Ultra-thin wearing layer of pavement

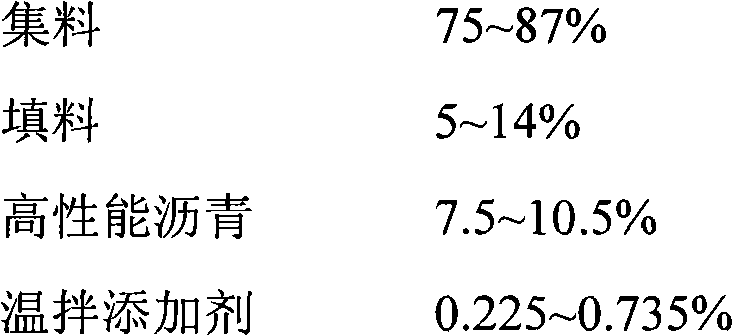

A wear layer, ultra-thin technology, applied in the field of asphalt mixture, can solve the problems of insignificant overall, difficult to achieve pertinence, reduced cost, etc., to improve water stability, good stability, and enhance resistance to dynamic water erosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Aggregate: basalt, the maximum nominal particle size is 6.7mm;

[0024] Filler: cement (ordinary Portland cement 42.5); limestone mineral powder; limestone mineral powder: ordinary Portland cement = 1:2;

[0025] The ore grading is:

[0026] Sieve hole(mm)

9.5

6.7

2.36

1.18

0.6

0.075

Passing rate(%)

100

95.5

10.7

8.9

7.3

4.2

[0027] Asphalt binder (high-performance asphalt): base asphalt is I-C type SBS modified asphalt, 40 mesh to 60 mesh waste tire rubber powder is 24% of SBS modified asphalt, and high-performance asphalt accounts for 8.5% of the total mass of the mixture.

[0028] Warm mix agent: DAT warm mix agent, the dosage is 6.0% of high-performance asphalt.

[0029] The void ratio of the mixture was 19.8%.

[0030] The performance indicators of the mixture are:

[0031] project

Embodiment 2

[0033] Aggregate: diabase, the maximum nominal particle size is 6.7mm;

[0034] Filler: cement (ordinary Portland cement 32.5); limestone mineral powder; limestone mineral powder: ordinary Portland cement = 1:3;

[0035] The ore grading is:

[0036] Sieve hole(mm)

9.5

6.7

2.36

1.18

0.6

0.075

Passing rate(%)

100

91.4

14

12.7

8.1

4.3

[0037] Asphalt binder (high-performance asphalt): base asphalt is I-C type SBS modified asphalt, 40 mesh to 60 mesh waste tire rubber powder is 25% of SBS modified asphalt, and high-performance asphalt accounts for 9.0% of the total mass of the mixture.

[0038] Warm mix agent: DAT warm mix agent, its dosage is 5.5% of high-performance asphalt.

[0039] The void ratio of the mixture was 17.5%.

[0040] The performance indicators of the mixture are:

[0041] project

Embodiment 3

[0043] Aggregate: diabase, the maximum nominal particle size is 6.7mm;

[0044] Filler: cement (ordinary Portland cement 42.5); limestone mineral powder; limestone mineral powder: ordinary Portland cement = 2:1;

[0045] The ore grading is:

[0046] Sieve hole(mm)

9.5

6.7

2.36

1.18

0.6

0.075

Passing rate(%)

100

97.8

24.4

18.3

11.7

8.5

[0047] Asphalt binder (high-performance asphalt): base asphalt is I-C type SBS modified asphalt, 60 mesh to 80 mesh waste tire rubber powder is 22% of SBS modified asphalt, and high-performance asphalt accounts for 8.5% of the total mass of the mixture.

[0048] Warm mix agent: DAT warm mix agent, its dosage is 5% of high-performance asphalt.

[0049] The void ratio of the mixture is 4.8%, the VMA of the mineral aggregate is 21.1%, and the asphalt saturation is 77.3%.

[0050] The performance indicators of the mixture are:

[0051] proje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com