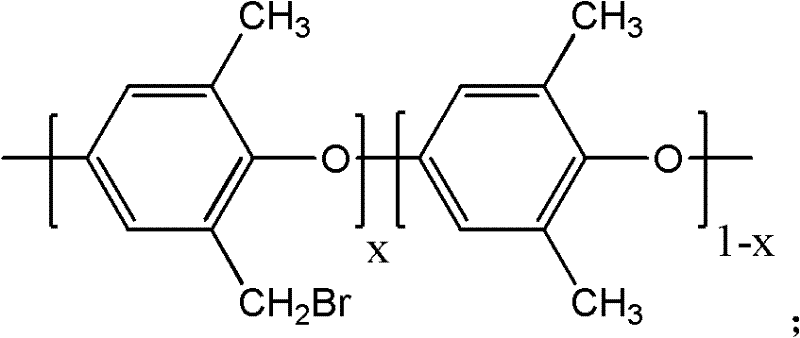

Method for preparing brominated-polyphenylene-ether-guanidination-based homogeneous anion exchange membrane

A technology of anion exchange membrane and brominated polyphenylene ether, which is applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of poor stability, low membrane conductance, constraints, etc., and achieve high ion exchange content, good Effect of thermal stability and mechanical strength, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

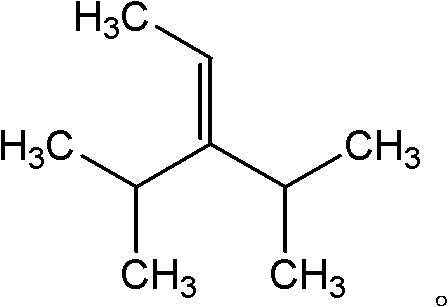

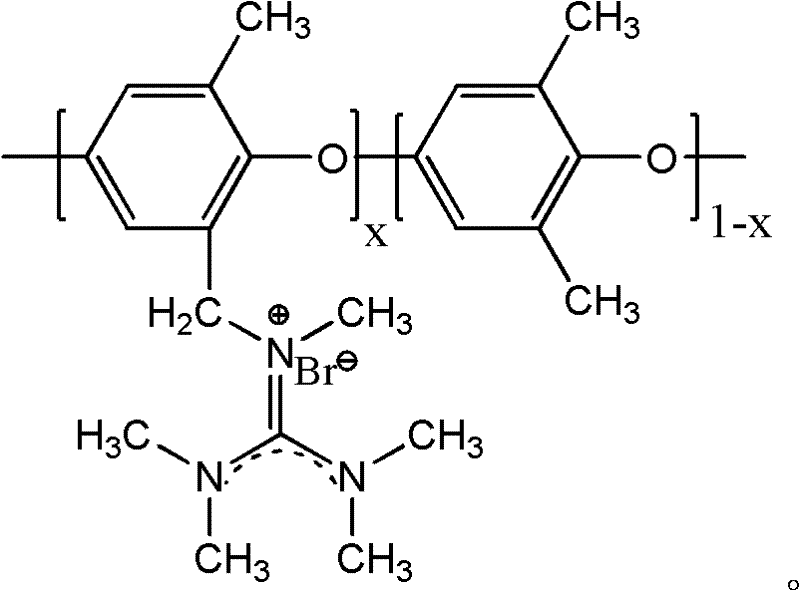

[0024] 1 g of brominated polyphenylene ether (bromomethyl: 0.4 mmol) with a degree of methyl bromination of 5% was dissolved in 10 ml of toluene, and 0.5 ml of 1,1,2,3,3-pentamethyl-substituted guanidine (4.0 mmol, 10 equivalents), stirred and reacted in an ice-water bath (0° C.) for 6 hours to obtain a casting solution; the casting solution was scraped on a polyethylene film, and the solvent was evaporated at room temperature to obtain a homogeneous anion exchange membrane. Soak the membrane in 1mol L -1 In NaOH aqueous solution for 24h, it will be converted into OH - type anion exchange membrane.

[0025] p-brominated polyphenylene ether and the resulting OH - The infrared test of the type anion exchange membrane found that the stretching vibration peak corresponding to C-Br in the original brominated polyphenylene ether was 742cm -1 , and in the anion exchange membrane prepared in this example, the above C-Br peak disappeared, and at the same time at 1600cm -1 and 1397c...

Embodiment 2

[0029] Dissolve 1 g of brominated polyphenylene ether (bromomethyl: 2.7 mmol) with a methyl bromination degree of 42% in 20 ml of N-methylpyrrolidone, and add 0.7 ml of 1,1,2,3,3-pentamethyl Substitute guanidine (5.4mmol, 2 equivalents), stir and react at 25°C for 24h to obtain a casting solution; scrape the casting solution on a glass plate, place it in an oven, and dry it at 30°C to obtain a homogeneous anion exchange membrane . Soak the membrane in 1mol L -1 In NaOH aqueous solution for 24h, it will be converted into OH - type anion exchange membrane.

[0030] The infrared test results of the anion exchange membrane prepared in this example are similar to the results of the infrared test in Example 1, indicating that the degree of reaction between bromomethyl and pentamethyl-substituted guanidine is relatively high.

[0031] Other properties of the test anion exchange membrane are as follows: water content 57.1%, ion exchange content 2.32mmolg -1 , the tensile strength ...

Embodiment 3

[0034] 1g of brominated polyphenylene ether (bromomethyl: 5.0mmol) with 100% degree of methyl bromination was dissolved in 40ml of chlorobenzene, and 0.32ml of 1,1,2,3,3-pentamethyl-substituted guanidine ( 2.5mmol, 0.5 equivalent), stirred and reacted at 25°C for 48h to obtain a casting solution; coated the casting solution on the surface of a polytetrafluoroethylene plate, placed in an oven, and dried at 130°C to obtain a homogeneous anion exchange membrane. Soak the membrane in 1mol L -1 In NaOH aqueous solution for 24h, it will be converted into OH - type anion exchange membrane.

[0035] Infrared testing of brominated polyphenylene ether and the final OH-type anion exchange membrane found that the stretching vibration peak corresponding to C-Br in the original brominated polyphenylene ether was 742cm -1 , the above-mentioned C-Br peak still exists in the anion exchange membrane prepared in this example, and at the same time at 1600cm -1 and 1397cm -1 Vibration peaks o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com