Homogeneous anion exchange membrane and preparation method thereof

An anion exchange membrane and coating technology are applied in the field of homogeneous anion exchange membrane and its preparation, which can solve the problems of reducing the electrochemical performance of the anion exchange membrane, wasting raw materials, and lacking the driving force for hydrophobic and hydrophilic phase separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

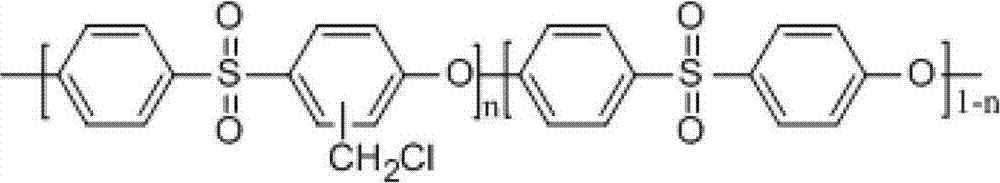

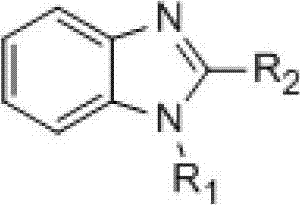

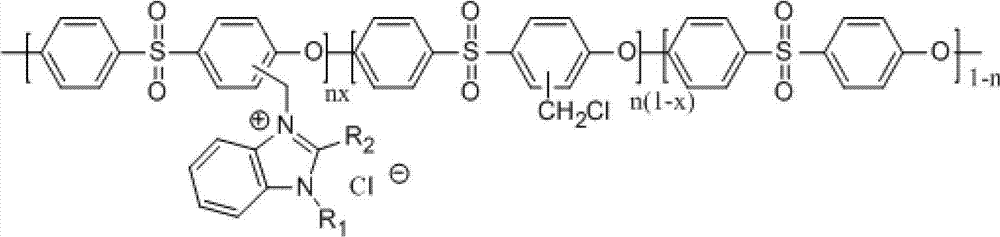

[0034] The invention discloses a method for preparing a homogeneous anion exchange membrane. The method comprises the following steps: dissolving a halomethylated aromatic high polymer in an organic solvent to form a solution to be reacted; mixing the solution to be reacted and The benzimidazole functional small molecules are mixed and undergo nucleophilic substitution reaction to obtain a casting solution of an aromatic polymer with a positively charged benzimidazole functional small molecule side group; and the casting solution A film is coated on a substrate and dried, after which the substrate is removed, or the cast solution is coated on a reinforcing fabric and dried to obtain a homogeneous anion exchange membrane.

[0035] The halomethylated aromatic high polymer is halomethylated polyphenylsulfone, polyethersulfone, bisphenol A polysulfone, polyether ether ketone, polyether ketone, polyphenylene ether, polynaphthyl biphenyl Ether sulfone, polynaphthalene polyether sulf...

Embodiment 1

[0058] The polyethersulfone (halomethyl 0.75mmol) that 1g halomethylation degree is 18mol% is dissolved in 10ml toluene and forms the solution to be reacted that mass volume concentration is 10m / v%, after adding 0.10g 1-methylbenzo Imidazole (0.75 mmol, 1 equivalent) was reacted with stirring at 25°C for 24 hours to obtain a casting solution. Cast the casting solution on a polytetrafluoroethylene plate, heat and dry at 60°C to obtain an anion exchange membrane.

[0059] The prepared anion exchange membrane has uniform and transparent appearance, good mechanical strength and high flexibility of the membrane. Test its related properties: water content 15%, ion exchange capacity 0.60mmolg -1 , with an ionic conductance of 10mS cm -1 , The mechanical strength is 27MPa.

Embodiment 2

[0061] Similar to Example 1, except that the casting solution was scraped on the polyethylene film, heated and dried at 100°C to obtain an anion exchange membrane.

[0062] Since the composition of the membrane liquid is the same, the properties of the anion exchange membrane prepared in this example are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com