Patents

Literature

169results about How to "Reduce shrinkage cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

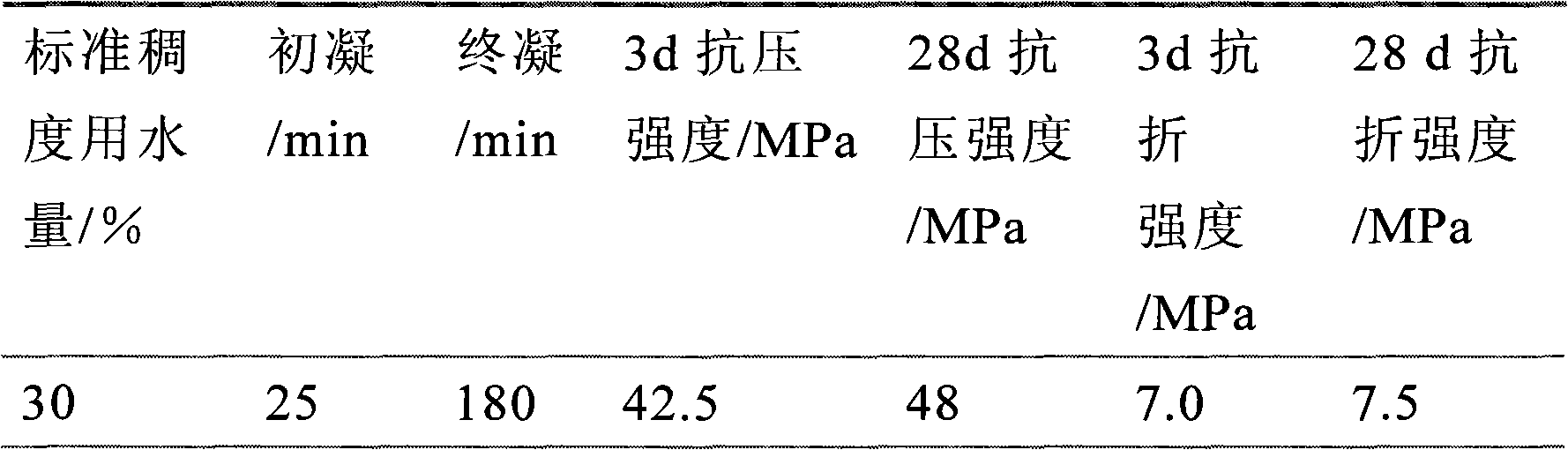

Environment-friendly colorful tile joint mixture and preparation method thereof

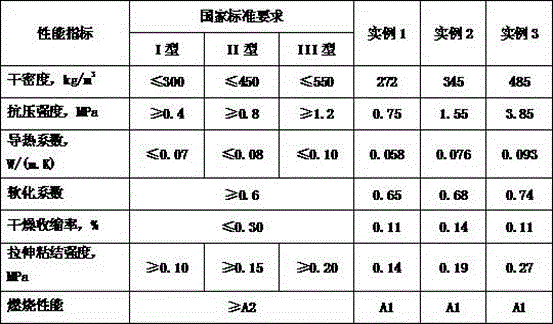

ActiveCN103172330AReduce consumptionImprove early strengthSolid waste managementEmulsionShrinkage coefficient

The invention discloses an environment-friendly colorful tile joint mixture. The environment-friendly colorful tile joint mixture is characterized by comprising the following components in percentage by weight: 35%-40% of white cement, 40.73%-47.75% of waste porcelain powder, 0-15% of quartz powder, 0-10% of titanium dioxide, 1%-1.5% of re-dispersible emulsion powder, 0.1% of water repellent, 0.15% of water-retaining agent, 0.4% of lignin fiber, 0.1%-0.25% of water reducing agent and 0-2% of pigment. The invention further discloses a preparation method of the environment-friendly colorful tile joint mixture. The consumption of quartz sand and heavy calcium powder is reduced by using the waste porcelain powder as the joint mixture filler; the early strength of the joint mixture is improved by virtue of early strength function of the white cement, so that the construction process requirements are satisfied. The waste porcelain powder is sintered at a high temperature, so that the physical and chemical performances are stable, the volume is stable, and the expansion-shrinkage coefficient is close to that of the tile; the material with the same expansion-shrinkage coefficient is used as the filler, so that the possibility that the tile joint mixture generates cracks can be further reduced.

Owner:厦门路桥翔通股份有限公司

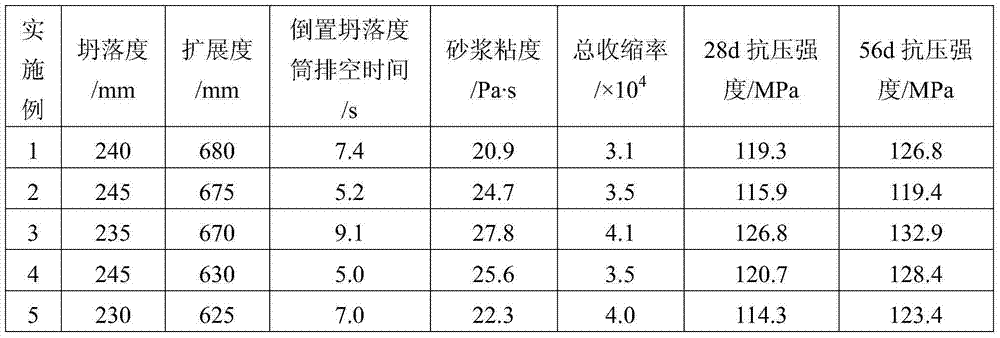

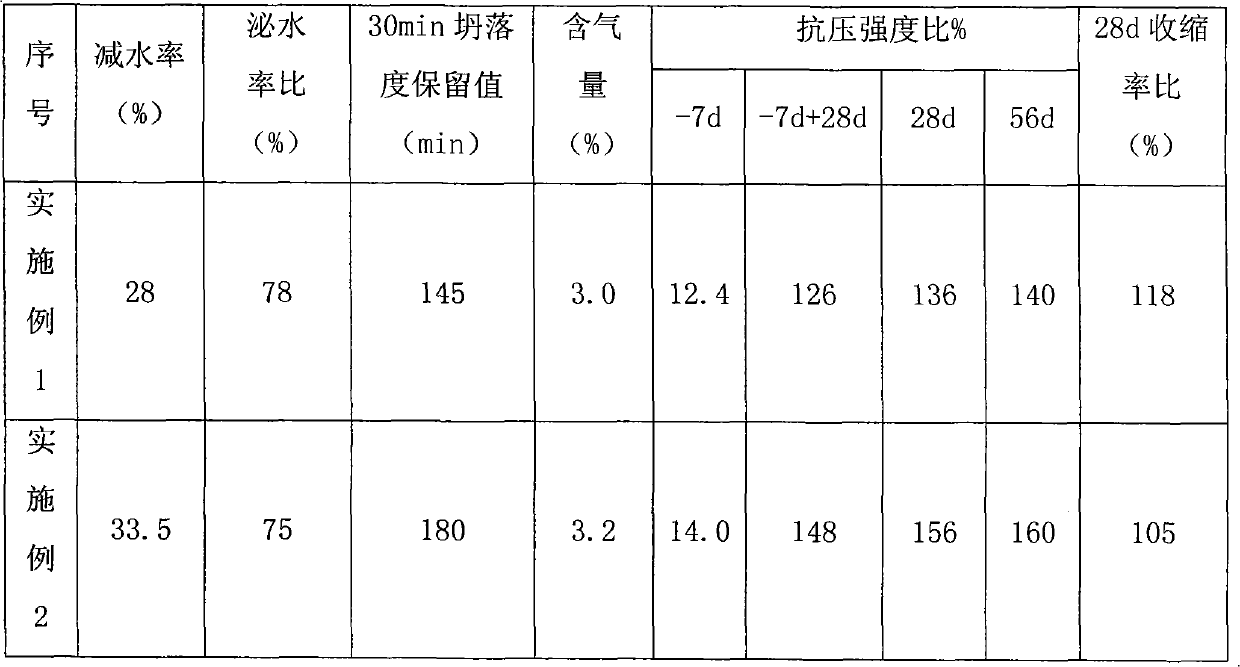

Low-shrinkage, low-viscosity and ultrahigh strength concrete

ActiveCN104844099AReduce hydration temperature riseReduce shrinkage cracksSolid waste managementWork performanceMicrosphere

The invention belongs to the technical field of building materials and particularly relates to low-shrinkage, low-viscosity and ultrahigh strength concrete. Based on a single formula proportional dosage, the low-shrinkage, low-viscosity and ultrahigh strength concrete comprises the following components by weight: 250-300kg of cement, 120-180kg of microspheres, 90-120kg of mineral powder, 820-860kg of machine-made sand, 950-1000kg of gravels, 7-11kg of a water reducer and 115-125kg of water. The components are mixed with stirring for 1.5-2 minutes to obtain a concrete mixture. The concrete provided by the invention is less in binding material use, the total shrinkage percentage is less than (0.03-0.04per mill), the emptying time of an inverted slump cone is 5-10 seconds, the viscosity of mortar in same proportion is 20-28 Mp.s, the 28d compressive strength is 110-130MPa, and the 56d compressive strength is 120-135MPa. The concrete has the characteristics of being low in bonding material use, short in stirring time, excellent in working performance and low in comprehensive cost, and can be produced on a large scale and has a broad application prospect.

Owner:中建商品混凝土(福建)有限公司 +1

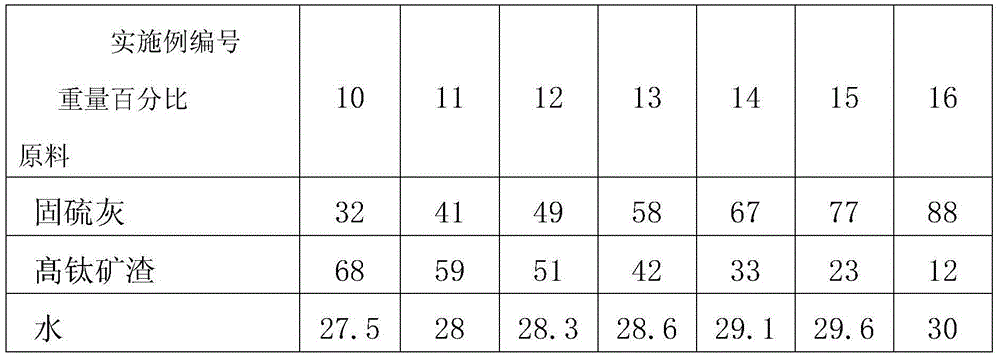

Fluidized bed combustion ash and high titanium slag compounded stable pavement base material

ActiveCN104003638AElicit activityHigh strengthSolid waste managementNatural resourceRoad engineering

The invention discloses a fluidized bed combustion ash and high titanium slag compounded stable pavement base material. The fluidized bed combustion ash and high titanium slag compounded stable pavement base material is formed by mixing 30-90wt% of fluidized bed combustion ash with 10-70wt% of high titanium slag. The fluidized bed combustion ash, the high titanium slag and water are stirred and mixed, and the obtained mixture is molded and maintained to make a fluidized bed combustion ash and high titanium slag compounded stable pavement base. The compounded stable pavement base material completely utilizes difficult-treatment and high-discharge-amount industrial wastes comprising the fluidized bed combustion ash and the high titanium slag, contains no lime or fly ash, and has better performances than traditional lime-fly ash stable pavement base material; and the compounded stable pavement base material has the advantages of low cost, no consumption of natural resources, simple and easy preparation method, suitableness for being used in areas short of traditional road engineering materials, substantial economic benefit, wide market prospect and strong practicality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

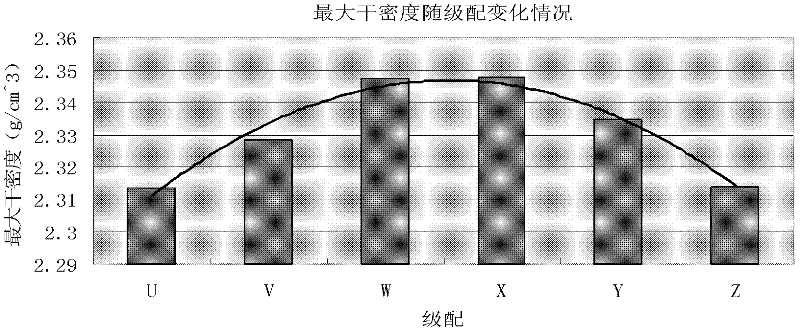

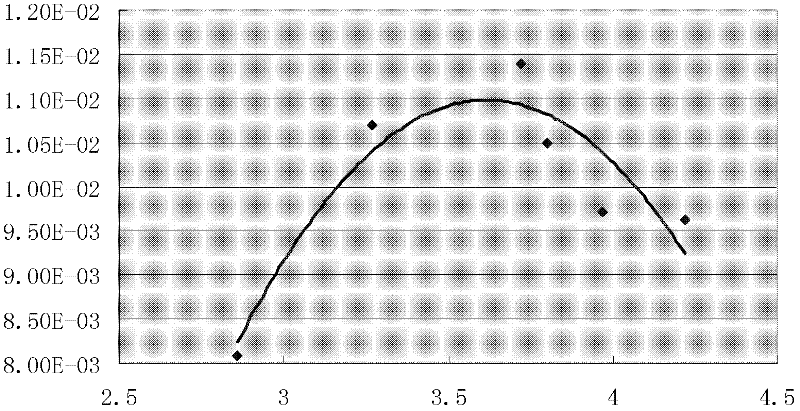

High-intensity low-crack cement-stabilized graded macadam and preparation method thereof

The invention relates to high-intensity low-crack cement-stabilized graded macadam and a preparation method thereof, belonging to the field of highway engineering design. The mineral aggregate gradation of the high-intensity low-crack cement-stabilized graded macadam is 5-6 grade, wherein the 4.75mm pass ratio is 35-40%, and the crushing value of large-particle macadam is lower than 22%. By adopting the above technical scheme, the invention has the following beneficial effects: (1) the 7d unconfined compressive strength of the cement-stabilized graded macadam is increased to 6-8MPa; and (2) the coefficient of shrinkage of the cement-stabilized graded macadam is decreased to 0.008-0.013. Therefore, the technical advantages of high intensity and low shrinkage crack of mixture are achieved; the macadam of the invention is applied to building the road surface with long service life, in this way, the bearing property of the road surface is improved, and the service life of the road surfaceis prolonged.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

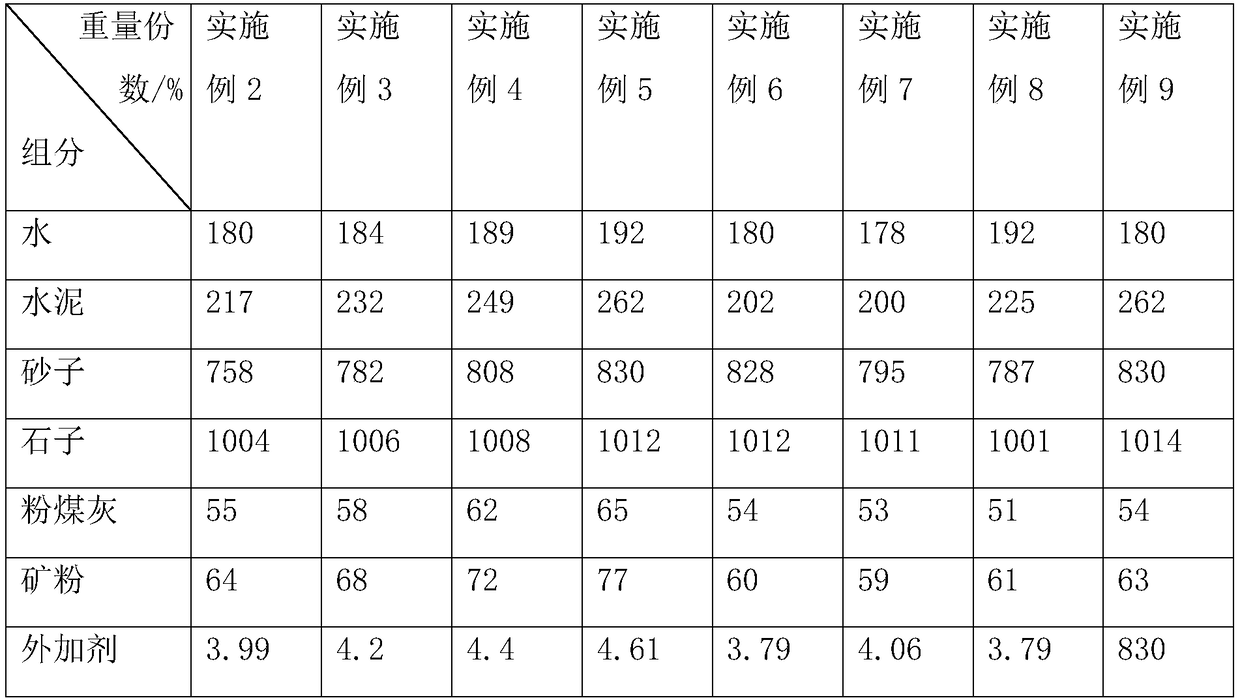

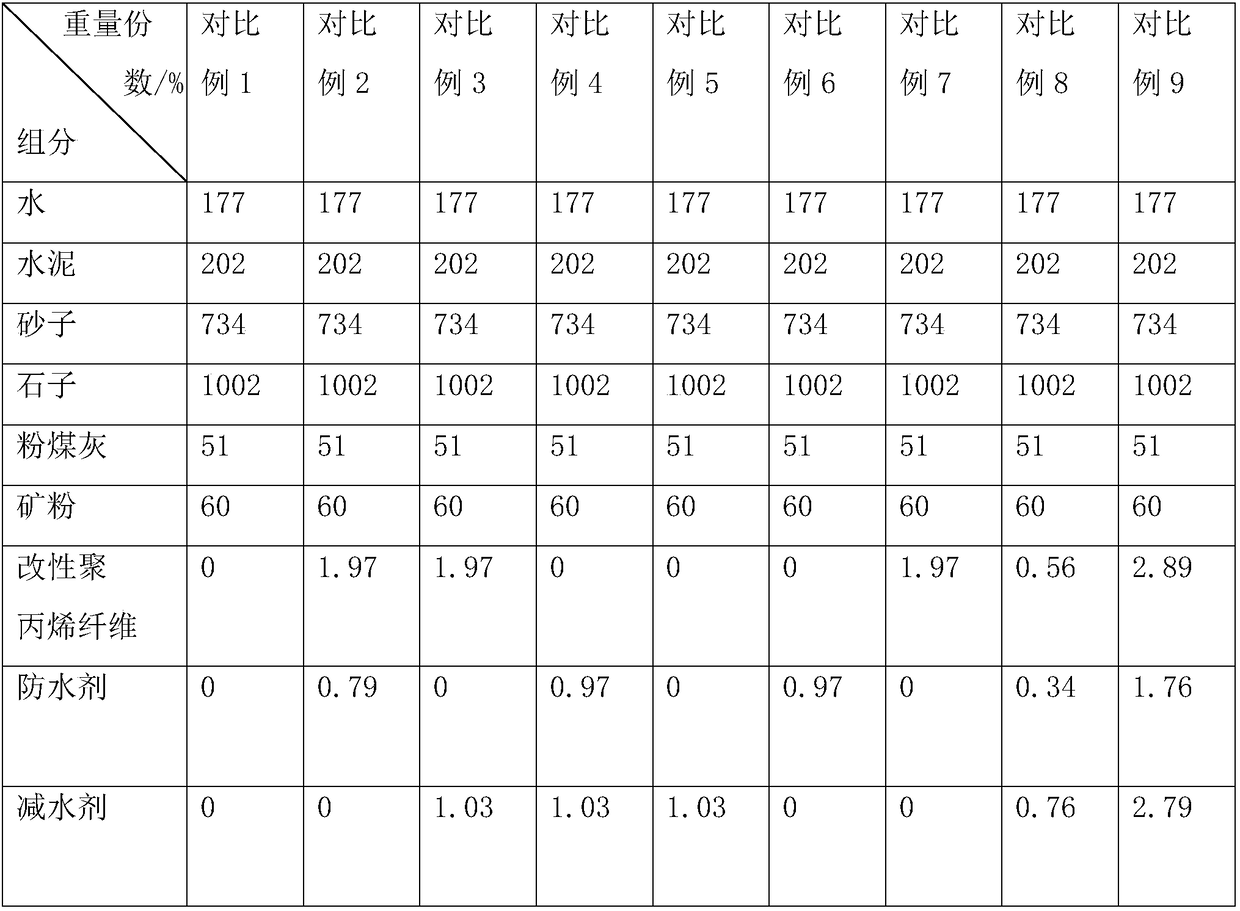

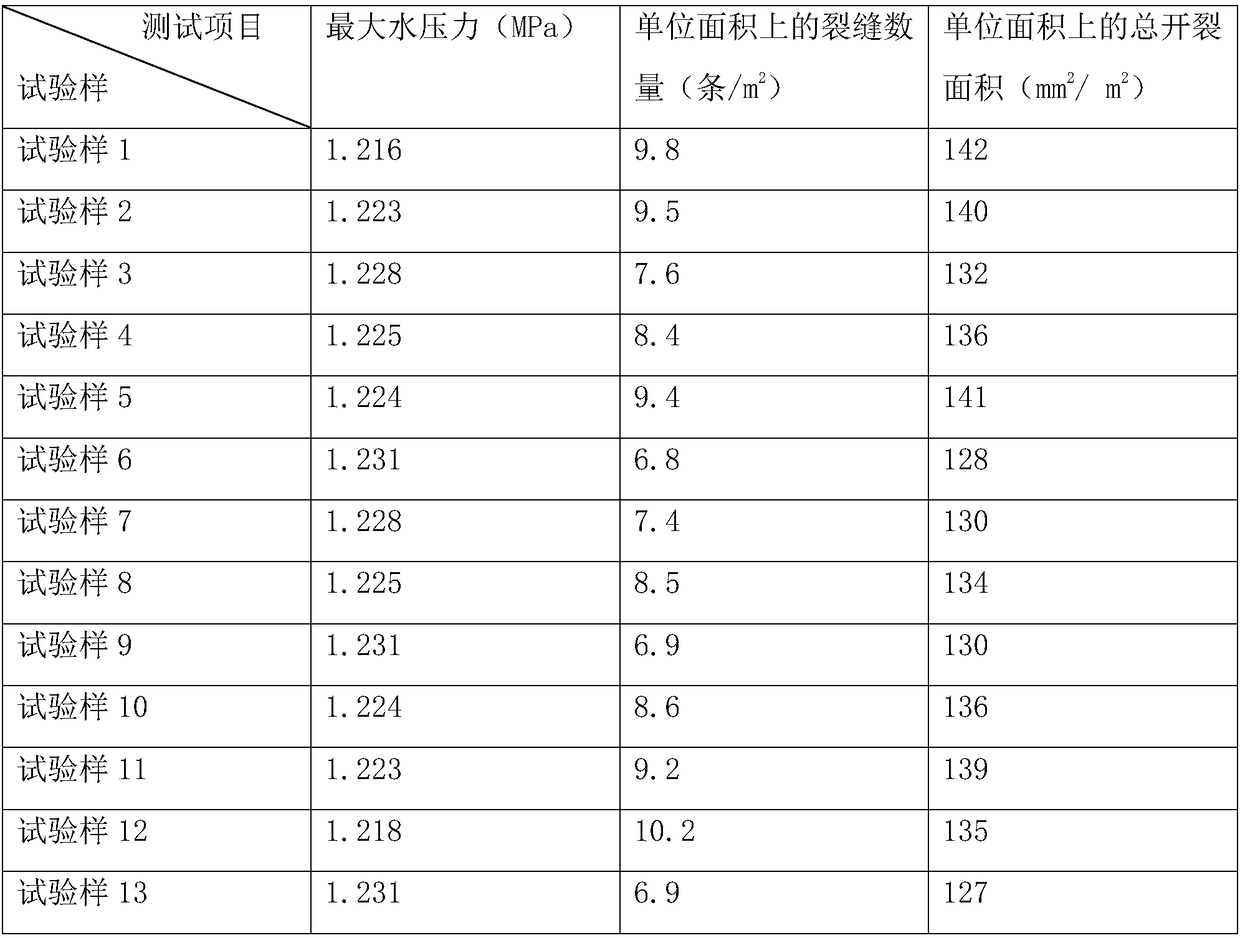

Anti-permeating and anti-cracking concrete and preparation method thereof

The invention discloses anti-permeating and anti-cracking concrete, which relates to the technical field of concrete. The technical scheme of the anti-permeating and anti-cracking concrete mainly comprises the following raw materials in parts by weight: 177-192 parts of water, 202-262 parts of portland cement, 734-830 parts of sand, 1,002-1,012 parts of stones, 51-65 parts of coal ash, 60-77 partsof mineral powder and 3.79-4.61 parts of an additive, wherein the additive comprises modified polypropylene fibers, a water-proofing agent and a water-reducing agent at a weight ratio of 3.2-4.7: 1.3-2.5: 1.7-2.3; the water-proofing agent comprises a triethanolamine water-proofing agent, an air-entraining water-reducing agent and a micro-expansion water-proofing agent at a weight ratio of 1.1-1.5: 1.3-1.7: 0.7-1.3. According to the anti-permeating and anti-cracking concrete, the problems that the concrete is cracked easily after hardening and is relatively poor in anti-permeating performanceare solved. By adding the modified polypropylene fibers and the water-proofing agent, the concrete can be prevented from being cracked when in hardening, so that the anti-permeating performance of theconcrete is improved.

Owner:上海石化安东混凝土有限公司

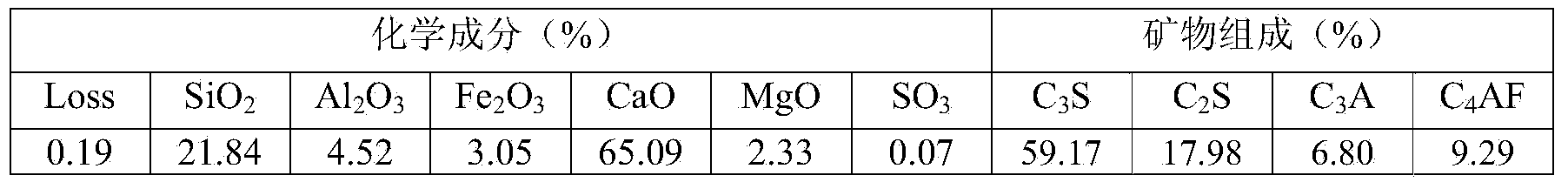

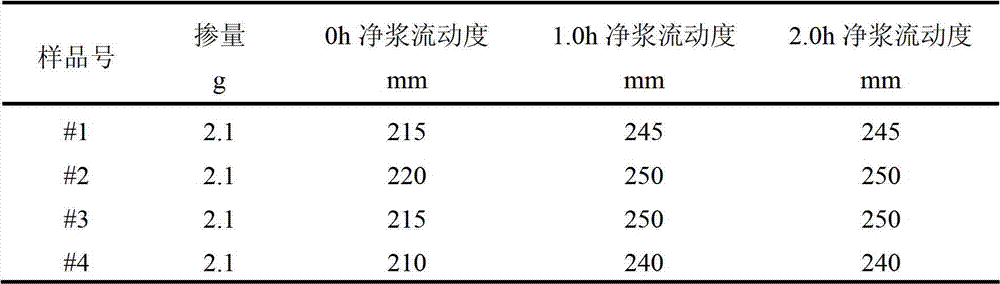

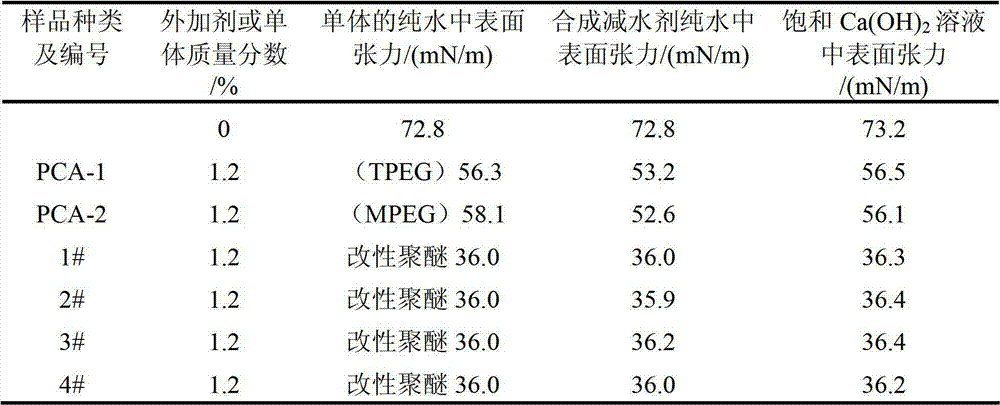

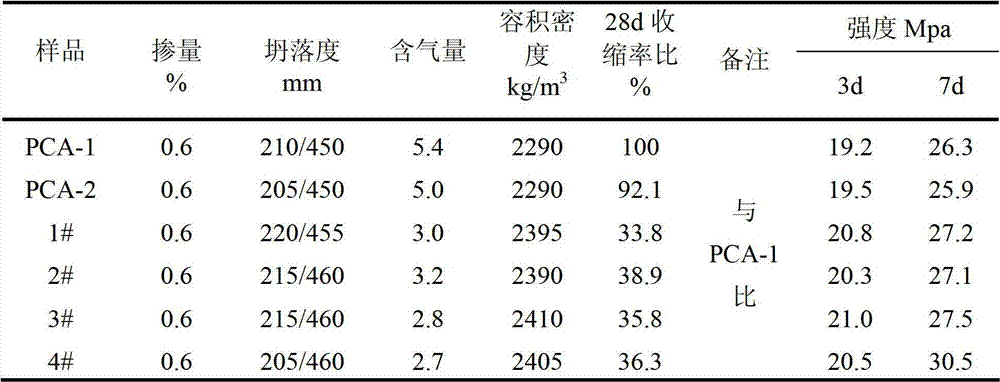

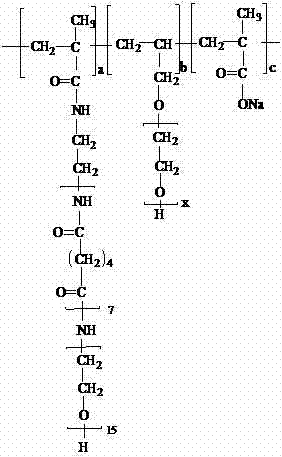

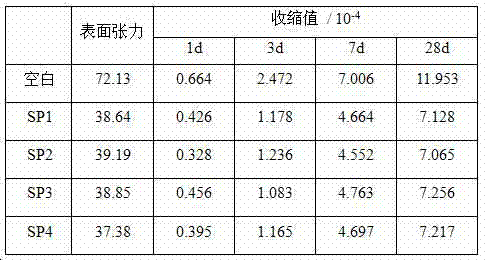

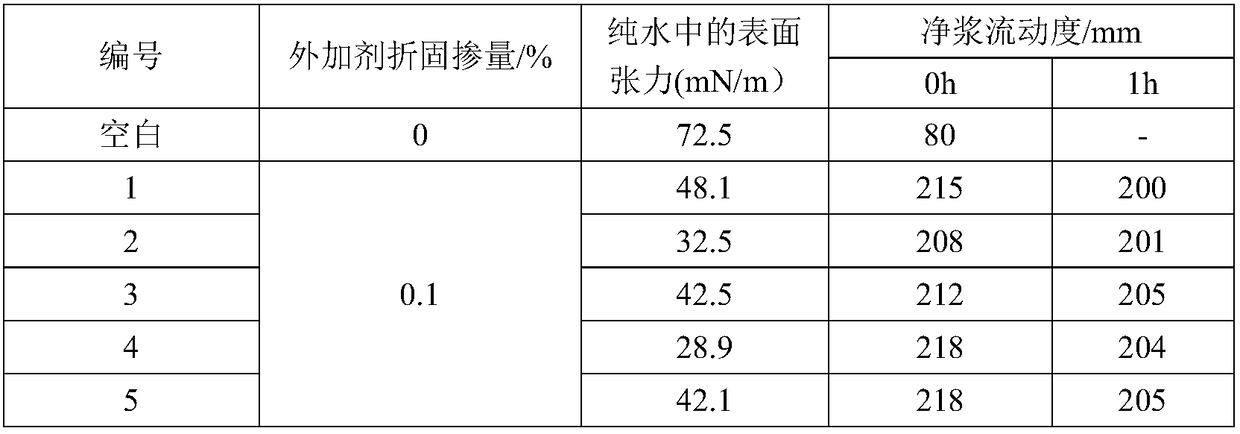

Surface tension adjustment reduction type polycarboxylate superplasticizer and preparation method thereof

The present invention provides a preparation method of a surface tension adjustment reduction type polycarboxylate superplasticizer. The method is simple and high in cost performance, wherein raw materials are easily available and low in cost. The invention also provides a surface tension adjustment reduction type polycarboxylate superplasticizer prepared by the above method. The surface tension adjustment reduction type polycarboxylate superplasticizer can significantly reduce the surface tension of the aqueous solution. The result of the reduction test on the concrete shows that, the surface tension adjustment reduction type polycarboxylate superplasticizer is good in reduction effect. Compared with a conventional ether type polycarboxylate superplasticizer produced by the company of the invention, the shrinkage ratio of the concrete is reduced by 71%. When the polycarboxylate superplasticizer is applied to the concrete, the workability and the strength of the concrete are not affected at all. Therefore, the cost performance is high.

Owner:GUANGDONG REDWALL NEW MATERIALS +1

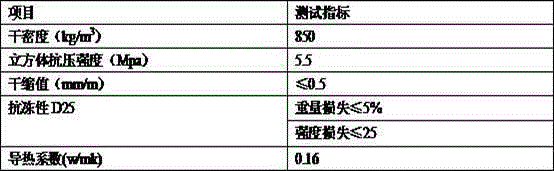

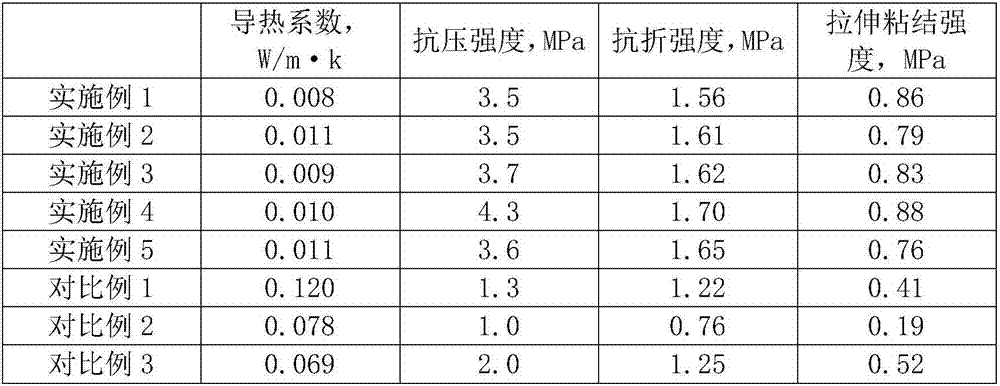

Foam concrete containing recycled inorganic lightweight aggregate and preparation method thereof

InactiveCN105777018AHigh strengthSmall shrinkageSolid waste managementCeramicwareBuilding materialWater reducer

The invention discloses foam concrete containing recycled inorganic lightweight aggregate. The foam concrete is prepared from 20-60 parts of cement, 20-60 parts of slag, 0-50 parts of sand, 0.5-3 parts of a water reducer, 0.1-3 parts of fibers, 25-60 parts of water, foam with the addition amount accounting for 1-80% of the total volume of the foam concrete and the recycled inorganic lightweight aggregate with the addition amount accounting for 1-80% of the total volume of the foam concrete, wherein the recycled inorganic lightweight aggregate is obtained by smashing, screening and grading one or more inorganic heat insulation building materials including but not limited to aerated concrete, foam concrete, foamed ceramic and foamed glass. The invention further discloses a preparation method of the foam concrete. The foam concrete containing the recycled inorganic lightweight aggregate has the advantages of being high in strength, small in shrink, free of formwork collapse, good in fluidity, homogeneous, low in cost and the like and is especially suitable for cast-in-situ lightweight walls, roofs, lightweight cement product elements and the like.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

Recycled concrete made of discarded fiber and preparation method thereof

The full name of the invention is recycled concrete made of discarded fiber and a preparation method thereof. The technology supplies a novel concrete material formed by using the discarded fiber and discarded concrete as aggregates. After the discarded fiber and the discarded concrete are disposed according to a regulation, the discarded fiber and the discarded concrete with cement, sands, macadam and water are mixed evenly according to a certain ratio, and then a novel construction material with high intensity is formed. By means of the recycled concrete, the discarded concrete can be largely consumed, recycling rate of the discarded fiber is improved, and environmental pollution is reduced. Improvement of use ratio of discarded textile fiber, recycling of construction waste and management of solid waste are of great significance. Therefore, the current situation of resource shortage of the country can be effectively improved, resources can be conserved, resource utilization rate can be improved, and better development of the novel construction material of the country can be achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

High-performance corrosion-resistant dry-mixed waterproof mortar

The invention discloses high-performance corrosion-resistant dry-mixed waterproof mortar. The high-performance corrosion-resistant dry-mixed waterproof mortar is prepared from the following raw materials in parts by weight: 60-70 parts of cement, 35-45 parts of mineral powder, 10-30 parts of coal ash, 300-500 parts of regenerated fine aggregates and 5-10 parts of a compounded additive, wherein the compounded additive is prepared from the following raw materials in parts by weight: 40-60 parts of coal ash, 5-7 parts of a water repellent, 40-50 parts of an expanding agent, 2-5 parts of an air-entraining and water-reducing agent, 2-4 parts of anti-crack short fiber and 2-10 parts of a water-retaining thickening agent. By virtue of a dry-mixing form, the high-performance corrosion-resistant dry-mixed waterproof mortar is convenient to use, and the sulfate corrosion can be effectively prevented.

Owner:潍坊德霖建材科技有限公司

Shrinkage reducing and curing agent for concrete

The invention relates to a shrinkage reducing and curing agent for concrete, which has double functions of a shrinkage reducing agent for concrete and a curing agent for concrete and belongs to a building material. The shrinkage reducing and curing agent for concrete comprises a multifunctional high molecular polymer, and is a high-efficiency shrinkage and reducing curing agent comprising a water-soluble organic high-molecular film-forming agent, an inorganic densification agent, a shrinkage reducing agent, and the like. The shrinkage reducing and curing agent is directly brushed on the concrete surface layer to prevent water evaporation, and is capable of permeating through the capillary pores of the concrete to block the channel from which water in the capillary pores evaporates outwards. Meanwhile, the shrinkage reducing and curing agent can reduce the surface tension of water in the capillary pores so as to reduce the drying shrinkage of the concrete, thereby playing a good role in reducing shrinkage, conserving water and curing.

Owner:JIANGSU NIGAO SCI & TECH +1

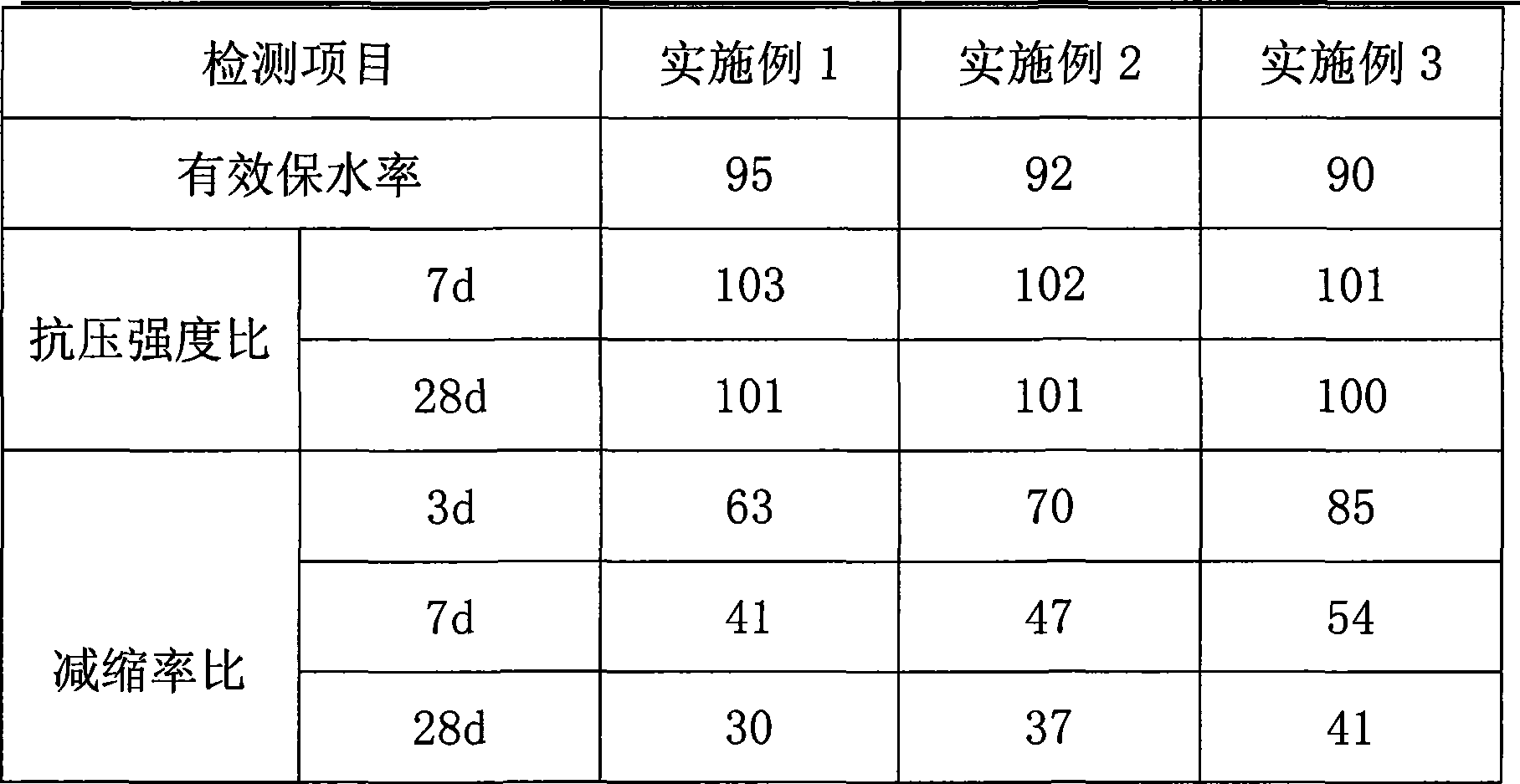

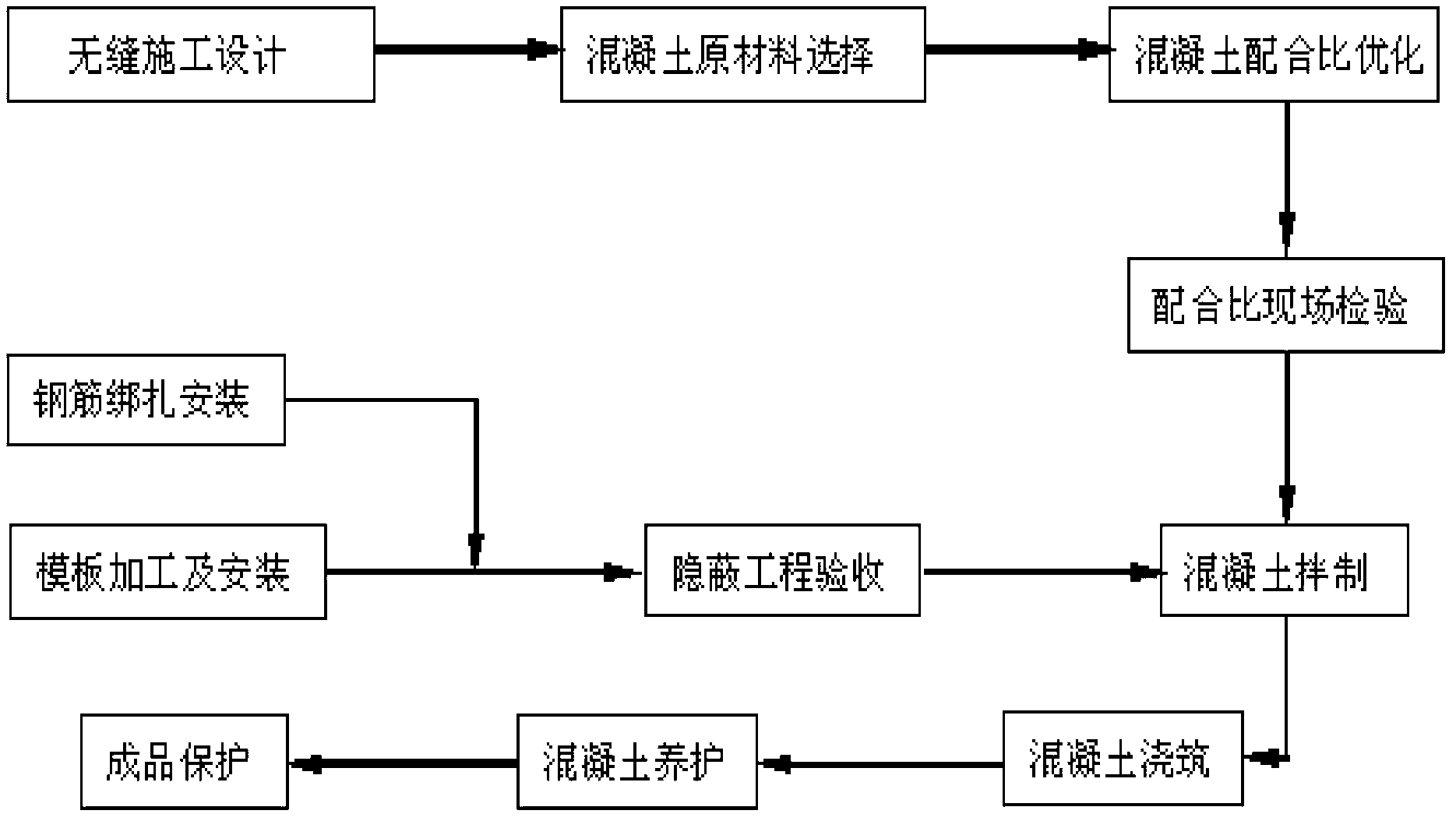

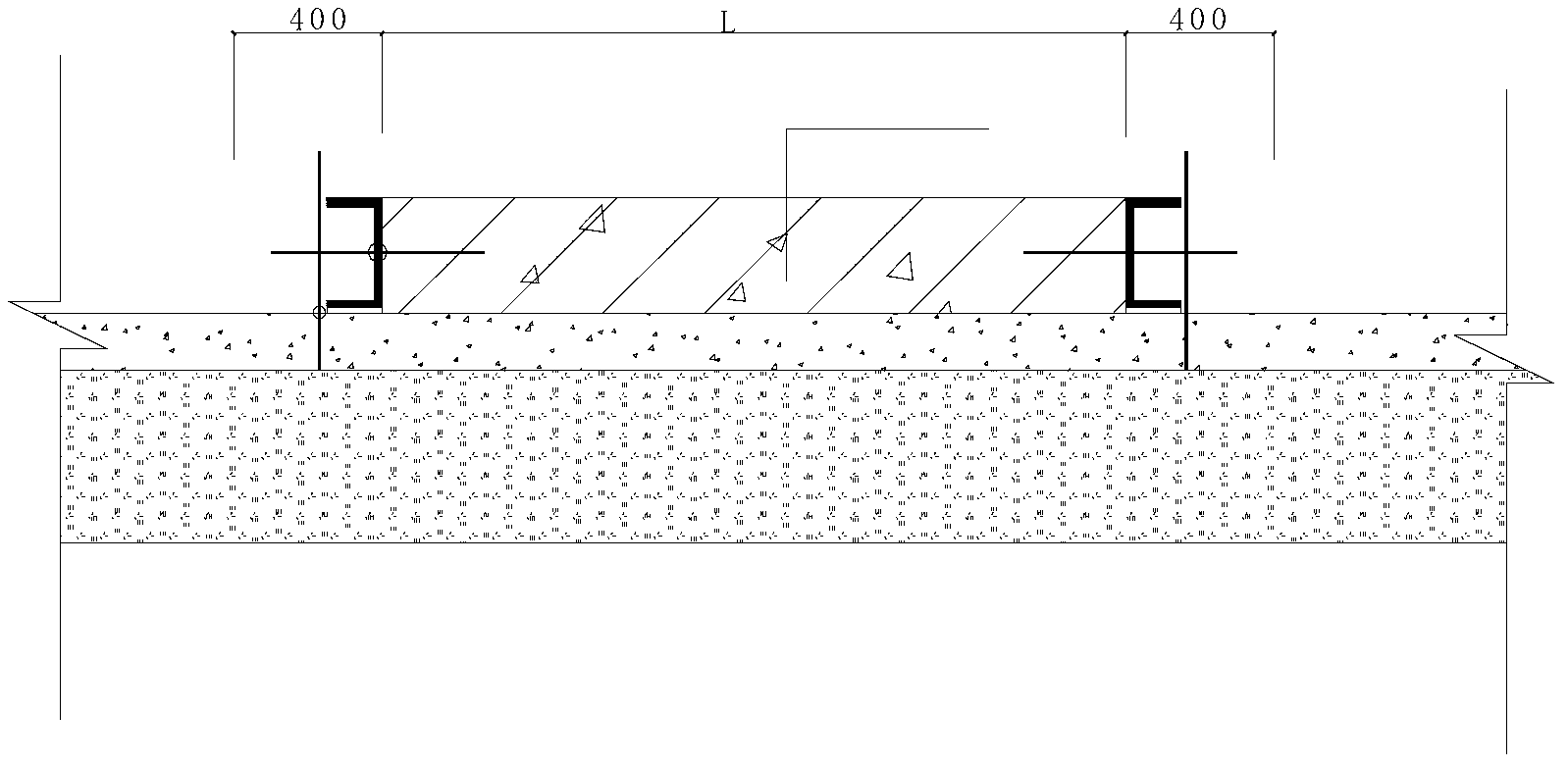

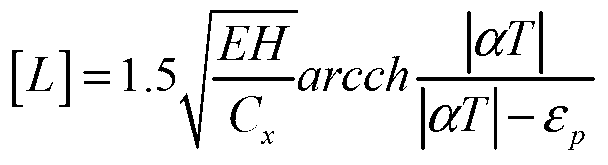

Seamless construction method of multi-layer super large-area reinforced concrete ground

InactiveCN103225406AShorten the construction periodImprove crack resistanceBuilding material handlingReinforced concreteRebar

Owner:中建五局第三建设有限公司

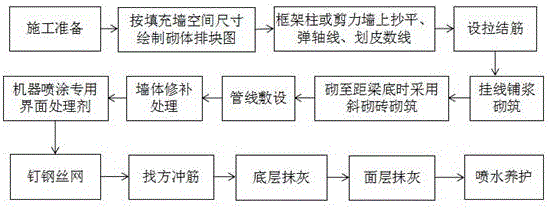

Improved anti-crack construction technique for aerated concrete block wall

The invention discloses an improved anti-crack construction technique for an aerated concrete block wall. The technological process of the improved anti-crack construction method comprises the steps of construction preparation; drawing of a masonry block arrangement map according to the spatial size of a filler wall; leveling of frame columns or a shear wall, snapping of axes, and scribing and brick layer lines; arrangement of tie bars; line hanging, mortar laying and construction; construction of skew bricks when construction is conducted to the position 130 mm away from the beam bottom; pipeline laying; repairing treatment of the wall; spraying of a special interface treating agent through a machine; nailing of a steel wire gauze; alignment and bar embedding; plastering of the bottom layer; plastering of the surface layer; and water spraying for curing. The improved anti-crack construction technique for the aerated concrete block wall has the characteristics that construction operation is easy and convenient, comprehensive cost is reduced, the construction period is shortened, the anti-crack requirement of the wall is met, and accordingly the quality of the wall is improved; and the improved anti-crack construction technique for the aerated concrete block wall has extremely good application prospects.

Owner:轩重建筑节能科技(上海)有限公司

Low air leading reducing type polycarboxylic acid concrete water reducer and preparation method thereof

The invention relates to a low air leading reducing type polycarboxylic acid concrete water reducer and a preparation method thereof. The water reducer is formed by a single body A and a single body B in copolymerization according to the molar ratio of 1:3-3.5. The single body A is modified polyether TPEG, and the single body B is one or several of crylic acid, methyl acrylate, acrylamide, methacrylic acid, methyl methacrylate and methacrylamide. The preparation method includes first adding H2O2 into modified polyether TPEG water solution under the temperature of 50-55 DEG C, stirring the mixture for 10-15min, simultaneously dropping mixed water solution of ascorbic acid and a chain transfer agent and single body B solution respectively and continuously conducting reaction for 0.5-1.0 hour in heat insulation mode after dropping is finished to obtain the polycarboxylic acid water reducer after pH value adjustment. The water reducer has higher water reducing rate, has low air content and a certain reducing function if used for concrete and is the multifunctional high-efficiency water reducer integrating water reducing, reducing and low air leading.

Owner:山东华伟银凯建材科技股份有限公司

Lightweight wall special-purpose cell concrete, and production method thereof

InactiveCN105272352AReduce shrinkage cracksMaintain good performanceSolid waste managementCeramicwareFiberPolyvinyl alcohol

The invention discloses a lightweight wall special-purpose cell concrete, and a production method thereof. The production method comprises following steps: (1) rapid hardening sulphoaluminate cement, ordinary Portland cement, and dry discharge fly ash are delivered into a double helix conical mixer so as to obtain a composite cementing agent via premixing; (2) water, cold-water-soluble polyvinyl alcohol powder, polypropylene reinforcing fiber, calcium stearate water repellent, a silane coupling agent, expanded perlite, and polyphenyl foam particle are delivered into an agitator; (3) the composite cementing agent obtained via step (1) is delivered into the agitator, and micropore foam prepared from a micropore foaming agent via compressed air is sprayed into the agitator, an uniform slurry is obtained via mixing stirring, and slurry volume weight is controlled to be 1000 to 1200kg / m3; (4) the uniform slurry is pumped into lightweight wall products or cast-in-situ wall forming moulds; and (5) finished products are obtained via curing, hardening, moulding, and demoulding. The lightweight wall special-purpose cell concrete can be used for producing various lightweight wall products and cast-in-situ lightweight concrete walls, and is an ideal material used for producing energy-saving lightweight walls and products.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES +2

Preparation method of waterproof concrete

Provided is a preparation method of a waterproof concrete; raw material components comprising cement, sand, carpolite, water, a water reducing agent, a swelling agent and fly ash are stirred and mixed and cured to obtain the waterproof concrete; the swelling agent allows the concrete to swell in a constrained environment, communication holes in the concrete are significantly reduced, the anti-permeability waterproof properties are enhanced, and the strength is also increased significantly; with addition of the water reducing agent, the stability and performance of the concrete are enhanced, problems of common dissociation and water segregation and collapsed slump loss of large-liquidity pumped concrete are avoided, a non-vibrating self-compacting effect is achieved, and construction is convenient; with the use of the fly ash, concrete pores and capillary pores are filled, and with the addition of the fly ash, a pore structure of the concrete is improved and the compactness is increased; and the prepared waterproof concrete is good in self-compacting performance and excellent in anti-permeability and anti-crack performance, and has the later strength improved significantly.

Owner:XIJING UNIV

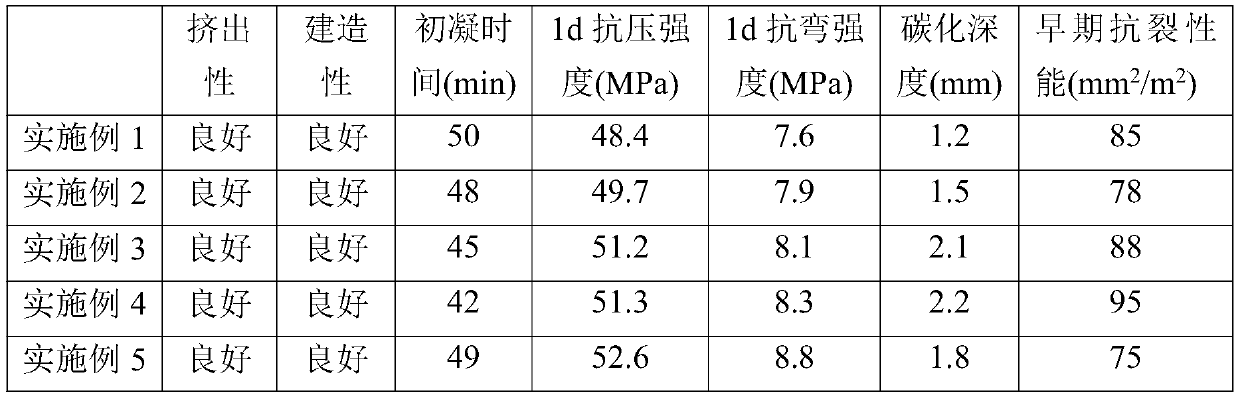

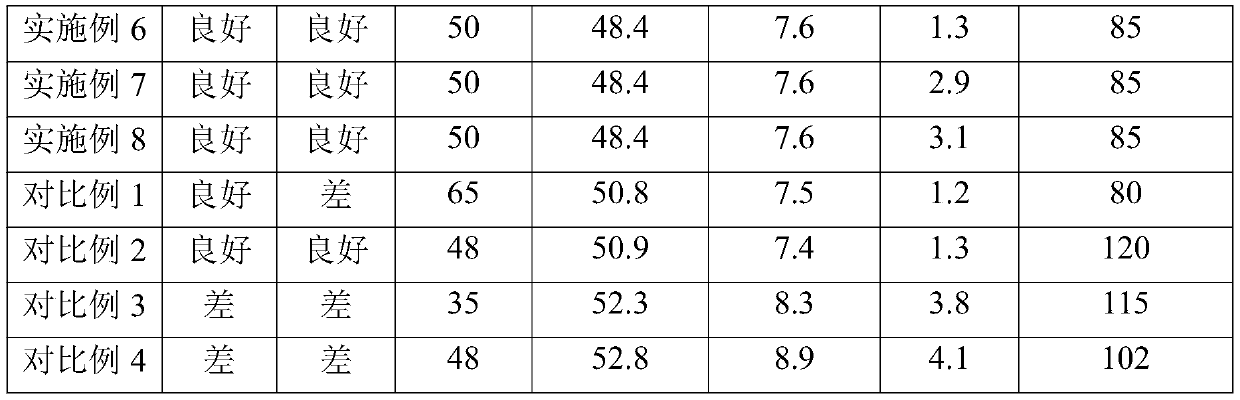

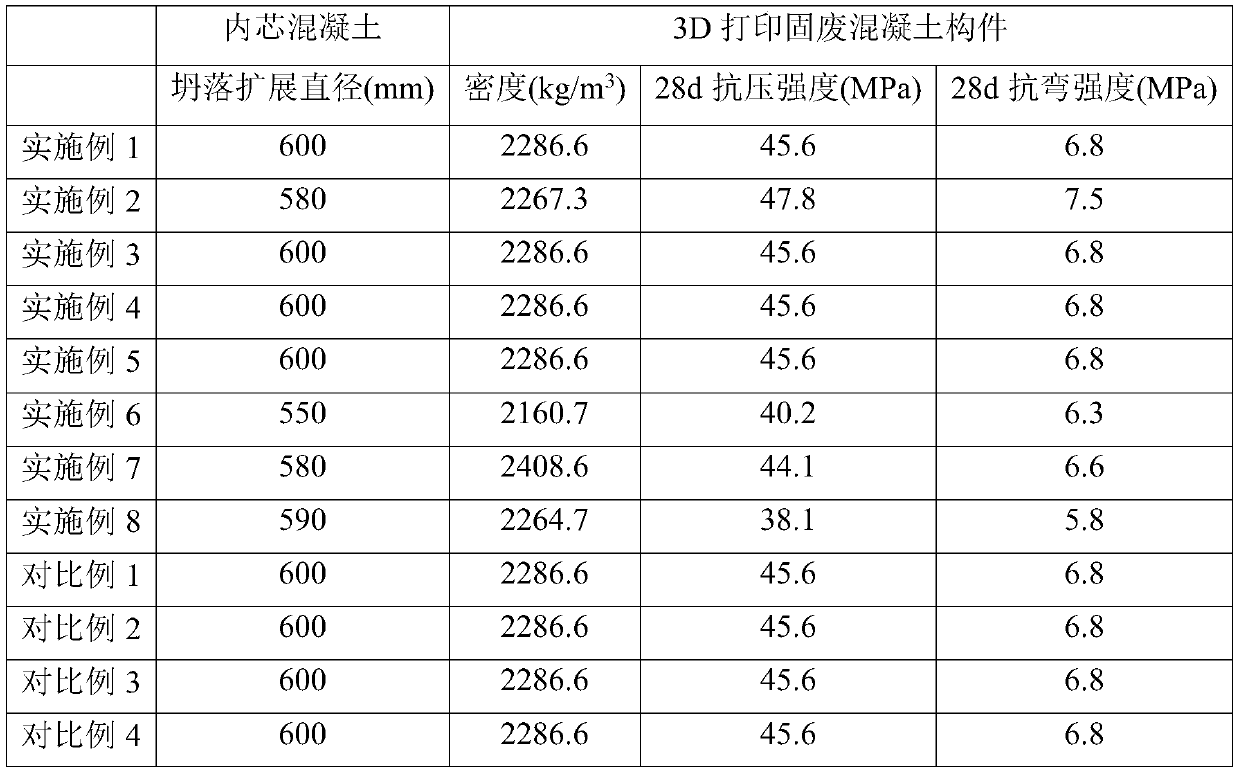

3D printed solid waste concrete member and preparation method

ActiveCN111233407AFast hardeningImprove buildabilityAdditive manufacturing apparatusRebarConstruction engineering

The invention relates to a 3D printed solid waste concrete member and a preparation method. The concrete member comprises a 3D printed mortar template and a concrete inner core which is filled in thetemplate and can be implanted with reinforcing steel bars, the 3D printed mortar template is made of 3D printing mortar with low shrinkage and high durability, and the concrete filled in the 3D printed mortar template has good fluidity, can realize self-compaction and has small later shrinkage. The 3D printed mortar template can realize quick hardening, early strength and low shrinkage and can beused as a permanent template of a component; the use amount of common wood and steel templates is reduced; the construction speed is accelerated, the internally filled concrete can be matched with reinforcing steel bars for use; the problem that reinforcing steel bars cannot be implanted into a 3D printed component is solved, the concrete inner core and the 3D printed mortar template have good bonding strength, a large amount of glass fiber reinforced plastic solid waste is consumed, solid waste resource recycling and 3D printing intelligent construction are combined, and actual engineering application of 3D printing concrete is promoted.

Owner:HEBEI UNIV OF TECH

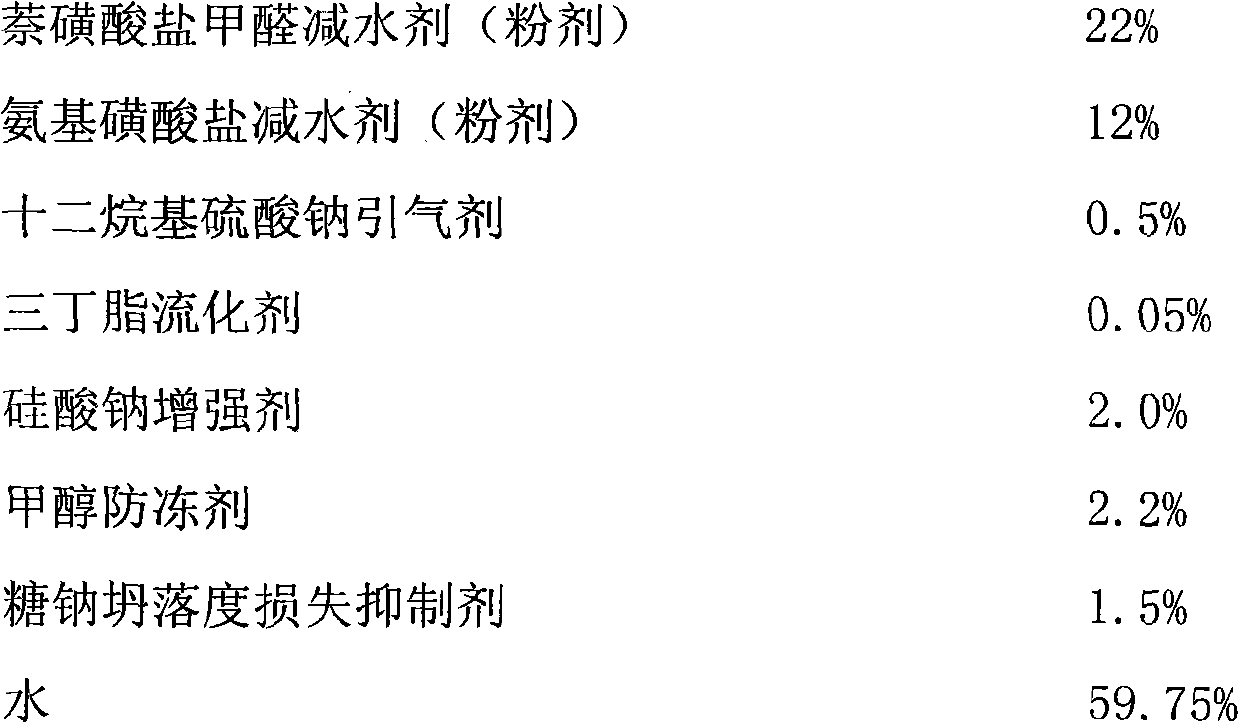

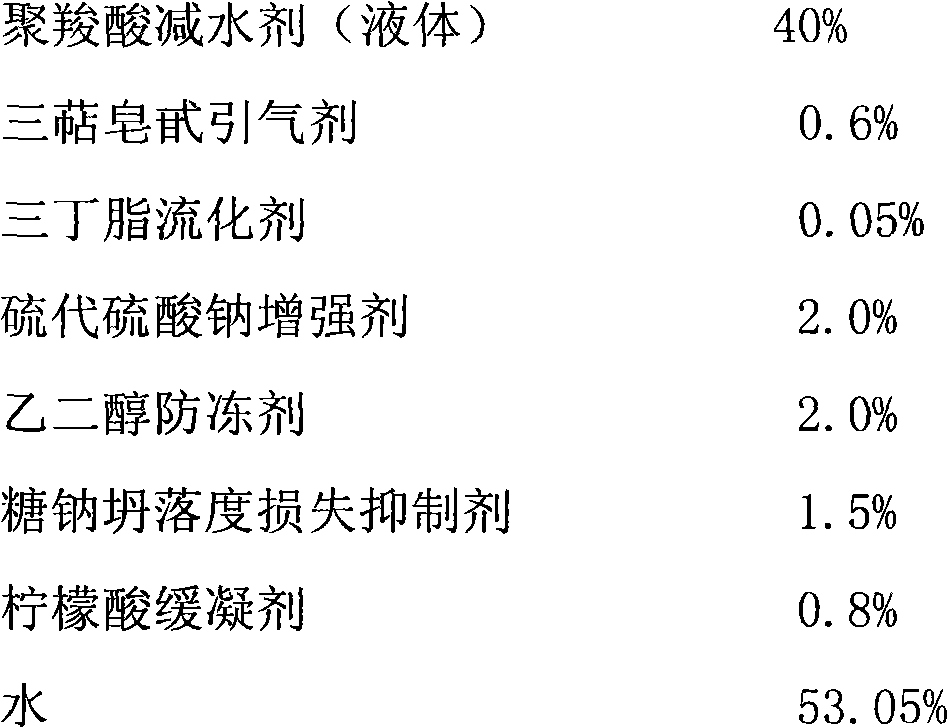

Concrete pumping antifreezing agent with adjustable performances

The invention relates to a concrete pumping antifreezing agent with adjustable performances, belonging to the field of building materials. The concrete pumping antifreezing agent comprises the following materials by weight percent: 28% -42% of water reducing agent, 0.3%-0.7% of air entraining agent, 0.05%-0.07% of fluidizing reagent, 1.5%-2.5% of reinforcing agent and 2.0%-3.0% of antifreezing agent, 1.5%-5.0% of slump loss inhibitor and 45%-65% of water, and the concrete pumping antifreezing agent is a novel pumping antifreezing agent and does not contain any chloride. The concrete pumping antifreezing agent is simple in production process, does not contain alkali and chlorine, and cannot corrode a steel bar. The concrete pumping antifreezing agent has the advantages that the peaceability of concrete is improved substantially, the volume is stable, the water-reducing rate is high, the anti-freezing performance is high, the early-strength performance is obvious, the increasing value of the later-stage concrete strength is high, the adaptability is good, and the like, and has good pumpability in the construction. The concrete pumping antifreezing agent is low in cost, good in performance and has good economical benefits and social benefits.

Owner:BAOTOU ANSHUN NEW BUILDING MATERIALS

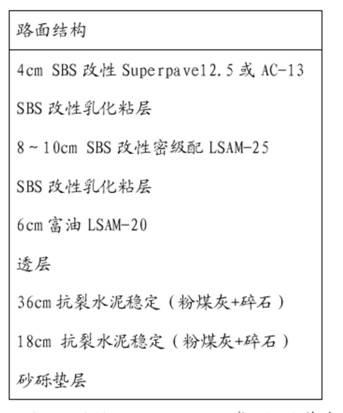

Structure of asphalt pavement applicable to very heavy traffic

InactiveCN102433815AIncreased durabilityReduce reflective cracksIn situ pavingsEngineeringStructural engineering

The invention discloses a structure of an asphalt pavement applicable to very heavy traffic. A wearing layer of the structure adopts 4cm of SBS (styrene butadiene styrene) modified Superpave 12.5 type or AC-13 type modified asphalt concrete; a middle layer of the structure adopts 8-10cm of SBS modified dense gradation LSAM (large stone asphalt mixture)-25; an anti-fatigue layer of the structure adopts 6cm of rich oil LSAM-20 asphalt concrete; a base layer of the structure adopts 36cm of anti-crack stabilized cement; and a subbase layer of the structure adopts treated original cement concrete pavement and treated original asphalt pavement or 18cm of anti-crack stabilized cement. The asphalt pavement structure resists the breaking such as penetrating, cracking, loosing, deforming and the like, resists high-temperature permanent deformation, resists fatigue loading damage, disperses the load, and slows down the reflection crack, so that the problems of rutting deformation resistance and the durability of the very heavy traffic asphalt pavement can be solved, and the service life of the asphalt pavement can be prolonged.

Owner:SHANXI PROVINCIAL RES INST OF COMM

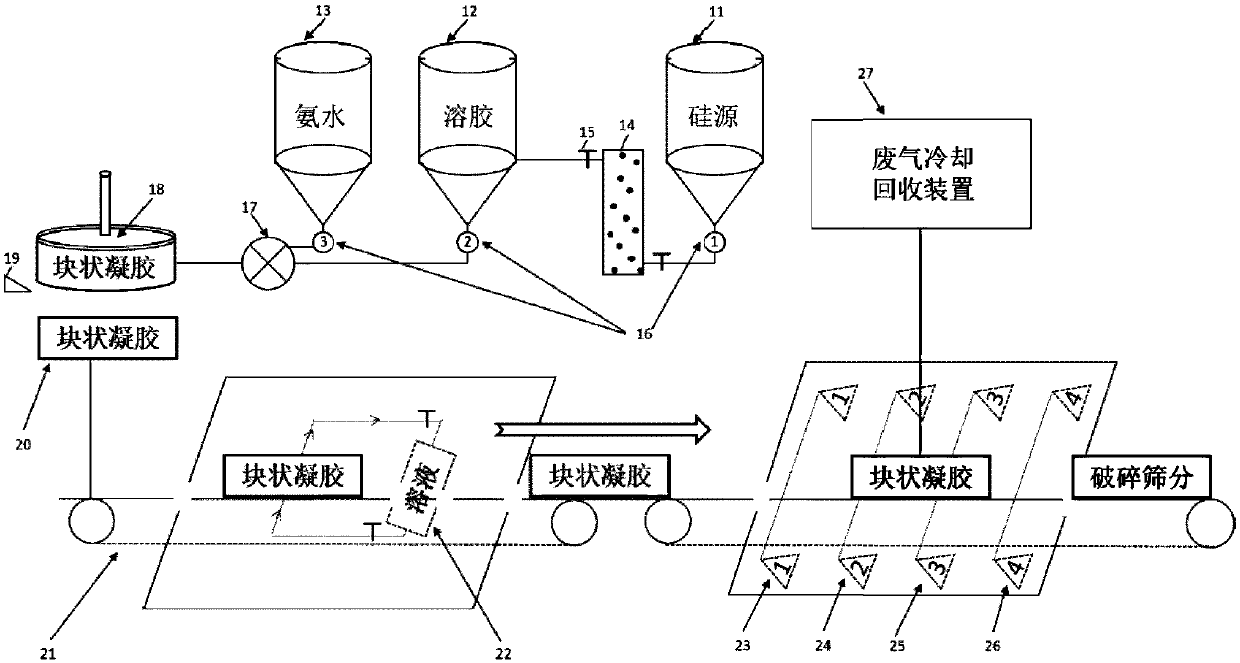

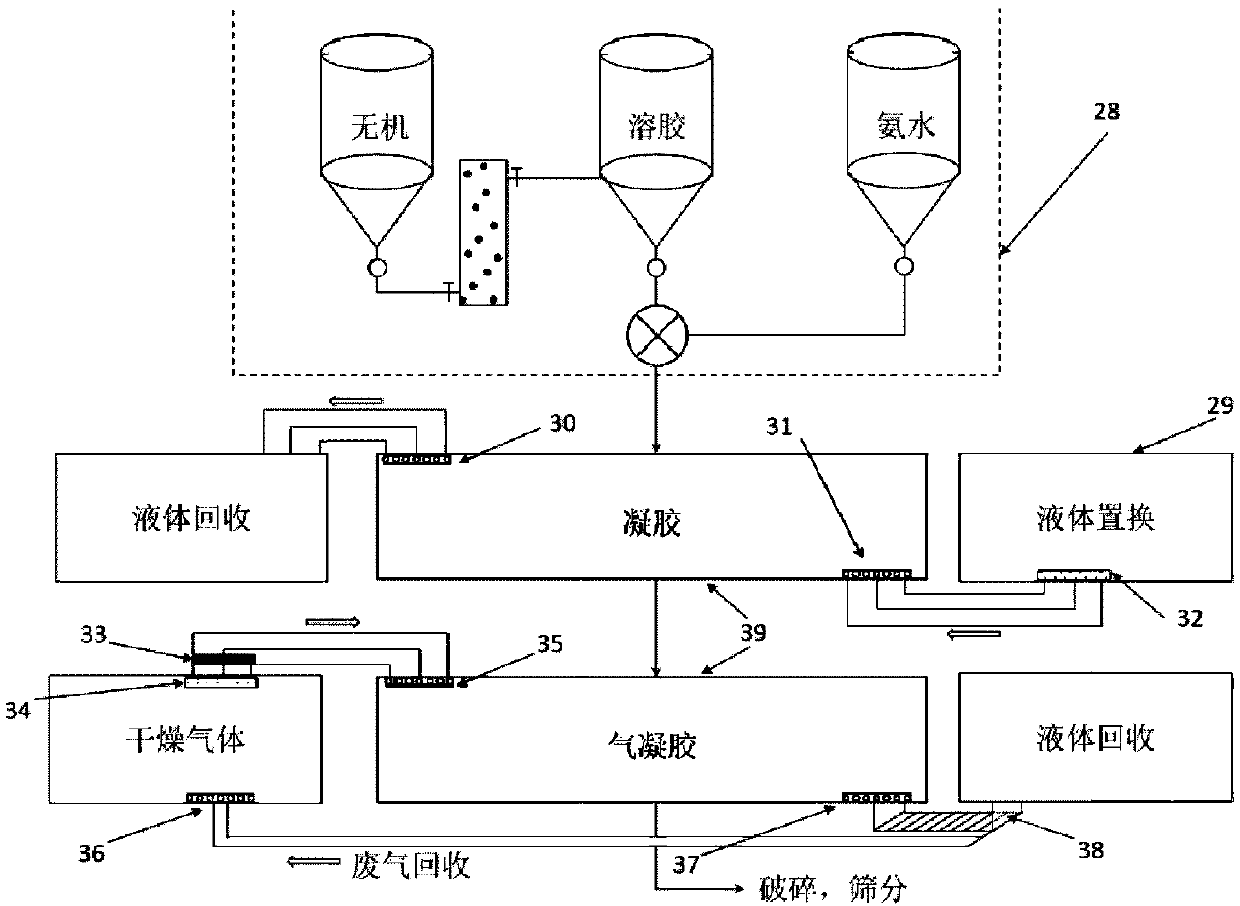

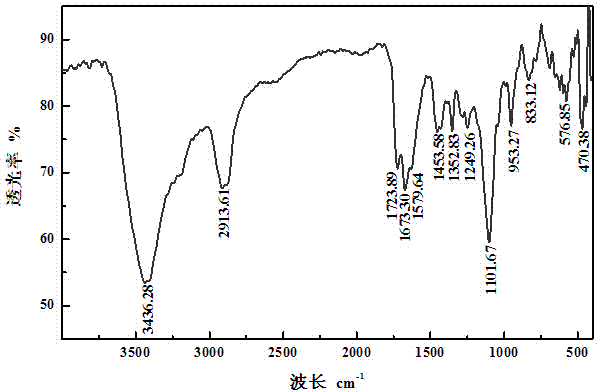

Method for continuously preparing boron-doped SiO2 aerogel

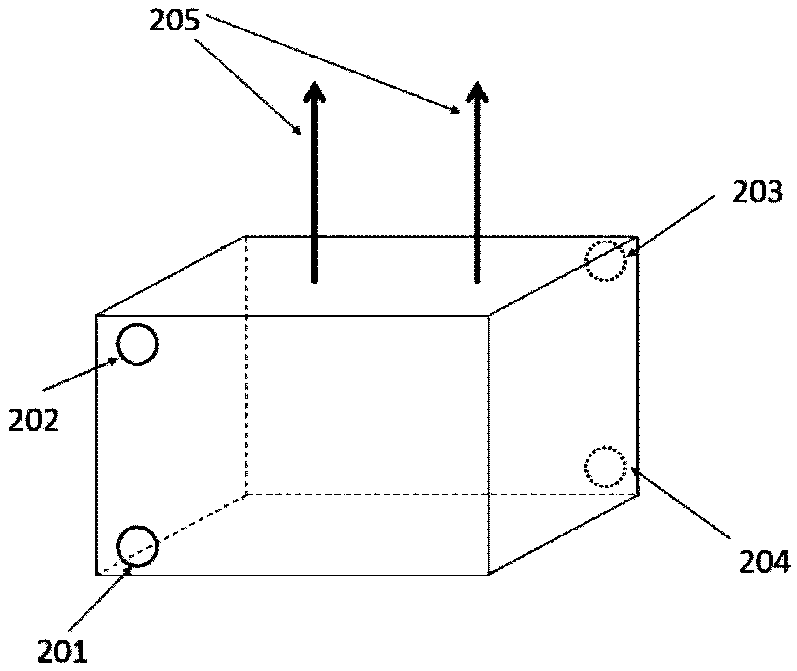

InactiveCN107662923APrecise thickness controlAccurate control of aging timeSilicon compoundsTransmittanceSmall footprint

The invention discloses a method for continuously preparing boron-doped SiO2 aerogel, belonging to the preparation field of novel porous materials. According to the method, by setting a preparation system with the functions of raw material feeding, sol preparation, gel preparation, solvent replacement, gel drying and waste material recycling, a large number of boron-doped SiO2 aerogel can be continuously produced. The method has the advantages that the occupied area of equipment is small, the preparation process is continuous and controllable, the production energy consumption is reduced, theequipment cost is lowered, and the labor cost is lowered. The prepared boron-doped SiO2 aerogel has good mechanical property, light transmittance performance and high-temperature stability.

Owner:CANEW TECH SHENZHEN CO LTD

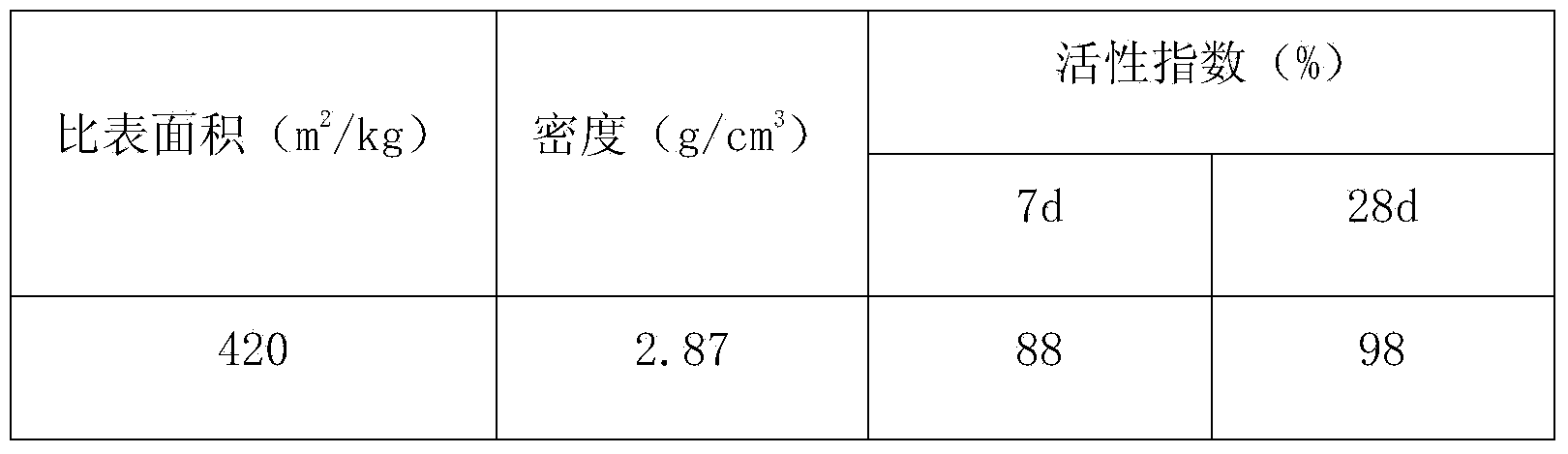

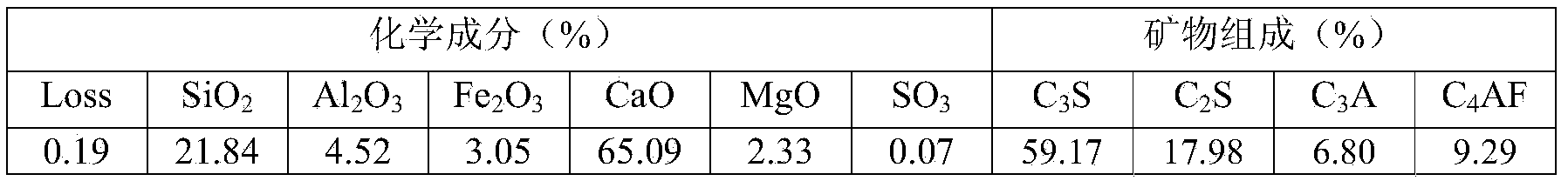

Secondary ettringite type expanding agent and preparation method and application thereof

ActiveCN102167536AReduce shrinkage cracksImprove stress statusSolid waste managementAluminitePolymer science

The invention discloses a secondary ettringite type expanding agent and a preparation method and application thereof. The preparation method comprises the following steps of: stirring a pozzolanic material, a calcium material, plaster and water, forming into a blank or spheres, naturally curing, performing dry heating curing in a curing cell for 0.5 to 10 hours, raising the temperature to 100-170DEG C, and keeping the temperature for 0.5 to 10 hours for dehydration and ettringite decomposition reaction, or standing the formed blank or spheres for 2 to 10 hours, curing under steam pressure, and dehydrating for 0.5 to 10 hours, or dehydrating the thermally synthesized aluminosilicate material and wastes thereof at the temperature of higher than 100DEG C for 0.5 to 10 hours; and mixing and grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum, or respectively grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum and uniformly mixing to obtain powder of which the specific surface area is more than 200m<2> / kg, namely the secondary ettringite type expanding agent. The secondary ettringite type expanding agent can endow mortar and concrete with micro-expansion property, and improve the volume stability of the mortar and concrete.

Owner:HOHAI UNIV +1

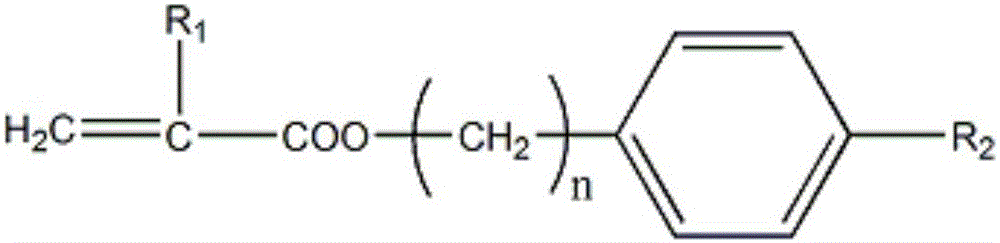

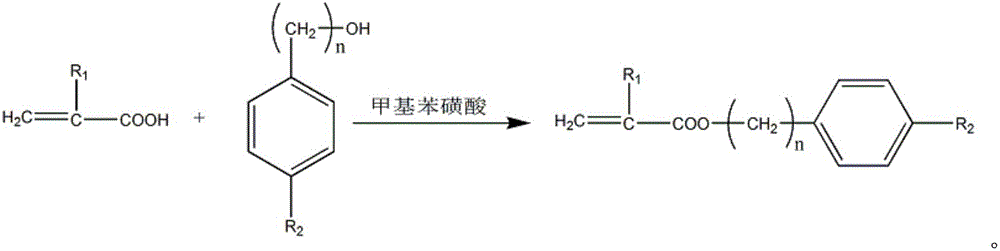

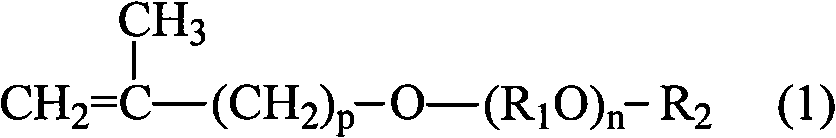

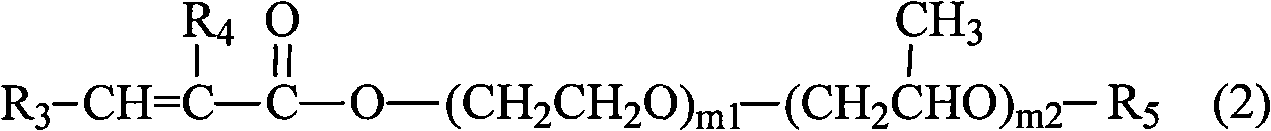

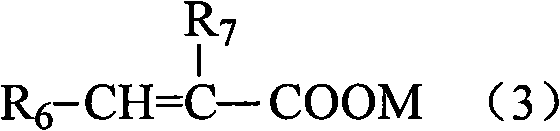

Reduction and early strength polymer additive

The invention discloses a reduction and early strength polymer additive which is obtained by copolymerizing 60-95 percent of monomer A, 1-10 percent of monomer B, 3-16 percent of monomer C and 0-30 percent of monomer D in an aqueous solution at 50-100 DEG C in the presence of an initiator and a chain transfer agent. The polymer additive has the advantages of high water reduction rate, high early strength, low shrinkage, and the like when used for mortar or concrete.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

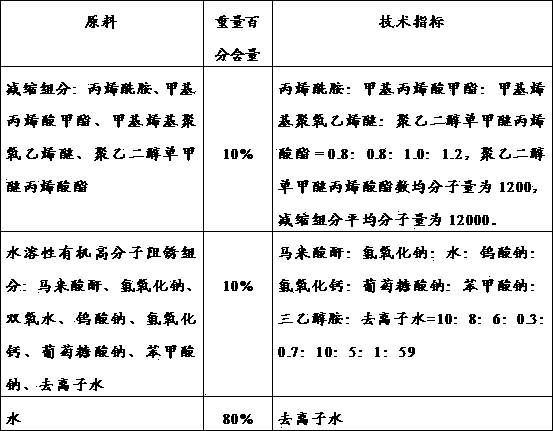

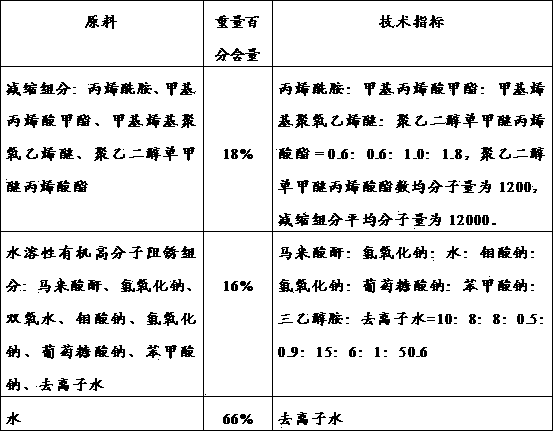

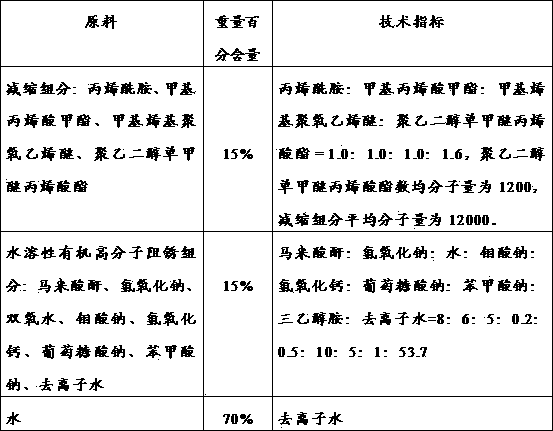

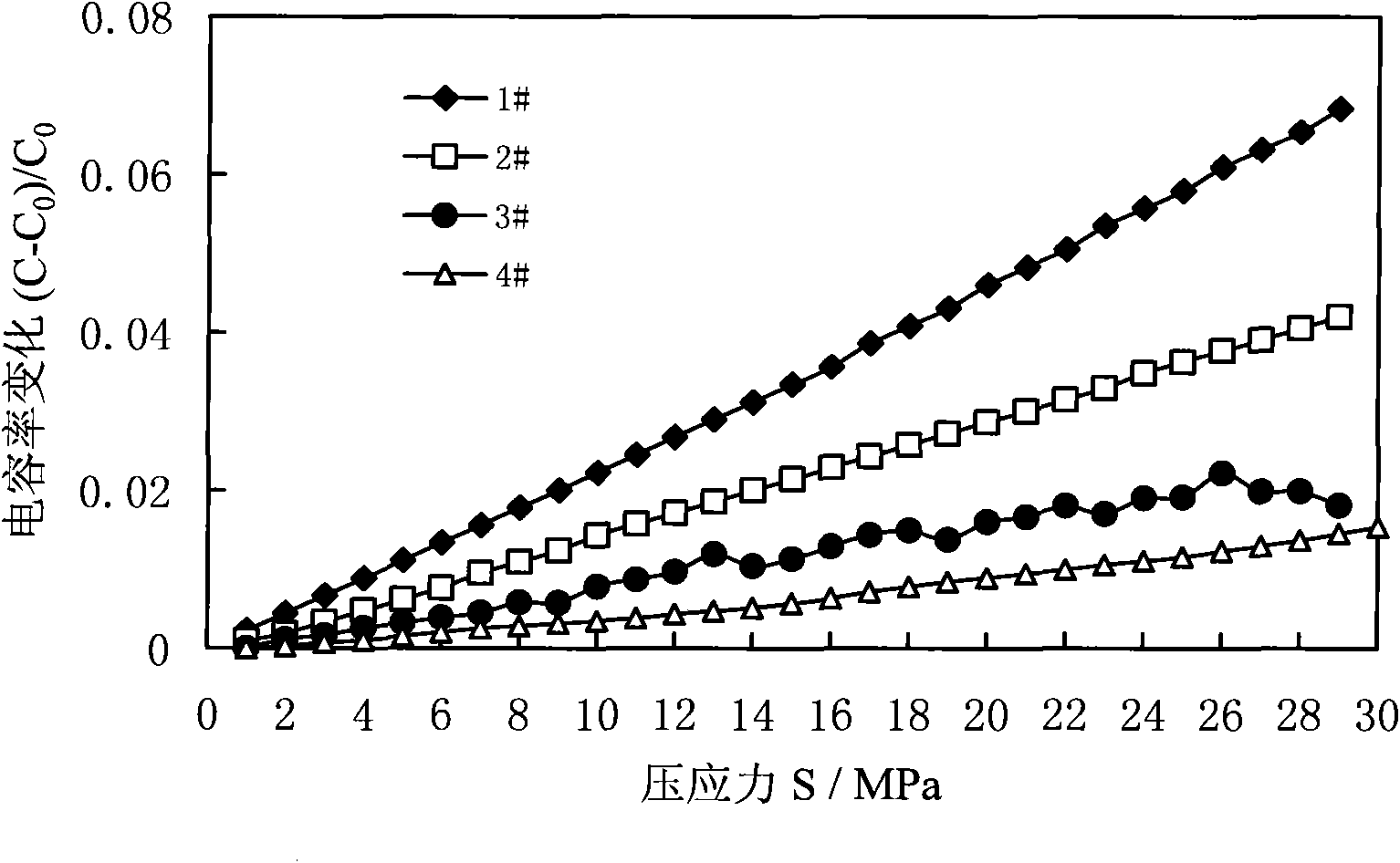

Mortar and concrete shrinkage reducing agent having antirust function, and preparation method thereof

ActiveCN103819123AReduced risk of shrinkage crackingIncreased durabilityShrinkage crackingNon toxicity

The invention discloses a mortar and concrete shrinkage reducing agent having an antirust function, and a preparation method thereof. The shrinkage reducing agent comprises 5-20wt% of a shrinkage reducing component, 5-20wt% of a water-soluble organic polymer corrosion inhibiting component, and the balance water. The preparation method of the shrinkage reducing agent comprises the following steps: preparing the shrinkage reducing component; preparing the water-soluble organic polymer corrosion inhibiting component; and weighing the shrinkage reducing component, the water-soluble organic polymer corrosion inhibiting component and water according to the above weight proportions, adding the shrinkage reducing component to the water-soluble organic polymer corrosion inhibiting component, stirring for 10-20min, adding water to adjust the concentration of the obtained solution, uniformly stirring, and discharging the finally obtained product. The shrinkage reducing agent can reduce the plastic shrinkage and the drying shrinkage of concrete, and reduces the drying shrinkage crack occurrence probability of the concrete, so the shrinkage cracking risk of the concrete is greatly reduced, the corrosion of carbon steel is prevented, and the durability of the concrete is improved; and the shrinkage reducing agent has the advantages of non-toxicity, tastelessness, no pollution to the environment and use convenience, and is suitable for concrete in any environment or under any conditions.

Owner:JIANGSU NIGAO SCI & TECH +1

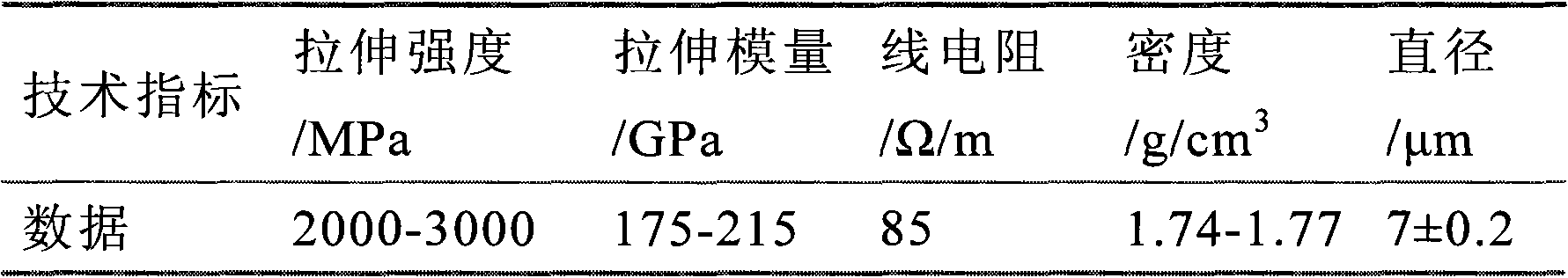

Freezing resistant cement based stress sensor element

The invention relates to a sensor element in the technical field of detection, in particular to a freezing resistant cement based stress sensor element, which comprises a test block and a pair of electrodes. The electrodes are respectively positioned on the upper surface and the lower surface of the test block, and the test block comprises a cement substrate and electric conductive fibers uniformly distributed in the cement substrate; and the cement substrate is made of calcium sulphoaluminate cement mortar, and the electric conductive fibers comprise short-cutting polypropylene hydrocarbon fibers and carbon nano tubes. The invention has the advantages that:1. by adopting calcium sulphoaluminate cement as the cement substrate, the stress sensor element has favorable freezing resistance with the application range broadened to the temperature below a freezing point; and 2. besides doping with the carbon fibers as functional bodies, the carbon nano tubes are introduced simultaneously, therefore, the sensor has sensitive changes of pressure-volume characteristics with stable data.

Owner:UNIV OF JINAN

Preparation method of environment-friendly phase-changed insulated anti-cracking fast-setting spraying mortar

The invention discloses a preparation method of environment-friendly phase-changed insulated anti-cracking fast-setting spraying mortar. The preparation method comprises the following steps: mixing and stirring common silicate cement and sulfate aluminum cement into mixed cement; modifying expanded perlite by using polystyrene emulsion; adsorbing paraffin into a pore of the expanded perlite by using a reduced pressure adsorption method; coating by using cement; preparing silica-coated polyphenyl particles; preparing silica sol-modified aluminum oxide ceramic powder; uniformly mixing and stirring the prepared remaining blended cement, gypsum, aggregate coated with the blended cement, the silica-coated polyphenyl particles and the ceramic powder, continuously adding sepiolite fibers, polypropylene fibers and a thickening agent, and continuously performing uniform stirring and mixing to obtain the spraying mortar. The spraying mortar is good in thermal insulation, strong in adhesion strength and excellent in mechanical performance.

Owner:SHAOXING YISHENG MORTAR

Reduced and reinforced type polycarboxylate having high water-reducing rate and preparation method thereof

The invention relates to reduced and reinforced type polycarboxylate having high water-reducing rate and a preparation method thereof. The preparation method comprises the following steps of: (1), carrying out free radical polymerization: adding methacrylic acid, allyl polyoxyethylene ether, acrylamide, maleic anhydride and deionized water into a synthesis reactor according to parts by weight, uniformly stirring and mixing under the protection of nitrogen, heating to 50-90 DEG C, respectively dropping ammonium persulfate aqueous solution and mercaptoacetic acid aqueous solution with the rate of 0.5-8 mL / min, continuously stirring for 2-8 h, and keeping the temperature at 40-80 DEG C for 0.5-5 h; and (2), cooling and neutralizing: adjusting pH to 6-8 after cooling to room temperature so as to obtain the reduced and reinforced type polycarboxylate having high water-reducing rate. The reduced and reinforced type polycarboxylate having high water-reducing rate prepared by the preparation method disclosed by the invention has high water-reducing rate; the surface tension of aqueous solution can be greatly reduced; the reduced and reinforced type polycarboxylate has the obvious function of reducing cement mortar; and, the early and later strength of the cement mortar can be increased with the same water cement ratio.

Owner:史才军

Preparation method of fluorine-containing shrink-reduced polycarboxylate water reducing agent

ActiveCN109280141AHigh water reduction rateLow plasticityShrinkage crackingOxidation-Reduction Agent

The invention discloses a preparation method of a fluorine-containing shrink-reduced polycarboxylate water reducing agent. The method particularly includes: 1) preparation of a polycarboxylate water reducing agent prepolymer: under effects of an initiator, a reducing agent and a chain transfer agent, performing a redox radical polymerization reaction to a carbonyl-containing monomer, an unsaturated acid monomer and an unsaturated macro-monomer to obtain a carbonyl-containing polycarboxylate water reducing agent prepolymer; 2) preparation of the fluorine-containing shrink-reduced polycarboxylate water reducing agent: performing a nucleophilic substitution reaction to the carbonyl-containing polycarboxylate water reducing agent prepolymer with a Prakash reagent (TMSCF3) to obtain the water reducing agent. The water reducing agent can significantly reduce surface tension and improve cement dispersibility, is high in shrinkage reducing performance on the basis of high water reduction, is good in compatibility with cement, is low in gas content when being applied to concrete, can effectively improve size stability of concrete and reduce shrinkage cracking and can improve the durabilityand service life of a concrete structure.

Owner:BEIJING UNIV OF TECH

Anti-cracking-shedding and strong-adhesion dry mixing plastering mortar

InactiveCN105294012AHigh bonding strengthImprove water retentionSolid waste managementPolymer scienceDry mixing

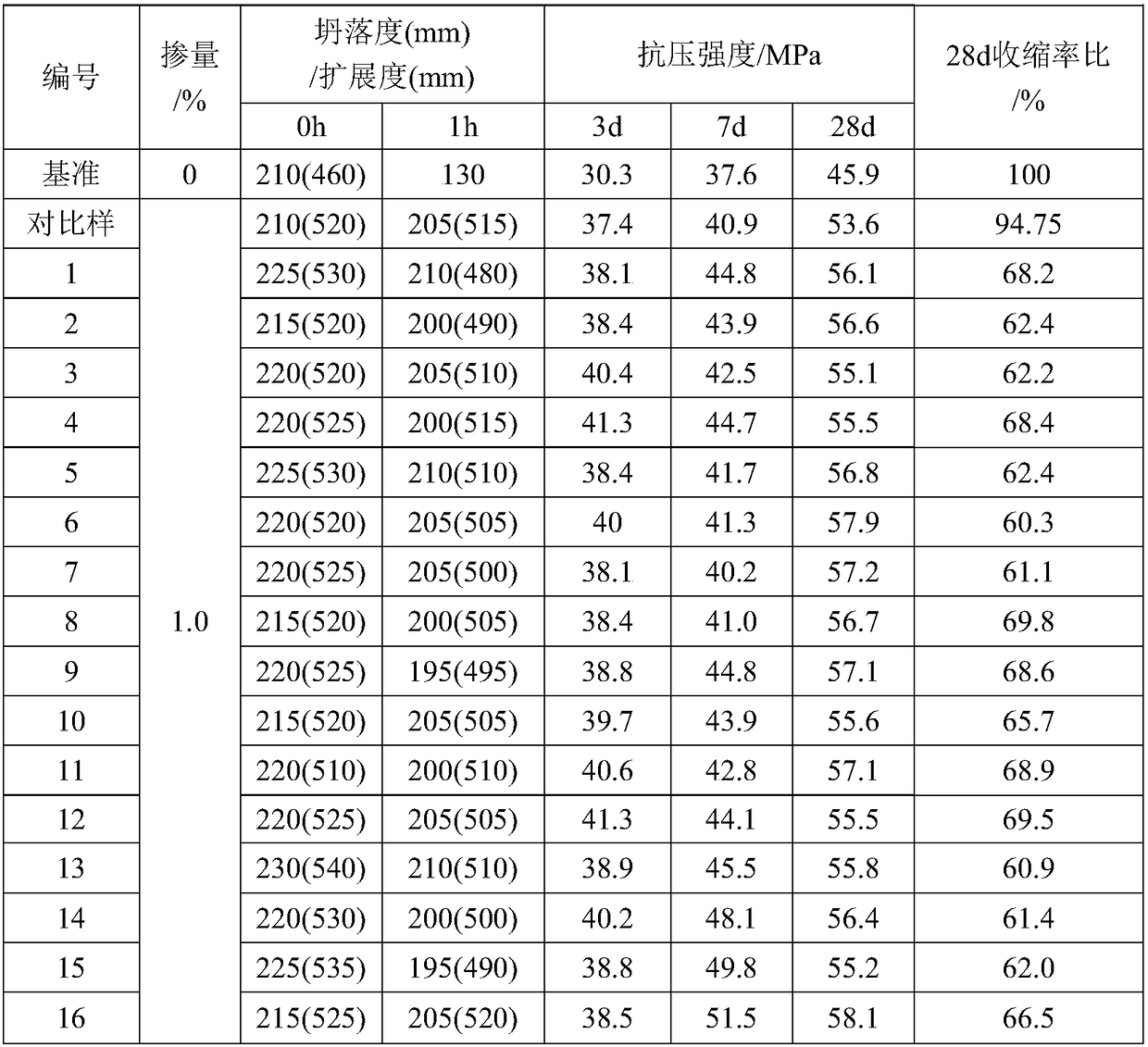

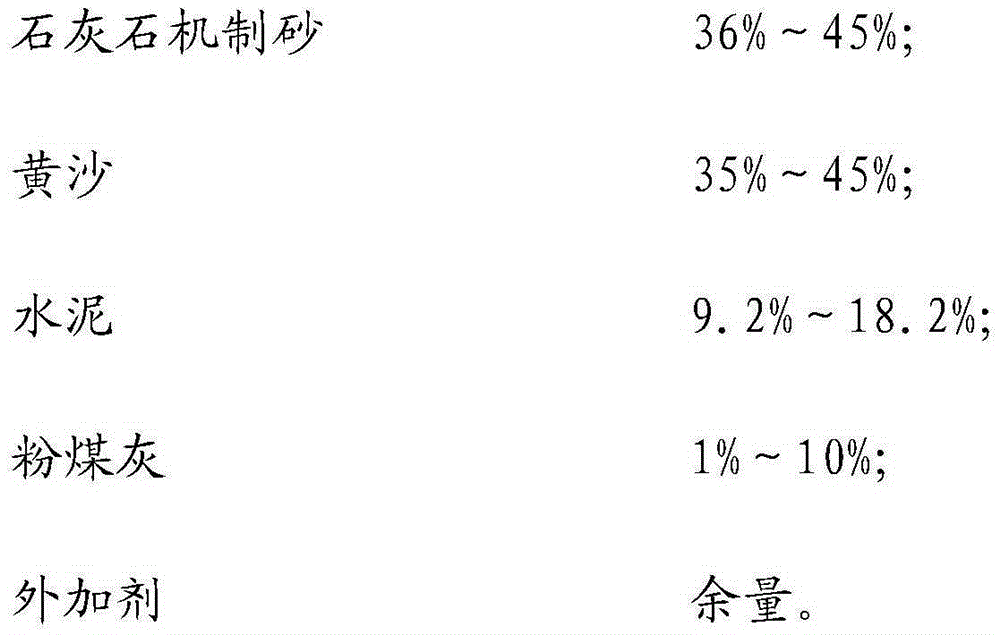

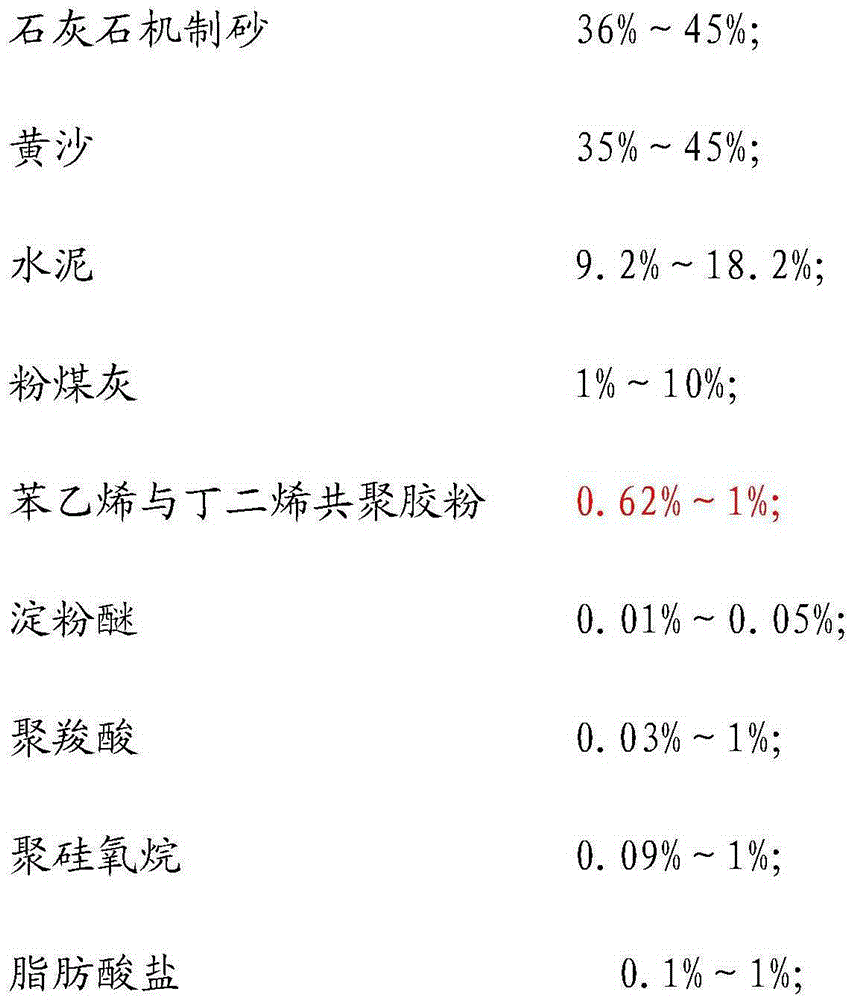

The invention relates to an anti-cracking-shedding and strong-adhesion dry mixing plastering mortar, which is characterized by comprising by mass: 36-45% of limestone machine-made sand, 35-45% of yellow sand, 9.2-18.2% of cement, 1-10% of fly ash, and the balance of an admixture, wherein the admixture comprises a modifier and a thickening agent, the modifier is a mixture of starch ether, polysiloxane and polycarboxylic acid, the thickening agent is styrene and butadiene copolymerization rubber powder, and a weight ratio of the styrene and butadiene copolymerization rubber powder to the starch ether to the polysiloxane to the polycarboxylic acid is 100:1.6:14.5:4.8.

Owner:浙江兆山建材科技有限公司

Biomass aggregate recycled concrete and preparation method thereof

The invention provides biomass aggregate recycled concrete and a preparation method thereof, and the biomass aggregate recycled concrete is characterized by comprising cement, broken corncob particlesand a recycled fine aggregate and comprising the components in parts by weight: 8-10 parts of the cement, 1-4 parts of corncob particles, 20-40 parts of the recycled fine aggregate and 8-20 parts ofwater. The volume rate of the corncob particle aggregate in the biomass aggregate recycled concrete is 30%-50%, and the particle size of the corncob particles is 2-10 mm. The preparation method comprises the steps: weighing the cement, the corncob particles, the recycled fine aggregate and the water according to the raw material ratio for later use; uniformly mixing the cement with the recycled fine aggregate, adding water, and stirring to obtain a uniform mixture; adding the corncob particles into the mixture, then compacting while stirring, and making the concrete mixture uniformly; and putting the concrete mixture into a mold, slightly vibrating by a vibrating table, and maintaining at normal temperature for a required number of days. A novel green building material and products thereofare developed by corncobs and construction wastes, and the novel green building material is rich in raw materials, low in cost and suitable for large-scale production.

Owner:QINGDAO AGRI UNIV

Inorganic thermal insulation mortar toughened by doping wheat straw fibers and application method thereof

InactiveCN105819801AImprove early strengthPromotes hydrationSolid waste managementThermal insulationMechanical property

The invention belongs to the technical field of construction materials, and specifically relates to an inorganic thermal insulation mortar toughened by doping wheat straw fibers and an application method thereof. The inorganic thermal insulation mortar is composed of silicate cement, calcium hydroxide, high calcium fly ash, aluminate cement, wheat straw fiber, polyacrylonitrile fiber, vitrified beads, short-cut wheat straw, butyl benzene emulsion, an air-entrainer, starch ether, and water. The problems of common vitrified bead thermal insulation mortar such as high cost, easy shrinkage and cracking, and the like are solved. The provided inorganic thermal insulation mortar has the advantages of good workability and mechanical properties, small shrinkage, no cracking, excellent thermal insulation performance and fireproof property, safety, durability, and flameproof property, and the fireproof property can reach the A grade. Agricultural wastes such as wheat straw and other solid wastes are fully utilized, the production cost is low, the construction is simple and quick, good economic benefits and social benefits can be generated, and the mortar is suitable for thermal insulation and energy saving engineering of inner / outer walls.

Owner:TONGJI UNIV

Self-compacting concrete prefabricated hollow plate girder with hybrid fibres instead of reinforcing steel bars and manufacturing method

ActiveCN105729616AGood gripReduce the degree of environmental corrosionCeramic shaping apparatusBridge structural detailsRebarHoneycomb

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com