Method for maintaining quartz boat

A quartz boat and deposition process technology, used in coatings, gaseous chemical plating, semiconductor devices, etc., can solve problems such as reducing the life of the quartz boat, reduce the probability of cracks or fractures, avoid stress conditions, and reduce stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present disclosure will be described in detail below. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present disclosure, but not to limit the present disclosure.

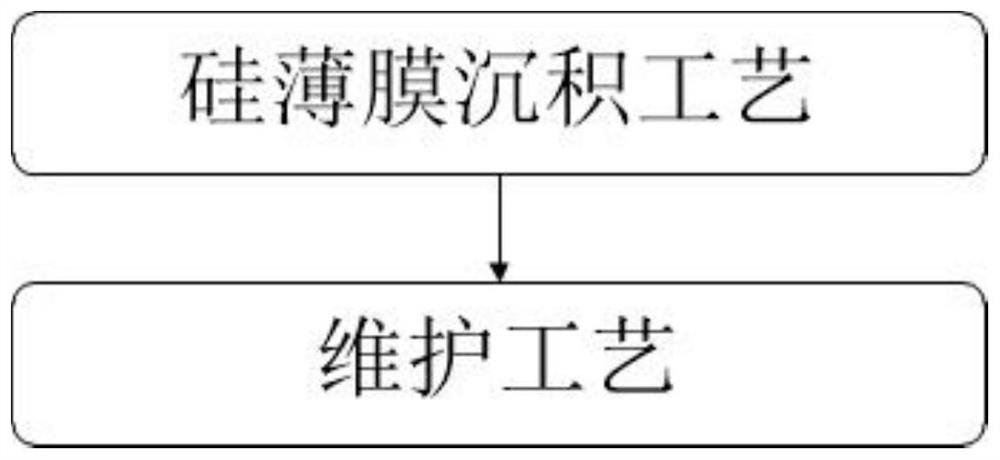

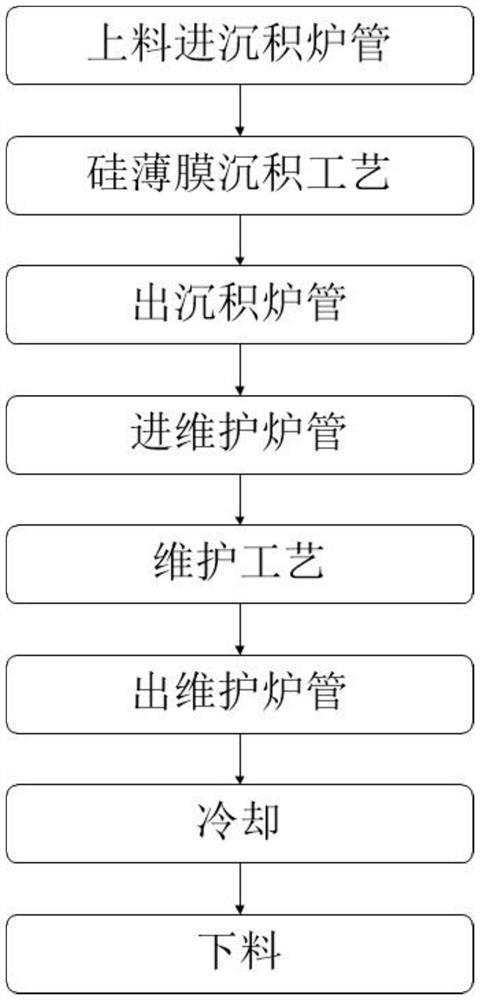

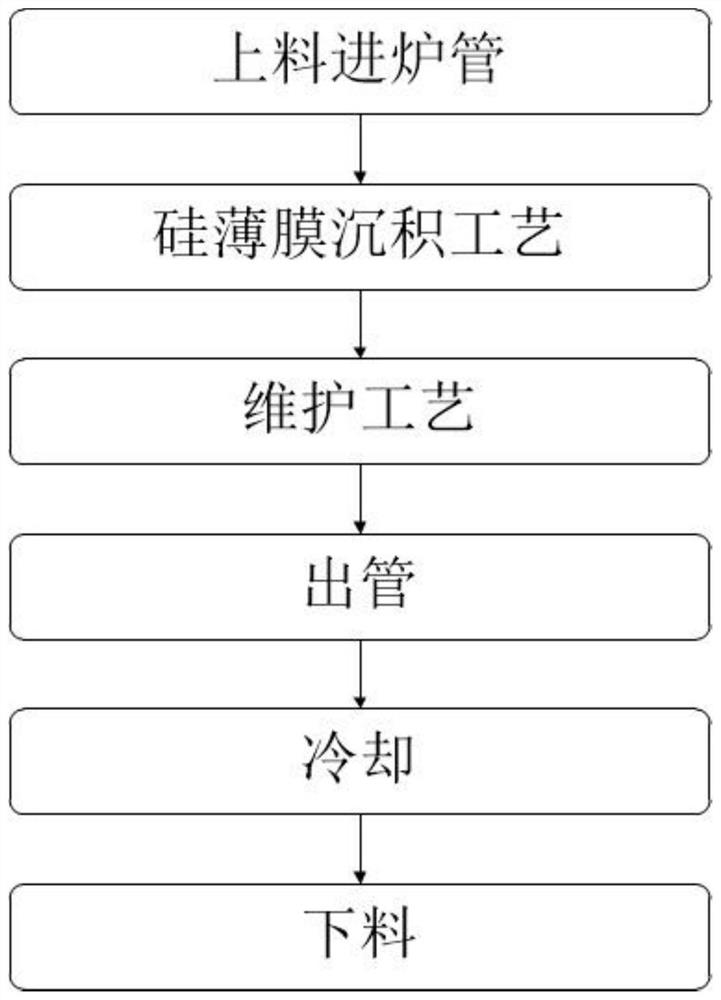

[0024] The present disclosure provides a method for maintaining a quartz boat, the method comprising:

[0025] The quartz boat loaded with the parts to be plated is subjected to the deposition process of the silicon film on the surface of the parts to be plated. Under the condition that the temperature of the quartz boat after the deposition process does not drop to room temperature, the The maintenance process of the quartz boat is carried out, and the maintenance process includes high temperature oxidation treatment.

[0026] In the present disclosure, the surface silicon in the silicon film deposited on the surface of the quartz boat is oxidized into silicon oxide by adding maintenance steps after the silicon f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com