Structure of asphalt pavement applicable to very heavy traffic

A technology for asphalt pavement and traffic, which is applied in the field of asphalt pavement structure to ensure the bearing capacity, improve the density and durability, and improve the permanent deformation resistance and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

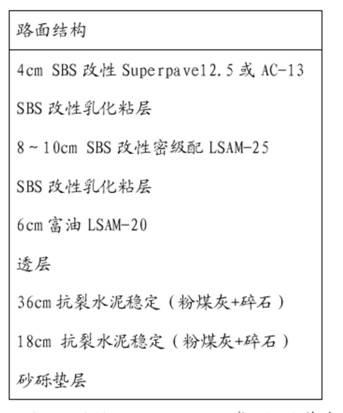

[0017] A coal-transporting main road was originally a cement concrete pavement. Due to heavy loads, the cement concrete panels were seriously broken, and the base course was cracked and scoured severely, so it needed to be rebuilt. Trucks account for about 45% of the road's traffic composition. Axle load conversion is carried out according to the asphalt pavement, and the accumulated equivalent axle times within the design period of the lane are 8.3×10 7 times / lane. The overlay plan that can be adopted is: 4cm SBS modified AC-13+SBS modified emulsified adhesive layer+8cm SBS modified densely graded large particle size asphalt mixture LSAM-25+SBS modified emulsified adhesive layer+6cmLSAM-20+ 36cm anti-cracking cement stabilized (fly ash + crushed stone) base + treated original cement concrete pavement (the old cement concrete slab is crushed and compacted as the subbase). Among them, the SBS content of SBS-modified AC-13 in the wear layer is 4.5%; the SBS content of SBS-modi...

Embodiment 2

[0019] An expressway was originally an asphalt pavement structure. Due to heavy loads, it was cracked and seriously damaged by subsidence, so it needed to be rebuilt. The proportion of large trucks in the traffic composition of the expressway accounts for 50% to 60%. According to the conversion of the existing axle load, the accumulated equivalent axle times within the design period of the lane are 6.5×10 7 times / lane. The overlay structure that can be used is: 4cm SBS modified Superpave12.5+SBS modified emulsified adhesive layer+8cm SBS modified densely graded large particle size asphalt mixture LSAM-25+SBS modified emulsified adhesive layer+6cmLSAM-20 +36cm anti-cracking cement stabilized (fly ash + gravel) base + original asphalt pavement after treatment. Among them, the SBS content of SBS-modified Superpave12.5 in the wearing layer is 4.5%; the SBS content of SBS-modified densely-graded large particle size asphalt mixture LSAM-25 in the middle layer is 4%; the content of ...

Embodiment 3

[0021] For a new expressway, the proportion of large trucks in the predicted traffic composition accounts for more than 43%, and the cumulative equivalent axle times within the design period are 7.2×10 7 times / lane. The structural form that can be used is: 4cm SBS modified Superpave12.5+SBS modified emulsified adhesive layer+10cm SBS modified densely graded large particle size asphalt mixture LSAM-25+SBS modified emulsified adhesive layer+6cmLSAM-20+36cm Anti-cracking cement stabilized (fly ash + gravel) base + 18cm anti-cracking cement (fly ash + gravel) subbase. Among them, the SBS content of SBS-modified Superpave12.5 in the wearing layer is 4.5%; the SBS content of SBS-modified densely-graded large particle size asphalt mixture LSAM-25 in the middle layer is 4%; the content of LSAM-20 in the anti-fatigue layer 4.3%; the same amount of fly ash in anti-cracking cement stabilization (fly ash + crushed stone) replaces 8% of stone chips. The above constitutes the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com