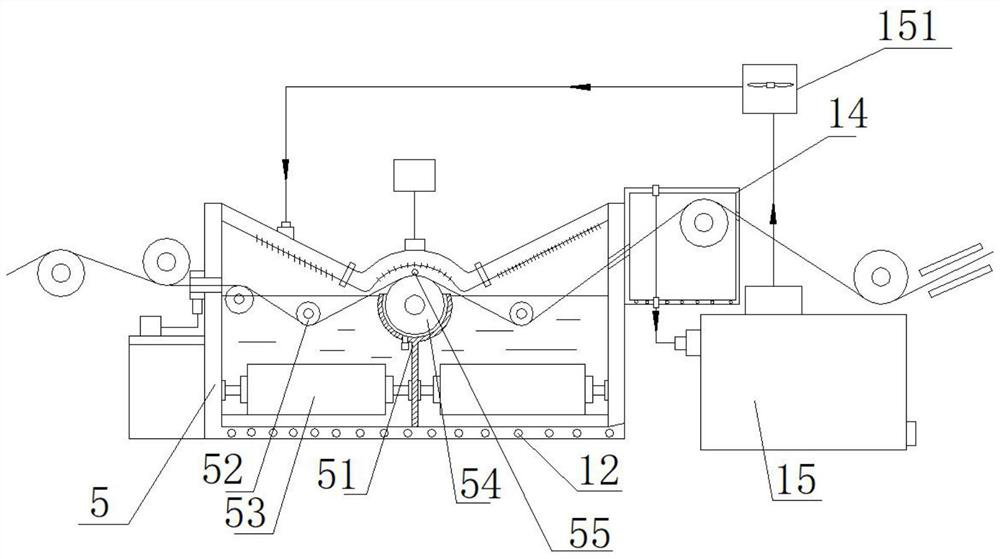

Preparation method and equipment of SiC fiber prepreg tape with attached interface layer

ActiveCN111058187AImprove toughnessAvoid wire breakageTextile treatment containersFibre treatmentSic fiberFiber bundle

The invention provides a preparation method of a SiC fiber prepreg tape with an attached interface layer. The preparation method comprises the following steps of introducing a continuous silicon carbide fiber bundle onto a tension pulley after being unwound through a godet roller and a guide wheel, sending the continuous silicon carbide fiber bundle straightly into a desizing device to expand thecontinuous silicon carbide fiber bundle; introducing the continuous silicon carbide fiber bundle onto a gluing device, so that glue fully infiltrates the continuous silicon carbide fiber, after that,introducing the continuous silicon carbide fiber bundle to a silk spreading device, and fully spreading and sizing the continuous silicon carbide fiber bundle by a drawing-in roller in the silk spreading device; and enabling the fully spread and sized continuous silicon carbide fiber bundle to enter a winding roller to obtain the flat and uniform prepreg tape. The prepreg tape prepared by the invention not only can greatly improve the toughness of the silicon carbide fiber, but also a deposited interface layer is uniform, meanwhile, the overlapped parts of two adjacent fiber bundles in the prepreg tape are few, the fiber bundle is good in flatness and thin in thickness, in addition, the preparation equipment can control parameters in real time, and full automation and complete controllability can be realized.

Owner:CENT SOUTH UNIV

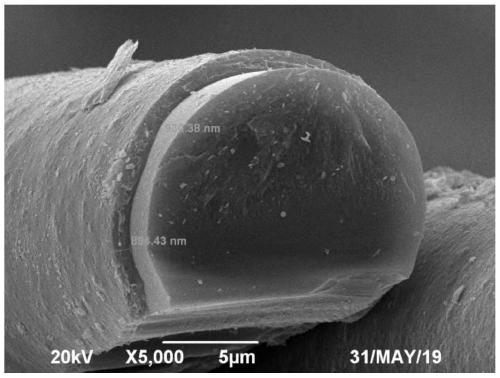

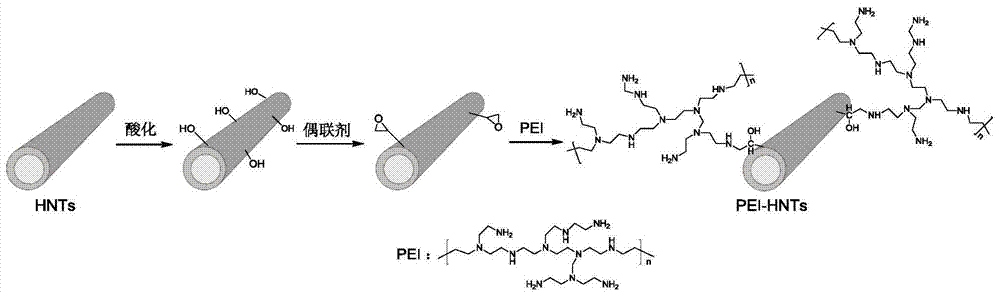

A kind of halloysite nanotube/epoxy resin nanocomposite material

The invention relates to the field of nanocomposite materials, in particular to a halloysite nanotube / epoxy resin nanocomposite material. The halloysite nanotubes of the present invention are branched polyethyleneimine grafted halloysite nanotubes, and the weight ratio of the branched polyethyleneimine grafted halloysite nanotubes to epoxy resin is 0.2~ 20:100; preferably 0.5-5:100; the present invention grafts hyperbranched polyethyleneimine onto epoxidized HNTs, and the branched structure has abundant amino groups, so that halloysite nanotubes and epoxy resin matrix Stronger chemical bonds or hydrogen bonds are formed between them to enhance the interfacial interaction. The modified halloysite nanotube prepared by the invention can effectively improve the impact resistance of the epoxy resin, reduce the brittle fracture of the epoxy resin, and has broad application prospects in the fields of automobiles, electronics, functional materials, aerospace and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

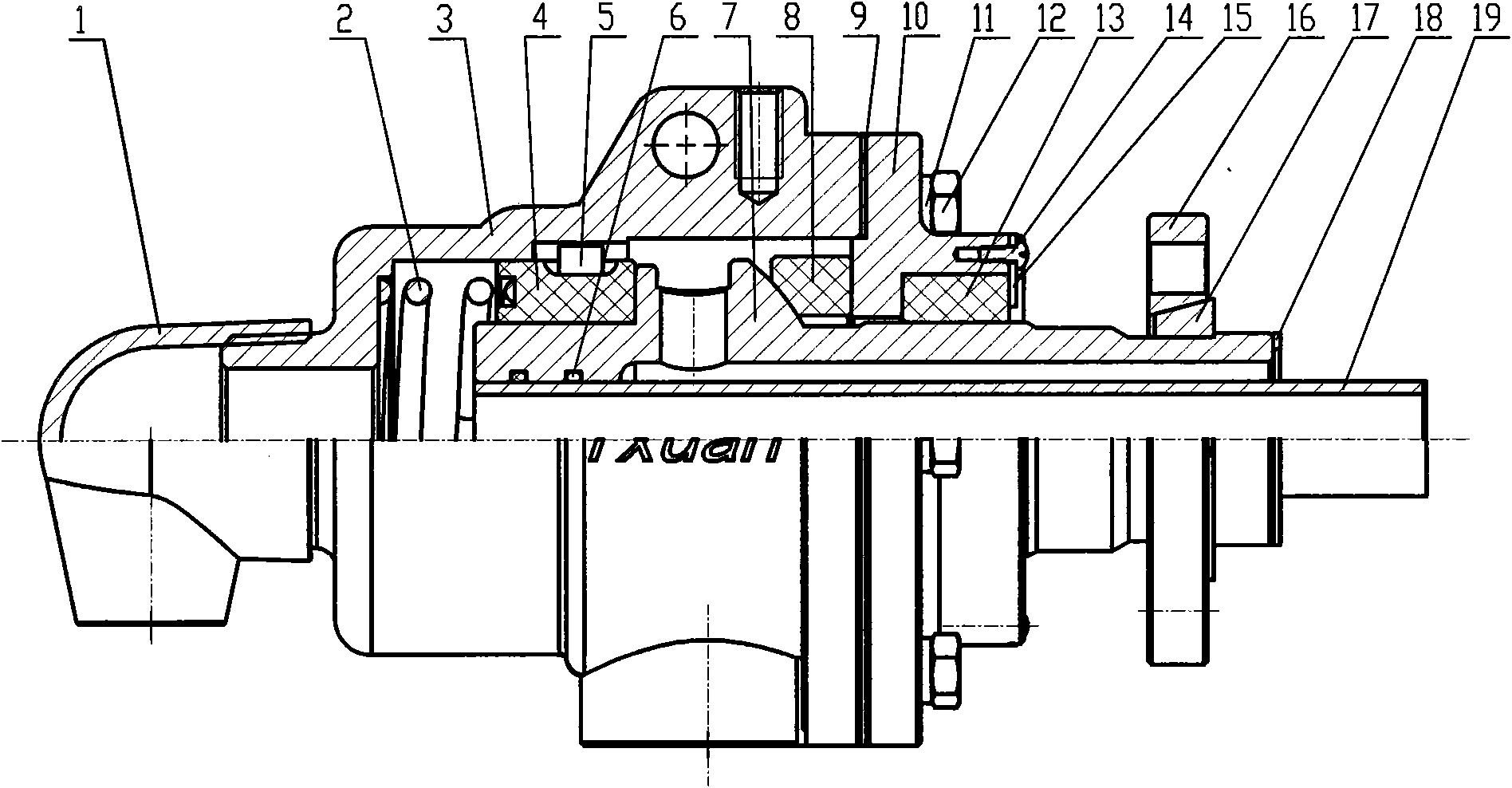

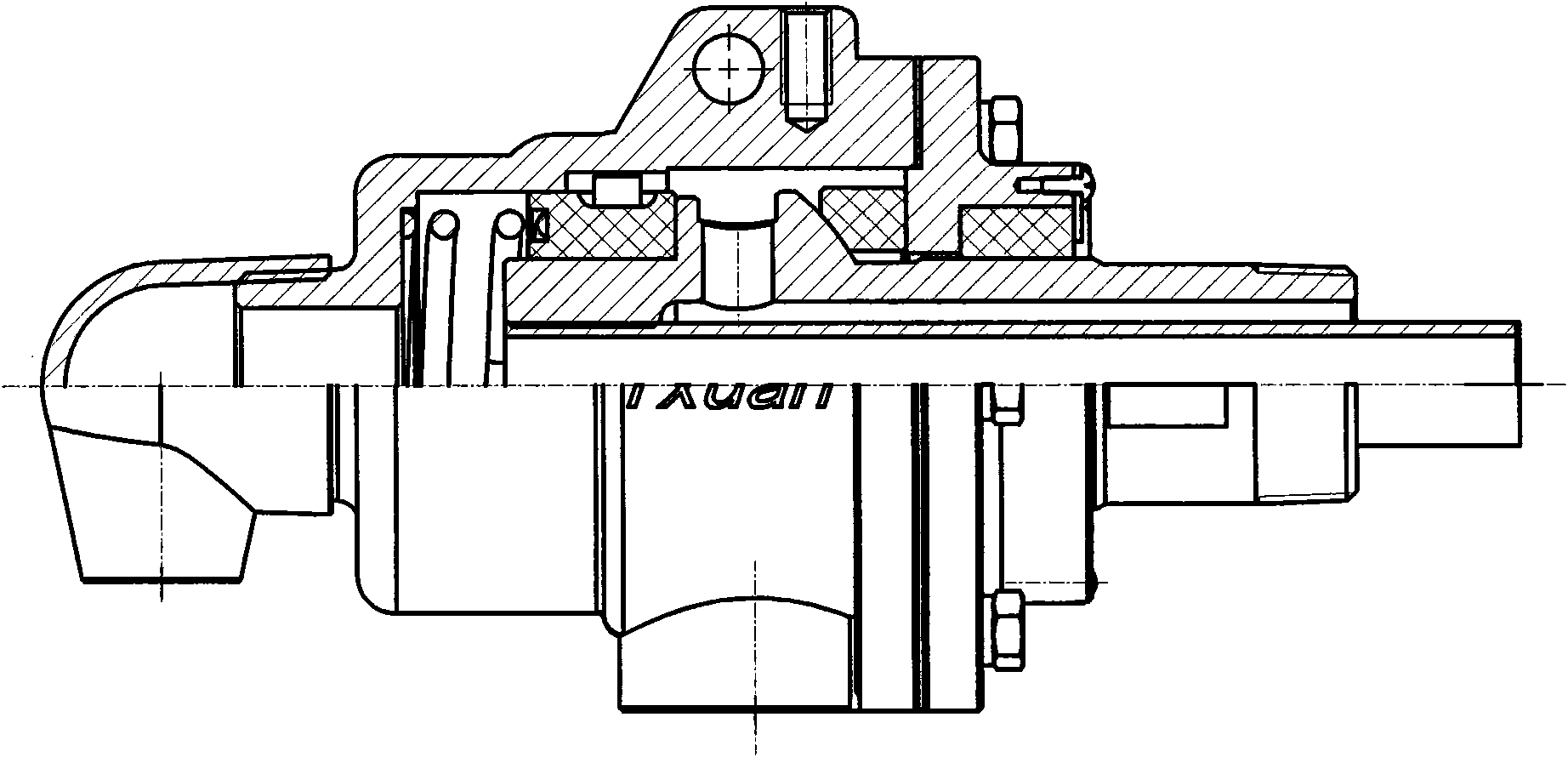

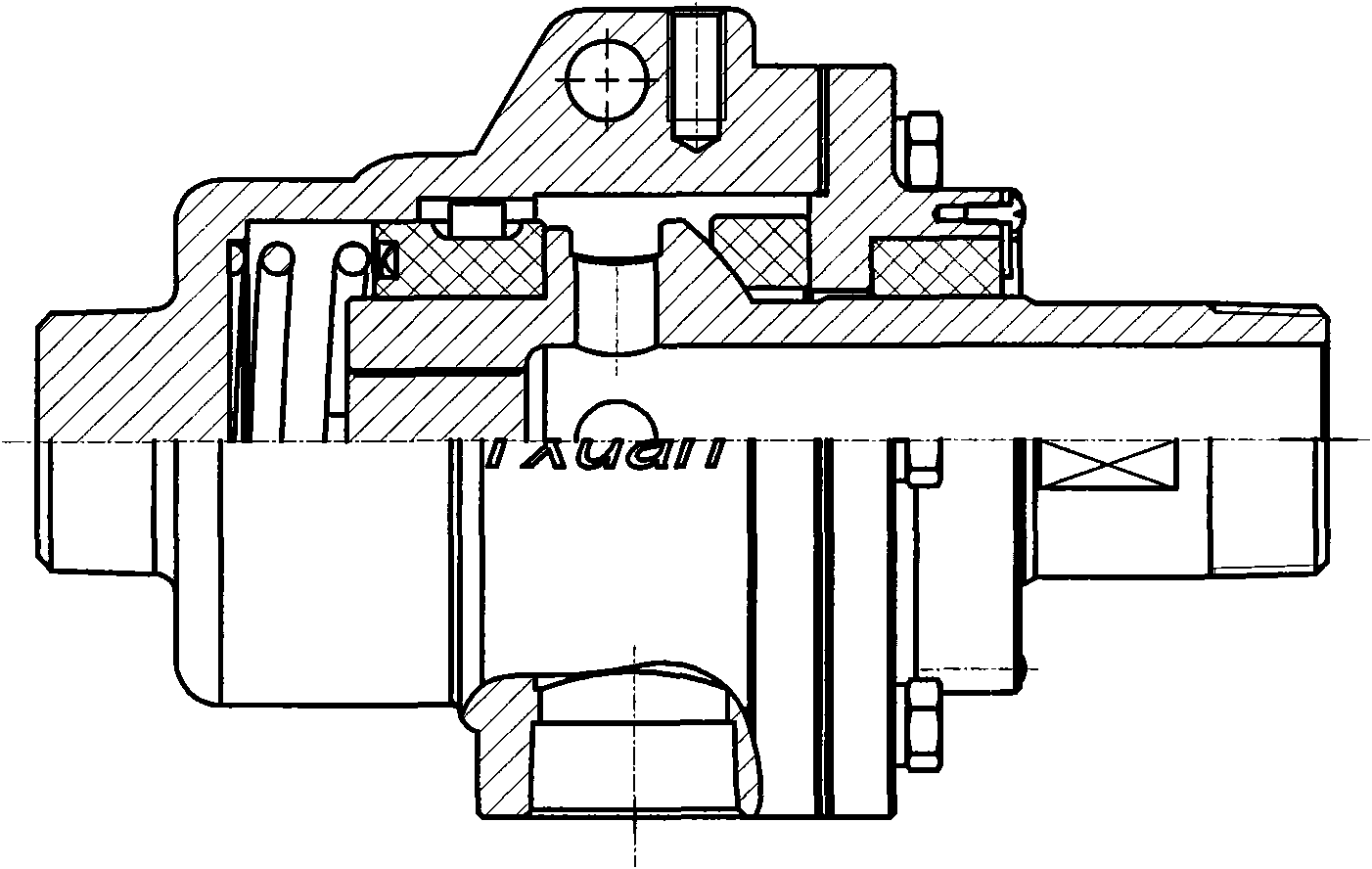

Rotary joint with temperature difference zone structure

ActiveCN101619788AReduce thermal deformationReduce brittle fractureAdjustable jointsTemperature differenceEngineering

The invention relates to a rotary joint, in particular to a connecting sealing member for conveying a fluid medium from a static pipeline to a swinging or rotating device, and belongs to the technical field of sealing devices. According to the technical scheme, the rotary joint with a temperature difference zone structure comprises a shell, a cylindrical spring mounted at the inner bottom of the shell and an outer tube positioned in the shell. A cylindrical ring is embedded on the end surface of the cylindrical spring; the outer tube is mounted in the inner hole of the cylindrical ring; and an O-shaped sealing ring is arranged in an inner hole at the tail part of the outer tube. The invention has the advantages of artistic and smooth outer appearance, stable rotation of the outer tube, temperature difference zone structure, reliable compensation on seal abrasion, good sealing performance and long service life.

Owner:TENGXUAN TECH

High-performance polystyrene toughened foam material and preparation method thereof

The invention relates to the technical field of polystyrene materials and preparation processes, in particular to a high-performance polystyrene toughened foam material and a preparation method thereof. The preparation system of the high-performance polystyrene toughened foam material comprises a continuous phase and a dispersed phase, the continuous phase comprises an oil-phase reaction monomer,an oil-phase cross-linking agent, an oil-phase toughening agent and an initiator, and the dispersed phase and the continuous phase do not react and are immiscible. On the premise that more than 95% ofthe prepared high-performance polystyrene toughened foam material is of a closed-cell structure, the high-performance polystyrene toughened foam material can keep good impact capacity when being impacted, and the possibility of brittle fracture is small so that the toughening effect of the high-performance polystyrene toughened foam material is better, the application range and field of the high-performance polystyrene toughened foam material are wider, and advantages of the high-performance polystyrene toughened foam material are more obvious.

Owner:深圳市方科马新材料有限公司

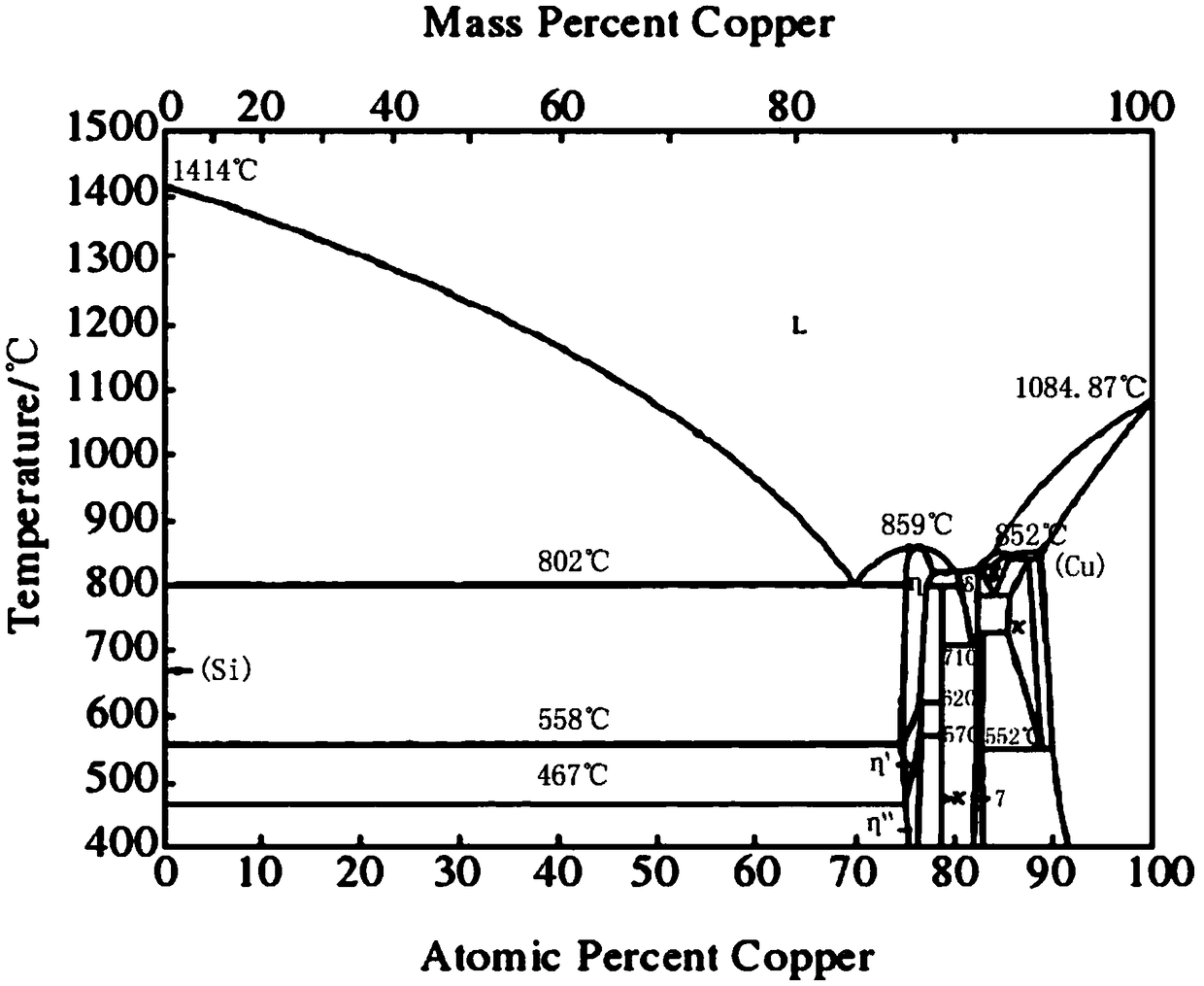

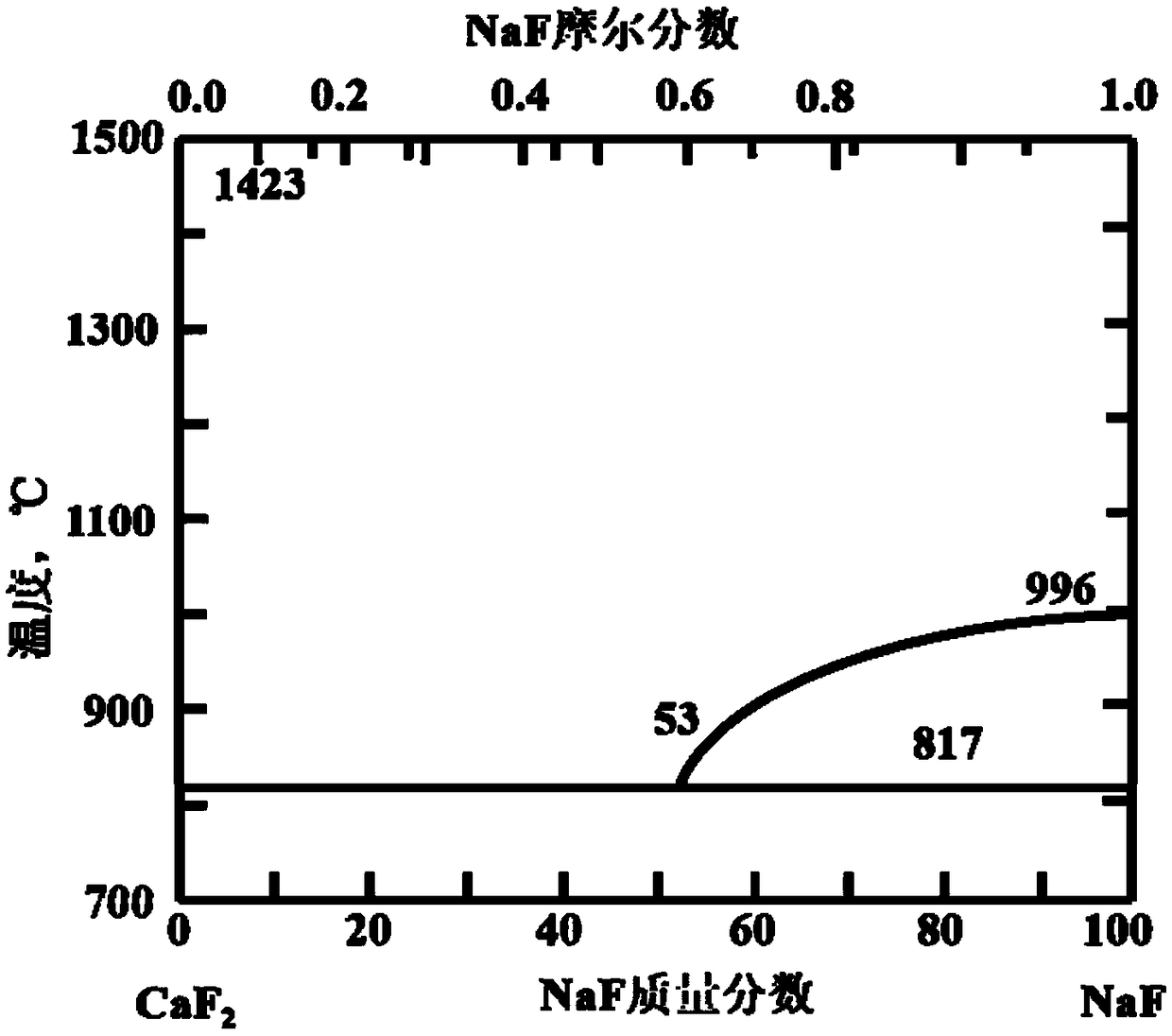

Copper-silicon alloy material, electroslag remelting preparation method thereof and copper-silicon alloy wire material

The invention discloses a copper-silicon alloy material, an electroslag remelting preparation method thereof and a copper-silicon alloy wire material, and belongs to the technical field of non-ferrousalloys. The copper-silicon alloy material is prepared by an electroslag remelting process. The copper-silicon alloy material comprises the chemical compositions of 1.85-2.65% of Si, 0.6-1.0% of Mn, 0.2-0.3% of Ni, 0.08-0.2% of Ag, and the balance Cu. In the preparation process, a CaF2-NaF binary slag system with a high purity NaF is used, wherein the content of the high purity NaF is 25.5-28wt. %. A copper-silicon alloy ingot is rolled and wiredrawn to obtain the copper-silicon alloy wire material with excellent tensile properties. The wire material has good folding resistance, good fusing property and stable resistivity.

Owner:沈阳赛美特新材料科技有限公司

Production process of rapid-absorbing fabric

The invention discloses a production process of a rapid-absorbing fabric. The production process comprises the following steps of product design, spooling, warping, sizing, threading and weaving. Theproduction process achieves a higher level of comfort, shape retention and rapid perspiration performance of the fabric by blending and interweaving three fibers of cool plus fiber, cotton and hemp fiber, and achieves complementary advantages in performance.

Owner:IANGSU COLLEGE OF ENG & TECH

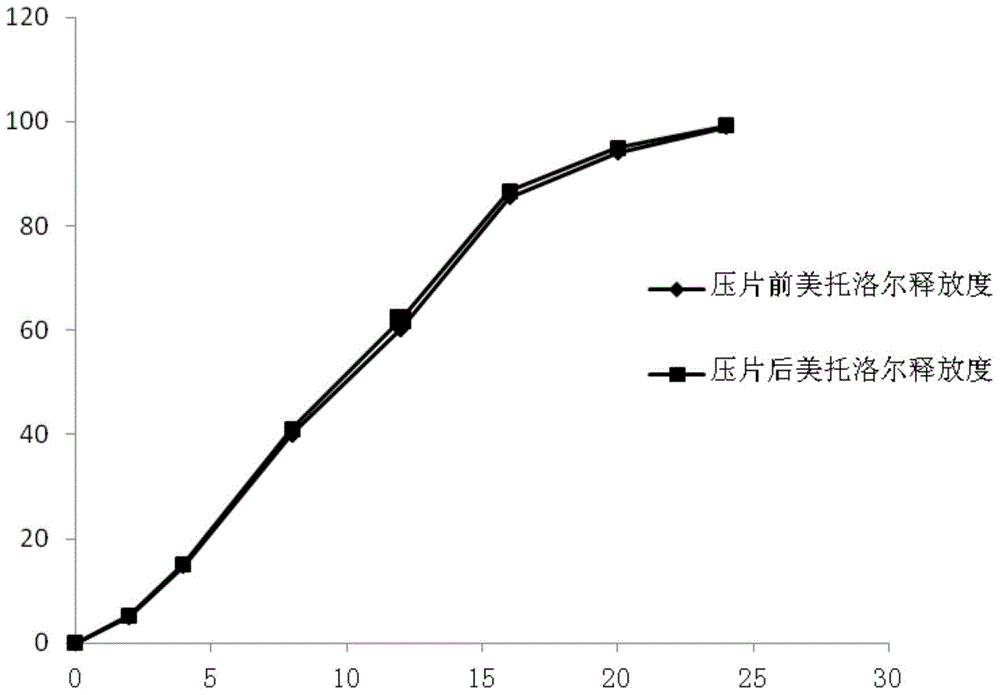

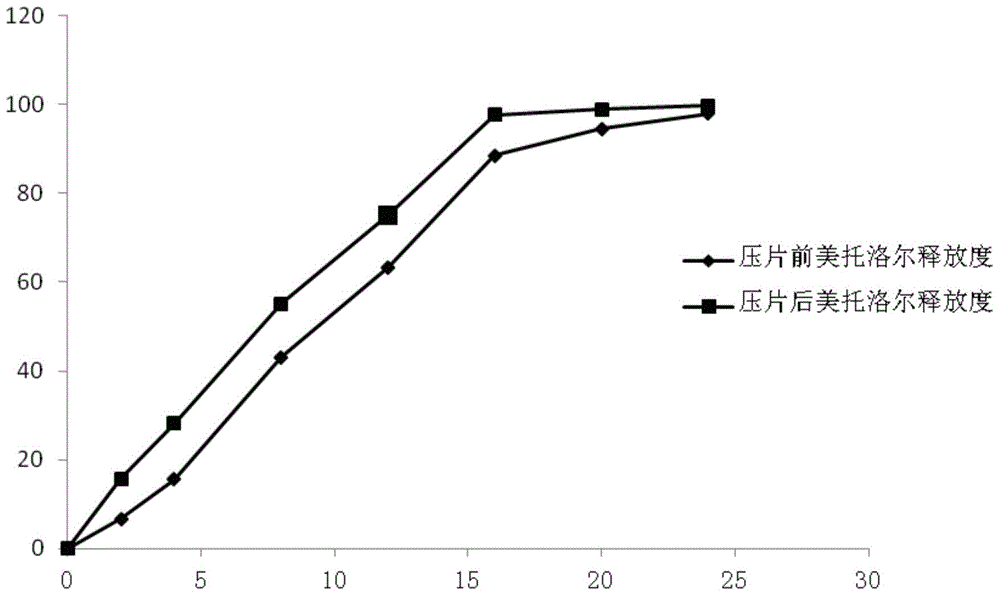

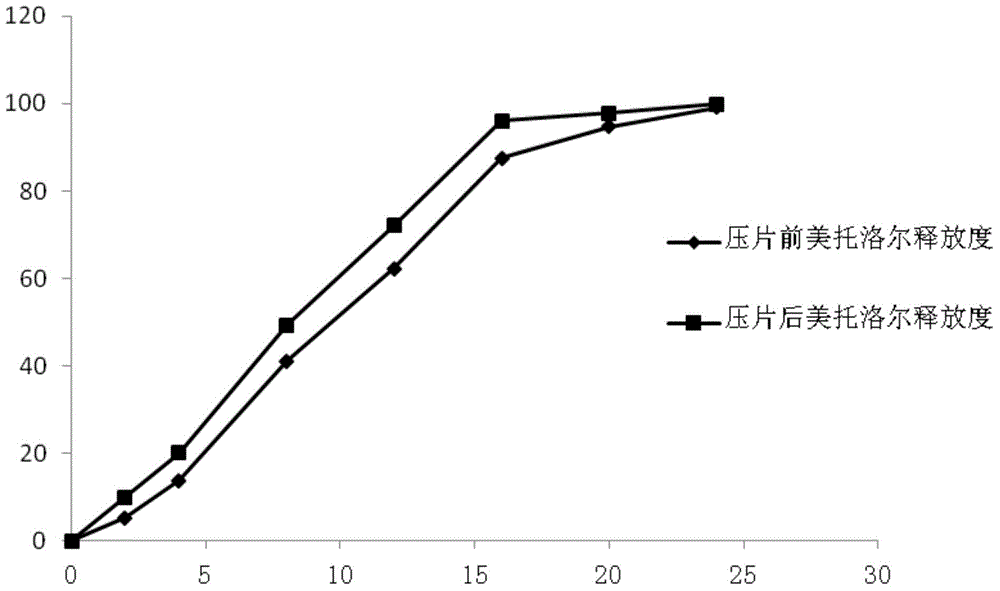

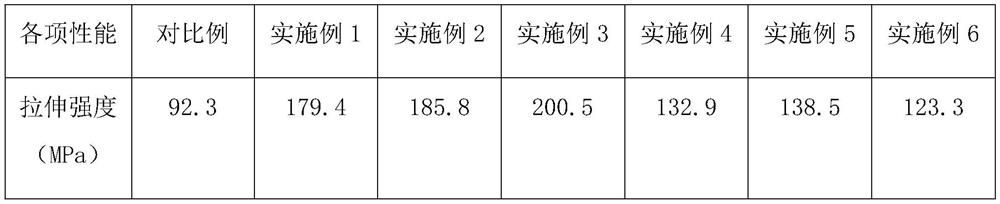

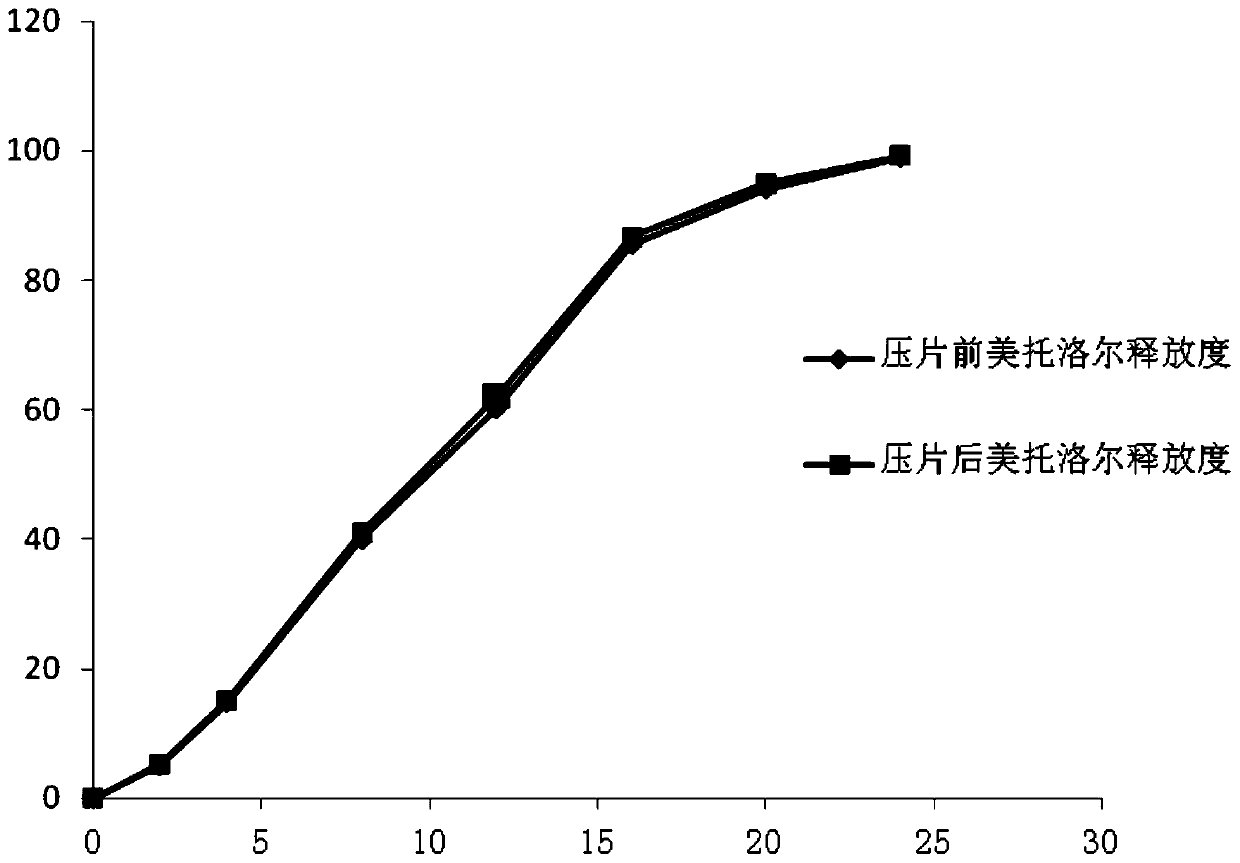

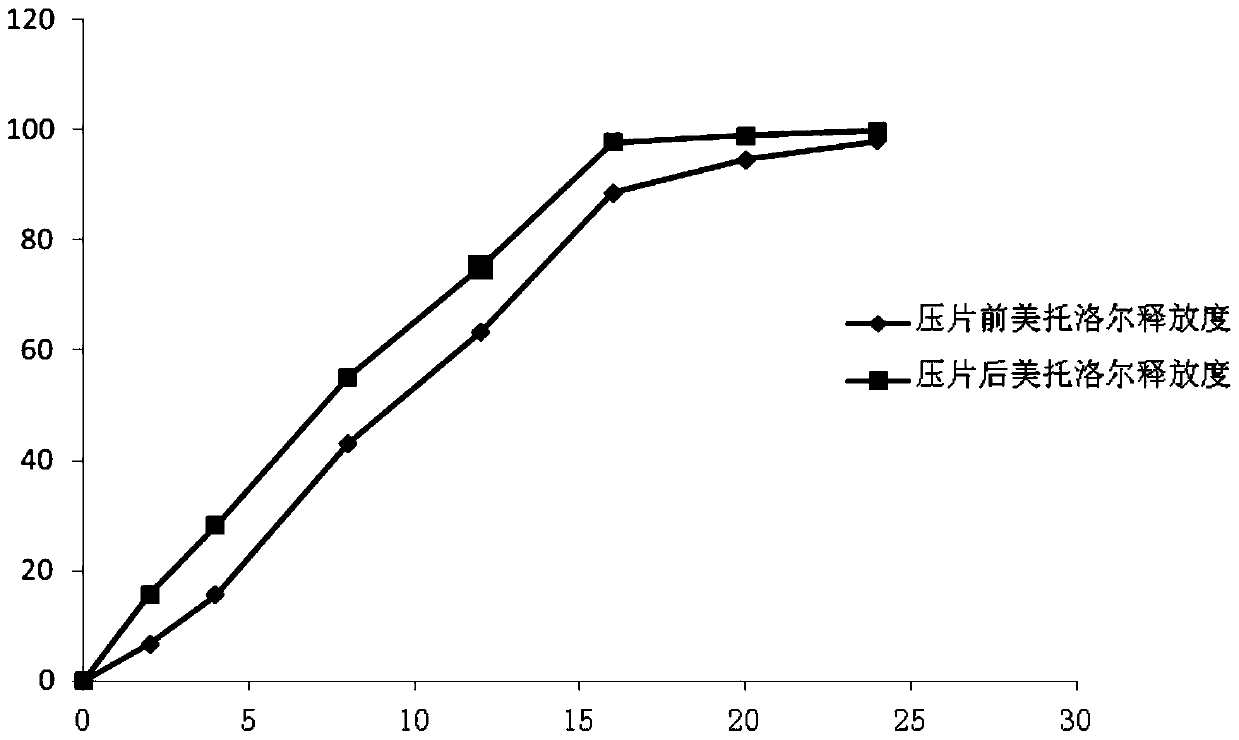

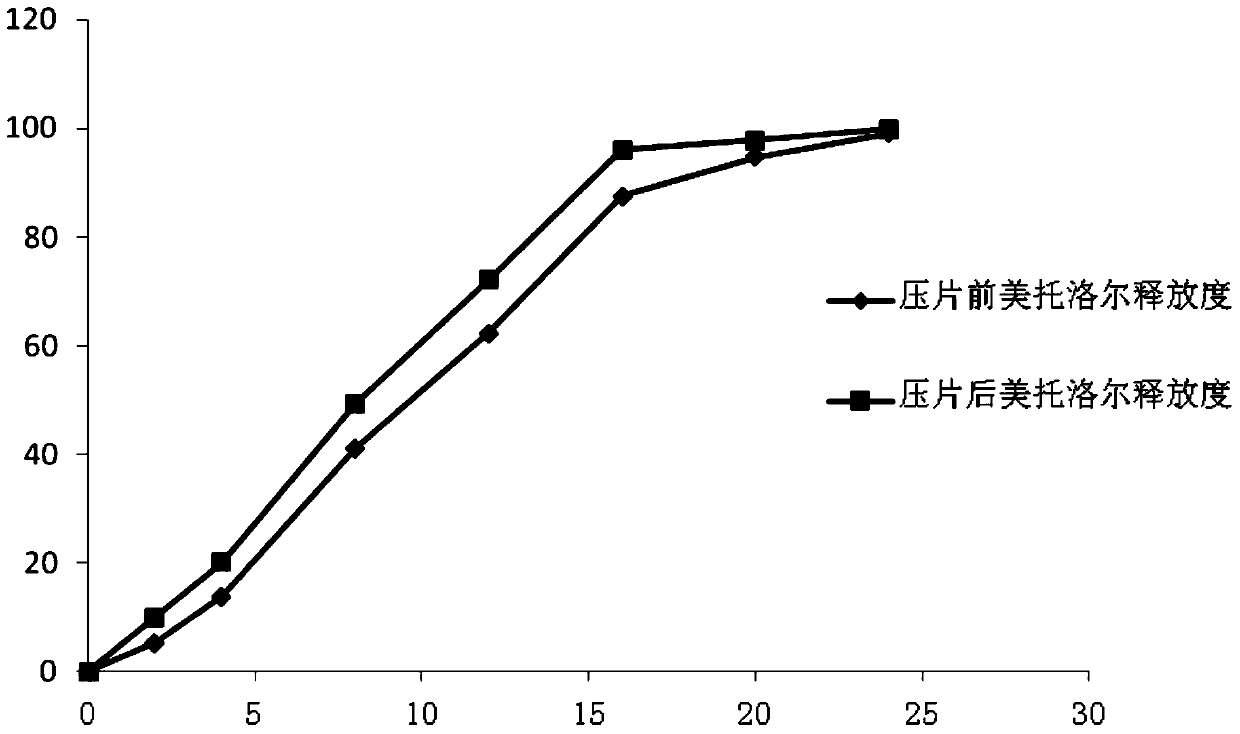

Pellet type sustained-release tablet and preparation method thereof

InactiveCN106309399AReduce the probability of ruptureGood reproducibilityOrganic active ingredientsPharmaceutical delivery mechanismPharmaceutical formulationSustained release pellets

The invention relates to the field of medicinal preparation, and especially relates to a pellet type sustained-release tablet and a preparation method thereof. The pellet type sustained-release tablet comprises metoprolol salts and felodipine. The preparation method can reduce the happening rate of rupture of the coating membrane of metroprolol succinate sustained-release pellets during the tablet compressing process; thus the release degrees of metoprolol are very similar before and after the tablet compressing; and compared with the preparations on the market, the release degree of metoprolol can be well repeated. The pellet type sustained-release tablet can simultaneously release metoprolol and felodipine for 24 hours in a sustained-release mode.

Owner:HYBIO PHARMA

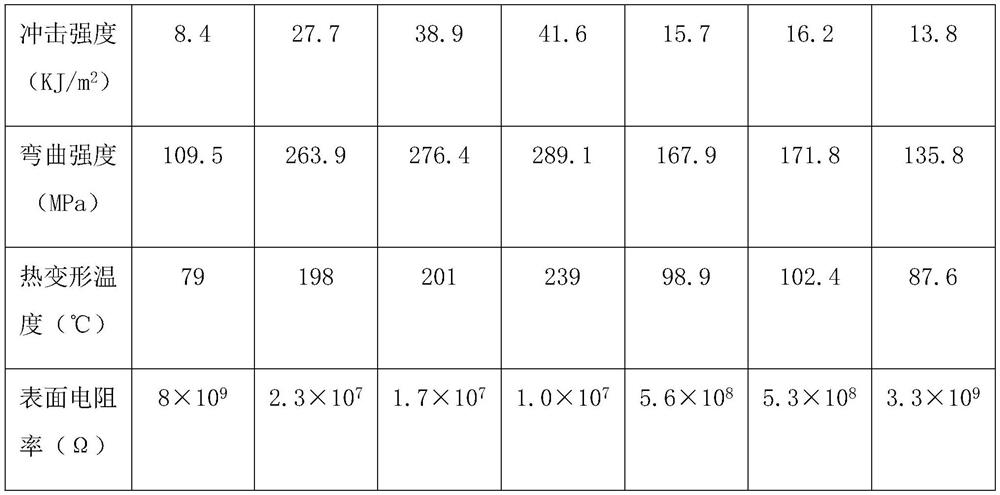

High-temperature-resistant antistatic modified polyamide and preparation method thereof

The invention discloses high-temperature-resistant antistatic modified polyamide and a preparation method thereof. The preparation method comprises the following steps: S1, uniformly mixing chlorobenzyl trichlorosilane, anhydrous toluene and anhydrous pyridine to obtain a mixed solution, and adding dried glass fibers into the mixed solution to obtain glass fibers A; s2, adding octadecyl dimethyl tertiary amine into trichloromethane, stirring and dispersing the component, and adding the glass fiber A to obtain a material A; s3, adding 3,4-vinyl dioxythiophene into the sulfonate solution, and stirring to obtain a material B; and S4, melting polyamide, sequentially adding the material A and the material B into the polyamide melt, then adding an antioxidant, a flexibilizer and water, and performing stirring and extrusive granulation to obtain the modified polyamide. The polyamide material prepared by the invention is good in mechanical property, high in thermal stability, good in antistatic property and antibacterial property, low in cost, simple in reaction principle, mild in condition, outstanding in comprehensive performance and relatively good in application prospect, and components such as an antistatic agent and a bacteriostatic agent do not need to be additionally added.

Owner:江阴市宏丰塑业有限公司

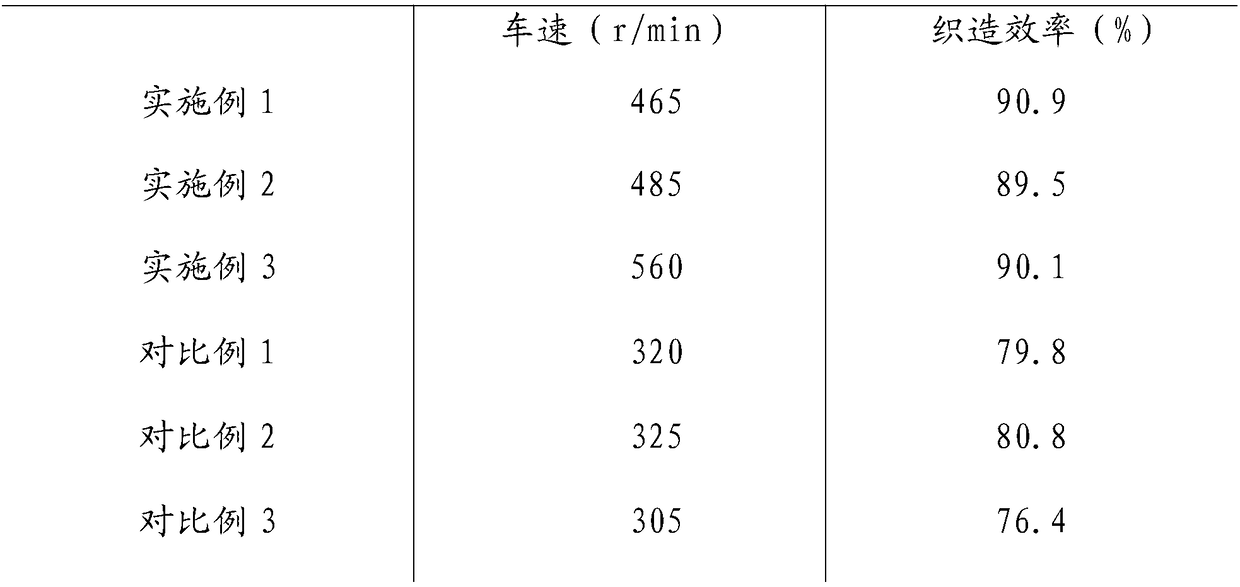

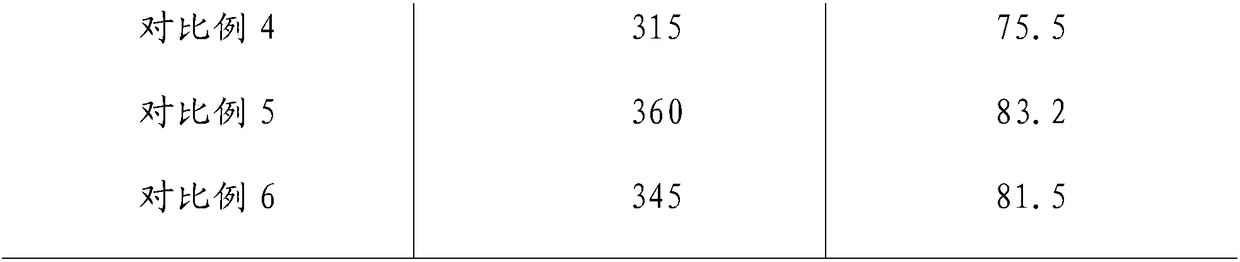

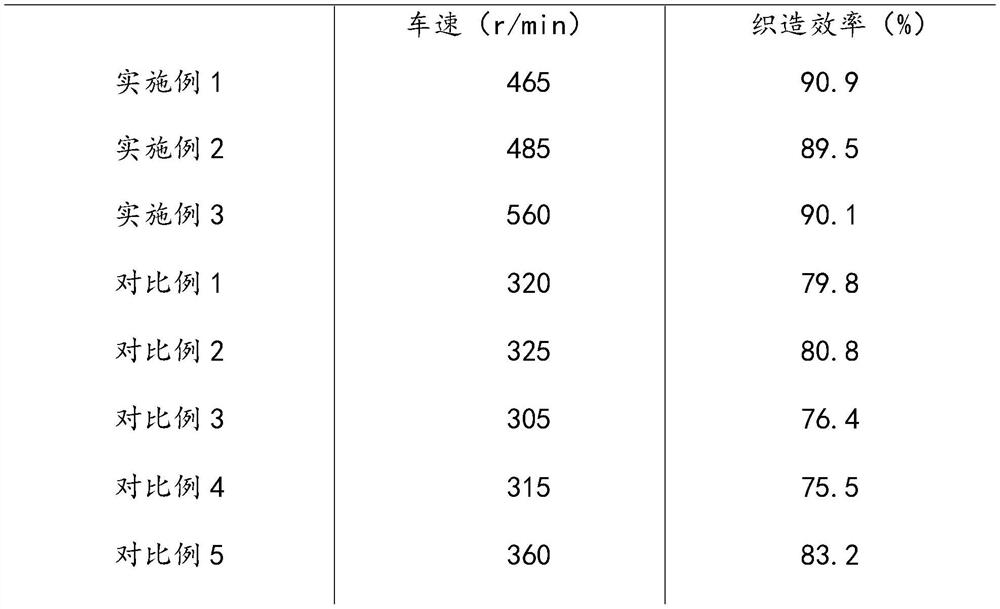

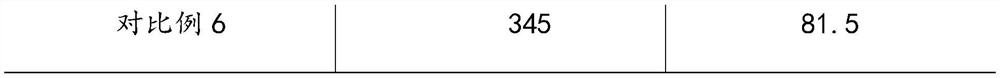

Pure cotton high count and high density compact spinning sized yarn production method

ActiveCN109457418ASolve the problem of low weaving efficiencyImproved beam quality and loom efficiencyLiquid/gas/vapor removalTextile treatment carriersHigh densityWax treatment

The invention relates to a pure cotton high count and high density compact spinning sized yarn production method. The method comprises the following steps that 1, the prepulp moisture regain of yarn is controlled to be 25-35%; 2, the yarn is subjected to sizing treatment, drying treatment and dry lease treatment in sequence, the vehicle speed of a sizing machine is 35-60 m / min, when the yarn is subjected to drying treatment, the moisture regain of the yarn is controlled to be 7-9%, the drying temperature is controlled to be 60-90 DEG C, and the yarn tension is controlled to be 350-650 N; 3, the yarn is subjected to waxing treatment and take-up treatment in sequence. According to the compact spinning sizing technology, the problem that brittle fracture is likely to occur, and then the weaving efficiency is low is effectively solved, and the warp beam quality and weaving efficiency are significantly improved.

Owner:JIHUA 3509 TEXTILE

Lightweight expanded perlite external wall heat insulation plate

The invention discloses a lightweight expanded perlite external wall heat insulation plate. The lightweight expanded perlite external wall heat insulation plate is prepared from, by weight, 100-120 parts of pretreated expanded perlite, 20-30 parts of flax fibers, 20-40 parts of aluminum oxide fibers, 10-20 parts of carbon nanotubes, 10-20 parts of gypsum powder, 8-16 parts of expanded vermiculitepowder, 8-16 parts of barite sand, 8-16 parts of coal ash, 7-10 parts of waste brick powder, 6-14 parts of calcium carbonate and 15-25 parts of basalt fibers. The pretreated expanded perlite is prepared by steps: mixing expanded perlite, xanthan gum and absolute ethyl alcohol, heating, stirring, adding hydrogen peroxide solution, stirring, adjusting a system pH value to 8.2-9, keeping the temperature, cooling, adjusting system pH to neutral, filtering, washing and drying to obtain the pretreated expanded perlite. The lightweight expanded perlite external wall heat insulation plate is low in density, effective in heat insulation and excellent in pressure resistance, and thickness is effectively reduced on the basis that strength is guaranteed.

Owner:安徽臻烁新材料技术有限公司

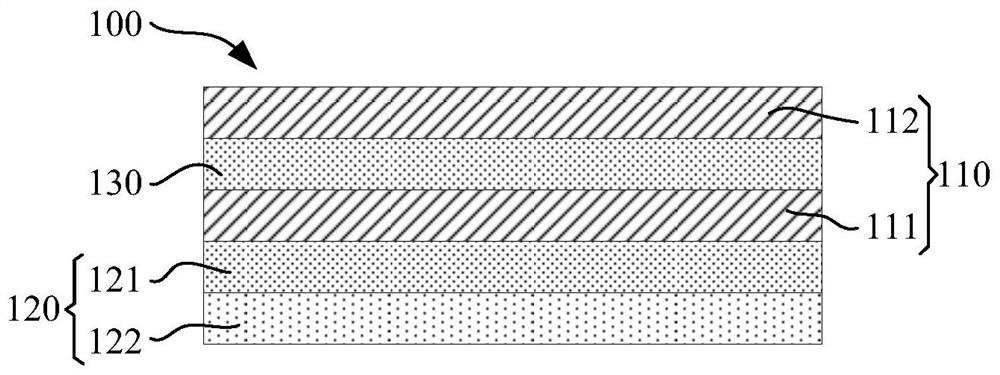

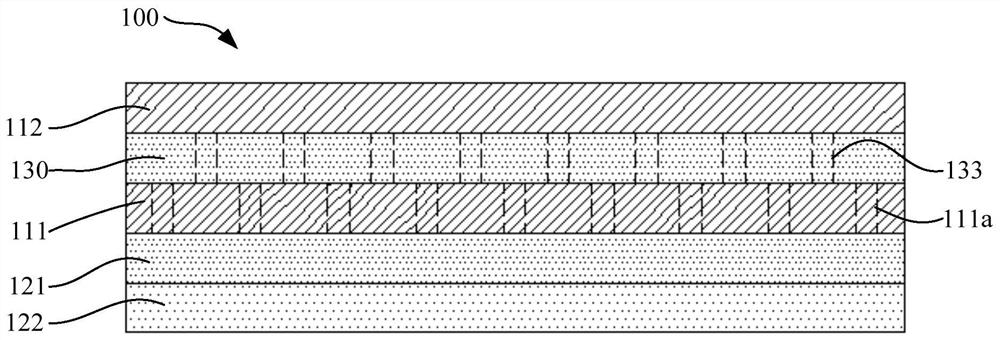

Flexible display device, organic light-emitting device and manufacturing method thereof

ActiveCN109256490BGuaranteed functional reliabilityReduce stress changesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceFlexible display

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

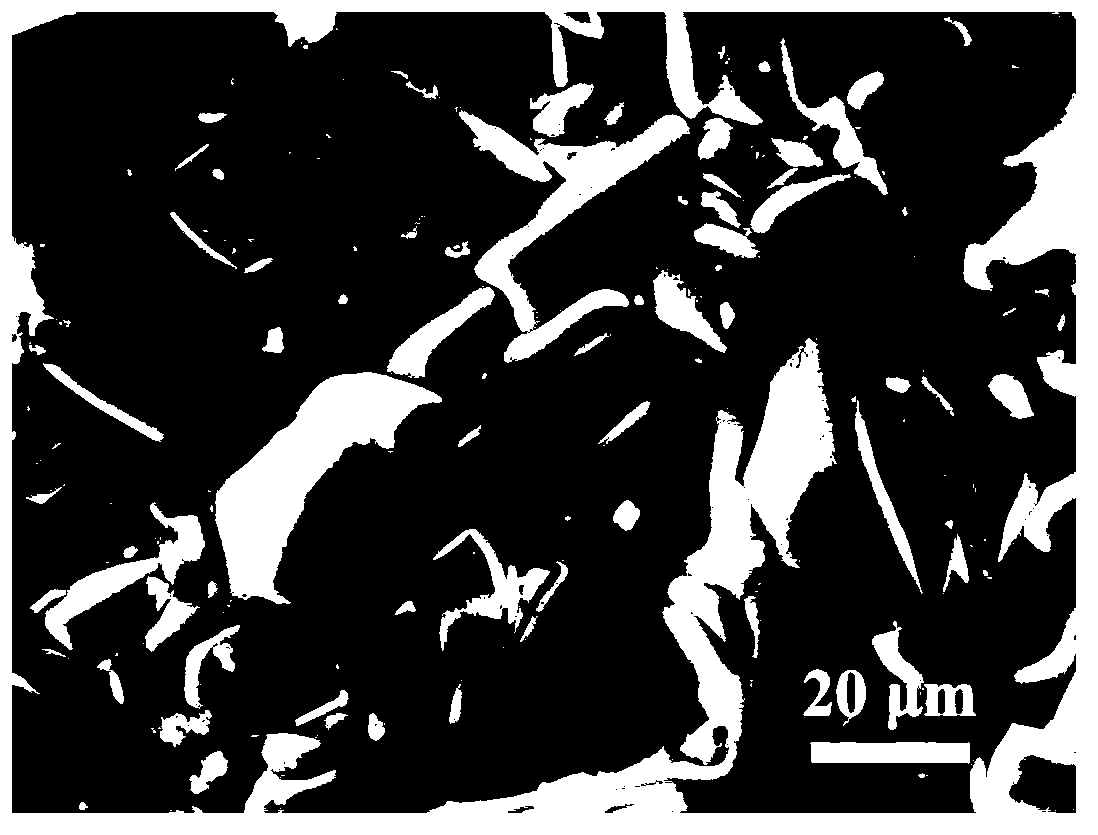

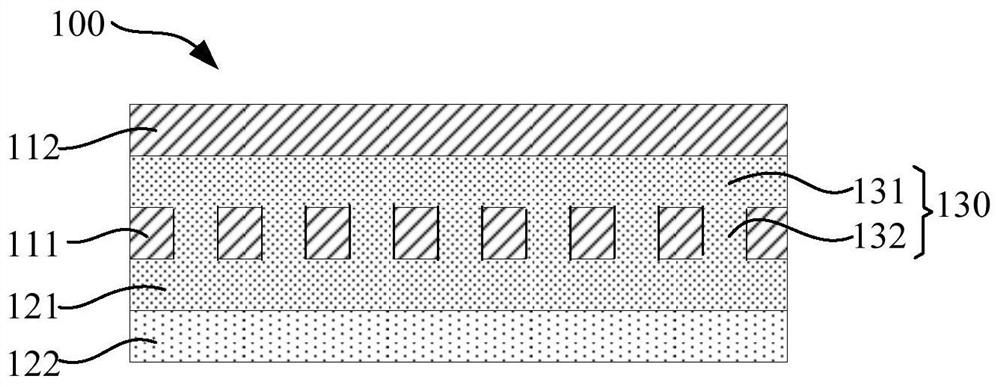

A kind of high-entropy alloy reinforced by ceramic particles and its preparation method

ActiveCN109338199BReduce decreaseImprove mechanical propertiesGrain boundary migrationHigh entropy alloys

The invention discloses a preparation method of a ceramic particle reinforced high-entropy alloy. The preparation method comprises the following steps that (1), ceramic particles and a high-entropy alloy are weighed, wherein the ceramic particles account for 0.1-0.5 wt.% of the sum of weights of high-entropy alloy powder and the ceramic particles, and the ceramic particles serve as alloy elementsto conduct ball milling with a first part of the high-entropy alloy to obtain high-entropy-ceramic alloy powder, wherein the first part of the high-entropy alloy accounts for 5-10% of the total weight; (2) the high-entropy-ceramic alloy powder and remaining high-entropy alloy powder are mixed; (3) the mixed powder is cold-pressed to be formed, and a pre-pressed part is obtained; and (4) the pre-pressed part is sintered at a high temperature, the grain boundary of the high-entropy alloy is migrated, thus the ceramic particles are wrapped, and natural cooling is conducted after sintering. The preparation method is less in consumed time and low in cost, the ceramic particles in the grain boundary of the high-entropy alloy are reduced, and thus the possibility of brittle fracture is decreased.According to the ceramic particle reinforced high-entropy alloy, the comprehensive mechanical properties of the high-entropy alloy are improved.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method and equipment of SIC fiber prepreg tape with interface layer attached

ActiveCN111058187BImprove toughnessImprove fluencyTextile treatment containersFibre treatmentFiber bundleSic fiber

The invention provides a preparation method of a SiC fiber prepreg tape with an attached interface layer. The preparation method comprises the following steps of introducing a continuous silicon carbide fiber bundle onto a tension pulley after being unwound through a godet roller and a guide wheel, sending the continuous silicon carbide fiber bundle straightly into a desizing device to expand thecontinuous silicon carbide fiber bundle; introducing the continuous silicon carbide fiber bundle onto a gluing device, so that glue fully infiltrates the continuous silicon carbide fiber, after that,introducing the continuous silicon carbide fiber bundle to a silk spreading device, and fully spreading and sizing the continuous silicon carbide fiber bundle by a drawing-in roller in the silk spreading device; and enabling the fully spread and sized continuous silicon carbide fiber bundle to enter a winding roller to obtain the flat and uniform prepreg tape. The prepreg tape prepared by the invention not only can greatly improve the toughness of the silicon carbide fiber, but also a deposited interface layer is uniform, meanwhile, the overlapped parts of two adjacent fiber bundles in the prepreg tape are few, the fiber bundle is good in flatness and thin in thickness, in addition, the preparation equipment can control parameters in real time, and full automation and complete controllability can be realized.

Owner:CENT SOUTH UNIV

Production method of waste plastic regenerated particles

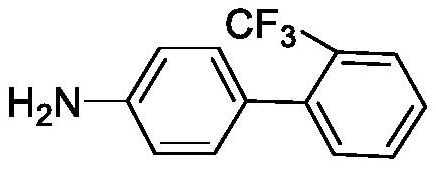

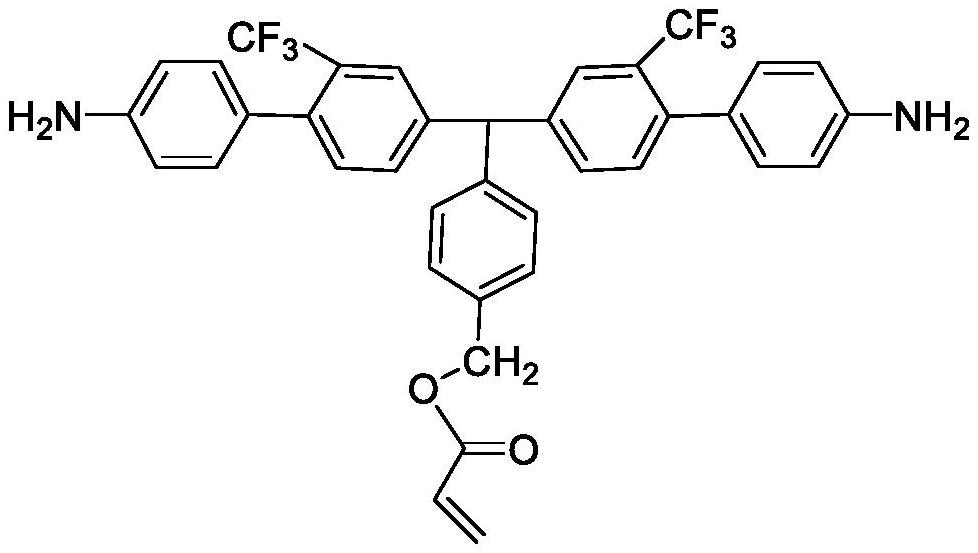

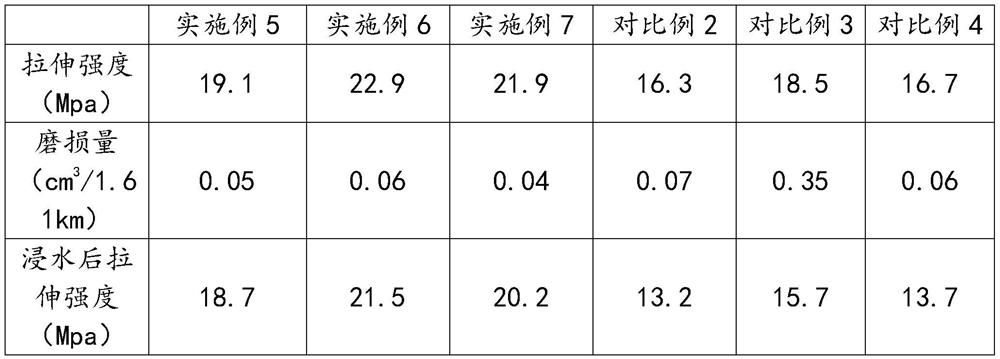

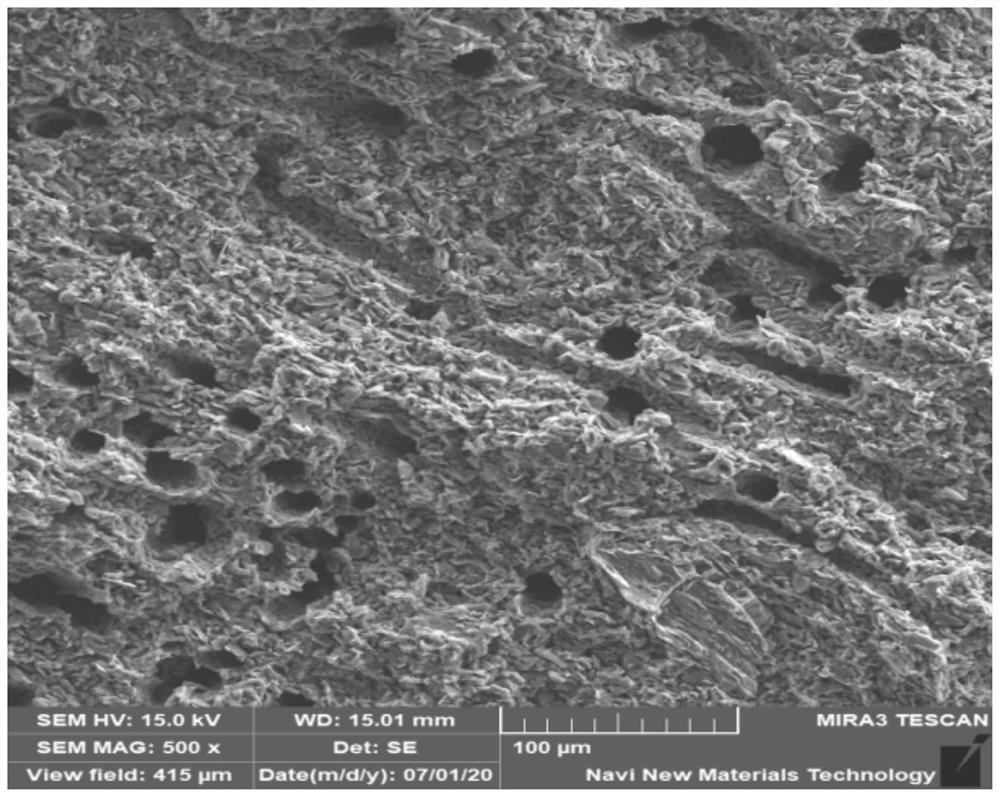

InactiveCN114085445AIncrease elasticityReduce brittle fractureAmino preparation from aminesOrganic compound preparationElastomerPolymer science

The invention relates to a production method of waste plastic regenerated particles, and belongs to the technical field of waste plastic regeneration. The production method comprises the following steps of: 1, preparing of waste plastic particles: obtaining waste plastic particles; and 2, mixing, extruding and granulating: putting the waste plastic particles, resin particles and asolubilizer into a stirrer, heating until the materials are completely molten in a stirring state, keeping the temperature for 20-35 minutes, then adding a dendritic elastomer, a light stabilizer and an antioxidant, stirring for 15-30 minutes at 110-120 DEG C, cooling to 40-60 DEG C, transferring the mixture into an extruder, and extruding and granulating to obtain waste plastic regenerated particles. The dendritic elastomer is introduced into the waste plastic particle system, so that the elasticity of the regenerated plastic is improved, the brittle fracture of the regenerated plastic is reduced, and the wear resistance of the regenerated plastic is improved.

Owner:界首市金吴再生资源利用有限公司

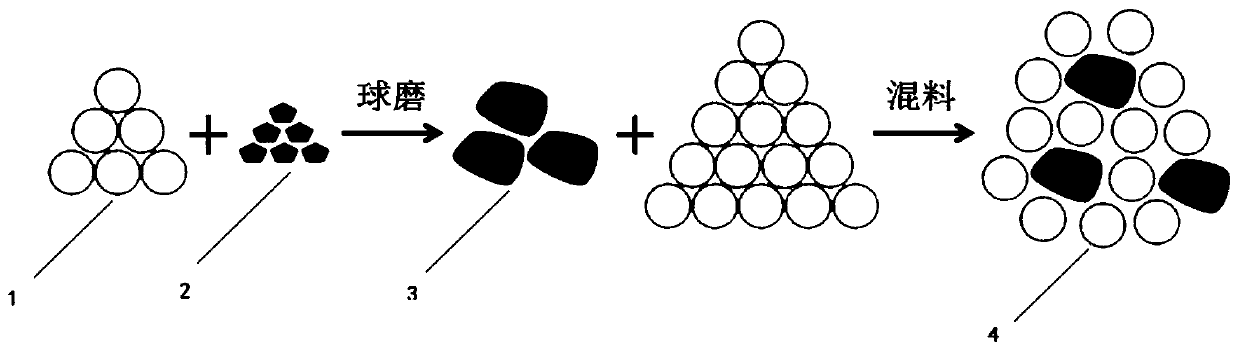

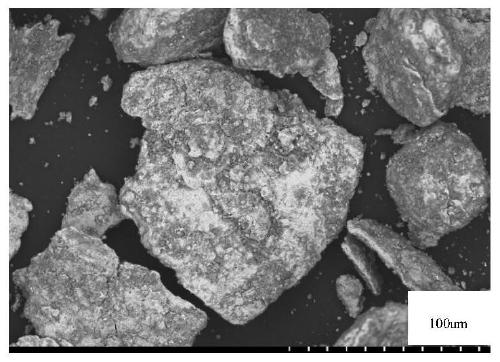

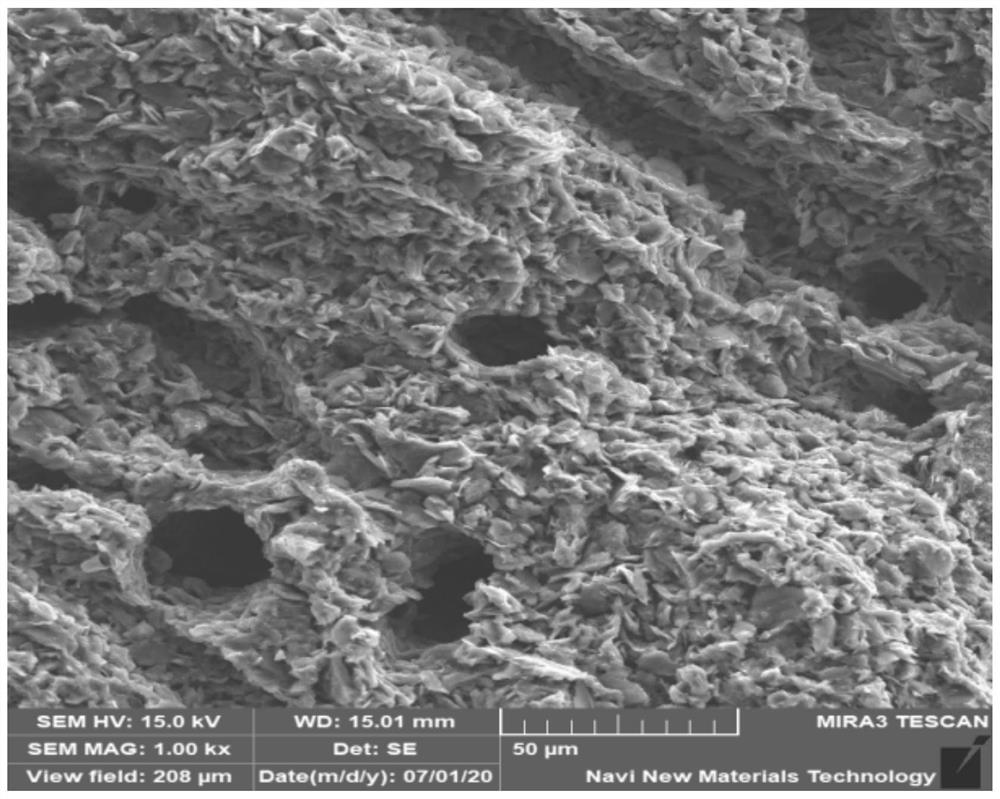

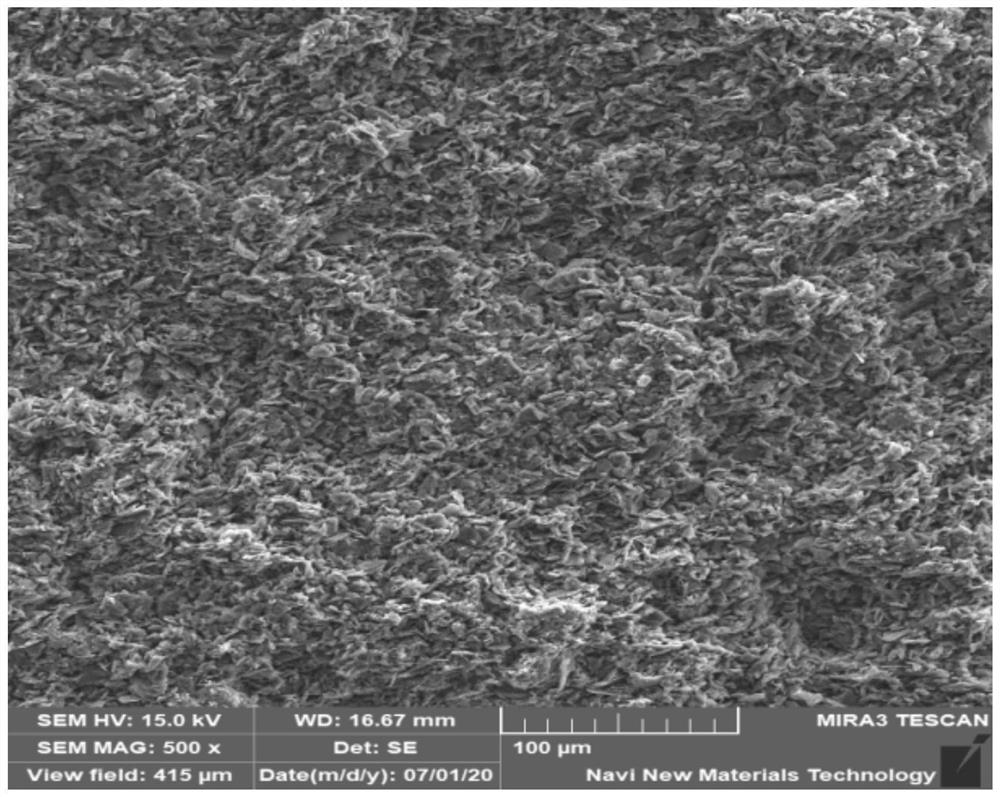

A kind of carbon graphite material and preparation method thereof

ActiveCN112028659BImprove mechanical propertiesReduce brittle fractureCeramicwareChemical industryDry mixing

The invention discloses a carbon graphite material, which has a connected hole structure. The preparation method of the carbon graphite material is as follows: put pitch coke, artificial graphite powder, and carbon black into a kneader for dry mixing and then hot mixing, then add molten modified pitch for wet mixing; then wet mix the paste The material is dried, crushed, and screened. The screened powder is evenly mixed with pitch-based pre-oxidized wire, and then shaped and roasted to obtain a carbon graphite material with a connected pore structure. The carbon graphite material of the present invention has a through-hole structure, which can realize the densification of homogeneous materials, realize the smooth introduction of functional materials, improve the comprehensive mechanical properties of the material, reduce the brittle fracture of the material, and realize the structural-functional integration of the structure; the through-hole Structured carbon graphite materials can be used in aerospace, transportation, chemical industry, mechanical energy and other fields.

Owner:HUNAN UNIV

A kind of production method of pure cotton high count and high density compact sizing yarn

ActiveCN109457418BSolve the problem of low weaving efficiencyQuality improvementLiquid/gas/vapor removalTextile treatment carriersSpinningEngineering

A production method of pure cotton high-count and high-density compact sizing yarn, comprising the following steps: controlling the pre-sizing moisture regain of the yarn to 25% to 35%; 2) sequentially performing sizing treatment and drying treatment on the yarn and dry splitting treatment, the speed of the sizing machine is 35m / min~60m / min, when the yarn is dried, the moisture regain of the yarn is controlled to be 7%~9%, and the drying temperature is 60°C~ 90°C, the tension of the yarn is 350N-650N; 3) Carrying out waxing treatment and winding treatment on the yarn in sequence. According to the compact sizing yarn process of the present invention, the problem of low weaving efficiency caused by brittle fracture is effectively solved, and the quality of the weaving shaft and the efficiency of the loom are significantly improved.

Owner:JIHUA 3509 TEXTILE

A high temperature resistant ceramic matrix composite component and its connection method

ActiveCN109485424BHigh mechanical strengthReduce brittle fractureCarbon fibersUltimate tensile strength

The invention relates to a high-temperature-resistant ceramic-based composite member and a connecting method thereof. The method comprises the following steps: (1) uniformly mixing silicon powder, chopped carbon fibers, an organic dispersing agent and a phenolic resin to obtain mixed slurry; (2) coating a joint face of a first to-be-connected prefabricated member and / or a second to-be-connected prefabricated member with the mixed slurry, and laminating and connecting the joint face of the first to-be-connected prefabricated member and the second to-be-connected prefabricated member so as to obtain a pre-connecting piece, wherein the first to-be-connected prefabricated member and / or the second to-be-connected prefabricated member are / is made from fiber preforms; (3) at least impregnating the joint of the pre-connecting piece with the mixed slurry, and sequentially curing and splitting the impregnated pre-connecting piece so as to obtain a pre-connected member; and (4) carrying out a silicon-zirconium alloy infiltration reaction on the pre-connected member, thereby obtaining the high-temperature-resistant ceramic-based composite member. The method disclosed by the invention has the advantages of being simple in process, capable of obviously enhancing the member connection strength and enabling the overall member to be high-temperature-resistant, and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of micropill type sustained-release tablet and preparation method thereof

InactiveCN106309399BReduce the probability of ruptureGood reproducibilityOrganic active ingredientsPharmaceutical delivery mechanismProlonged-release tabletPharmaceutical formulation

The invention relates to the field of medicinal preparation, and especially relates to a pellet type sustained-release tablet and a preparation method thereof. The pellet type sustained-release tablet comprises metoprolol salts and felodipine. The preparation method can reduce the happening rate of rupture of the coating membrane of metroprolol succinate sustained-release pellets during the tablet compressing process; thus the release degrees of metoprolol are very similar before and after the tablet compressing; and compared with the preparations on the market, the release degree of metoprolol can be well repeated. The pellet type sustained-release tablet can simultaneously release metoprolol and felodipine for 24 hours in a sustained-release mode.

Owner:HYBIO PHARMA

A rare earth modified particle reinforced steel-based surface space configuration composite material and its preparation method

The invention discloses a reinforced steel-based surface-layer spatial-configuration composite containing rear earth and modified particles and a preparation method thereof, and belongs to the technical field of powder metallurgy and composite preparation. The composite is composed of a reinforced body and a base body; the reinforced body is mixed powder of rear earth powder, the reinforced particles and 45 steel metal powder, and the base body is mixed powder of rear earth powder and 45 steel metal powder, wherein the rear earth powder is yttrium powder or neodymium powder; the preparation method comprises the steps that ball-milling is conducted on the reinforced body powder and the base body powder; the base body powder is put into a lower die, and corresponding holes are formed by means of upper dies in different shapes and filled with the reinforced body powder; vibration and pre-bulking are conducted, then forming is conducted by means of SPS, and finally, the reinforced steel-based surface-layer spatial-configuration composite containing the rear earth and the modified particles is obtained through heating treatment. According to the composite and the preparation method thereof, the technology is simple, the cost is low, the evenness of distribution of the reinforced particles with the spatial configuration in the base body is good, the bonding strength is high, and thecomposite has good durability and capability of impact resistance, corrosion resistance and oxidation resistance.

Owner:KUNMING UNIV OF SCI & TECH

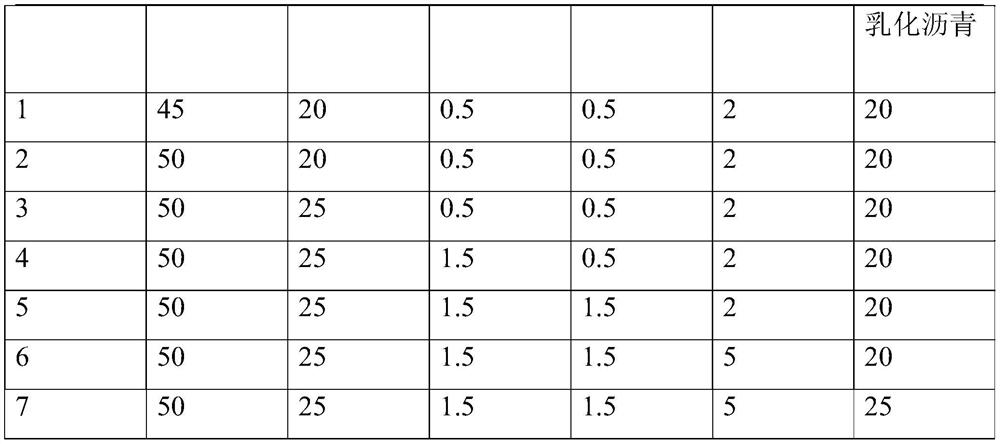

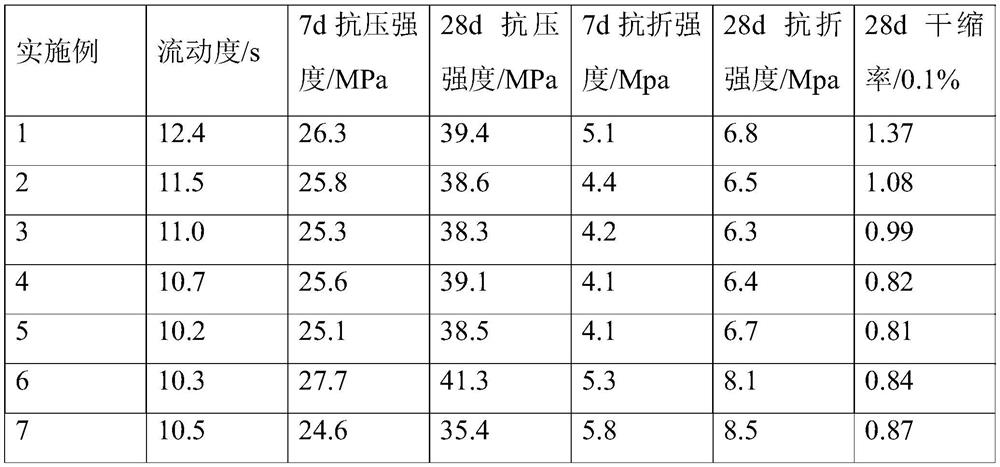

Adhesive cement material for repairing hidden spalling of asphalt pavement and preparation method of adhesive cement material

InactiveCN114180908ACounteract shrinkage stressReduce shrinkage cracksSolid waste managementAdhesive cementEpoxy

The invention discloses a mucilage material for repairing hidden spalling of an asphalt pavement and a preparation method of the mucilage material. The mucilage material comprises the following components in parts by weight: 45-50 parts of cement; 20 to 25 parts of water; 20 to 25 parts of waterborne epoxy emulsified asphalt; 2-5 parts of nano silica fume; 0.5 to 1.5 parts of an expanding agent; and 0.5-1 part of a water reducing agent. The adhesive cement material has high permeability, high bonding strength and hydrophilicity, can react with moisture in recessive spalling to generate cement gel so as to increase the bonding strength between the cement adhesive cement and a base material, has higher breaking strength, can have better deformation coordination with the base material, and can be used for preparing the cement adhesive cement. In addition, the adhesive cement material has the micro-expansion characteristic and toughness, pores of a base material can be better filled, meanwhile, brittle cracking is reduced, and finally the pavement performance and the service life of the hidden peeling position of the asphalt pavement are improved and prolonged.

Owner:中铁建公路运营有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com