A kind of carbon graphite material and preparation method thereof

A technology of carbon graphite and artificial graphite powder, which is applied in the field of carbon graphite material with interconnected pore structure and its preparation, can solve the problems of impregnation reinforcement limitation, etc., so as to reduce crack defects, improve structural integrity, and reduce material brittle fracture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

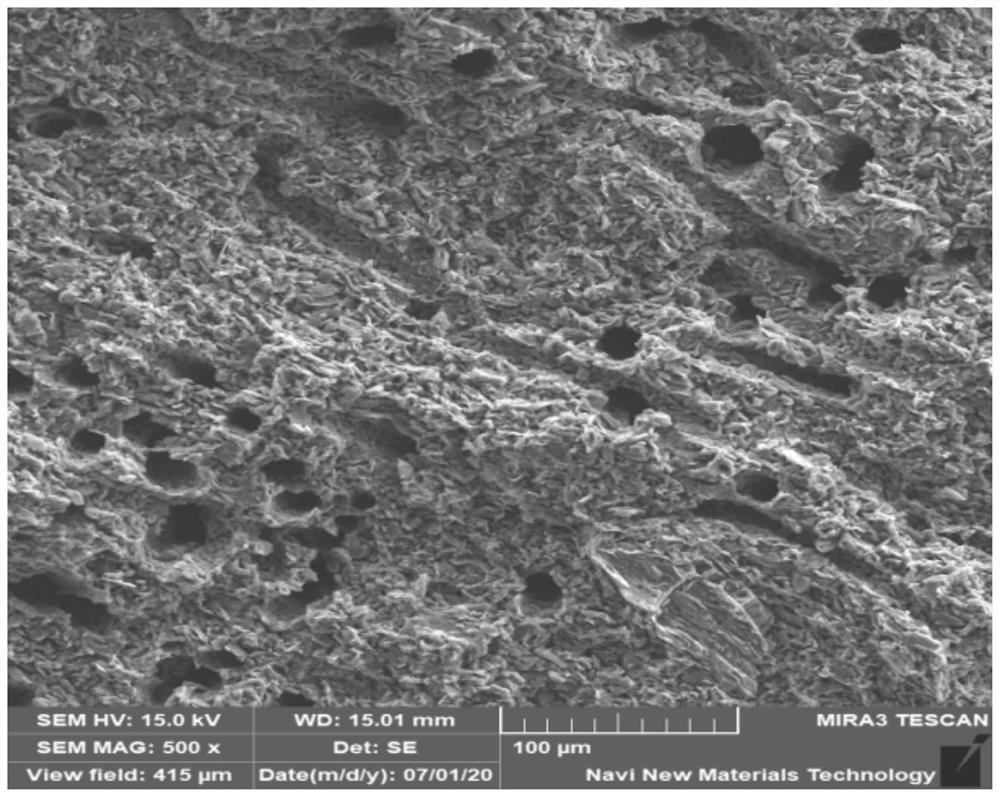

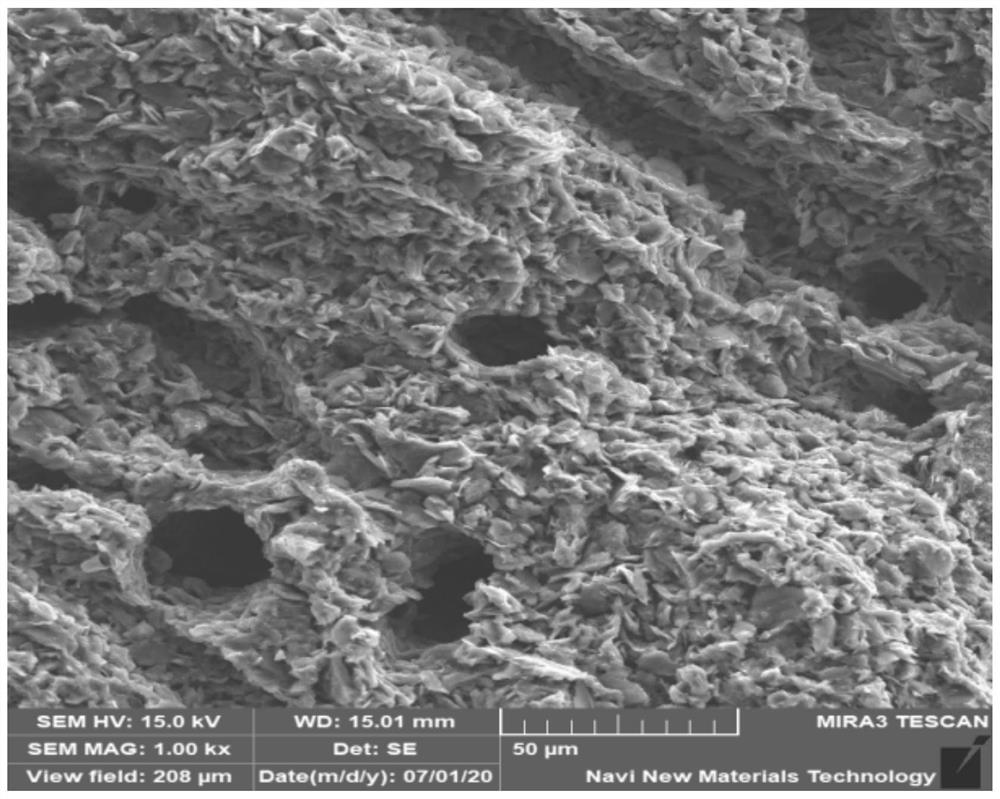

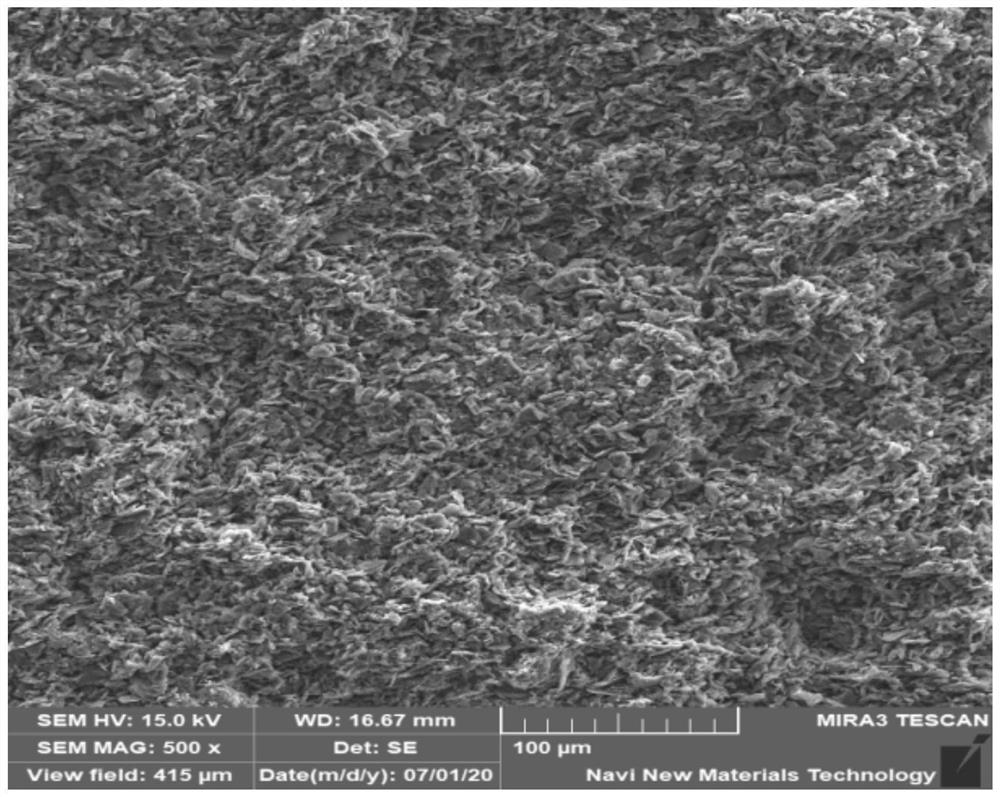

[0028] A carbon-graphite material of the present invention has a through-hole structure; the carbon-graphite material is mainly made of the following component raw materials in parts by mass: 65 parts of pitch coke, 25 parts of artificial graphite powder, 10 parts of carbon black, a small amount of bonding modified pitch and pore-forming agent pitch-based pre-oxidized wire, wherein the amount of modified pitch accounted for 70wt% of the total mass of pitch coke, artificial graphite powder and carbon black; the added amount of pitch-based pre-oxidized wire accounted for pitch coke, 5wt% of the total mass of artificial graphite powder and carbon black.

[0029] The preparation method of the carbon graphite material of the present embodiment comprises the following steps:

[0030] (1) Put pitch coke, artificial graphite powder, and carbon black into a kneader for dry mixing for 1 hour, then raise the temperature of the kneader to 120°C for hot mixing for 1 hour, and then add molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com