Zinc-based alloy membrane for guided bone tissue regeneration

A technology for bone tissue regeneration and membrane regeneration, which is applied in the field of oral GTR/GBR membrane materials, can solve the problems of too fast degradation of barrier membrane absorbable collagen membrane, poor mechanical strength, non-degradable barrier membrane, etc., and achieve good cell compatibility and tissue compatibility, reduce production costs, and promote bone regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. Preparation of zinc-based alloy barrier films with different apertures

[0037] 1) Select the original zinc-based alloy to make a 30 μm thick barrier film;

[0038] 2) Step 1) The membrane material is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes in sequence, and dried at 25° C.;

[0039] 3) A laser drilling process is used to prepare holes with a diameter of 300 μm and a hole spacing of 1.2 mm on the zinc-based alloy barrier film material treated in step 2).

Embodiment 2

[0040] Embodiment 2, zinc-based alloy barrier film corrosion performance test

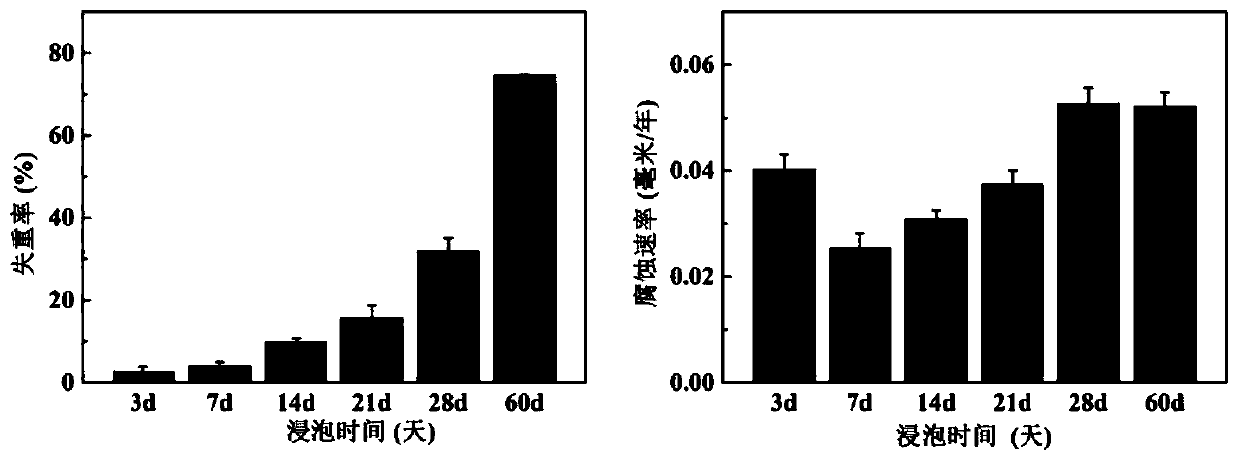

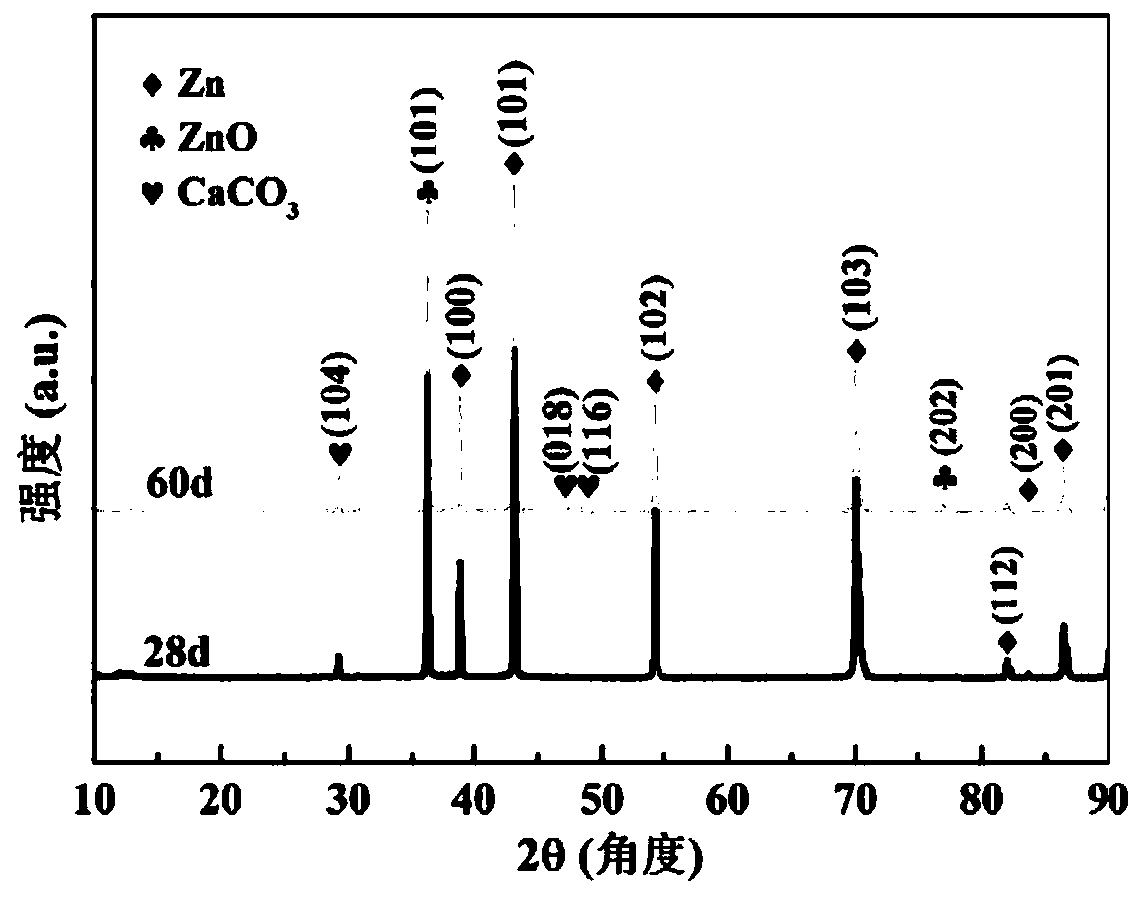

[0041] The two zinc-based alloy barrier films prepared in Example 1 were cut to a size of 10×10×0.03 mm, ultrasonically cleaned in acetone, absolute ethanol and deionized water for 15 minutes, and then dried at 25° C. After soaking in Hank's simulated body fluid (NaCl 8.0g, CaCl 2 0.14g, KCl 0.4g, NaHCO 3 0.35g, glucose 1.0g, MgCl 2 ·6H 2 O 0.1g, Na 2 HPO 4 2H 2 O 0.06g, KH 2 PO 4 0.06g, MgSO4 7H 2 (0.06g, be dissolved in 1L deionized water), take out after soaking different time intervals, observe the sample surface, figure 1 These are scanning electron micrographs of non-porous zinc-based alloys soaked in Hank's simulated body fluid for 3, 7, 14, 21, 28, and 60 days respectively. The results show that the surface of the sample remains intact, and with the extension of immersion time, a large amount of surface deposits Hydroxyapatite minerals indicate that zinc-based alloy barrier mem...

Embodiment 3

[0043] Example 3, in vitro cytocompatibility experiment of zinc-based alloy barrier membrane

[0044] According to the method described in Example 2, zinc-based alloy barrier film samples of corresponding sizes and specifications were prepared. The titanium film was used as the control group, sterilized by gamma rays, placed in a sterile culture bottle, and measured according to the surface area of the sample and α-MEM The cell culture medium volume ratio is 1.25cm 2 / mL ratio into α-MEM cell culture medium, placed at 37 ° C, 95% relative humidity, 5% CO 2 After 72 hours in the incubator, the original solution of the zinc-based alloy barrier membrane leaching solution was obtained, sealed, and stored in a refrigerator at 4°C for later use.

[0045] Extraction solution, cell inoculation culture and result observation: MC3T3-E1 cells were resuscitated and passaged, suspended in α-MEM cell culture medium, seeded on 96-well culture plates, so that the final cell concentration was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com