Copper-silicon alloy material, electroslag remelting preparation method thereof and copper-silicon alloy wire material

A technology of copper-silicon alloy and electroslag remelting, which is applied in the field of preparation of copper-silicon alloy wire, copper-silicon alloy material and its electroslag remelting, can solve the problem of affecting the quality and application field of heating cables, unstable resistivity, resistance Poor foldability and other problems, to achieve the effect of less brittle fracture, stable resistivity, and good stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

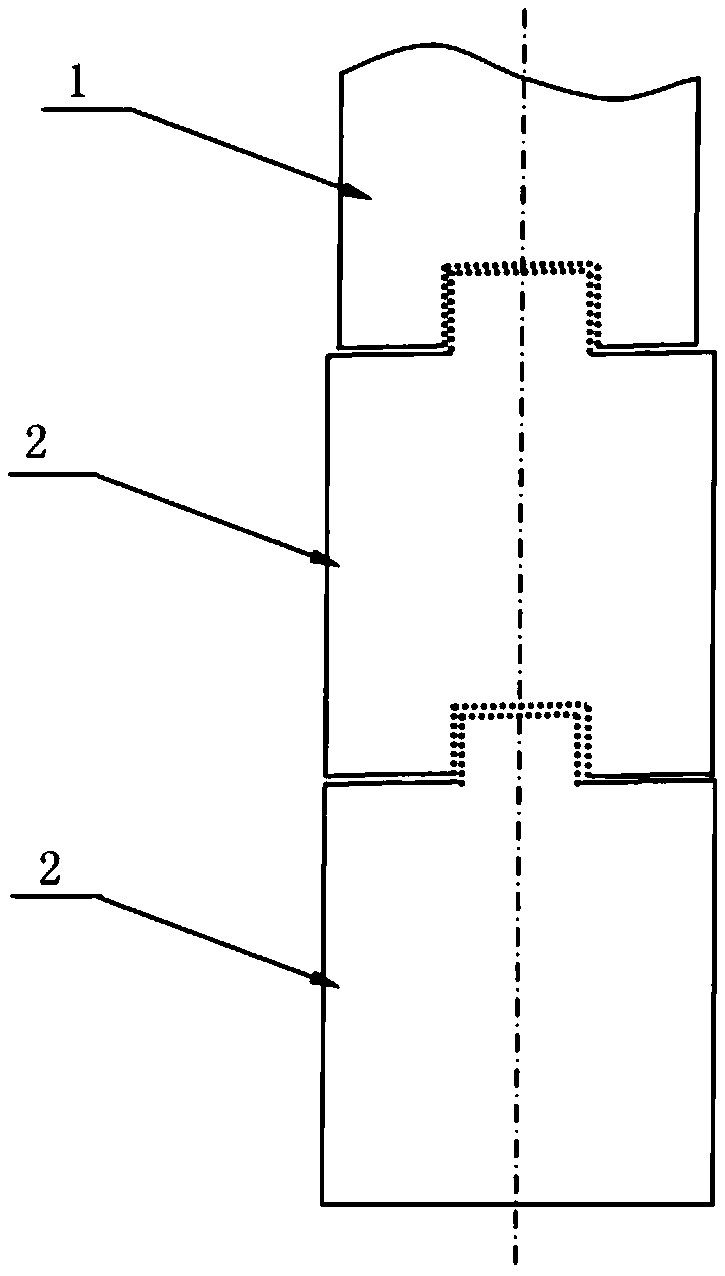

[0057] In this embodiment, the process of preparing a high-performance copper-silicon alloy material by electroslag remelting is as follows:

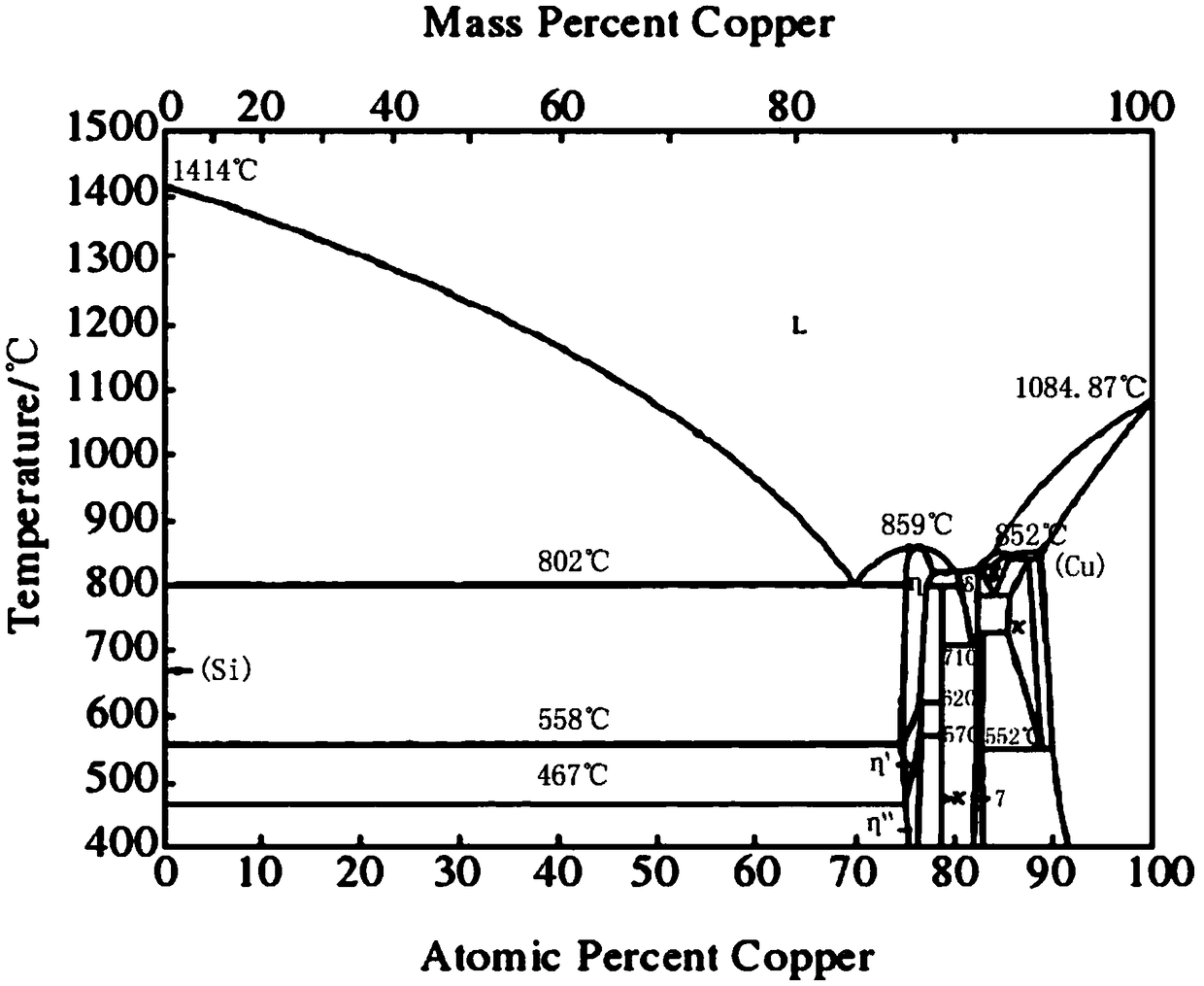

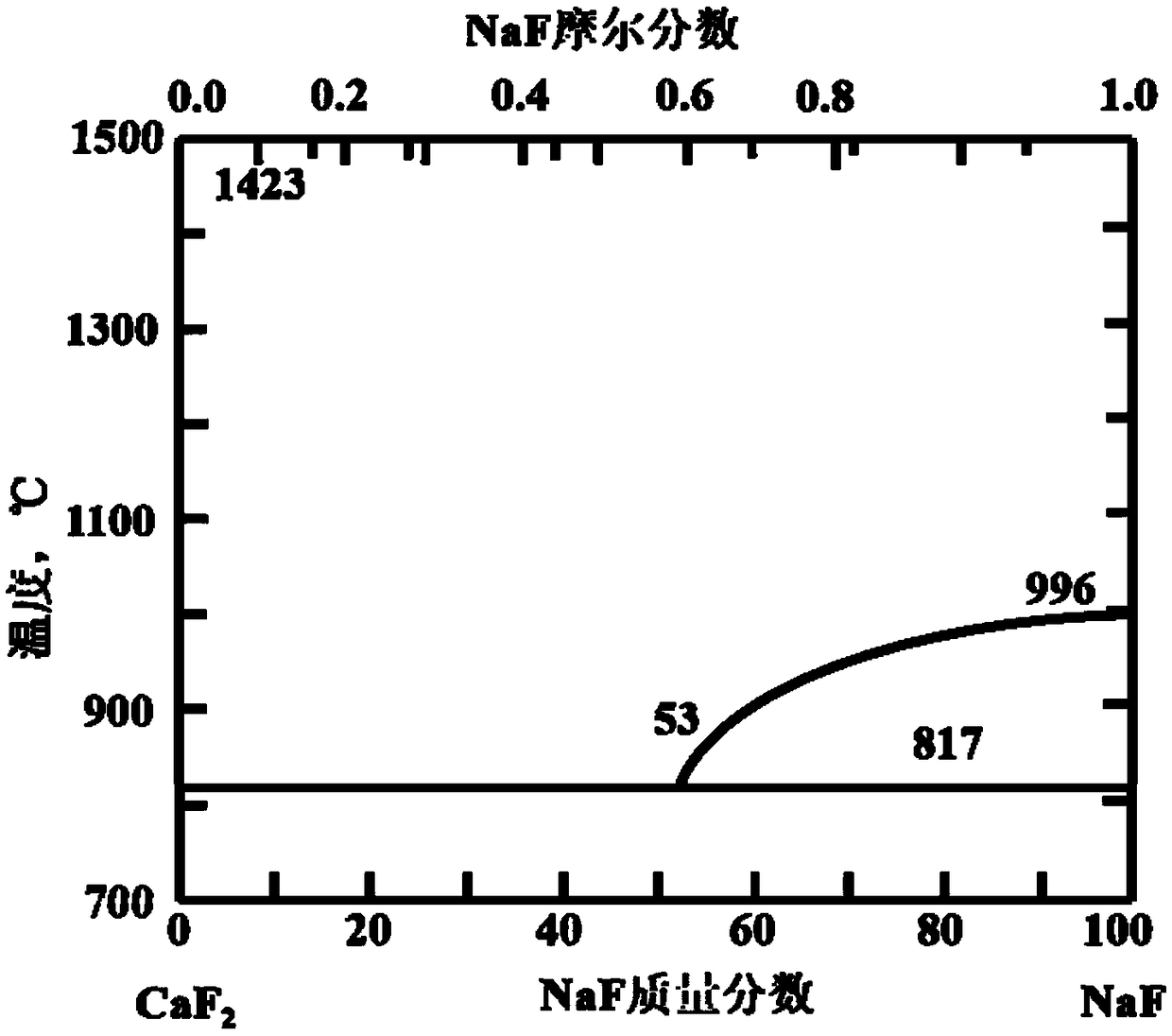

[0058] (1) The chemical composition is (wt%): Si=2.1%, Mn=0.82%, Ni=0.23%, Ag=0.1%; Mg=0.1%, Al=0.1%, and the balance is copper-silicon mother of Cu Alloy ingots are used as raw materials; the ratio of slag system is: the mass percentage of high-purity NaF is 26%, and the balance is fluorite. The NaF content in high-purity NaF is greater than 98%, and the SiO2 content is less than 0.5%. The mass percentage of CaF2 in the fluorite is not less than 98.5% and the mass percentage of silicon dioxide is less than 1%. The prepared copper-iron alloy electroslag remelted ingot has a smooth surface after removing the surface slag crust.

[0059] (2) After the alloy ingot prepared by electroslag remelting is turned, it is rolled and drawn to make a Φ1.5mm wire.

[0060] (3) The wire material of Φ1.5mm is annealed at 620~650℃, and can be drawn in...

Embodiment 2

[0067] In this embodiment, the process of preparing a high-performance copper-silicon alloy material by electroslag remelting is as follows:

[0068] (1) Adopt chemical composition as (wt%): Si=2.42%, Mn=0.90%, Ni=0.25%%, Ag=0.1%; Mg=0.1%; Al=0.1%; Surplus is the silicon bronze of Cu The master alloy ingot is used as the raw material; the ratio of the slag system is: the mass percentage of high-purity NaF is 27%, and the balance is fluorite. The NaF content in high-purity NaF is greater than 98%, and the SiO2 content is less than 0.5%. The mass percentage of CaF2 in the fluorite is not less than 98.5% and the mass percentage of silicon dioxide is less than 1%. The prepared copper-iron alloy electroslag remelted ingot has a smooth surface after removing the surface slag crust.

[0069] (2) After the alloy ingot prepared by electroslag remelting is turned, it is made into a Φ1.5mm wire through a specific rolling and wire drawing process.

[0070] (3) The wire material of Φ1.5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com