Patents

Literature

183 results about "Wearing course" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The wearing course is the upper layer in roadway, airfield, and dockyard construction. The term 'surface course' is sometimes used, however this term is slightly different as it can be used to describe very thin surface layers such as chip seal. In rigid pavements the upper layer is a portland cement concrete slab. In flexible pavements, the upper layer consists of asphalt concrete, that is a construction aggregate with a bituminous binder. The wearing course is typically placed on the binder course which is then laid on the base course, which is normally placed on the subbase, which rests on the subgrade. There are various different types of flexible pavement wearing course, suitable for different situations.

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

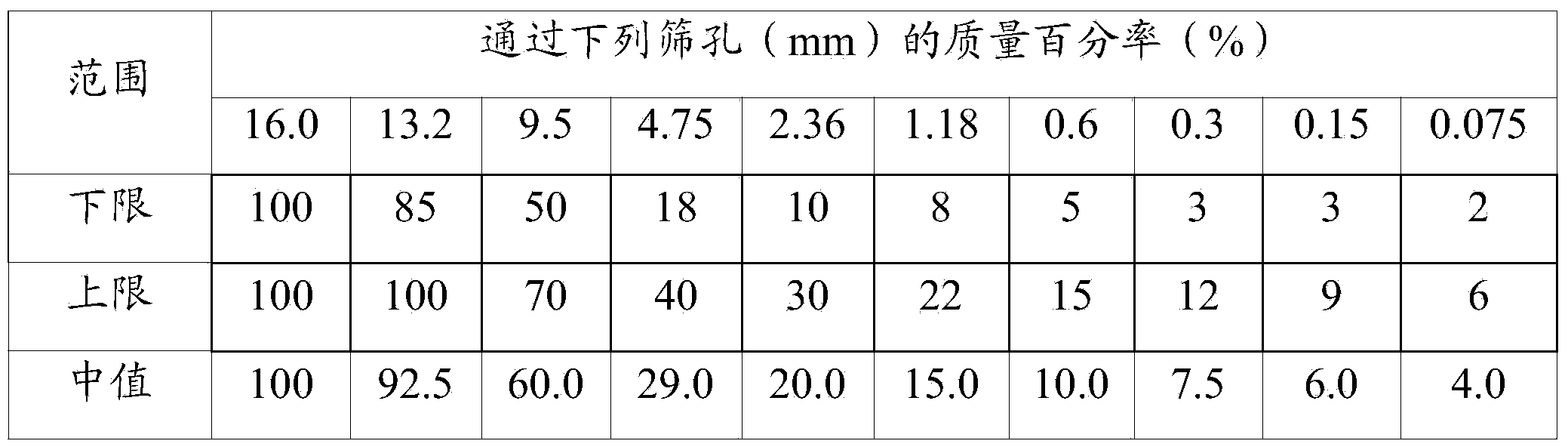

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

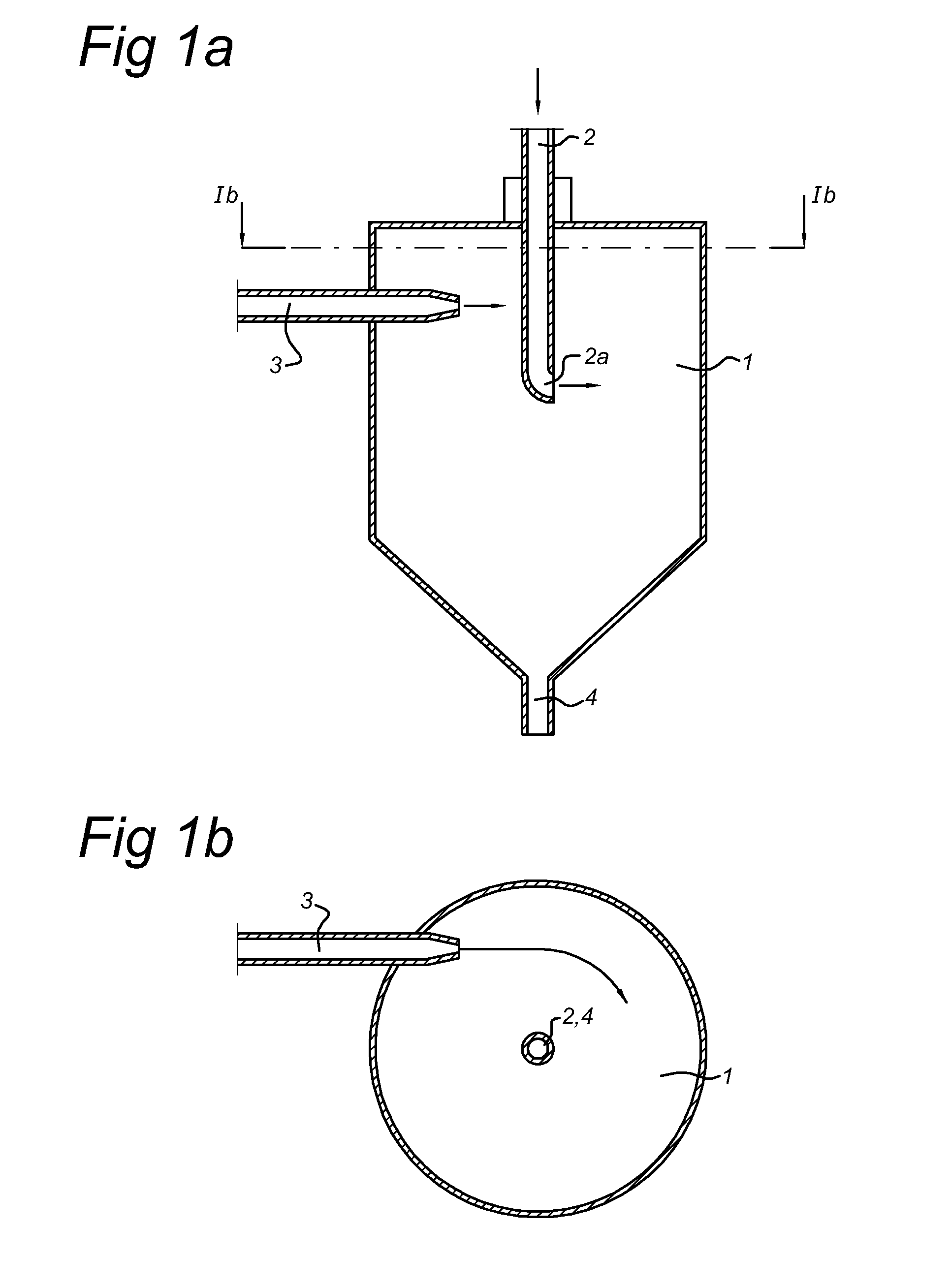

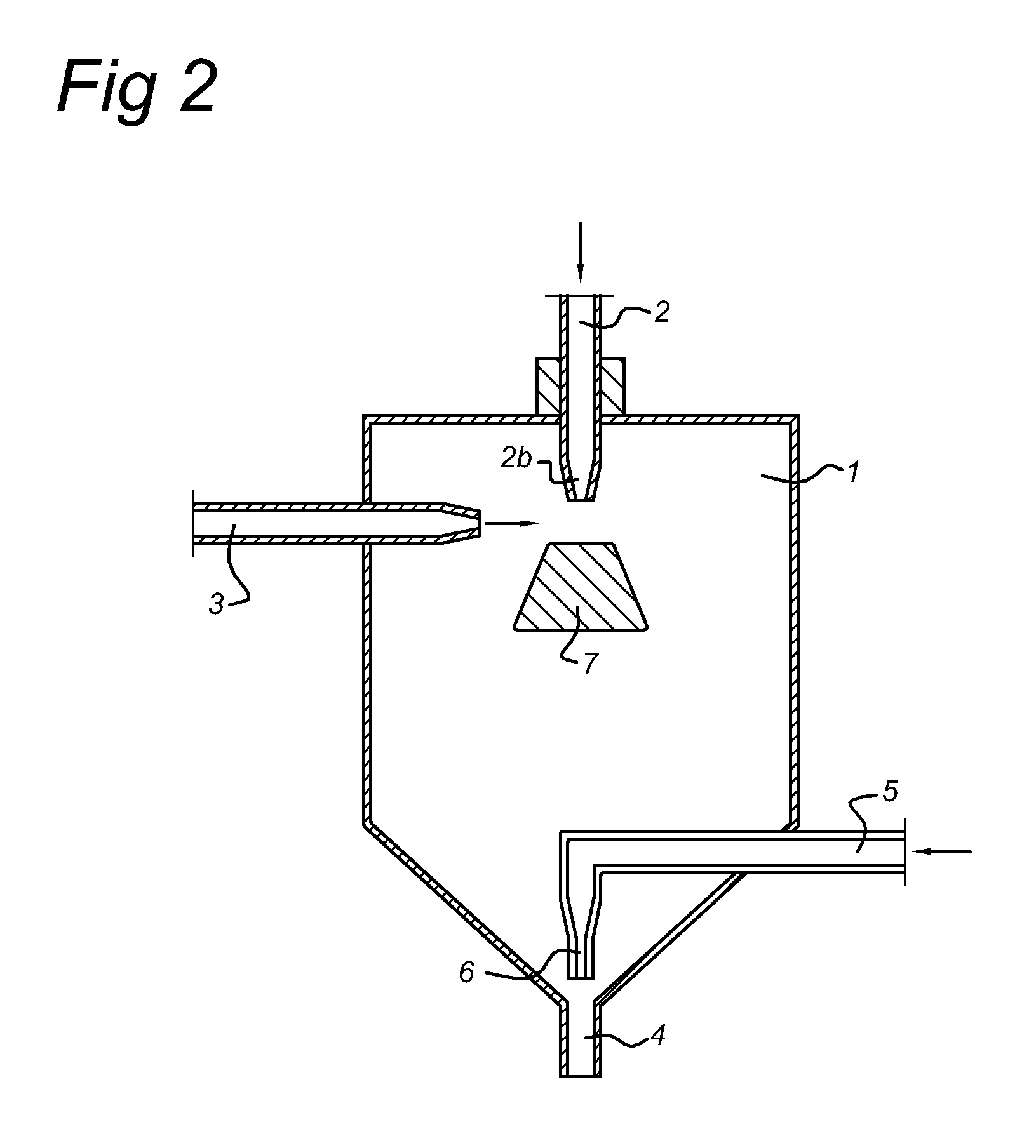

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

Ultra-thin wearing layer of pavement

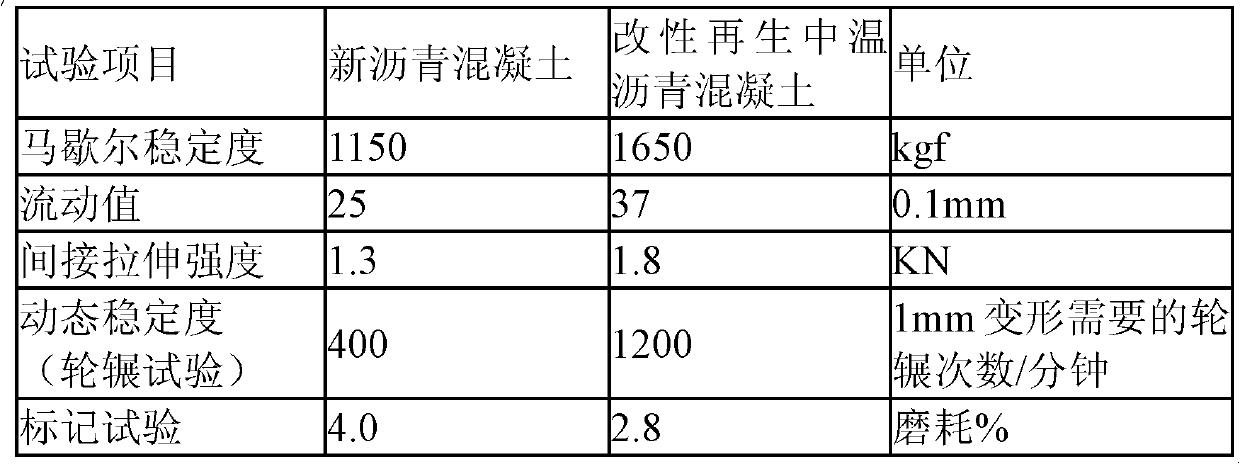

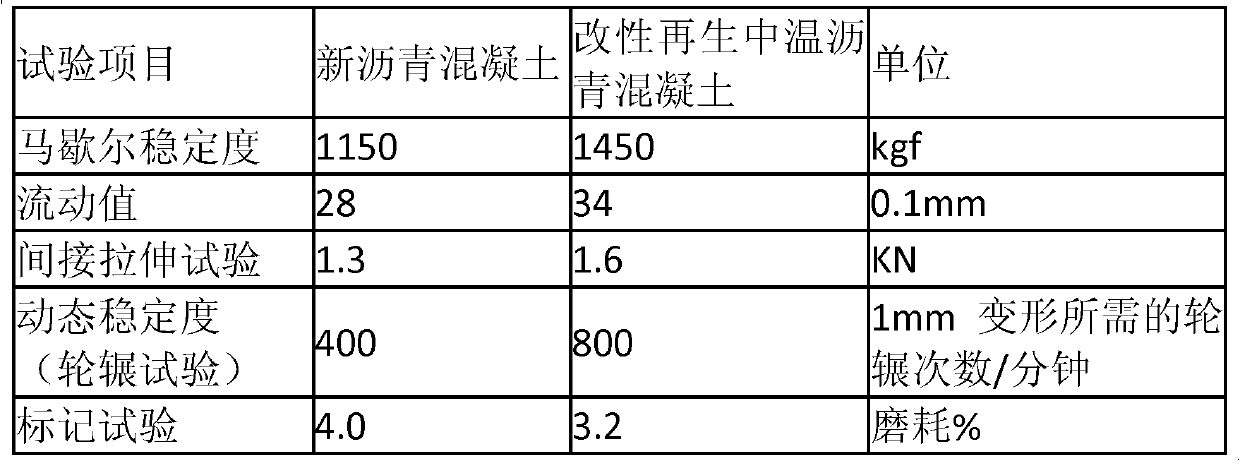

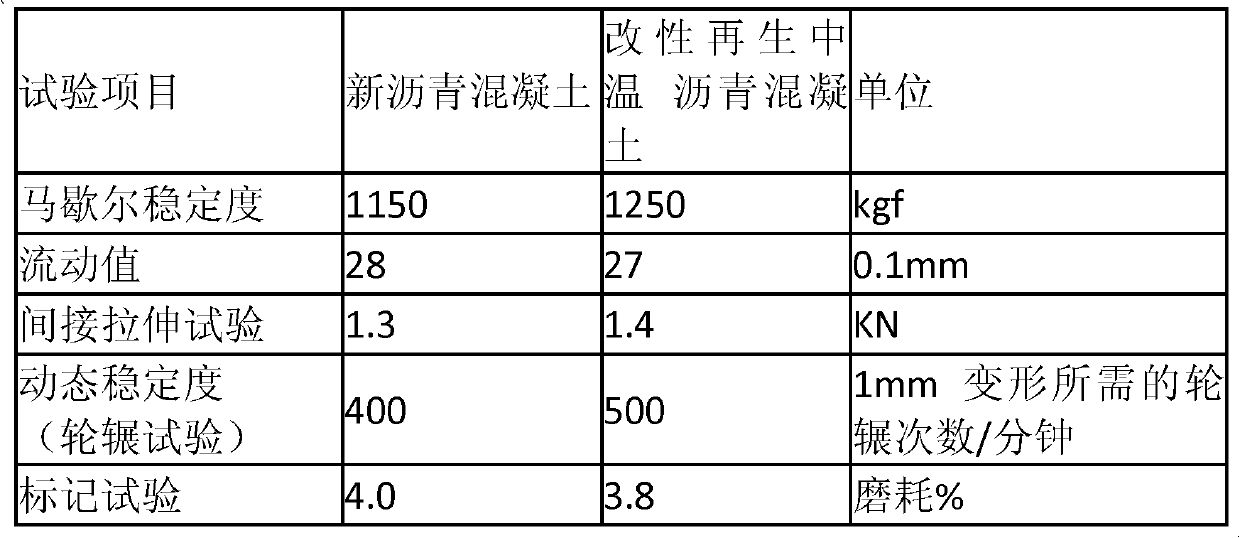

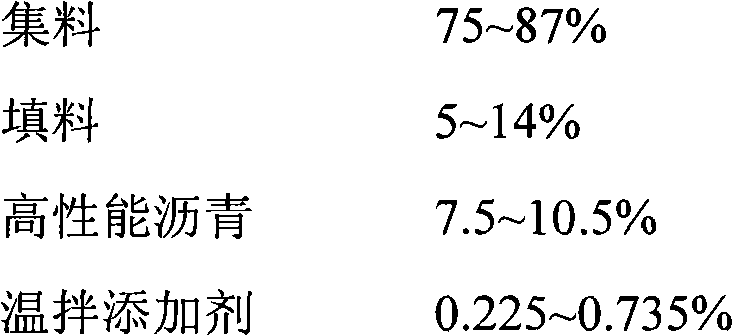

The invention belongs to the technical field of a building material used in road engineering, and specifically relates to drainage asphalt mixture for an ultra-thin wearing layer. The mixture comprises aggregated material, stuffing, high-performance asphalt and warm mixing additive; the maximal nominal size of the mixture is 6.7mm; the thickness of a pavement layer is 10-20mm; the aggregated material is basalt or dolerite; the used stuffing is mixture of limestone powder and common silicate cement, and the used high-performance asphalt is prepared from general modified asphalt by adding waste tire rubber powder which is 20-28% of weight of the asphalt and modifying. An ultra-thin finishing coat and low-temperature construction are realized by the asphalt mixture by adding the warm mixing additive; the ultra-thin wearing layer has the advantages of low construction cost, convenience in construction and the like, and is suitable for building of an asphalt concrete pavement and function-improving works of the pavement.

Owner:上海砼仁环保技术发展有限公司

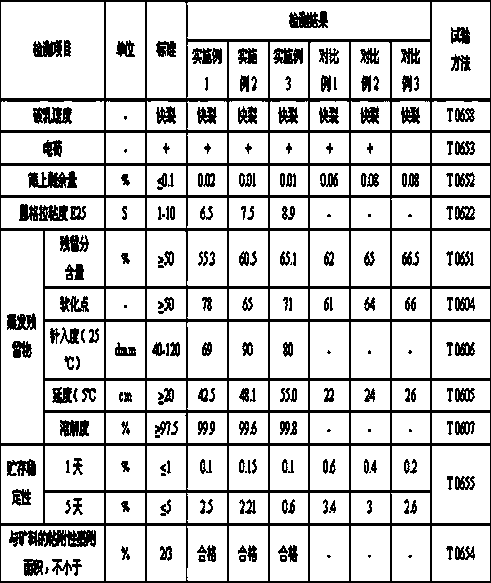

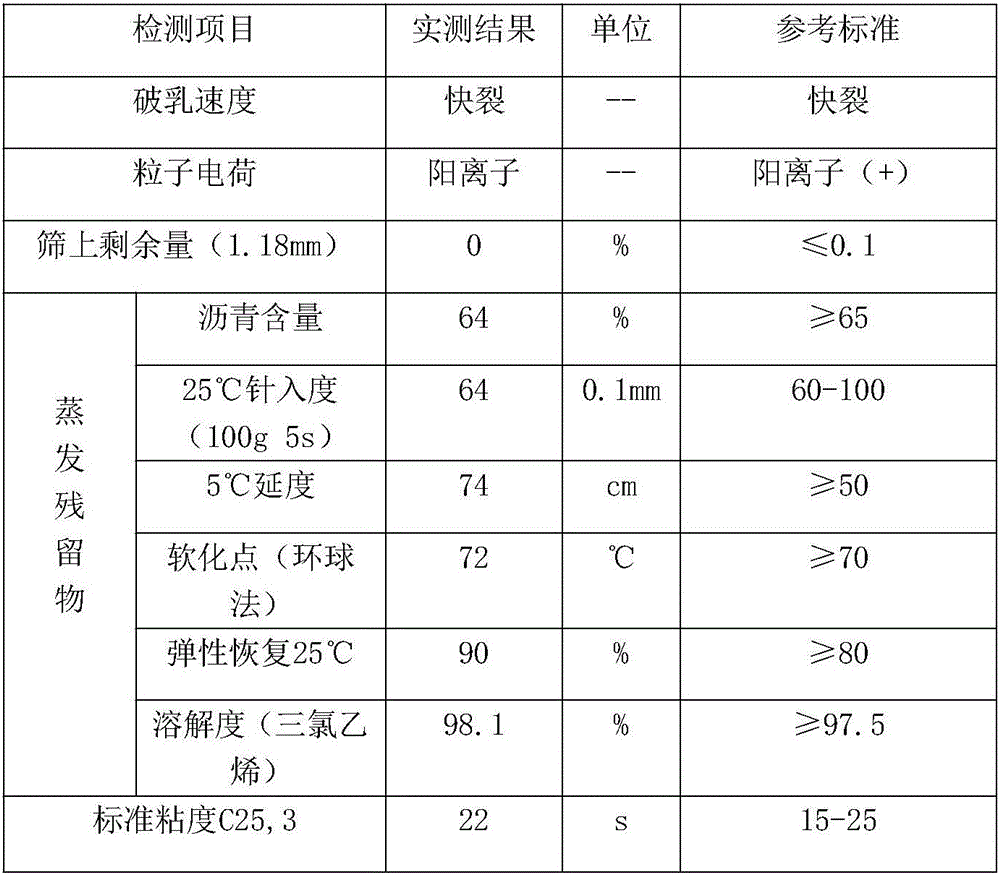

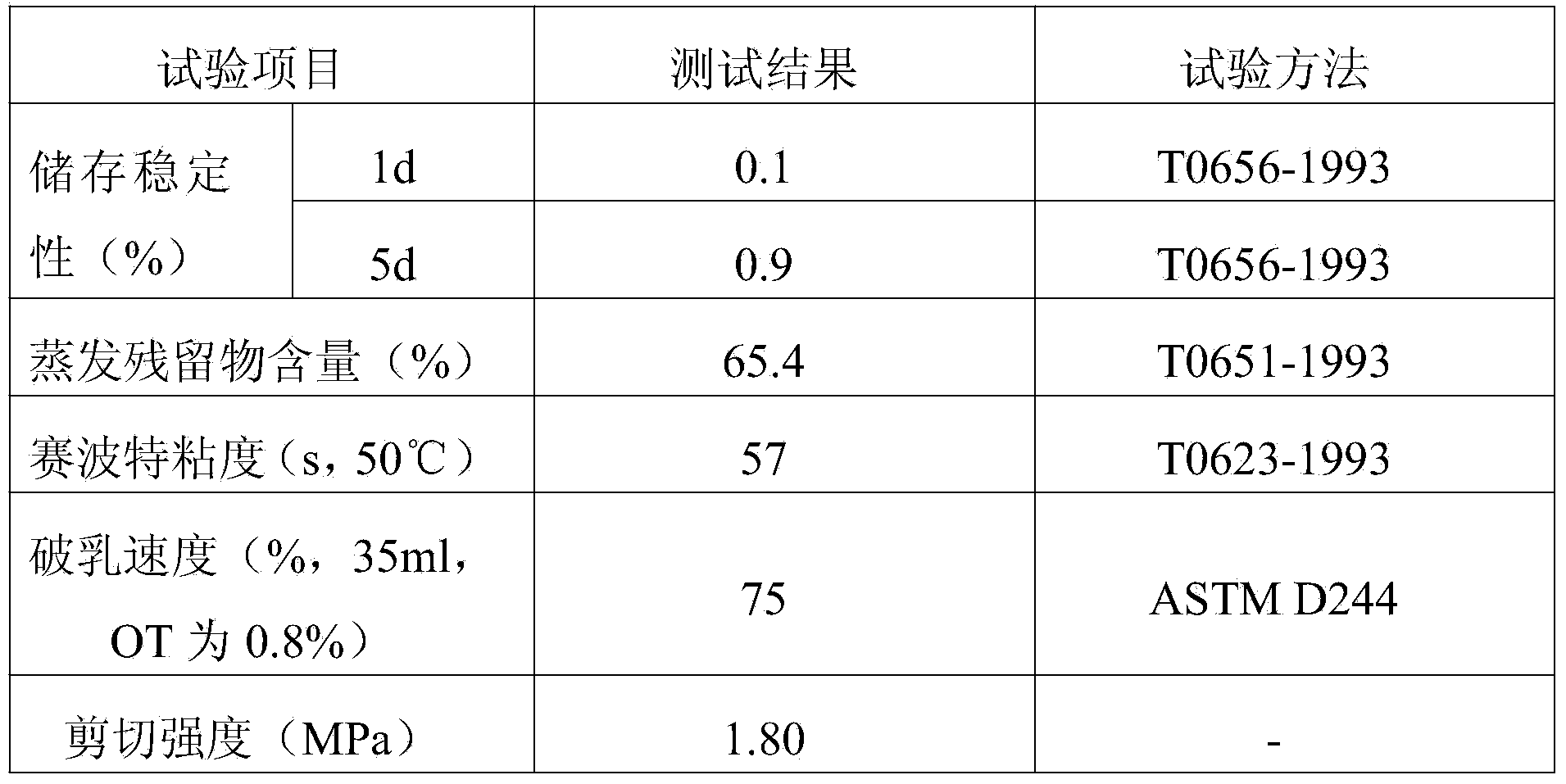

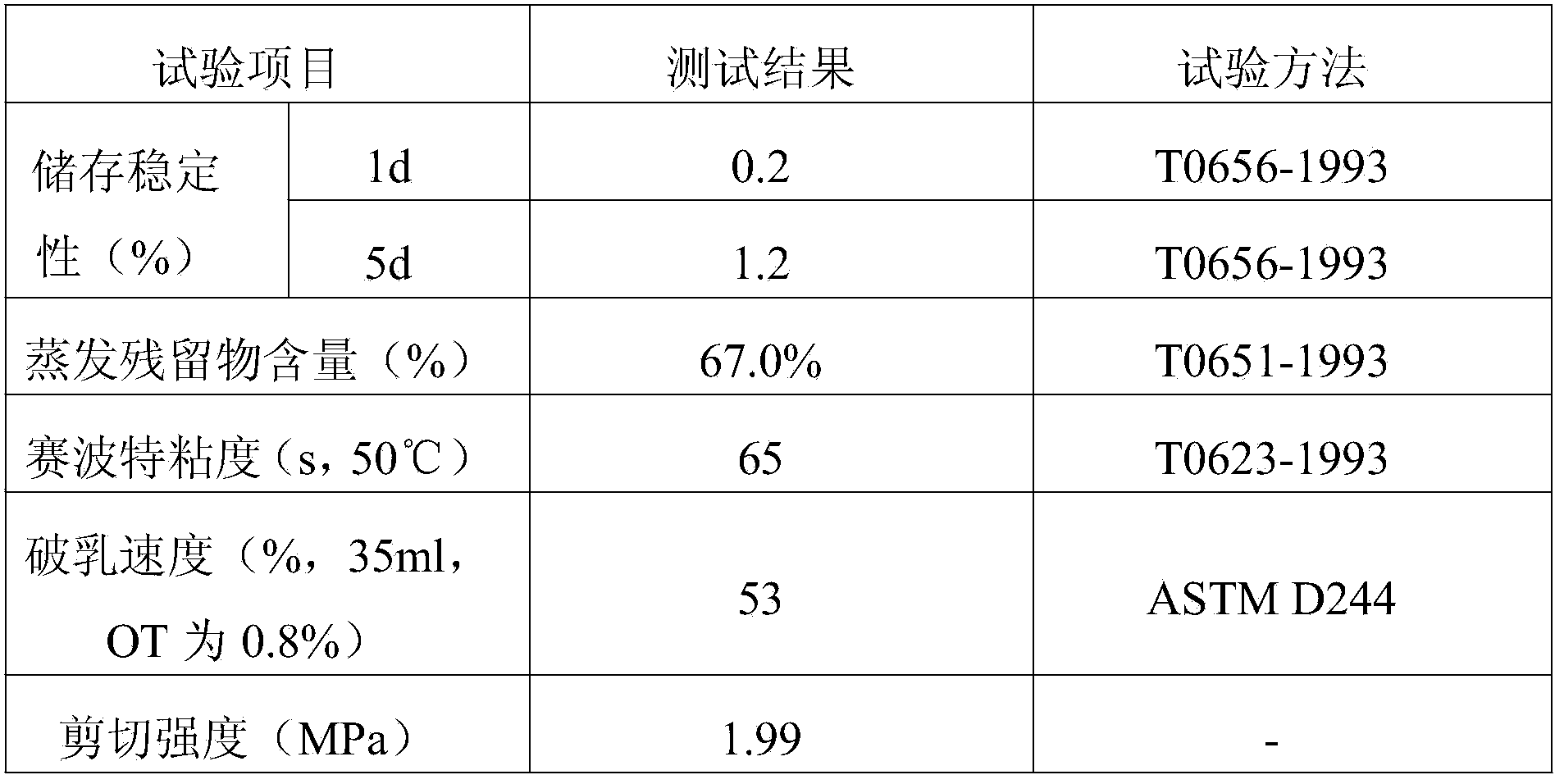

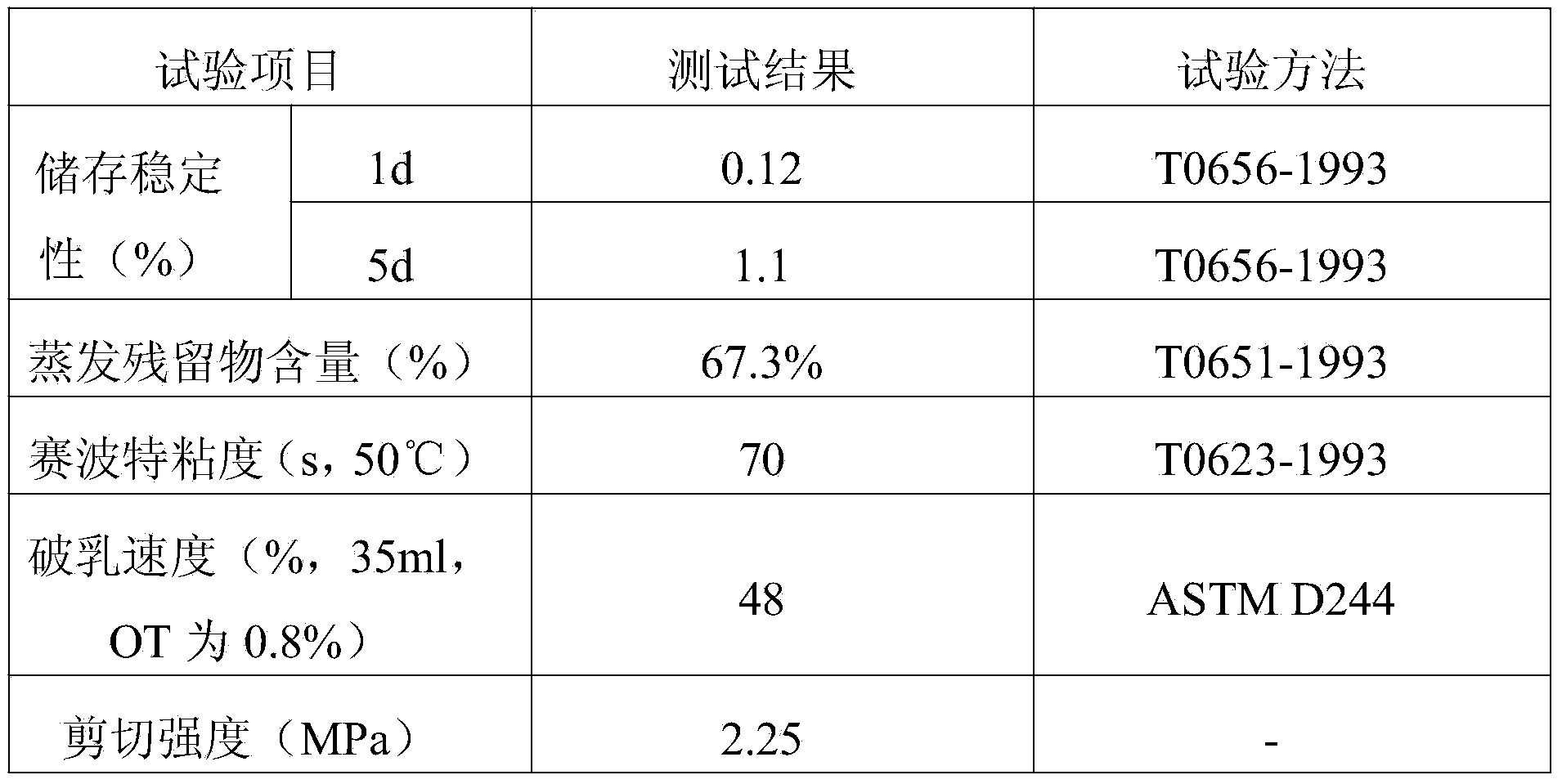

SBS (styrene butadiene styrene)/SBR (styrene butadiene rubber) composite modified emulsified asphalt and preparation method thereof

InactiveCN103951994AHigh softening pointImprove ductilityBuilding insulationsPolymer scienceBitumen emulsion

The invention relates to SBS (styrene butadiene styrene) / SBR (styrene butadiene rubber) composite modified emulsified asphalt. The SBS / SBR composite modified emulsified asphalt consists of matrix asphalt, linear SBS which accounts for 3.5%-5.5% of the weight of the matrix asphalt, compatilizer which accounts for 1%-4% of the weight of the matrix asphalt, stabilizer which accounts for 0.1%-0.4% of the weight of the matrix asphalt, viscosity reducer which accounts for 2.0%-10.0% of the weight of the matrix asphalt, emulsifier which accounts for 0.5%-1.5% of the weight of the matrix asphalt and SBS rubber latex which accounts for 1%-5% of the weight of the matrix asphalt. The SBS / SBR composite modified emulsified asphalt obtained in the invention has characteristics of being high in softening point, high in ductility, high in solid content and low in viscosity, achieves and is further higher than JTGF40-2004 product specification requirements of Ministry of Communications, and can be suitable for special high-grade bituminous pavements such as an ultrathin wearing layer, and the like as well as an associated construction process thereof.

Owner:中海沥青(泰州)有限责任公司

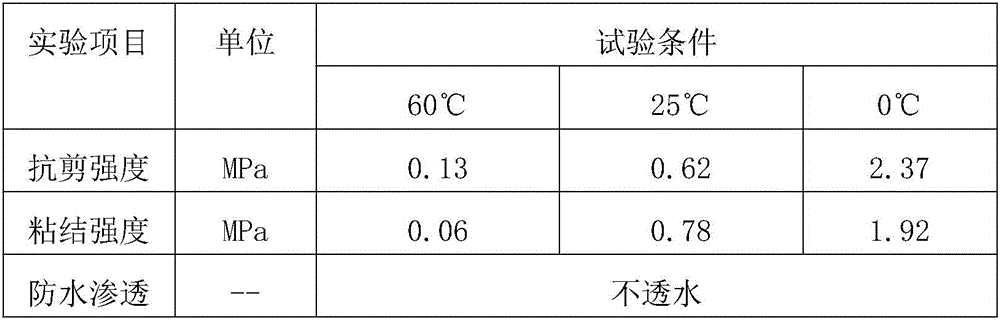

Strong-viscosity emulsified modified asphalt and preparation method thereof

ActiveCN102061099AImprove road performanceImprove adhesionBuilding insulationsPolymer scienceChipseal

The invention discloses strong-viscosity emulsified modified asphalt and a preparation method thereof. The emulsified modified asphalt comprises the following components in percent by mass: 62-70 percent of SBS (Styrene Butadiene Styrene block copolymer) modified asphalt, 0.5-1.5 percent of blender, 0.8-1.5 percent of emulsifying agent, 1-2 percent of stabilizing agent, 0.3-0.5 percent of thickening agent and the balance of water. The preparation method comprises the steps of: preparing the SBS modified asphalt, adding the blender; adding the emulsifying agent, the stabilizing agent and the thickening agent into water to prepare liquid soap; and uniformly dispersing the modified asphalt and the liquid soap by using a colloid mill to obtain the emulsified modified asphalt. The method disclosed by the invention has the advantages of easy obtaining of the raw materials and simple preparation process; and the strong-viscosity emulsified modified asphalt has excellent road service performance, solves the technical problems of poor caking effect of tack coat oil for the common ultrathin wear layer, easiness of bleeding and low strength of a stone-chip seal coat, can remarkably improve the interlayer caking capacity when used as the tack coat oil, and can remarkably improve the strength and the deformation-resisting capacity of the seal coat when used as the stone-chip seal coat.

Owner:辽宁省交通科学研究院有限责任公司

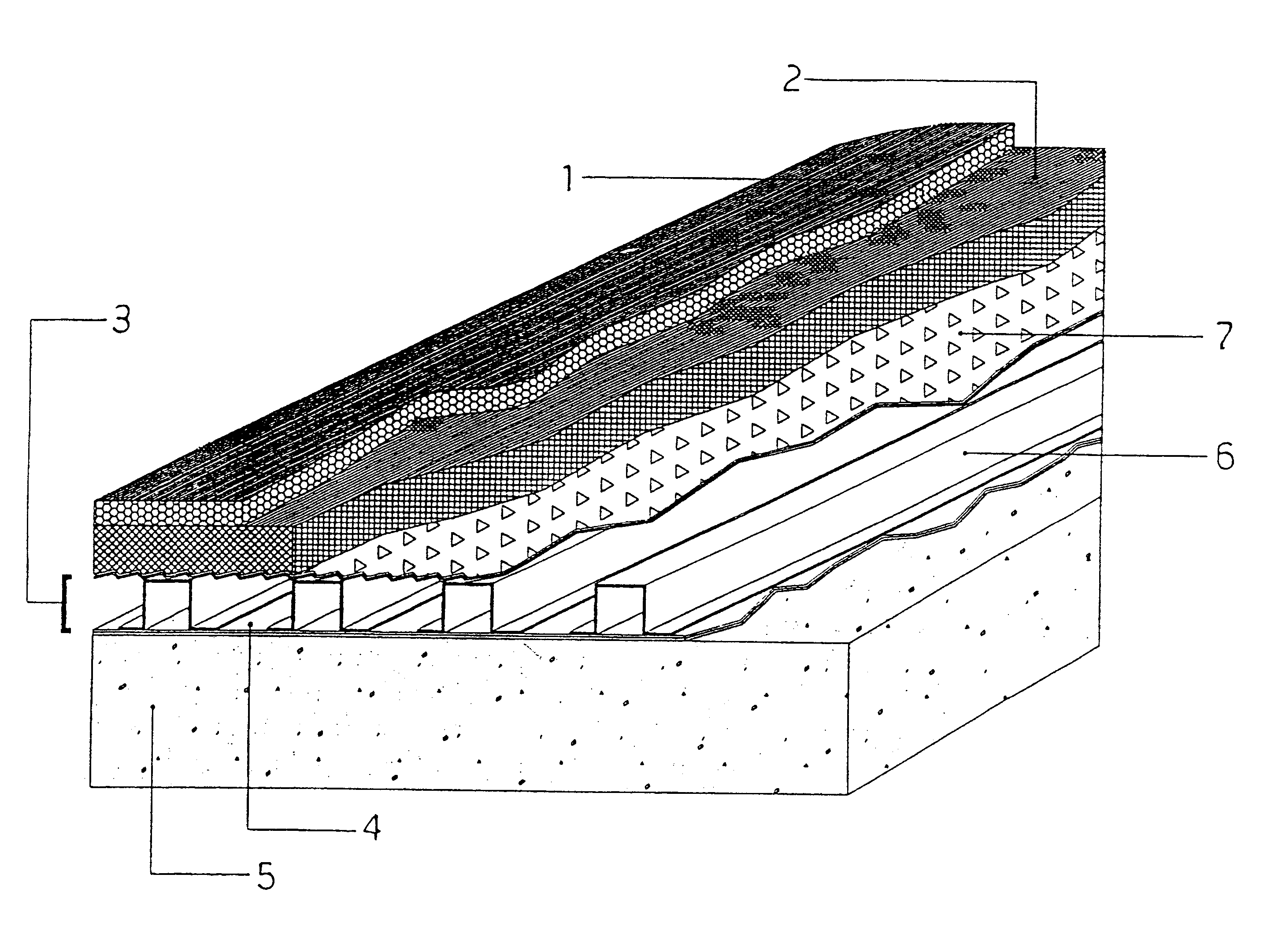

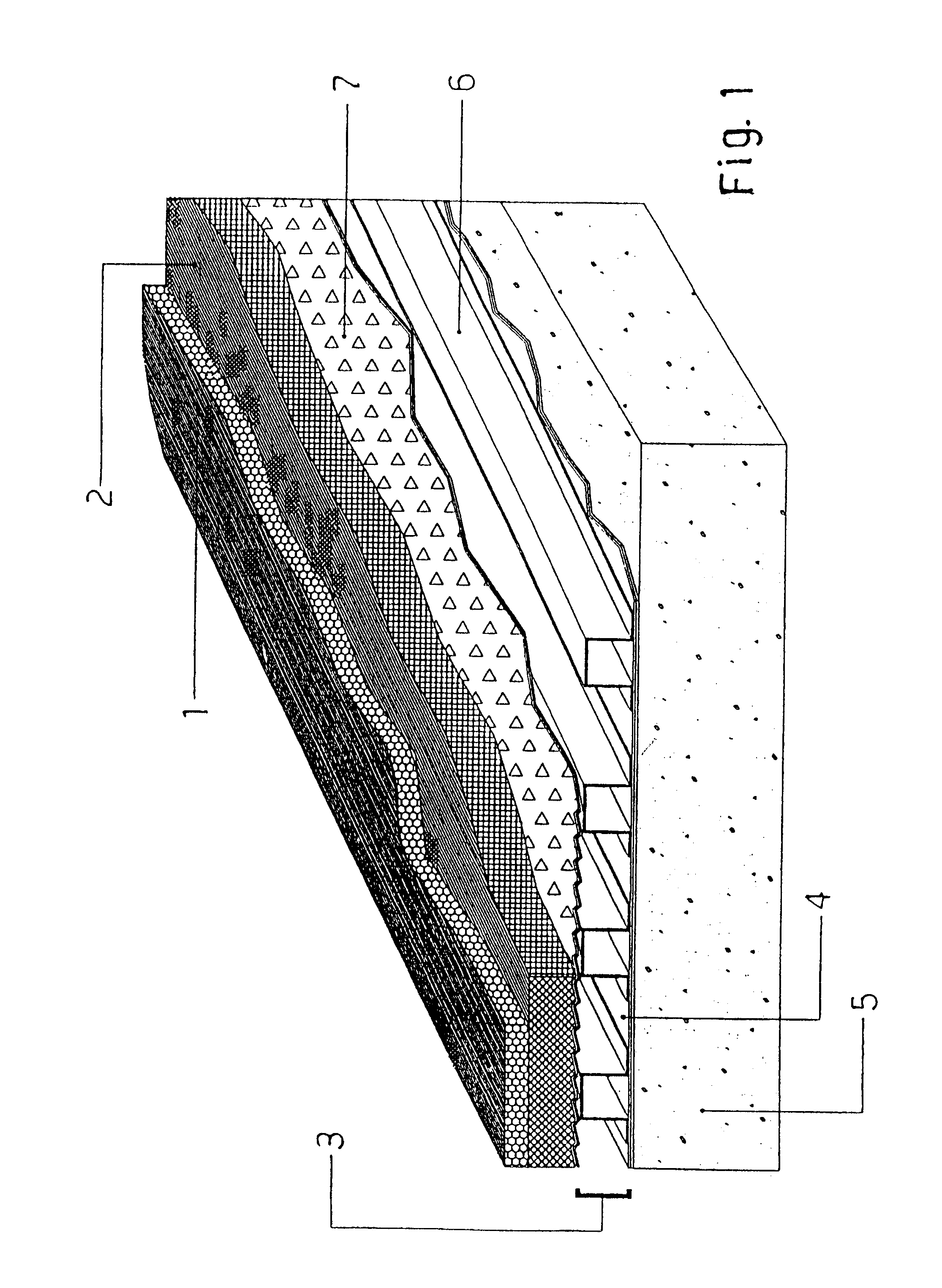

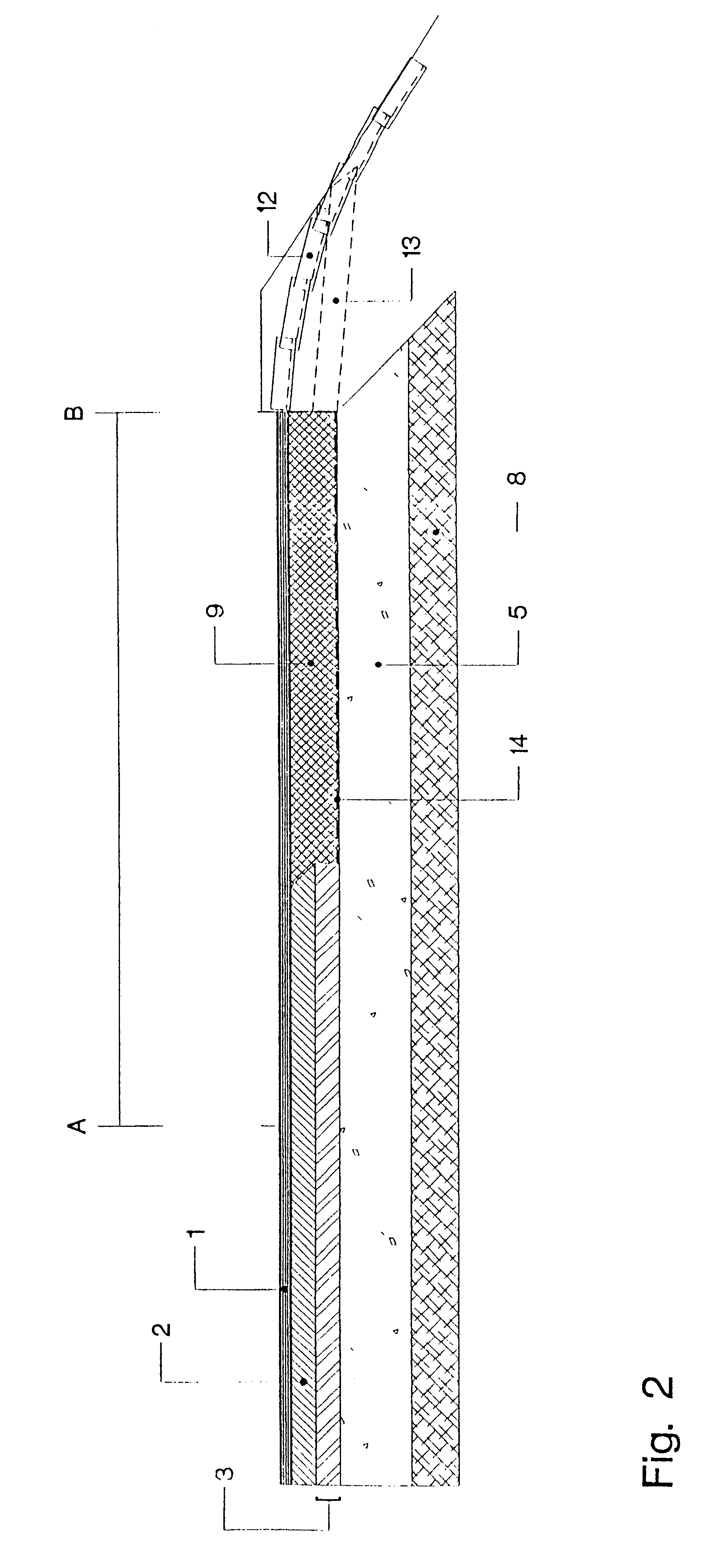

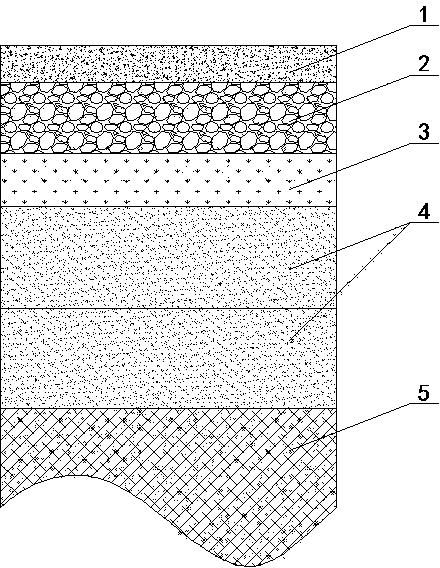

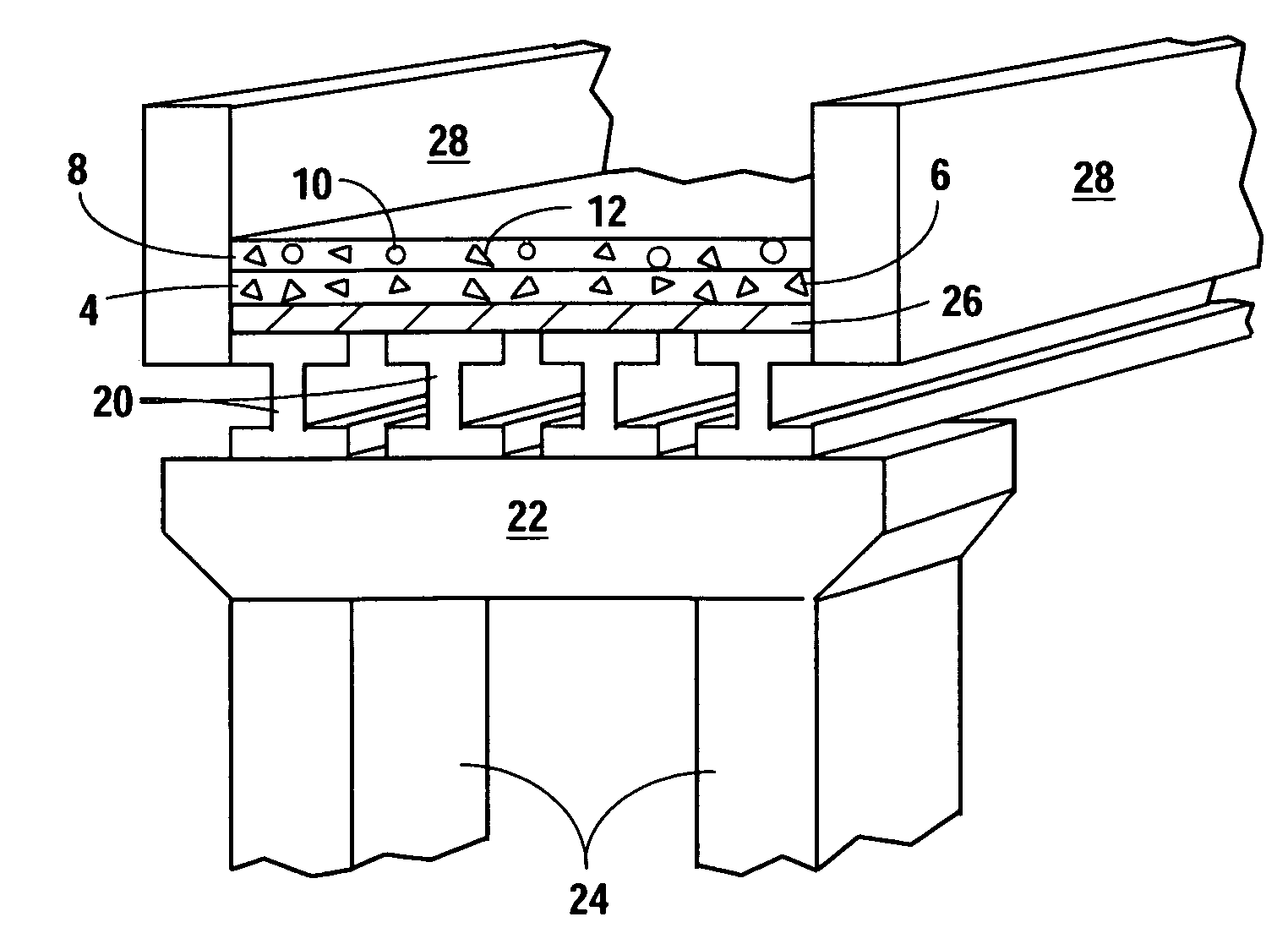

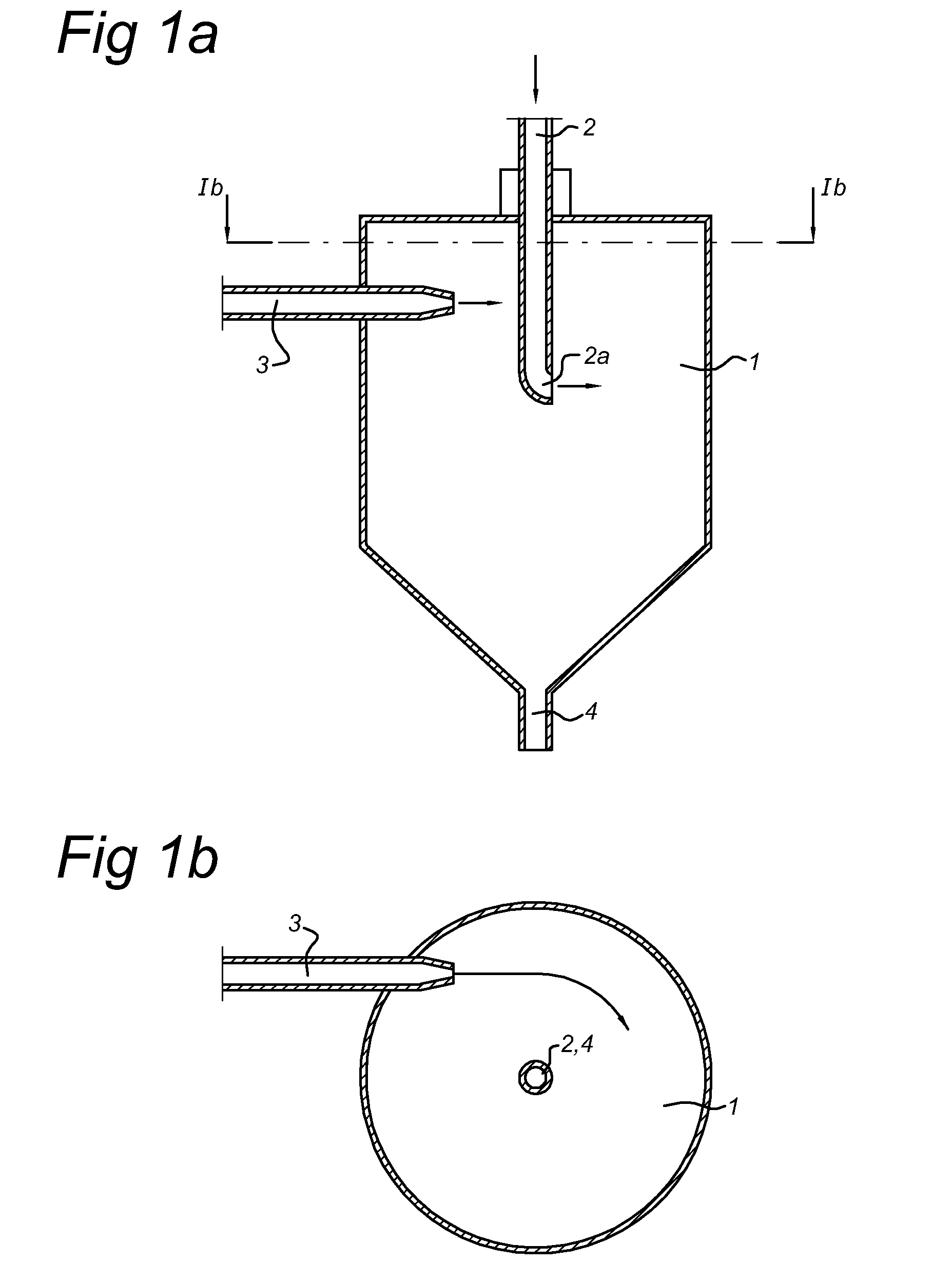

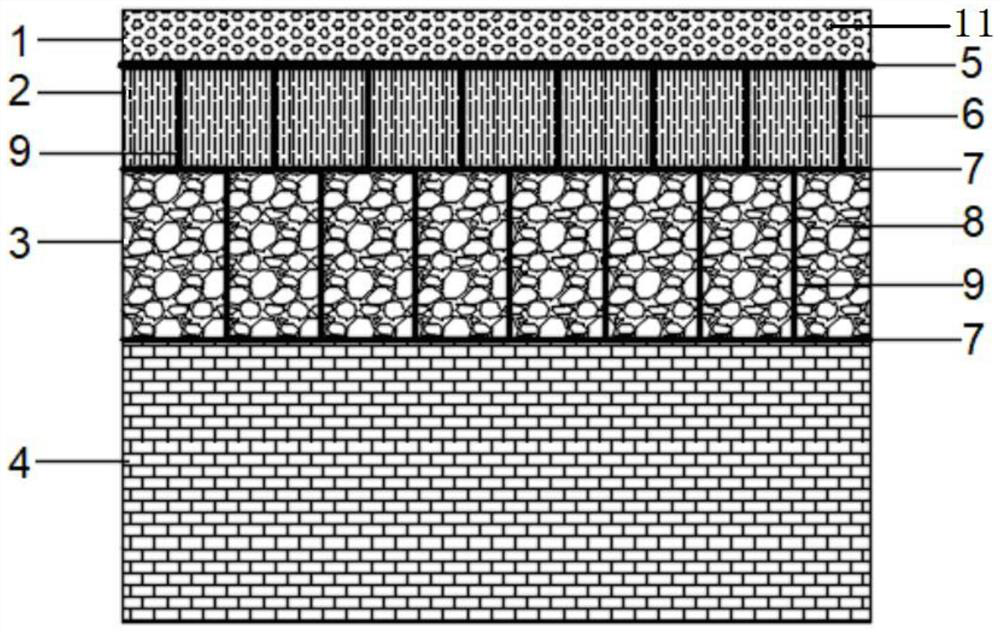

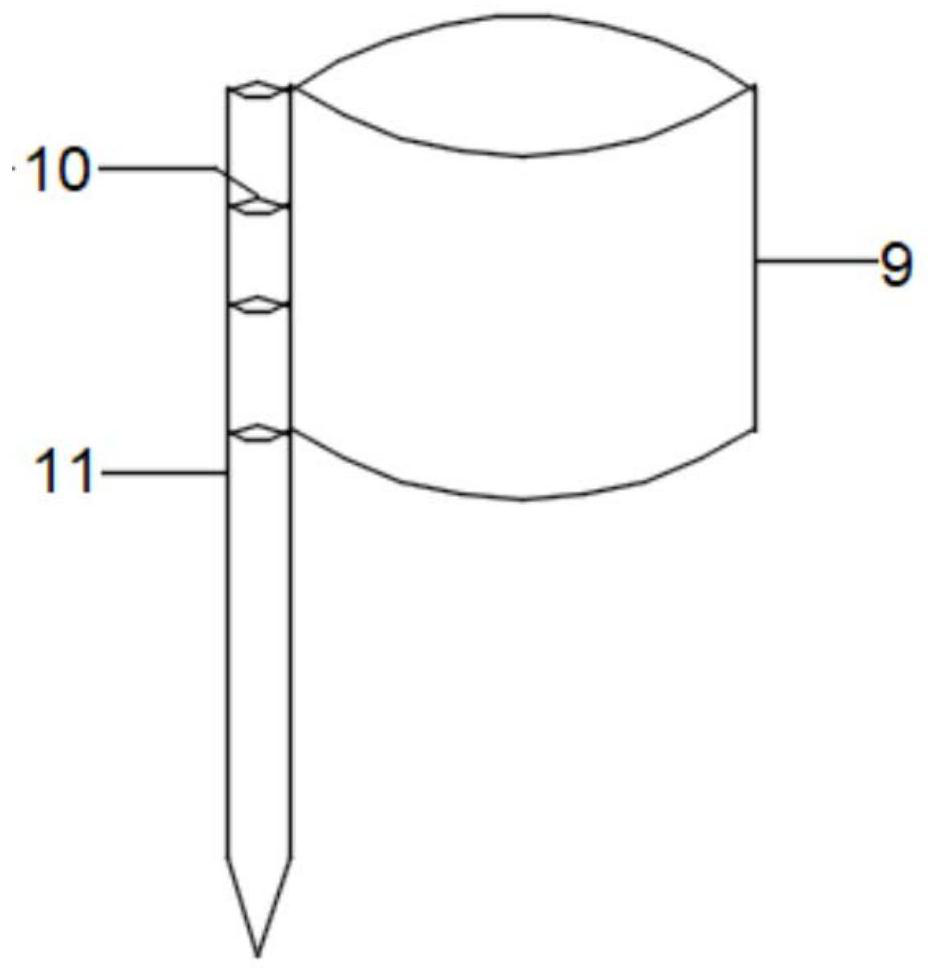

Ecotechnical cooperating separation layer for a pavement and its manufacturing process

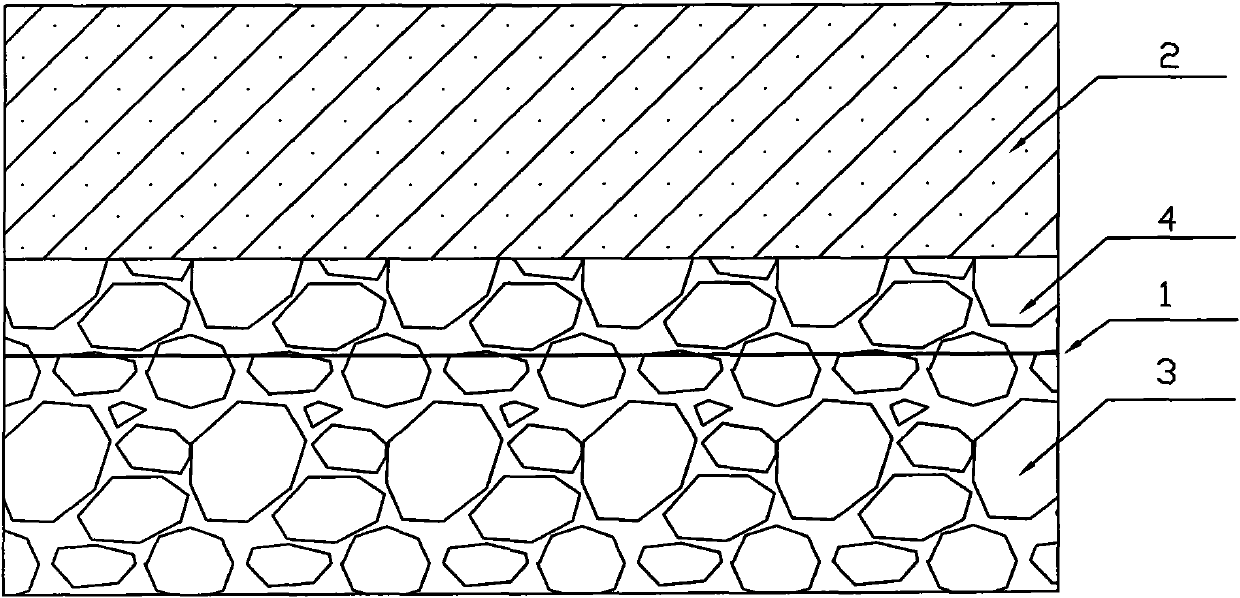

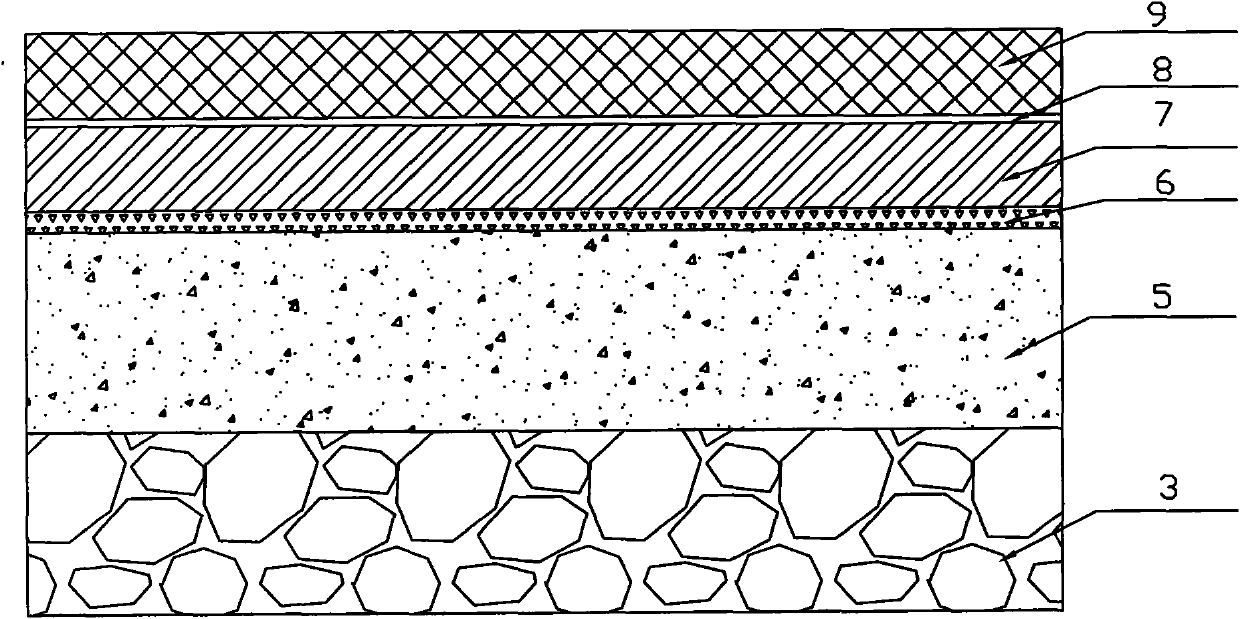

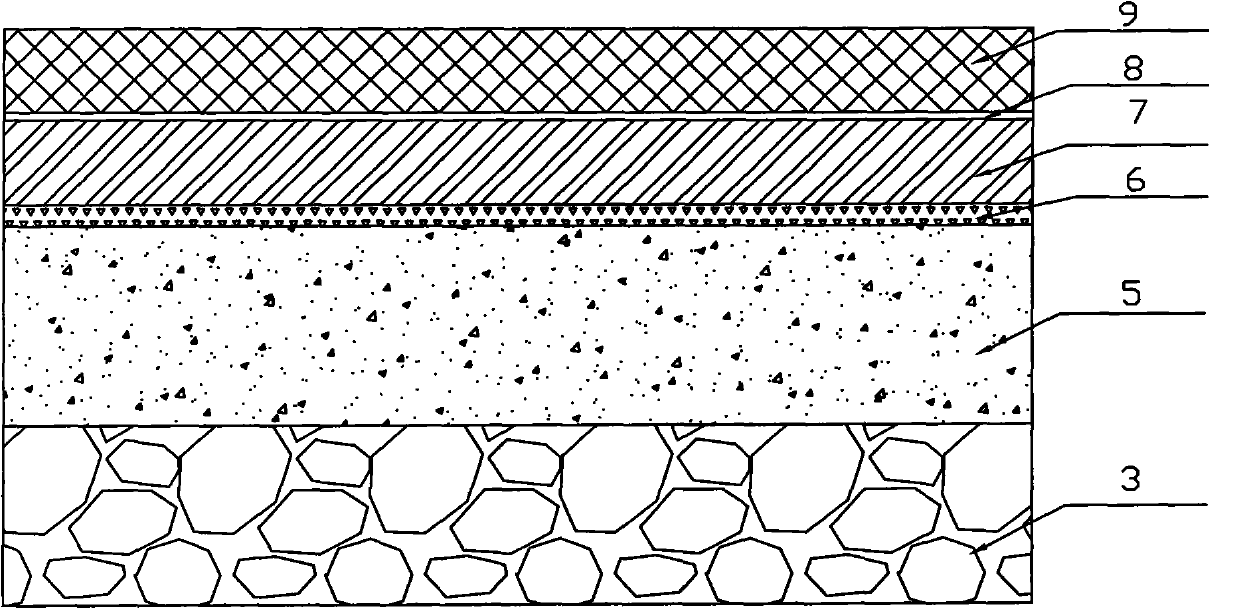

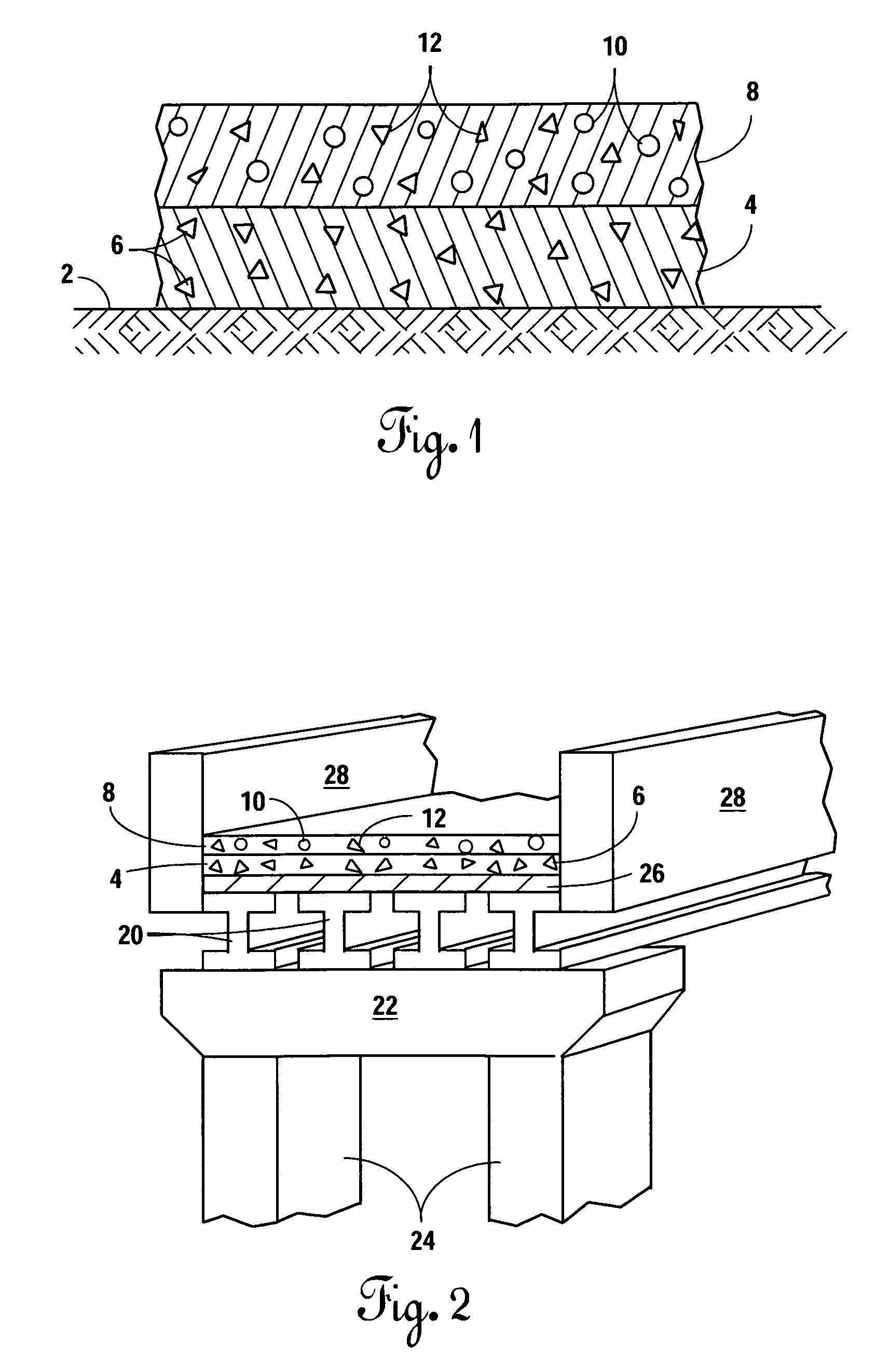

InactiveUS6379079B1High-frequency noiseReduce frequency noiseIn situ pavingsGround-workRoad surfaceWearing course

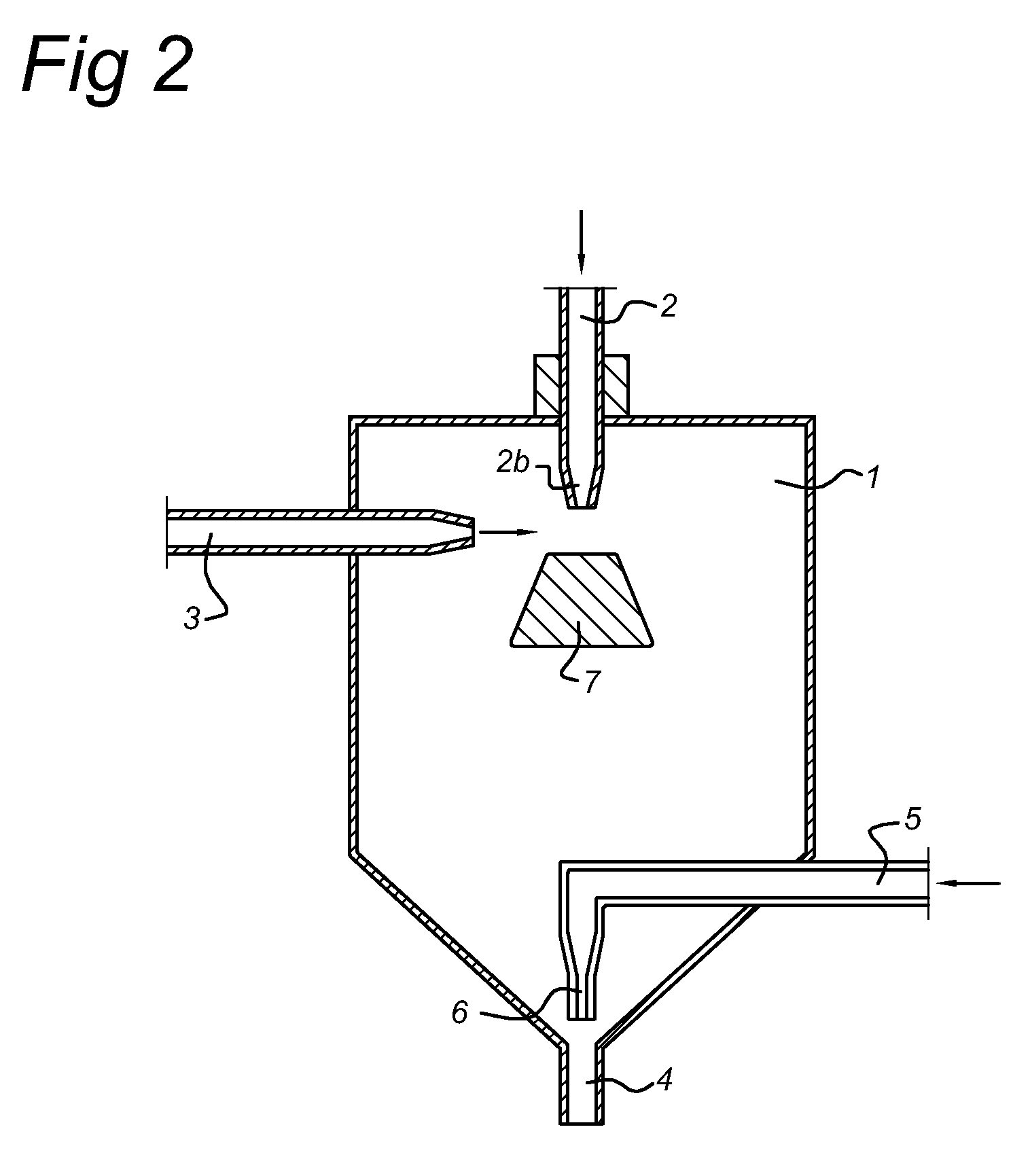

Ecotechnical pavement comprising a draining and wearing course (1) and at least a second lower layer (2) of analogous structure. The particular granulometry of the layers (1, 2) and the choice of aggregates, insure both an optimum adherence and the absorption of medium and high acoustic frequencies produced by vehicle traffic. Between the two layers (1, 2) and the lower supporting layer (5) there is provided a "cooperating separation layer" (3) which transmits the forces produced by vehicle traffic to the supporting layer (5). The layer (3) acts as a Helmhotz resonator in order to absorb sound at low frequencies, besides allowing an easy transversal flow of rainwater, the passage of powder of heavy metals or the passage of other types of liquids; the latter, which may be dangerous or polluting, are collected in a lateral "reservoir pavement" (9). The separation layer prevents cracks due to fatigue from rising.

Owner:AUTOSTRADE SPA

Pavement structure for structure transfer and performance recovery of semi-rigid base asphalt pavement

The invention discloses a pavement structure for structure transfer and performance recovery of a semi-rigid base asphalt pavement, which is characterized in that a transferred-structural cold recycled semi-flexible base is on the non-damaged semi-rigid base of the original asphalt pavement; a modified asphalt emulsion slurry seal layer is coated on a cold recycled semi-flexible base; an asphalt pavement bottom layer is on the modified asphalt emulsion slurry seal layer; a modified asphalt emulsion bonding layer is on the asphalt pavement bottom layer; and a surface abrasion layer is on the modified asphalt emulsion bonding layer. The construction method comprises the following steps of: a) cleaning the semi-rigid base asphalt pavement; and b) carrying out the structure transfer and performance recovery of the pavement. The invention has the advantages that the structure transfer of the damaged semi-rigid base of the original asphalt pavement and the damaged surface layer is realized, and the performance of the pavement is recovered and improved, the repaired pavement had good high-temperature stability and less water damage, and the cracking of the base can be effectively prevented, stopped or slowed down; not only the original pavement material is fully used, but also the energy is saved, and the second pollution on the environment is prevented; and the service function of the original pavement is recovered or improved, and the service life of the pavement is prolonged.

Owner:江苏世丰企业管理咨询有限公司

Ultra-viscous seal coat on bituminous pavement and construction method thereof

InactiveCN102425092AGood low temperature crack resistanceImprove water stabilityIn situ pavingsFiberLow noise

The invention relates to an ultra-viscous seal coat on the bituminous pavement and a construction method thereof. The ultra-viscous seal coat comprises a high performance modified emulsified bitumen bonding layer and an ultra-viscous cold-mixed material wearing layer which is obtained by cold-mixing aggregates, cement, water, composite modified emulsified bitumen, a fiber and a liquid additive. According to the construction method of the seal coat, the ultra-viscous cold-mixed material wearing layer mixing and lying and the high performance modified emulsified bitumen sprinkling are synchronously carried out. The seal coat has the characteristics of ultra bonding, high water resistance, high sliding resistance, low noise, crack resistance, low carbon, energy saving and environmental protection.

Owner:XIAN GUOLIN IND

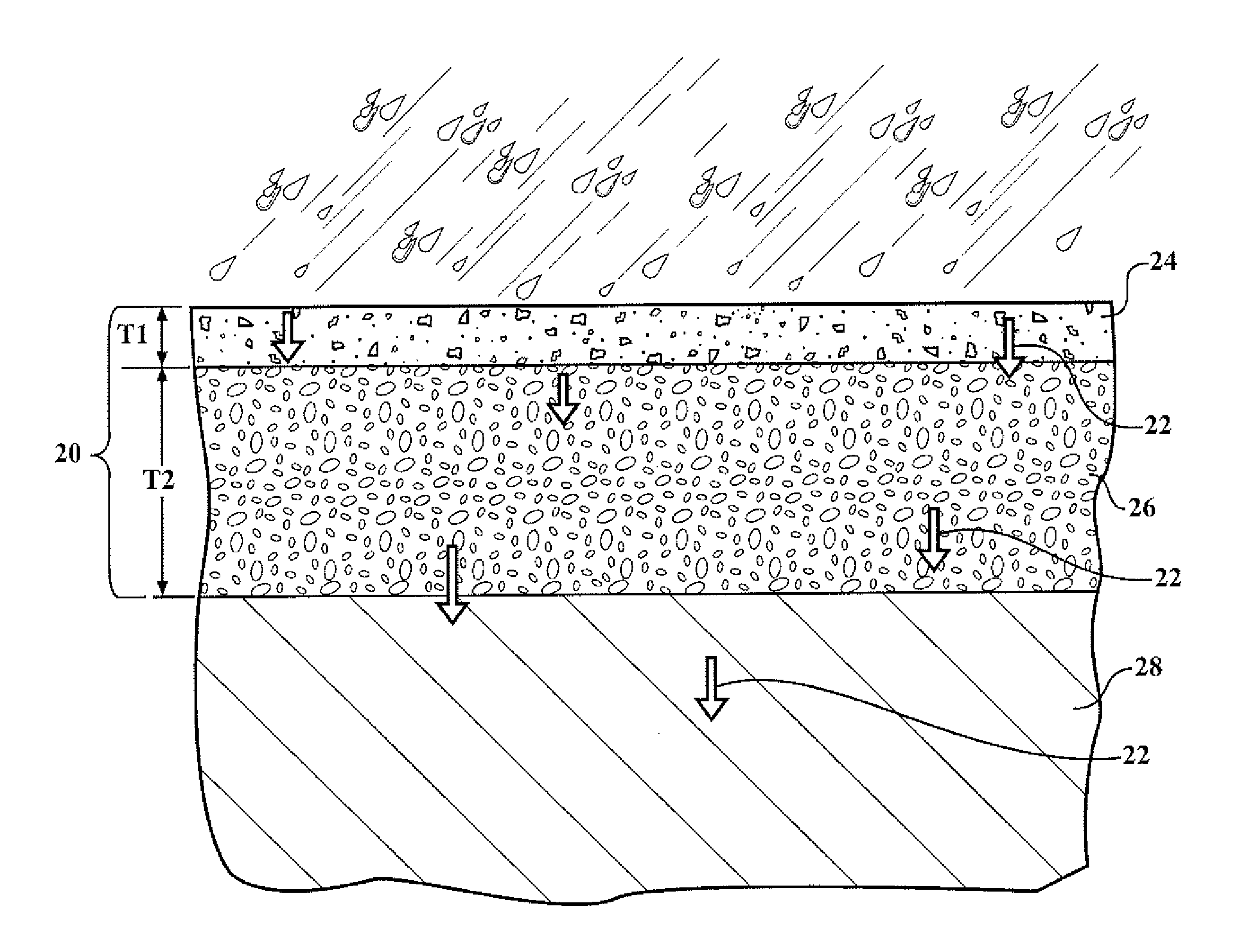

Composite Pavement Structures

ActiveUS20130011195A1Good physical propertiesReduce flakingIn situ pavingsSolid waste managementElastomerPolyol

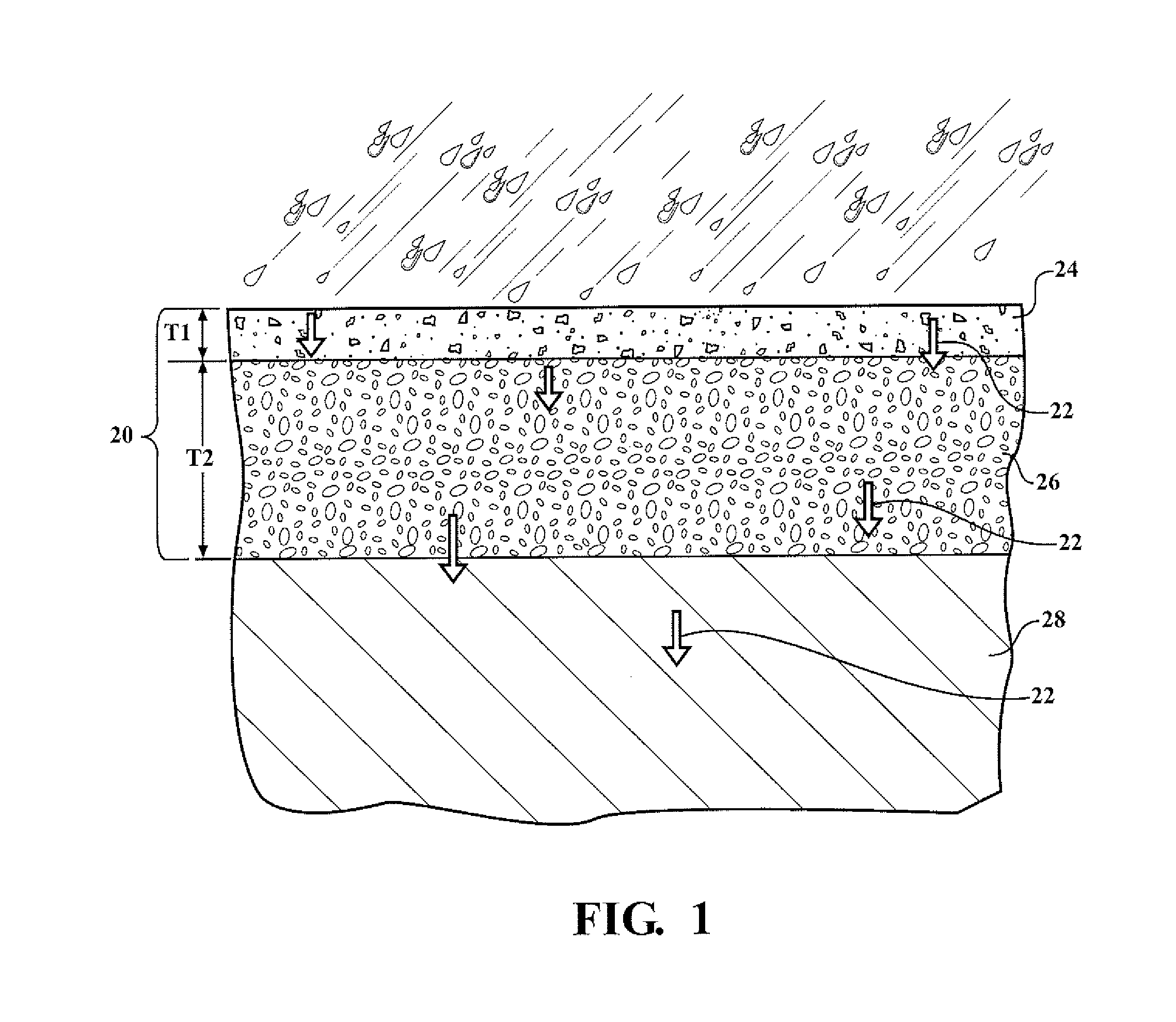

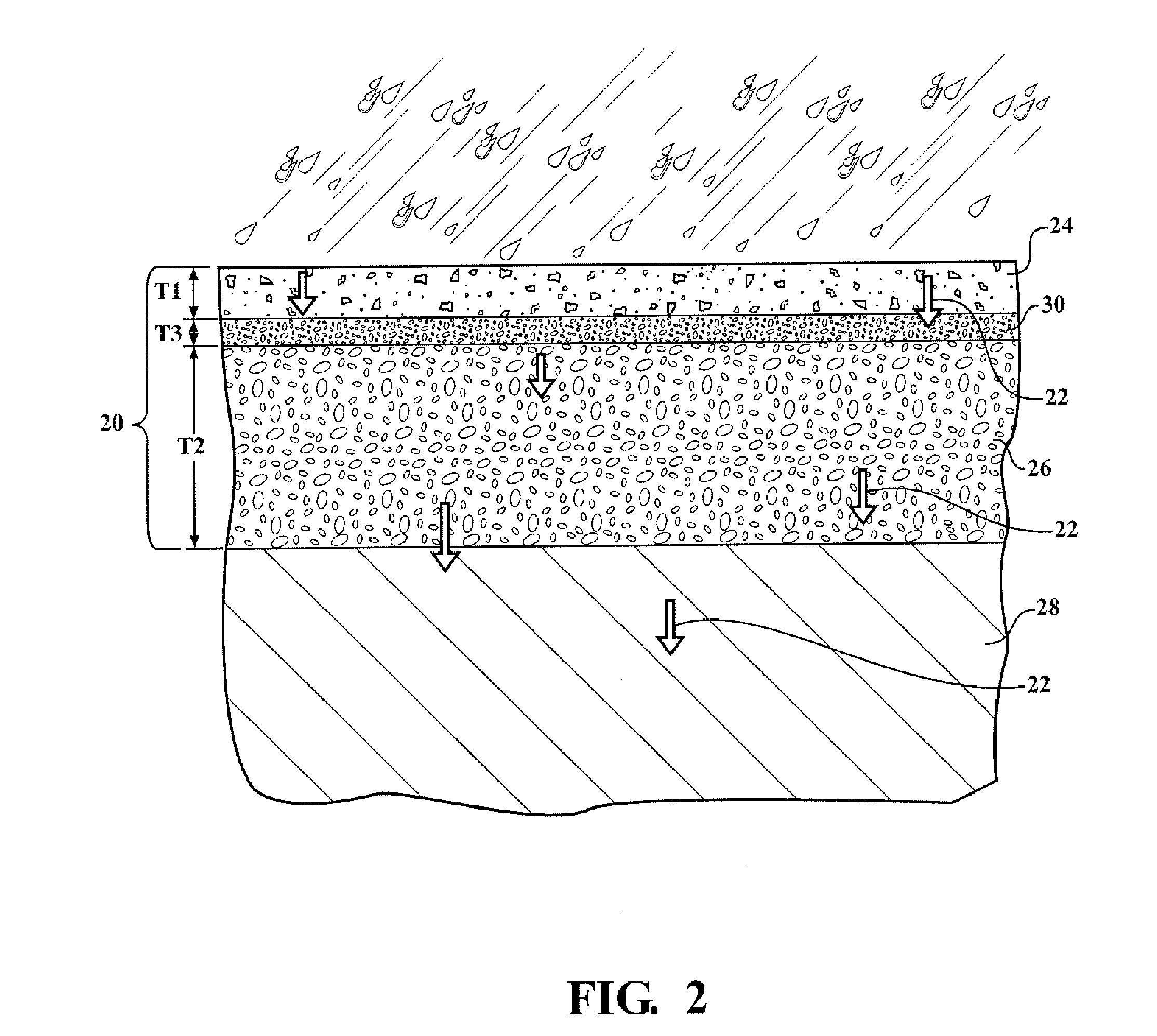

A composite pavement structure comprises a wearing course layer and a base course layer disposed below the wearing course layer. The wearing course layer comprises aggregate, e.g. glass and rock, and an elastomeric composition. The elastomeric camposition comprises the reaction product of an isocyanate component and an isocyanate-reactive component. The isocyanate component comprises a polymeric isocyanate, and optionally, an isocyanate-prepolymer. The isocyanate-reactive component comprises a hydrophobic polyol and a chain extender having at least two hydroxyl groups and a molecular weight of from about 62 to about 220. The chain extender is present in the isocyanate-reactive component in an amount of from about 1 to about 20 parts by weight based on 100 parts by weight of the isocyanate-reactive component. The base course layer comprises aggregate which is the same or different than the aggregate of the wearing course layer. Methods of forming the composite pavement structure are also disclosed.

Owner:BASF AG +1

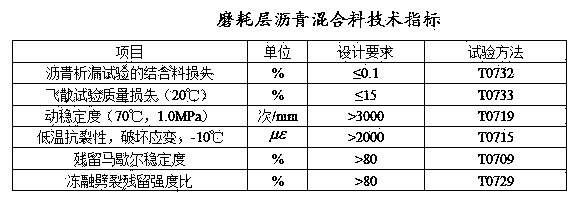

Ultra-thin wearing layer asphalt mixture and preparation method thereof

The invention discloses an ultra-thin wearing layer asphalt mixture and a preparation method thereof, and belongs to the field of building materials for road engineering. The ultra-thin wearing layerasphalt mixture is prepared from the following raw materials in parts by weight: 100 parts of aggregate, 7-8 parts of high-viscosity modified asphalt, 2-4 parts of mineral powder, 3-5 parts of carbonblack, 1-3 parts of a curing agent, 3-5 parts of a compound stabilizer, and 7-12 parts of phenolic resin. After the ultra-thin wearing layer asphalt mixture is paved, a formed road ultra-thin wearinglayer is capable of solving problems in preventability maintenance that an anti-rutting property and a mechanical property are improved, and has the advantages of good skid resistance, abrasion resistance and ultralong durability.

Owner:平湖市中建沥青混凝土工程有限公司

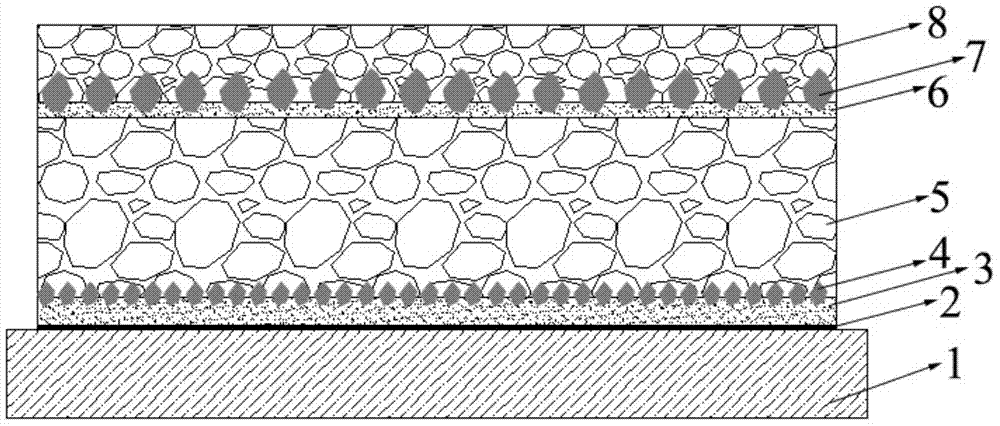

Long-life pavement structure for steel bridge deck and pavement method of pavement structure

ActiveCN104499431AAvoid performance requirementsAdd depthIn situ pavingsBridge structural detailsSteel platesWear resistant

The invention discloses a long-life pavement structure for a steel bridge deck and a pavement method of the pavement structure. The long-life pavement structure comprises an anti-corrosion layer, a lower adhesive layer, a lower gravel layer, a structural layer, an upper adhesive layer, an upper gravel layer and a wearing layer which are sequentially arranged on the steel bridge deck from bottom to top. The pavement structure has excellent antiskid and waterproof performances, low-temperature cracking resistance, high-temperature rutting resistance, fatigue resistance and water stability, is fine in deformation compatibility with a steel plate and wear-resistant, surface aggregates do not easily fall off, the pavement method of the pavement structure is high in mechanization degree and strong in feasibility, the paved steel bridge deck can be put into operation in a short time, only the wearing layer of the pavement structure is damaged, only regular surface milling and top facing repair are needed, the pavement structure does not need to be structurally reconstructed in a long service life period, maintenance is facilitated, maintenance cost is saved, and the pavement method conforms to the design concept of a long-life pavement and also conforms to the energy conservation and environmental protection concept of modern society.

Owner:SOUTHEAST UNIV

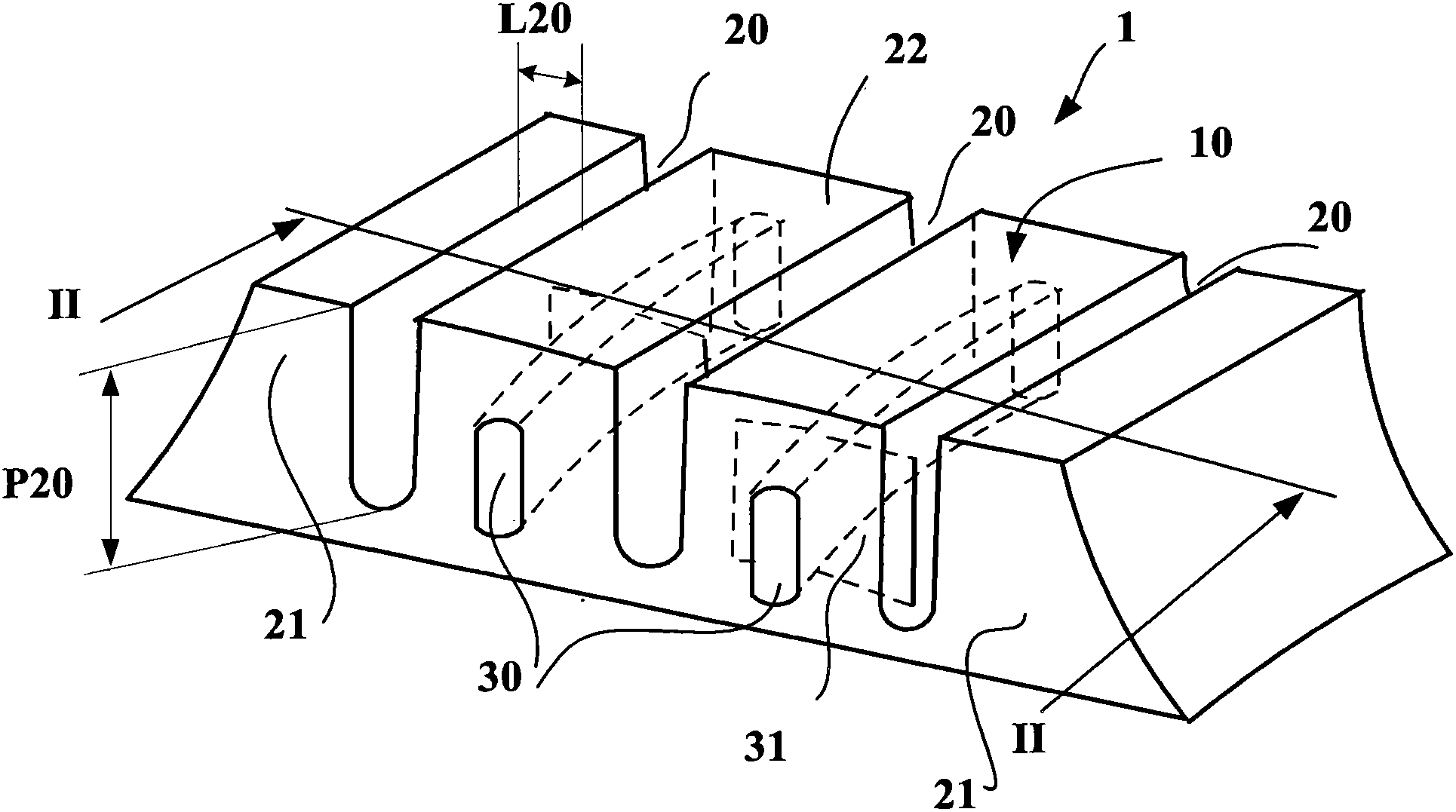

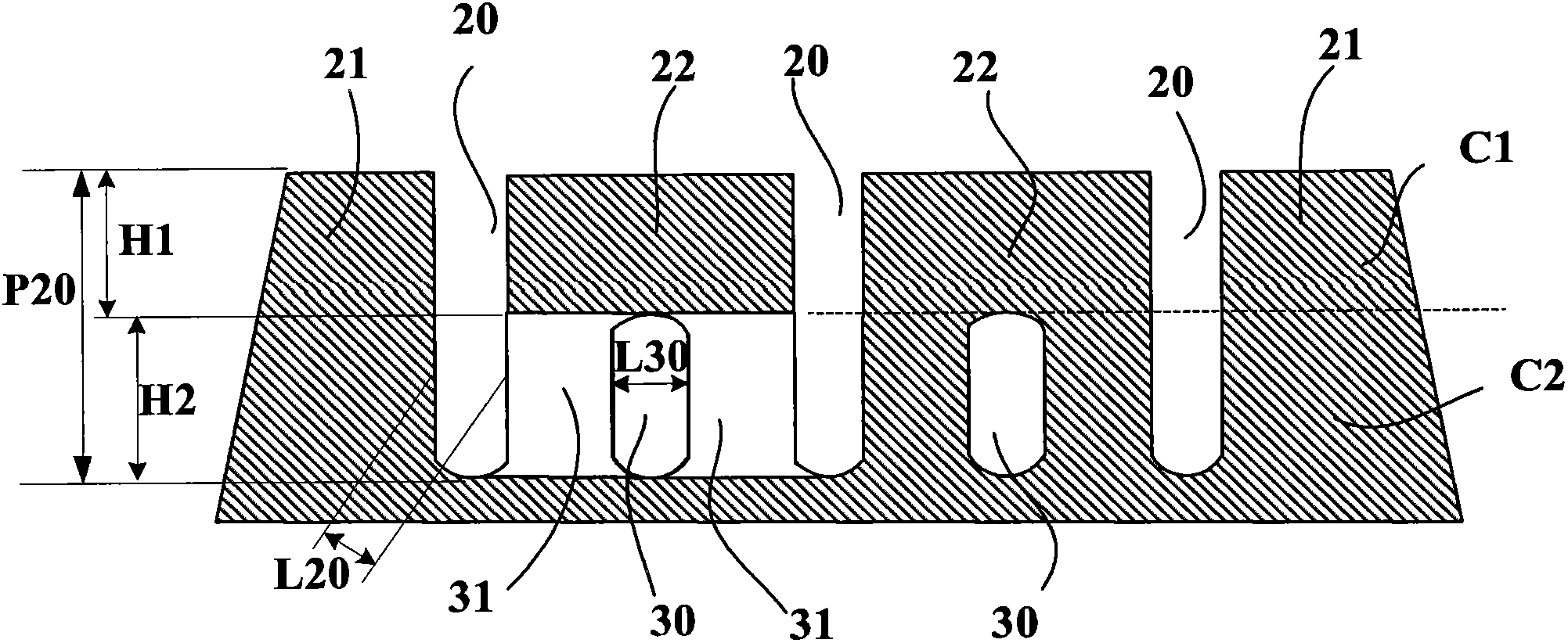

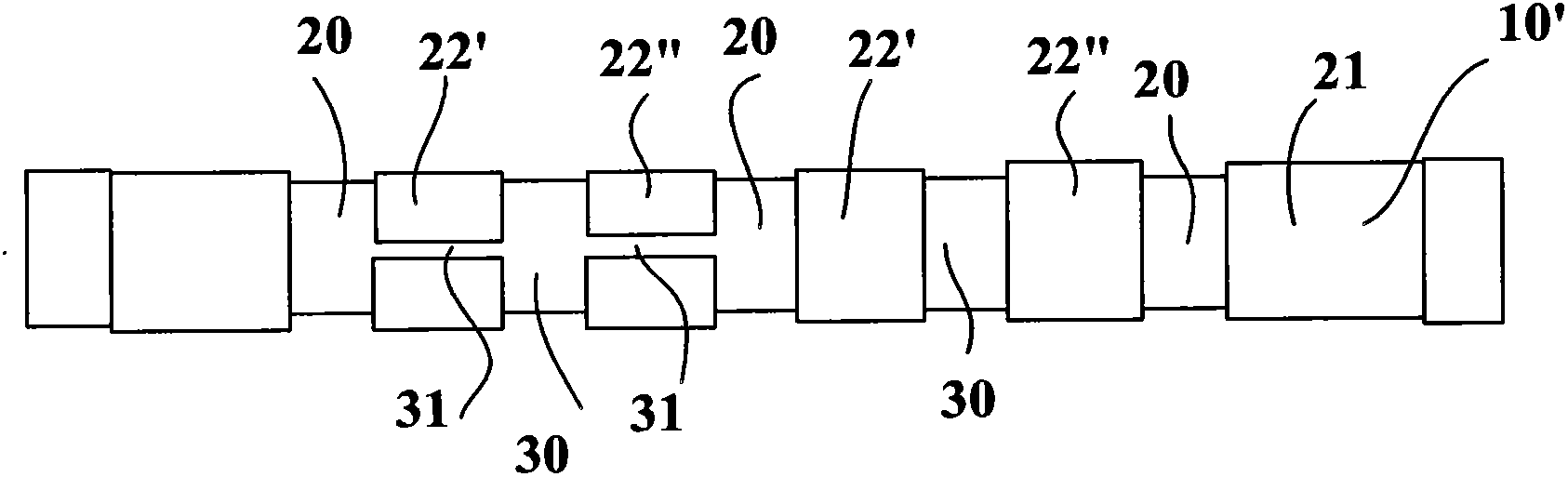

Tread with an improved drainage space

The invention relates to a tread (1) for a tyre having a wheel tread (10), at least two wearing courses (C1, C2, C3) overlapping in the body of the tread, a first wearing course (C1) made up of a plurality of raised elements (21, 22) each including a contact area, including at least circumferential grooves (20, 20'), and contacting the road when the tread is new, and at least one other wearing course (C2, C3) contacting the road once the first course (C1) is completely worn out, said courses comprising at least one channel (30) extending in the circumferential direction, and leading into the wheel tread whenever said wearing course is reached, each of the other wearing courses (C2, C3) comprising a plurality of transverse cuts (31) distributed in the circumferential direction and extending from a channel (30); of the course in question in a direction other than the circumferential direction to completely or partially lead into at least one other circumferential groove (20, 20'), regardless of the wear of said other wearing course.

Owner:OCIETE DE TECH MICHELIN

Colorful asphalt emulsion, preparation, and application in colorful slurry sealing layer

ActiveCN101319091AIncrease coefficient of frictionReduce maintenance costsBuilding insulationsEmulsionBridge deck

The invention discloses colorful asphalt latex, a preparation method thereof and an application of the colorful asphalt latex in colorful slurry seal coat. A colorful asphalt cementing agent, an emulsifying agent, an additive and water are mixed and stirred according to certain ratio to prepare the colorful asphalt latex. The colorful asphalt latex, inert solid, a colorant and water are stirred to prepare colorful slurry mixture, and then paving construction is performed to prepare the colorful slurry seal coat. The colorful slurry seal coat has simple manufacturing technique, not only can be applied to the paving of a colorful slurry seal coat road surface but also is applied to the aspects such as the maintenance of an old asphalt road surface, the paving of a wearing coarse on the sand-gravel surface, and the maintenance of a cement concrete roadway and a bridge deck, reduces the cost of road maintenance, and increases the prior road friction coefficient; the striking color has good landscape and alarm function, high application value and high popularization value.

Owner:深圳前海海川新材料科技有限公司

Method for designing mix proportion of bituminous mixture for ultra-thin wearing course

InactiveCN106320129AImprove shear resistanceGood high temperature performanceIn situ pavingsRoad surfaceDesign methods

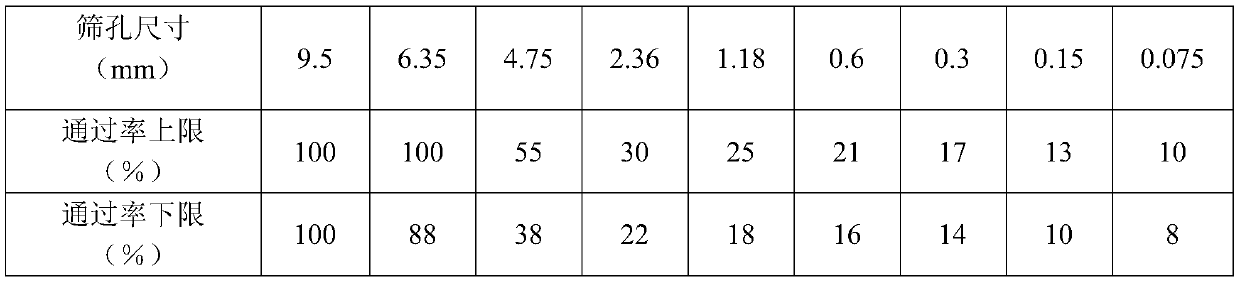

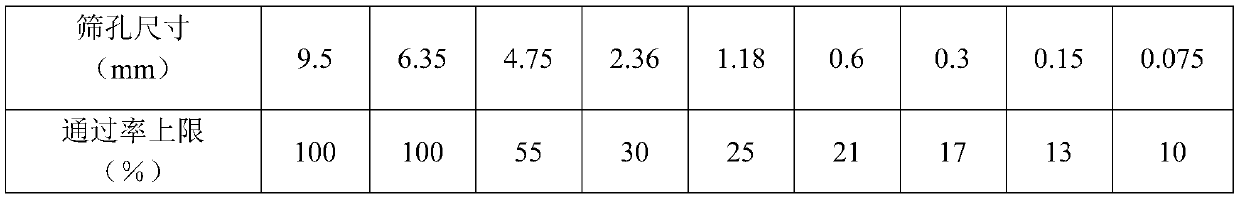

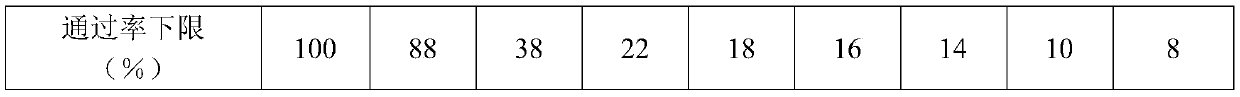

The invention discloses a method for designing a mix proportion of a bituminous mixture for an ultra-thin wearing course. The method comprises the following steps: step 1, selecting raw materials comprising bitumen and ore aggregate which comprises coarse aggregate, fine aggregate and filler; step 2, designing the mix proportion of the bituminous mixture for the ultra-thin wearing course; step 2a, determining grading; step 2b, determining the optimal bitumen-aggregate ratio; step 3, preparing the bituminous mixture for the ultra-thin wearing course according to the designed mix proportion of the bituminous mixture for the ultra-thin wearing course and inspecting whether the shearing resistance of the bituminous mixture meets the shearing resistance standard for roads. On the basis of shearing resistance for roads, a road surface destroy form is integrated into the design method, inspection of various properties and standards of the bituminous mixture for the ultra-thin wearing course in the process of designing of the mix proportion of the bituminous mixture for the ultra-thin wearing course is put forward, and the mix proportion of the bituminous mixture for the ultra-thin wearing course is designed reasonably on the basis.

Owner:XIAN HIGHWAY INST

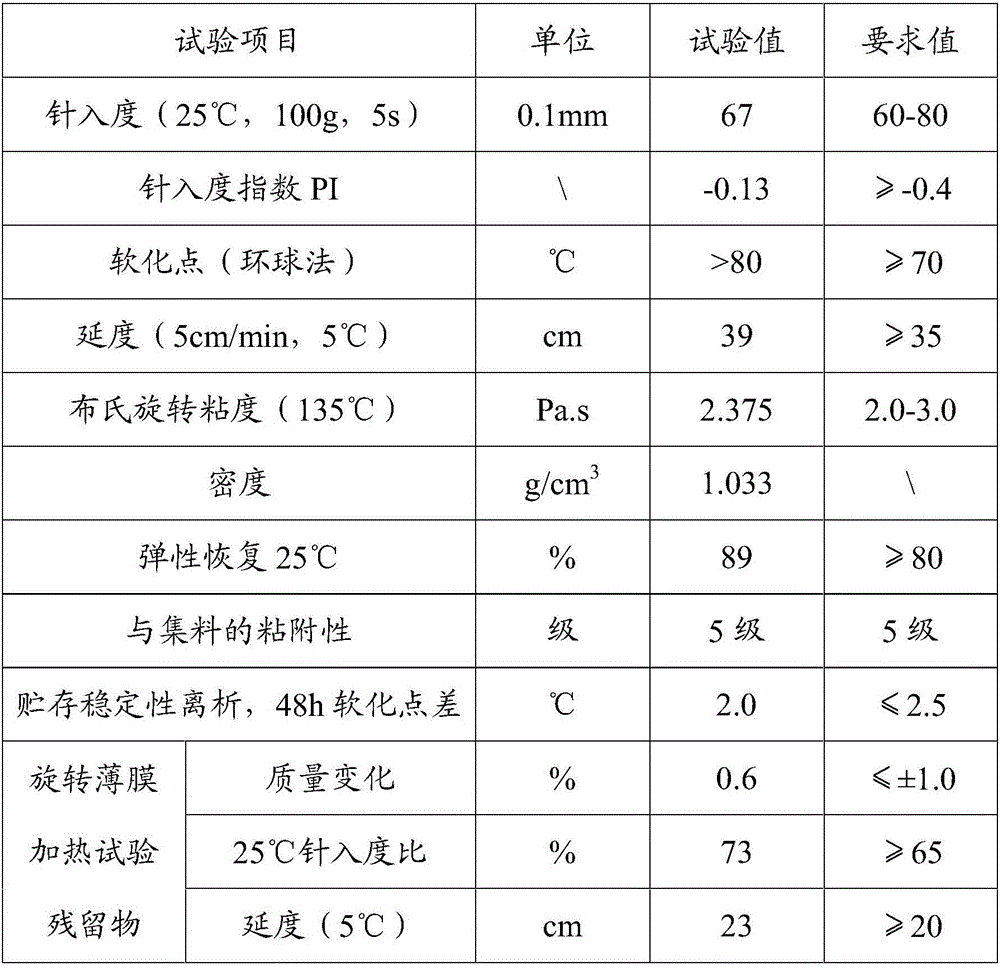

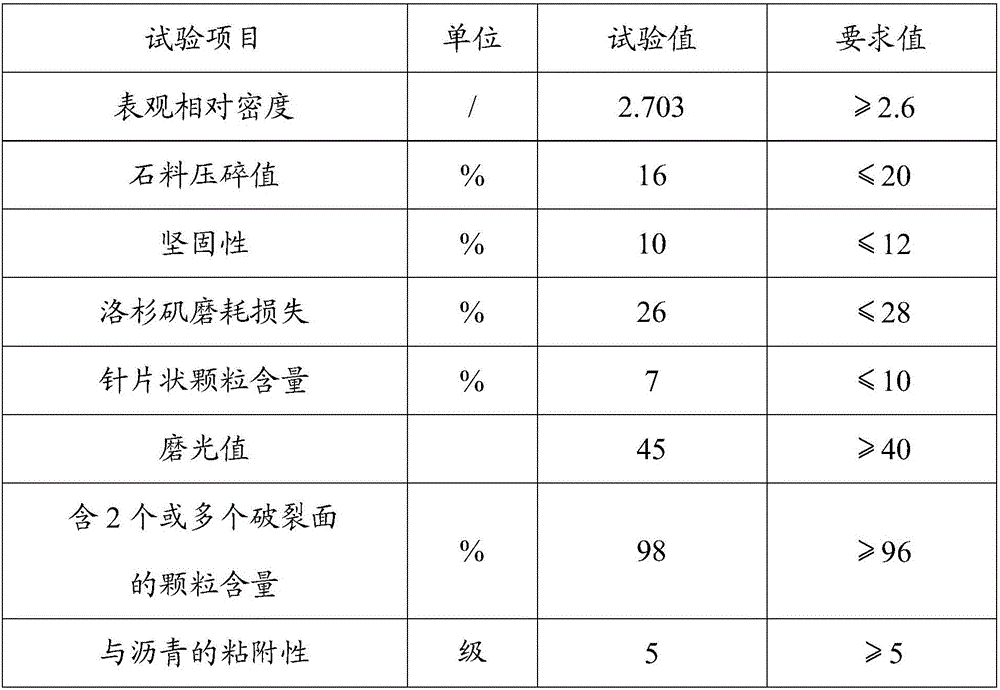

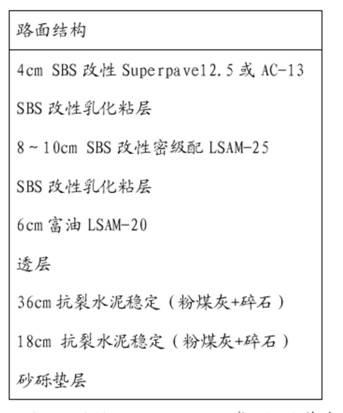

Structure of asphalt pavement applicable to very heavy traffic

InactiveCN102433815AIncreased durabilityReduce reflective cracksIn situ pavingsEngineeringStructural engineering

The invention discloses a structure of an asphalt pavement applicable to very heavy traffic. A wearing layer of the structure adopts 4cm of SBS (styrene butadiene styrene) modified Superpave 12.5 type or AC-13 type modified asphalt concrete; a middle layer of the structure adopts 8-10cm of SBS modified dense gradation LSAM (large stone asphalt mixture)-25; an anti-fatigue layer of the structure adopts 6cm of rich oil LSAM-20 asphalt concrete; a base layer of the structure adopts 36cm of anti-crack stabilized cement; and a subbase layer of the structure adopts treated original cement concrete pavement and treated original asphalt pavement or 18cm of anti-crack stabilized cement. The asphalt pavement structure resists the breaking such as penetrating, cracking, loosing, deforming and the like, resists high-temperature permanent deformation, resists fatigue loading damage, disperses the load, and slows down the reflection crack, so that the problems of rutting deformation resistance and the durability of the very heavy traffic asphalt pavement can be solved, and the service life of the asphalt pavement can be prolonged.

Owner:SHANXI PROVINCIAL RES INST OF COMM

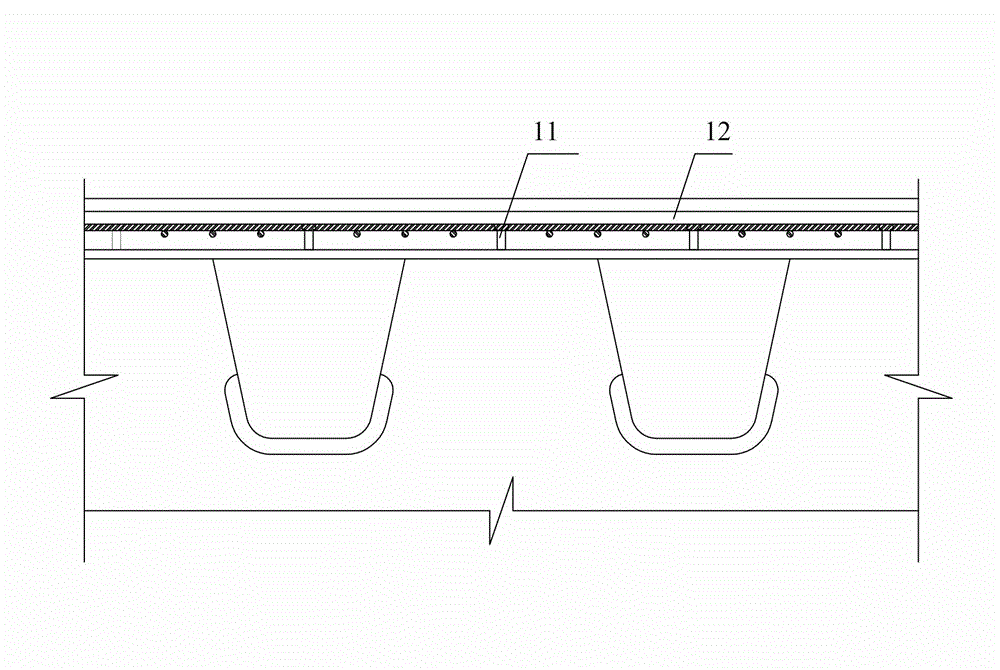

Steel-ultra-high performance concrete combined bridge deck structure with shearing resisting structure and construction method thereof

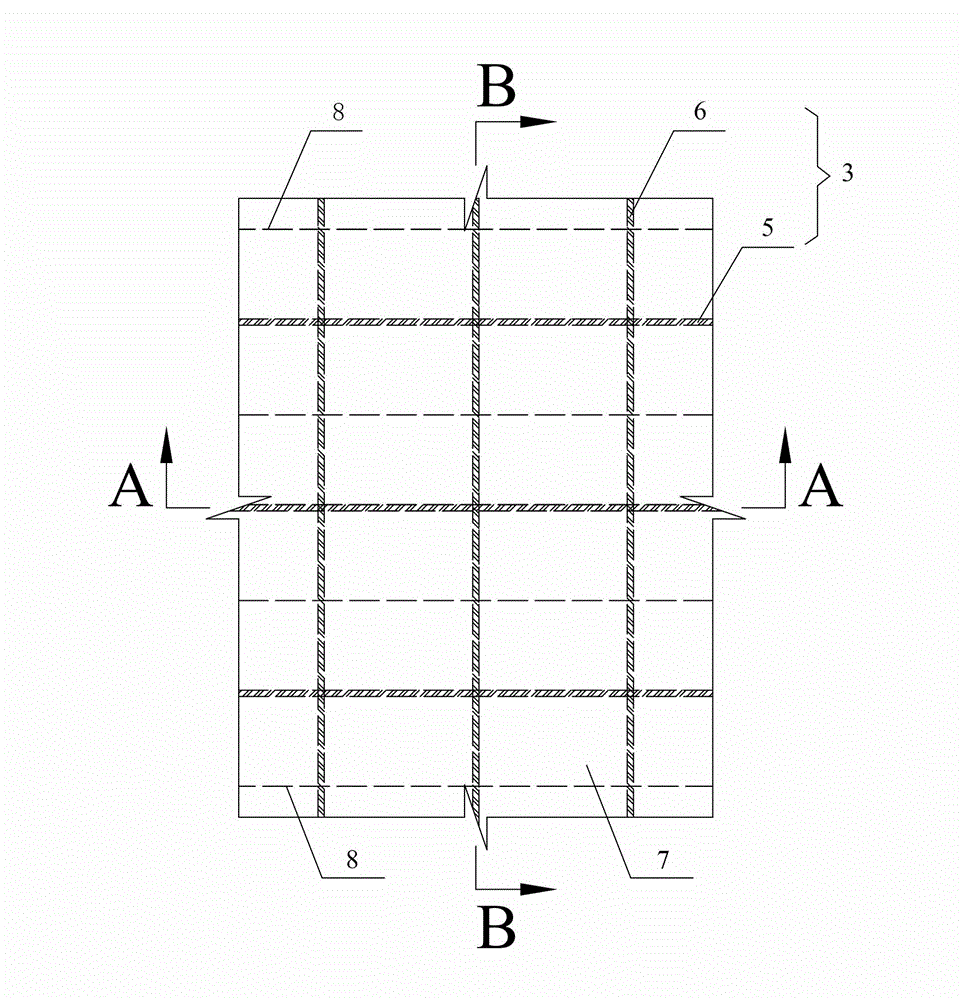

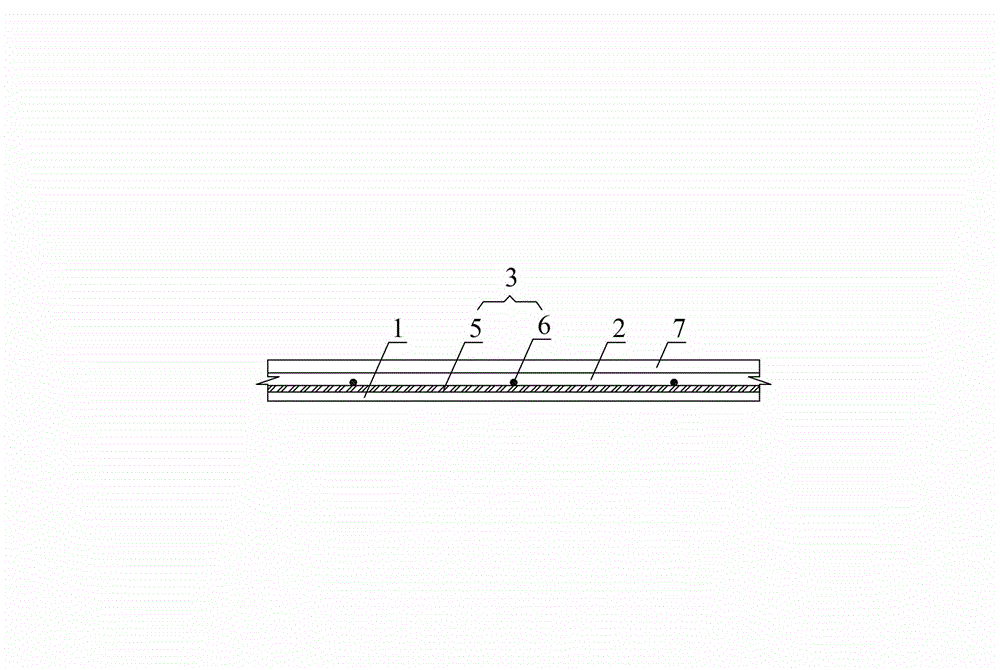

ActiveCN102943436AEasy to get materialsEasy to processBridge structural detailsBridge erection/assemblyArchitectural engineeringMesh reinforcement

The invention discloses a steel-ultra-high performance concrete combined bridge deck structure with a shearing resisting structure and a construction method thereof. The structure comprises a steel bridge deck layer and an ultra-high performance concrete layer, wherein a shearing-resisting reinforcing mesh structure is fixedly connected with the steel bridge deck layer; and the shearing-resisting reinforcing mesh structure is embedded in the ultra-high performance concrete layer. The construction method comprises the following steps of: firstly, erecting a steel beam so as to obtain the steel bridge deck layer; secondly, constructing and welding a reinforcing mesh, wherein the reinforcing mesh can adopt the mode that a lower longitudinal rib distributed layer is combined with an upper transverse rib distributed layer, or a mode that a lower transverse spacing rib distributed layer, a longitudinal rib distributed layer and the upper transverse rib distributed layer are combined, and longitudinal reinforcing ribs and transverse reinforcing ribs can be arranged among shearing-resisting longitudinal ribs and shearing-resisting transverse ribs; subsequently casting the ultra-high performance concrete layer so as to embed the shearing-resisting reinforcing mesh structure into the ultra-high performance concrete layer; and finally paving a wearing layer so as to accomplish the construction. The steel-ultra-high performance concrete combined bridge deck structure has the advantages of being small in building height, large in partial rigid, reliable in shearing-resisting connection between combined layers, good in fatigue resistance, convenient to construct and the like.

Owner:HUNAN UNIV

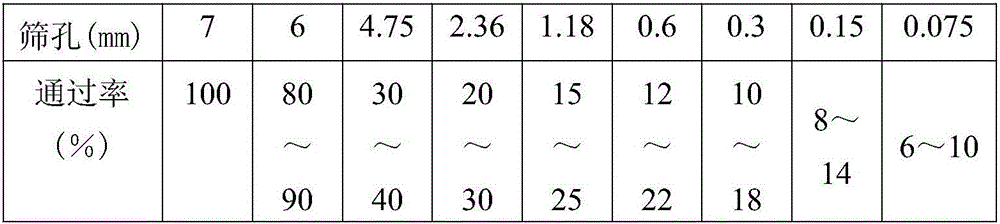

Asphalt concrete for ultra-thin wearing course with easily-compactable skeleton and thickness of 1 to 1.5 cm

The invention relates to asphalt concrete for an ultra-thin wearing course with an easily-compactable skeleton and a thickness of 1 to 1.5 cm. The ultra-thin wearing course is characterized by comprising an upper asphalt concrete layer and a lower high-viscosity modified emulsified asphalt bonding layer, wherein the laying thickness of the upper asphalt concrete layer is 1.0 to 1.5 cm, and a proper spraying amount of the lower layer is 0.8 to 1.0 kg / m<2>. The mixture for the ultra-thin wearing course forms a skeleton-compact ultrathin pavement and enables the pavement to have good stability, durability and safety performance. The ultra-thin wearing course is applicable to prevention and maintenance of newly-built pavements and old pavements.

Owner:TIANJIN HIGHWAY ENG GENERAL

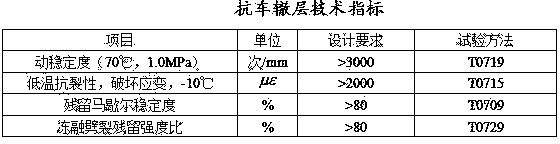

Paving structure of heavy-duty traffic road based on high stiffness modulus asphalt mixture

ActiveCN104074115AImprove wear resistanceHigh modulus of stiffnessIn situ pavingsHigh stiffnessArchitectural engineering

The invention discloses a paving structure of a heavy-duty traffic road based on a high stiffness modulus asphalt mixture and belongs to the technical field of road paving. The paving structure consists of an anti-wear layer, an anti-rutting deformation layer, an anti-fatigue layer and a semi-rigid base layer which are paved on a roadbed from top to bottom, wherein the anti-wear layer, the anti-rutting deformation layer and the anti-fatigue layer are high stiffness modulus asphalt mixture functional layers. Compared with the prior art, the paving structure disclosed by the invention solves the problem that a pavement structure of a conventional semi-rigid base layer asphalt pavement is damaged under the effect of heavy duty, has the characteristics of fatigue cracking resistance, permanent rutting deformation resistance, water damage resistance and the like, is low in life cycle cost, can be widely applied to heavy-duty traffic roads and has a high popularization and application value.

Owner:SHANDONG TRANSPORTATION INST

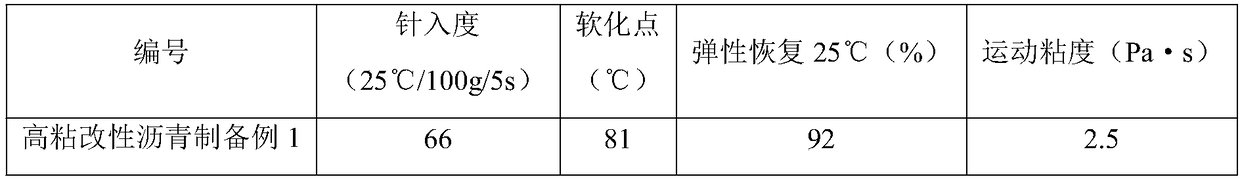

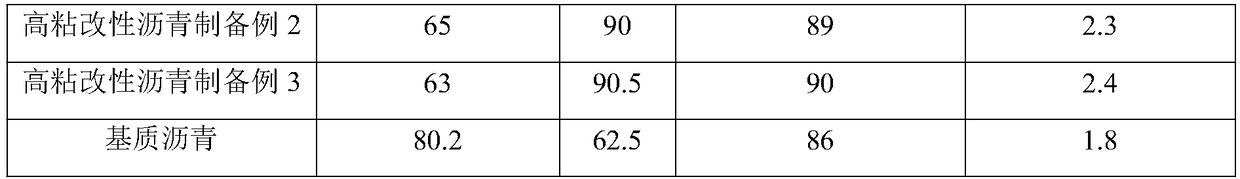

Ultrathin wearing layer modified asphalt and preparation method thereof

The invention relates to ultrathin wearing layer modified asphalt and a preparation method thereof. The ultrathin wearing layer modified asphalt is prepared from, by mass, 79.8%-91.6% of matrix asphalt, 3.0%-8.0% of a modifier SBS, 2.0%-4.0% of compatilizer, 0.1%-0.5% of a stabilizer, 2.0%-8.0% of a viscosity regulating agent and 0.3%-0.7% of an anti-aging agent. The preparation method of the ultrathin wear layer modified asphalt comprises the following steps that 1, the matrix asphalt is heated; 2, the modifier, the compatilizer and the anti-aging agent are added into the matrix asphalt simultaneously, and stirring is conducted at constant temperature; 3, a high-speed shearing machine is started, and shearing and dispersing are conducted; 4, the stabilizer is added, and stirring and developing are conducted; 5, the viscosity regulating agent is added, stirring continues, and then the ultrathin wearing layer modified asphalt can be prepared. The ultrathin wearing layer modified asphalt prepared through the method has the high 60-DEG-C viscosity (higher than 50,000 Pa.S) and the low 135-DEG-C viscosity (lower than 3.0 Pa.S).

Owner:CNOOC TAIZHOU PETROCHEM CO LTD

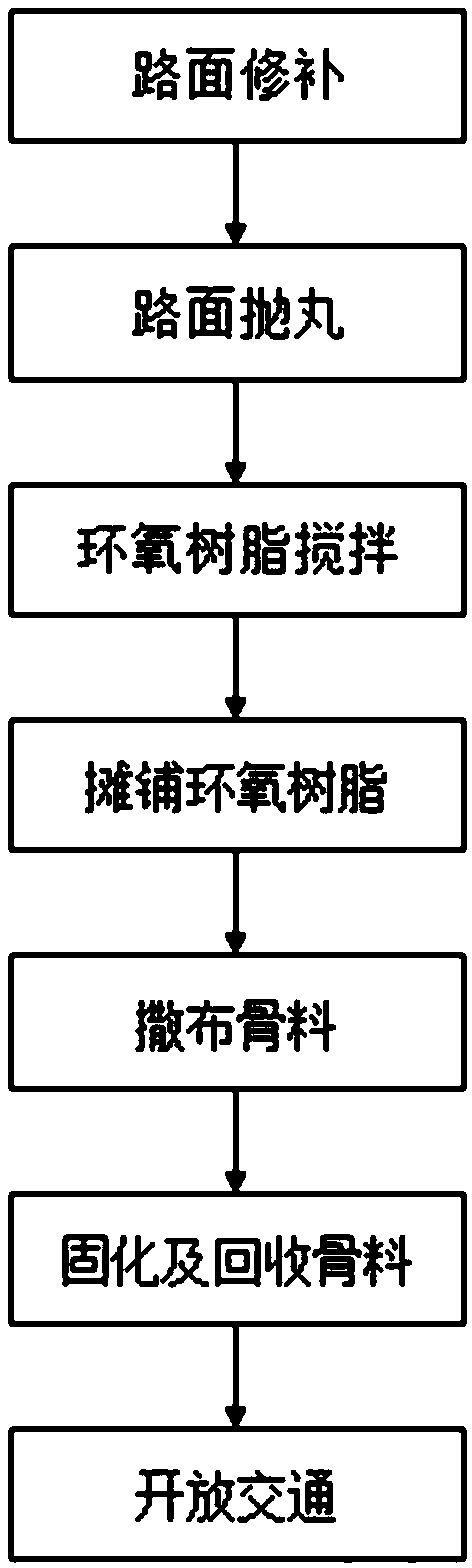

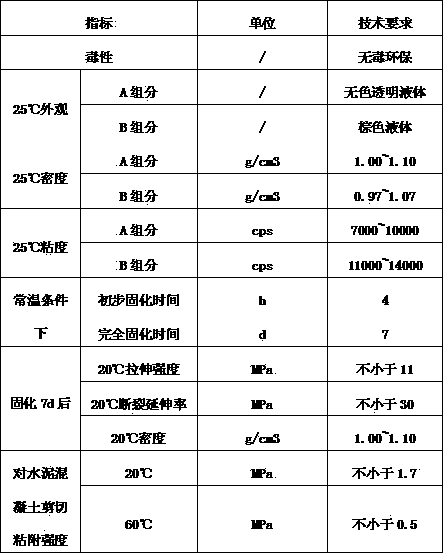

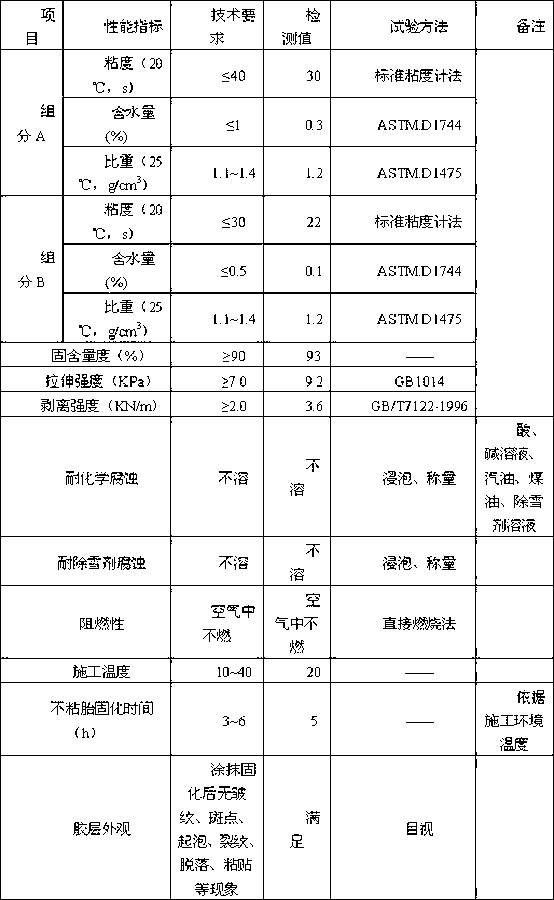

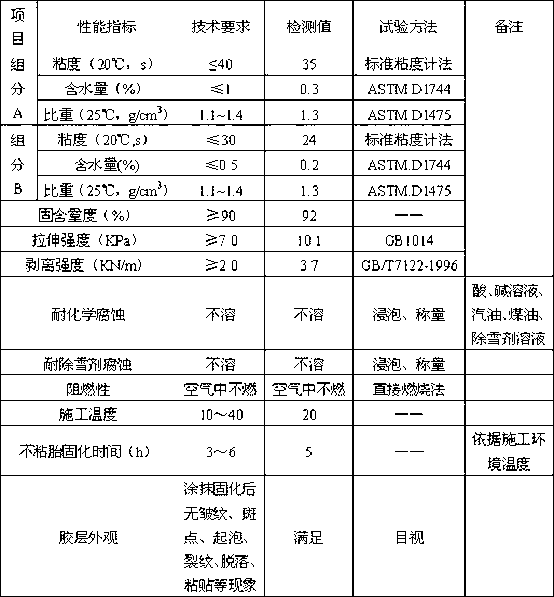

Construction process of colored pavement epoxy non-slip wearing layer structure

ActiveCN103938513ASimple construction processEasy constructionIn situ pavingsPaving detailsEpoxyRoad surface

The invention discloses a construction process of a colored pavement epoxy non-slip wearing layer structure. The construction process comprises the following steps: (1) pavement patching; (2) pavement shot blasting; (3) epoxy resin stirring; (4) paving of epoxy resin; (5) spreading of aggregates; (6) curing and recovering of the aggregates; and (7) opening of transit. Compared with the prior art, the construction process has the advantages that the wearing layer structure is simple in process, easy to operate, good in non-slip performance, high in bonding strength, small in thickness, convenient in construction, rapid in curing and high in material water resistance; running noise of vehicles is lowered; driving conditions are improved; the wearing layer structure is excellent in corrosion resistance, high in flame retardant property, high in ductility, uniform in expansion, high in low-temperature resistance, low in low-temperature brittleness, excellent in thermal ageing resistance, high in high-temperature stability and high in wear resistance, the surface aggregate is high in wear resistance, a conventional road elevation and the conventional clear height of a bridge are not changed, existing various structural and non-structural pavement diseases can be repaired at a time, the maintenance cost is saved, and the service life of a pavement is greatly prolonged.

Owner:上海仁路科技有限公司

Stable bitumen foam and its preparation and use

A process for the preparation of bitumen foam, wherein a gas is dispersed into the bitumen with a temperature of less than 200° C. and with a viscosity van 100-10.000 mPas measured at the temperature using EN 12596, wherein the process includes bringing the gas tangentially into contact with a bitumen stream, to obtain a bitumen foam that is not dehydrogenated, oxidised or otherwise chemically modified, and in which at least 10 vol % gas is distributed substantially homogeneously. This process can be applied simply and safely, and results in bitumen foam without additions being necessary for this. In this way bitumen can be processed at lower temperatures, even below 100° C., to asphalt or wearing course. The foam bitumen thereby has a half-life time that is much longer than the one of existing bitumen foams

Owner:DE VEENVOORT

Ice condensation resistant ultra-thin wearing course pavement and preparation method thereof

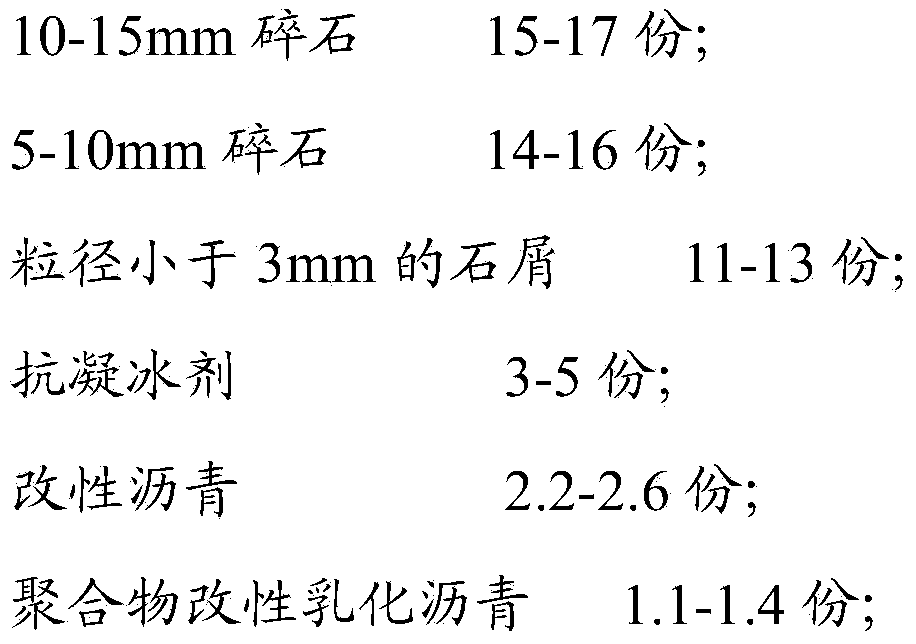

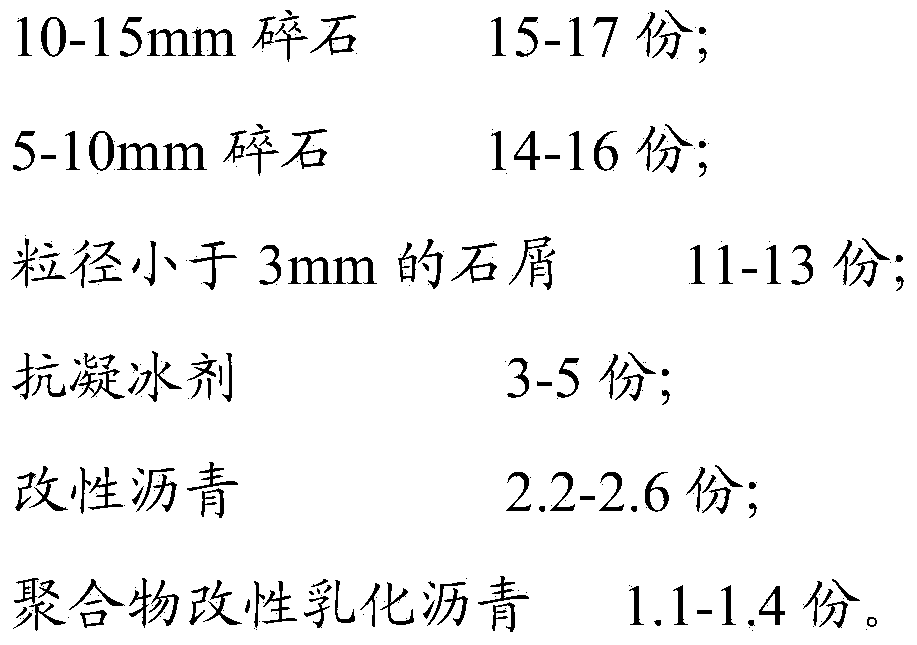

ActiveCN104032639ADelayed snow and icingEnsure driving safetyIn situ pavingsSnowpackPolymer modified

The invention discloses an ice condensation resistant ultra-thin wearing course pavement and a preparation method thereof. The ice condensation resistant ultra-thin wearing course pavement is prepared from the following raw materials in parts by weight: 15-17 parts of 10-15 mm gravels, 14-16 parts of 5-10 mm gravels, 11-13 parts of stone chips of which the particle size is smaller than 3 mm, 3-5 parts of ice condensation resistant agents, 2.2-2.6 parts of modified asphalt, and 1.1-1.4 parts of polymer modified emulsified asphalt, wherein the content of sodium chloride in the ice condensation resistant agents is 50-60%, and the solid content of the polymer modified emulsified asphalt is greater than or equal to 65%. According to the invention, ice condensation resistant ultra-thin wearing courses are paved on the pavement, so that the ice point of water in the surface of the pavement is reduced, snow accumulation and icing on the pavement are delayed, a new solution is put forward for solving the problem of the congelation of the pavement in winter is restrained, and safe running on the pavement is ensured.

Owner:广州新粤交通技术有限公司

Express highwey construction technology for heavy loading vehicle running

InactiveCN1624242AIncrease the consolidation rateImprove carrying capacityIn situ pavingsSurface layerChipseal

This invention relates to a construction technique of the highway used to run carrying full car. At present, the tonnage of these cars on the highway ranges from 30-50 tons, but some of the freight cars exceed 100 tons, and some highways cannot afford such heavy load; in this invention, the construction of the roadbed, the formation, the wearing course, antiskid layer, and surface construction firstly adopt agitating slaked lime and earth mass, laminar lamination, dabbling flocculant to strengthen welding ability of the earth mass; adopt bedload and laying bed course and pouring serosity of BR-C; prepare C80-C100 concrete bearing bed by common cement; add the mixture of rubber particles, little carpolites, and adhesion agent to the asphalt, lay the wearing course, antiskid layer and surface layer in order to improve the expansion, shrinking, and adhesion quality of the different layers of the asphalt mixture, resist the influences of temperature changes and improve its bearing ability.

Owner:王衡

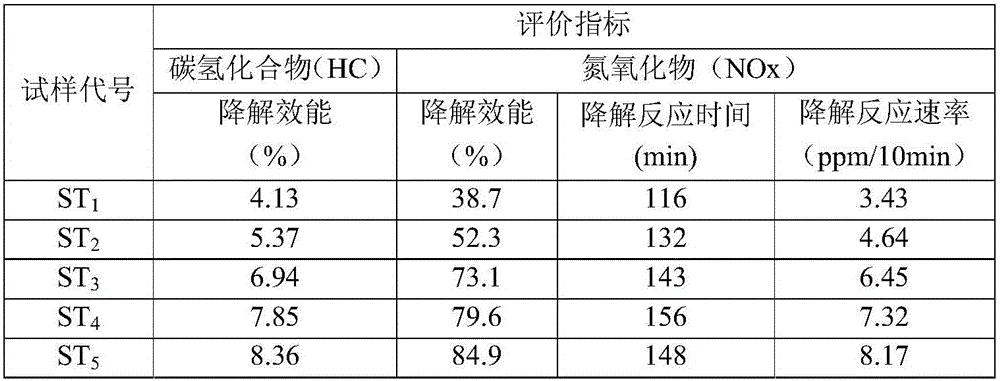

Color anti-skid ultrathin wearing layer capable of degrading automobile exhaust and preparation method thereof

The invention relates to a color anti-skid ultrathin wearing layer capable of degrading automobile exhaust and a preparation method thereof. The wearing layer consists of the raw materials as follows: epoxy resin, modified epoxy resin, a composite photocatalyst, amine-terminated polyether, a curing agent, a curing accelerator and aggregates. The wearing layer also can be prepared from the raw materials as follows: double-component polyurethane, a composite photocatalyst, a curing agent, a curing accelerator and aggregates. Before the wearing layer is laid, the original road surface needs to be treated, then paying-off and edge protection are performed, binders are mixed, color anti-wear aggregates capable of degrading exhaust gas are scattered uniformly, non-bonded aggregates are recovered, and finally maintenance of the wearing layer, traffic control and opening are performed. The wearing layer has performances of degrading the automobile exhaust and purifying air, can increase the road friction so as to enable the road surface to maintain excellent water mist-proof and anti-skid pavement performance, achieves effects of traffic warning and environment beautifying visually, and has excellent environmental benefit and social benefit.

Owner:TONGJI UNIV

Method and composition for enhancing the insulating properties of a trafficked surface

Owner:STENGER EARL M

Emulsifier as well as preparation method and application thereof

InactiveCN103665396AImprove performanceDemulsification speed guaranteeBuilding insulationsRoad surfaceViscosity

The invention provides an emulsifier as well as a preparation method and application thereof. The invention discloses the emulsifier applicable to emulsifying SBS modified asphalt and used for substituting for an amphiprotic cationic emulsifier, and provides a preparation process for the emulsifier. The prepared emulsifier is used for emulsifying the SBS modified asphalt to obtain high-viscosity modified and emulsified asphalt, and the high-viscosity modified and emulsified asphalt is applied to a pavement ultra-thin wearing course. The preparation method for the emulsifier is simple in operating procedure and moderate in reaction condition, and can be adopted to prepare the high-viscosity modified and emulsified asphalt with high asphalt content, high viscosity and high bonding property.

Owner:JSTI GRP CO LTD +1

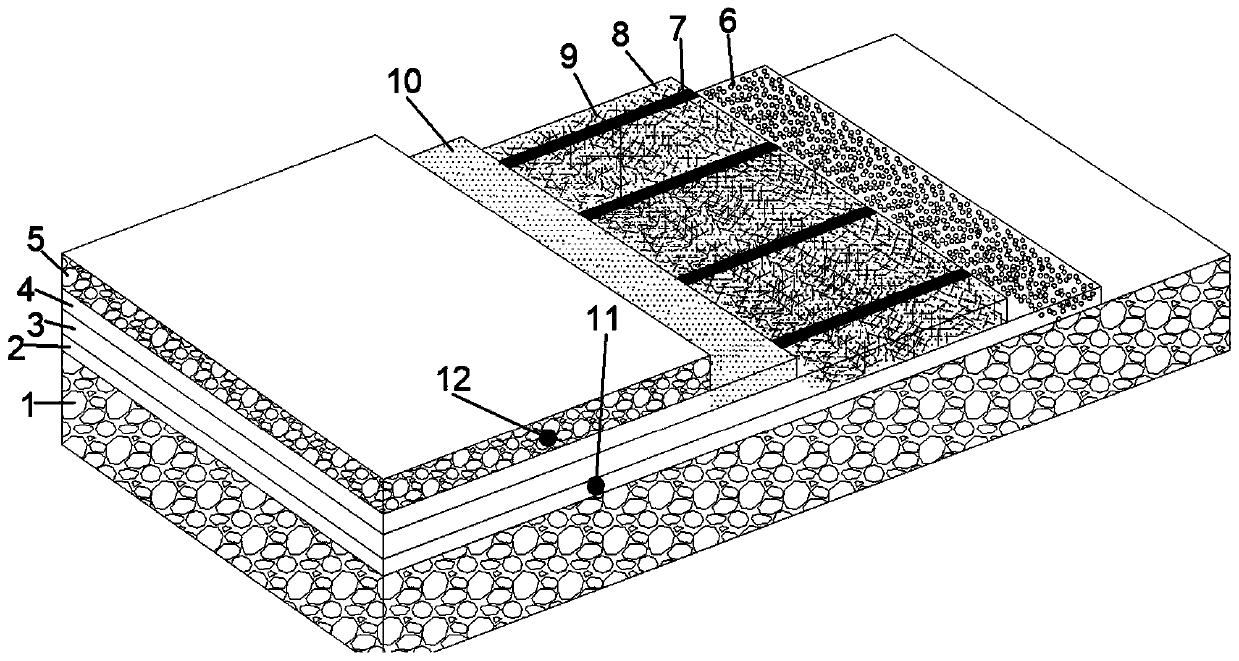

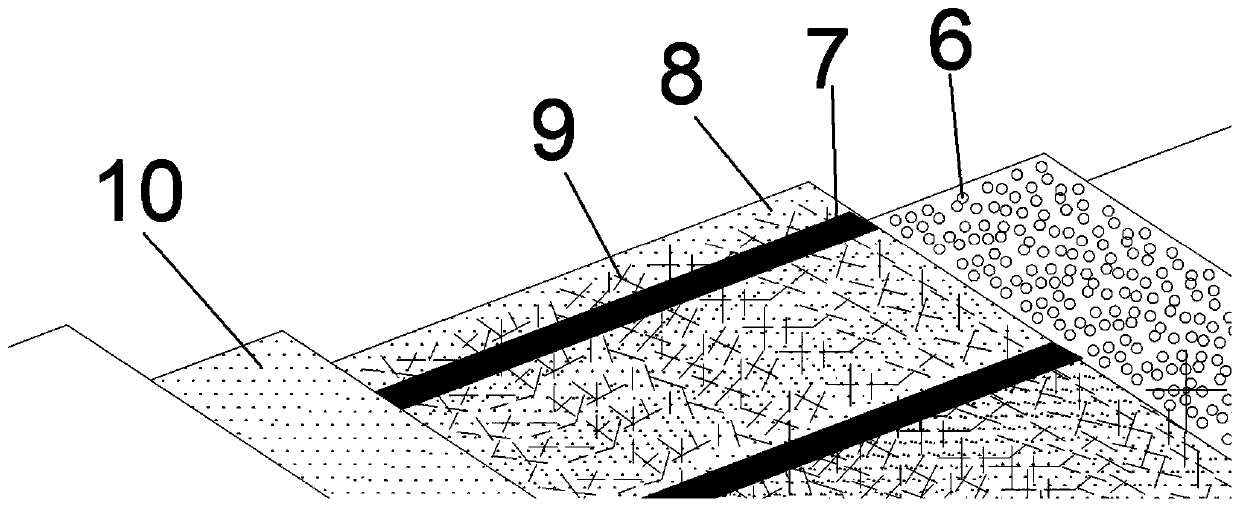

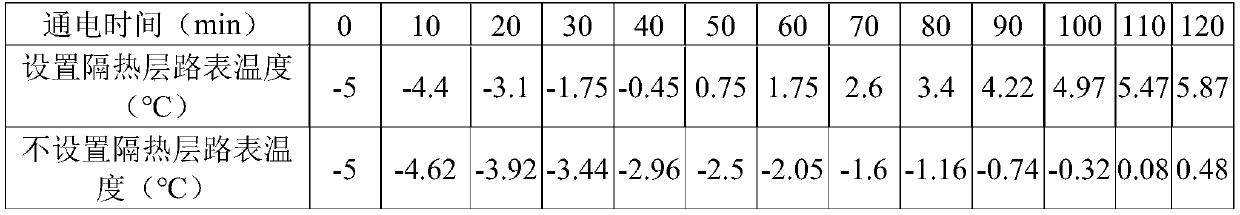

Pavement paving structure for melting snow and ice and using method thereof

InactiveCN111021180AReduce lossImprove conductivityIn situ pavingsPaving detailsInsulation layerThermal break

The invention, which belongs to the technical field of pavement snow melting and ice melting, discloses a pavement paving structure for melting snow and ice and a use method thereof. The structure comprises a heat insulation layer, a conductive bonding layer, a waterproof bonding heat conduction layer and a wearing layer which are sequentially arranged from bottom to top. The heat insulation layeris arranged on the lower portion of the conductive bonding layer, so that the downward transmission of heat generated by the conductive bonding layer is reduced effectively and the heat losses are reduced; with the waterproof bonding heat conduction layer, a waterproof layer is arranged to prevent electric leakage caused by water entrance on the premise that heat conduction is guaranteed; the conductive electrode has a good conductive effect, and snow melting and deicing of the road surface can be effectively guaranteed. The snow and ice melting structure has the high applicability; the snowmelting and deicing of road surfaces in multiple occasions are realized in time under ice and snow weather in winter; the green and environment-friendly effects are realized; the road smoothness and driving safety are guaranteed, and low-temperature cracking of asphalt road surfaces can be effectively relieved.

Owner:CHANGAN UNIV

Stable bitumen foam and its preparation and use

A process for the preparation of bitumen foam, wherein a gas is dispersed into the bitumen with a temperature of less than 200° C. and with a viscosity from 100-10,000 mPas measured at the temperature using EN 12596, wherein the process includes bringing the gas tangentially into contact with a bitumen stream, to obtain a bitumen foam that is not dehydrogenated, oxidised or otherwise chemically modified, and in which at least 10 vol % gas is distributed substantially homogeneously. This process can be applied simply and safely, and results in bitumen foam without additions being necessary for this. In this way bitumen can be processed at lower temperatures, even below 100° C., to asphalt or wearing course. The foam bitumen thereby has a half-life time that is much longer than the one of existing bitumen foams

Owner:DE VEENVOORT

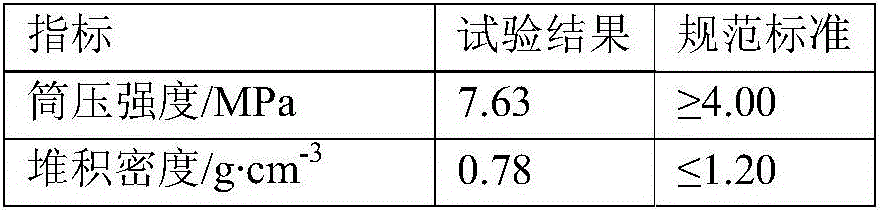

Porous ceramsite and asphalt concrete and application thereof

The invention provides porous ceramsite and asphalt concrete. The porous ceramsite and asphalt concrete is prepared from components in percentage by mass as follows: 45%-55% of nano-TiO2 sintering-free porous ceramsite, 4.5%-5.5% of SBS modified asphalt and 39.5%-50.5% of supplementing mineral aggregate. The porous ceramsite and asphalt concrete can be applied to laying of automobile exhaust degradation type ultra-thin wearing courses of pavements and has economic benefit, environmental protection benefit and social benefit.

Owner:ZHEJIANG UNIV OF TECH

Ultra-thin high-sliding-resistance surface layer of asphalt pavement and construction method thereof

The invention discloses an ultra-thin high-sliding-resistance surface layer of an asphalt pavement and a construction method thereof. The ultra-thin high-sliding-resistance surface layer comprises a wearing layer and an adhesive layer, wherein the wearing layer adopts an asphalt mastic gravel mixture with the nominal maximum size of aggregate being 6.35 mm, a new form of the grading range SMA-7 isprovided, the asphalt mastic gravel mixture is composed of calcined bauxite and limestone, differential burnishing is formed between the calcined bauxite and the limestone, the limestone with the particle size being 4.75 mm to 6.35 mm and the particle size being 6.35 mm to 9.5 mm is replaced with the calcined bauxite in an equivoluminal manner, and the content of aluminum oxide in the calcined bauxite ore is not lower than 88%; the burnishing value of the calcined bauxite is larger than that of the limestone, and the blending amount of the calcined bauxite is 10%-15% according to the mass fraction; and the wearing layer and the asphalt pavement are bonded into a whole through the adhesive layer. According to the ultra-thin high-sliding-resistance surface layer, the skid resistance, the wear resistance and the driving comfort and safety of the road surface can be improved, and the driving noise of the road surface is reduced.

Owner:CHANGAN UNIV

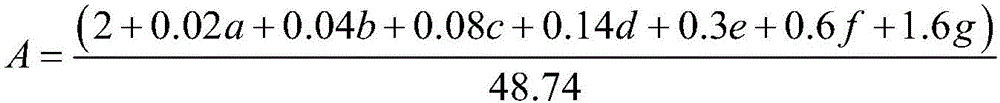

Geocell reinforced cement concrete pavement structure and surface layer plate thickness calculation method

PendingCN111962350AReduce crackingReduce thicknessIn situ pavingsRoads maintainenceCrushed stoneGeocells

The invention discloses a geocell reinforced cement concrete pavement structure and a surface layer plate thickness calculation method. The pavement structure mainly comprises a base layer, a surfacelayer and a wearing layer which are sequentially laid from bottom to top. The base layer is composed of an upper geotextile layer, a lower geotextile layer and a middle geocell reinforced graded broken stone layer; the surface layer is a cement concrete layer reinforced by a geocell; the wearing layer comprises a cement mixture wearing layer and a geogrid; pull rings are reserved on the two sidesof each geocell in a road direction, the geocells are stretched to be in a tensioned state, and wooden wedges penetrate through the pull rings to fix the geocell at the outermost end. The surface layer plate thickness calculation method mainly comprises the steps of traffic analysis, initial simulation of a pavement structure, determination of pavement material parameters, and checking of load stress, temperature stress and a structure limit state. The problems that an existing pavement structure is low in strength, and a cement concrete pavement is subjected to fatigue fracture, mud pumping,slab staggering and the like under heavy-load traffic are solved, so that the pavement structure has high bearing capacity and deformation resistance, and damage to the pavement structure is reduced.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com