Overturning type automatic wheat airing and drying device

A drying device and automatic technology, applied in drying, drying, transportation and packaging, etc., can solve the problems of increased work and rest, affecting work, poor drying effect, etc., to achieve improved stability, uniform heating, and grip good soil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] see Figure 1-4 :

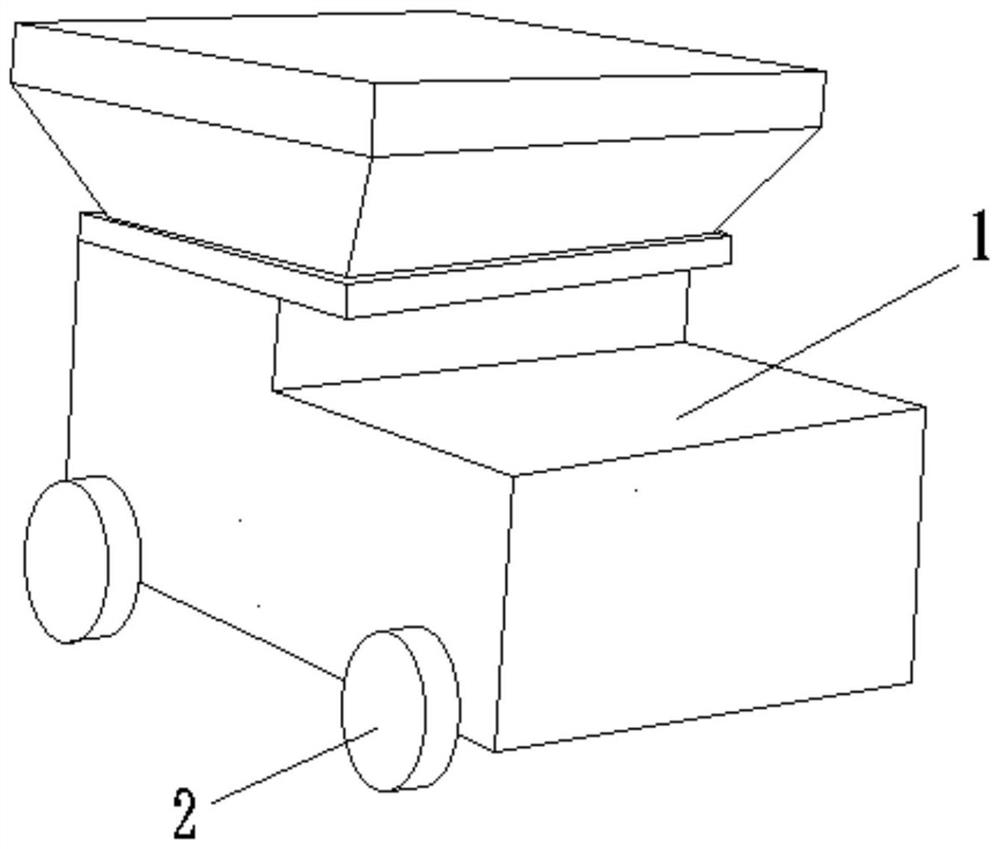

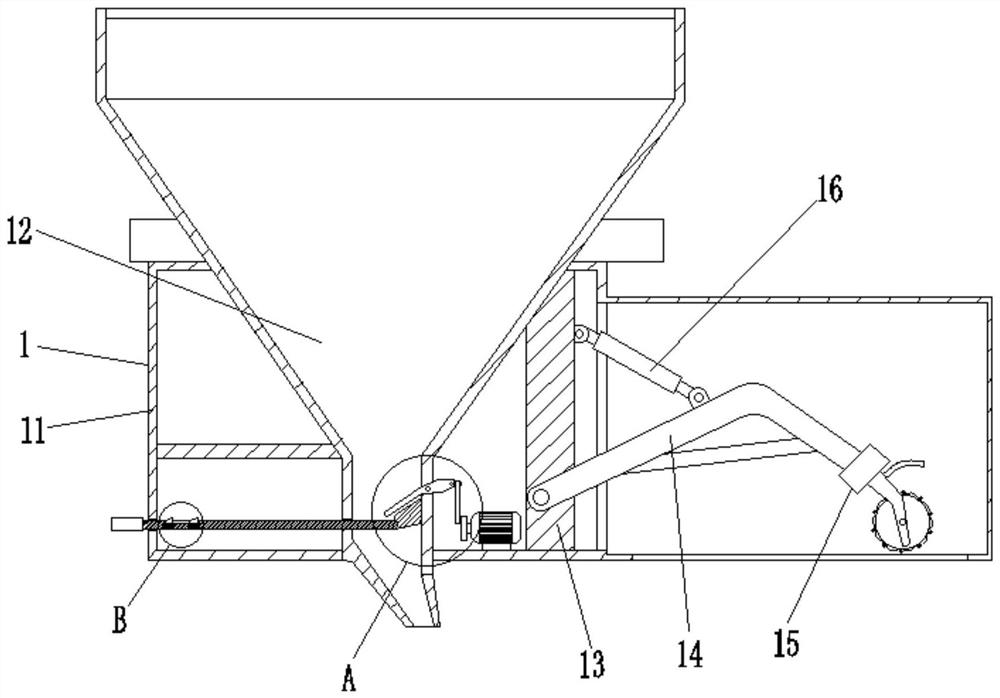

[0029] The present invention provides a technical solution: a flip-type automatic drying device for wheat, including a storage mechanism 1, the four corners of the bottom of the storage mechanism 1 are equipped with moving wheels 2, and the storage mechanism 1 includes a housing 11, a storage box 12, and a support column 13. The movable frame 14, the turning mechanism 15 and the hydraulic cylinder 16, the casing 11 is arranged inside the storage mechanism 1, the storage box 12 is arranged inside the casing 11, the support column 13 is arranged on the right side of the storage box 12, the movable frame 14 and the support The columns 13 are movably connected, the turning mechanism 15 is arranged on the right side of the movable frame 14 , and the hydraulic cylinder 16 is arranged above the movable frame 14 .

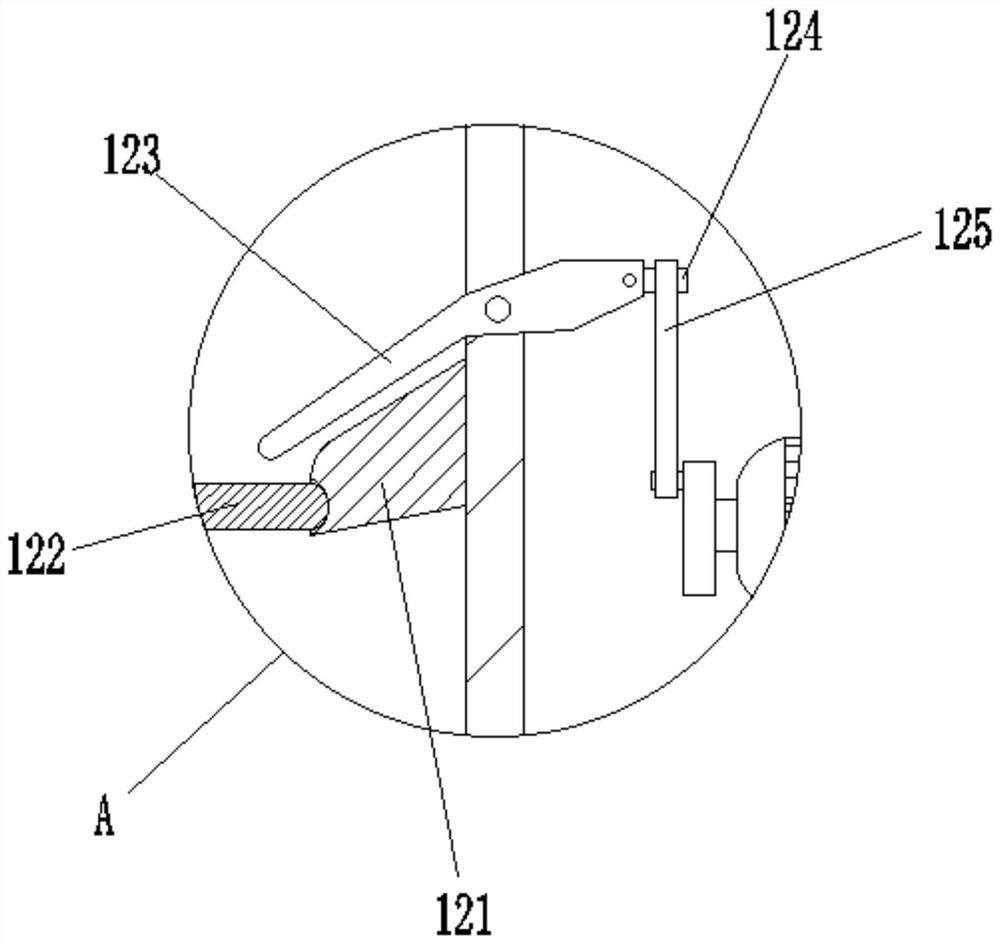

[0030] The storage box 12 comprises a deflector block 121, a pull rod 122, a top plate 123, a movable block 124 and a movable rod 125, the defl...

Embodiment 2

[0033] see Figure 5-8 :

[0034] The turning mechanism 15 includes a support rod 151, a baffle plate 152, a turning wheel 153, a scraping head 154 and a fixed shaft 155. The supporting rod 151 is arranged inside the turning mechanism 15, the scraping head 154 is fixedly connected to the bottom of the supporting plate 151, and the turning wheel 153 is arranged on the bottom of the supporting plate 151. Below the support rod 151, the fixed shaft 155 is installed at the center of the turning wheel 153. Both ends of the fixed shaft 155 are fixedly connected to the scraper head 154, and the baffle 152 is fixedly connected to the right side of the scraper 154. By setting the baffle 152, the wheat is prevented from Sprinkle to a distance during the flipping process.

[0035] The turning wheel 153 includes a pressing wheel b1, a bearing b2, a gripping head b3, a concentration groove b4 and a protective cover b5, the pressing wheel b1 is arranged at the center of the turning wheel 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com