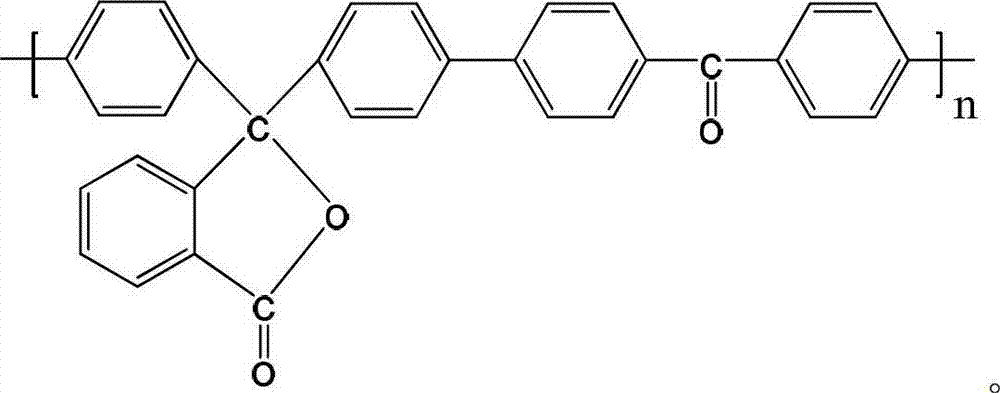

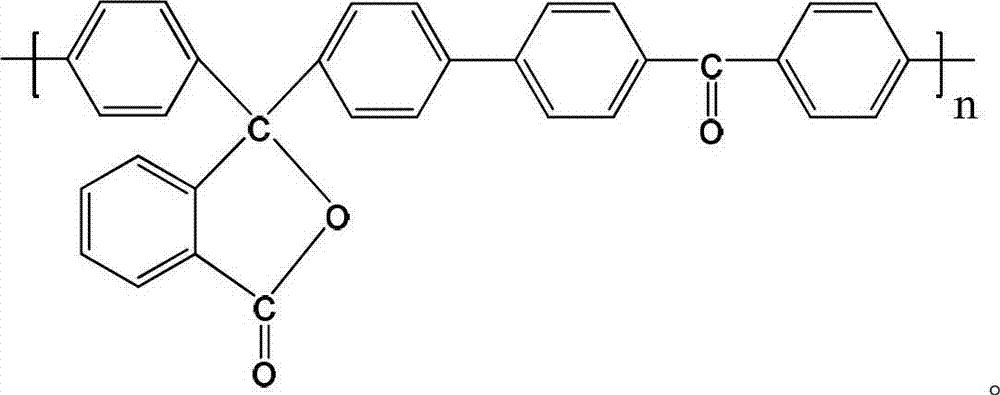

Monomer in situ polymerization-based homogeneous anion-exchange membrane and preparation method thereof

An anion exchange membrane and in-situ polymerization technology, which is applied in the field of homogeneous anion exchange membranes based on in-situ polymerization of monomers and their preparation, can solve the problems of insufficient local polymerization, reduced membrane mechanical properties, and uneven local morphology. To achieve the effect of reducing the cost of film production, reducing the number of use, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Mix 4ml of p-chloromethylstyrene and 0.08ml of divinylbenzene to form a mixed solution, dissolve 1g of phenolphthalein polyether ketone in this mixed solution, then add 0.08g of dibenzoyl peroxide, and wait until all components are dissolved And after mixing evenly, the casting solution is obtained; the casting solution is coated on a polypropylene cloth with a thickness of 0.10 mm, and the base film is obtained after in-situ polymerization at 70 ° C for 7 hours; finally, the base film is soaked in The quaternization reaction was carried out in a 10% trimethylamine aqueous solution for 36 hours, washed with deionized water, and then placed in the air at room temperature to dry naturally to obtain an anion exchange membrane.

[0016] Infrared testing is carried out on the base membrane and anion exchange membrane prepared above: for the base membrane: 791-812cm -1 Corresponding to the C-Cl stretching vibration peak in p-chloromethyl styrene, 1745-1760cm -1 Corresponding...

Embodiment 2

[0019] Mix 4ml of p-chloromethylstyrene and 0.24ml of divinylbenzene to form a mixed solution, dissolve 1g of phenolphthalein polyether ketone in this mixed solution, then add 0.08g of dibenzoyl peroxide, and wait until all components are dissolved and mix uniformly to obtain a casting solution, which is coated on a polypropylene cloth with a thickness of 0.10mm, and is thermally initiated at 80°C for in-situ polymerization for 8h, and finally in a 10% trimethylamine aqueous solution by mass fraction The quaternization reaction was carried out for 48 hours, washed with deionized water, and placed in the air at room temperature to dry naturally to obtain an anion exchange membrane.

[0020] The water content of the anion exchange membrane prepared in this example is 66.0%, and the ion exchange content is 1.64mmol g -1 ,OH - The conductance is 0.025S·cm -1 , indicating that the membrane has good electrical conductivity, suitable water content and ion exchange content, and meet...

Embodiment 3

[0022] Mix 4ml of p-chloromethylstyrene and 0.80ml of divinylbenzene to form a mixed solution, dissolve 1g of phenolphthalein polyether ketone in this mixed solution, then add 0.08g of dibenzoyl peroxide, and wait until all components are dissolved And after mixing uniformly, the casting solution is obtained; the casting solution is coated on a polypropylene cloth with a thickness of 0.10mm, and the in-situ polymerization is initiated at 80°C for 48h, and finally the mass fraction is 10% trimethylamine aqueous solution The quaternization reaction was carried out in the medium for 48 hours, washed with deionized water, and then placed in the air at room temperature to dry naturally to obtain an anion exchange membrane.

[0023] It is measured that the water content of the anion exchange membrane prepared in this example is 7.5%, and the ion exchange content is 0.54mmol g -1 ,OH - The conductance is 0.004S·cm -1 ,

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com