Patents

Literature

114results about How to "Uniform polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

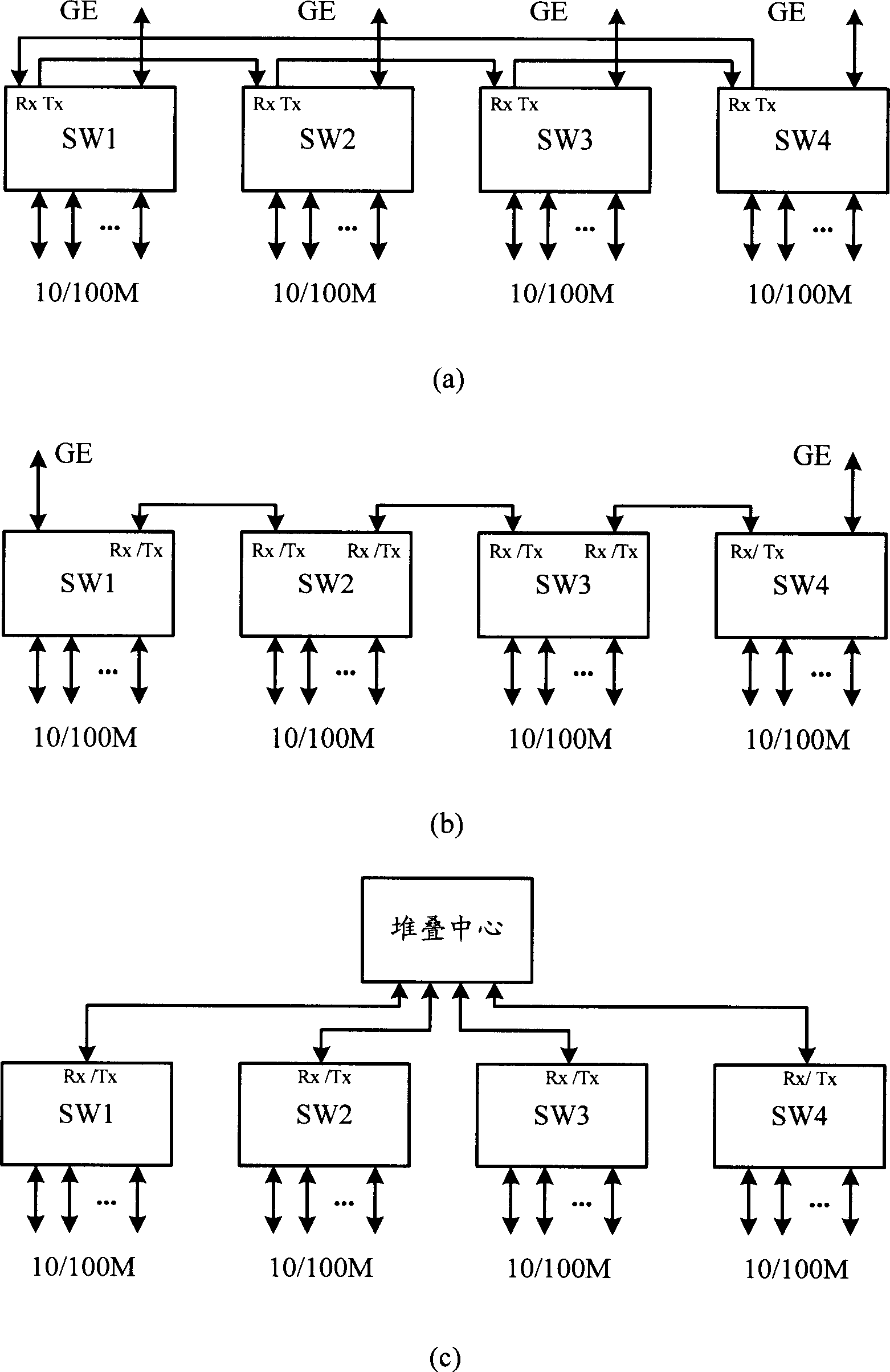

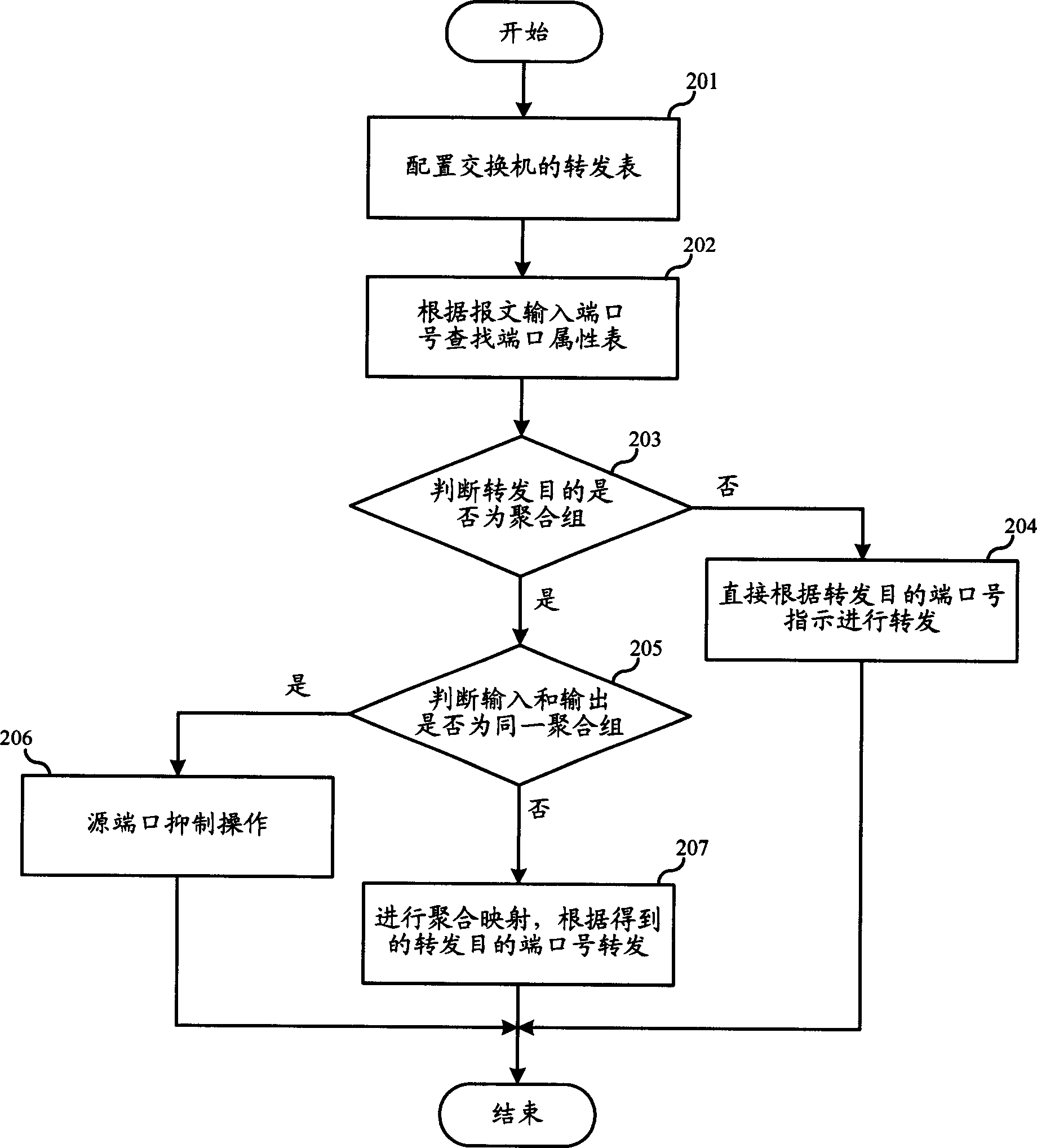

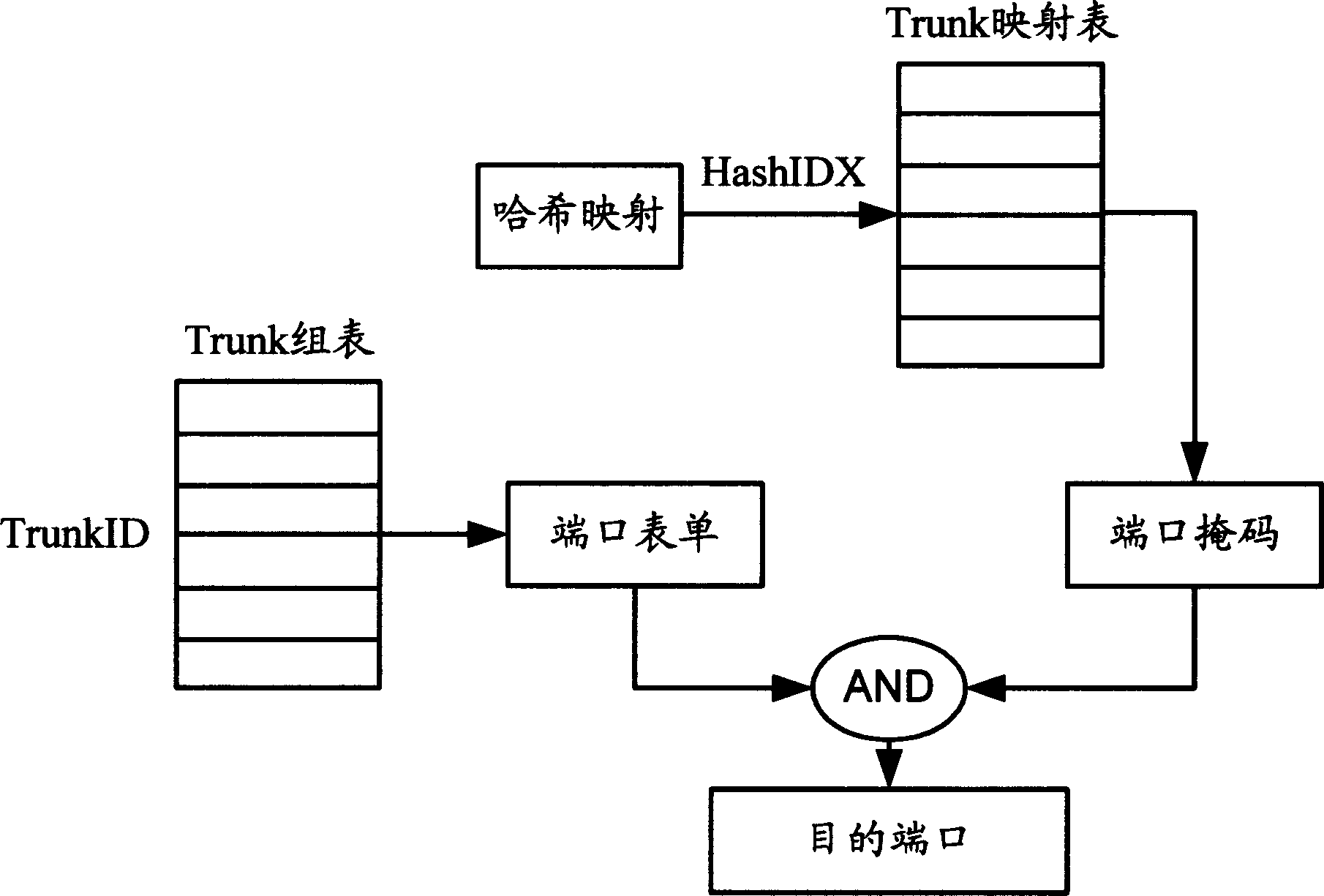

Ethernet device stacking method and its system

ActiveCN1809022AUniform polymerizationLoad balancingData switching networksLink aggregationCombined technique

This invention relates to communication combined technique and discloses one Ethernet device overlap method and its system to freely dispatch higher band connection with multiple devices to realize high effective overlapping. This invention adopts linkage polymer method on multiple overlap terminals as stack linkage Ethernet devices. The linkage polymer method realizes linkage polymer and load even through terminal property list, Trunk list, mapping list and message transfer process.

Owner:HUAWEI TECH CO LTD

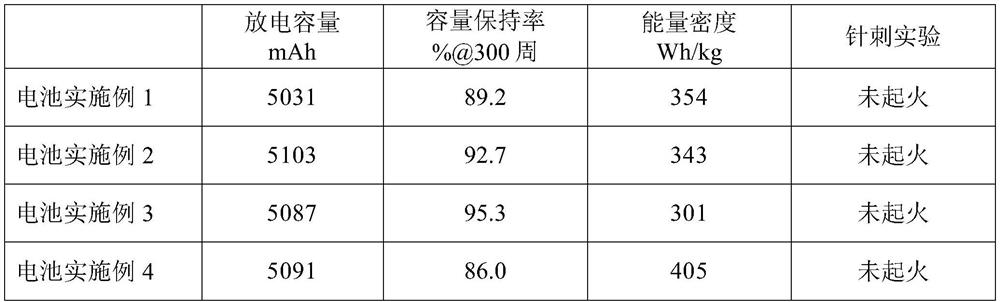

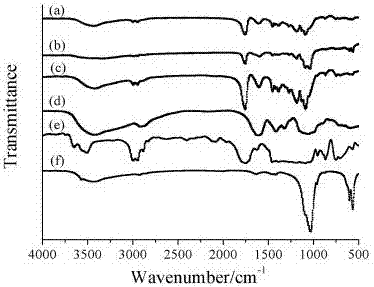

Preparation method of polyacrylonitrile carbon fiber with evenly distributed copolymerization sequence

ActiveCN104372445AAggregation continuousUniform polymerizationArtificial filament heat treatmentFibre chemical featuresCarbon fibersPAN copolymer

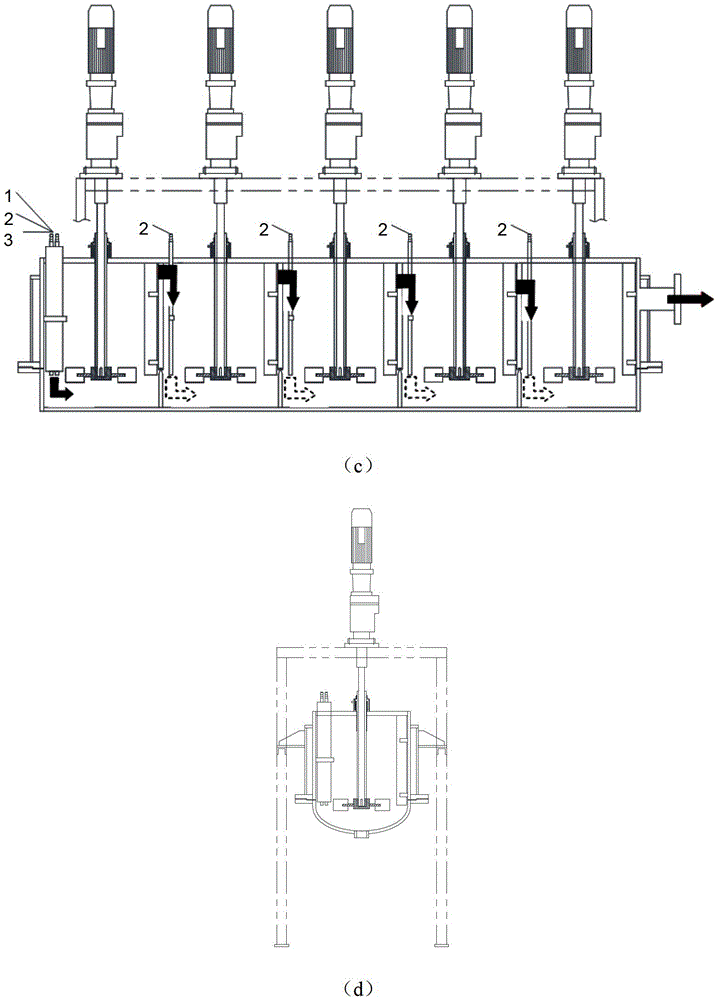

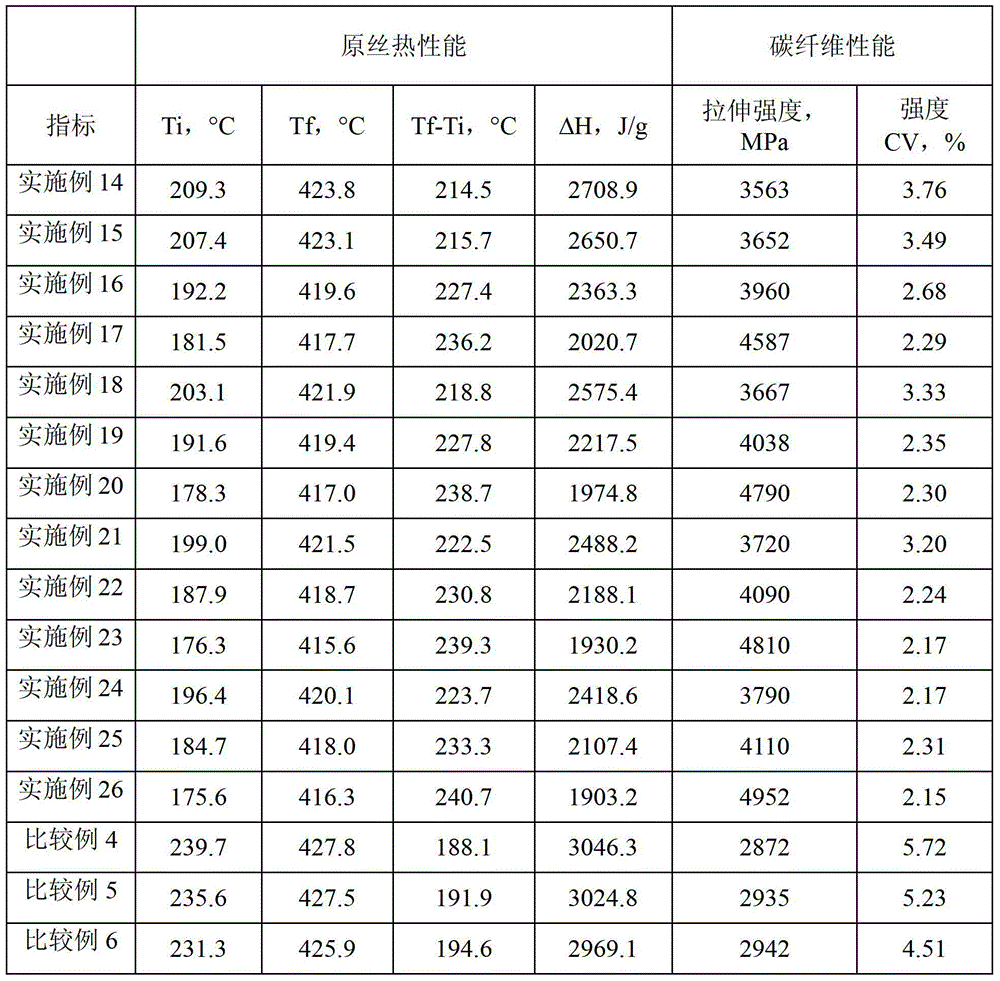

The invention relates to a preparation method of a polyacrylonitrile carbon fiber with an evenly distributed copolymerization sequence. The preparation method comprises the following steps: determining the number of serially connected reactors; determining the ratio of fed materials of different areas in the third co-monomer zone; carrying out precipitation polymerization by taking water as the medium, drying so as to obtain polyacrylonitrile powder; dissolving the polyacrylonitrile powder to prepare a spinning solution, removing the bubbles from the solution, filtering, spraying, and curing to form primary fibers, washing and subjecting the primary fibers to a post treatment so as to obtain polyacrylonitrile-based carbon precursor fibers; and finally subjecting the precursor fibers to pre-oxidation, carbonation, and a post treatment so as to obtain the high performance carbon fiber. The preparation method adopts multi-grade serially-connected stirred tank polymerization reactors, and raw materials are supplemented in the third co-monomer zone according to a certain ratio in different areas so as to obtain a PAN copolymer with evenly distributed copolymerization sequence. Because the distribution uniformity of the copolymerization sequence of polyacrylonitrile precursor fibers is high, the possibility that fibers with a shell-core structure appear during the pre-oxidation process is small. Moreover, the diffusion of oxygen gas in the radical direction of fibers is also promoted, thus the pre-oxidation reactions can be stably carried out and the heat dissipation can be controlled so as to obtain carbon fiber with an excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

In-situ polymerized organic-inorganic composite solid-state battery

ActiveCN111933894AIncrease elasticityGood compatibilityFinal product manufactureSecondary cellsElectrical conductorIn situ polymerization

The invention discloses an in-situ polymerized organic-inorganic composite solid-state battery, which is characterized in that a polymer solid-state electrolyte monomer or oligomer small molecule is compactly connected with an electrode active material, an inorganic fast ion conductor and a lithium salt in an in-situ polymerization manner, wherein the polymer solid electrolyte monomer or oligomersmall molecule at least comprises one compound containing an unsaturated carbon-carbon bond and carbonyl or sulfonyl or sulfinyl; the polymer solid electrolyte monomer or oligomer small molecule at least comprises one compound containing two or more unsaturated carbon-carbon bonds. The battery is small in interface resistance, high in conductivity and resistant to high voltage, the problem that asolid-state battery is poor in room-temperature and low-temperature performance is solved, and the production technological process is simple and reliable.

Owner:安普瑞斯(无锡)有限公司

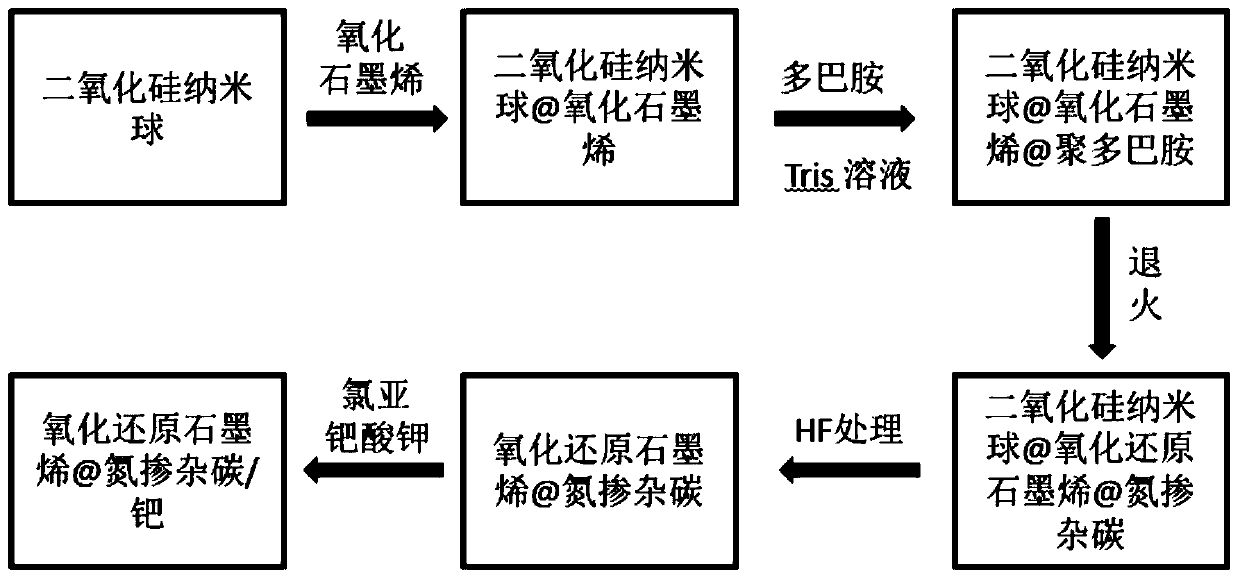

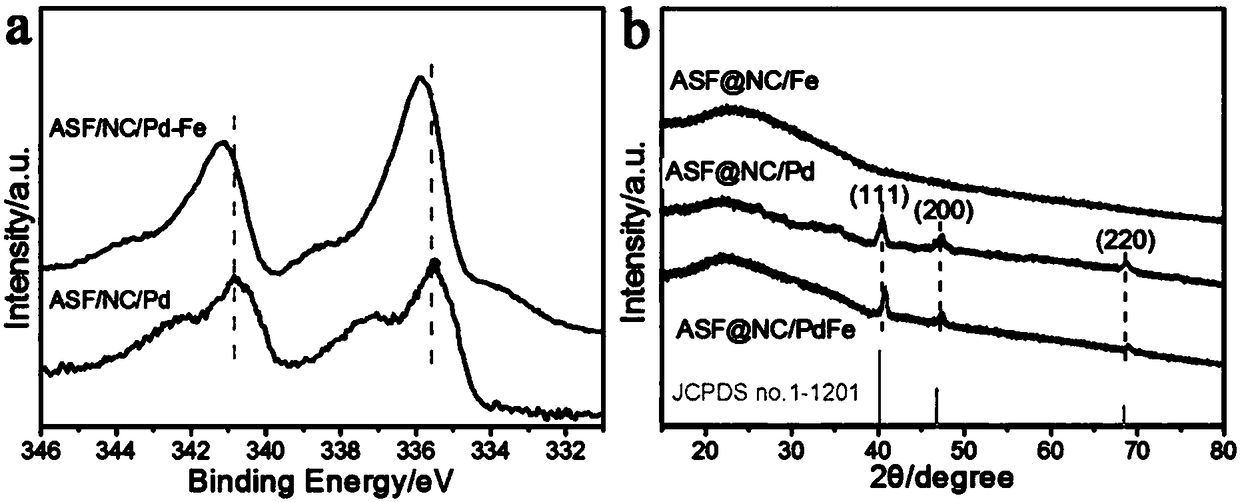

Monatomic catalyst, and preparation method and application thereof

InactiveCN110787827AImprove stabilityEnhanced interactionPhysical/chemical process catalystsOrganic compound preparationPtru catalystOrganic chemistry

The invention belongs to the field of catalysts, and discloses a monatomic catalyst, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) synthesizing a SiO2-coated GO composite material by coating SiO2 nanospheres with graphene oxide; (2) synthesizing a SiO2-coated GO-coated PDA composite material by coating the SiO2-coated GO composite material with polydopamine; (3) synthesizing an RGO-coated NC composite material by coating reduced graphene oxide with nitrogen-doped carbon; and (4) synthesizing an RGO-coated NC / Pd monatomic catalystby loading the RGO-coated NC composite material with Pd monatoms. According to the preparation method disclosed by the invention, the overall process flow of the preparation method is set, and the reaction conditions and parameters of each key process step are improved, so that the dispersity, the catalyst activity and the cycling stability of metallic single atom can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

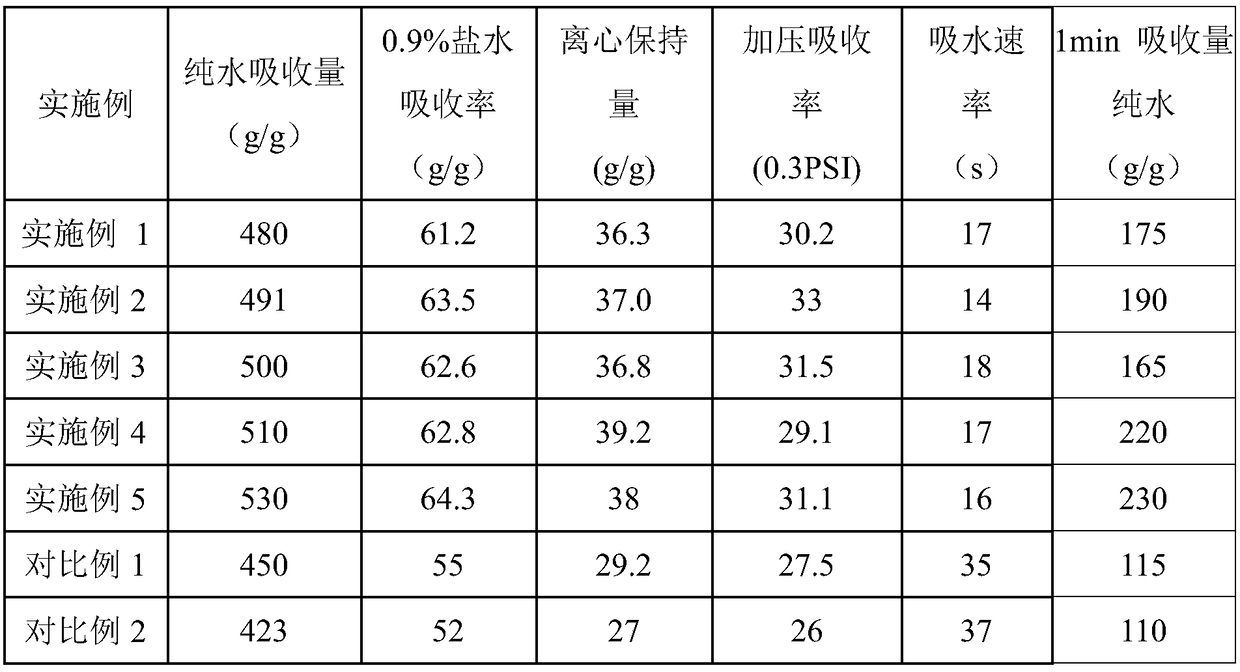

Superabsorbent polymer and preparation method thereof

ActiveUS20160184799A1High gel strengthUniform polymerizationOther chemical processesAbsorbent padsCross-linkAbsorption capacity

The present invention relates to a superabsorbent polymer showing a low degree of decrease in absorption capacity, and a preparation method thereof. Specifically, the present invention provides a superabsorbent polymer having an excellent rewetting prevention ability such that moisture hardly leaks out under pressure even after a certain time, and a preparation method thereof, by preparing an acrylic resin with a high molecular weight main chain that is evenly cross-linked for maintaining high gel strength by minimizing an amount of an initiator with respect to a monomer.

Owner:LG CHEM LTD

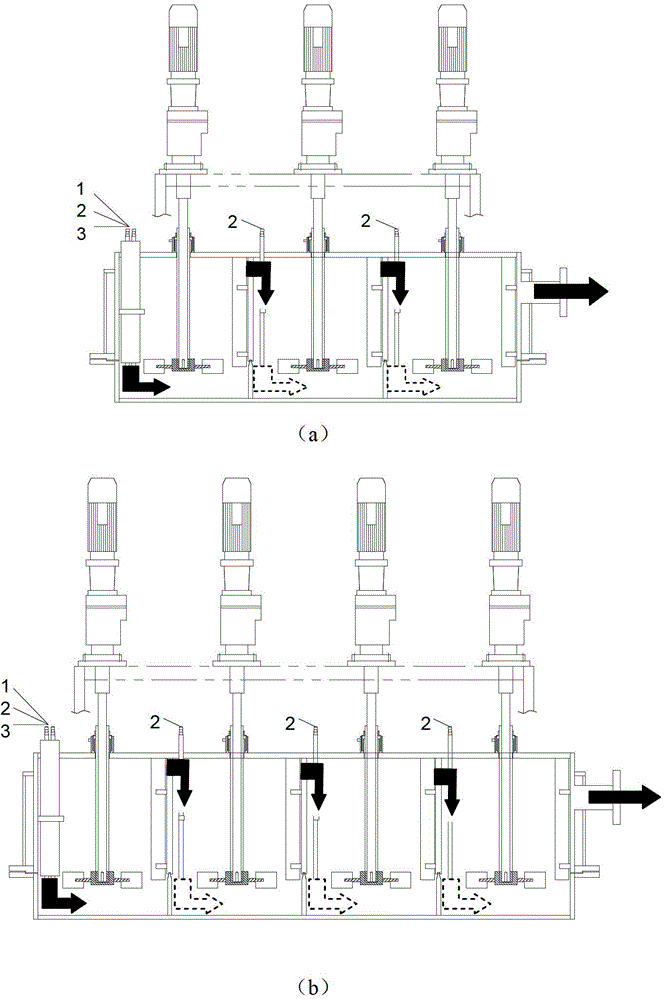

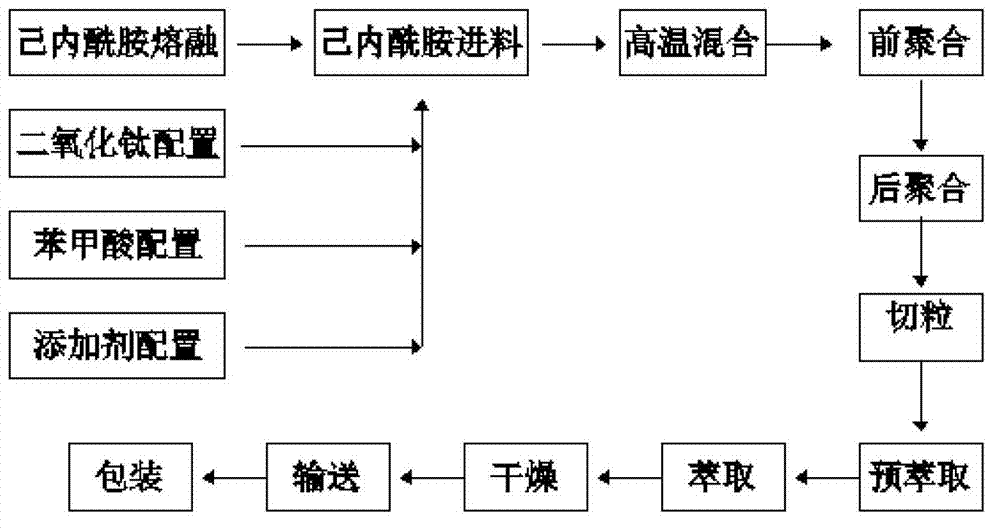

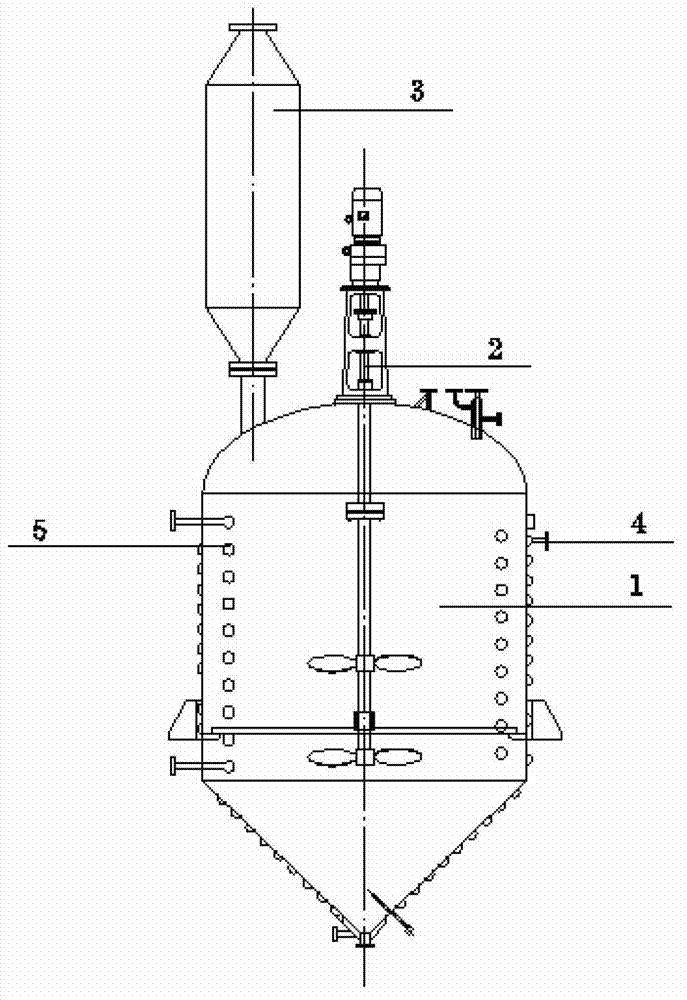

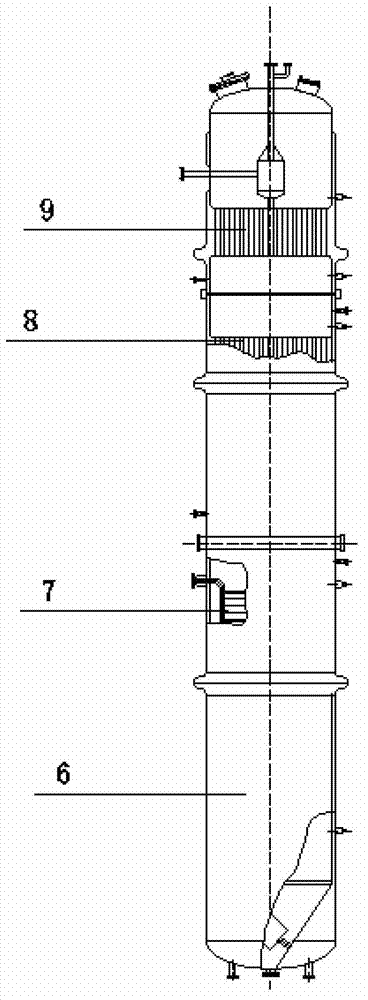

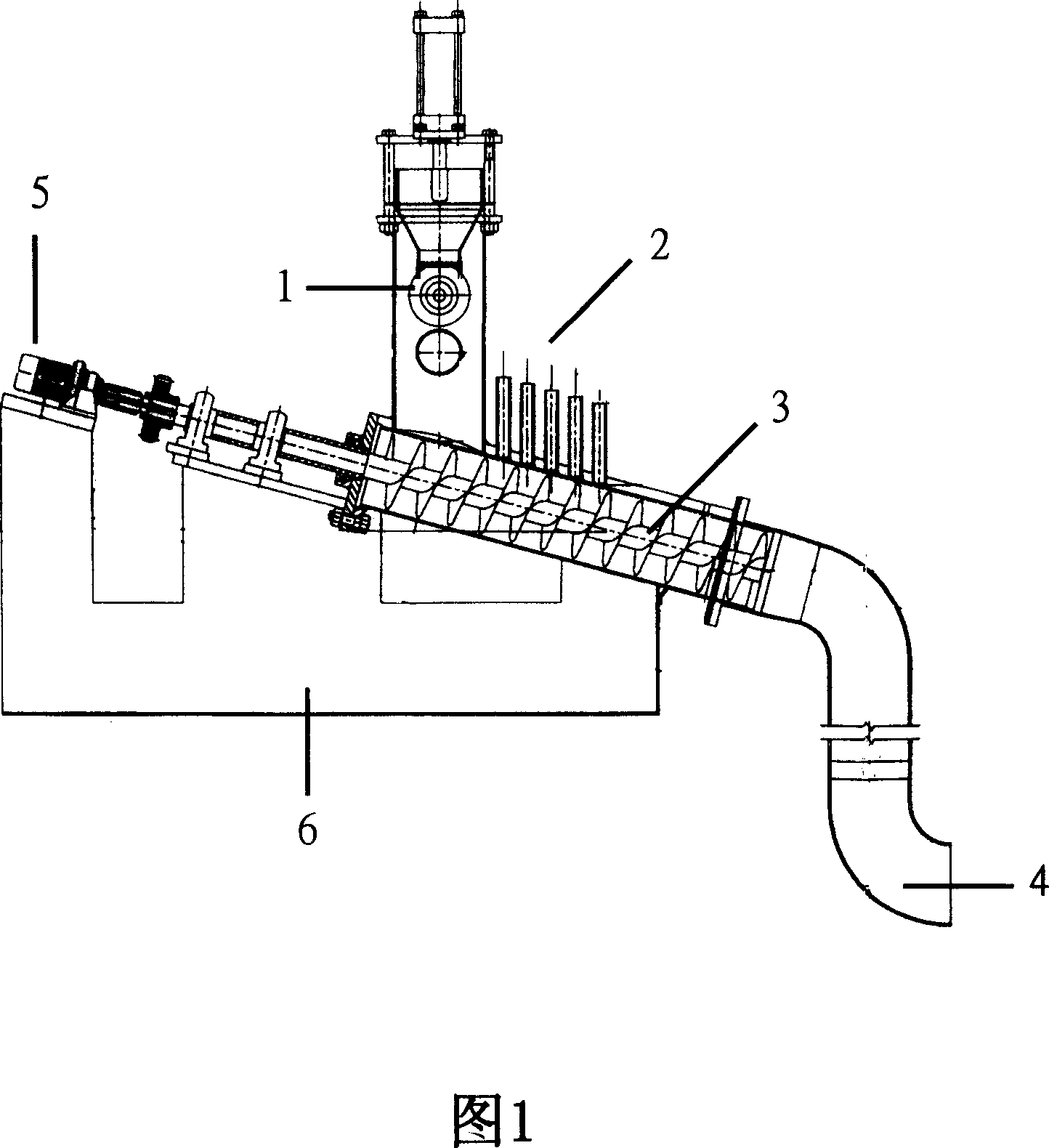

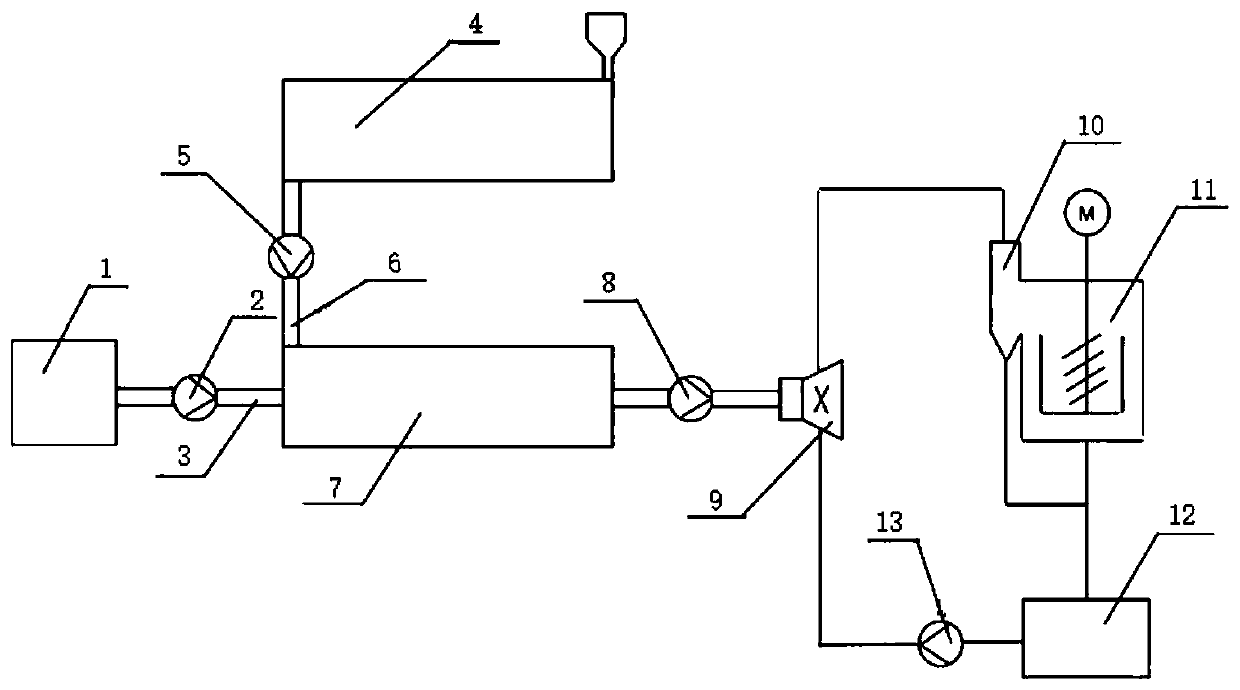

Polymerization manufacturing technique and device for polyamide

The invention relates to a polymerization manufacturing technique and device for polyamide. The manufacturing technique comprises the steps of feeding molten caprolactam, titanium dioxide, benzoic acid and an additive, dynamically mixing at a high temperature for prepolymerization and postpolymerization, granulating, pre-extracting, extracting and drying to obtain the final product. The device comprises a melting system, a feed system, a high-temperature dynamic mixing system, prepolymerization and postpolymerization towers, a pre-extraction column, an extraction column, a recycling system and a drying tower. According to the invention, a high-temperature dynamic mixing tank is set additionally. The mixing of the raw materials and hydrolysis for ring opening and dehydration of polyamide are performed at a state of dynamically mixing to achieve a more sufficient and stable pre-addition polymerization and a more uniform and stable molecular distribution of post-polycondensation. A slice and a water separator of the extraction column are used for mainly extracting oligomers through the pre-extraction column and extracting a caprolactam monomer through the extraction column with a stable concentration. A slice cooler of the drying tower is used for cooling the slices rapidly. An extraction water recycling system is used for recycling the oligomers in the pre-extraction water and the caprolactam monomer in the extraction water.

Owner:武汉森大科技研究发展中心

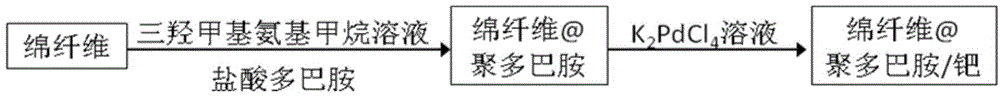

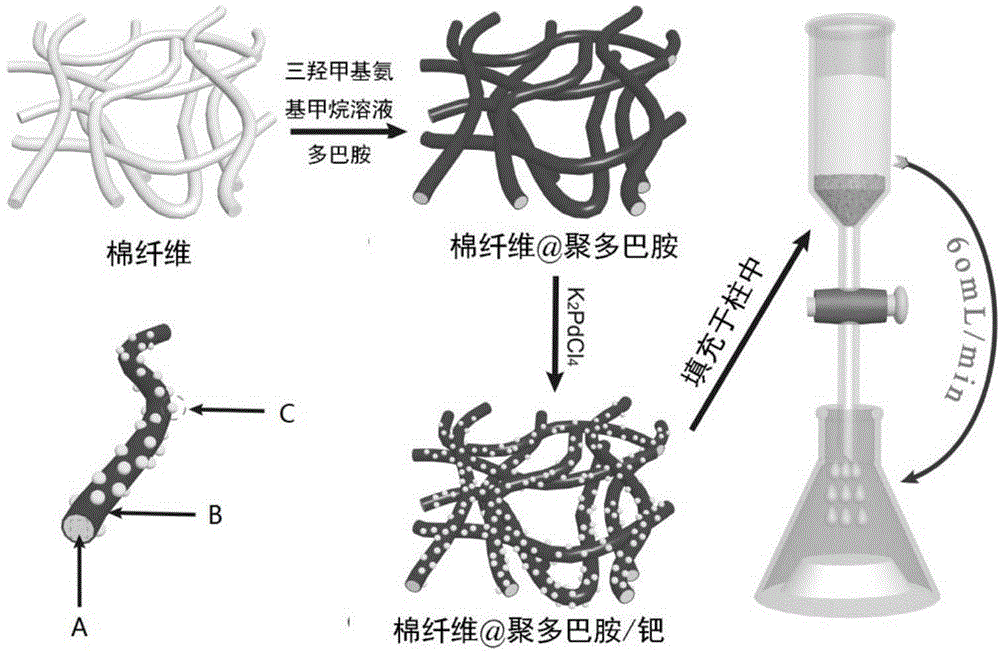

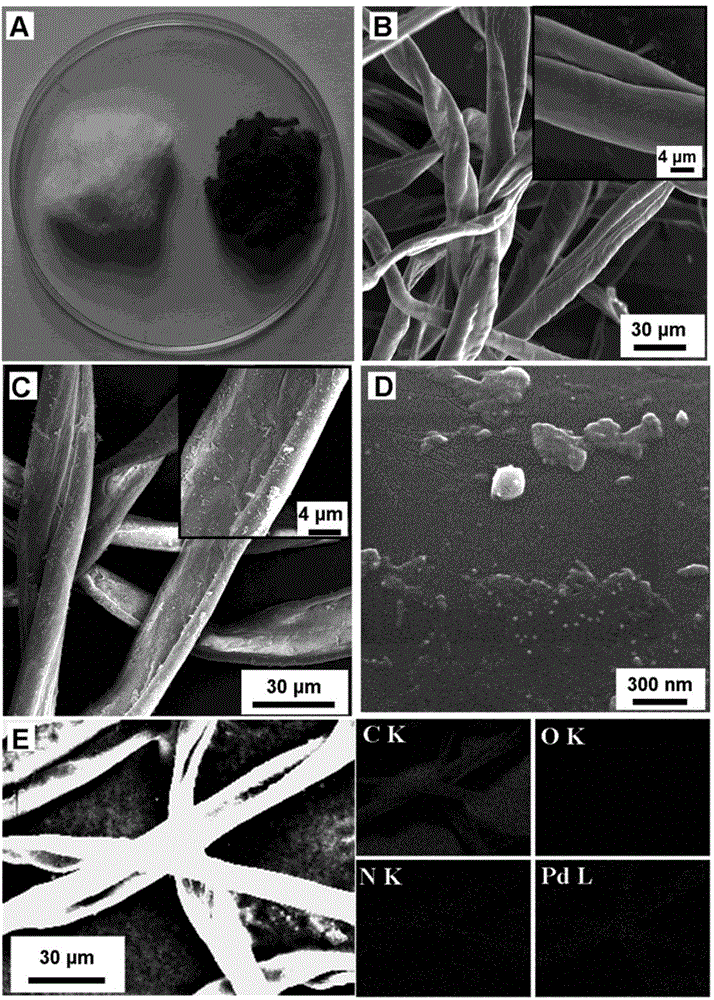

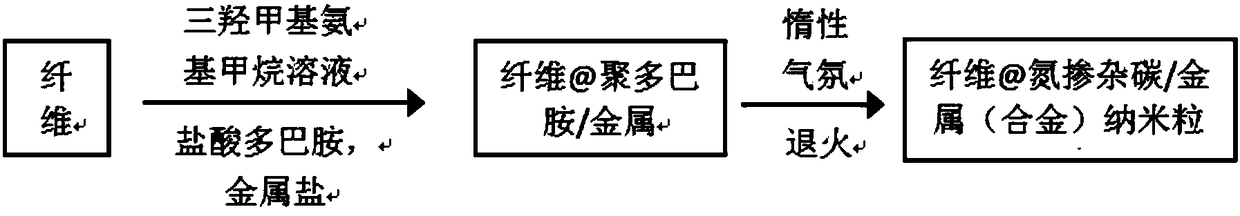

Preparation method and application of fibrous catalyst

InactiveCN104549499ACatalytic activity is not affectedEasy to separate and recycleOrganic-compounds/hydrides/coordination-complexes catalystsFiberPolymer science

The invention discloses a preparation method and application of a fibrous catalyst. The preparation method comprises the following steps: (1) synthesizing a fiber @ polydopamine composite material; (2) preparing a fiber@ polydopamine-precious metal composite material; (3) finally obtaining the fibrous catalyst. The fibrous catalyst is applied to fixed beds. By using reaction materials which are low in cost and easy to get, the prepared fibrous catalyst is easy to separate and recover, can be applied to fixed beds, can be used for realizing continuous catalystic reaction, has positive effect for reducing the application cost of the catalyst and has the advantage of improving the production efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

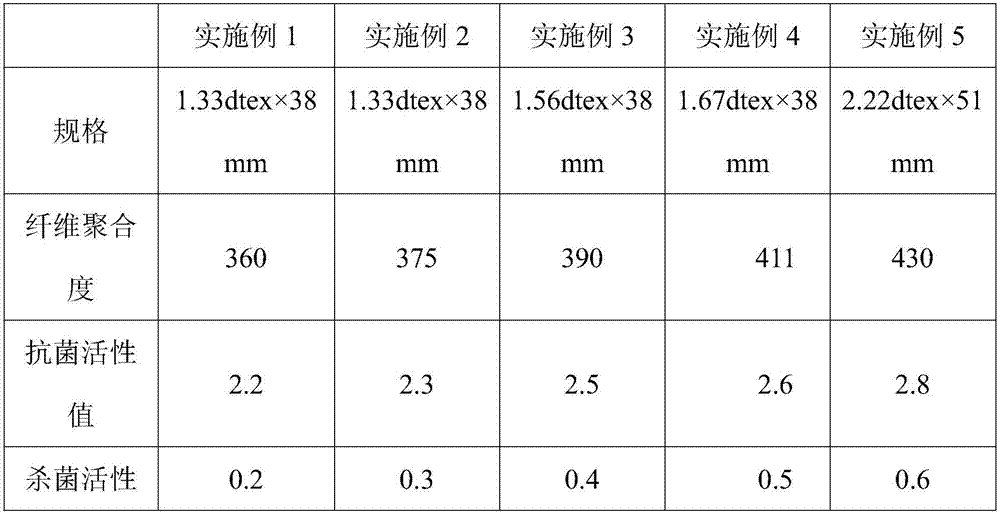

Multifunctional compound cellulose fiber and preparation method thereof

ActiveCN107502966AStable functionImprove solubilityArtificial filaments from cellulose derivativesArtifical filament manufacturePolymer scienceCellulose fiber

The invention discloses a multifunctional compound cellulose fiber and a preparation method thereof. By adoption of an advanced microcapsule preparation technique and modification of a cellulose fiber solution preparation process, a cellulose fiber is modified through polyvinyl alcohol, herba centellae, proteins and vitamins to obtain the multifunctional compound cellulose fiber by means of a cellulose fiber wet spinning process. The multifunctional compound cellulose fiber prepared according to the method is capable of meeting people's demands on moisture absorption, bacteria resistance, skin caring and the like of fibers, and a product is excellent in physical and mechanical performance and stable functionally and has a promising development prospect.

Owner:山东欣悦健康科技有限公司 +1

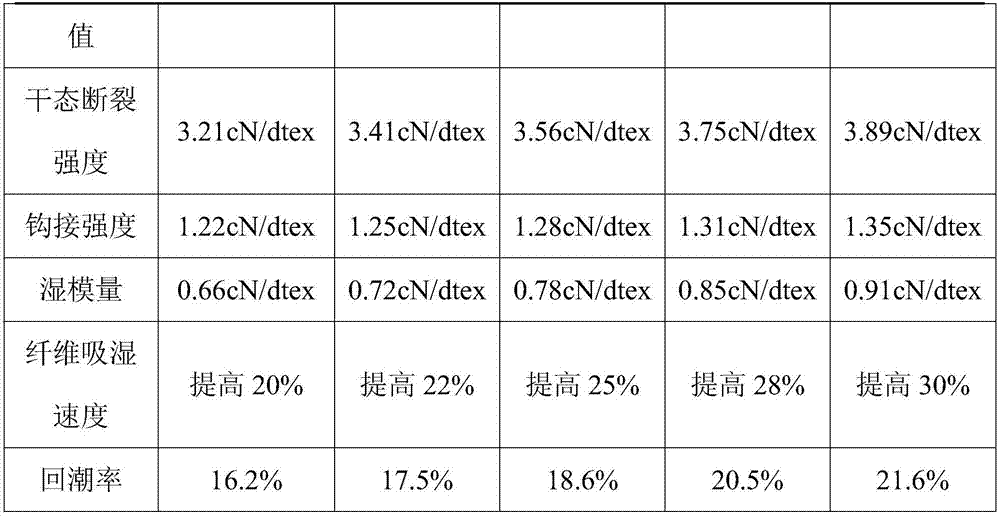

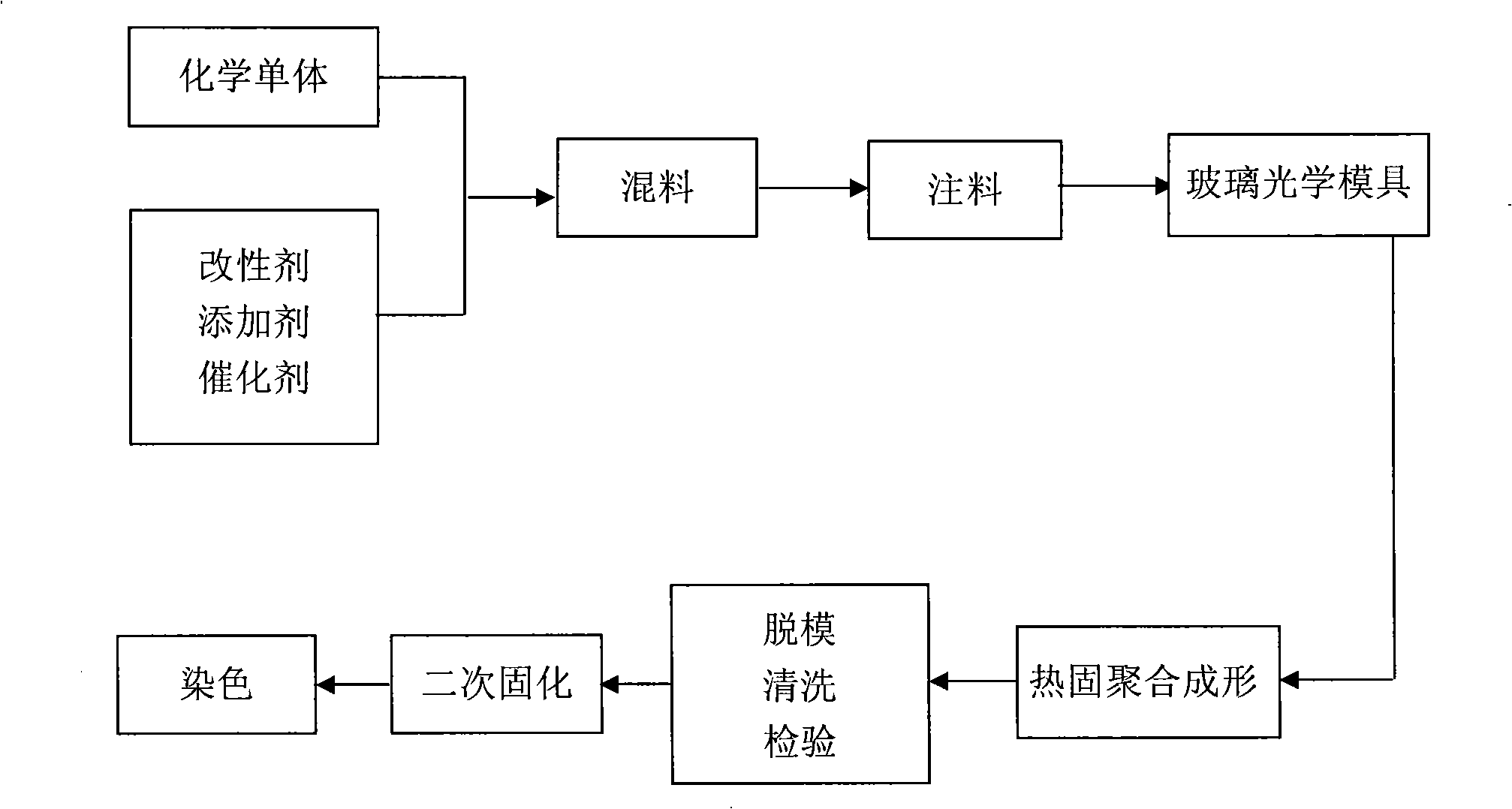

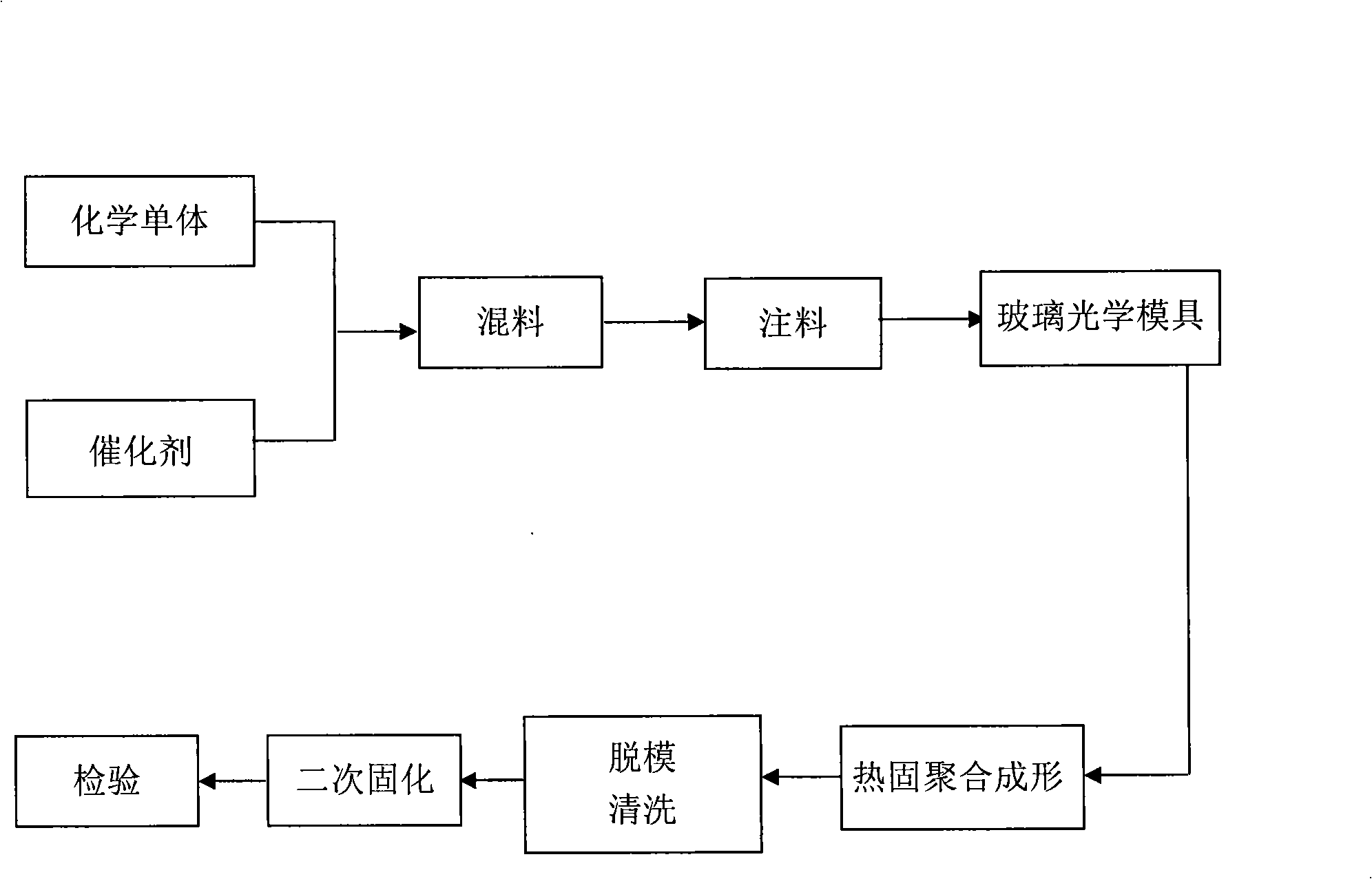

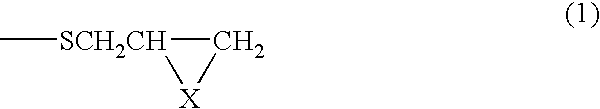

High refractivity resin lens with good pigmenting property and method of manufacture

ActiveCN101334488AImprove mass densitySimple structureOptical partsOptical elementsWater bathsStaining

The invention relates to a resin lens with good coloring performance and high refractive index and a manufacturing method thereof, and the resin lens is characterized in that: the weight percentage ratio of chemical monomer, modifier, additive and initiator in the lens material is 85 to 92 : 5 to 12 : 2.0 to 8.0 : 0.20 to 0.30. The manufacturing method of the resin lens is characterized in that: when in material preparation, the main chemical monomer, the modifier, the additive and the initiator are fully mixed under the room temperature according to the mixture ratio, then stirring and heating are carried out in a hot water bath tank, a filter core with 0.1Mum is used for filtration, the vacuum pumping is further carried out for 40 to 60 minutes; the prepared materials are pressurized and poured into a closed mold through filter paper and a polytetrafluoroethylene filter film; when in polymerization process of the raw materials, a computer is adopted for the temperature control; the lens is carried out with the secondary curing after opening the mold and cleaning; the BPI staining test is carried out; the volume ratio of dye to deionized water is 3.5 to 5 : 1, the temperature is 90 to 97 DEG C, the coloring time is 20 to 30 minutes and the transmittance after the staining is 19 to 30 percent.

Owner:SHANGHAI CONANT OPTICS CO LTD

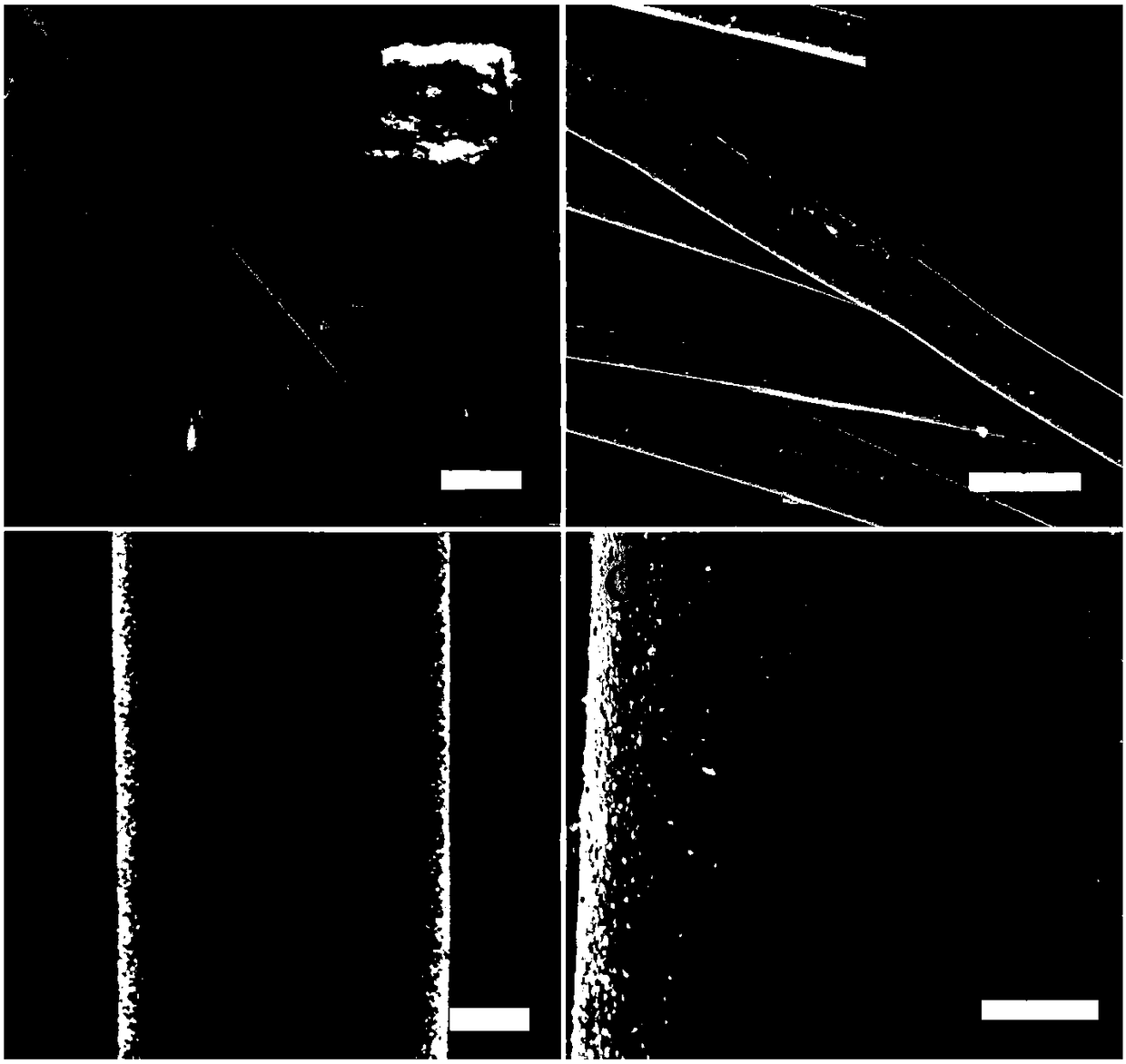

Preparation of fibrous catalyst loaded with metal nanoparticles and application

ActiveCN108212193AImprove catalytic performanceLow application costPhysical/chemical process catalystsFiberMetal catalyst

The invention discloses preparation of a fibrous catalyst loaded with metal nanoparticles and application. The preparation method comprises the following steps: adding metal salt into a solution system containing trihydroxy methyl aminomethane, fiber and dopamine hydrochloride to obtain mixed solution, then stirring, polymerizing dopamine to obtain polydopamine, wrapping fiber with the polydopamine, and simultaneously loading the metal nanoparticles; then, carrying out heat annealing treatment under the atmosphere of inertial gas to prepare a fiber@nitrogen-doped carbon metal compound material, namely the fibrous catalyst loaded with metal nanoparticles. The preparation and the application disclosed by the invention have the beneficial effects that by setting of a whole process flow of thepreparation method and improvement on reaction conditions and parameters of all key process steps, the activity and the cycling stability of the loaded nano-metal catalyst can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Shock resistance optical resin lens and method of manufacture

ActiveCN101339301ARelieve internal polymeric stressGuaranteed Optical AccuracyOptical articlesOptical partsChemistryLens plate

The invention relates to an impact resistance optical resin glasses and a manufacturing method thereof, which is characterized in that optical resins materials consist of materials which have A component and B component, and the weigh percentage ratio of the two components is that: A component: B component = 40-50: 60-50, wherein, the A component is prepared by bi-isocyanic acid hexyl ester with the weigh percentage ratio 44-56 percent and multivariate isocyanate-group compounds which have a benzene ring and have the weigh percentage ratio of 56-44 percent; the B component is prepared by the reaction products of pentaerythritol and 3-sulfhydryl-acrylic acid with the weigh percentage ratio 85-95 percent and tetrathio-pentaerythritol with the weigh percentage ratio 15-5 percent; a catalyst adopts double dodecyl halide stannous: R-D2Sn-R; and the addition amount of the catalyst is 0.05-0.12 percent of the total weight of the A and the B components. A computer temperature control curing oven which is provided with a quick cooling device is adopted by the invention, thus guaranteeing the optical precision and the optical quality of the glasses, well and uniformly mixing the raw materials and greatly improving the qualification rate of the glasses.

Owner:SHANGHAI CONANT OPTICS CO LTD

Preparation method of ammonium polyphosphate having high polymerization degree

ActiveCN106586998AUniform polymerizationSmooth responsePhosphorus compoundsSeed crystalPolymerization

The invention provides a preparation method of ammonium polyphosphate having high polymerization degree. II type ammonium polyphosphate is added and acts as a seed crystal and a solid catalyst is added, so that a polymerization reaction of II type ammonium polyphosphate is more uniform and is stable, the temperature in a synthetic process is easy to control, and the polymerization degree of a synthetized product is improved.

Owner:山东瑞兴阻燃科技有限公司

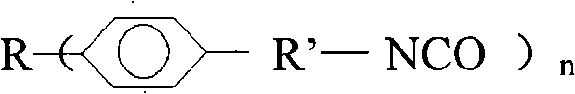

Nano-hydroxyapatite/carboxymethyl chitosan/poly(lactic-co-glycolic acid) micro-nano hybrid drug-loaded scaffold and bionic preparation method thereof

ActiveCN107362392AImprove material stabilityGood biocompatibilityTissue regenerationProsthesisChemistryBiocompatibility Testing

The invention belongs to the field of composite materials, and concretely relates to a nano-hydroxyapatite / carboxymethyl chitosan / poly(lactic-co-glycolic acid) micro-nano hybrid drug-loaded scaffold and a bionic preparation method thereof. The three-dimensional bionic hybrid drug-loaded scaffold is prepared through combining solvent evaporation and freeze drying technologies by using a high speed emulsifying machine via adopting nano-hydroxyapatite and carboxymethyl chitosan as a water phase and an emulsion continuous phase, adopting a methylene chloride solution of poly(lactic-co-glycolic acid) as an oil phase and an emulsion dispersion phase, using glutaraldehyde as a cross-linking agent to immobilize the carboxymethyl chitosan in the continuous phase and adopting the main component icariin in a traditional Chinese medicine epimeddium as a carrier drug. The preparation method has the advantages of simple preparation process and mild reaction conditions, and the obtained scaffold overcomes the performance defects of single natural polymer materials or synthetic polymer materials, has the advantages of intercommunicated pores, uniform pore diameter, figurability, slow drug release, good bone bonding ability and good biocompatibility, and is expected to become a new osteoporosis treatment composite material.

Owner:FUZHOU UNIVERSITY

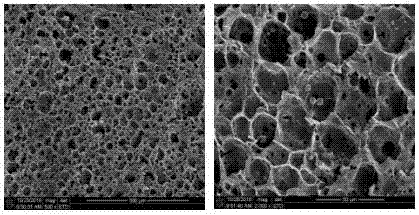

Nitrogen-containing porous polymer chelating resin and preparation and uranium-containing wastewater treatment method

InactiveCN106824124AEasy to prepareLow costOther chemical processesRadioactive decontaminationWastewaterNitrogen

The invention discloses a nitrogen-containing porous polymer chelating resin and a preparation and an uranium-containing wastewater treatment method. The nitrogen-containing porous polymer chelating resin is characterized in that the nitrogen-containing porous polymer chelating resin is prepared by a solvent heat method, and a chelating group is a nitrogen-containing group; the BET (Brunauer, Emmett and Teller) specific surface area of the porous polymer chelating resin containing nitrogen group is 100 to 500m<2> / g; the BJH (Barrett, Joyner and Halenda) pore diameter is 10 to 50nm; the BJH pore volume is 0.5 to 1.5cm<3> / g. The porous polymer chelating resin containing the nitrogen group has the advantages that the preparation process is simple and rapid, and the operation is easy; the adsorbing ability on uranium ions is strong, the adsorbing amount is large, the adsorbing speed is high, and the like; the porous polymer chelating resin can be easily separated from a water solution, and can effectively adsorb and recycle uranyl ions in the water solution.

Owner:EAST CHINA UNIV OF TECH

Preparation method of powdery, water-insoluble high hydroscopicity resin capable of adsorbing water, urine or blood and containing low content soluble substance

ActiveCN1970584AUniform polymerizationImprove processing stabilityAbsorbent padsBandagesInorganic saltsWater insoluble

The invention discloses a making method of powder-shaped, insoluble, water, urine or blood absorbable low-soluble material high-hydroscopicity resin, which comprises the following steps: adding crosslinking agent in the acid group monomer solution with neutralizing rate over 50%; proceeding free radical polymerization for monomer solution and polymer initiator in the double-screw blender for 3-600s; drying through hot wind at 100-250 deg.c; grinding; sieving; coating surface crosslinking agent; heating surface at 80-230 deg.c; adding inert inorganic salt powder.

Owner:FORMOSA PLASTICS CORP

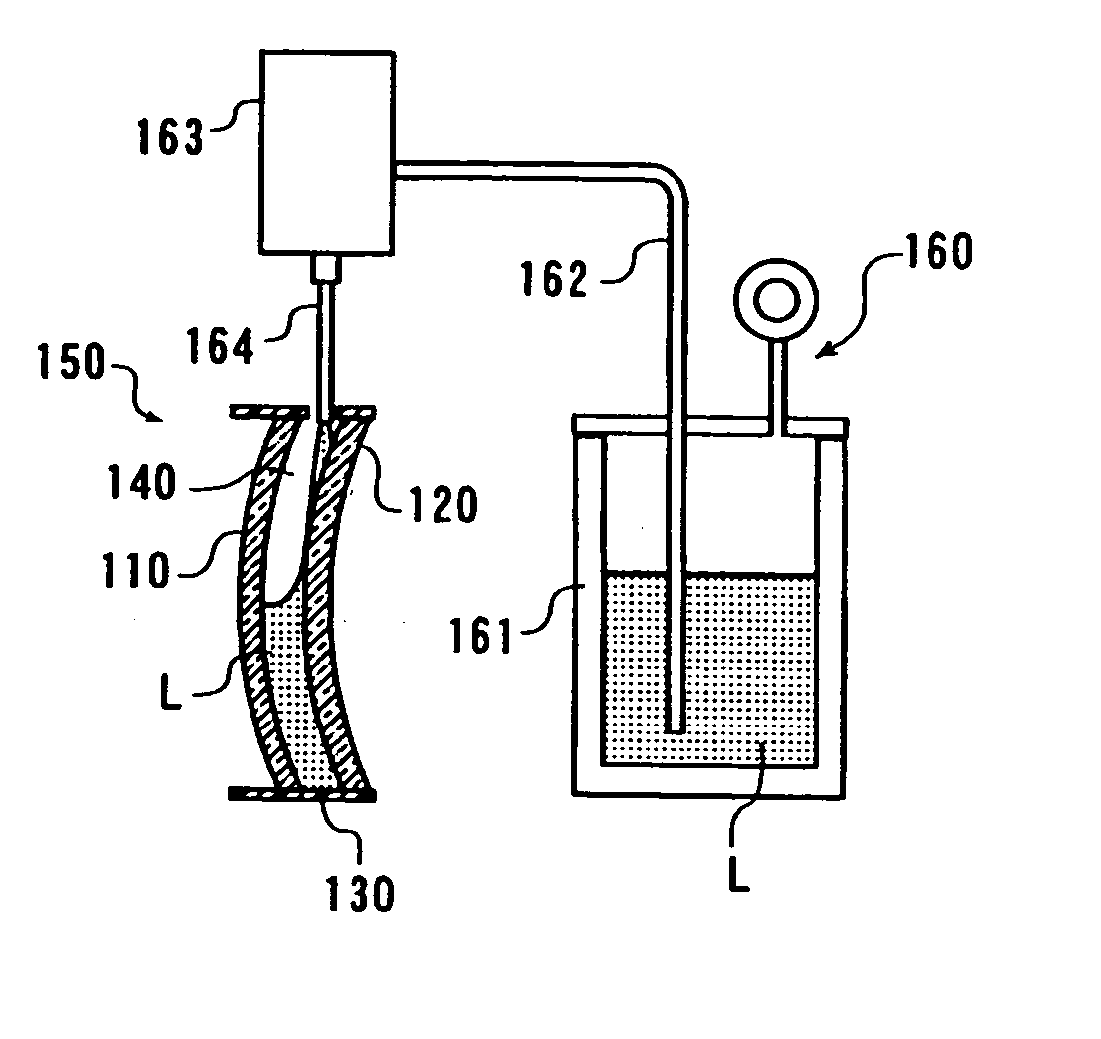

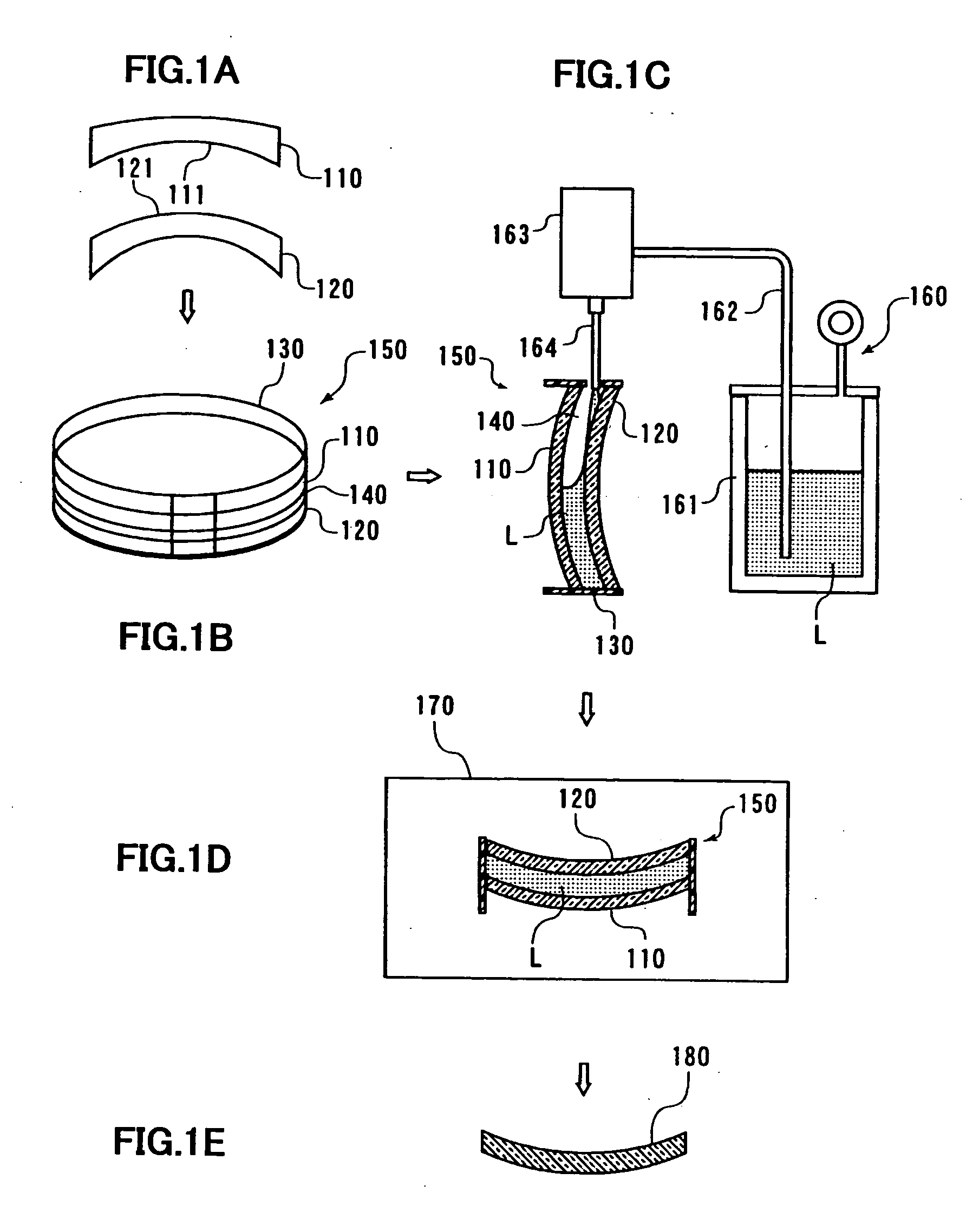

Producing method for plastic lens and raw material storage/supply apparatus

InactiveUS20040178526A1Difficult to dissipateEasy to disassembleOptical articlesLensRoom temperatureEngineering

Provided is a producing method and apparatus for a plastic lens capable of hardening a hardenable composition including a compound having an episulfide group under suppression of generation of an optical strain, and a raw material storage / supply apparatus adapted for storage and supply of such hardenable composition. A raw material storage / supply apparatus is provided by supporting, on a movable base, a storage container capable of storing a liquid raw material. A temperature regulating pipe is included for regulating the temperature of the storage container. Also provided is a temperature regulating apparatus capable of regulating a fluid flowing in the temperature regulating pipe at a temperature less than the room temperature.

Owner:SEIKO EPSON CORP

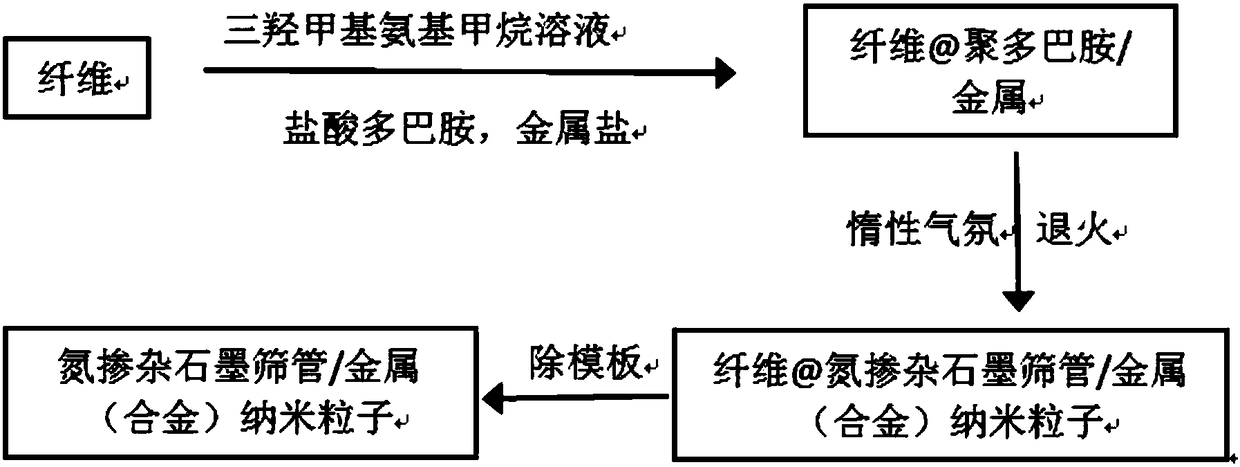

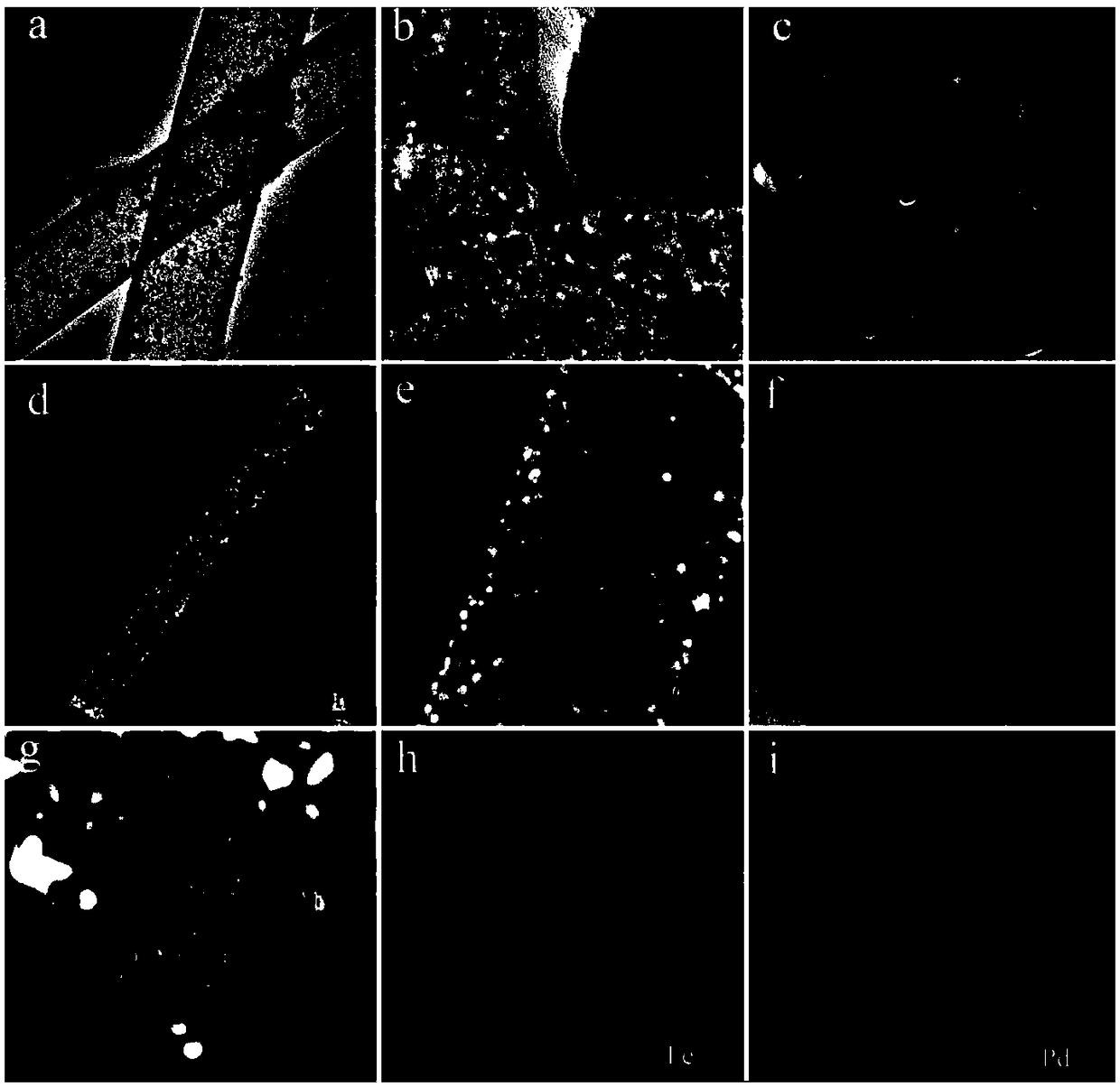

Preparation method of nitrogen-doped graphite sieve tube loaded with metal nanoparticles

ActiveCN108273537ALarge specific surface areaEnhanced mass transferMaterial nanotechnologyCatalyst activation/preparationFiberAlloy

The invention discloses a preparation method of a nitrogen-doped graphite sieve tube loaded with metal nanoparticles. The preparation method comprises the following steps: adding metal salt into a solution system containing tris hydroxyl methyl aminomethan, fiber and dopamine hydrochloride simultaneously to obtain a mixed solution, then stirring to form polydopamine coating the fiber, and simultaneously loading metal nanoparticles; then, carrying out thermal annealing treatment under the atmosphere of inert gas; and finally using a hydrofluoric acid solution to remove fiber so as to obtain a nitrogen-doped graphite sieve tube / metal (alloy) nanoparticle composite material. By setting the whole technological process and improving each critical processing step, the problem that a loaded typemetal catalyst preparation is complex in technology and rigorous in pore-forming conditions can be solved effectively.

Owner:HUAZHONG UNIV OF SCI & TECH

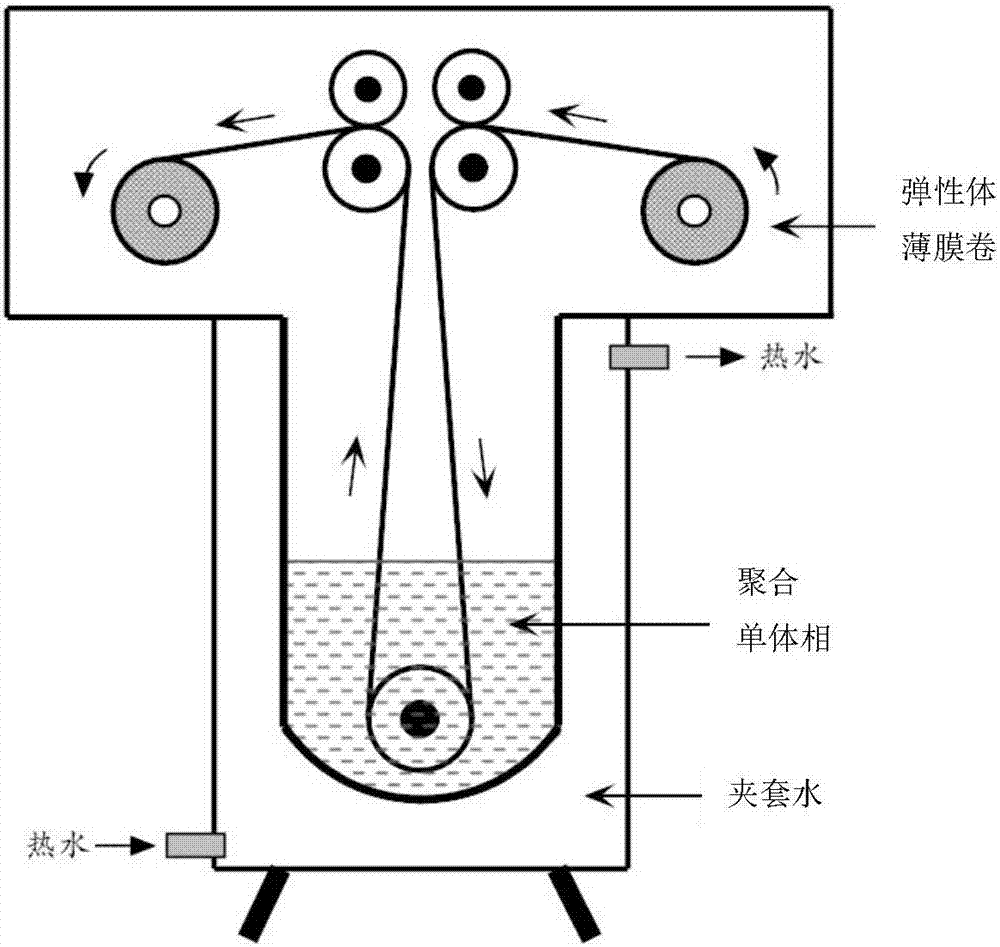

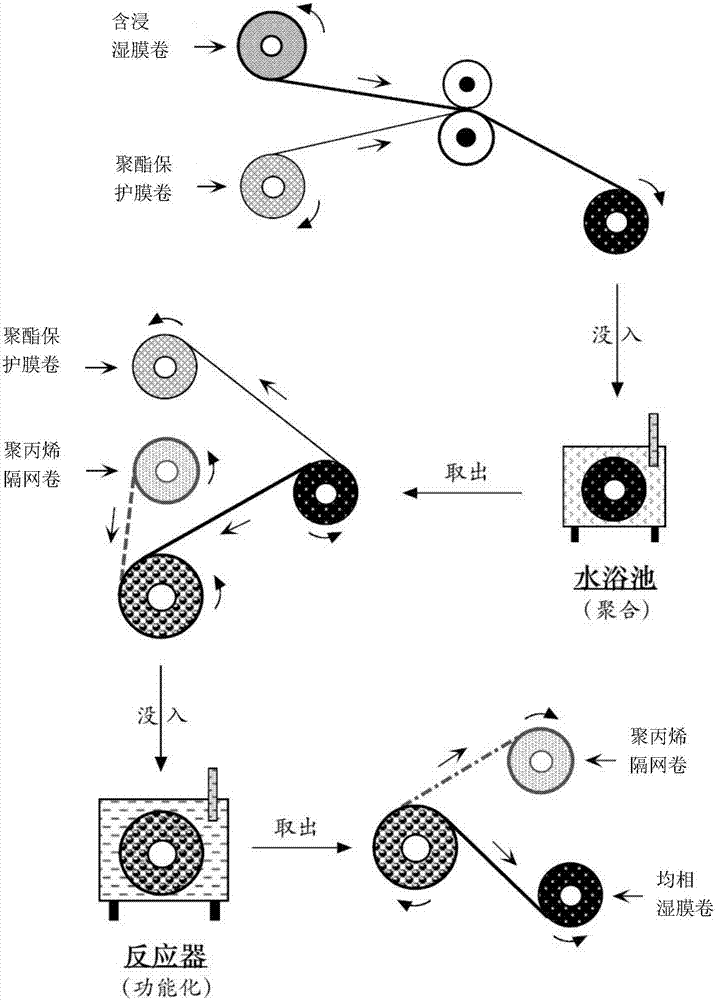

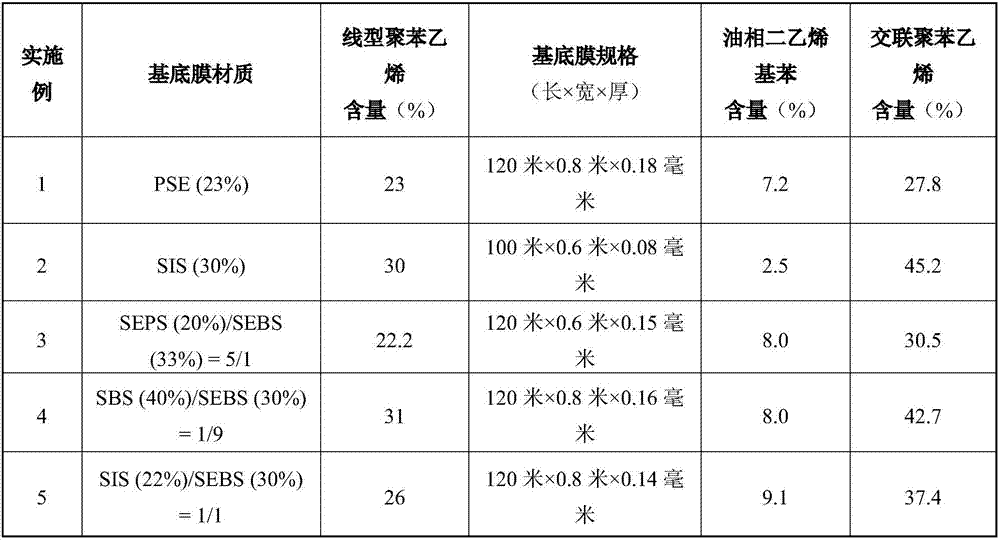

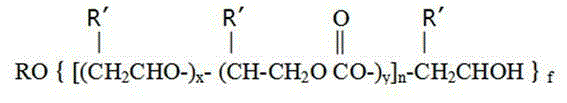

Manufacturing method of rolled ion exchange homogeneous membrane

ActiveCN107321199AEvenly distributedGood compatibilitySemi-permeable membranesMembranesElastomerTectorial membrane

The invention discloses a manufacturing method of a rolled ion exchange homogeneous membrane. The manufacturing method comprises the following steps: (1) installing an elastomer film roll containing a linear polystyrene component onto a roller type soaking trough provided with a jacket water circulation temperature control system, balancing the unreeling / reeling speed, repeatedly reeling and unreeling the roll, and continuously impregnating the roll into a polymeric monomer phase composed of styrene, divinyl benzene, and an initiator; (2) taking out the impregnated roll, unreeling the roll, laminating a polyester protective film onto the roll, pressing, reeling, heating the roll and the polyester protective film in a water bath to trigger polymerization, and peeling off the polyester protective film to obtain a composite basic membrane containing crosslinked polystyrene; and (3) using a polypropylene partition net to loosen, partition and reel the composite basic membrane obtained in the step (2), placing the whole body into concentrated sulfuric acid to carry out sulfonation reactions, (or placing the whole body into chloromethyl ether to carry out chloromethylation reactions, and then placing the whole body into a trimethylamine solution to carry out quaternary amination reactions), washing the reaction product, peeling off the polypropylene partition net, and reeling the wet membrane individually to obtain the rolled ion exchange homogeneous membrane.

Owner:QUZHOU LANRAN NEW MATERIAL CO LTD

Vinyl acetate-acrylate-ethylene multipolymer emulsion and preparation method thereof

ActiveCN109517102AUniform polymerizationImprove the single-pot conversion rateMonocarboxylic acid ester polymer adhesivesHyposulfiteSodium sulfate

The invention relates to the field of emulsion polymerization and discloses a vinyl acetate-acrylate-ethylene multipolymer emulsion and a preparation method thereof. The method comprises the followingsteps: under an emulsion polymerization reaction condition, (1) in the presence of an oxidization-reduction initiating system, carrying out a first polymerization reaction on a part of mixed monomercontaining a vinyl acetate monomer and an acrylate monomer and vinyl monomer, wherein in the oxidization-reduction initiating system, the oxidizing agent is tert-butyl hydroperoxide and the reducing agent is zinc formaldehyde sulfoxylate and / or sodium formaldehyde hyposulfite; and (2) adding the vinyl monomer and residual part of the mixed monomer into the system after the first polymerization reaction for a second polymerization reaction, wherein in the second polymerization reaction, tert-butyl peroxybenzoate is added into the reaction system. The content of acrylics in the copolymer emulsion obtained by the method is obviously higher than those in common modified EVA in the prior art, and the emulsion is good in bonding strength.

Owner:北京东方石油化工有限公司

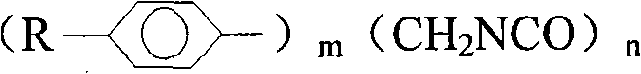

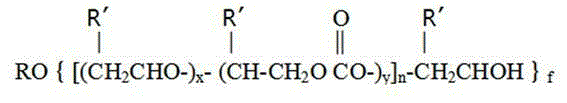

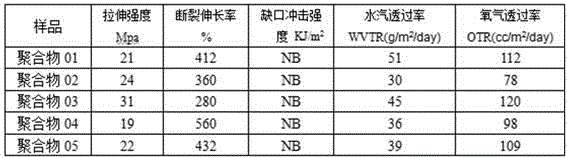

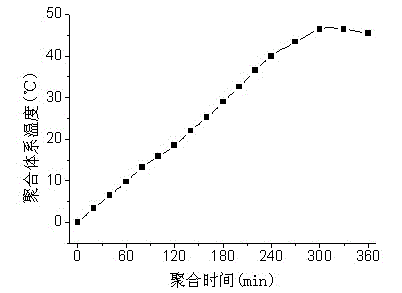

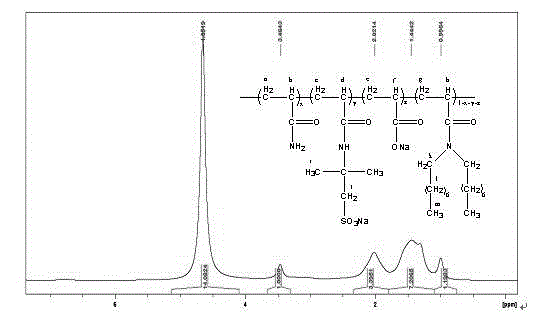

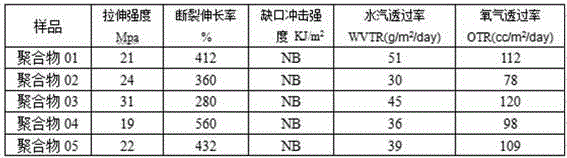

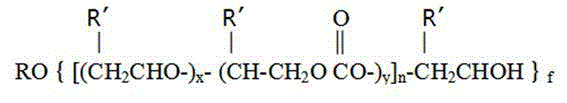

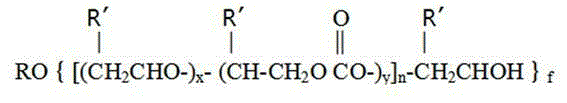

Biodegradable high-barrier thermoplastic polymer

The invention provides a biodegradable high-barrier thermoplastic polymer, a preparation method thereof, and an application thereof. Polymer monomers comprises (a) composite polyol of polycarbonate segment and polyether segment, (b) one or more small-molecular compounds with two or more hydroxyl groups and amine groups, (c) one or more diisocyanate compounds, and (d) one or more cross-linking agents. The preparation method comprises the following steps: (a), (b) and (c) are subjected to a mixed reaction; the monomer (d) is added into the product obtained from the mixed reaction, and grafting cross-linking is carried out. According to the invention, synthesizing monomers are finely selected, and reaction route and conditions are reasonably designed, such that the polymer has a good barrier property against water vapour and oxygen. The polymer has good physical and mechanical performances, and good biodegradability. The polymer has a wider application scope.

Owner:JIANGSU ZHONGKE JINLONG CHEM

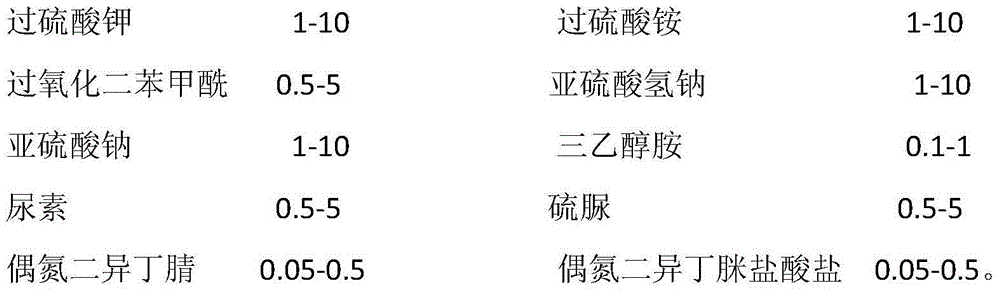

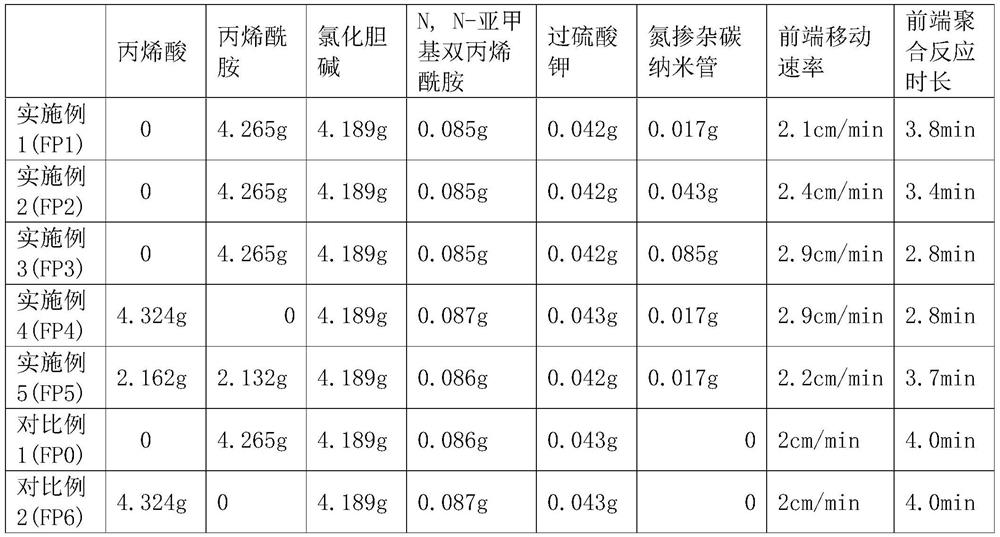

Composite initiator of hydrophobic associated polymer and preparation method of hydrophobic associated polymer

ActiveCN104672355ALow residual acrylamide contentUniform polymerizationPotassium persulfatePolymer science

The invention provides a composite initiator of a hydrophobic associated polymer and a preparation method of the hydrophobic associated polymer. The composite initiator is prepared from the following raw materials in parts by weight: 1-10 parts of potassium persulfate, 1-10 parts of ammonium persulfate, 0.5-5 parts of dibenzoyl peroxide, 1-10 parts of sodium hydrogen sulfite, 1-10 parts of sodium sulfite, 0.1-1 part of triethanolamine, 0.5-5 parts of urea, 0.5-5 parts of thiourea, 0.05-0.5 part of azodiisobutyronitrile and 0.05-0.5 part of azobis(isobutylamidine hydrochloride). The method comprises the following steps: a sequentially adding disodium ethylenediamine tetraacetate, sodium formate, lauryl sodium sulfate, acrylamide, AMPS-Na and DiC8AM to deionized water under a magnetic stirring condition, and fully stirring evenly; b introducing high-purity nitrogen into a mixed solution obtained from the step a, adding the composite initiator, and polymerizing to obtain hydrophobic associated polymer gel; and c coarsely crushing the hydrophobic associated polymer gel obtained from the step b, adding sodium hydroxide, hydrolyzing, drying in a blast drying oven, drying and crushing to obtain the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

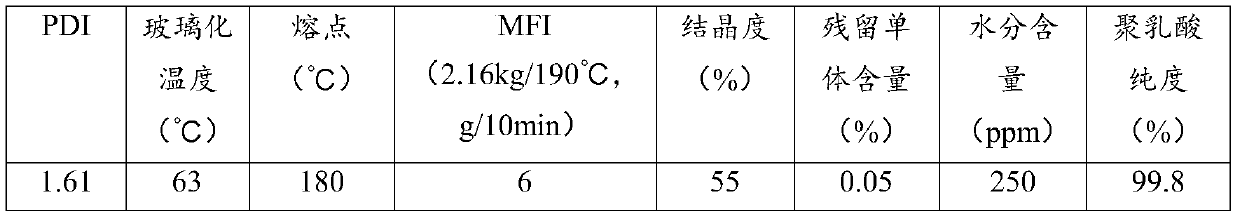

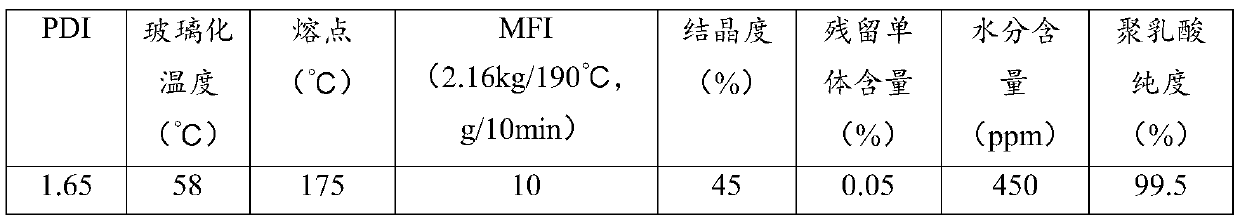

Colored polylactic acid particle and preparation method thereof

The invention belongs to the technical field of polylactic acid production, and specifically discloses a colored polylactic acid particle and a preparation method thereof. The provided colored polylactic acid particle is composed of polylactic acid and pigments. The colored polylactic acid particle is prepared by directly mixing a polymerized molten colorless polylactic acid material with coloredpolylactic acid prepared from polylactic acid based color master batch to prepare colored polylactic acid mixed melt, cutting the mixed melt in water, and drying. The colored polylactic acid particlecan be used in more application fields and can be made into colored fibers, colored plastic products, colored films, and the like. For the polylactic acid downstream application production enterprises, the colored polylactic acid particle can be directly used for production, the step of coloring colorless polylactic acid can be eliminated, and thus the equipment investment and raw material cost are both prominently reduced.

Owner:安徽丰原福泰来聚乳酸有限公司

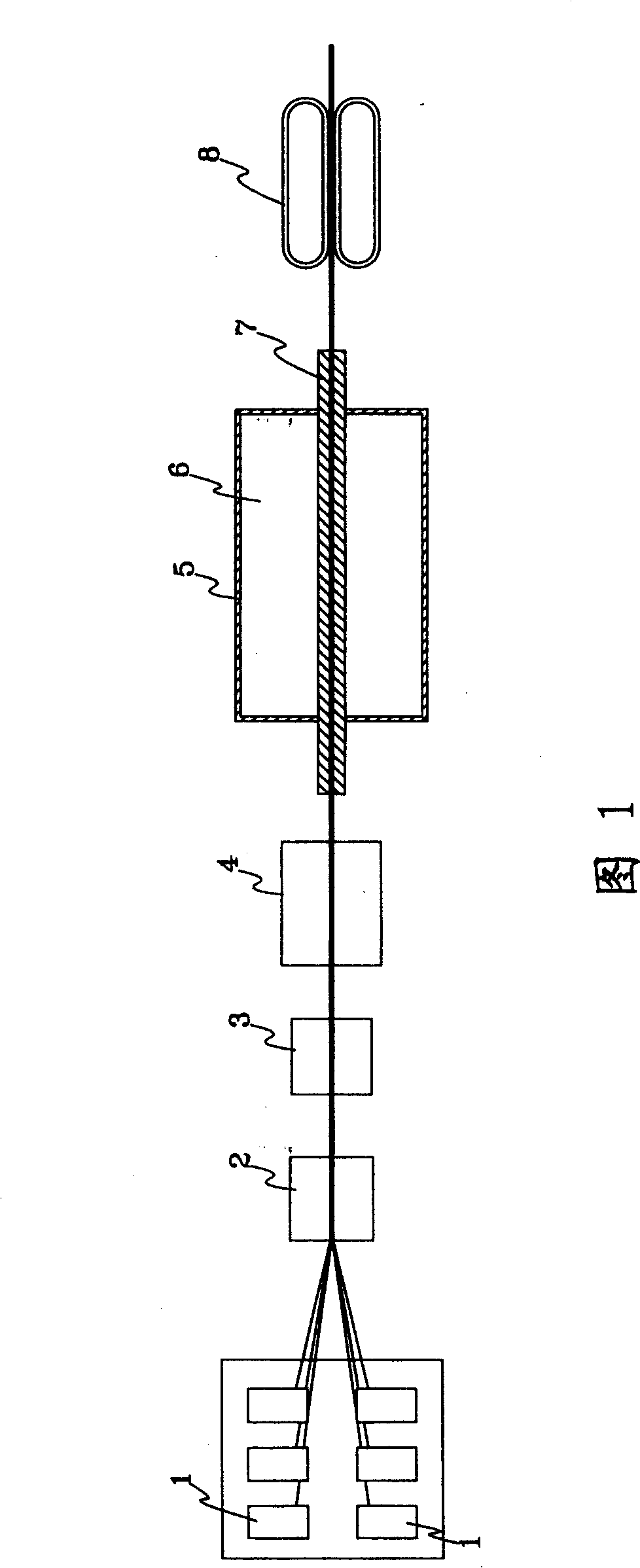

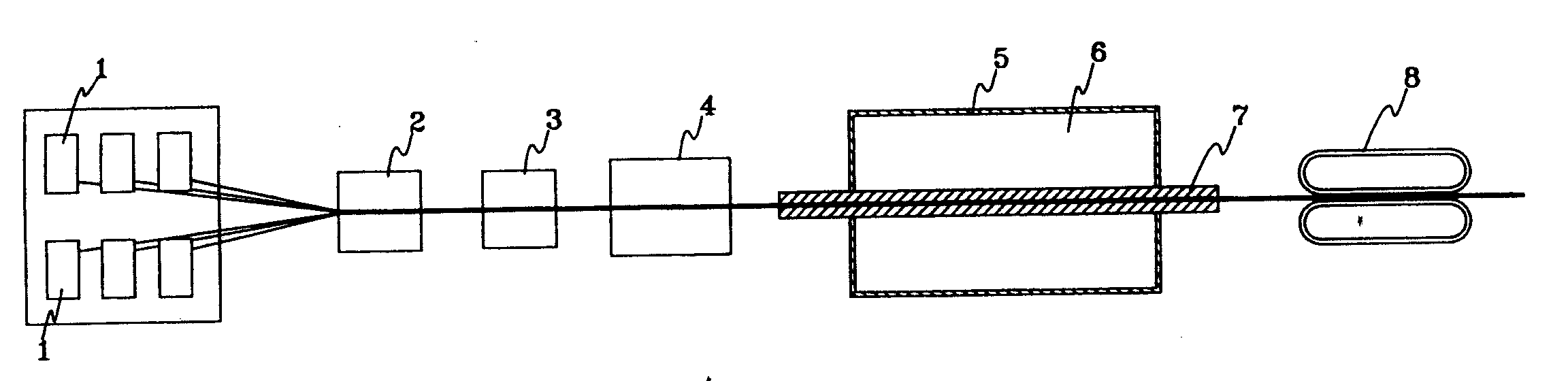

Manufacturing method of continuous long fiber reinforced reaction type resin

A continuous long fibre-reinforced reactive resin product is made up from the monomer able to be polymerized by free radicals through immersing long fibres, pre-shaping by a mould, microwave reactive cavity for polymerizing and curing, moulding, cooling and solidifying. Its advantages are high polymerizing speed, and high adhesion between fibres and resin.

Owner:鄂尔多斯市永杰科技有限公司

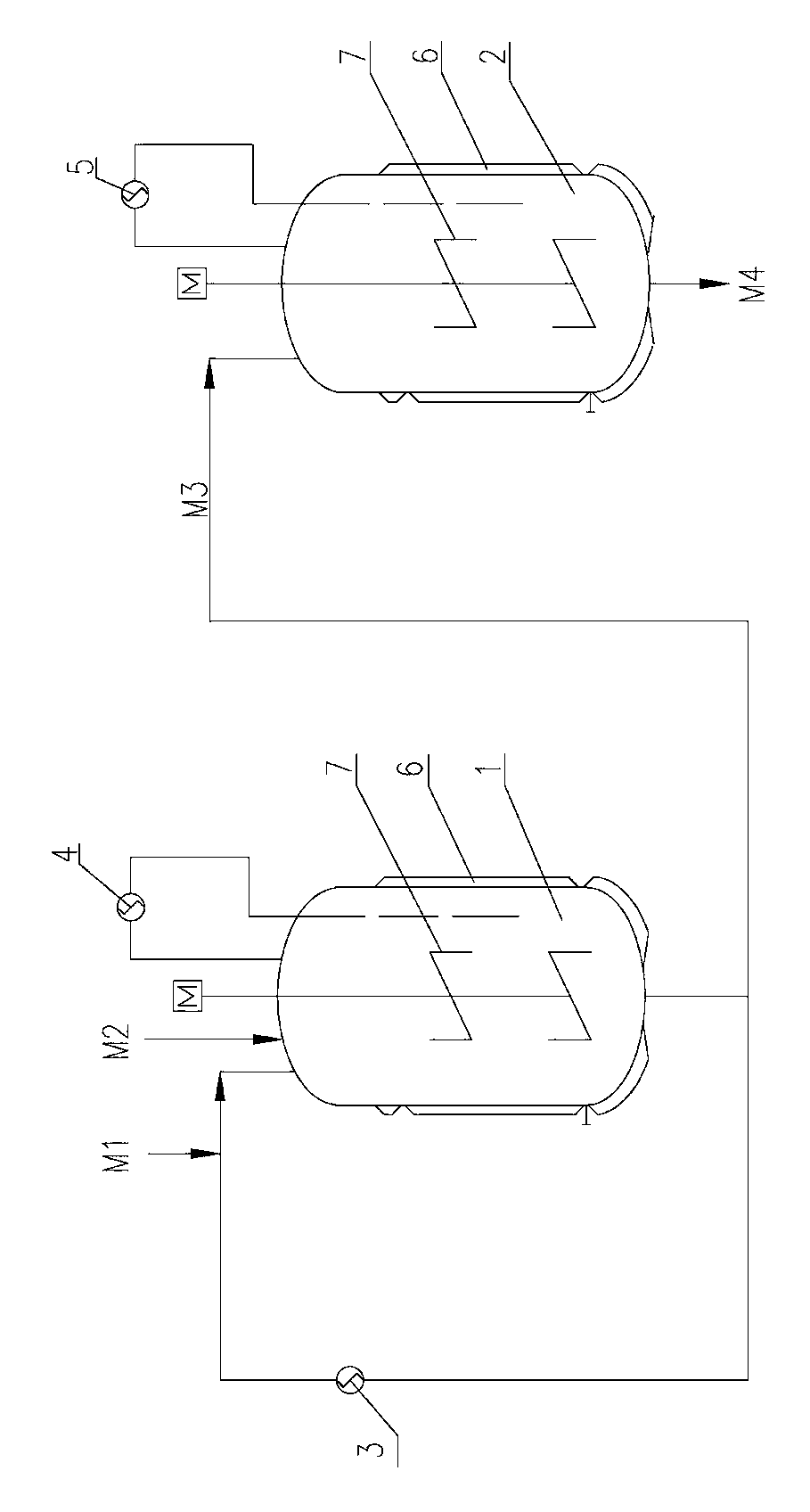

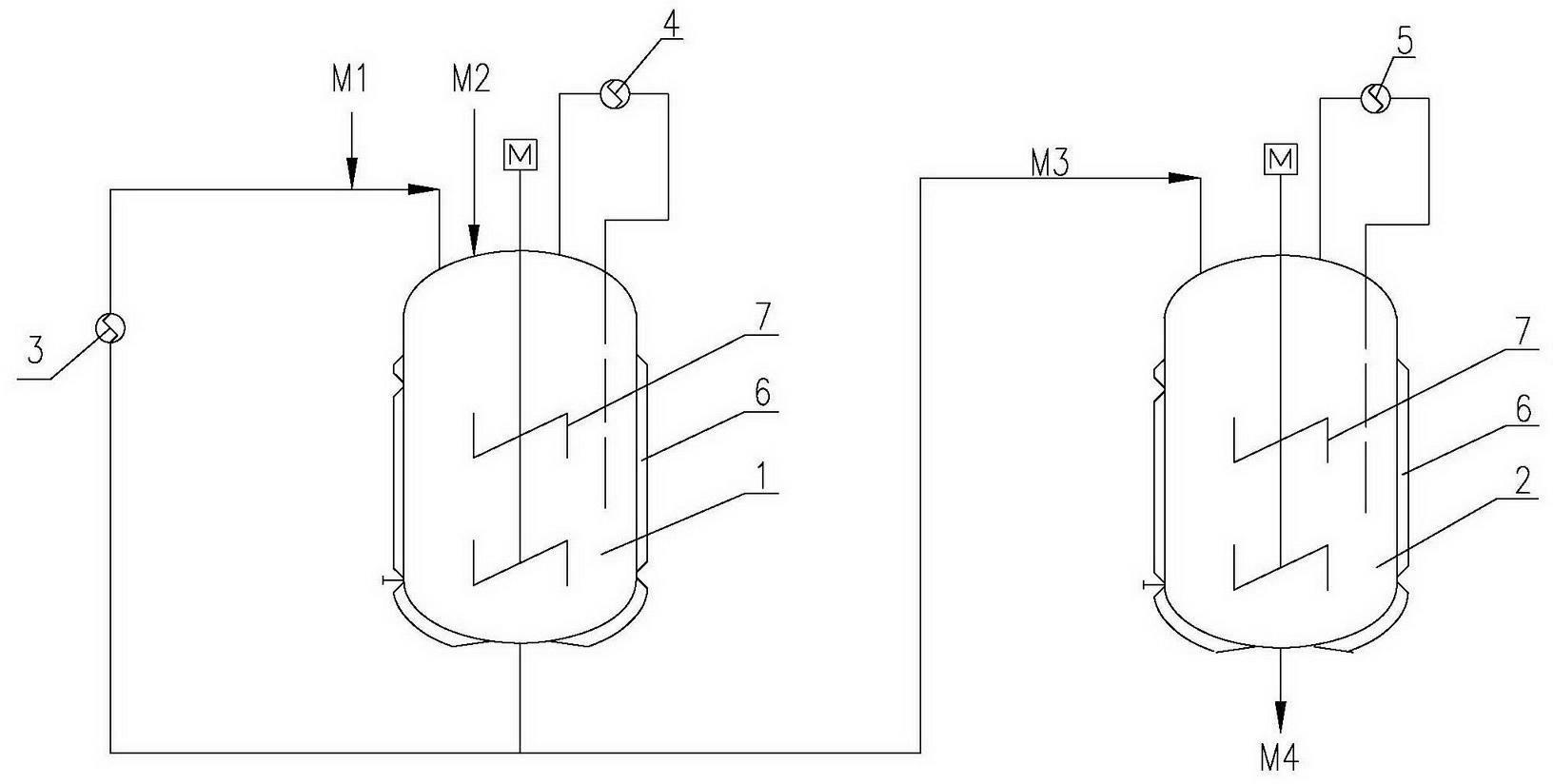

Method of two-stage continuous polymerization production of petroleum resin

The invention discloses a method of two-stage continuous polymerization production of petroleum resin, which comprises the following steps of: (1) continuously adding raw materials for polymerization and catalyst into a polymerization reactor (1) for the first stage of polymerization, with the polymerization temperature of 55-75 DEG C, the polymerization pressure of 0.2-0.35MPa and the material retention time of 1-3 hour(s);(2)delivering the materials into a delay reactor (2) for the second stage of polymerization, with the polymerization temperature of 55-75 DEG C, the polymerization pressure of 0.2-0.35MPa and the material retention time of 0.5-2 hour(s); and (3)carrying out desorption of the materials with the catalyst and solvent to obtain the petroleum resin. Since the process of feeding materials or feeding the catalyst is eliminated, the concentration of the catalyst and active components for polymerization in the polymerization system is relatively stable. Compared with the single-stage continuous polymerization, the second stage of polymerization is added, the mixing in the polymerization reaction is more uniform, the heat of reaction can be removed promptly, the quality of the resin can be improved effectively, and C5 petroleum resin with narrow molecular weight distribution and small weight-average molecular weight can be obtained.

Owner:FUSHUN QILONG CHEM

Polymerization method of biodegradable high-barrier thermoplastic polymer

The invention provides a polymerization method of a biodegradable high-barrier thermoplastic polymer. Polymer monomers comprising (a) composite polyatomic alcohol of polycarbonate segment and polyether segment; (b) one or more small-molecular compounds with two or more hydroxyl groups and amino groups; (c) one or more diisocyanate compounds; and (d) one or more cross-linking agents. A preparation method comprises the steps that (a), (b) and (c) are subjected to mixed reaction; and the monomer (d) is added into the product of the mixed reaction, such that grafting cross-linking is carried out. According to the invention, polymerization monomers are finely selected, and reaction route and conditions are reasonably designed, such that the polymer has good barrier property against water vapour and oxygen, and that the polymer has good physical and mechanical performances. The polymer also has good biodegradability and wider application scope.

Owner:JIANGSU ZHONGKE JINLONG CHEM

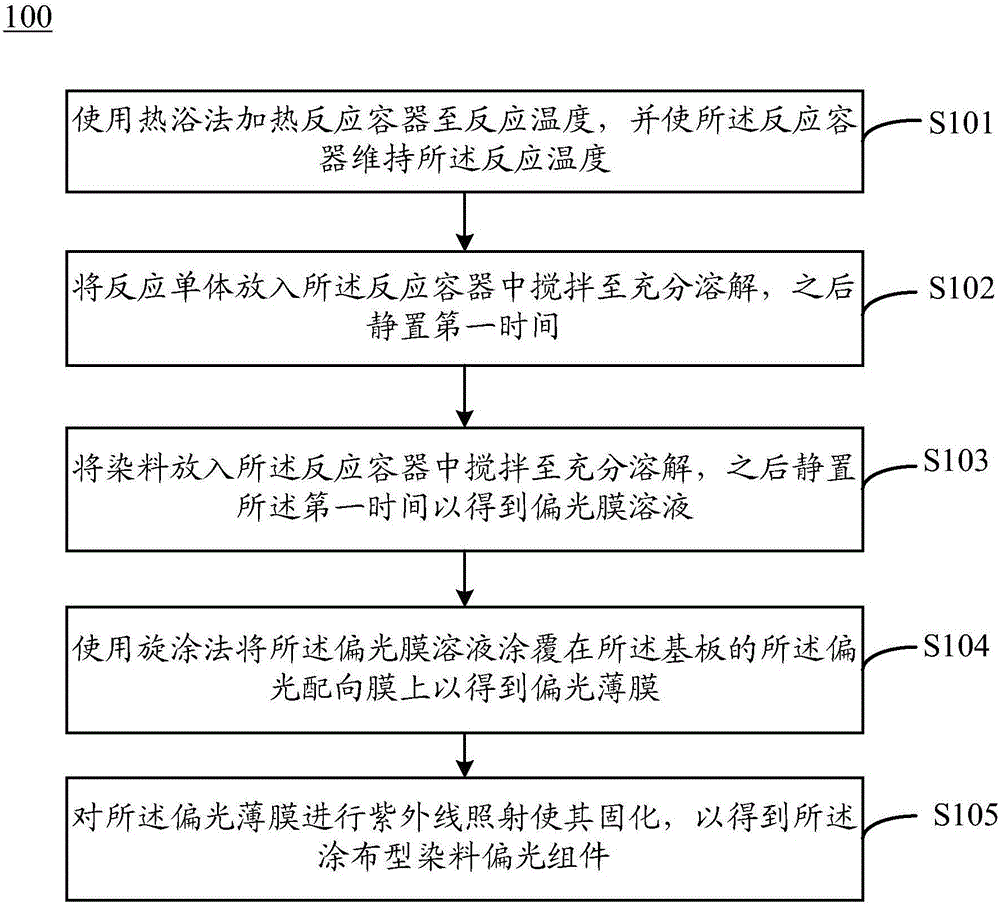

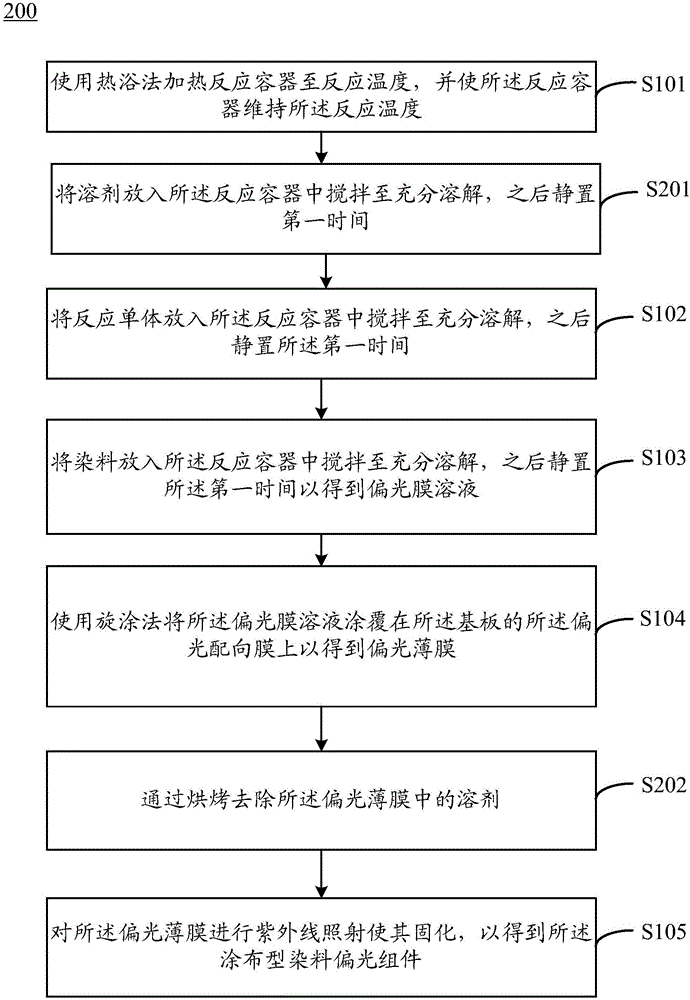

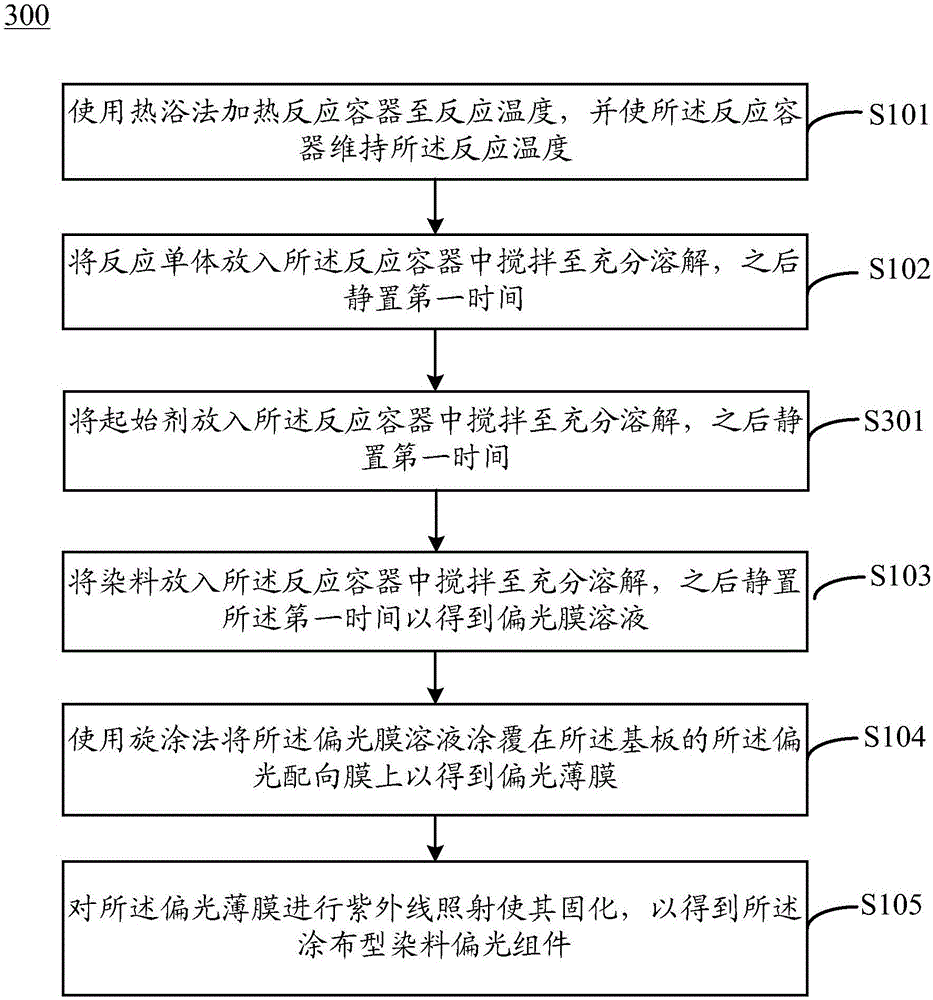

Preparation method of coating type dye polarization component and liquid crystal panel

ActiveCN106154390AAvoid reunionReunion is not easy to happenPolarising elementsNon-linear opticsLiquid-crystal displayUltraviolet

The invention provides a preparation method of a coating type dye polarization component, wherein the coating type dye polarization component comprises a substrate; a polarization alignment film is arranged on the substrate; the preparation method comprises the following steps: heating a reaction vessel to a reaction temperature according to a hot bath method, maintaining the reaction temperature in the reaction vessel; placing a reaction monomer in the reaction vessel, stirring and fully dissolving, then standing for a first time interval; placing a dye in the reaction vessel, stirring and fully dissolving, then standing for the first time interval to obtain a polarization film solution; coating the polarization film solution on the polarization alignment film of the substrate by using a spin-coating method to obtain a polarization film; curing the polarization film through ultraviolet irradiation to obtain the coating type dye polarization component. The invention further provides a liquid crystal panel. The solution of the invention can improve a polarization degree of a polarizer and improve a contrast ratio of the liquid crystal panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

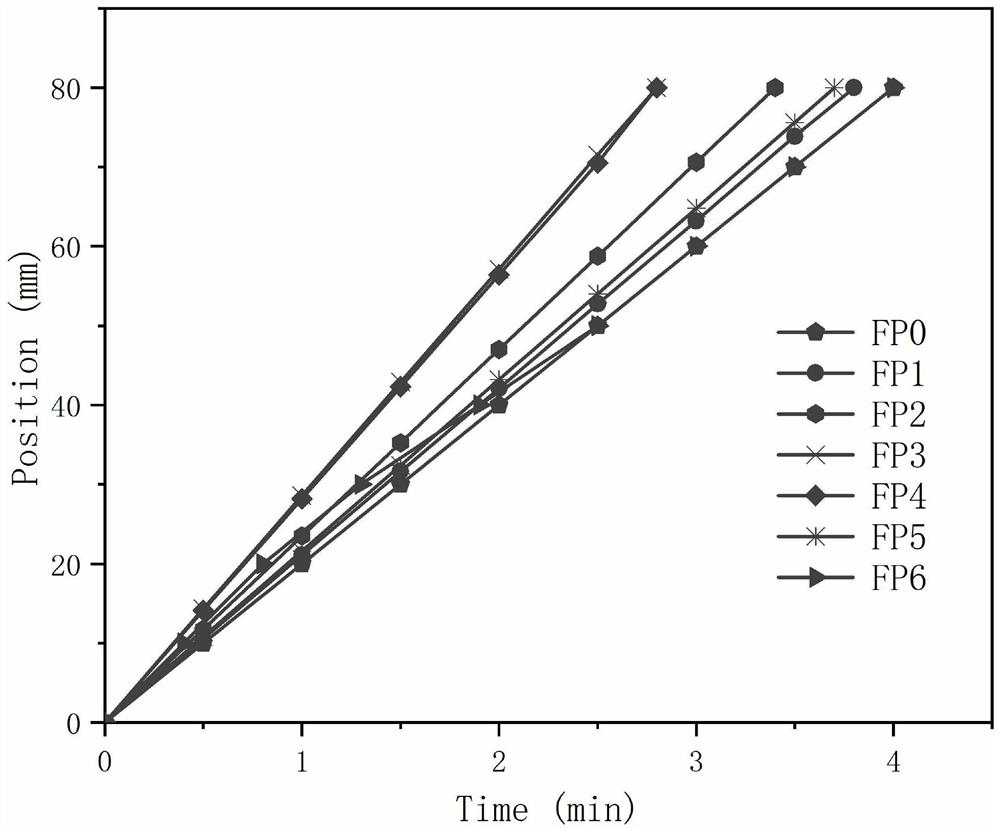

Preparation method of rapid absorption type super absorbent resin

The invention relates to a preparation method of rapid absorption type super absorbent resin. The preparation method comprises the following steps: adding acrylic acid, quantitative water and alkali liquor into a reaction still for carrying out neutral reaction and respectively adding a crosslinking agent, a foaming agent, wood fibers and polyethylene glycol; then adding resin powder crushed and sieved to be greater than 100 meshes, an initiator and a reducing agent, and forming foam colloid through polymerization; chopping, granulating, drying, crushing and screening and carrying out surfacecrosslinking treatment to obtain the rapid absorption type super absorbent resin. According to the preparation method disclosed by the invention, the foaming effect is improved by introducing a compound foaming agent; the water retention and permeability are improved by adding the wood fibers; the stability and gel strength of the colloidal foam are improved by adding the polyethylene glycol and the resin powder; special equipment does not need to be added in the production process; meanwhile, the generation of by-products is reduced, as well as the absorption rate and water retention of the product are effectively improved; the performance index is relatively balanced, the drying time is shortened, the production efficiency is improved, and the scale-up production is facilitated.

Owner:杭州考拉之屋贸易有限公司

Hydrogel filled with nitrogen-doped carbon nanotubes and preparation method of hydrogel

The invention discloses hydrogel filled with nitrogen-doped carbon nanotubes and a preparation method of the hydrogel, and the method comprises the following steps: mixing a hydrogen bond acceptor compound, a hydrogen bond donor compound and a cross-linking agent, and stirring in an oil bath until transparent and clear liquid is obtained, so as to obtain deep eutectic solvent liquid; successively adding an initiator and a nitrogen-doped carbon nanotube into a deep eutectic solvent liquid at a temperature above 35 DEG C, uniformly stirring to form a mixture solution, transferring the formed mixture solution into a tubular reactor, heating the reactor by using a heat source to initiate a polymerization reaction, and evacuating the heat source till the liquid in the whole reactor is completely converted into polymer gel; and soaking and washing the polymer gel with distilled water, and freeze-drying to obtain the target nitrogen-doped carbon nanotube filled hydrogel. The reaction rate of front-end polymerization is increased by filling a small amount of nitrogen-doped carbon nanotubes with general applicability, so that the target hydrogel is rapidly prepared.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Lithium-sulfur battery positive copolymer sulfur material and prepared lithium-sulfur battery made from material

ActiveCN109546149AEasy to operateSimple processCell electrodesLi-accumulatorsTriple bondCarbon nitrogen

The invention provides a lithium-sulfur battery positive copolymer sulfur material. The lithium-sulfur battery positive copolymer sulfur material is prepared through steps as follows, (1), sublimed sulfur powder and organic polymerization agent are collected to obtain uniform mixture through grinding, and the organic polymerization agent is nitrile organic substance; (2), the uniform mixture of the sublimed sulfur and the organic polymerization agent is sealed in a container under the high temperature condition and is insulated and stirred; and (3), the copolymerized sulfur obtained in the step (2) is pulverized to obtain positive electrode copolymerized sulfur particles. The invention further provides a lithium-sulfur battery made from the lithium-sulfur battery positive copolymer sulfurmaterial. The lithium-sulfur battery positive copolymer sulfur material is advantaged in that preparation requirements can be met through simple heating equipment, and the preparation process has characteristics of convenient operation and simple process. The preparation method is advantaged in that chemical bonding between the organic matter and the sulfur is produced through bond opening reaction of nitrile compounds'unique carbon-nitrogen triple bond and the 8-membered ring structure of the sublimated sulfur at the high temperature, and the polymeric sulfur copolymer can be formed.

Owner:BEIHANG UNIV

Method for producing dyed hollow filaments by recycled polyester

InactiveCN107447271AUniform average molecular weight distributionHigh strengthHollow filament manufactureFilament/thread formingMasterbatchPolyester

The invention discloses a method for producing dyed hollow filaments by recycled polyester in the field of polyester fiber production methods. The method includes: preparing a recycled material, and making the recycled material into recycled masterbatch; subjecting the recycled masterbatch to solid-phase tackifying under a vacuum state; mixing the tackified material and masterbatch, sending into a screw extruder to realize mixing and extruding, and spinning through a hollow spinneret plate to obtain hollow filaments; cooling and blowing the filaments under the protection of nitrogen; oiling, and subjecting multiple strands of filaments to interlacing treatment through an interlacing jet; winding and storing. The method can be used for recycling of various waste beverage bottles and textile offcut materials, and environmental friendliness and low energy consumption are realized.

Owner:JIANGSU FEILIN FIBER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com