Adhesive cement material for repairing hidden spalling of asphalt pavement and preparation method of adhesive cement material

An asphalt pavement, invisible technology, used in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of long time required, low strength, poor bond strength, etc., to improve the hydration reaction and hydration rate, improving strength and interfacial bond strength, promoting the formation of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

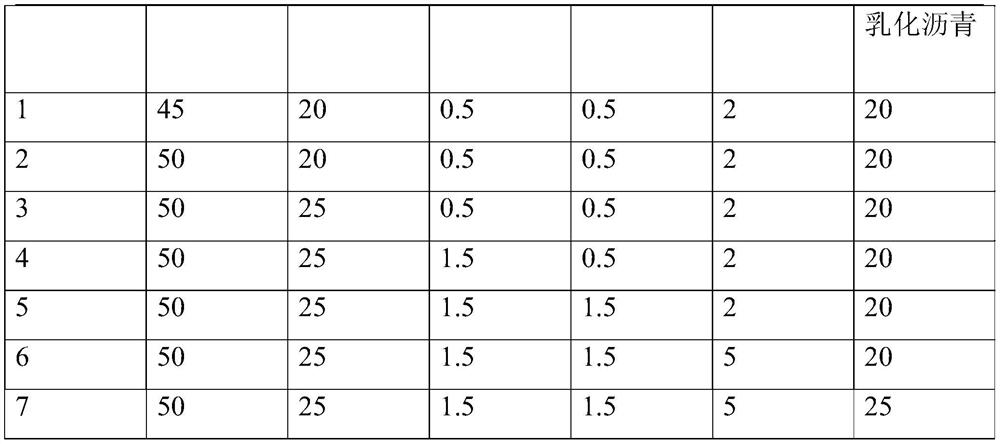

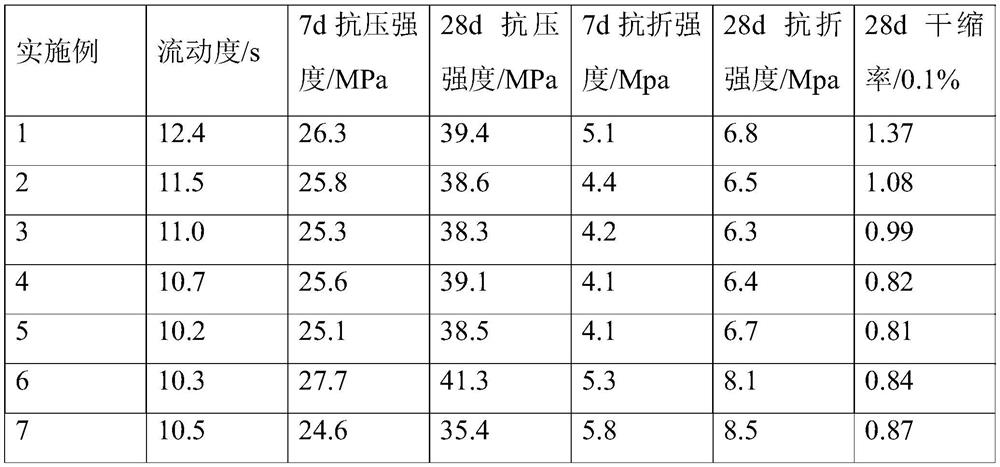

[0032] A kind of mortar material with high permeability and high toughness for repairing the hidden spalling of asphalt pavement. The proportioning ratio of each component material is shown in Table 1. The solid components such as agent and nano-silica fume are put into the mixing pot in turn for 1-2 minutes until they are evenly stirred, then add 2 / 3 of the water, stir for 2 minutes, add water reducing agent, stir for 1 minute, and finally add water-based ring Oxygen-emulsified asphalt and the remaining water continue to stir for 2 minutes; a well-mixed cement-nanometer silica fume-water-based epoxy emulsified asphalt composite cementing material is obtained, that is, a high-permeability, high-toughness mortar material for asphalt pavement hidden spalling repair .

[0033] Table 1 is the weight proportion of each component raw material in a kind of high permeability and high toughness mortar material for repairing hidden spalling of asphalt pavement described in Examples 1-7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com