Self-compacting concrete prefabricated hollow plate girder with hybrid fibres instead of reinforcing steel bars and manufacturing method

A self-compacting concrete and hybrid fiber technology, applied in bridges, manufacturing tools, bridge parts, etc., to achieve the effect of improving accuracy, increasing spacing, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments do not limit the present invention in any form.

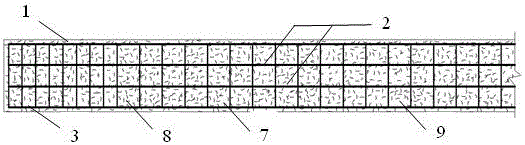

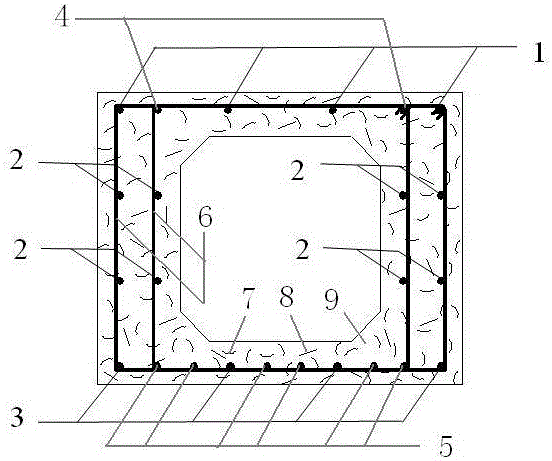

[0029] see figure 1 , figure 2 , a self-compacting concrete prefabricated hollow slab girder in which hybrid fiber replaces steel bar, which is composed of steel bar, concrete, and fiber. The steel bar includes prestressed steel bar, ribbed steel bar and smooth round steel bar. The ribbed steel bars are respectively used for ribbed longitudinal tension steel bar 3, ribbed longitudinal compression steel bar 1, ribbed web longitudinal force steel bar 2 and ribbed shear stirrup 6, and smooth round steel bars are used to fix the top frame of the stirrup Vertical bars 4; concrete is high-performance self-compacting concrete 9 with a compressive strength not greater than 50MPa, and the components of self-compacting concrete 9 include 425 Portland cement, Class I fly ash, medium sand, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com